muffler SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 9 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-4

General PrecautionsS7RS0B0000002

The WARNING and CAUTION describe some general

precautions that you should observe when servicing a

vehicle. These general precautions apply to many of the

service procedures, and they will not necessarily be

repeated with each procedure to which they apply.

WARNING!

• Whenever raising a vehicle for service, be sure to follow the instructions under

“Vehicle Lifting Points in Section 0A”.

• When it is necessary to do service work with the engine running, make sure that

the parking brake is set fully and the

transmission is in Neutral (for manual

transmission vehicles) or Park (for

automatic transmission vehicles), Keep

hands, hair, clothing, tools, etc. away from

the fan and belts when the engine is

running.

• When it is necessary to run the engine indoors, make sure that the exhaust gas is

forced outdoors.

• Do not perform service work in areas where combustible materials can come in

contact with a hot exhaust system. When

working with toxic or flammable materials

(such as gasoline and refrigerant), make

sure that the area you work in is well-

ventilated.

• To avoid getting burned, keep away from hot metal parts such as the radiator,

exhaust manifold, tail pipe, muffler, etc.

• New and used engine oil can be hazardous. Children and pets may be

harmed by swallowing new or used oil.

Keep new and used oil and used engine oil

filters away from children and pets.

Continuous contact with used engine oil

has been found to cause [skin] cancer in

laboratory animals. Brief contact with used

oil may irritate skin. To minimize your

exposure to used engine oil, wear a long-

sleeve shirt and moisture-proof gloves

(such as dish washing gloves) when

changing engine oil. If engine oil contacts

your skin, wash thoroughly with soap and

water. Launder any clothing or rags if wet

with oil, recycle or properly dispose of

used oil and filters. • Be sure to observe following instructions

when handling service materials such as

fuel, oil, fluid, coolant, grease, sealant,

thread lock cement, etc. Otherwise, your

health may be ruined.

– Whenever handling any of these service materials, wear safety glasses to protect

your eyes. If it gets into your eye, it may

cause inflammation.

– Whenever handling any of these service materials, wear moistu re-proof gloves to

protect your skin. If it adheres to your

skin, it may cause inflammation.

– Do not swallow any of these service materials. It would cause diarrhea or

nausea.

– Keep all these materials out of children’s reach.

• Make sure the bonnet is fully closed and latched before driving. If it is not, it can fly

up unexpectedly during driving,

obstructing your view and resulting in an

accident.

• Before starting any service work, cover fenders, seats and any other parts that are likely to get scratched or

stained during servicing. Also, be aware that what you

wear (e.g., buttons) ma y cause damage to the

vehicle’s finish.

I2RH01010025-01

Page 49 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 1-v

Ignition Timing Inspection ................................... 1H-8

Specifications ....................................................... 1H-9

Tightening Torque Specifications ........................ 1H-9

Special Tools and Equipmen t ............................. 1H-9

Special Tool ........................................................ 1H-9

Starting System ................. ........................ 1I-1

Schematic and Routing Diagram ......................... 1I-1

Cranking System Circuit Diagram ........................ 1I-1

Diagnostic Information and Procedures ............. 1I-1

Cranking System Symptom Diagnosis ................. 1I-1

Cranking System Test.......................................... 1I-3

Repair Instructions ............................................... 1I-4 Starting Motor Dismounting and Remounting ...... 1I-4

Starting Motor Components ................................. 1I-5

Starting Motor Inspection ..................................... 1I-6

Specifications ........................................................ 1I-9

Cranking System Specifications........................... 1I-9

Tightening Torque Specifications ......................... 1I-9

Special Tools and Equipment .............................. 1I-9

Recommended Service Material .......................... 1I-9

Charging System ............ .......................... 1J-1

General Description ......... .................................... 1J-1

Battery Description ...............................................1J-1

Generator Descripti on ..........................................1J-2

Diagnostic Information and Procedures ............ 1J-4 Battery Inspection ................................................1J-4

Generator Symptom Diagnosis ............................1J-4 Generator Test (Undercharged Battery

Check) ............................................................... 1J-5

Generator Test (Overcharg ed Battery Check) .... 1J-6

Repair Instructions ........... ................................... 1J-6

Jump Starting in Case of Emergency.................. 1J-6

Battery Dismounting and Remounting ................ 1J-7

Water Pump / Generator Drive Belt Tension Inspection and Adjustment ................................ 1J-7

Water Pump / Generator Drive Belt Removal and Installation .................................................. 1J-8

Generator Unit Co mponents ............................... 1J-9

Generator Dismounting a nd Remounting............ 1J-9

Generator Components........ ............................. 1J-10

Generator Insp ection......................................... 1J-11

Specifications ..................................................... 1J-13 Charging System Specifications ....................... 1J-13

Tightening Torque Specifications ...................... 1J-13

Exhaust System .............. ......................... 1K-1

General Description .............................................1K-1

Exhaust System Description ............................... 1K-1

Diagnostic Information and Procedures ............1K-1 Exhaust System Check ....................................... 1K-1

Repair Instructions ........... ...................................1K-2

Exhaust System Components ............................. 1K-2

Exhaust Manifold Removal and Installation ........ 1K-3

Exhaust Pipe and Muffler Removal and Installation ......................................................... 1K-4

