differential SUZUKI SWIFT 2008 2.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 486 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-8 Drive Shaft / Axle:

Reassembly

Tripod joint

Judging from abnormality noted before disassembly and

what is found through visual check of component parts

after disassembly, prepare replacing parts and proceed

to reassembly.

Make sure that wheel side joint assembly (1) and tripod

joint housing (2) are washed thoroughly and air dried.

Replace boot(s) (3) with new one(s).

CAUTION!

• Do not wash boots in degreaser such as gasoline or kerosene. etc. Washing in

degreaser causes deterioration of boot.

• To ensure full performance of joint as designed, be sure to distinguish between

two types of grease in repair set and apply

specified volume to respective joint

referring to the followings for identification

of the grease.

1) Wash disassembled parts (except boots). After washing, dry parts comp letely by blowing air.

2) Clean boots with cloth.

3) Apply grease to wheel side joint. Use specified grease in tube in wheel side boot set as a spare

parts.

Grease color

: Black

Amount

: 55 – 75 g (1.9 – 2.6 oz)

4) Install wheel side boot on shaft.

5) Fill up boot inside with specified grease.

6) Place new wheel side boot big band (3) and small band (4) onto boot putting band outer end (1) against

forward rotation (2) as shown in figure.

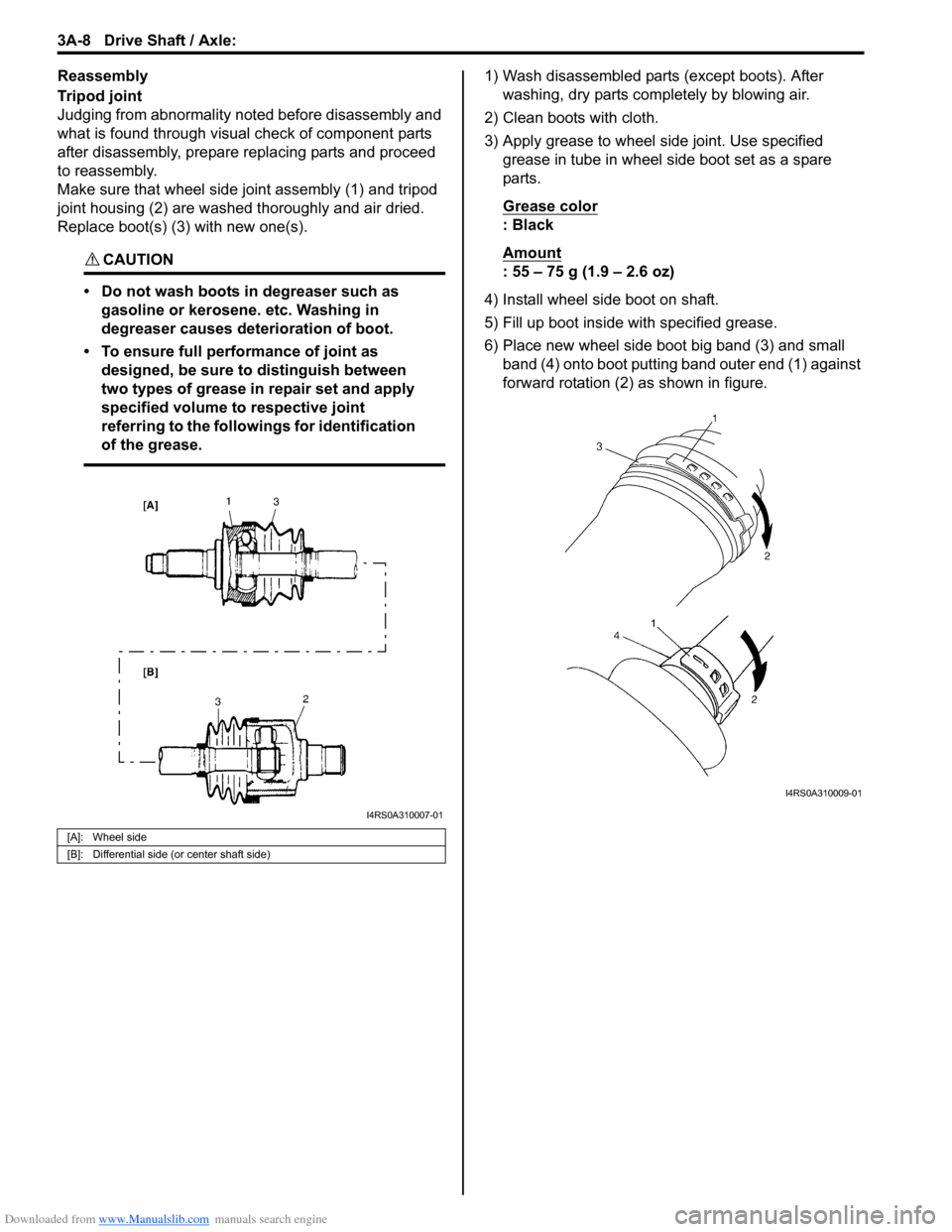

[A]: Wheel side

[B]: Differential side (or center shaft side)

