Outside SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 271 of 1496

Downloaded from www.Manualslib.com manuals search engine Aux. Emission Control Devices: 1B-4

EVAP Canister InspectionS7RS0B1206006

WARNING!

DO NOT SUCK nozzles on EVAP canister.

Fuel vapor inside EVAP canister is harmful.

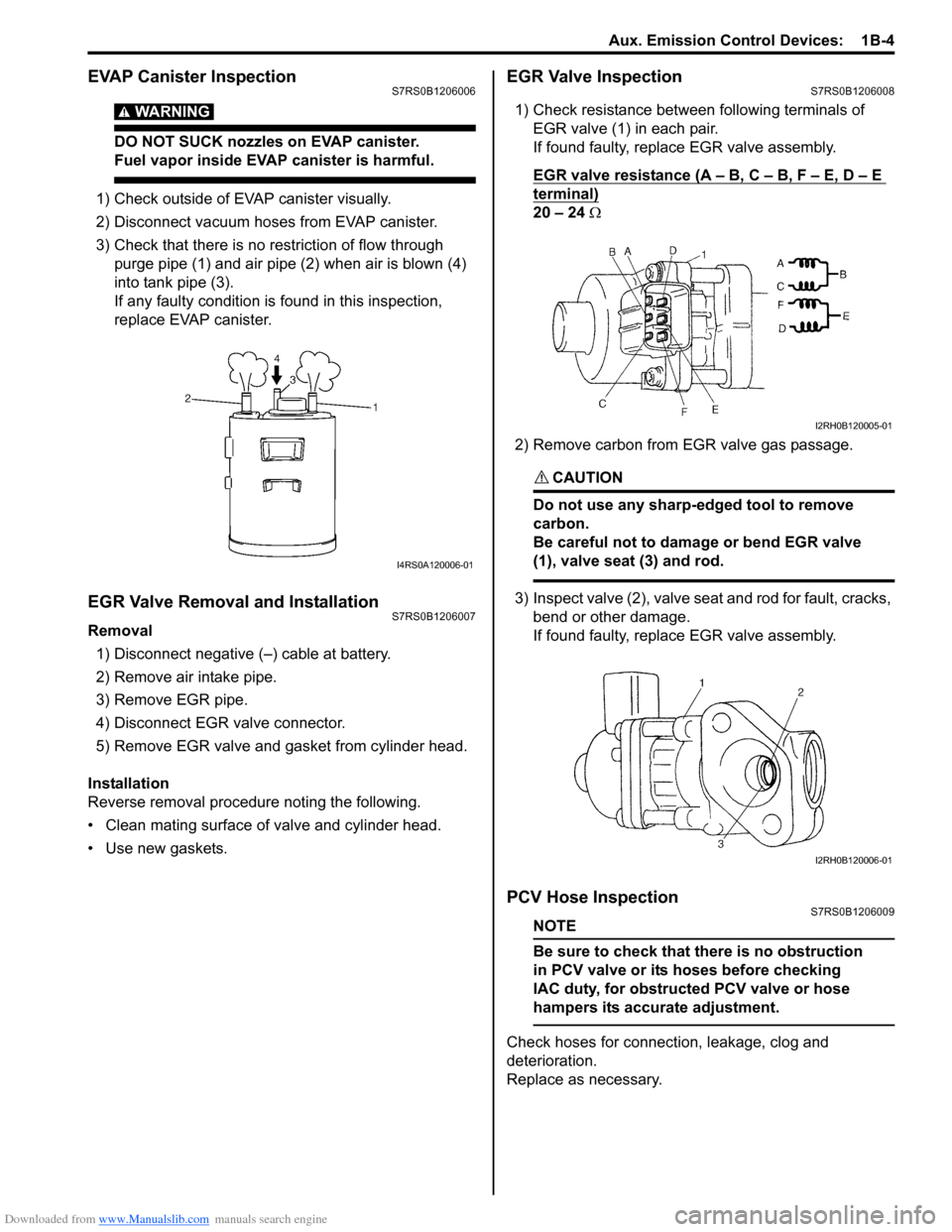

1) Check outside of EVAP canister visually.

2) Disconnect vacuum hoses from EVAP canister.

3) Check that there is no restriction of flow through purge pipe (1) and air pipe (2) when air is blown (4)

into tank pipe (3).

If any faulty condition is found in this inspection,

replace EVAP canister.

EGR Valve Removal and InstallationS7RS0B1206007

Removal

1) Disconnect negative (–) cable at battery.

2) Remove air intake pipe.

3) Remove EGR pipe.

4) Disconnect EGR valve connector.

5) Remove EGR valve and gasket from cylinder head.

Installation

Reverse removal procedure noting the following.

• Clean mating surface of valve and cylinder head.

• Use new gaskets.

EGR Valve InspectionS7RS0B1206008

1) Check resistance between following terminals of EGR valve (1) in each pair.

If found faulty, replace EGR valve assembly.

EGR valve resistance (A – B, C – B, F – E, D – E

terminal)

20 – 24 Ω

2) Remove carbon from EGR valve gas passage.

CAUTION!

Do not use any sharp-edged tool to remove

carbon.

Be careful not to damage or bend EGR valve

(1), valve seat (3) and rod.

3) Inspect valve (2), valve seat and rod for fault, cracks, bend or other damage.

If found faulty, replace EGR valve assembly.

PCV Hose InspectionS7RS0B1206009

NOTE

Be sure to check that there is no obstruction

in PCV valve or its hoses before checking

IAC duty, for obstructed PCV valve or hose

hampers its accurate adjustment.

Check hoses for connection, leakage, clog and

deterioration.

Replace as necessary.