Specifications .................... ...................................1K-5

Tightening Torque Specifications ........................ 1K-5

Page 303 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-18

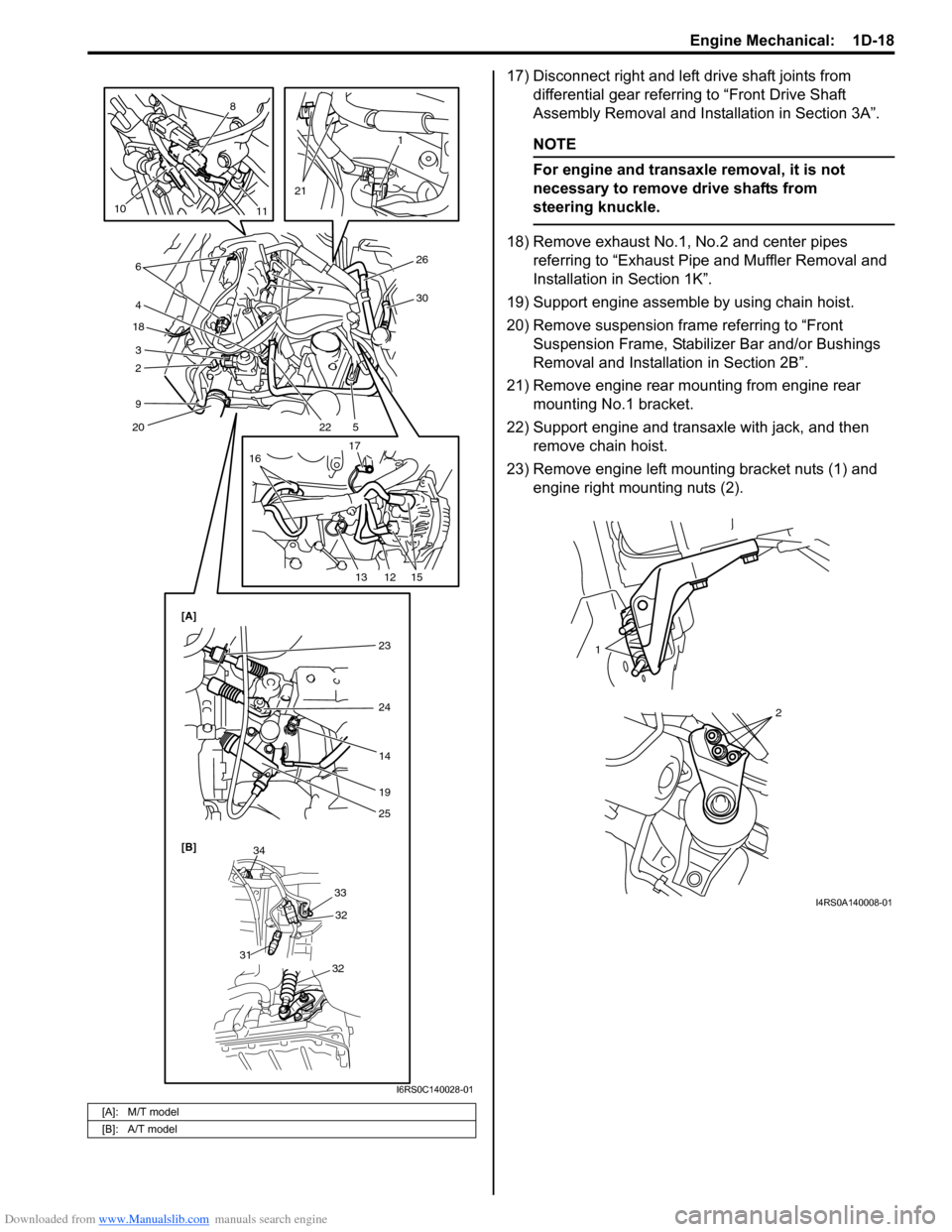

17) Disconnect right and left drive shaft joints from differential gear referring to “Front Drive Shaft

Assembly Removal and Installation in Section 3A”.

NOTE

For engine and transaxle removal, it is not

necessary to remove drive shafts from

steering knuckle.

18) Remove exhaust No.1, No.2 and center pipes referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

19) Support engine assemble by using chain hoist.

20) Remove suspension frame referring to “Front Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

21) Remove engine rear mounting from engine rear mounting No.1 bracket.

22) Support engine and transaxle with jack, and then remove chain hoist.

23) Remove engine left mounting bracket nuts (1) and engine right mounting nuts (2).

[A]: M/T model

[B]: A/T model

7

26

30

5

4

22

3

2

20

6

9

18

8

11

10

21 1

16

17

151213

[B]

23

24

14

25 19

34

33

32

32

31

[A]

I6RS0C140028-01

1

2

I4RS0A140008-01

Page 304 of 1496

Downloaded from www.Manualslib.com manuals search engine 1D-19 Engine Mechanical:

24) Before removing engine with transaxle from engine compartment, recheck to make sure all hoses,

electric wires and cables are disconnected from

engine and transaxle.

25) Lower engine with transaxle from engine compartment.

CAUTION!

Before lowering engine, to avoid damage to

A/C compressor and clutch operating

cylinder, make clearance by rising them. Be

sure not to damage suspended A/C

compressor and clutch operating cylinder.

26) Disconnect transaxle from engine, referring to “Manual Transaxle Unit Dismounting and

Remounting in Section 5B” or “Automatic Transaxle

Unit Dismounting and Re mounting in Section 5A”.

27) For M/T model, remove clutch cover and clutch disk referring to “Clutch Cover, Clutch Disc and Flywheel

Removal and Installa tion in Section 5C”.

Installation 1) For M/T model, install clutch cover and clutch disk referring to “Clutch Cover, Clutch Disc and Flywheel

Removal and Installa tion in Section 5C”.

2) Connect transaxle to engine referring to “Manual Transaxle Unit Dismounting and Remounting in

Section 5B” or “Automatic Transaxle Unit

Dismounting and Remounting in Section 5A”.