I4RS0A310007-01

I4RS0A310009-01

Page 487 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-9

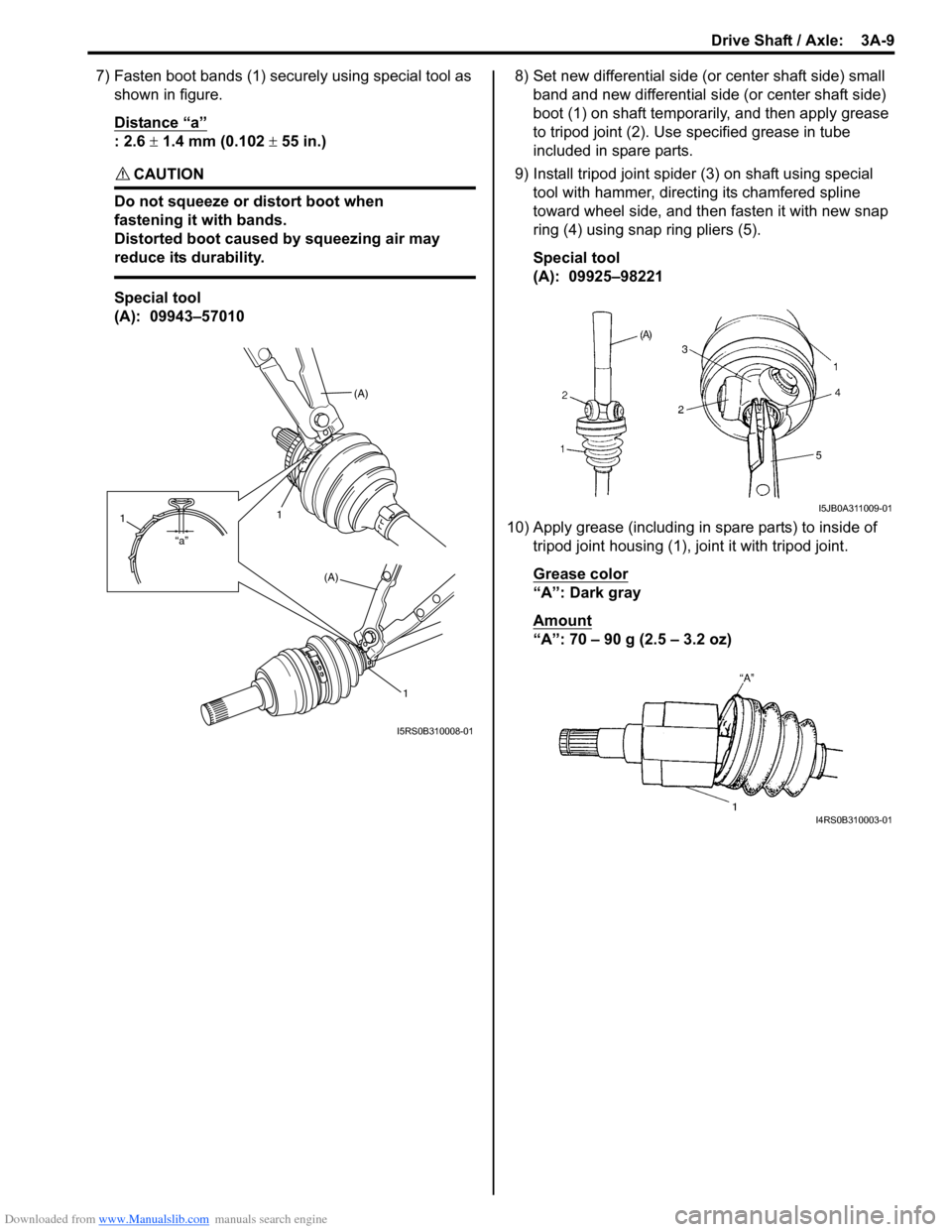

7) Fasten boot bands (1) securely using special tool as

shown in figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 55 in.)

CAUTION!

Do not squeeze or distort boot when

fastening it with bands.

Distorted boot caused by squeezing air may

reduce its durability.

Special tool

(A): 09943–57010 8) Set new differential side (or center shaft side) small

band and new differential side (or center shaft side)

boot (1) on shaft temporarily, and then apply grease

to tripod joint (2). Use specified grease in tube

included in spare parts.

9) Install tripod joint spider (3) on shaft using special

tool with hammer, directing its chamfered spline

toward wheel side, and then fasten it with new snap

ring (4) using snap ring pliers (5).

Special tool

(A): 09925–98221

10) Apply grease (including in spare parts) to inside of tripod joint housing (1), jo int it with tripod joint.

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz)

(A)

1

(A)

1

“a”

1

I5RS0B310008-01

I5JB0A311009-01

I4RS0B310003-01

Page 488 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-10 Drive Shaft / Axle:

