Turn SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 13 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-8

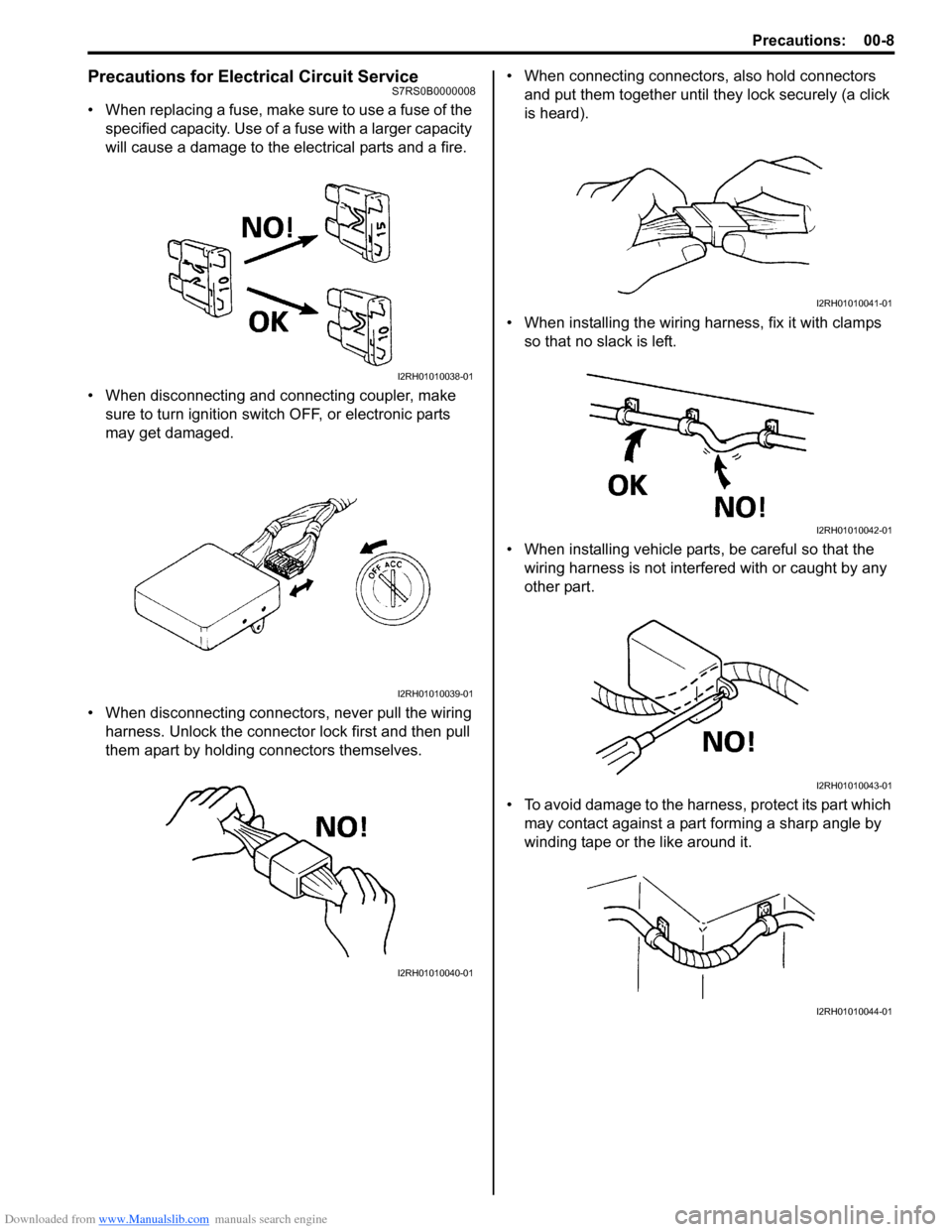

Precautions for Electrical Circuit ServiceS7RS0B0000008

• When replacing a fuse, make sure to use a fuse of the specified capacity. Use of a fuse with a larger capacity

will cause a damage to the electrical parts and a fire.

• When disconnecting and connecting coupler, make sure to turn ignition switch OFF, or electronic parts

may get damaged.

• When disconnecting connectors, never pull the wiring harness. Unlock the connecto r lock first and then pull

them apart by holding connectors themselves. • When connecting connectors, also hold connectors

and put them together until th ey lock securely (a click

is heard).

• When installing the wiring harness, fix it with clamps so that no slack is left.

• When installing vehicle parts, be careful so that the wiring harness is not interfered with or caught by any

other part.

• To avoid damage to the harnes s, protect its part which

may contact against a part forming a sharp angle by

winding tape or the like around it.

I2RH01010038-01

I2RH01010039-01

I2RH01010040-01

I2RH01010041-01

I2RH01010042-01

I2RH01010043-01

I2RH01010044-01

Page 15 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-10

Air Bag WarningS7RS0B0000009

WARNING!

For vehicles equipped with Supplemental

Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer. Refer

to “Air Bag System Components, Wiring

and Connectors Location in Section 8B” in

order to confirm whether you are

performing service on or near the air bag

system components or wiring. Please

observe all WARNINGS in Air Bag System

section and “Precautions on Service and

Diagnosis of Air Bag System in Section

8B” before performing service on or

around the air bag system components or

wiring. Failure to follow WARNINGS could

result in unintentional activation of the

system or could render the system

inoperative. Either of these two conditions

may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is

turned to the LOCK position and the

negative cable is disconnected from the

battery. Otherwise, the system may be

activated by reserve energy in the Sensing

and Diagnostic Module (SDM).

Air Bag System Service WarningS7RS0B0000010

WARNING!

• Service on or around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer.

Please observe all WARNINGS in Air Bag

System section and “Precautions on

Service and Diagnosis of Air Bag System

in Section 8B” before performing service

on or around the air bag system

components or wiring. Failure to follow

WARNINGS could result in unintended

activation of the system or could render

the system inoperative. Either of these two

conditions may result in severe injury.

• The procedures in the air bag system section must be followed in the order

listed to disable the air bag system

temporarily and prevent false DTCs from

setting. Failure to follow procedures could

result in possible activation of the air bag

system, personal injury or otherwise

unneeded air bag system repairs.

Fastener CautionS7RS0B0000011

CAUTION!

When fasteners are removed, always reinstall

them at the same location from which they

were removed. If a fastener needs to be

replaced, use the correct part number

fastener for that application. If the correct

part number fastener is not available, a

fastener of equal size and strength (or

stronger) may be used. Fasteners that are not

reused, and those requiring thread-locking

compound, will be called out. The correct

torque value must be used when installing

fasteners that require it. If the conditions are

not followed, parts or system damage could

result.

Suspension CautionS7RS0B0000012

CAUTION!

• All suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems,

and/or could result in major repair

expense. They must be replaced with one

of the same part number or with an

equivalent part if replacement becomes

necessary. Do not use a replacement part

of lesser quality or substitute design.

Torque values must be used as specified

during reassembly to assure proper

retention of this part.

• Never attempt to heat, quench or straighten any suspension part. Replace it

with a new part or damage to the part may

result.

Wheels and Tires CautionS7RS0B0000013

CAUTION!

All wheel fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of the same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts.

There is to be no welding as it may result in

extensive damage and weakening of the

metal.