I4RS0A120006-01

I2RH0B120005-01

I2RH0B120006-01

Page 318 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-33 Engine Mechanical:

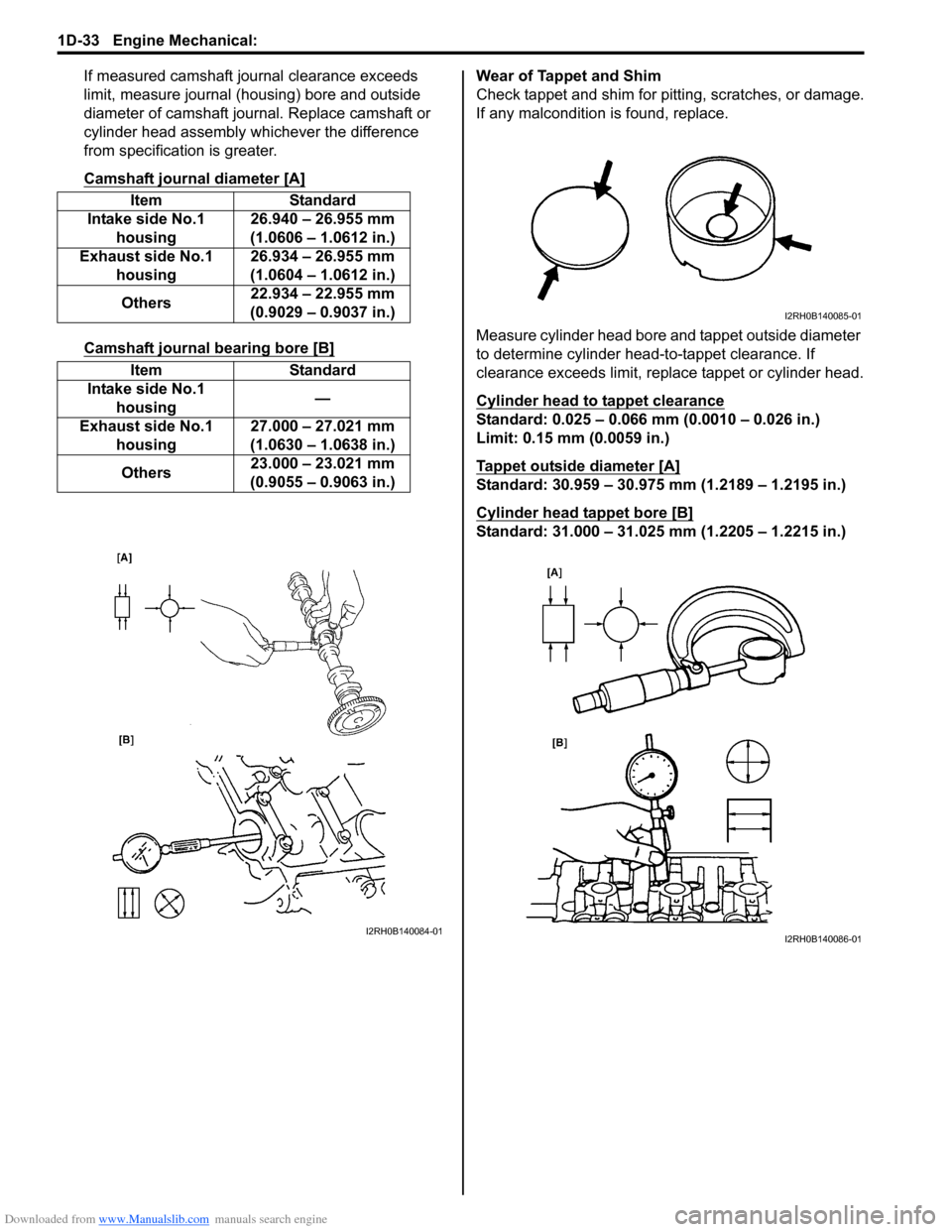

If measured camshaft journal clearance exceeds

limit, measure journal (housing) bore and outside

diameter of camshaft journal. Replace camshaft or

cylinder head assembly whichever the difference

from specification is greater.

Camshaft journal diameter [A]

Camshaft journal bearing bore [B]

Wear of Tappet and Shim

Check tappet and shim for pitting, scratches, or damage.

If any malcondition is found, replace.

Measure cylinder head bore and tappet outside diameter

to determine cylinder head-to-tappet clearance. If

clearance exceeds limit, replace tappet or cylinder head.

Cylinder head to tappet clearance

Standard: 0.025 – 0.066 mm (0.0010 – 0.026 in.)

Limit: 0.15 mm (0.0059 in.)

Tappet outside diameter [A]

Standard: 30.959 – 30.975 mm (1.2189 – 1.2195 in.)

Cylinder head tappet bore [B]

Standard: 31.000 – 31.025 mm (1.2205 – 1.2215 in.)

Item Standard

Intake side No.1 housing 26.940 – 26.955 mm

(1.0606 – 1.0612 in.)

Exhaust side No.1 housing 26.934 – 26.955 mm

(1.0604 – 1.0612 in.)

Others 22.934 – 22.955 mm

(0.9029 – 0.9037 in.)

Item Standard

Intake side No.1 housing —

Exhaust side No.1 housing 27.000 – 27.021 mm

(1.0630 – 1.0638 in.)

Others 23.000 – 23.021 mm

(0.9055 – 0.9063 in.)