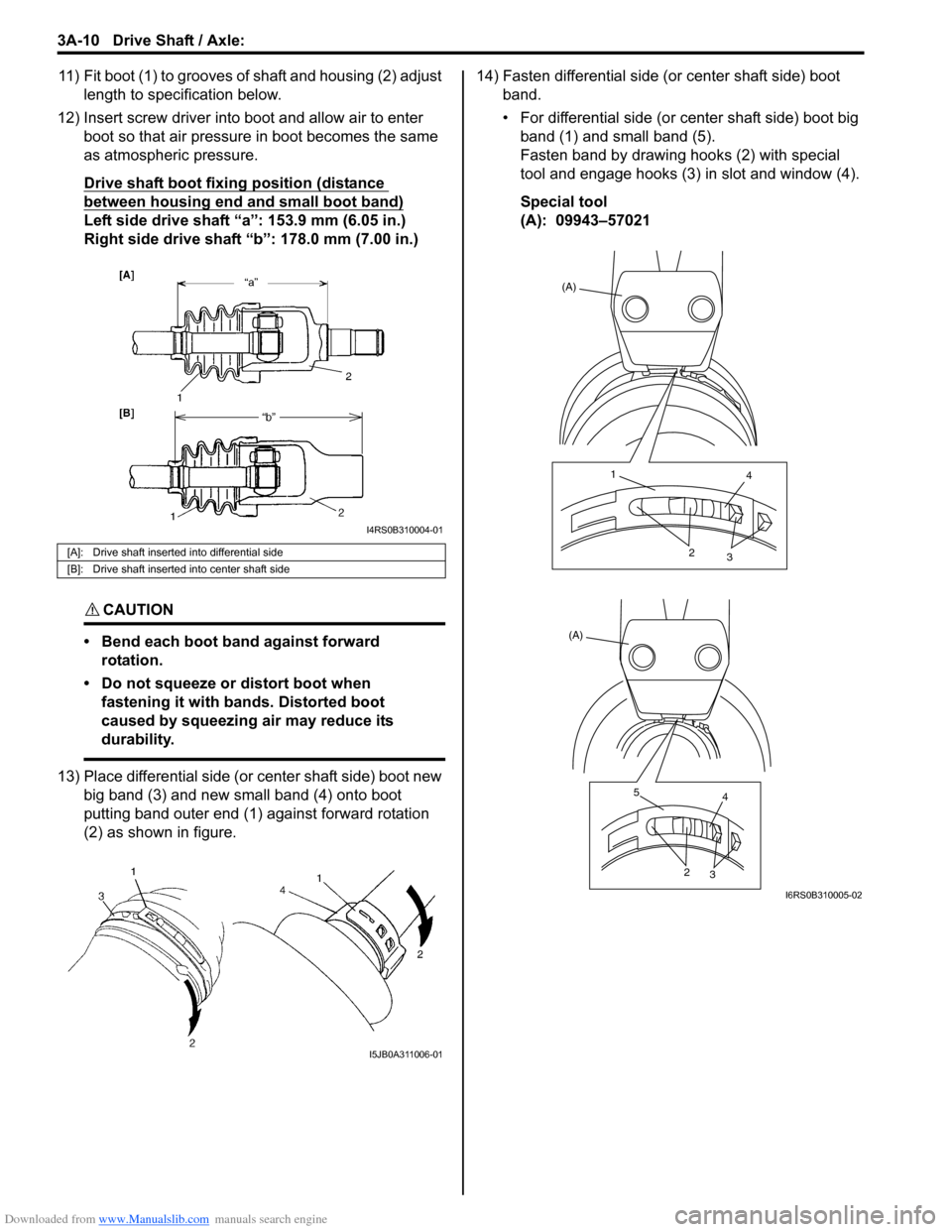

11) Fit boot (1) to grooves of shaft and housing (2) adjust

length to specification below.

12) Insert screw driver into boot and allow air to enter boot so that air pressure in boot becomes the same

as atmospheric pressure.

Drive shaft boot fixing position (distance

between housing end and small boot band)

Left side drive shaft “a”: 153.9 mm (6.05 in.)

Right side drive shaft “b”: 178.0 mm (7.00 in.)

CAUTION!

• Bend each boot band against forward rotation.

• Do not squeeze or distort boot when fastening it with bands. Distorted boot

caused by squeezing air may reduce its

durability.

13) Place differential side (or center shaft side) boot new big band (3) and new small band (4) onto boot

putting band outer end (1) against forward rotation

(2) as shown in figure. 14) Fasten differential side (or center shaft side) boot

band.

• For differential side (or center shaft side) boot big band (1) and small band (5).

Fasten band by drawing hooks (2) with special

tool and engage hooks (3) in slot and window (4).

Special tool

(A): 09943–57021

[A]: Drive shaft inserted into differential side

[B]: Drive shaft inserted into center shaft side

I4RS0B310004-01

I5JB0A311006-01

(A)

1 4

2 3

(A)

5 4

2 3

I6RS0B310005-02

Page 490 of 1496

Downloaded from www.Manualslib.com manuals search engine 3A-12 Drive Shaft / Axle:

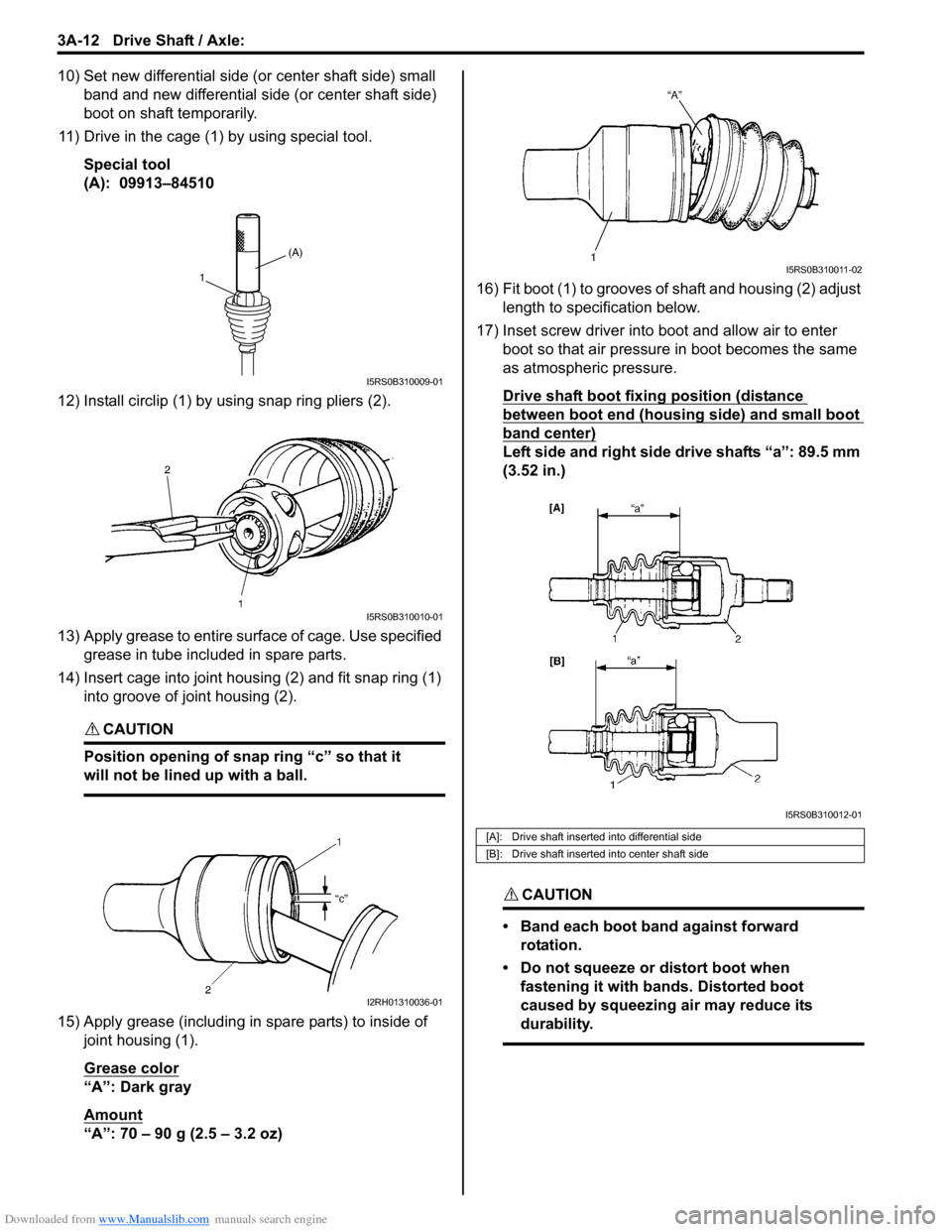

10) Set new differential side (or center shaft side) small band and new differential side (or center shaft side)

boot on shaft temporarily.