Page 40 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-10 Maintenance and Lubrication:

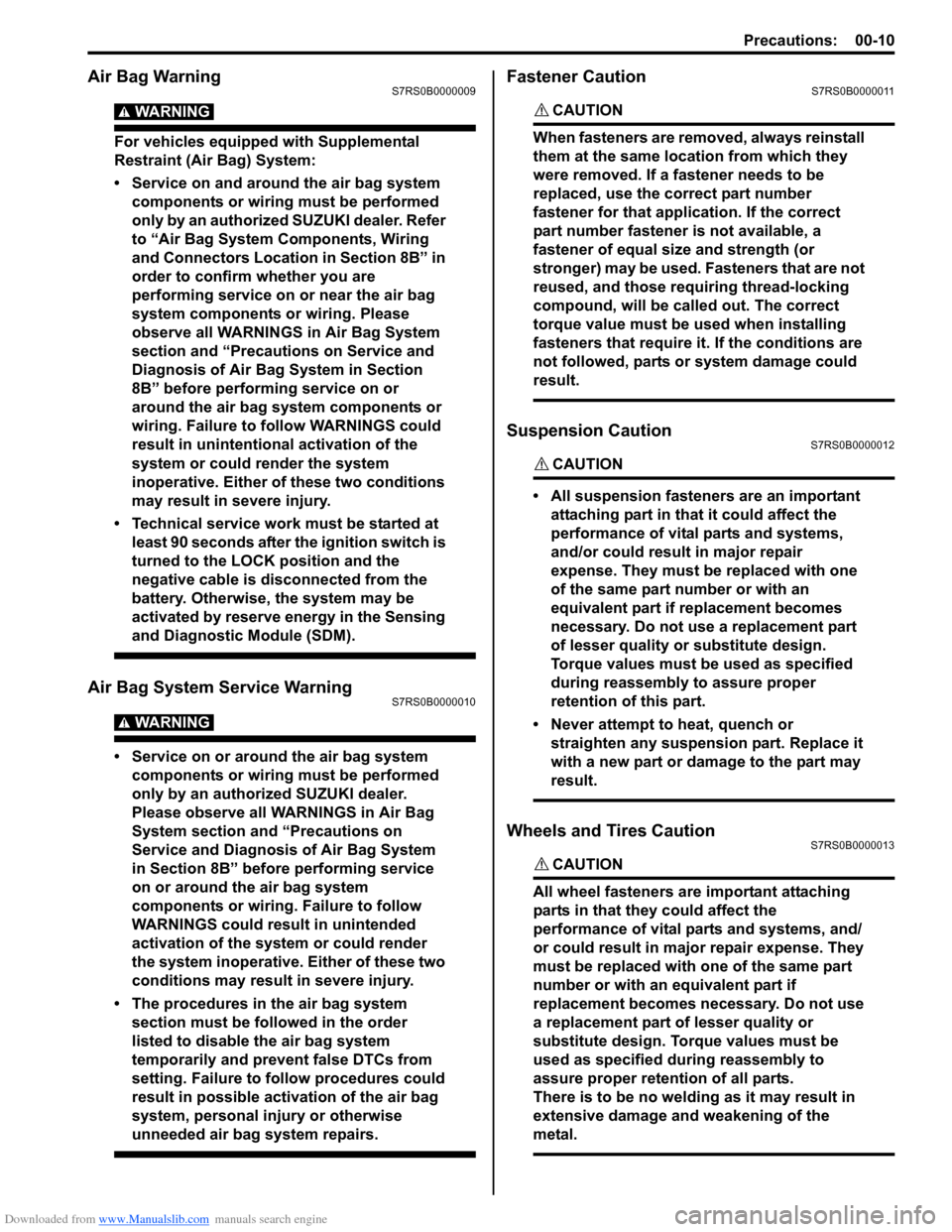

Steering System InspectionS7RS0B0206024

1) Check steering wheel for play and rattle, holding vehicle straight on ground.

Steering wheel play

“a”: 0 – 30 mm (0 – 1.1 in.)

2) Check bolts and nuts for tightness and retighten them as necessary. Repair or replace defective

parts, if any.

3) Check steering linkage for looseness and damage. Repair or replace defective parts, if any.

4) Check boots (1) and (2) of steering linkage and steering gear case for damage (leak, detachment,

tear, etc.). If damage is fo und, replace defective boot

with new one.

If any dent is found on steering gear case boots,

correct it to original shape by turning steering wheel

to the right or left as far as it stops and holding it for a

few seconds.

5) Check universal joints (3) of steering shaft for rattle and damage. If rattle or damage is found, replace

defective part with a new one.

6) Check that steering wheel can be turned fully to the

right and left. Repair or replace defective parts, if

any.

7) If equipped with power steering system, check also, in addition to check items, that steering wheel can be

turned fully to the right and left more lightly when

engine is running at idle speed than when it is

stopped. Repair, if found faulty.

8) Check wheel alignment referring to “Front Wheel Alignment Inspection and Adjustment in Section 2B”.

Drive Shaft (Axle) Boots InspectionS7RS0B0206025

Check drive shaft boots (wheel side and differential side)

for leaks, detachment, tear or other damage.

Replace defective parts as necessary.

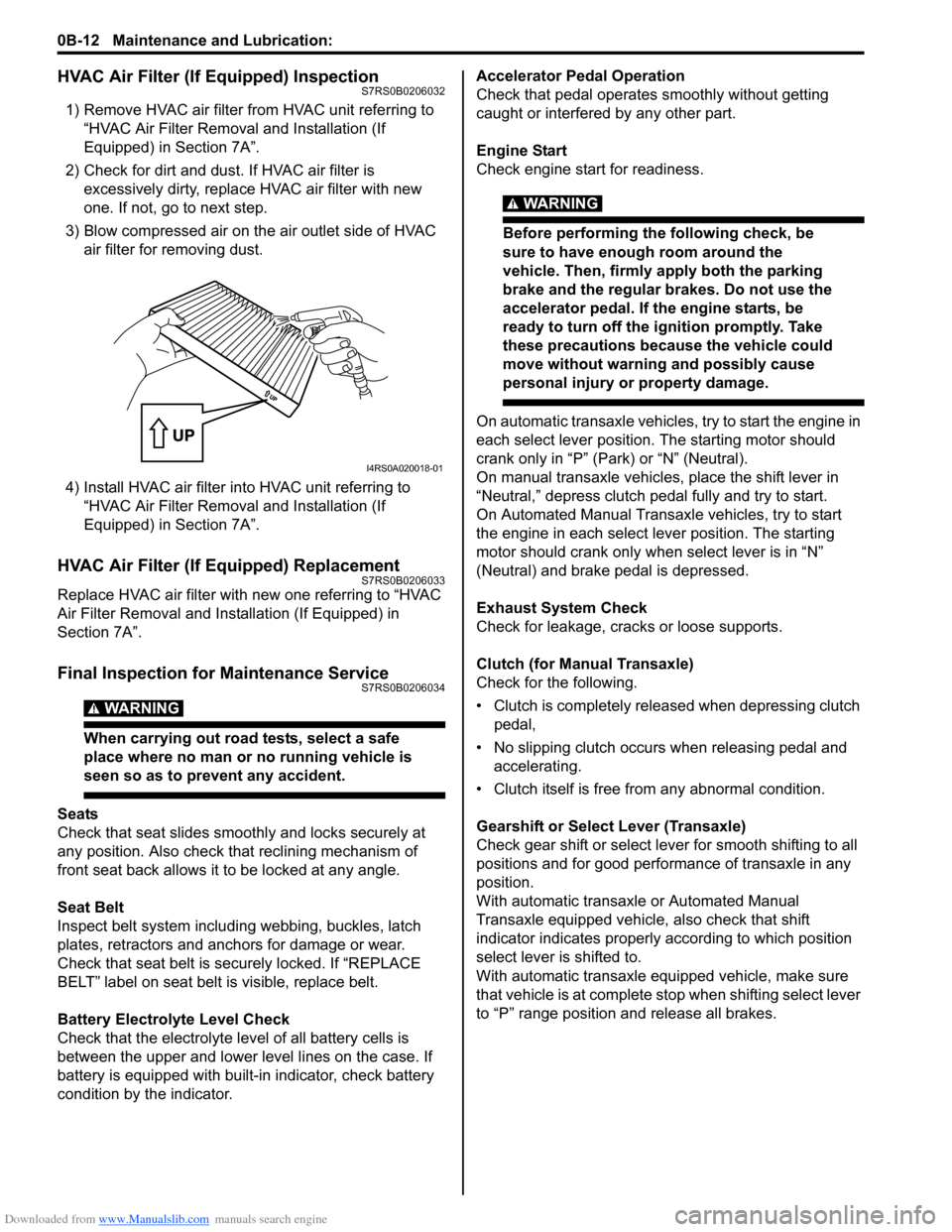

Manual Transaxle Oil InspectionS7RS0B0206026

1) Inspect transaxle case for evidence of oil leakage. Repair leaky point if any.