I2RH0B140084-01

I2RH0B140085-01

I2RH0B140086-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

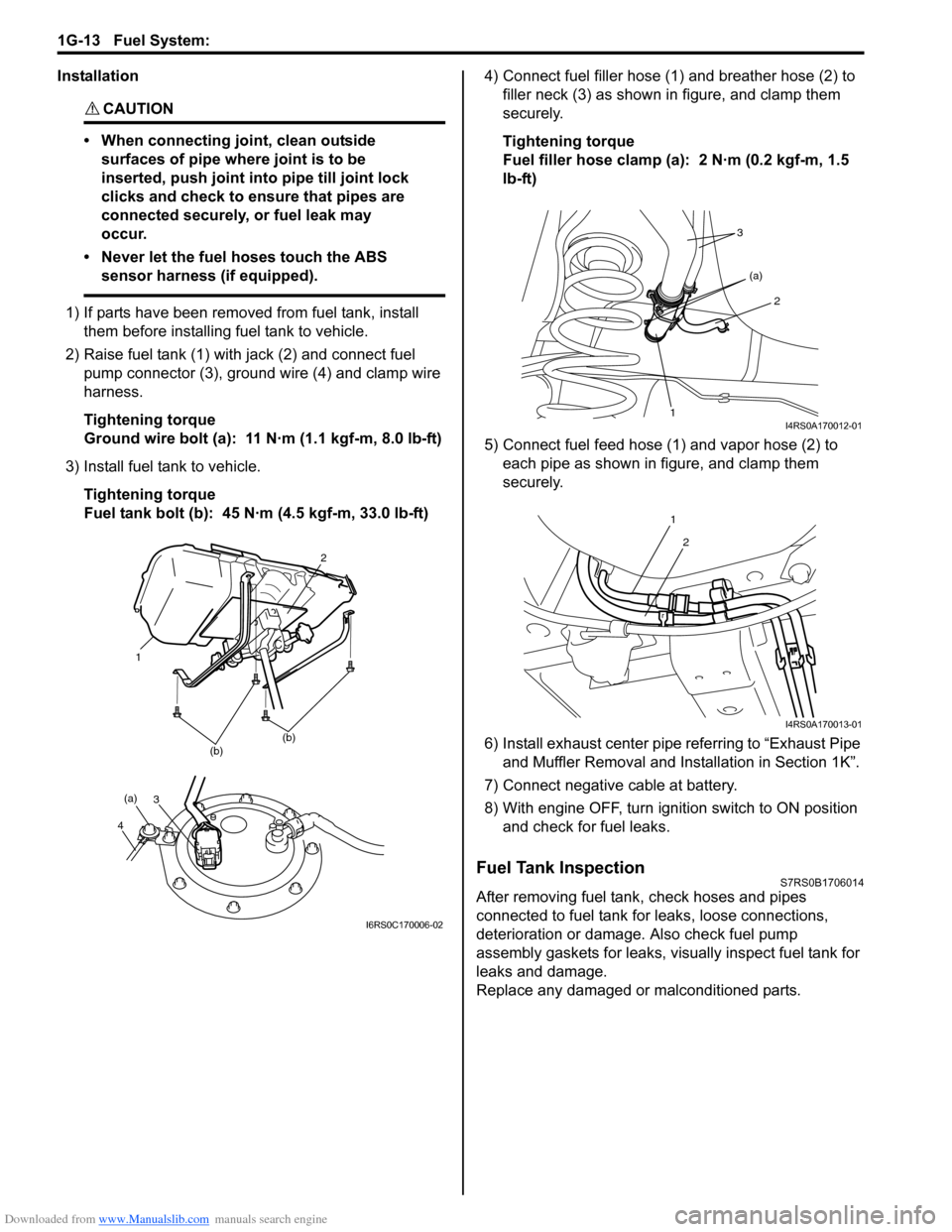

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 390 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-15 Fuel System:

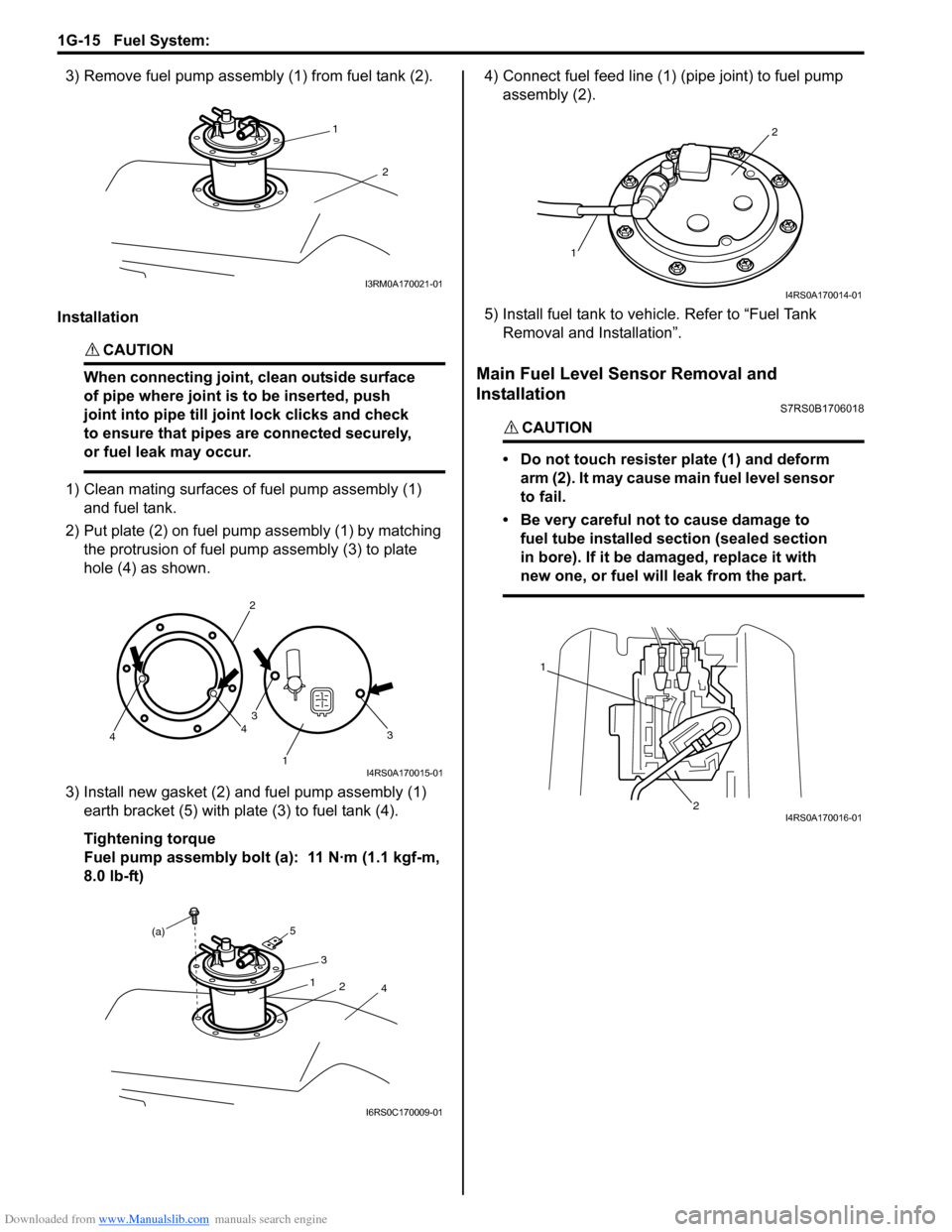

3) Remove fuel pump assembly (1) from fuel tank (2).

Installation

CAUTION!

When connecting joint, clean outside surface

of pipe where joint is to be inserted, push

joint into pipe till jo int lock clicks and check

to ensure that pipes are connected securely,

or fuel leak may occur.

1) Clean mating surfaces of fuel pump assembly (1) and fuel tank.

2) Put plate (2) on fuel pump assembly (1) by matching the protrusion of fuel pump assembly (3) to plate

hole (4) as shown.

3) Install new gasket (2) and fuel pump assembly (1) earth bracket (5) with plate (3) to fuel tank (4).

Tightening torque

Fuel pump assembly bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft) 4) Connect fuel feed line (1) (pipe joint) to fuel pump

assembly (2).

5) Install fuel tank to vehi cle. Refer to “Fuel Tank

Removal and Installation”.

Main Fuel Level Sensor Removal and

Installation

S7RS0B1706018

CAUTION!