11) Drive in the cage (1) by using special tool.

Special tool

(A): 09913–84510

12) Install circlip (1) by using snap ring pliers (2).

13) Apply grease to entire su rface of cage. Use specified

grease in tube included in spare parts.

14) Insert cage into joint housing (2) and fit snap ring (1) into groove of joint housing (2).

CAUTION!

Position opening of snap ring “c” so that it

will not be lined up with a ball.

15) Apply grease (including in spare parts) to inside of joint housing (1).

Grease color

“A”: Dark gray

Amount

“A”: 70 – 90 g (2.5 – 3.2 oz) 16) Fit boot (1) to grooves of shaft and housing (2) adjust

length to specification below.

17) Inset screw driver into boot and allow air to enter boot so that air pressure in boot becomes the same

as atmospheric pressure.

Drive shaft boot fixing position (distance

between boot end (housing side) and small boot

band center)

Left side and right side drive shafts “a”: 89.5 mm

(3.52 in.)

CAUTION!

• Band each boot band against forward rotation.

• Do not squeeze or distort boot when fastening it with bands. Distorted boot

caused by squeezing air may reduce its

durability.

(A)

1

I5RS0B310009-01

I5RS0B310010-01

I2RH01310036-01

[A]: Drive shaft inserted into differential side

[B]: Drive shaft inserted into center shaft side

I5RS0B310011-02

I5RS0B310012-01

Page 491 of 1496

Downloaded from www.Manualslib.com manuals search engine Drive Shaft / Axle: 3A-13

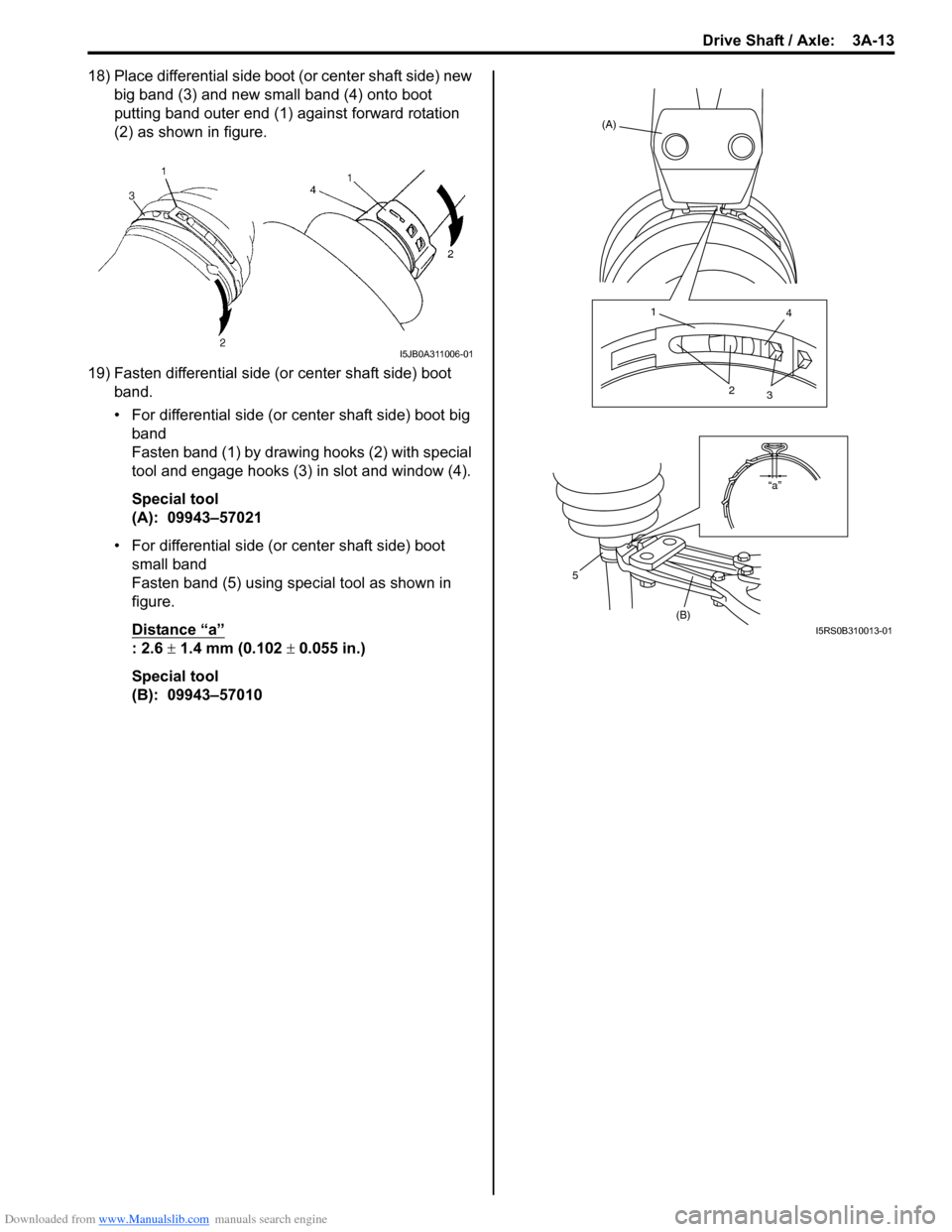

18) Place differential side boot (or center shaft side) new

big band (3) and new small band (4) onto boot

putting band outer end (1) against forward rotation

(2) as shown in figure.

19) Fasten differential side (or center shaft side) boot band.

• For differential side (or center shaft side) boot big band

Fasten band (1) by drawing hooks (2) with special

tool and engage hooks (3) in slot and window (4).

Special tool

(A): 09943–57021

• For differential side (or center shaft side) boot small band

Fasten band (5) using special tool as shown in

figure.

Distance “a”

: 2.6 ± 1.4 mm (0.102 ± 0.055 in.)