2) Make sure that vehicle is placed level for oil level

check.

3) Remove oil filler/leve l plug (1) of transaxle.

4) Check oil level. Oil level can be checked roughly by means of filler/

level plug hole. That is, if oil flows out of level plug

hole or if oil level is found up to hole when level plug

is removed, oil is properly filled.

If oil is found insufficient, po ur specified oil up to level

hole. For specified oil, refe r to “Manual Transaxle Oil

Change in Section 5B”.

5) Apply sealant to filler/leve l plug and tighten it to

specified torque.

Manual Transaxle Oil ReplacementS7RS0B0206027

Change transaxle oil with new specified oil referring to

“Manual Transaxle Oil Change in Section 5B”.

I2RH01020026-01

2

3

2

1

1

I4RS0B020007-01

I2RH01310001-01

I6RS0C020001-01

Page 42 of 1496

Downloaded from www.Manualslib.com manuals search engine 0B-12 Maintenance and Lubrication:

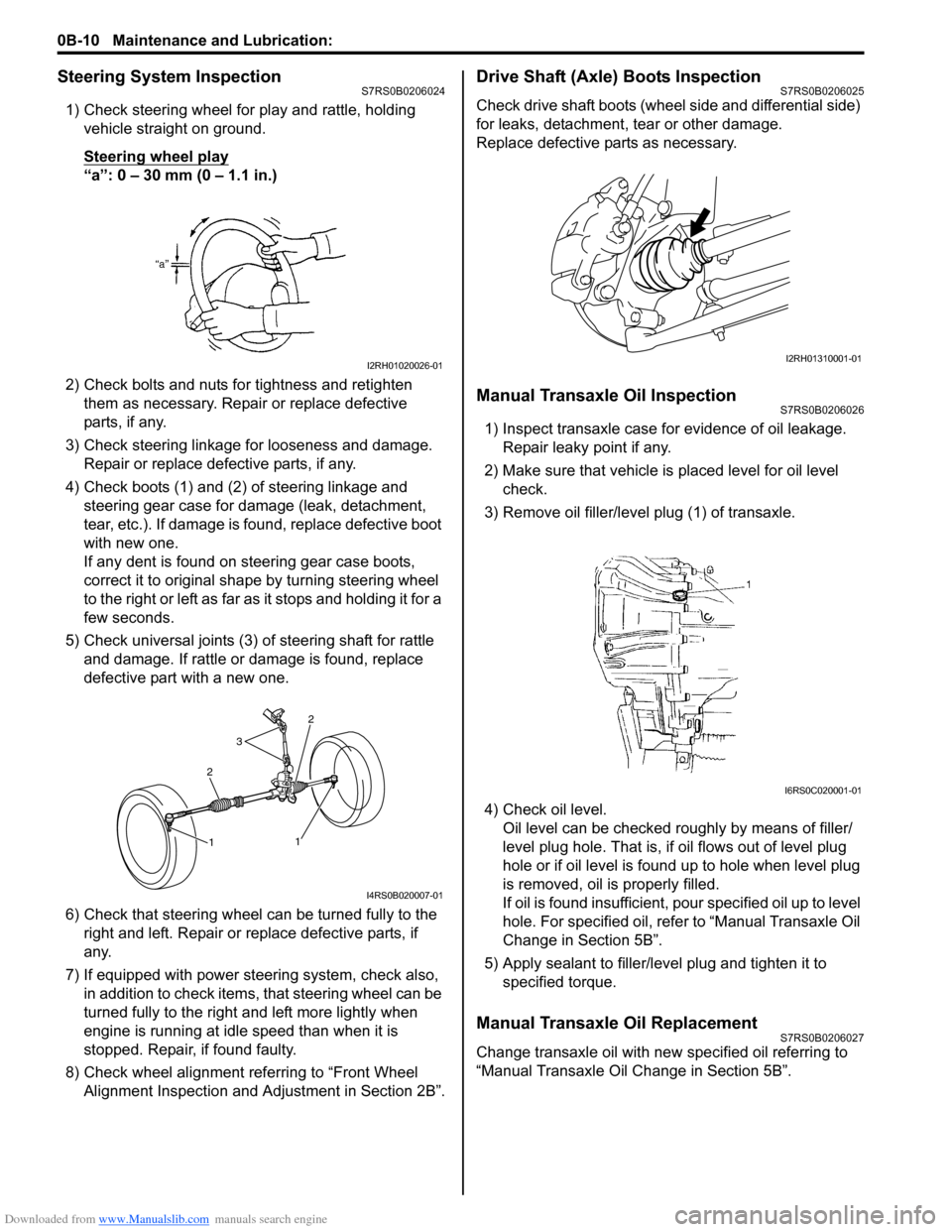

HVAC Air Filter (If Equipped) InspectionS7RS0B0206032

1) Remove HVAC air filter from HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

2) Check for dirt and dust. If HVAC air filter is excessively dirty, replace HVAC air filter with new

one. If not, go to next step.

3) Blow compressed air on the air outlet side of HVAC air filter for removing dust.

4) Install HVAC air filter in to HVAC unit referring to

“HVAC Air Filter Removal and Installation (If

Equipped) in Section 7A”.

HVAC Air Filter (If Equipped) ReplacementS7RS0B0206033

Replace HVAC air filter with new one referring to “HVAC

Air Filter Removal and Installation (If Equipped) in

Section 7A”.

Final Inspection for Maintenance ServiceS7RS0B0206034

WARNING!

When carrying out road tests, select a safe

place where no man or no running vehicle is

seen so as to prevent any accident.

Seats

Check that seat slides smoot hly and locks securely at

any position. Also check that reclining mechanism of

front seat back allows it to be locked at any angle.

Seat Belt

Inspect belt system including webbing, buckles, latch

plates, retractors and anchors for damage or wear.

Check that seat belt is securely locked. If “REPLACE

BELT” label on seat belt is visible, replace belt.

Battery Electrolyte Level Check

Check that the electrolyte le vel of all battery cells is

between the upper and lower level lines on the case. If

battery is equipped with built-in indicator, check battery

condition by the indicator. Accelerator Pedal Operation

Check that pedal operates

smoothly without getting

caught or interfered by any other part.

Engine Start

Check engine start for readiness.

WARNING!

Before performing th e following check, be

sure to have enough room around the

vehicle. Then, firmly apply both the parking

brake and the regular brakes. Do not use the

accelerator pedal. If the engine starts, be

ready to turn off the ignition promptly. Take

these precautions because the vehicle could

move without warning and possibly cause

personal injury or property damage.