• Do not touch resister plate (1) and deform arm (2). It may cause main fuel level sensor

to fail.

• Be very careful not to cause damage to fuel tube installed section (sealed section

in bore). If it be damaged, replace it with

new one, or fuel will leak from the part.

1

2

I3RM0A170021-01

3

1

3

2

44

I4RS0A170015-01

3

1 2

(a)

4

5

I6RS0C170009-01

2

1

I4RS0A170014-01

1

2I4RS0A170016-01

Page 408 of 1496

Downloaded from www.Manualslib.com manuals search engine 1I-7 Starting System:

Spring

Inspect brush springs for wear, damage or other

abnormal conditions. Replace if necessary.

Brush spring tension

Standard: 2.2 kg (4.85 lb)

Limit: 0.6 kg (1.33 lb)

Brush Holder

• Check movement of brush in brush holder. If brush movement within brush holder is sluggish, check

brush holder for distortion and sliding faces for

contamination.

Clean or correct as necessary.

• Check for continuity across insulated brush (positive side) and grounded brush (negative side).

If continuity exists, brus h holder is grounded due to

defective insulation and should be replaced.

Armature

• Inspect commutator for dirt or burn. Correct with sandpaper or lathe, if necessary.

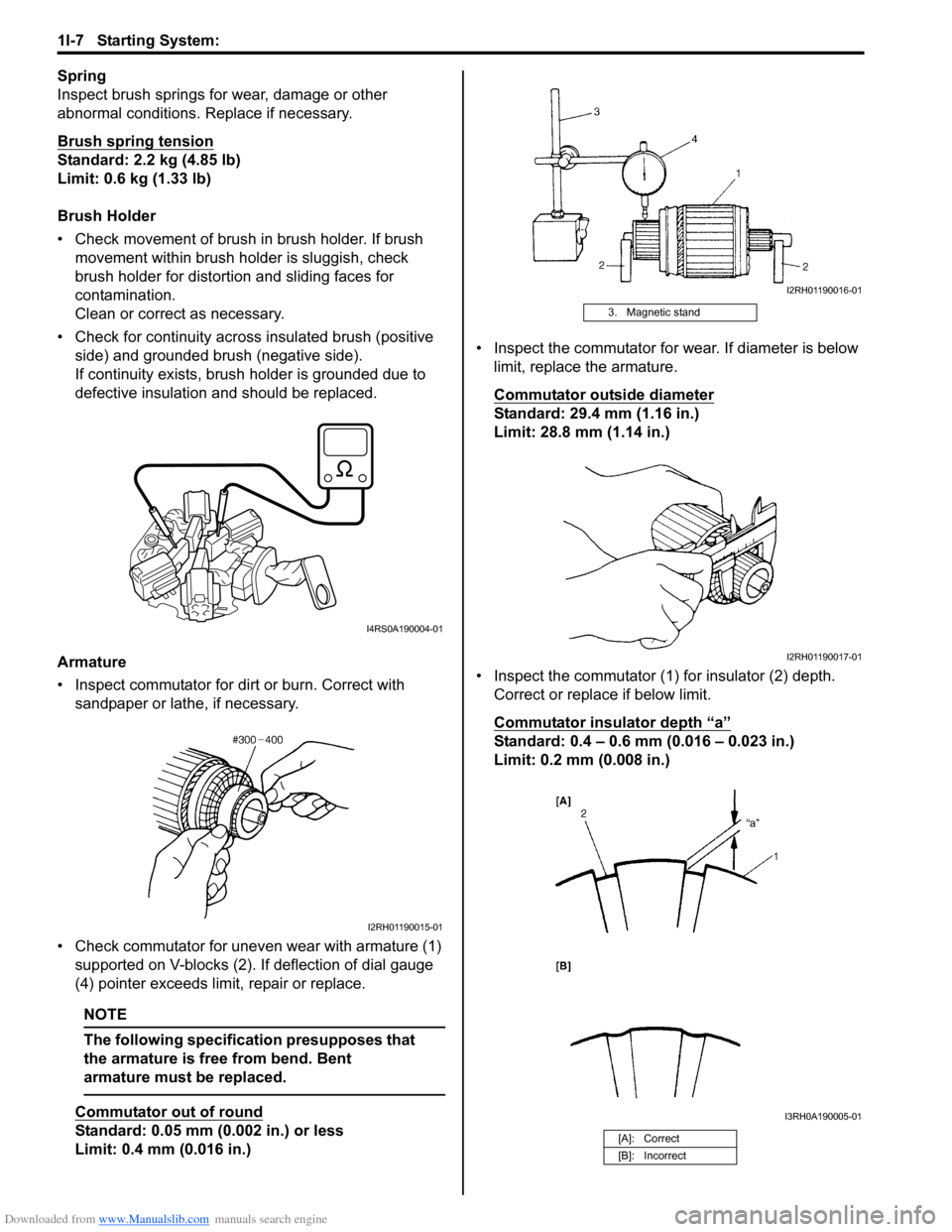

• Check commutator for uneven wear with armature (1) supported on V-blocks (2). If deflection of dial gauge

(4) pointer exceeds limit, repair or replace.

NOTE

The following specification presupposes that

the armature is free from bend. Bent

armature must be replaced.

Commutator out of round

Standard: 0.05 mm (0.002 in.) or less

Limit: 0.4 mm (0.016 in.) • Inspect the commutator for wear. If diameter is below

limit, replace the armature.

Commutator outside diameter

Standard: 29.4 mm (1.16 in.)

Limit: 28.8 mm (1.14 in.)

• Inspect the commutator (1) for insulator (2) depth. Correct or replace if below limit.

Commutator insulator depth “a”

Standard: 0.4 – 0.6 mm (0.016 – 0.023 in.)

Limit: 0.2 mm (0.008 in.)