Special tool

(B): 09943–57010

I5JB0A311006-01

(A)

1 4

2 3

(B)

5 “a”

I5RS0B310013-01

Page 642 of 1496

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1878: Torque Converter Clutch Shudder .......................................................... 5A-75

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Sole noid Control Circuit

Range /Performance ....................................... 5A-76

DTC P2763: Torque Converter Clutch Pressure Control Sole noid Control Circuit

High ................................................................. 5A-78

DTC P2764: Torque Converter Clutch Circuit Pressure Control Sole noid Control Circuit

Low ................................................................. 5A-80

Inspection of TCM and Its Circuits .................... 5A-82

TCM Power and Ground Circuit Check ............. 5A-86

Brake Interlock System Inspection .................... 5A-87

Repair Instructions ........... .................................5A-88

Learning Control Initializat ion ............................ 5A-88

A/T Fluid Level Check ....................................... 5A-89

A/T Fluid Change .............................................. 5A-90

Select Lever Components ... .............................. 5A-90

Select Lever Assembly Removal and Installation ....................................................... 5A-90

Select Lever Knob Installa tion........................... 5A-90

Select Lever Inspection .... ................................. 5A-91

“3” Position Switch Inspec tion ........................... 5A-91

Shift Lock Solenoid Inspec tion .......................... 5A-91

Shift Lock Solenoid Replacement ..................... 5A-91

Select Cable Components ................................ 5A-92

Select Cable Removal and Installation ............. 5A-92

Select Cable Adjustment ................................... 5A-93

Key Interlock Cable Removal and Installation... 5A-93

Transmission Range Sensor (Shift Switch) Inspection and Adjustment .............................. 5A-95

Output Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Output Shaft Speed Sensor Inspection ............. 5A-96

Input Shaft Speed Sensor Removal and Installation ....................................................... 5A-96

Input Shaft Speed Sensor Inspection................ 5A-97

Transmission Fluid Temperature Sensor Removal and Installation ................................. 5A-97

Transmission Fluid Temperature Sensor Inspection ........................................................ 5A-98

Solenoid Valves (Shift Solenoid Valves and Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-98

Solenoid Valves (Shift Solenoid Valves, and Timing Solenoid Valve) Inspection .................. 5A-99

Pressure Control Soleno id Valves (Pressure

Control Solenoid and TCC Pressure Control

Solenoid) Removal and Inst allation .............. 5A-101

Pressure Control Solenoid Valve Inspection ... 5A-101

Transmission Control Module (TCM) Removal and Installation ............................... 5A-102

A/T Relay Inspection ....................................... 5A-103

Differential Side Oil Seal Replacement ........... 5A-103

A/T Fluid Cooler Hoses Replacement ............. 5A-104

Automatic Transaxle Unit Components........... 5A-105

Automatic Transaxle Unit Dismounting and Remounting ................................................... 5A-106

Automatic Transaxle Asse mbly Components . 5A-108 Automatic Transaxle Unit

Disassembly........... 5A-110

Oil Pump Assembly Components ................... 5A-121

Oil Pump Assembly Disassembly and Reassembly .................................................. 5A-122

Oil Pump Assembly Inspection ....................... 5A-122

Direct Clutch Assembly Components.............. 5A-124

Direct Clutch Assembly Preliminary Check ..... 5A-124

Direct Clutch Assembly Disassembly and Reassembly .................................................. 5A-125

Direct Clutch Assembly Inspection.................. 5A-127

Forward and Reverse Clutch Assembly Components .................................................. 5A-128

Forward and Reverse Clutch Assembly Preliminary Check ......................................... 5A-129

Forward and Reverse Clutch Assembly Disassembly and Reassembly ...................... 5A-129

Forward and Reverse Clutch Assembly Inspection ...................................................... 5A-133

2nd Brake Piston Assembly Components ....... 5A-134

2nd Brake Piston Assembly Disassembly and Reassembly .................................................. 5A-134

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Components........... 5A-135

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-136

Transaxle Rear Cover (O/D and 2nd Coast Brake Piston) Assembly Inspection............... 5A-137

Countershaft Assembly Co mponents.............. 5A-138

Countershaft Assembly Disassembly and Reassembly .................................................. 5A-138

Valve Body Assembly Components ................ 5A-139

Valve Body Assembly Disassembly and Reassembly .................................................. 5A-140

Differential Assembly Components ................. 5A-141

Differential Assembly Disassembly and Reassembly .................................................. 5A-142

Differential Assembly Inspection ..................... 5A-143

Torque Converter Housing Disassembly and Reassembly .................................................. 5A-144

Transaxle Case Disassembly and Reassembly .................................................. 5A-146

Automatic Transaxle Unit Inspection and Adjus

tment .................................................... 5A-147

Automatic Transaxle Unit Assembly ............... 5A-150

Specifications .................. .................................5A-167

Tightening Torque Specifications .................... 5A-167

Special Tools and Equipmen t .........................5A-168

Recommended Service Material ..................... 5A-168

Special Tool .................................................... 5A-168

Manual Transmission/Tr ansaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction and Servicing .... 5B-1

Diagnostic Information and Procedures ............5B-3 Manual Transaxle Symptom Diagnosis............... 5B-3

Repair Instructions ............ ..................................5B-3

Manual Transaxle Oil Change............................. 5B-3

Differential Side Oil Seal Replacement ............... 5B-4

Page 643 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5-iii

Gear Shift Control Lever and Cable Components...................................................... 5B-5

Gear Shift Control Le ver and Cable Removal

and Installation .................................................. 5B-6

Gear Select Control Cable Adjustment ............... 5B-6

Back Up Light Switch Removal and Installation ......................................................... 5B-7

Back Up Light Switch Inspection ......................... 5B-7

Manual Transaxle Unit Components ................... 5B-8

Manual Transaxle Unit Dismounting and Remounting....................................................... 5B-9

Gear Shift and Sele ct Shaft Assembly

Components.................................................... 5B-11

Gear Shift and Sele ct Shaft Assembly

Removal and Installation................................. 5B-11

Gear Shift and Select Shaft Disassembly and Assembly ........................................................ 5B-12