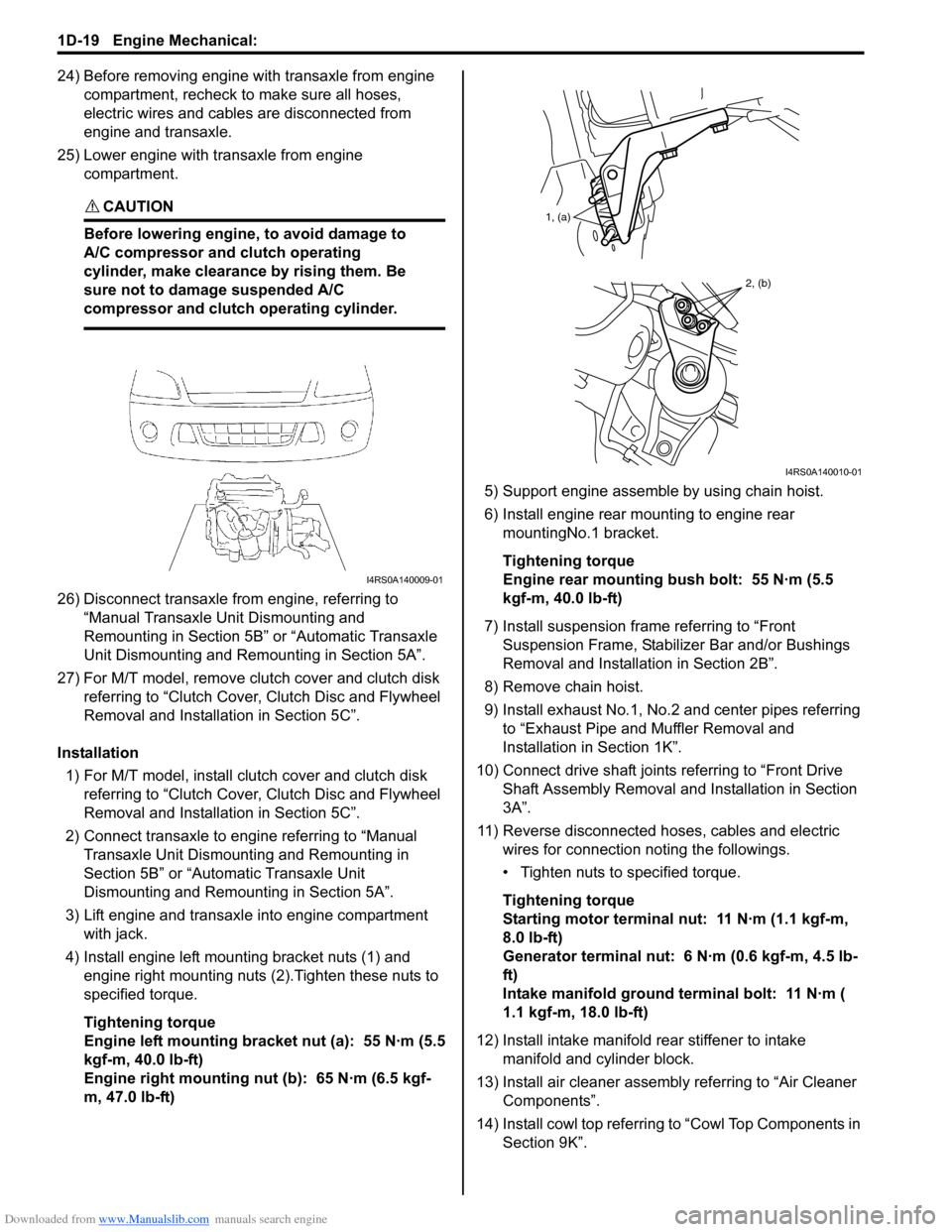

3) Lift engine and transaxle into engine compartment with jack.

4) Install engine left mounting bracket nuts (1) and engine right mounting nuts (2).Tighten these nuts to

specified torque.

Tightening torque

Engine left mounting bracket nut (a): 55 N·m (5.5

kgf-m, 40.0 lb-ft)

Engine right mounting nut (b): 65 N·m (6.5 kgf-

m, 47.0 lb-ft) 5) Support engine assemble by using chain hoist.

6) Install engine rear mounting to engine rear

mountingNo.1 bracket.

Tightening torque

Engine rear mounting bush bolt: 55 N·m (5.5

kgf-m, 40.0 lb-ft)

7) Install suspension frame referring to “Front Suspension Frame, Stabiliz er Bar and/or Bushings

Removal and Installati on in Section 2B”.

8) Remove chain hoist.

9) Install exhaust No.1, No.2 and center pipes referring to “Exhaust Pipe and Muffler Removal and

Installation in Section 1K”.

10) Connect drive shaft joints referring to “Front Drive Shaft Assembly Removal and Installation in Section

3A”.

11) Reverse disconnected hoses, cables and electric wires for connection noting the followings.

• Tighten nuts to specified torque.

Tightening torque

Starting motor terminal nut: 11 N·m (1.1 kgf-m,

8.0 lb-ft)

Generator terminal nut: 6 N·m (0.6 kgf-m, 4.5 lb-

ft)

Intake manifold ground terminal bolt: 11 N·m (

1.1 kgf-m, 18.0 lb-ft)

12) Install intake manifold rear stiffener to intake

manifold and cylinder block.

13) Install air cleaner assembly referring to “Air Cleaner Components”.

14) Install cowl top referring to “Cowl Top Components in

Section 9K”.

I4RS0A140009-01

1, (a)

2, (b)

I4RS0A140010-01

Page 388 of 1496

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

Installation

CAUTION!

• When connecting joint, clean outside surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS sensor harness (if equipped).