I4RS0A190004-01

I2RH01190015-01

3. Magnetic stand

[A]: Correct

[B]: Incorrect

I2RH01190016-01

I2RH01190017-01

I3RH0A190005-01

Page 434 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-1 Front Suspension:

Suspension

Front Suspension

General Description

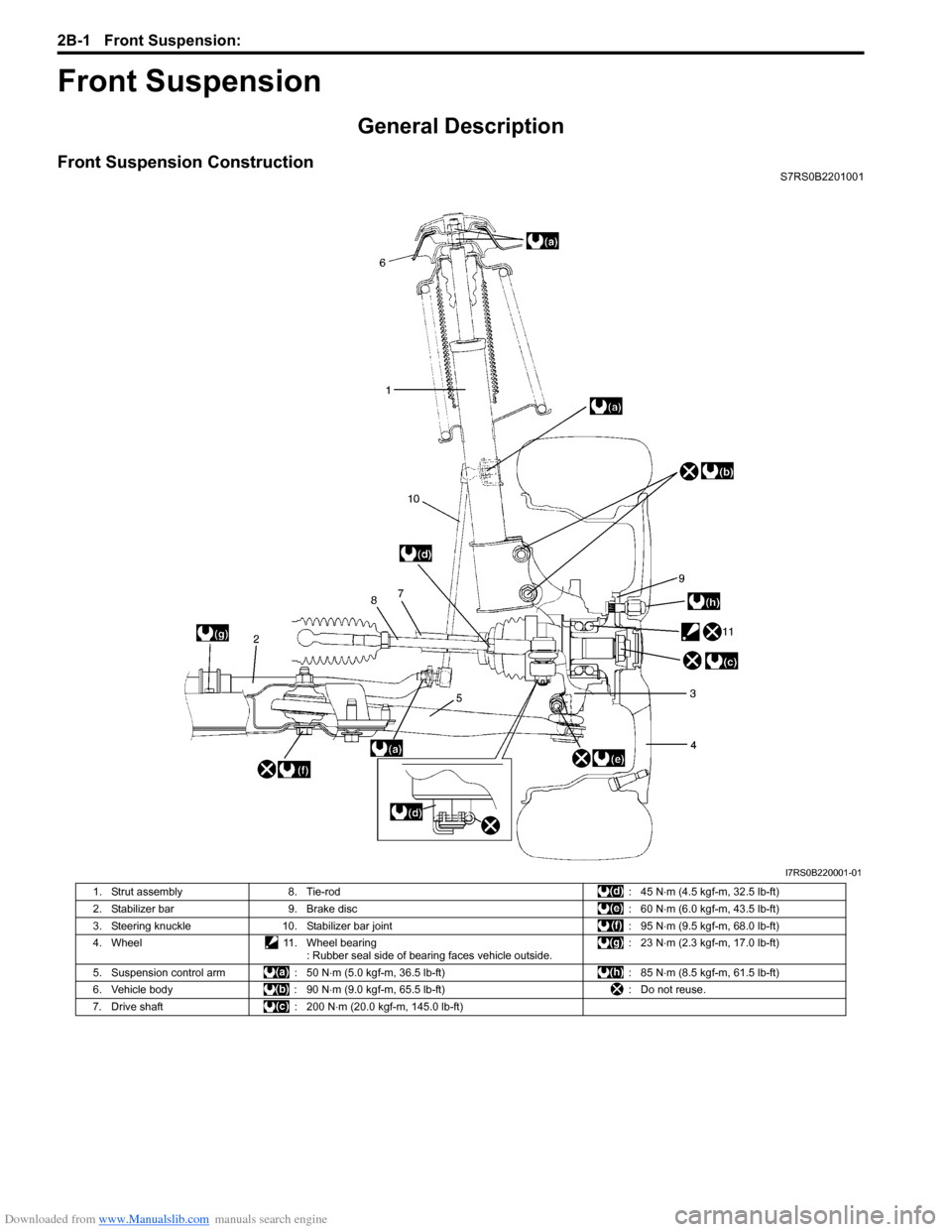

Front Suspension ConstructionS7RS0B2201001

I7RS0B220001-01

1. Strut assembly8. Tie-rod : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

2. Stabilizer bar 9. Brake disc : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

3. Steering knuckle 10. Stabilizer bar joint : 95 N⋅m (9.5 kgf-m, 68.0 lb-ft)

4. Wheel 11. Wheel bearing

: Rubber seal side of bearing faces vehicle outside. : 23 N

⋅m (2.3 kgf-m, 17.0 lb-ft)

5. Suspension control arm : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft) : 85 N⋅m (8.5 kgf-m, 61.5 lb-ft)

6. Vehicle body : 90 N⋅m (9.0 kgf-m, 65.5 lb-ft) : Do not reuse.

7. Drive shaft : 200 N⋅m (20.0 kgf-m, 145.0 lb-ft)

Page 436 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

Adjustment1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5 lb-

ft)

NOTE

Make sure that rack boots are not twisted.