Manual Transaxle Assembly Components........ 5B-13

Fifth Gear Disassembly and Assembly ............. 5B-14

Manual Transaxle Assembly Disassembly and Reassembly ............................................. 5B-16

Transaxle Right Case Disassembly and Assembly ........................................................ 5B-23

Transaxle Left Case Disassembly and Assembly ........................................................ 5B-24

Input Shaft and Countershaft Components....... 5B-25

Input Shaft Assembly Disassembly and Reassembly .................................................... 5B-26

Countershaft Assembly Disassembly and Reassembly .................................................... 5B-28

Synchronizer Parts Inspec tion .......................... 5B-31

Gear Shift Shaft Components ........................... 5B-31

5th and Reverse Gear Shift Shafts Disassembly and Assembly ............................ 5B-32

Gear Shift Shaft and Fork Inspection ................ 5B-32

Differential Components ................................... 5B-33

Differential Disassembly and Assembly ............ 5B-33

Specifications ..................................................... 5B-35

Tightening Torque Specifications ...................... 5B-35

Special Tools and Equipmen t ........................... 5B-36

Recommended Service Material ....................... 5B-36 Special Tool ...................................................... 5B-36

Clutch ................

.............................. ......... 5C-1

General Description .............................................5C-1

Clutch Construction .............................................5C-1

Diagnostic Information and Procedures ............5C-2 Clutch System Symptom Diagnosis ....................5C-2

Repair Instructions ........... ...................................5C-2

Clutch Pedal Inspection ......................................5C-2

Clutch Fluid Level Inspection ..............................5C-3

Air Bleeding of Clutch System.............................5C-3

Clutch Pedal Position (CPP) Switch Removal and Installation ..................................................5C-4

Clutch Pedal Position (CPP) Switch Inspection and Adjustment ................................5C-5

Clutch Fluid Pipe and Hose Components ...........5C-5

Clutch Fluid Pipe Removal and Installation.........5C-6

Clutch Fluid Pipe Inspection................................5C-6

Clutch Master Cylinder Removal and Installation .........................................................5C-6

Clutch Operating Cylinder Removal and Installation .........................................................5C-7

Clutch Operating Cylinder Inspection..................5C-7

Clutch Pedal and Clutch Pedal Bracket Components ......................................................5C-7

Clutch Cover, Clutch Disc and Flywheel Components ......................................................5C-8

Clutch Cover, Clutch Disc and Flywheel Removal and Installation ...................................5C-8

Clutch Cover, Clutch Disc and Flywheel Inspection ........................................................5C-10

Clutch Release Syst em Removal and

Installation .......................................................5C-11

Clutch Release System Inspection ...................5C-13

Specifications .................... .................................5C-13

Tightening Torque Specifications ......................5C-13

Special Tools and Equipmen t ...........................5C-14

Recommended Service Material .......................5C-14

Special Tool ......................................................5C-14

Page 648 of 1496

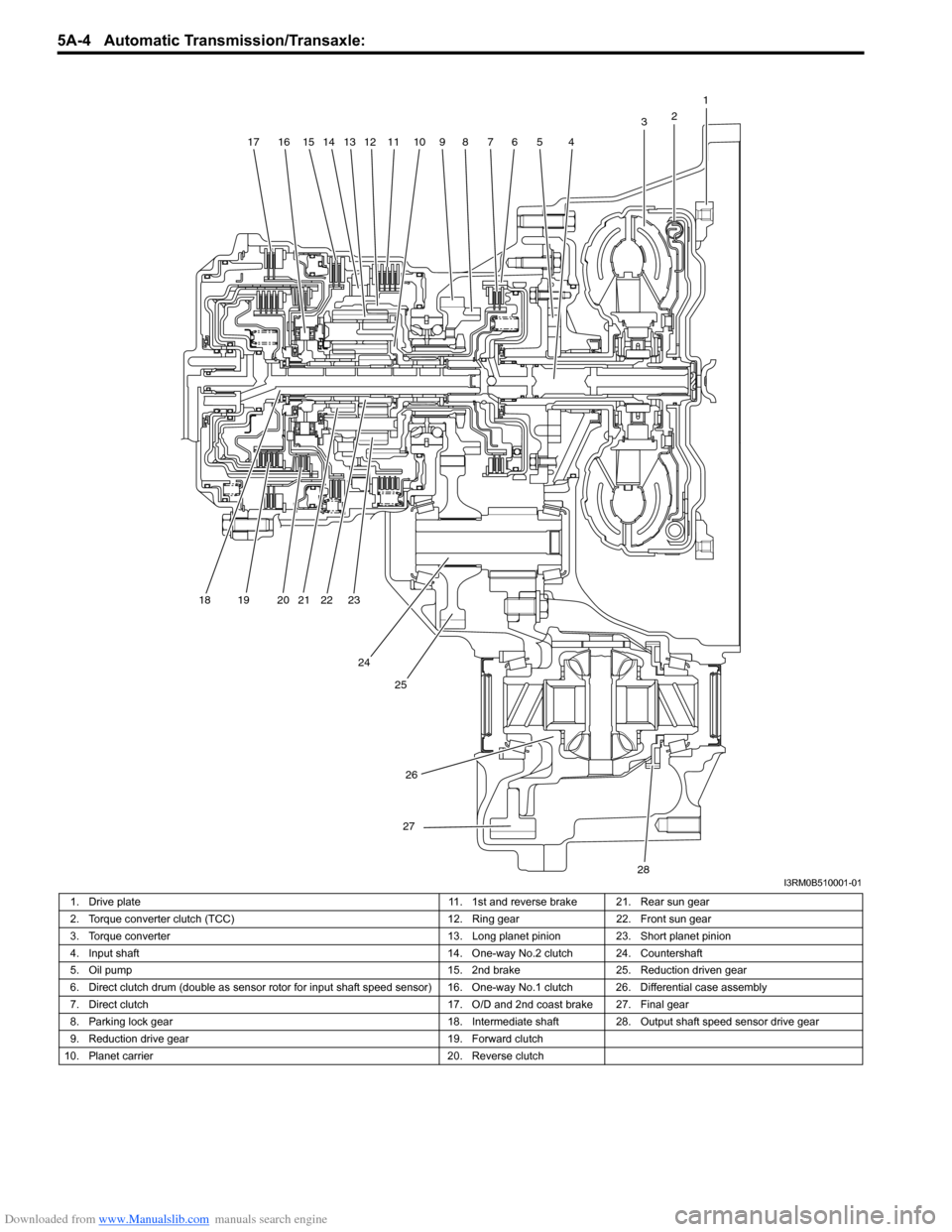

Downloaded from www.Manualslib.com manuals search engine 5A-4 Automatic Transmission/Transaxle:

