Ecm wire SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 14 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-9 Precautions:

• Be careful not to touch the electrical terminals of parts which use microcomputers (e.g. electronic control unit

like as ECM, PCM, P/S controller, etc.). The static

electricity from your body can damage these parts.

• Never connect any tester (voltmeter, ohmmeter, or whatever) to electronic control unit when its coupler is

disconnected. Attempt to do it may cause damage to

it.

• Never connect an ohmmeter to electronic control unit with its coupler connected to it. Attempt to do it may

cause damage to electronic control unit and sensors.

• Be sure to use a specified voltmeter / ohmmeter. Otherwise, accurate measurements may not be

obtained or personal injury ma y result. If not specified,

use a voltmeter with high impedance (M Ω/V

minimum) or a digital type voltmeter.

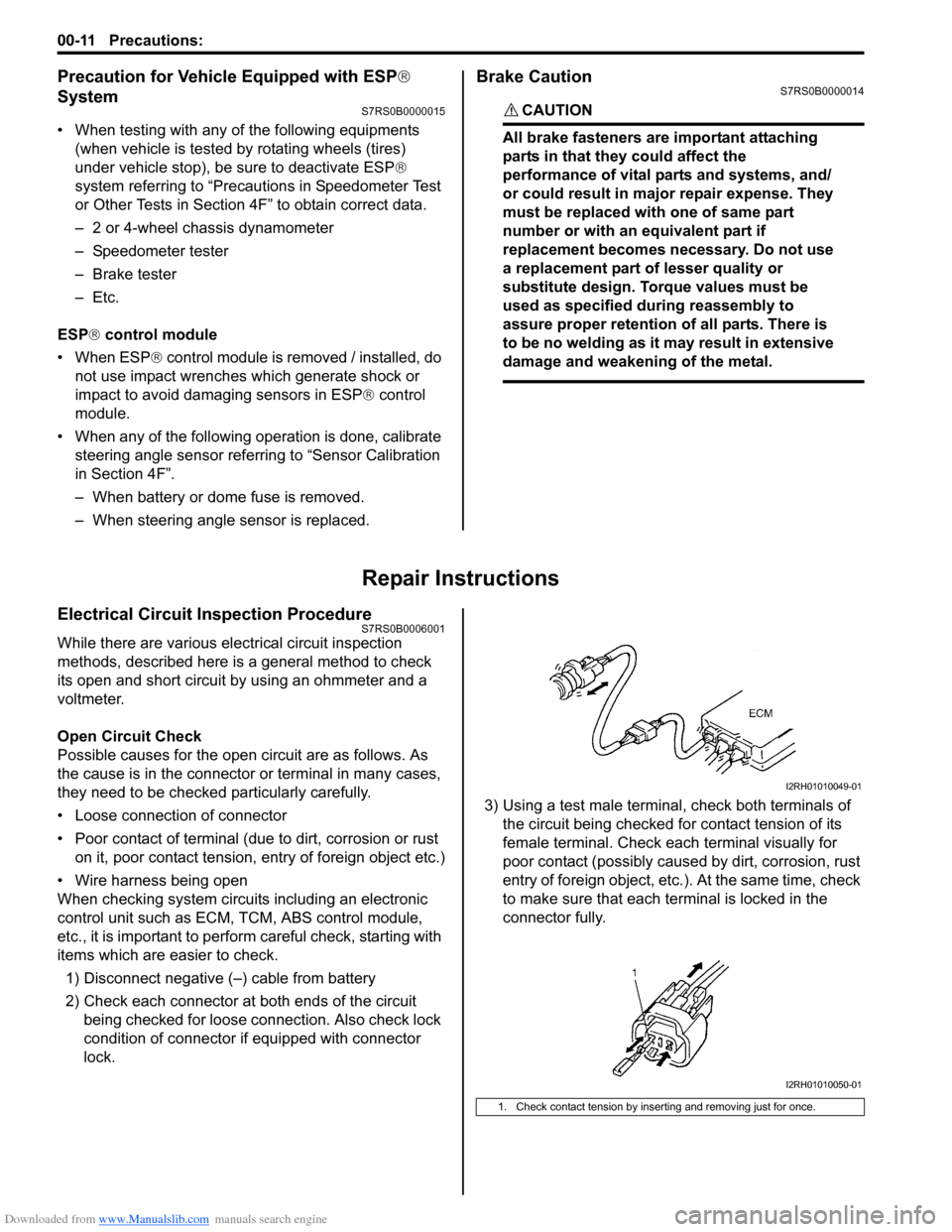

• When taking measurements at electrical connectors using a tester probe, be sure to insert the probe (2)

from the wire harness side (backside) of the

connector (1). • When connecting meter probe (2) from terminal side

of coupler (1) because it can’t be connected from

harness side, use extra care not to bend male

terminal of coupler of force its female terminal open

for connection.

In case of such coupler as shown connect probe as

shown to avoid opening female terminal.

Never connect probe where male terminal is

supposed to fit.

• When checking connection of terminals, check its

male half for bend and female half for excessive

opening and both for locking (looseness), corrosion,

dust, etc.