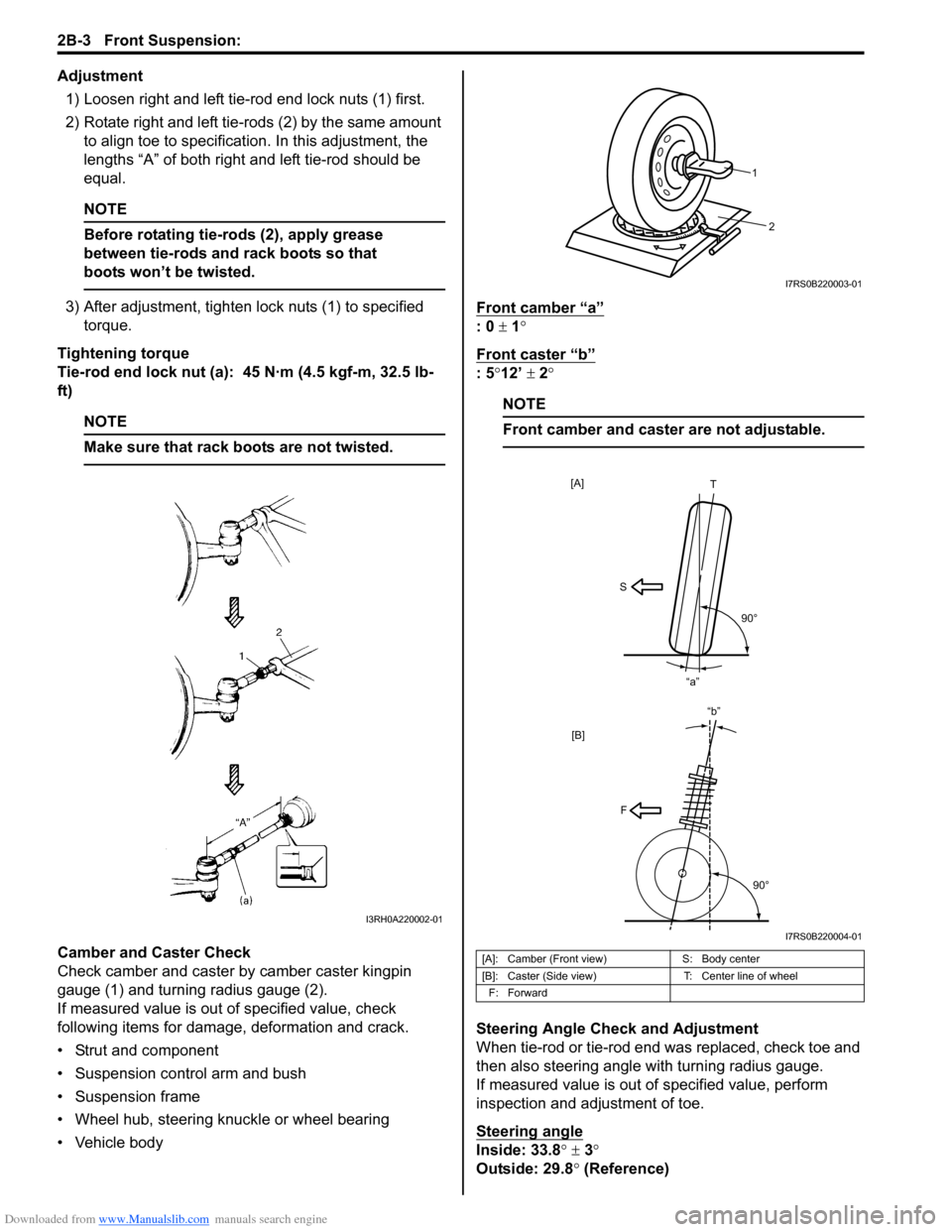

Camber and Caster Check

Check camber and caster by camber caster kingpin

gauge (1) and turning radius gauge (2).

If measured value is out of specified value, check

following items for damage, deformation and crack.

• Strut and component

• Suspension control arm and bush

• Suspension frame

• Wheel hub, steering knuckle or wheel bearing

• Vehicle body Front camber “a”

: 0

± 1°

Front caster “b”

: 5 °12’ ± 2°

NOTE

Front camber and caster are not adjustable.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge.

If measured value is out of specified value, perform

inspection and adjustment of toe.

Steering angle

Inside: 33.8 ° ± 3 °

Outside: 29.8 ° (Reference)

I3RH0A220002-01

[A]: Camber (Front view) S: Body center

[B]: Caster (Side view) T: Center line of wheel

F: Forward

2

1

I7RS0B220003-01

[B]

S T

90°

“a”

[A]

F

90°

“b”

I7RS0B220004-01

Page 442 of 1496

Downloaded from www.Manualslib.com manuals search engine 2B-9 Front Suspension:

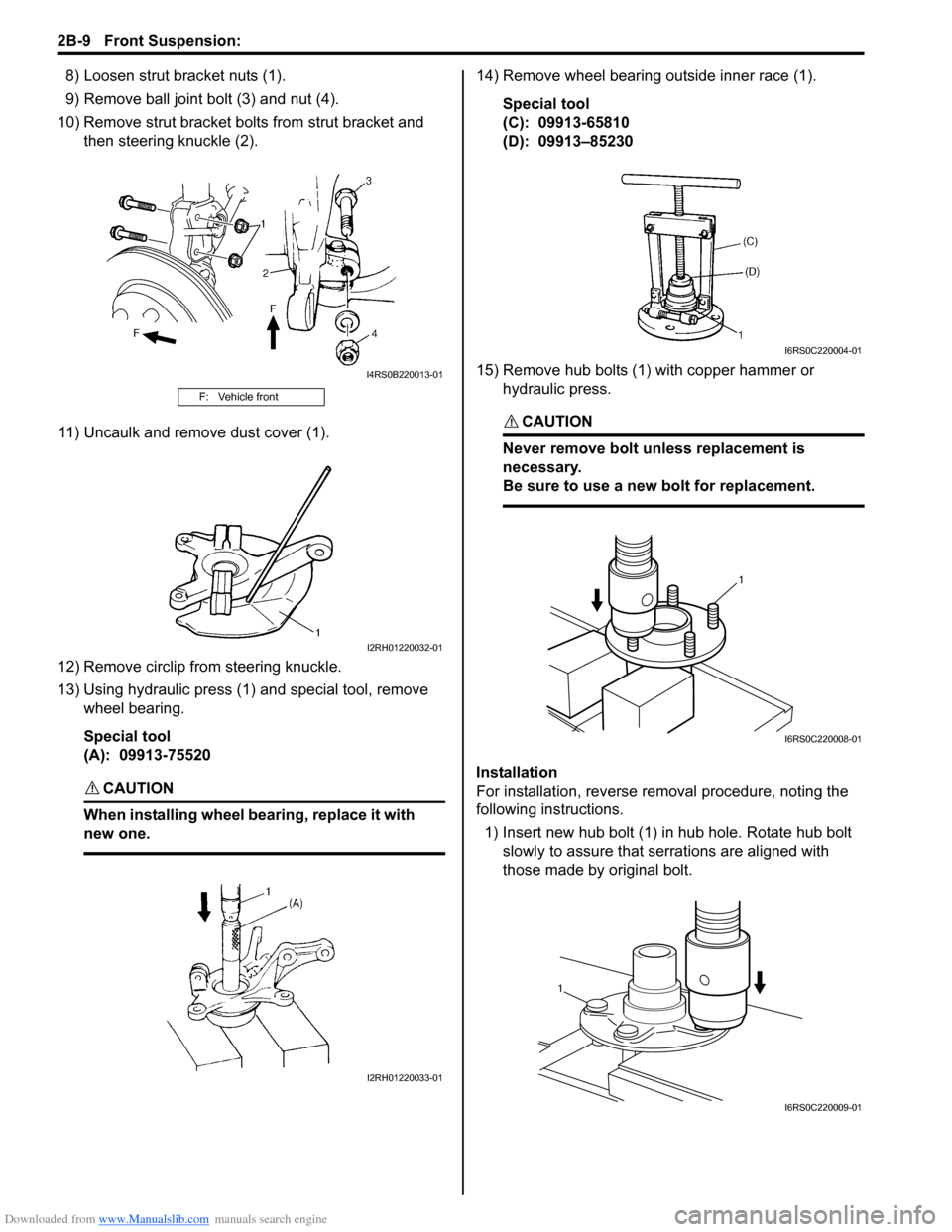

8) Loosen strut bracket nuts (1).

9) Remove ball joint bolt (3) and nut (4).

10) Remove strut bracket bolt s from strut bracket and

then steering knuckle (2).

11) Uncaulk and remove dust cover (1).