1

2

3

4567891011121314151617

18 19 20 21 22 23

24 25

26

27

28I3RM0B510001-01

1. Drive plate 11. 1st and reverse brake 21. Rear sun gear

2. Torque converter clutch (TCC) 12. Ring gear22. Front sun gear

3. Torque converter 13. Long planet pinion23. Short planet pinion

4. Input shaft 14. One-way No.2 clutch 24. Countershaft

5. Oil pump 15. 2nd brake25. Reduction driven gear

6. Direct clutch drum (double as sensor ro tor for input shaft speed sensor) 16. One-way No.1 clutch 26. Differential case assembly

7. Direct clutch 17. O/D and 2nd coast brake 27. Final gear

8. Parking lock gear 18. Intermediate shaft28.Output shaft speed sensor drive gear

9. Reduction drive gear 19. Forward clutch

10. Planet carrier 20. Reverse clutch

Page 697 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-53

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Shift select lever to “D” range and drive vehicle at 50 km /h (31 mile/h) or more vehicle speed at least for 3 minutes.

4) Stop vehicle and check DTC.

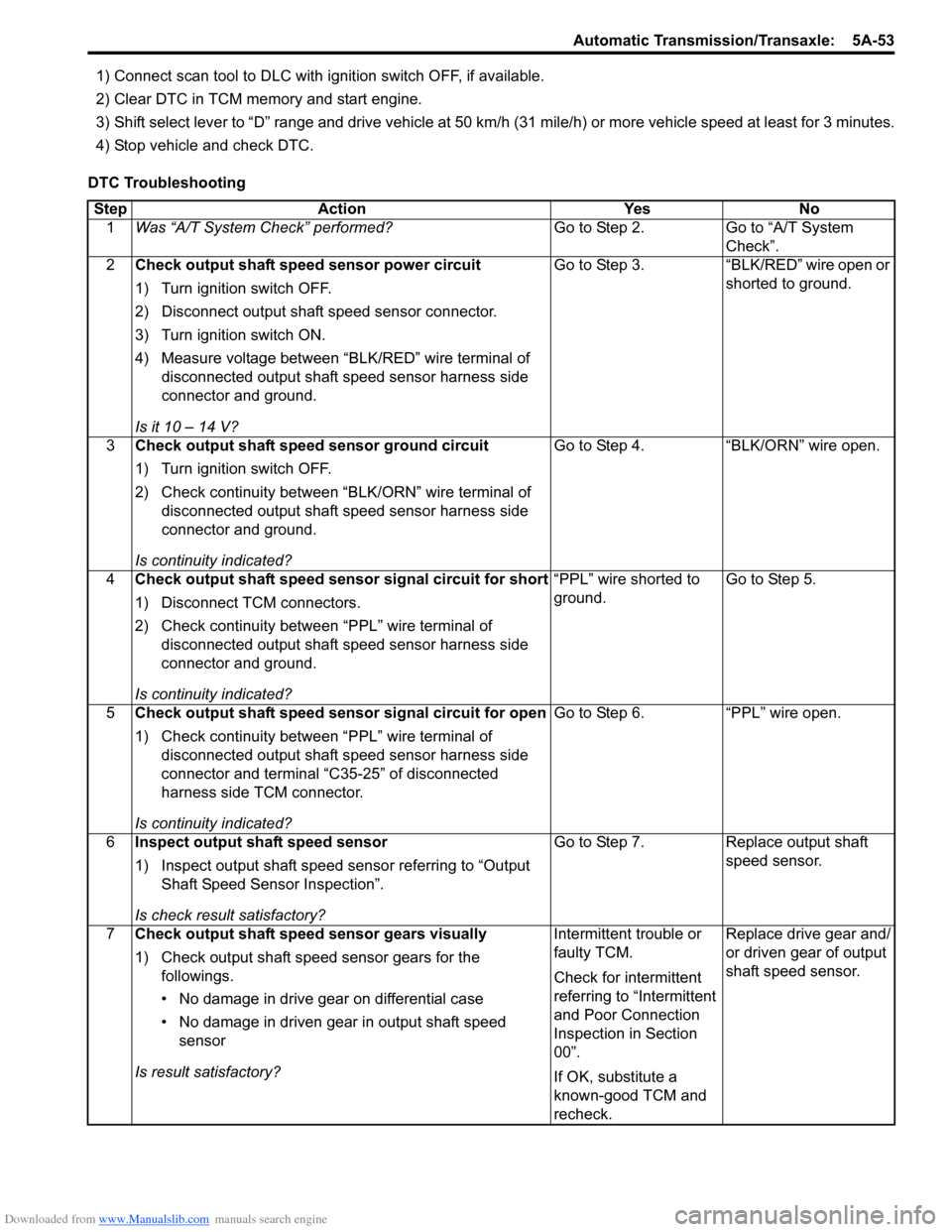

DTC Troubleshooting Step Action Yes No 1 Was “A/T System Check” performed? Go to Step 2. Go to “A/T System

Check”.

2 Check output shaft speed sensor power circuit

1) Turn ignition switch OFF.

2) Disconnect output shaft speed sensor connector.

3) Turn ignition switch ON.

4) Measure voltage between “BLK/RED” wire terminal of

disconnected output shaft speed sensor harness side

connector and ground.

Is it 10 – 14 V? Go to Step 3. “BLK/RED” wire open or

shorted to ground.

3 Check output shaft speed sensor ground circuit

1) Turn ignition switch OFF.

2) Check continuity between “BLK/ORN” wire terminal of

disconnected output shaft speed sensor harness side

connector and ground.

Is continuity indicated? Go to Step 4. “BLK/ORN” wire open.