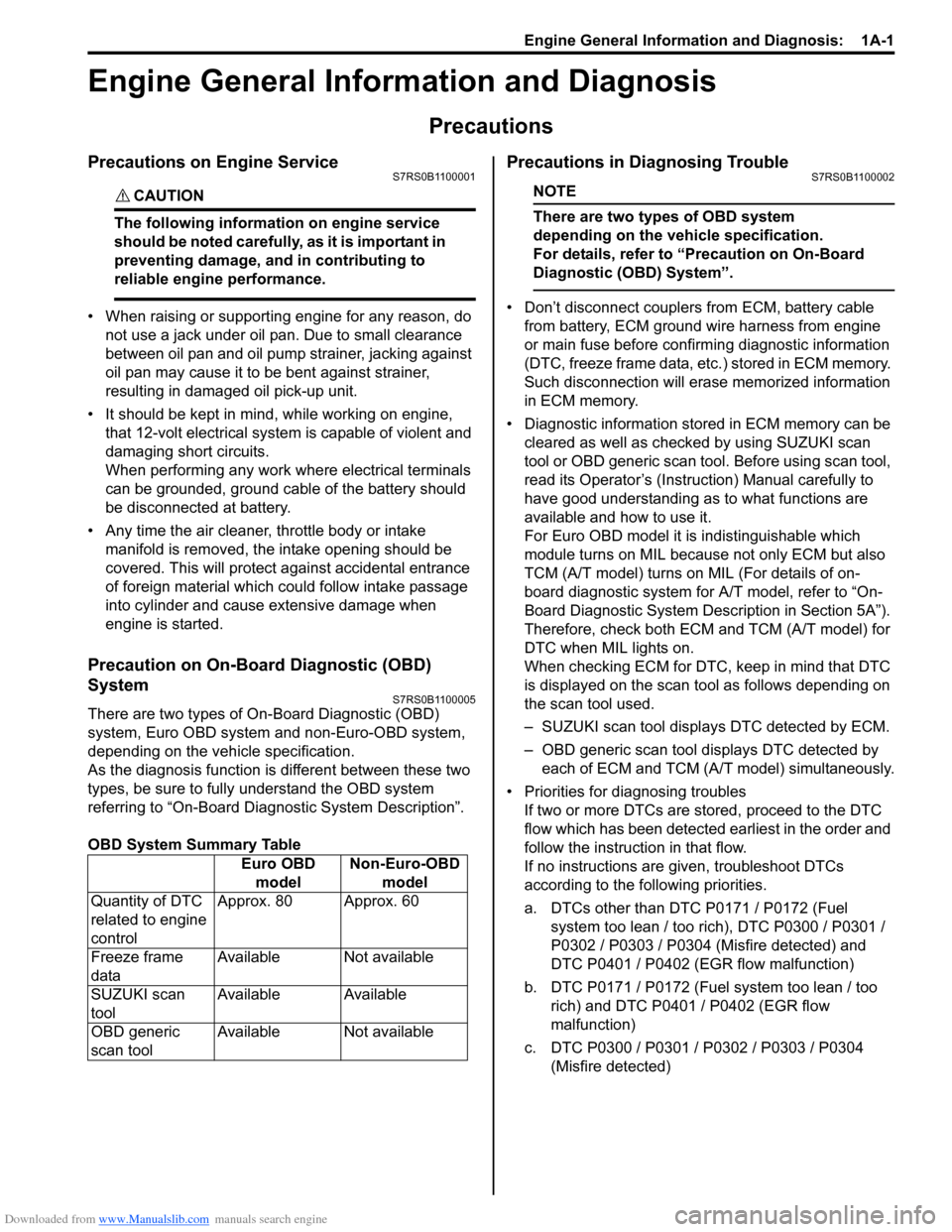

• Before measuring voltage at each terminal, check to make sure that battery voltage is 11 V or higher. Such

terminal voltage check at lo w battery voltage will lead

to erroneous diagnosis.

I3RM0A000004-01

I2RH01010046-01

I2RH01010047-01

I2RH01010048-01

Page 16 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-11 Precautions:

Precaution for Vehicle Equipped with ESP®

System

S7RS0B0000015

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP ®

system referring to “Precautions in Speedometer Test

or Other Tests in Section 4F” to obtain correct data.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

–Etc.

ESP ® control module

• When ESP ® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP ® control

module.

• When any of the following operation is done, calibrate steering angle sensor referring to “Sensor Calibration

in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

Brake CautionS7RS0B0000014

CAUTION!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

Repair Instructions

Electrical Circuit Inspection ProcedureS7RS0B0006001

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perfor m careful check, starting with

items which are easier to check.

1) Disconnect negative (–) cable from battery

2) Check each connector at both ends of the circuit being checked for loose connection. Also check lock