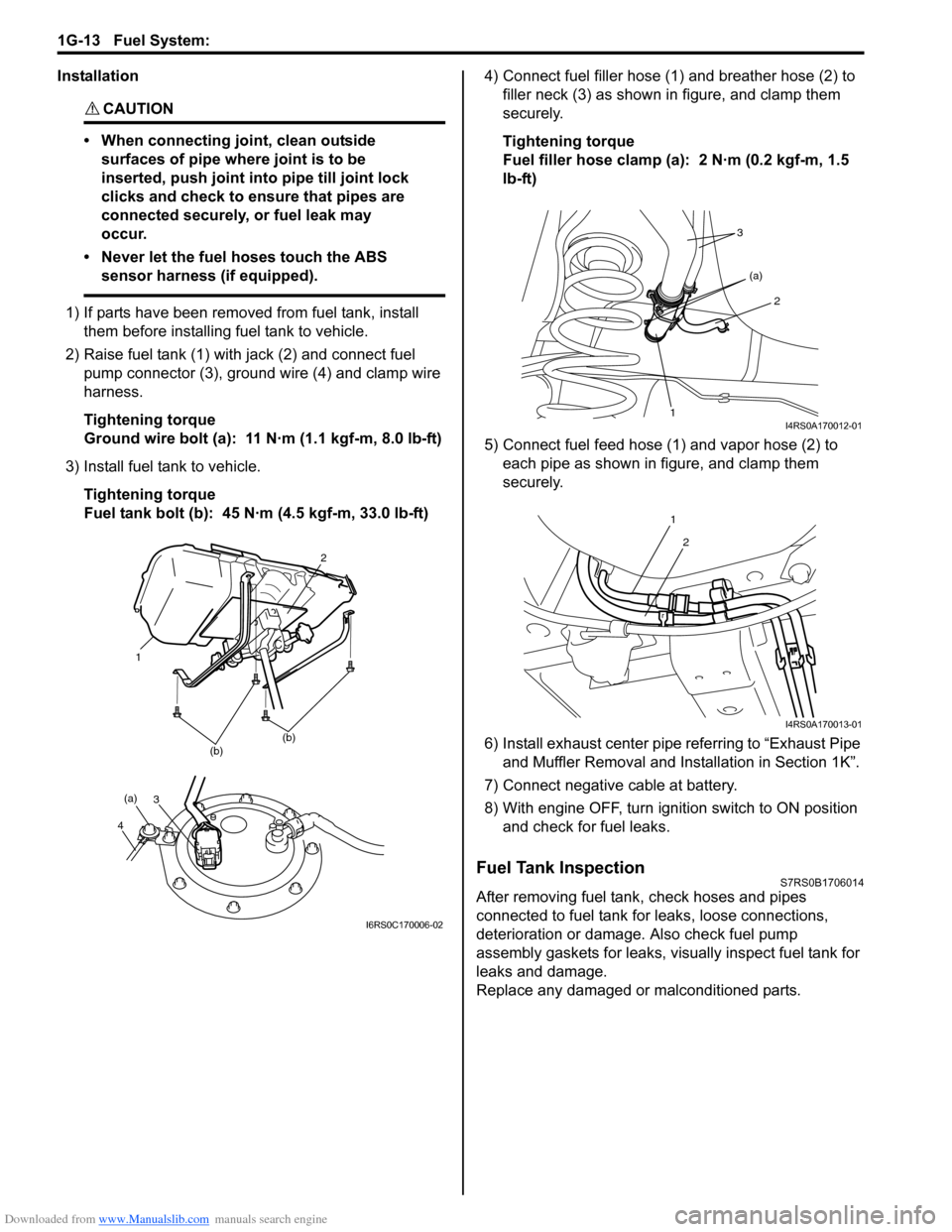

1) If parts have been removed from fuel tank, install them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle. Tightening torque

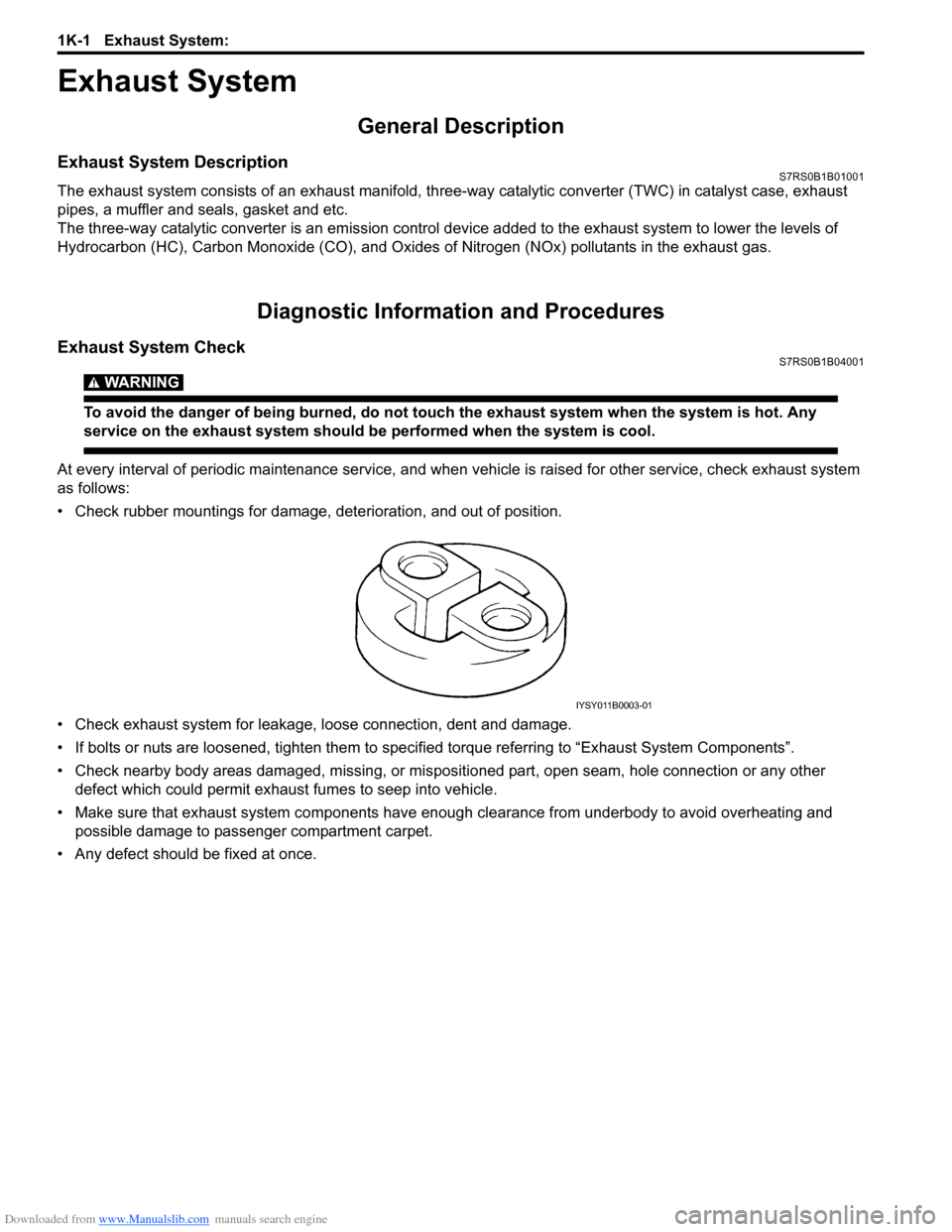

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft) 4) Connect fuel filler hose (1

) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 2 N·m (0.2 kgf-m, 1.5

lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe and Muffler Removal and Installation in Section 1K”.