12) Remove circlip from steering knuckle.

13) Using hydraulic press (1) and special tool, remove wheel bearing.

Special tool

(A): 09913-75520

CAUTION!

When installing wheel bearing, replace it with

new one.

14) Remove wheel bearing outside inner race (1).

Special tool

(C): 09913-65810

(D): 09913–85230

15) Remove hub bolts (1) with copper hammer or hydraulic press.

CAUTION!

Never remove bolt unle ss replacement is

necessary.

Be sure to use a new bolt for replacement.

Installation

For installation, reverse removal procedure, noting the

following instructions.

1) Insert new hub bolt (1) in hub hole. Rotate hub bolt slowly to assure that serrations are aligned with

those made by original bolt.

F: Vehicle front

I4RS0B220013-01

I2RH01220032-01

I2RH01220033-01

I6RS0C220004-01

1

I6RS0C220008-01

1

I6RS0C220009-01

Page 469 of 1496

Downloaded from www.Manualslib.com manuals search engine Wheels and Tires: 2D-2

Lower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

Replacement Tires

When replacement is necessary, the original equipment

type tire should be used. Refer to the Tire Placard.

Replacement tires should be of the same size, load

range and construction as those originally on the vehicle.

Use of any other size or type tire may affect ride,

handling, speedometer / odometer calibration, vehicle

ground clearance and tire or snow chain clearance to the

body and chassis.

It is recommended that new tires be installed in pairs on

the same axle. If necessary to replace only one tire, it

should be paired with the tire having the most tread, to

equalize braking traction.

WARNING!

Do not mix different types of tires on the

same vehicle such as radial, bias and bias-

belted tires except in emergencies, because

handling may be seriously affected and may

result in loss of control.

The metric term for tire infl ation pressure is the kilo

pascal (kPa). Tire pressures is usually printed in both

kPa and kgf/cm

2 on the “Tire Placard”.

Metric tire gauges are available from tool suppliers.

The chart, shown the table, converts commonly used

inflation pressures from kPa to kgf/cm

2 and psi.

Wheels DescriptionS7RS0B2401002

Wheel Maintenance

Wheel repairs that use welding, heating, or peening are

not approved. All damaged wheels should be replaced.

Replacement Wheels

Wheels must be replaced if they are bent, dented, have

excessive lateral or radial runout, air leak through welds,

have elongated bolt holes, if lug wheel bolts won’t stay

tight, or if they are heavily rusted. Wheels with greater

runout than shown in the following may cause

objectional vibrations.

Replacement wheels must be equivalent to the original

equipment wheels in load capacity, diameter, rim with

offset and mounting configuration. A wheel of improper

size or type may affect wheel and bearing life, brake

cooling, speedometer / odometer calibration, vehicle

ground clearance and tire clearance to body and

chassis.

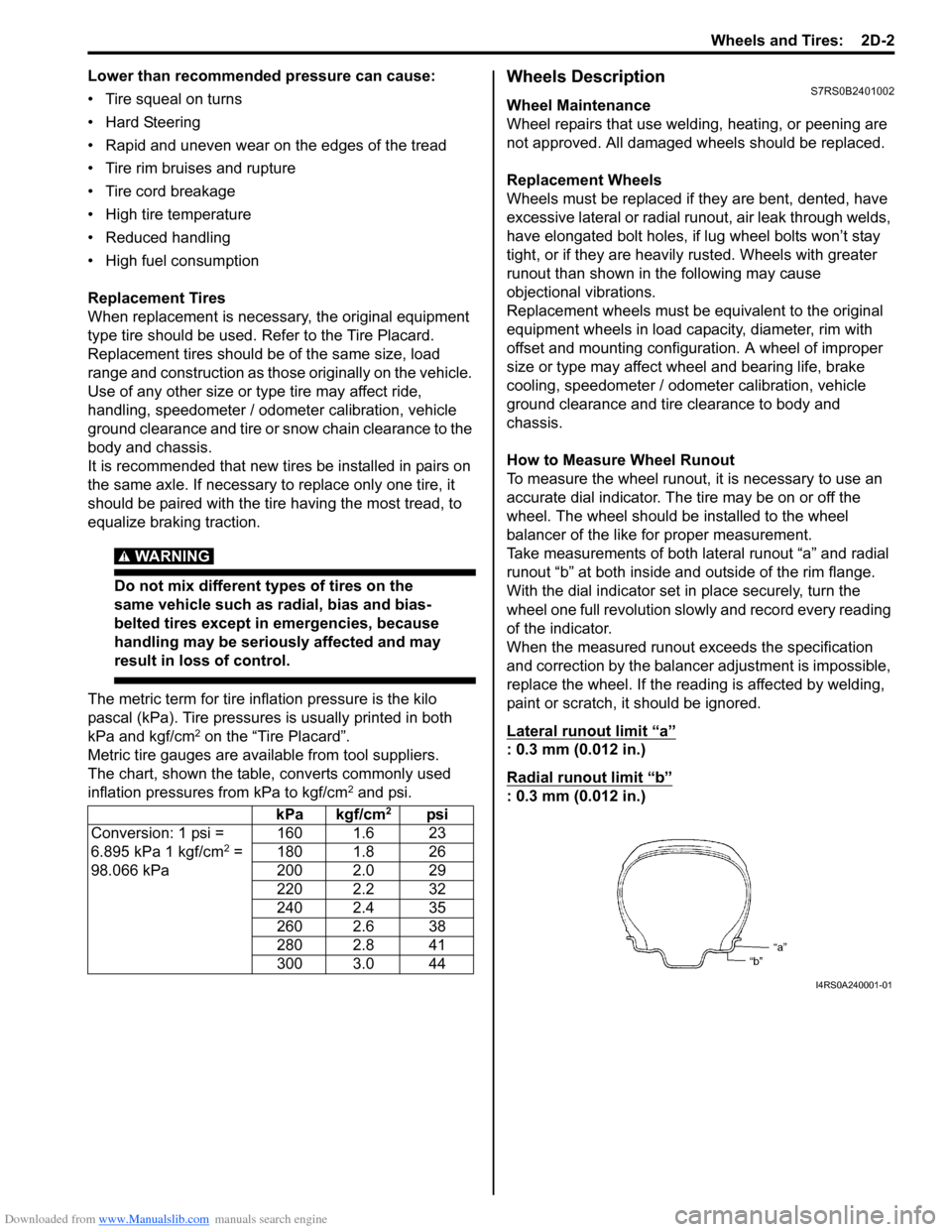

How to Measure Wheel Runout

To measure the wheel runout, it is necessary to use an

accurate dial indicator. The tire may be on or off the

wheel. The wheel should be installed to the wheel

balancer of the like for proper measurement.