condition of connector if equipped with connector

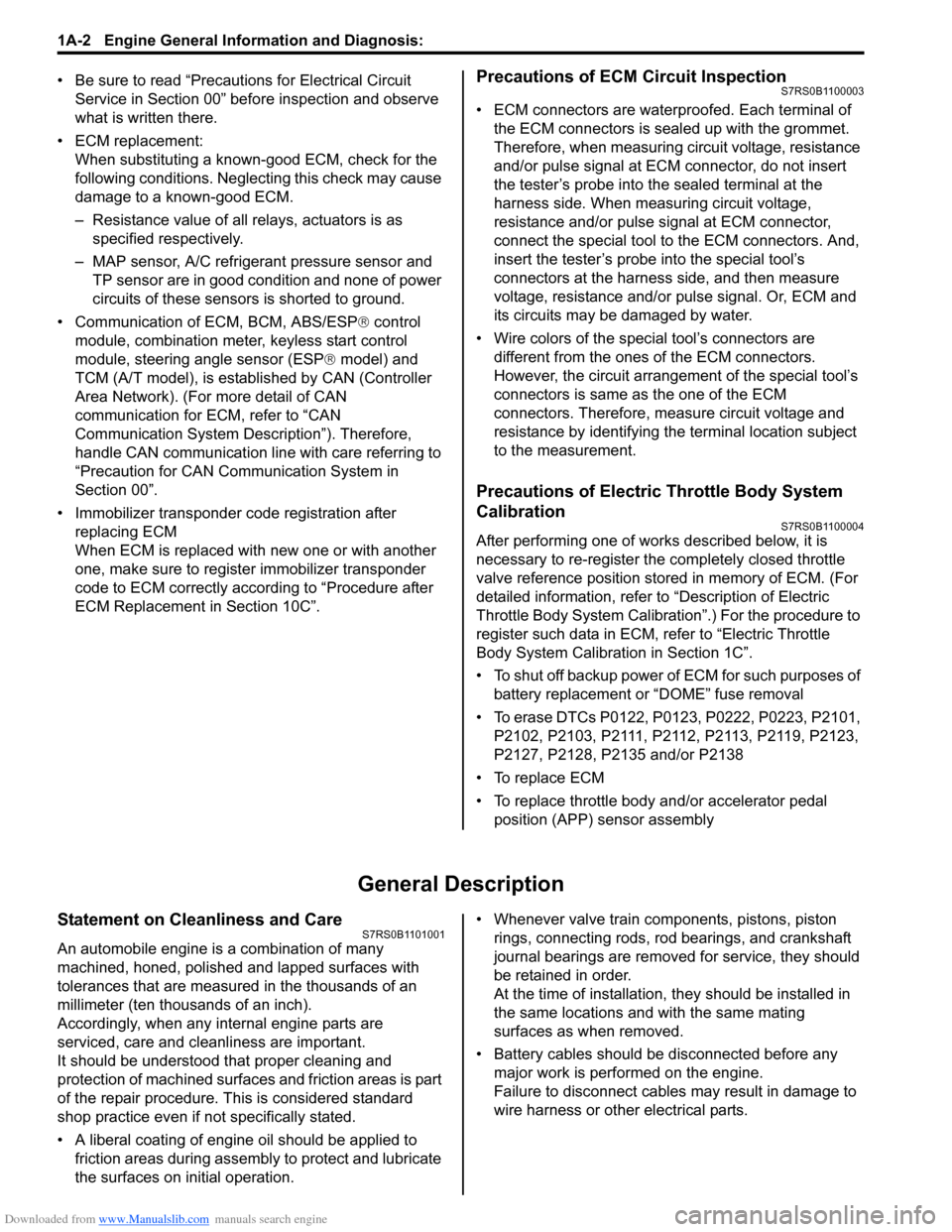

lock. 3) Using a test male terminal

, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each te rminal is locked in the

connector fully.

1. Check contact tension by inserting and removing just for once.

I2RH01010049-01

I2RH01010050-01

Page 51 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS7RS0B1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind , while working on engine,

that 12-volt electrical syste m is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S7RS0B1100005

There are two types of On -Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

OBD System Summary Table

Precautions in Diagnosing TroubleS7RS0B1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be cleared as well as checke d by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

For Euro OBD model it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (A/T model) turns on MIL (For details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”).

Therefore, check both ECM and TCM (A/T model) for

DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instructi on in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 (Misfire detected)

Euro OBD

model Non-Euro-OBD

model

Quantity of DTC

related to engine

control Approx. 80 Approx. 60

Freeze frame

data Available Not available

SUZUKI scan

tool Available Available

OBD generic

scan tool Available Not available

Page 52 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-2 Engine General Information and Diagnosis:

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” befo re inspection and observe

what is written there.

• ECM replacement: When substituting a known-good ECM, check for the

following conditions. Neglec ting this check may cause

damage to a known-good ECM.

– Resistance value of all relays, actuators is as specified respectively.

– MAP sensor, A/C refrigerant pressure sensor and TP sensor are in good condition and none of power

circuits of these sensors is shorted to ground.

• Communication of ECM, BCM, ABS/ESP ® control

module, combination meter, keyless start control

module, steering angle sensor (ESP ® model) and

TCM (A/T model), is esta blished by CAN (Controller

Area Network). (For more detail of CAN

communication for ECM, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Immobilizer transponder code registration after

replacing ECM

When ECM is replaced with new one or with another

one, make sure to register immobilizer transponder

code to ECM correctly according to “Procedure after

ECM Replacement in Section 10C”.Precautions of ECM Circuit InspectionS7RS0B1100003

• ECM connectors are waterproofed. Each terminal of the ECM connectors is sealed up with the grommet.

Therefore, when measuring ci rcuit voltage, resistance

and/or pulse signal at ECM connector, do not insert

the tester’s probe into th e sealed terminal at the

harness side. When measuring circuit voltage,

resistance and/or pulse signal at ECM connector,

connect the special tool to the ECM connectors. And,

insert the tester’s probe into the special tool’s

connectors at the harness side, and then measure

voltage, resistance and/or pulse signal. Or, ECM and

its circuits may be damaged by water.

• Wire colors of the special tool’s connectors are different from the ones of the ECM connectors.

However, the circuit arrangement of the special tool’s

connectors is same as the one of the ECM

connectors. Therefore, measure circuit voltage and

resistance by identifying the terminal location subject

to the measurement.

Precautions of Electric Throttle Body System

Calibration

S7RS0B1100004

After performing one of works described below, it is

necessary to re-register the completely closed throttle

valve reference position stored in memory of ECM. (For

detailed information, refer to “Description of Electric

Throttle Body System Calibration”.) For the procedure to

register such data in ECM, refer to “Electric Throttle

Body System Calibration in Section 1C”.

• To shut off backup power of ECM for such purposes of battery replacement or “DOME” fuse removal

• To erase DTCs P0122, P01 23, P0222, P0223, P2101,

P2102, P2103, P2111, P2112, P2113, P2119, P2123,

P2127, P2128, P2135 and/or P2138

• To replace ECM

• To replace throttle body and/or accelerator pedal position (APP) sensor assembly

General Description

Statement on Cleanliness and CareS7RS0B1101001

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the thousands of an

millimeter (ten thous ands of an inch).

Accordingly, when any internal engine parts are

serviced, care and cleanliness are important.

It should be understood that proper cleaning and

protection of machined surfaces and friction areas is part

of the repair procedure. This is considered standard

shop practice even if not specifically stated.

• A liberal coating of engine oil should be applied to friction areas during assembly to protect and lubricate

the surfaces on initial operation. • Whenever valve train components, pistons, piston

rings, connecting rods, rod bearings, and crankshaft

journal bearings are removed for service, they should

be retained in order.

At the time of installation, they should be installed in

the same locations and with the same mating

surfaces as when removed.

• Battery cables should be disconnected before any major work is performed on the engine.

Failure to disconnect cables may result in damage to

wire harness or other electrical parts.