7) Connect negative cable at battery.

8) With engine OFF, turn ignition switch to ON position and check for fuel leaks.

Fuel Tank InspectionS7RS0B1706014

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I6RS0C170006-02

1

2

(a)

3

I4RS0A170012-01

1

2

I4RS0A170013-01

Page 424 of 1496

Downloaded from www.Manualslib.com manuals search engine 1K-1 Exhaust System:

Engine

Exhaust System

General Description

Exhaust System DescriptionS7RS0B1B01001

The exhaust system consists of an exhaust manifold, three-way catalytic converter (TWC) in catalyst case, exhaust

pipes, a muffler and seals, gasket and etc.

The three-way catalytic converter is an emission control device added to the exhaust system to lower the levels of

Hydrocarbon (HC), Carbon Monoxide (CO), and Oxides of Nitrogen (NOx) pollutants in the exhaust gas.

Diagnostic Information and Procedures

Exhaust System CheckS7RS0B1B04001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

At every interval of periodic maintenance service, and when vehicle is raised for other service, check exhaust system

as follows:

• Check rubber mountings for damage, deterioration, and out of position.

• Check exhaust system for leakage, loose connection, dent and damage.

• If bolts or nuts are loosened, tighten them to specified torque referring to “Exhaust System Components”.

• Check nearby body areas damaged, missing, or mispositio ned part, open seam, hole connection or any other

defect which could permit exhaust fumes to seep into vehicle.

• Make sure that exhaust system components have enough clearance from underbody to avoid overheating and

possible damage to passenger compartment carpet.

• Any defect should be fixed at once.

IYSY011B0003-01

Page 425 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-2

Repair Instructions

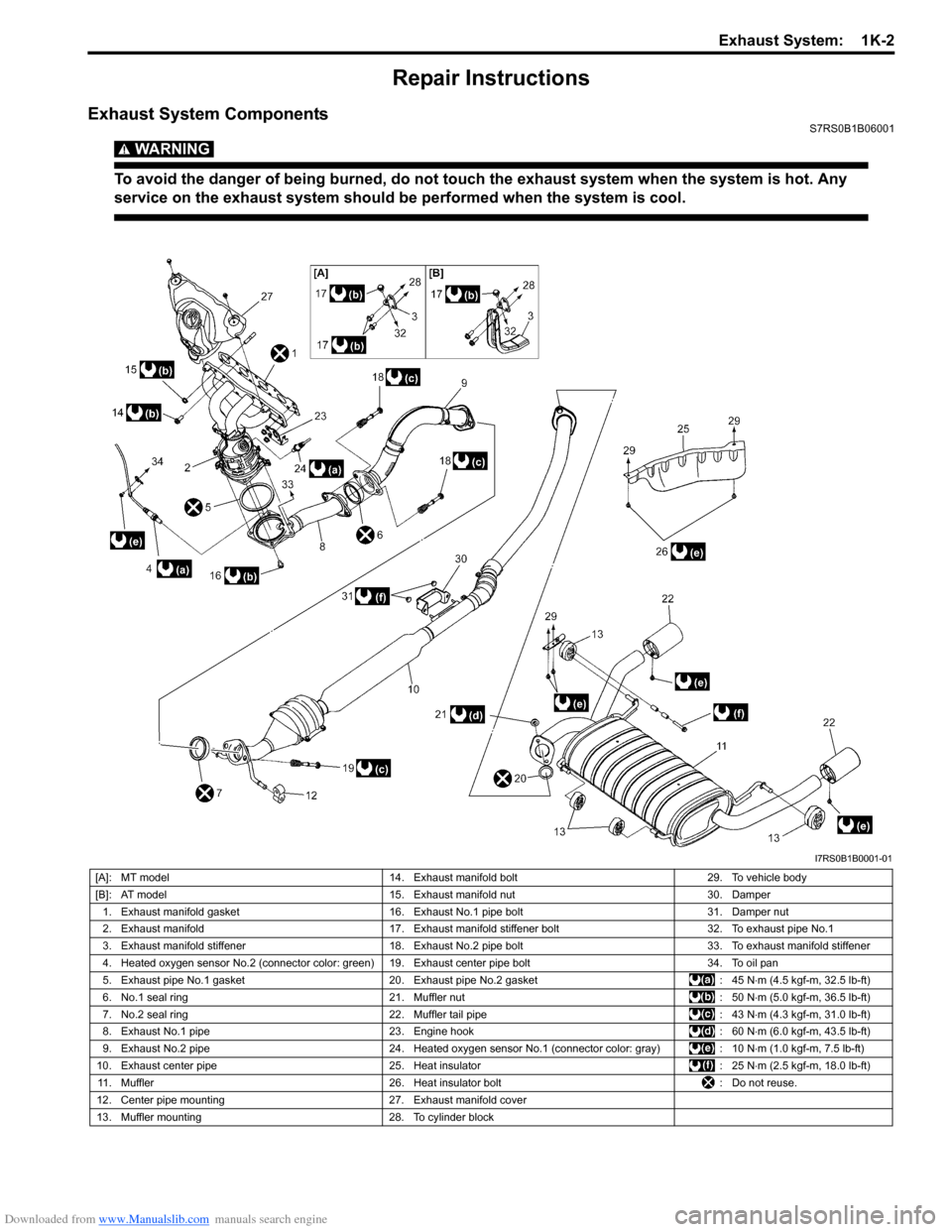

Exhaust System ComponentsS7RS0B1B06001

WARNING!