Take measurements of both lateral runout “a” and radial

runout “b” at both inside an d outside of the rim flange.

With the dial indicator set in place securely, turn the

wheel one full revolution slowly and record every reading

of the indicator.

When the measured runout exceeds the specification

and correction by the balancer adjustment is impossible,

replace the wheel. If the reading is affected by welding,

paint or scratch, it should be ignored.

Lateral runout limit “a”

: 0.3 mm (0.012 in.)

Radial runout limit “b”

: 0.3 mm (0.012 in.)

kPa kgf/cm2psi

Conversion: 1 psi =

6.895 kPa 1 kgf/cm

2 =

98.066 kPa 160 1.6 23

180 1.8 26

200 2.0 29

220 2.2 32

240 2.4 35

260 2.6 38

280 2.8 41

300 3.0 44

I4RS0A240001-01

Page 510 of 1496

Downloaded from www.Manualslib.com manuals search engine 4A-12 Brake Control System and Diagnosis:

Master Cylinder Assembly Removal and

Installation

S7RS0B4106011

CAUTION!

Do not allow brake fluid to get on painted

surfaces. Painted surfaces will be damaged

by brake fluid, flush it with water immediately

if any fluid is spilled.

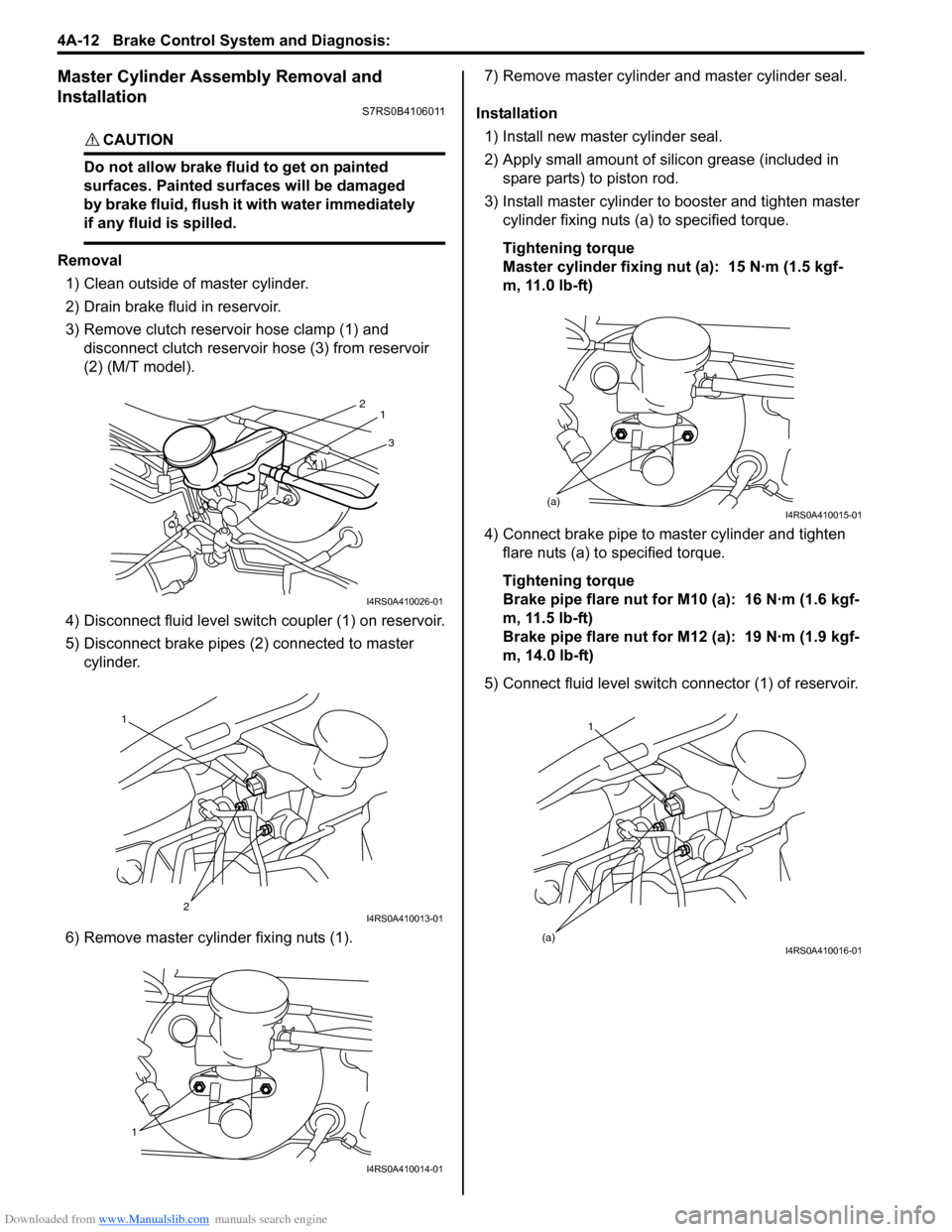

Removal

1) Clean outside of master cylinder.

2) Drain brake fluid in reservoir.

3) Remove clutch reservoir hose clamp (1) and disconnect clutch reservoir hose (3) from reservoir

(2) (M/T model).

4) Disconnect fluid level switch coupler (1) on reservoir.

5) Disconnect brake pipes (2) connected to master cylinder.

6) Remove master cylinder fixing nuts (1). 7) Remove master cylinder and master cylinder seal.

Installation 1) Install new master cylinder seal.

2) Apply small amount of silic on grease (included in

spare parts) to piston rod.

3) Install master cylinder to booster and tighten master cylinder fixing nuts (a) to specified torque.

Tightening torque

Master cylinder fixing nut (a): 15 N·m (1.5 kgf-

m, 11.0 lb-ft)

4) Connect brake pipe to master cylinder and tighten flare nuts (a) to specified torque.

Tightening torque

Brake pipe flare nut for M10 (a): 16 N·m (1.6 kgf-

m, 11.5 lb-ft)

Brake pipe flare nut for M12 (a): 19 N·m (1.9 kgf-

m, 14.0 lb-ft)

5) Connect fluid level switch connector (1) of reservoir.

3

2

1

I4RS0A410026-01

1

2

I4RS0A410013-01

1

I4RS0A410014-01

(a)I4RS0A410015-01

1

(a)

I4RS0A410016-01