Page 55 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-5

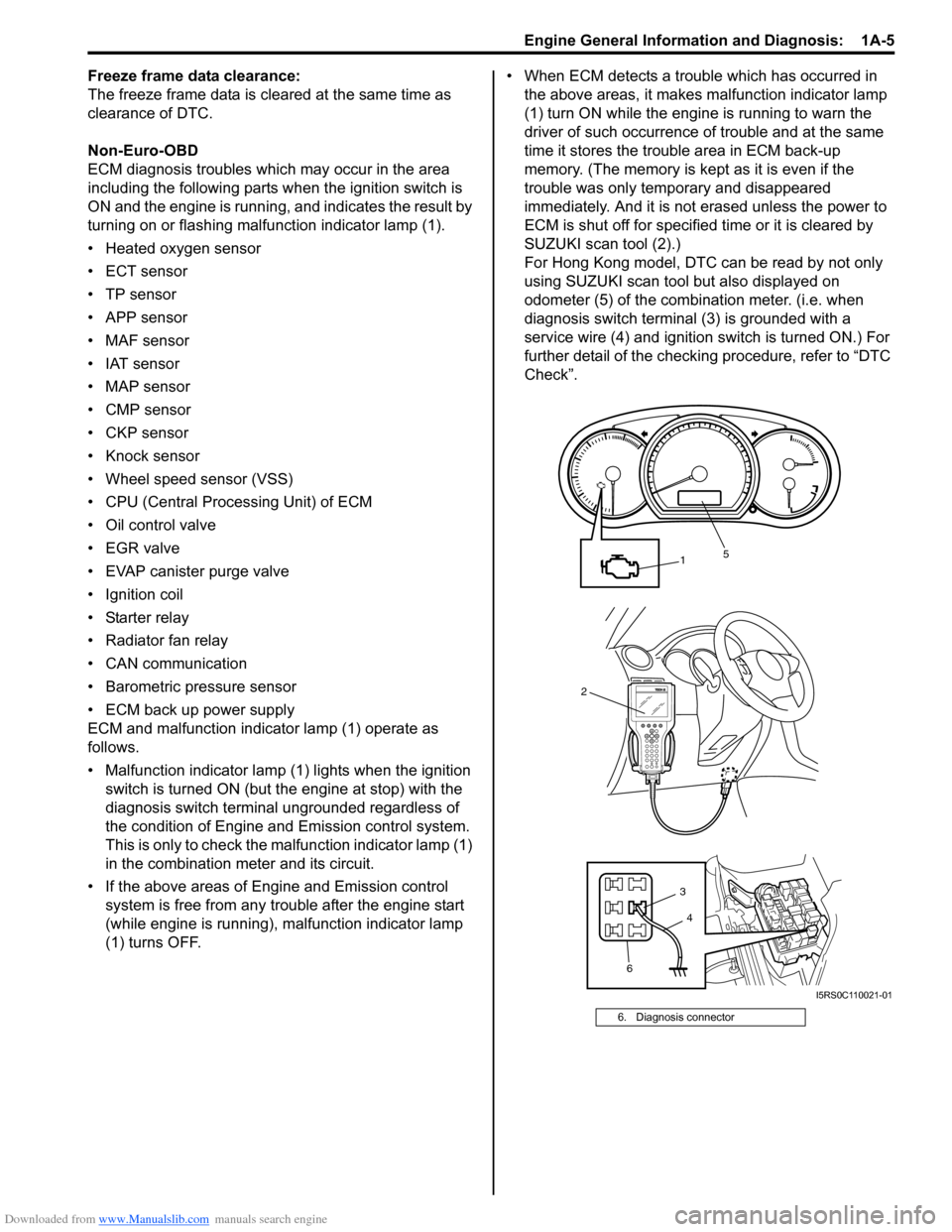

Freeze frame data clearance:

The freeze frame data is cleared at the same time as

clearance of DTC.

Non-Euro-OBD

ECM diagnosis troubles which may occur in the area

including the following parts w hen the ignition switch is

ON and the engine is running, and indicates the result by

turning on or flashing malfunction indicator lamp (1).

• Heated oxygen sensor

• ECT sensor

•TP sensor

• APP sensor

• MAF sensor

• IAT sensor

• MAP sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor (VSS)

• CPU (Central Processing Unit) of ECM

• Oil control valve

• EGR valve

• EVAP canister purge valve

• Ignition coil

• Starter relay

• Radiator fan relay

• CAN communication

• Barometric pressure sensor

• ECM back up power supply

ECM and malfunction indicator lamp (1) operate as

follows.

• Malfunction indicator lamp (1) lights when the ignition switch is turned ON (but t he engine at stop) with the

diagnosis switch terminal ungrounded regardless of

the condition of Engine and Emission control system.

This is only to check the ma lfunction indicator lamp (1)

in the combination meter and its circuit.

• If the above areas of Engine and Emission control system is free from any trouble after the engine start

(while engine is running), malfunction indicator lamp

(1) turns OFF. • When ECM detects a trouble which has occurred in

the above areas, it makes malfunction indicator lamp

(1) turn ON while the engi ne is running to warn the

driver of such occurrence of trouble and at the same

time it stores the trouble area in ECM back-up

memory. (The memory is kept as it is even if the

trouble was only temporary and disappeared

immediately. And it is not erased unless the power to

ECM is shut off for specified time or it is cleared by

SUZUKI scan tool (2).)

For Hong Kong model, DTC can be read by not only

using SUZUKI scan tool but also displayed on

odometer (5) of the combination meter. (i.e. when

diagnosis switch terminal (3) is grounded with a

service wire (4) and ignition switch is turned ON.) For

further detail of the checking procedure, refer to “DTC

Check”.