To avoid the danger of being burned, do not touch the exhaust system when the system is hot. Any

service on the exhaust system should be performed when the system is cool.

I7RS0B1B0001-01

[A]: MT model14. Exhaust manifold bolt 29. To vehicle body

[B]: AT model 15. Exhaust manifold nut 30. Damper

1. Exhaust manifold gasket 16. Exhaust No.1 pipe bolt 31. Damper nut

2. Exhaust manifold 17. Exhaust manifold stiffener bolt 32. To exhaust pipe No.1

3. Exhaust manifold stiffener 18. Exhaust No.2 pipe bolt 33. To exhaust manifold stiffener

4. Heated oxygen sensor No.2 (connector color: green) 19. Exhaust center pipe bolt 34. To oil pan

5. Exhaust pipe No.1 gasket 20. Exhaust pipe No.2 gasket : 45 N⋅m (4.5 kgf-m, 32.5 lb-ft)

6. No.1 seal ring 21. Muffler nut : 50 N⋅m (5.0 kgf-m, 36.5 lb-ft)

7. No.2 seal ring 22. Muffler tail pipe : 43 N⋅m (4.3 kgf-m, 31.0 lb-ft)

8. Exhaust No.1 pipe 23. Engine hook : 60 N⋅m (6.0 kgf-m, 43.5 lb-ft)

9. Exhaust No.2 pipe 24. Heated oxygen sensor No.1 (connector color: gray) : 10 N⋅m (1.0 kgf-m, 7.5 lb-ft)

10. Exhaust center pipe 25. Heat insulator : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

11. Muffler 26. Heat insulator bolt : Do not reuse.

12. Center pipe mounting 27. Exhaust manifold cover

13. Muffler mounting 28. To cylinder block

Page 427 of 1496

Downloaded from www.Manualslib.com manuals search engine Exhaust System: 1K-4

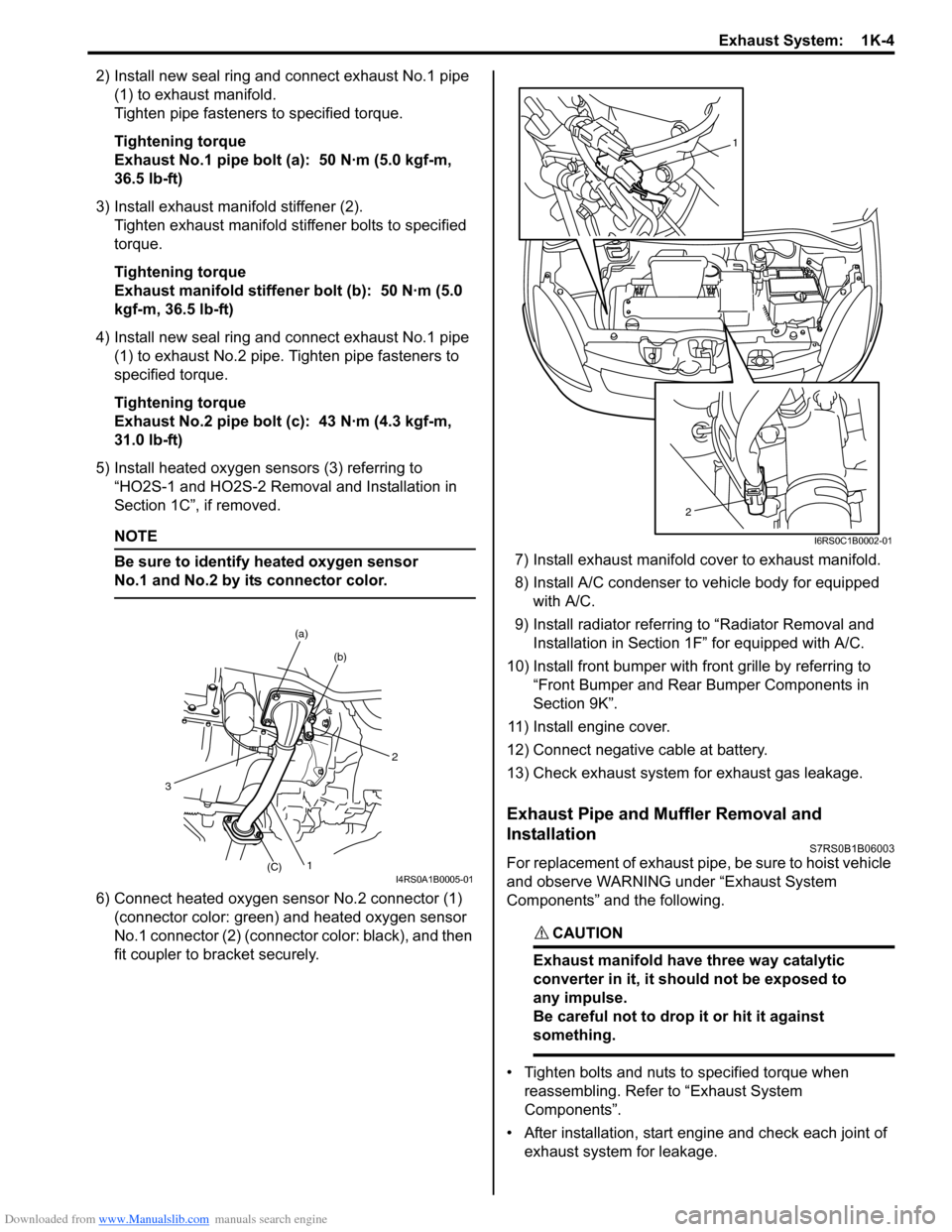

2) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust manifold.

Tighten pipe fasteners to specified torque.

Tightening torque

Exhaust No.1 pipe bolt (a): 50 N·m (5.0 kgf-m,

36.5 lb-ft)

3) Install exhaust manifold stiffener (2). Tighten exhaust manifold stiffener bolts to specified

torque.