On automatic transaxle vehicles, try to start the engine in

each select lever position. The starting motor should

crank only in “P” (Park) or “N” (Neutral).

On manual transaxle vehicles, place the shift lever in

“Neutral,” depress clutch pedal fully and try to start.

On Automated Manual Transaxl e vehicles, try to start

the engine in each select le ver position. The starting

motor should crank only when select lever is in “N”

(Neutral) and brake pedal is depressed.

Exhaust System Check

Check for leakage, cracks or loose supports.

Clutch (for Manual Transaxle)

Check for the following.

• Clutch is completely released when depressing clutch pedal,

• No slipping clutch occurs when releasing pedal and accelerating.

• Clutch itself is free fr om any abnormal condition.

Gearshift or Select Lever (Transaxle)

Check gear shift or select lever for smooth shifting to all

positions and for good performance of transaxle in any

position.

With automatic transaxle or Automated Manual

Transaxle equipped vehicle, also check that shift

indicator indicates properly according to which position

select lever is shifted to.

With automatic transaxle equipped vehicle, make sure

that vehicle is at complete stop when shifting select lever

to “P” range position and release all brakes.

I4RS0A020018-01

Page 51 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS7RS0B1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind , while working on engine,

that 12-volt electrical syste m is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S7RS0B1100005

There are two types of On -Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

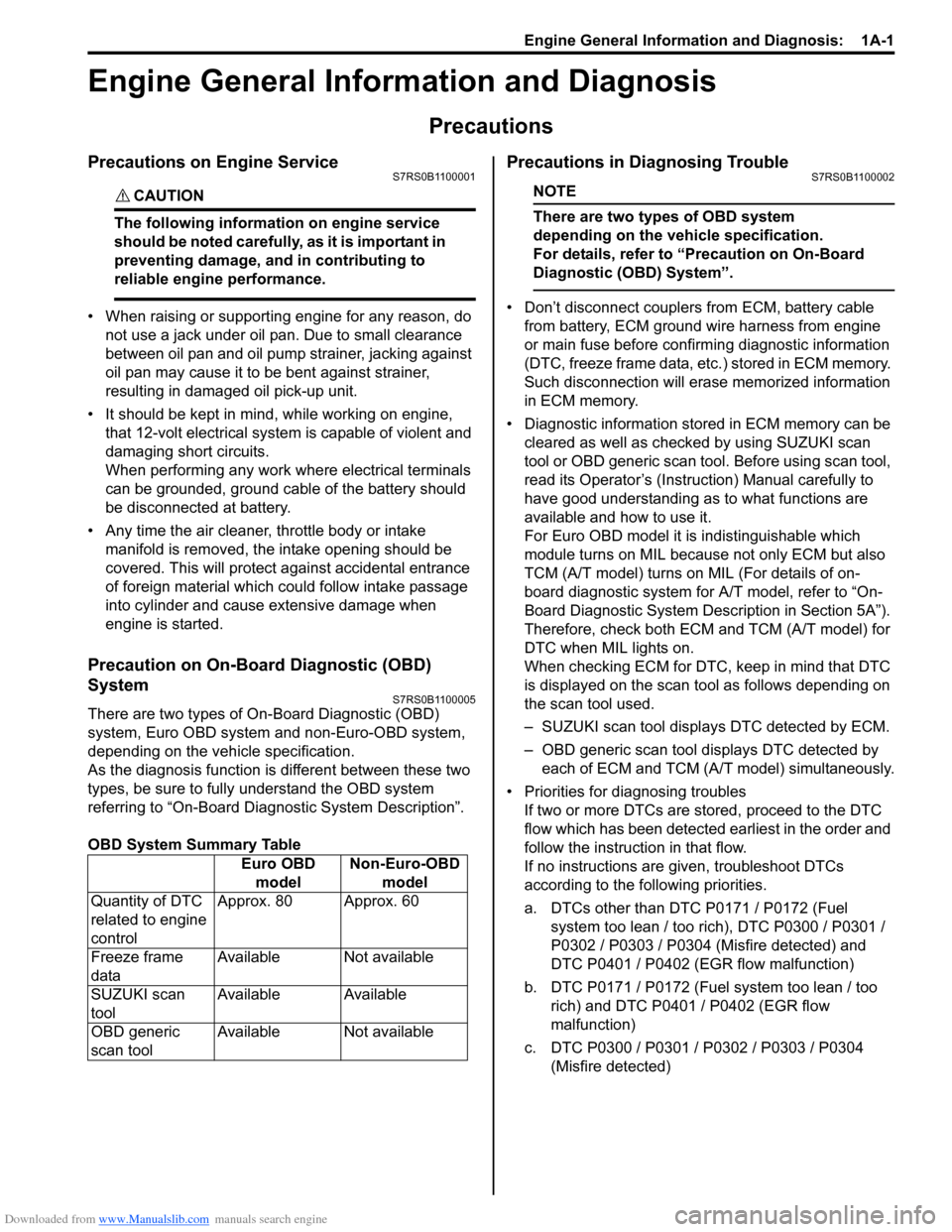

OBD System Summary Table

Precautions in Diagnosing TroubleS7RS0B1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

• Don’t disconnect couplers from ECM, battery cable

from battery, ECM ground wire harness from engine

or main fuse before confirming diagnostic information

(DTC, freeze frame data, etc.) stored in ECM memory.

Such disconnection will erase memorized information

in ECM memory.

• Diagnostic information stored in ECM memory can be cleared as well as checke d by using SUZUKI scan

tool or OBD generic scan tool. Before using scan tool,

read its Operator’s (Instruction) Manual carefully to

have good understanding as to what functions are

available and how to use it.

For Euro OBD model it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (A/T model) turns on MIL (For details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”).

Therefore, check both ECM and TCM (A/T model) for

DTC when MIL lights on.

When checking ECM for DTC, keep in mind that DTC

is displayed on the scan tool as follows depending on

the scan tool used.

– SUZUKI scan tool displays DTC detected by ECM.

– OBD generic scan tool displays DTC detected by each of ECM and TCM (A/T model) simultaneously.

• Priorities for diagnosing troubles If two or more DTCs are stored, proceed to the DTC

flow which has been detected earliest in the order and

follow the instructi on in that flow.

If no instructions are given, troubleshoot DTCs

according to the following priorities.

a. DTCs other than DTC P0171 / P0172 (Fuel system too lean / too rich), DTC P0300 / P0301 /

P0302 / P0303 / P0304 (Misfire detected) and

DTC P0401 / P0402 (EGR flow malfunction)

b. DTC P0171 / P0172 (Fuel system too lean / too rich) and DTC P0401 / P0402 (EGR flow

malfunction)

c. DTC P0300 / P0301 / P0302 / P0303 / P0304 (Misfire detected)