6. Diagnosis connector

2

1

6 3

5

4

I5RS0C110021-01

Page 65 of 1496

![SUZUKI SWIFT 2008 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / SUZUKI SWIFT 2008 2.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS /](/img/20/7607/w960_7607-64.png)

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-15

Terminal Arrangement of ECM Coupler (Viewed from Harness Side)

[A]: Manual A/C model24. ABS / ESP® control module 49. Radiator cooling fan motor

[B]: Auto A/C model 25. TCM 50. “RDTR FAN” fuse

1. ECM 26. To other control module connected CAN 51. A/C compressor relay

2. APP sensor assembly 27. Generator 52. Magnet clutch of compressor (A/C model)

3. Shield wire 28. Electric load current sensor (if equipped) 53. “A/C CPRSR” fuse

4. CMP sensor 29. Brake light 54. Ignition coil assembly (for No.1 and No.4 spark

plugs)

5. CKP sensor 30. Brake light switch 55. Ignition coil assembly (for No.2 and No.3 spark

plugs)

6. MAF and IAT sensor 31. Diagnosis connector (Hong Kong model) 56. P/S control module

7. MAP sensor 32. Throttle actuator control relay 57. “RADIO” fuse

8. ECT sensor 33. “THR MOT” fuse 58. Main relay

9. A/C refrigerant pressure sensor 34. Throttle throttle body assembly 59. “IG COIL” fuse

10. A/C evaporator outlet air temp. sensor (Manual A/C model) 35. Throttle actuator

60. Ignition switch

11. HO2S-1 36. TP sensor 61. “IG ACC” fuse

12. HO2S-2 37. Injector No.1 62. “FI” fuse

13. Knock sensor 38. Injector No.2 63. Starting motor control relay

14. Blower motor relay 39. Injector No.3 64. “ST SIG” fuse

15. Blower motor 40. Injector No.4 65. “ST MOT” fuse

16. Blower motor resistor 41. EVAP canister purge valve66. Transmission range switch (A/T model) or CPP

switch (Hong Kong model with M/T)

17. Blower speed selector 42. EGR valve 67. Starting motor

18. A/C switch 43. Oil control valve (Camshaft position

control) (VVT model) 68. Immobilizer coil antenna

19. Blower motor controller 44. Fuel pump relay 69. Main fuse box

20. HVAC control module 45. Fuel pump 70. Battery

21. Data link connector (DLC) 46. Radiator cooling fan motor relay No.1 71. Barometric pressure sensor

22. To other control module connected with DLC 47. Radiator cooling fan motor relay No.2

72. Engine ground

23. BCM 48. Radiator cooling fan motor relay No.3 73. Body ground

E23 C37

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

34

1819

567

1011

17

20

47 46

495051

2122

52 16

25 9

24

14

29

55

57 54 53

59

60 58 2

262728

15

30

56 4832 31

34353637

40

42 39 38

44

45 43 41 331

1213

238

I4RS0A110008-01

Page 66 of 1496

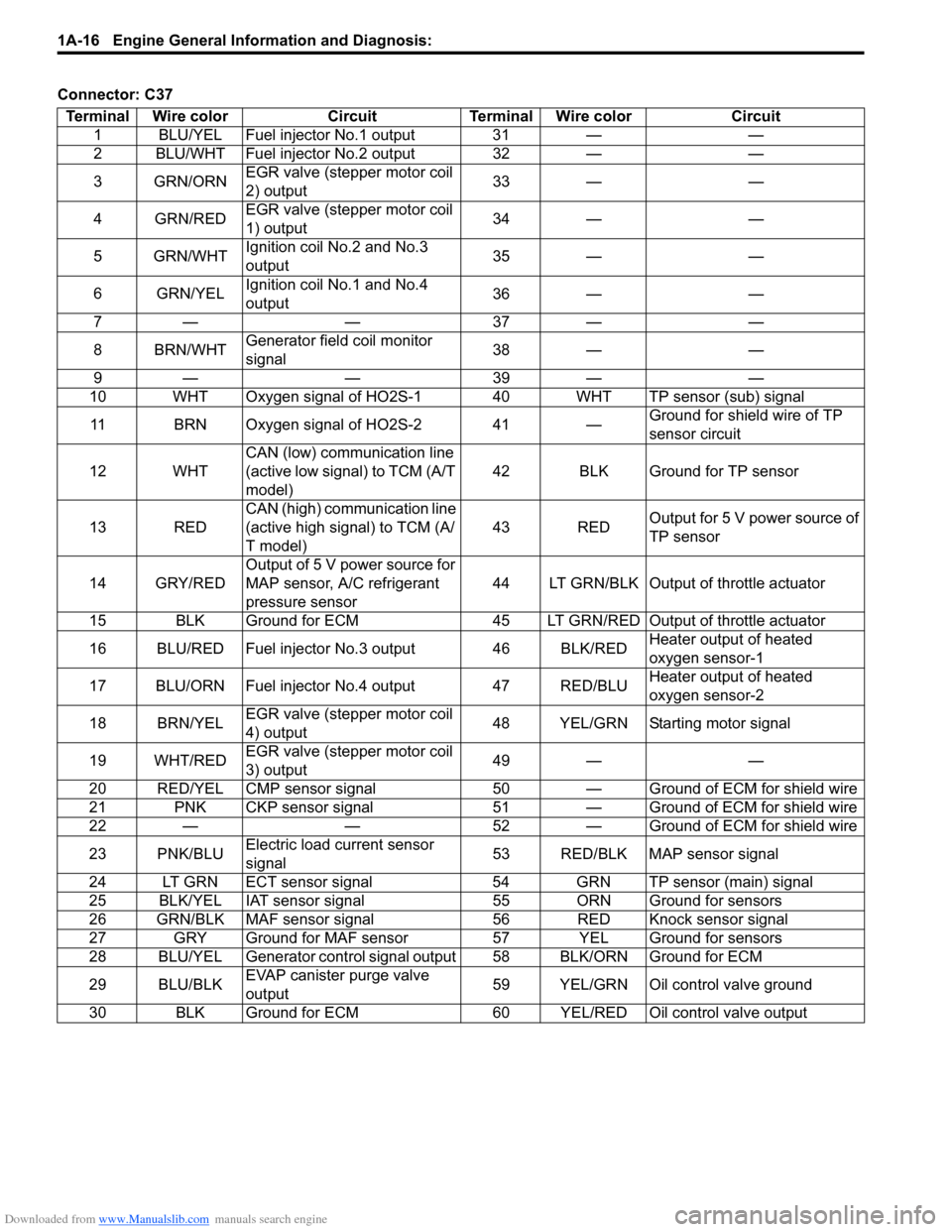

Downloaded from www.Manualslib.com manuals search engine 1A-16 Engine General Information and Diagnosis:

Connector: C37Terminal Wire color Circuit Terminal Wire color Circuit 1 BLU/YEL Fuel injector No.1 output 31 — —