Tightening torque

Exhaust manifold stiffener bolt (b): 50 N·m (5.0

kgf-m, 36.5 lb-ft)

4) Install new seal ring and connect exhaust No.1 pipe (1) to exhaust No.2 pipe. Tighten pipe fasteners to

specified torque.

Tightening torque

Exhaust No.2 pipe bolt (c): 43 N·m (4.3 kgf-m,

31.0 lb-ft)

5) Install heated oxygen sensors (3) referring to “HO2S-1 and HO2S-2 Removal and Installation in

Section 1C”, if removed.

NOTE

Be sure to identify heated oxygen sensor

No.1 and No.2 by its connector color.

6) Connect heated oxygen sensor No.2 connector (1)

(connector color: green) and heated oxygen sensor

No.1 connector (2) (connector color: black), and then

fit coupler to br acket securely. 7) Install exhaust manifold cover to exhaust manifold.

8) Install A/C condenser to vehicle body for equipped

with A/C.

9) Install radiator referrin g to “Radiator Removal and

Installation in Section 1F” for equipped with A/C.

10) Install front bumper with fr ont grille by referring to

“Front Bumper and Rear Bumper Components in

Section 9K”.

11) Install engine cover.

12) Connect negative cable at battery.

13) Check exhaust system for exhaust gas leakage.

Exhaust Pipe and Muffler Removal and

Installation

S7RS0B1B06003

For replacement of exhaust pipe, be sure to hoist vehicle

and observe WARNING under “Exhaust System

Components” and the following.

CAUTION!

Exhaust manifold have three way catalytic

converter in it, it should not be exposed to

any impulse.

Be careful not to drop it or hit it against

something.

• Tighten bolts and nuts to specified torque when reassembling. Refer to “Exhaust System

Components”.

• After installation, start engine and check each joint of exhaust system for leakage.

2

(b)

(a)

1(C)

3

I4RS0A1B0005-01

1

2

I6RS0C1B0002-01

Page 449 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-16

4) Hoist vehicle and remove both wheels referring to “Wheel Removal and Installation in Section 2D”.

5) Remove cotter pins and tie-rod end nuts, and then disconnect both tie-rod ends from steering knuckles

referring to “Tie-Rod End Re moval and Installation in

Section 6C”.

6) Disconnect couplers of torque sensor and P/S motor.

7) Remove suspension control arm referring to “Suspension Control Arm / Bushing Removal and

Installation”.

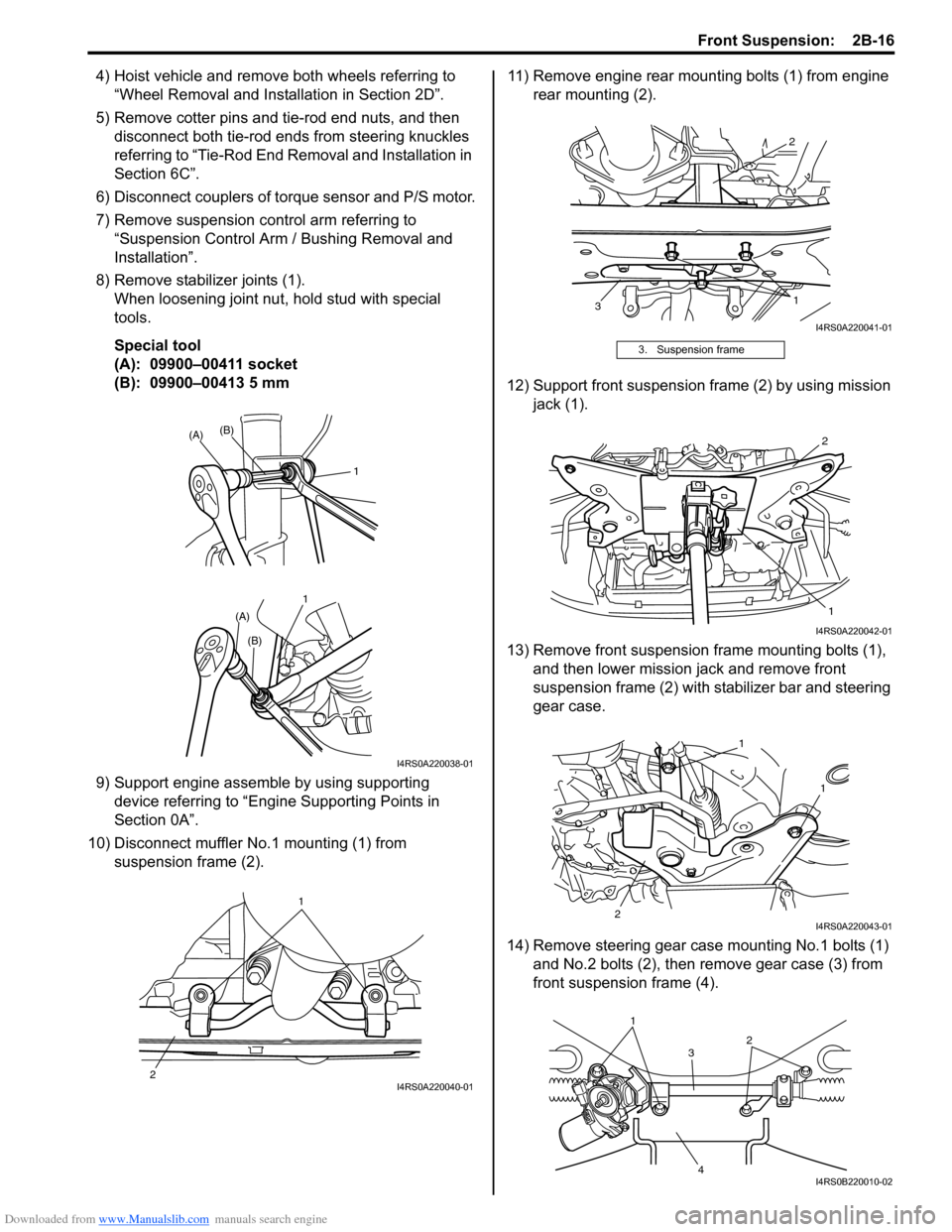

8) Remove stabilizer joints (1). When loosening joint nu t, hold stud with special

tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

9) Support engine assemble by using supporting device referring to “Engine Supporting Points in

Section 0A”.