Euro OBD

model Non-Euro-OBD

model

Quantity of DTC

related to engine

control Approx. 80 Approx. 60

Freeze frame

data Available Not available

SUZUKI scan

tool Available Available

OBD generic

scan tool Available Not available

Page 53 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-3

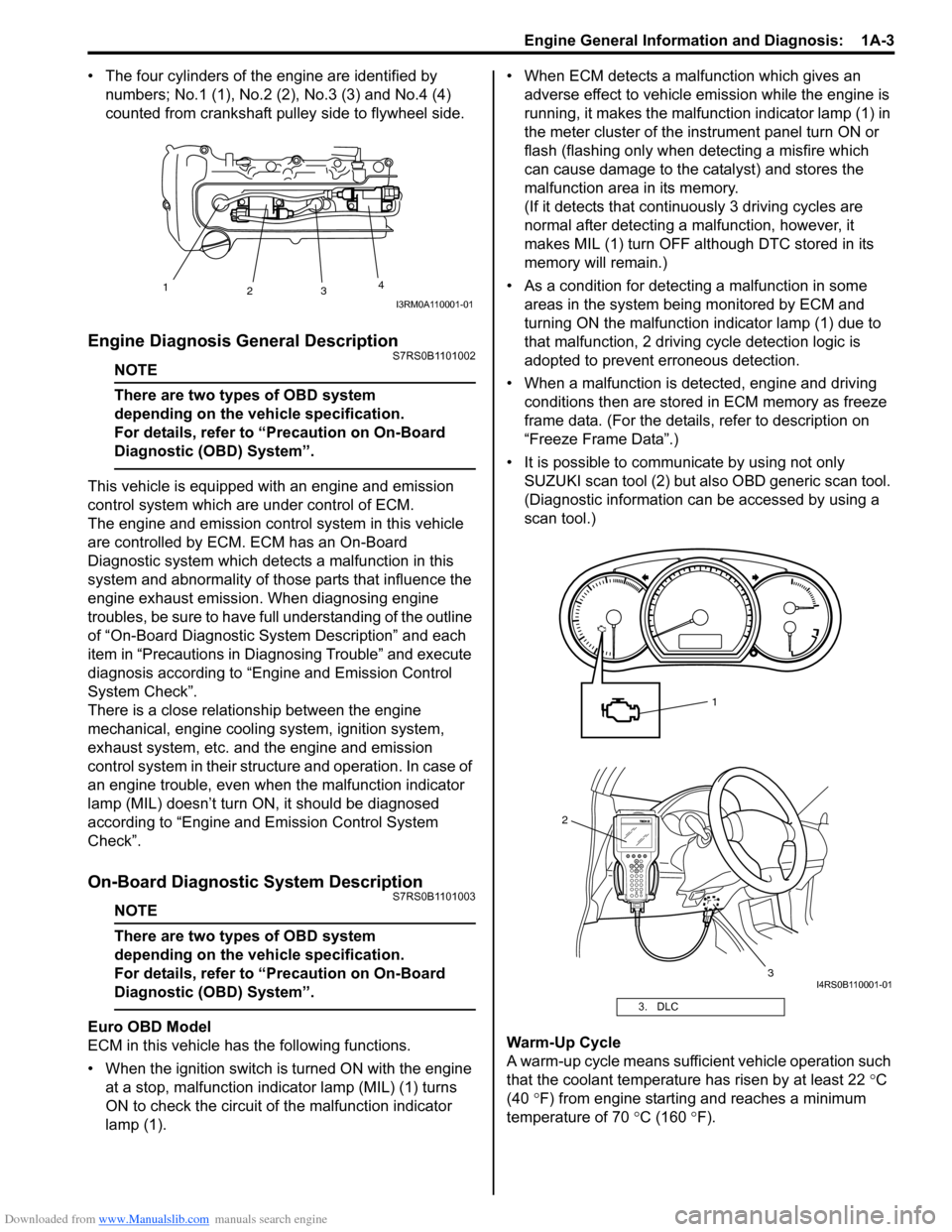

• The four cylinders of the engine are identified by numbers; No.1 (1), No.2 (2 ), No.3 (3) and No.4 (4)

counted from crankshaft pulley side to flywheel side.

Engine Diagnosis General DescriptionS7RS0B1101002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

This vehicle is equipped with an engine and emission

control system which are under control of ECM.

The engine and emission control system in this vehicle

are controlled by ECM. ECM has an On-Board

Diagnostic system which detects a malfunction in this

system and abnormality of those parts that influence the

engine exhaust emission. When diagnosing engine

troubles, be sure to have full understanding of the outline

of “On-Board Diagnostic System Description” and each

item in “Precautions in Diagnosing Trouble” and execute

diagnosis according to “Engine and Emission Control

System Check”.

There is a close relationship between the engine

mechanical, engine cooling system, ignition system,

exhaust system, etc. and the engine and emission

control system in their structure and operation. In case of

an engine trouble, even when the malfunction indicator

lamp (MIL) doesn’t turn ON, it should be diagnosed

according to “Engine and Emission Control System

Check”.

On-Board Diagnostic System DescriptionS7RS0B1101003

NOTE

There are two types of OBD system

depending on the vehicle specification.

For details, refer to “Precaution on On-Board

Diagnostic (OBD) System”.

Euro OBD Model

ECM in this vehicle has the following functions.

• When the ignition switch is turned ON with the engine at a stop, malfunction indicator lamp (MIL) (1) turns

ON to check the circuit of the malfunction indicator

lamp (1). • When ECM detects a malfunction which gives an

adverse effect to vehicle emission while the engine is

running, it makes the malfunction indicator lamp (1) in

the meter cluster of the inst rument panel turn ON or

flash (flashing only when detecting a misfire which

can cause damage to the catalyst) and stores the

malfunction area in its memory.

(If it detects that contin uously 3 driving cycles are

normal after detecting a malfunction, however, it

makes MIL (1) turn OFF although DTC stored in its

memory will remain.)

• As a condition for detecting a malfunction in some areas in the system being monitored by ECM and

turning ON the malfunction indicator lamp (1) due to

that malfunction, 2 driving cycle detection logic is

adopted to prevent erroneous detection.

• When a malfunction is detected, engine and driving conditions then are stored in ECM memory as freeze

frame data. (For the details, refer to description on

“Freeze Frame Data”.)

• It is possible to communicate by using not only SUZUKI scan tool (2) but also OBD generic scan tool.

(Diagnostic information can be accessed by using a

scan tool.)

Warm-Up Cycle

A warm-up cycle means sufficie nt vehicle operation such

that the coolant temperature has risen by at least 22 °C

(40 °F) from engine starting and reaches a minimum

temperature of 70 °C (160 ° F).

1

23 4

I3RM0A110001-01

3. DLC

2

3

1

I4RS0B110001-01

Page 55 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-5

Freeze frame data clearance:

The freeze frame data is cleared at the same time as

clearance of DTC.