2 BLU/WHT Fuel injector No.2 output 32 — —

3GRN/ORN EGR valve (stepper motor coil

2) output 33 — —

4 GRN/RED EGR valve (stepper motor coil

1) output 34 — —

5 GRN/WHT Ignition coil No.2 and No.3

output 35 — —

6 GRN/YEL Ignition coil No.1 and No.4

output 36 — —

7— — 37— —

8 BRN/WHT Generator field coil monitor

signal 38 — —

9— — 39— —

10 WHT Oxygen signal of HO2S-1 40 WHT TP sensor (sub) signal

11 BRN Oxygen signal of HO2S-2 41 — Ground for shield wire of TP

sensor circuit

12 WHT CAN (low) communication line

(active low signal) to TCM (A/T

model) 42 BLK Ground for TP sensor

13 RED CAN (high) communication line

(active high signal) to TCM (A/

T model) 43 RED

Output for 5 V power source of

TP sensor

14 GRY/RED Output of 5 V power source for

MAP sensor, A/C refrigerant

pressure sensor 44 LT GRN/BLK Output of throttle actuator

15 BLK Ground for ECM 45 LT GRN/RE D Output of throttle actuator

16 BLU/RED Fuel injector No.3 output 46 BLK/RED Heater output of heated

oxygen sensor-1

17 BLU/ORN Fuel injector No.4 output 47 RED/BLU Heater output of heated

oxygen sensor-2

18 BRN/YEL EGR valve (stepper motor coil

4) output 48 YEL/GRN Starting motor signal

19 WHT/RED EGR valve (stepper motor coil

3) output 49 — —

20 RED/YEL CMP sensor signal 50 — G round of ECM for shield wire

21 PNK CKP sensor signal 51 — Ground of ECM for shield wire

22 — — 52 — Ground of ECM for shield wire

23 PNK/BLU Electric load current sensor

signal 53 RED/BLK MAP sensor signal

24 LT GRN ECT sensor signal 54 GRN TP sensor (main) signal

25 BLK/YEL IAT sensor signal 55 ORN Ground for sensors

26 GRN/BLK MAF sensor signal 56 RED Knock sensor signal

27 GRY Ground for MAF sensor 57 YEL Ground for sensors

28 BLU/YEL Generator control signal output 58 BLK/ORN Ground for ECM

29 BLU/BLK EVAP canister purge valve

output 59 YEL/GRN Oil control valve ground

30 BLK Ground for ECM 60 YEL/RED Oil control valve output

Page 67 of 1496

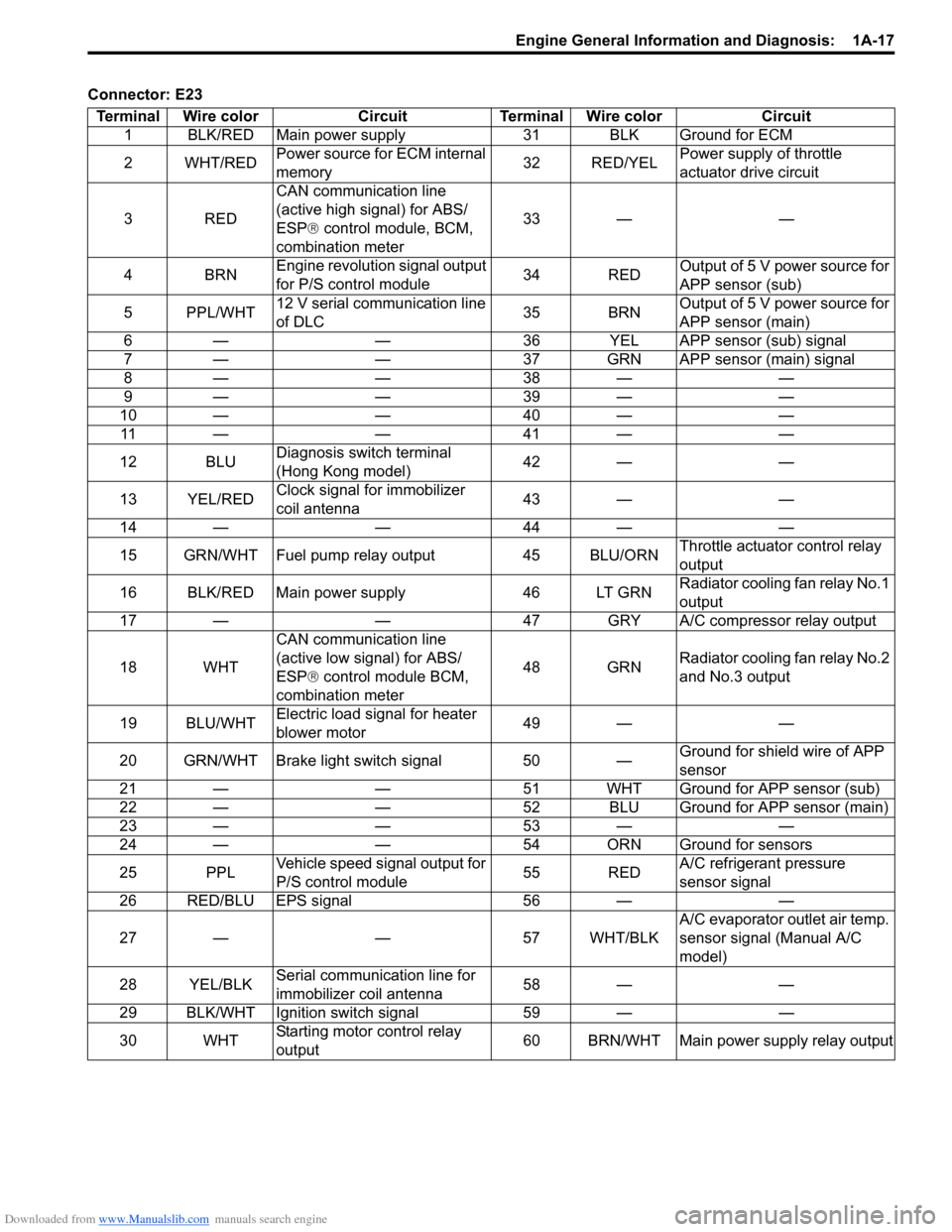

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-17

Connector: E23Terminal Wire color Circuit Terminal Wire color Circuit 1 BLK/RED Main power supply 31 BLK Ground for ECM