4 Check output shaft speed sensor signal circuit for short

1) Disconnect TCM connectors.

2) Check continuity between “PPL” wire terminal of

disconnected output shaft speed sensor harness side

connector and ground.

Is continuity indicated? “PPL” wire shorted to

ground.

Go to Step 5.

5 Check output shaft speed sensor signal circuit for open

1) Check continuity between “PPL” wire terminal of

disconnected output shaft speed sensor harness side

connector and terminal “C35-25” of disconnected

harness side TCM connector.

Is continuity indicated? Go to Step 6. “PPL” wire open.

6 Inspect output shaft speed sensor

1) Inspect output shaft speed sensor referring to “Output

Shaft Speed Sensor Inspection”.

Is check result satisfactory? Go to Step 7. Replace output shaft

speed sensor.

7 Check output shaft speed sensor gears visually

1) Check output shaft speed sensor gears for the

followings.

• No damage in drive gear on differential case

• No damage in driven gear in output shaft speed sensor

Is result satisfactory? Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Replace drive gear and/

or driven gear of output

shaft speed sensor.

Page 747 of 1496

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-103

Installation

Reverse removal procedure noting the following.

• Connect TCM connectors securely.

• If the vehicle is equipped with air bag system, be sure to enable air bag system after TCM is back in place.

Refer to “Enabling Air Bag System in Section 8B”.

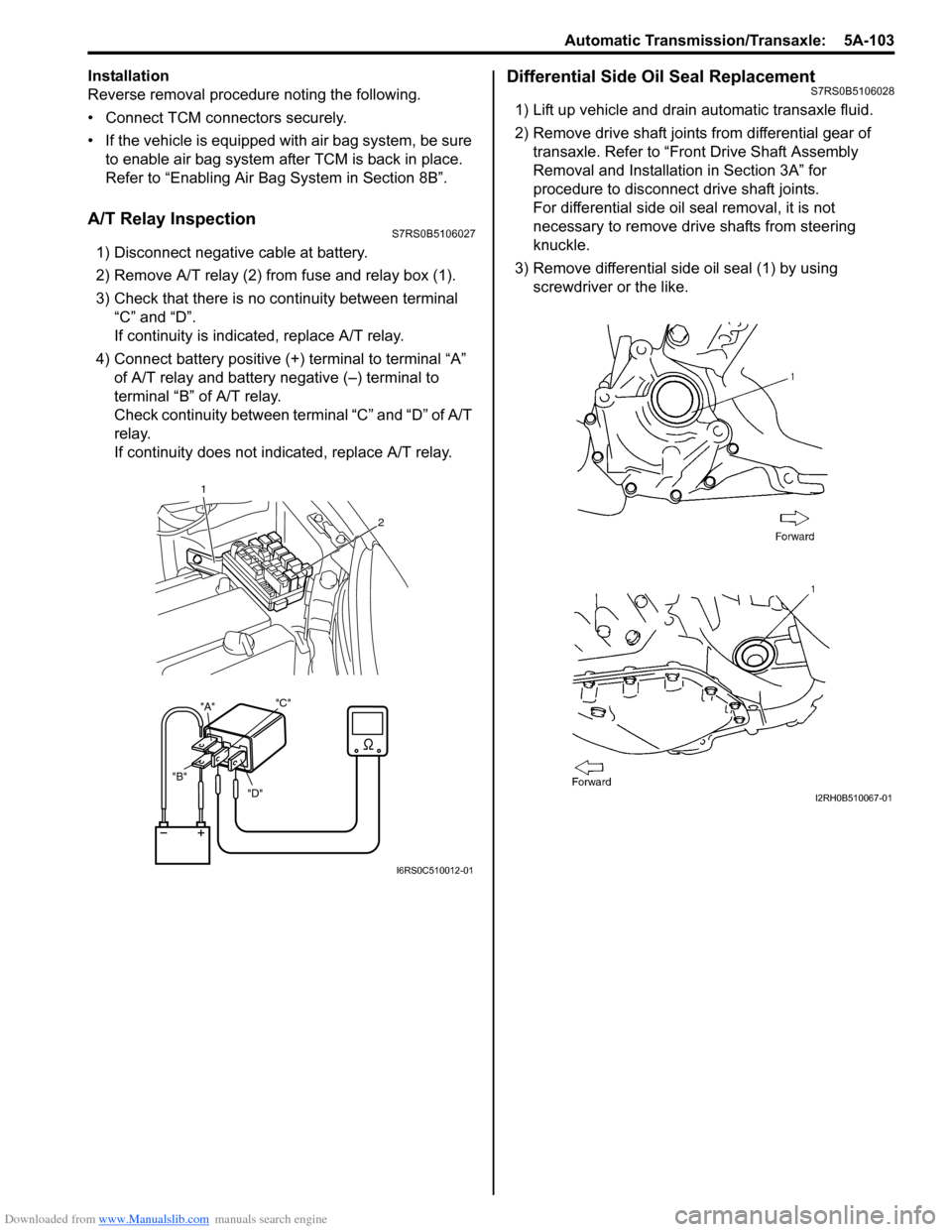

A/T Relay InspectionS7RS0B5106027

1) Disconnect negative cable at battery.

2) Remove A/T relay (2) from fuse and relay box (1).

3) Check that there is no continuity between terminal “C” and “D”.

If continuity is indicated, replace A/T relay.

4) Connect battery positive (+ ) terminal to terminal “A”

of A/T relay and battery negative (–) terminal to

terminal “B” of A/T relay.

Check continuity between terminal “C” and “D” of A/T

relay.

If continuity does not indicated, replace A/T relay.

Differential Side Oil Seal ReplacementS7RS0B5106028

1) Lift up vehicle and drain automatic transaxle fluid.

2) Remove drive shaft joints from differential gear of transaxle. Refer to “Front Drive Shaft Assembly

Removal and Installation in Section 3A” for

procedure to disconnect drive shaft joints.

For differential side oil seal removal, it is not

necessary to remove drive shafts from steering

knuckle.

3) Remove differential side oil seal (1) by using screwdriver or the like.

"D"

"B" "A"

"C"

1

2

I6RS0C510012-01

I2RH0B510067-01