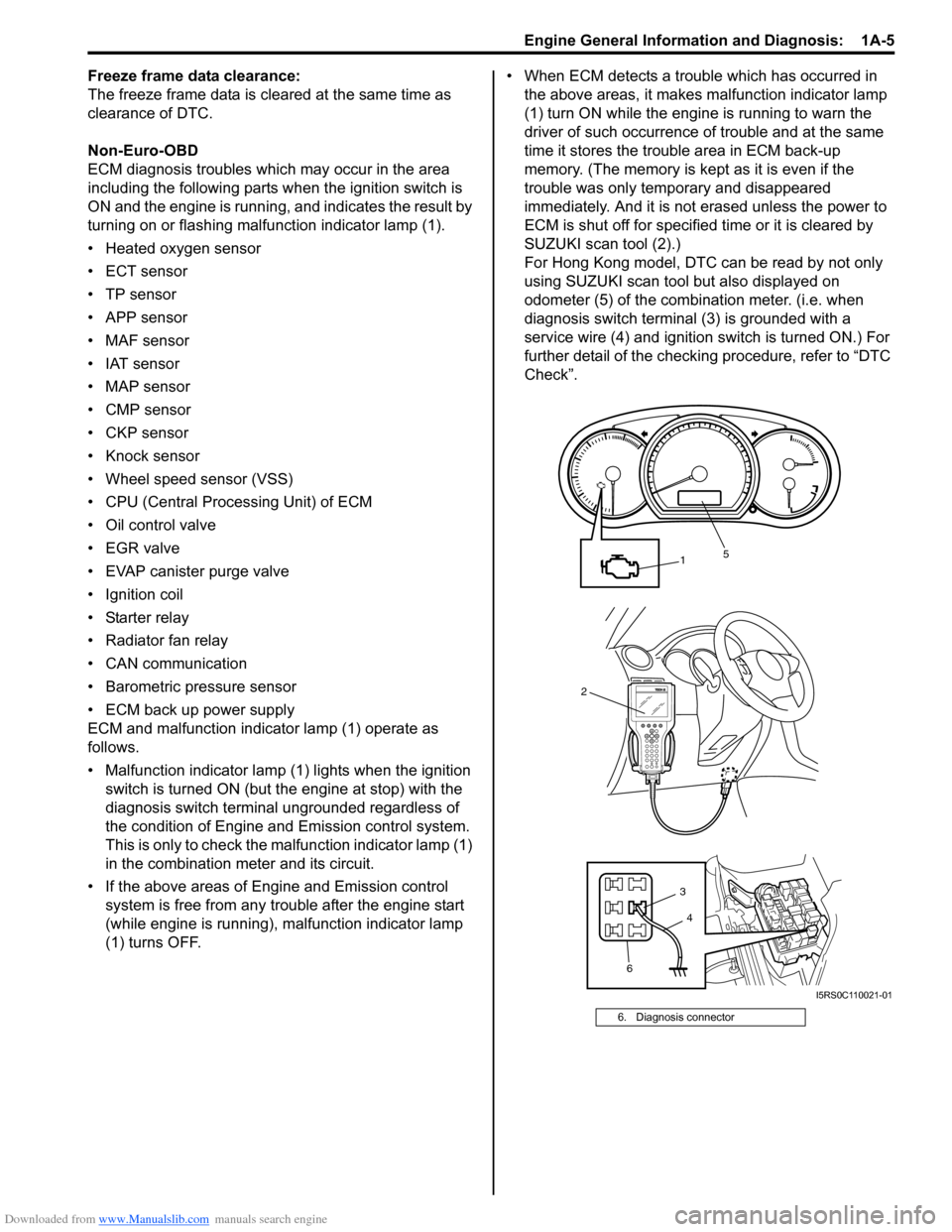

Non-Euro-OBD

ECM diagnosis troubles which may occur in the area

including the following parts w hen the ignition switch is

ON and the engine is running, and indicates the result by

turning on or flashing malfunction indicator lamp (1).

• Heated oxygen sensor

• ECT sensor

•TP sensor

• APP sensor

• MAF sensor

• IAT sensor

• MAP sensor

• CMP sensor

• CKP sensor

• Knock sensor

• Wheel speed sensor (VSS)

• CPU (Central Processing Unit) of ECM

• Oil control valve

• EGR valve

• EVAP canister purge valve

• Ignition coil

• Starter relay

• Radiator fan relay

• CAN communication

• Barometric pressure sensor

• ECM back up power supply

ECM and malfunction indicator lamp (1) operate as

follows.

• Malfunction indicator lamp (1) lights when the ignition switch is turned ON (but t he engine at stop) with the

diagnosis switch terminal ungrounded regardless of

the condition of Engine and Emission control system.

This is only to check the ma lfunction indicator lamp (1)

in the combination meter and its circuit.

• If the above areas of Engine and Emission control system is free from any trouble after the engine start

(while engine is running), malfunction indicator lamp

(1) turns OFF. • When ECM detects a trouble which has occurred in

the above areas, it makes malfunction indicator lamp

(1) turn ON while the engi ne is running to warn the

driver of such occurrence of trouble and at the same

time it stores the trouble area in ECM back-up

memory. (The memory is kept as it is even if the

trouble was only temporary and disappeared

immediately. And it is not erased unless the power to

ECM is shut off for specified time or it is cleared by

SUZUKI scan tool (2).)

For Hong Kong model, DTC can be read by not only

using SUZUKI scan tool but also displayed on

odometer (5) of the combination meter. (i.e. when

diagnosis switch terminal (3) is grounded with a

service wire (4) and ignition switch is turned ON.) For

further detail of the checking procedure, refer to “DTC

Check”.

6. Diagnosis connector

2

1

6 3

5

4

I5RS0C110021-01

Page 59 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-9

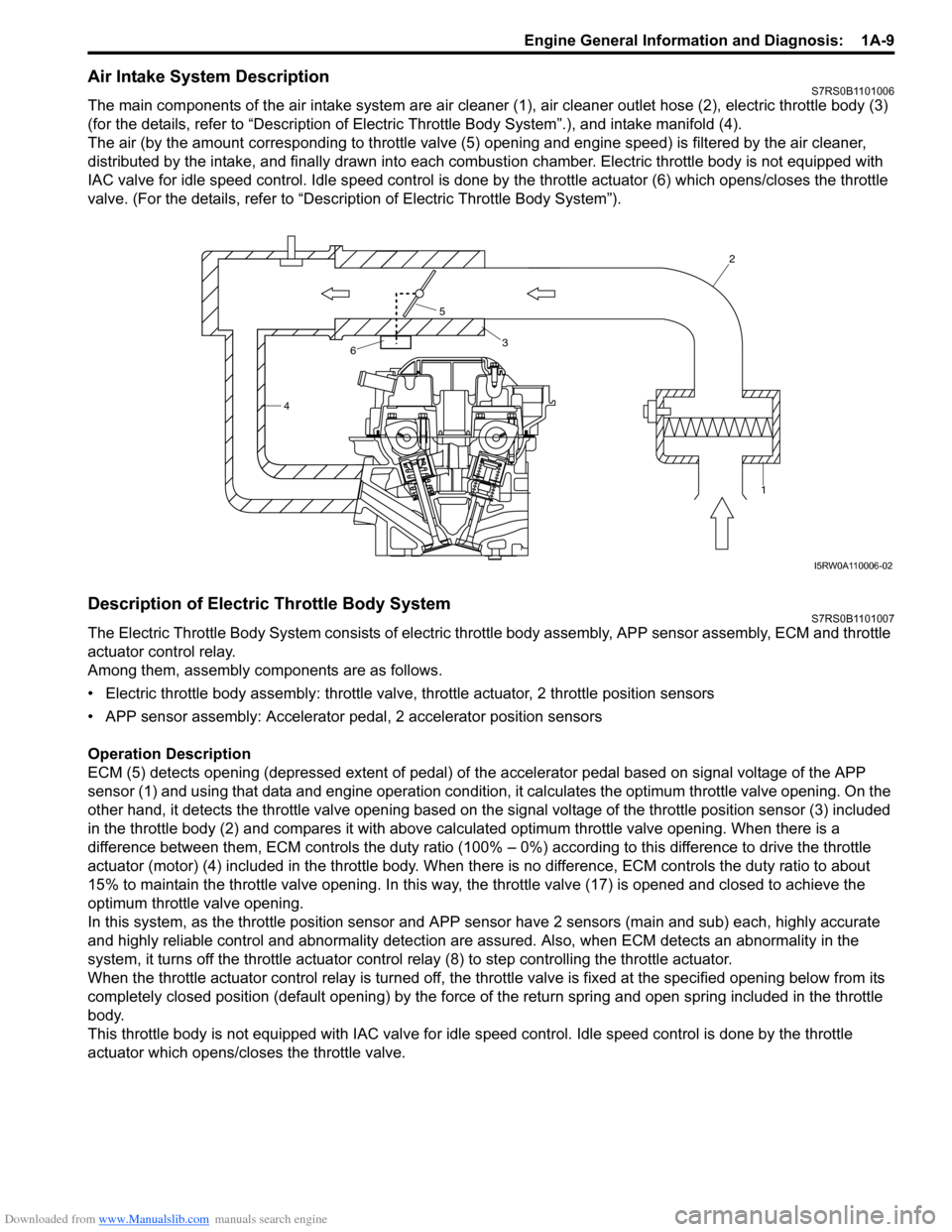

Air Intake System DescriptionS7RS0B1101006

The main components of the air intake system are air cleaner (1), air cleaner outlet hose (2), electric throttle body (3)

(for the details, refer to “Description of Electric Throttle Body System”.), and intake manifold (4).