2WHT/RED Power source for ECM internal

memory 32 RED/YELPower supply of throttle

actuator drive circuit

3RED CAN communication line

(active high signal) for ABS/

ESP®

control module, BCM,

combination meter 33 — —

4BRN Engine revolution signal output

for P/S control module 34 REDOutput of 5 V power source for

APP sensor (sub)

5 PPL/WHT 12 V serial communication line

of DLC 35 BRNOutput of 5 V power source for

APP sensor (main)

6 — — 36 YEL APP sensor (sub) signal

7 — — 37 GRN APP sensor (main) signal

8— — 38— —

9— — 39— —

10——40—— 11——41——

12 BLU Diagnosis switch terminal

(Hong Kong model) 42 — —

13 YEL/RED Clock signal for immobilizer

coil antenna 43 — —

14——44——

15 GRN/WHT Fuel pump relay output 45 BLU/ORN Throttle actuator control relay

output

16 BLK/RED Main power supply 46 LT GRN Radiator cooling fan relay No.1

output

17 — — 47 GRY A/C compressor relay output

18 WHT CAN communication line

(active low signal) for ABS/

ESP®

control module BCM,

combination meter 48 GRN

Radiator cooling fan relay No.2

and No.3 output

19 BLU/WHT Electric load signal for heater

blower motor 49 — —

20 GRN/WHT Brake light switch signal 50 — Ground for shield wire of APP

sensor

21 — — 51 WHT Ground for APP sensor (sub)

22 — — 52 BLU Ground for APP sensor (main)

23——53——

24 — — 54 ORN Ground for sensors

25 PPL Vehicle speed signal output for

P/S control module 55 REDA/C refrigerant pressure

sensor signal

26 RED/BLU EPS signal 56 — —

27 — — 57 WHT/BLK A/C evaporator outlet air temp.

sensor signal (Manual A/C

model)

28 YEL/BLK Serial communication line for

immobilizer coil antenna 58 — —

29 BLK/WHT Ignition switch signal 59 — —

30 WHT Starting motor control relay

output 60 BRN/WHT Main power supply relay output

Page 75 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the sy mptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts. Step 10: Intermittent Problems Check

Check parts where an intermit

tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is re lated to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

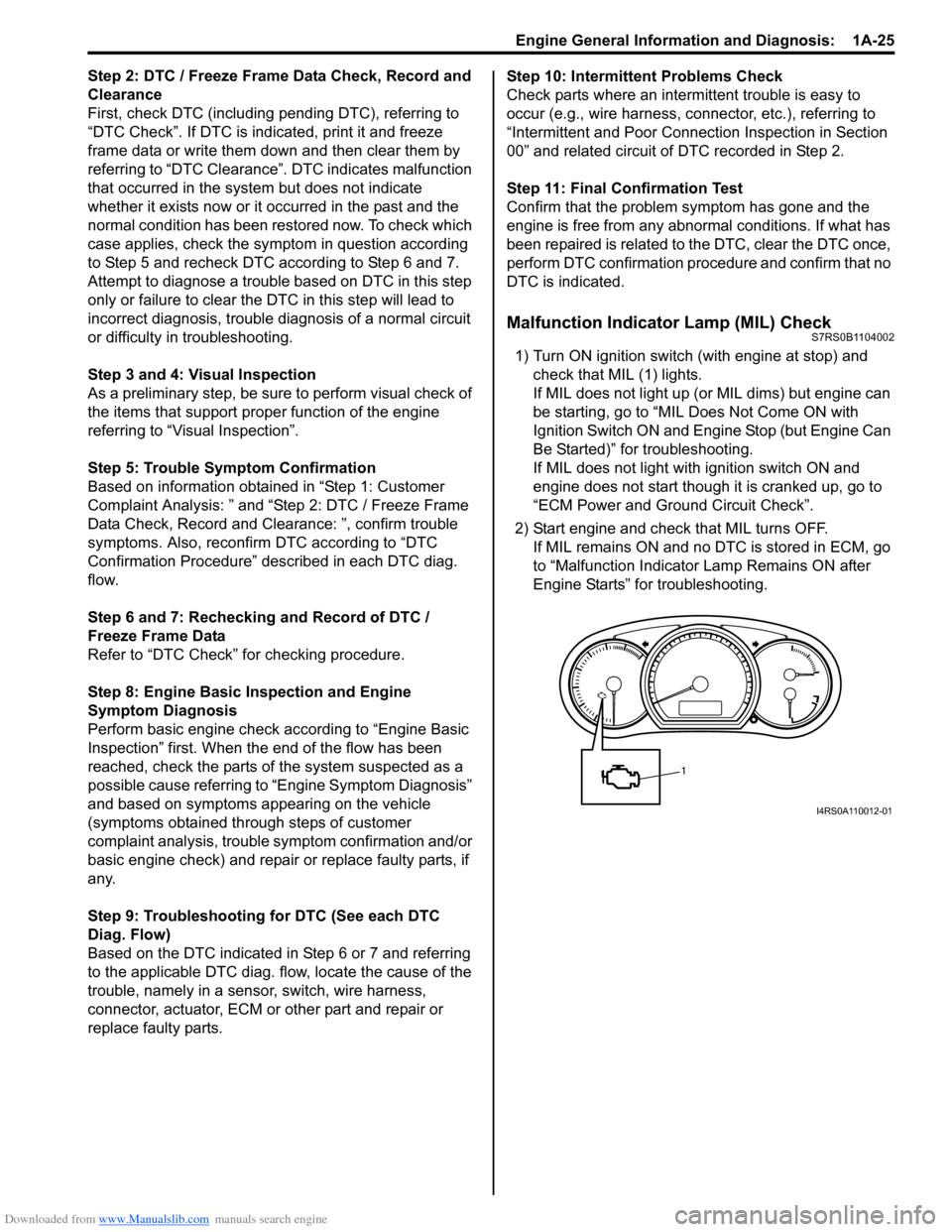

Malfunction Indicator Lamp (MIL) CheckS7RS0B1104002

1) Turn ON ignition switch (with engine at stop) and check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “MIL Does Not Come ON with

Ignition Switch ON and Engine Stop (but Engine Can

Be Started)” for troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF. If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

1

I4RS0A110012-01

Page 76 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

DTC CheckS7RS0B1104003

NOTE

• There are two types of OBD system depending on the vehicle specification.