10) Disconnect muffler No.1 mounting (1) from suspension frame (2). 11) Remove engine rear mounting bolts (1) from engine

rear mounting (2).

12) Support front suspension frame (2) by using mission jack (1).

13) Remove front suspension frame mounting bolts (1), and then lower mission jack and remove front

suspension frame (2) with st abilizer bar and steering

gear case.

14) Remove steering gear case mounting No.1 bolts (1) and No.2 bolts (2), then remove gear case (3) from

front suspensio n frame (4).

11

(A)

(A)

(B)

(B)

I4RS0A220038-01

1

2

I4RS0A220040-01

3. Suspension frame

2

3 1

I4RS0A220041-01

2

1

I4RS0A220042-01

1

2 1

I4RS0A220043-01

1

3

4 2

I4RS0B220010-02

Page 451 of 1496

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-18

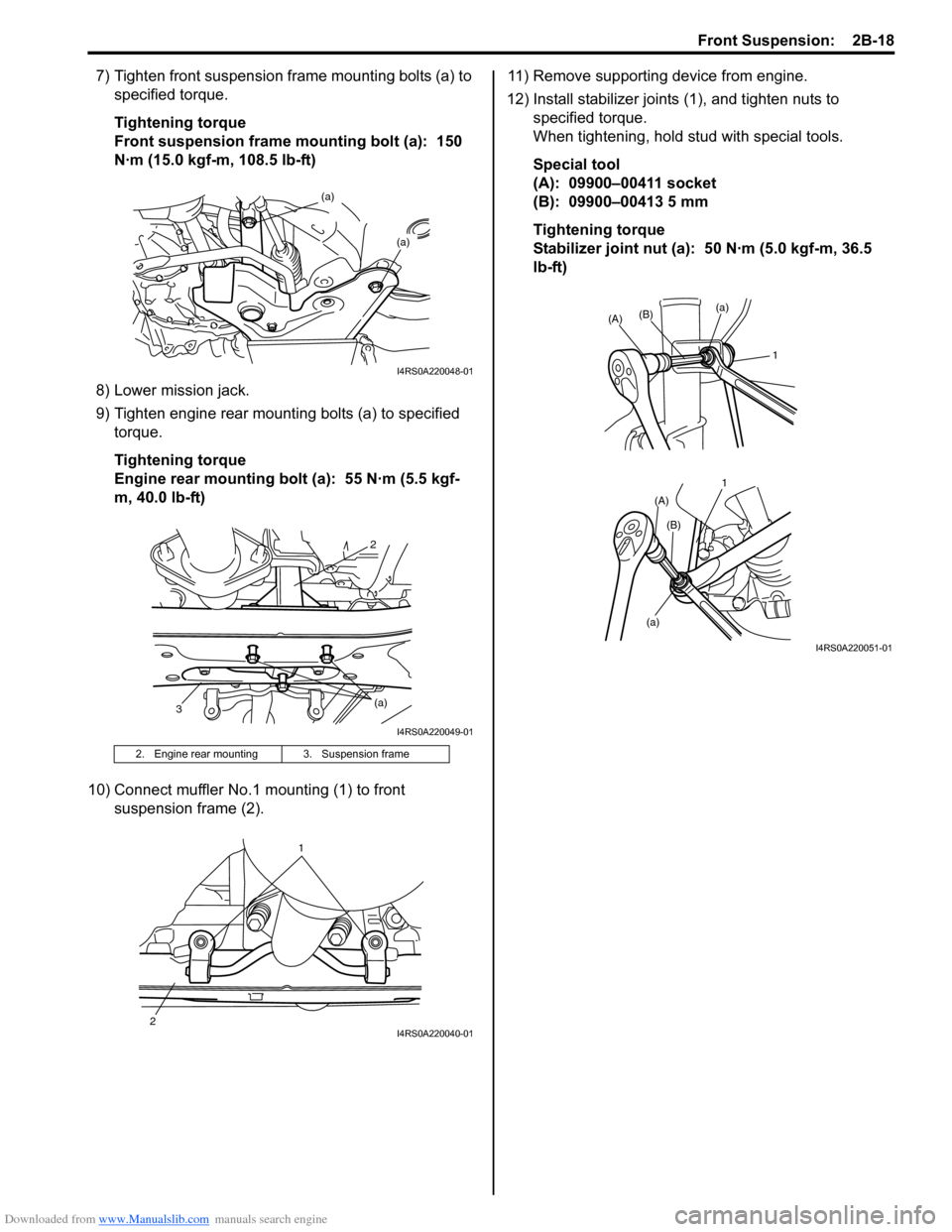

7) Tighten front suspension frame mounting bolts (a) to specified torque.

Tightening torque

Front suspension frame mounting bolt (a): 150

N·m (15.0 kgf-m, 108.5 lb-ft)

8) Lower mission jack.

9) Tighten engine rear mounting bolts (a) to specified torque.

Tightening torque

Engine rear mounting bolt (a): 55 N·m (5.5 kgf-

m, 40.0 lb-ft)

10) Connect muffler No.1 mounting (1) to front suspension frame (2). 11) Remove supporting device from engine.

12) Install stabilizer joints (1), and tighten nuts to

specified torque.

When tightening, hold stud with special tools.

Special tool

(A): 09900–00411 socket

(B): 09900–00413 5 mm

Tightening torque

Stabilizer joint nut (a): 50 N·m (5.0 kgf-m, 36.5

lb-ft)

2. Engine rear mounting 3. Suspension frame

(a)

(a)

I4RS0A220048-01

2

3 (a)

I4RS0A220049-01

1

2

I4RS0A220040-01

1 1

(A)

(A)

(a) (a)

(B)

(B)

I4RS0A220051-01