The air (by the amount corresponding to throttle valve (5) opening and engine speed) is filtered by the air cleaner,

distributed by the intake, and finally drawn into each combusti on chamber. Electric throttle body is not equipped with

IAC valve for idle speed control. Idle speed control is done by the throttle actuator (6) which opens/closes the throttle

valve. (For the details, refer to “Description of Electric Throttle Body System”).

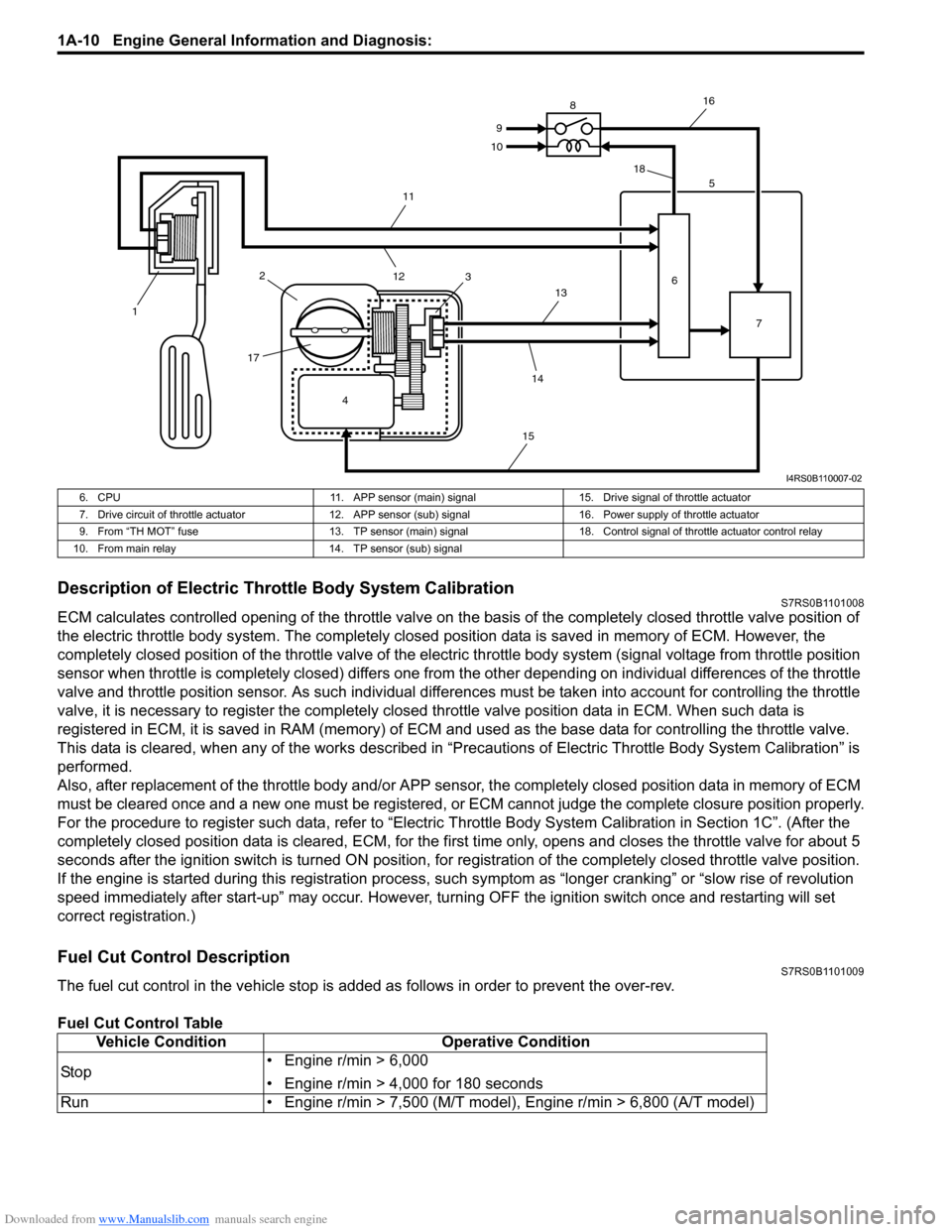

Description of Electric Throttle Body SystemS7RS0B1101007

The Electric Throttle Body System consists of electric throttle body asse mbly, APP sensor assembly, ECM and throttle

actuator control relay.

Among them, assembly components are as follows.

• Electric throttle body assembly: throttle valve, throttle actuator, 2 throttle position sensors

• APP sensor assembly: Accelerator pe dal, 2 accelerator position sensors

Operation Description

ECM (5) detects opening (depressed extent of pedal) of the accelerator pedal based on signal voltage of the APP

sensor (1) and using that data and engi ne operation condition, it calculates the optimum throttle valve opening. On the

other hand, it detects the throttle valve opening based on the signal voltage of the throttle position sensor (3) included

in the throttle body (2) and compares it with above calculated optimum throttle valve opening. When there is a

difference between them, ECM controls the duty ratio (100% – 0%) according to this difference to drive the throttle

actuator (motor) (4) included in the throttle body. When th ere is no difference, ECM controls the duty ratio to about

15% to maintain the throttle valve opening . In this way, the throttle valve (17) is opened and closed to achieve the

optimum throttle valve opening.

In this system, as the thrott le position sensor and APP sensor have 2 sensors (main and sub) each, highly accurate

and highly reliable control and abnormality detection are assured. Also, when ECM detects an abnormality in the

system, it turns off the th rottle actuator control relay (8) to step controlling the throttle actuator.

When the throttle actuator control relay is turned off, the throttle valve is fixed at the specified opening below from its

completely closed position (default openin g) by the force of the return spring and open spring included in the throttle

body.

This throttle body is not equipped with IAC valve for idle speed control. Idle speed control is done by the throttle

actuator which opens/closes the throttle valve.

4 2

1

3

5

6

I5RW0A110006-02

Page 60 of 1496

Downloaded from www.Manualslib.com manuals search engine 1A-10 Engine General Information and Diagnosis:

Description of Electric Throttle Body System CalibrationS7RS0B1101008

ECM calculates controlled opening of the throttle valve on the basis of the completely closed throttle valve position of

the electric throttle body system. The completely closed position data is saved in memory of ECM. However, the

completely closed position of the throttle valve of the electric throttle body system (signal voltage from throttle position

sensor when throttle is completely closed) differs one from the other depending on individual differences of the throttle

valve and throttle position sensor. As such individual diff erences must be taken into account for controlling the throttle

valve, it is necessary to register the completely closed throttle valve position data in ECM. When such data is

registered in ECM, it is sa ved in RAM (memory) of ECM and used as the base data for controlling the throttle valve.

This data is cleared, when any of the works described in “Preca utions of Electric Throttle Body System Calibration” is

performed.

Also, after replacement of the throttle body and/or APP sensor , the completely closed position data in memory of ECM

must be cleared once and a new one must be registered, or ECM cannot judge the complete closure position properly.