For details, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

• The MIL is turned on when the ECM and/or TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs th e DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the SUZUKI scan tool

because the DTC stored in ECM and TCM

is not read and displayed at a time.

However, each of the ECM and TCM needs

not to be checked with the generic scan

tool because the DTC stored in ECM and

TCM is read and displayed at a time.

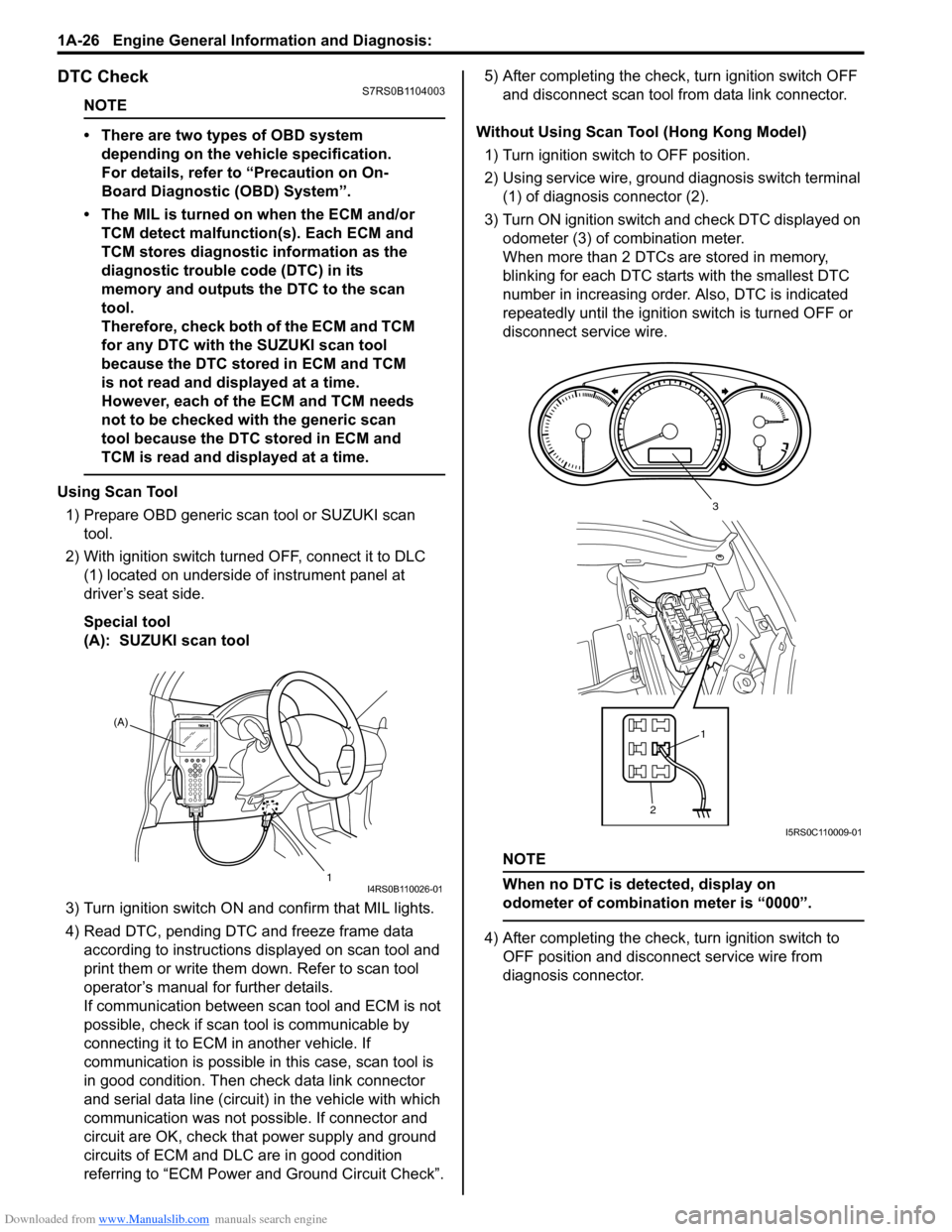

Using Scan Tool

1) Prepare OBD generic scan tool or SUZUKI scan tool.

2) With ignition switch turned OFF, connect it to DLC (1) located on underside of instrument panel at

driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC, pending DTC and freeze frame data according to instructions displayed on scan tool and

print them or write them down. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, check if scan tool is communicable by

connecting it to ECM in another vehicle. If

communication is possible in this case, scan tool is

in good condition. Then check data link connector

and serial data line (circuit) in the vehicle with which

communication was not possible. If connector and

circuit are OK, check that power supply and ground

circuits of ECM and DLC are in good condition

referring to “ECM Power and Ground Circuit Check”. 5) After completing the check,

turn ignition switch OFF

and disconnect scan tool from data link connector.

Without Using Scan Tool (Hong Kong Model) 1) Turn ignition switch to OFF position.

2) Using service wire, ground diagnosis switch terminal (1) of diagnosis connector (2).

3) Turn ON ignition switch and check DTC displayed on

odometer (3) of combination meter.

When more than 2 DTCs are stored in memory,

blinking for each DTC star ts with the smallest DTC

number in increasing order. Also, DTC is indicated

repeatedly until the ignition switch is turned OFF or

disconnect service wire.

NOTE

When no DTC is detected, display on

odometer of combinatio n meter is “0000”.

4) After completing the check, turn ignition switch to

OFF position and disconnect service wire from

diagnosis connector.

(A)

1

I4RS0B110026-01

21

3

I5RS0C110009-01