For the procedure to register such data, refer to “Electric Throttle Body System Calibration in Section 1C”. (After the

completely closed position data is cleared , ECM, for the first time only, opens and closes the throttle valve for about 5

seconds after the ignition switch is turned ON position, for re gistration of the completely closed throttle valve position.

If the engine is started during this registration process, such symptom as “longe r cranking” or “slow rise of revolution

speed immediately after start-up” may occur. However, turning OFF the ignition switch once and restarting will set

correct registration.)

Fuel Cut Control DescriptionS7RS0B1101009

The fuel cut control in the vehicle stop is add ed as follows in order to prevent the over-rev.

Fuel Cut Control Table

4

1

2

17 3 5

6 7

8

9

10

11

12 13

14

15 16

18

I4RS0B110007-02

6. CPU 11. APP sensor (main) signal15. Drive signal of throttle actuator

7. Drive circuit of throttle actuator 12. APP sensor (sub) signal 16. Power supply of throttle actuator

9. From “TH MOT” fuse 13. TP sensor (main) signal 18. Control signal of throttle actuator control relay

10. From main relay 14. TP sensor (sub) signal

Vehicle ConditionOperative Condition

Sto p • Engine r/min > 6,000

• Engine r/min > 4,000 for 180 seconds

Run • Engine r/min > 7,500 (M/T model), Engine r/min > 6,800 (A/T model)

Page 75 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-25

Step 2: DTC / Freeze Frame Data Check, Record and

Clearance

First, check DTC (including pending DTC), referring to

“DTC Check”. If DTC is indicated, print it and freeze

frame data or write them down and then clear them by

referring to “DTC Clearance”. DTC indicates malfunction

that occurred in the system but does not indicate

whether it exists now or it occurred in the past and the

normal condition has been restored now. To check which

case applies, check the sy mptom in question according

to Step 5 and recheck DTC according to Step 6 and 7.

Attempt to diagnose a trouble based on DTC in this step

only or failure to clear the DTC in this step will lead to

incorrect diagnosis, trouble diagnosis of a normal circuit

or difficulty in troubleshooting.

Step 3 and 4: Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis: ” and “Step 2: DTC / Freeze Frame

Data Check, Record and Clearance: ”, confirm trouble

symptoms. Also, reconfirm DTC according to “DTC

Confirmation Procedure” described in each DTC diag.

flow.

Step 6 and 7: Rechecking and Record of DTC /

Freeze Frame Data

Refer to “DTC Check” for checking procedure.

Step 8: Engine Basic Inspection and Engine

Symptom Diagnosis

Perform basic engine check according to “Engine Basic

Inspection” first. When the end of the flow has been

reached, check the parts of the system suspected as a

possible cause referring to “Engine Symptom Diagnosis”

and based on symptoms appearing on the vehicle

(symptoms obtained through steps of customer

complaint analysis, trouble symptom confirmation and/or

basic engine check) and repair or replace faulty parts, if

any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, ECM or other part and repair or

replace faulty parts. Step 10: Intermittent Problems Check

Check parts where an intermit

tent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connec tion Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the

engine is free from any abnormal conditions. If what has

been repaired is re lated to the DTC, clear the DTC once,

perform DTC confirmation procedure and confirm that no

DTC is indicated.

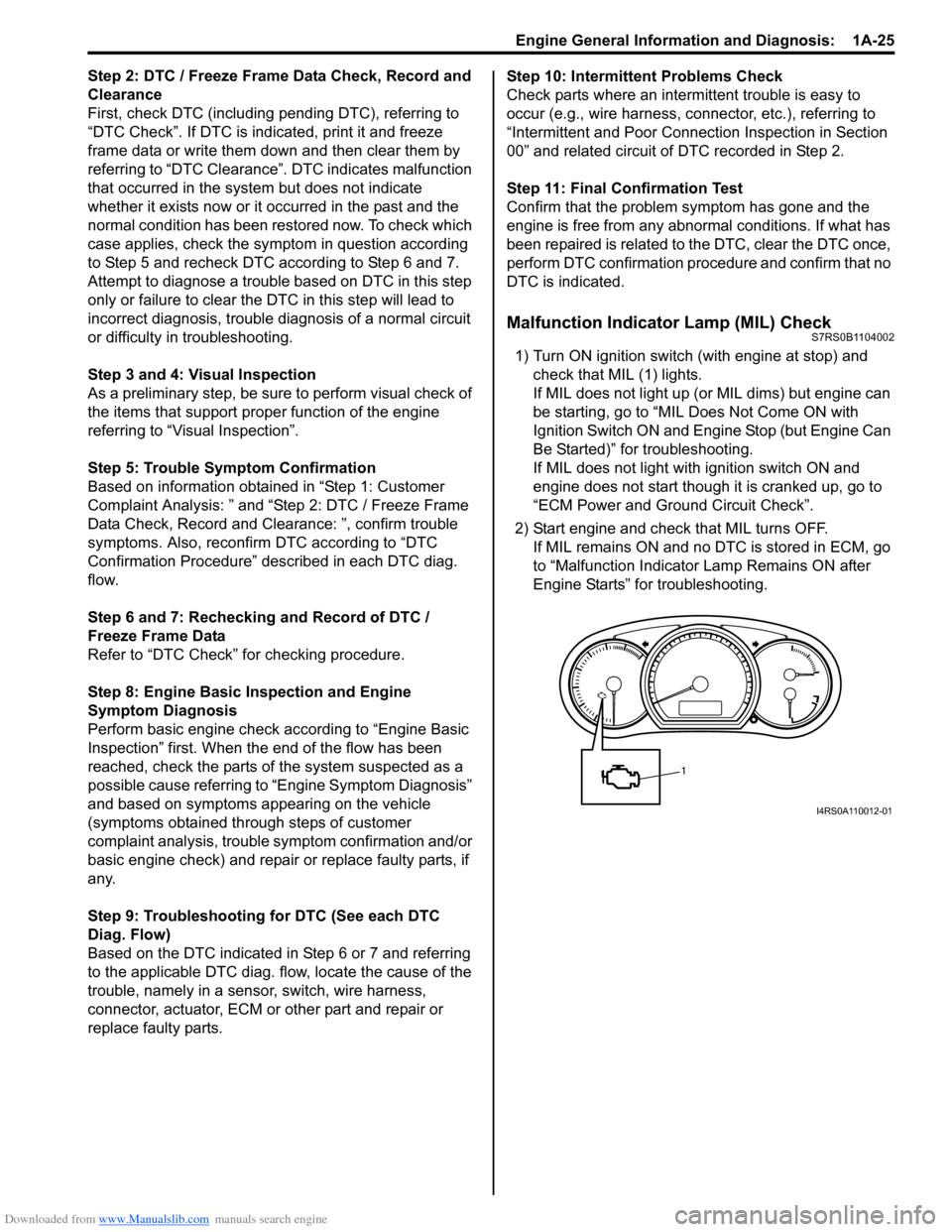

Malfunction Indicator Lamp (MIL) CheckS7RS0B1104002

1) Turn ON ignition switch (with engine at stop) and check that MIL (1) lights.

If MIL does not light up (or MIL dims) but engine can

be starting, go to “MIL Does Not Come ON with

Ignition Switch ON and Engine Stop (but Engine Can

Be Started)” for troubleshooting.

If MIL does not light with ignition switch ON and

engine does not start though it is cranked up, go to

“ECM Power and Ground Circuit Check”.

2) Start engine and check that MIL turns OFF. If MIL remains ON and no DTC is stored in ECM, go

to “Malfunction Indicator Lamp Remains ON after

Engine Starts” for troubleshooting.

1

I4RS0A110012-01