tire SUZUKI SWIFT 2008 2.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2008, Model line: SWIFT, Model: SUZUKI SWIFT 2008 2.GPages: 1496, PDF Size: 34.44 MB

Page 4 of 1496

Downloaded from www.Manualslib.com manuals search engine 00

0

1

2

3

4

5

6

7

8

9

10

11

Vo l u m e 1

Precautions............................................................... 00-iPrecautions ............................................................ 00-1

General Information ................ ................................... 0-i

General Information ............................................... 0A-1

Maintenance and Lubricatio n ................................. 0B-1

Engine ......................................................................... 1-i Precautions .............................................................. 1-1

Engine General Information and Diagnosis ........... 1A-1

Aux. Emission Control Devices .............................. 1B-1

Engine Electrical Devices....................................... 1C-1

Engine Mechanical ................................................. 1D-1

Engine Lubrication System .................................... 1E-1

Engine Cooling System .......................................... 1F-1

Fuel System ...........................................................1G-1

Ignition System....................................................... 1H-1

Starting System ....................................................... 1I-1

Charging System.....................................................1J-1

Exhaust System ..................................................... 1K-1

Suspension ................................................................. 2-i Precautions .............................................................. 2-1

Suspension General Diagnosis .............................. 2A-1

Front Suspension ................................................... 2B-1

Rear Suspension................ .................................... 2C-1

Wheels and Tires ................................................... 2D-1

Driveline / Axle ........................................................... 3-i Precautions .............................................................. 3-1

Drive Shaft / Axle ................................................... 3A-1

Brakes ......................................................................... 4-i Precautions .............................................................. 4-1

Brake Control System and Diagnosis .................... 4A-1

Front Brakes........................................................... 4B-1

Rear Brakes ........................................................... 4C-1

Parking Brake......................................................... 4D-1

ABS ........................................................................ 4E-1

Electronic Stability Program ................................... 4F-1

Vo l u m e 2

Precautions ............................................................... 00-iPrecautions ............................................................ 00-1

Transmission / Transaxle .... ...................................... 5-i

Precautions .............................................................. 5-1

Automatic Transmission/Transaxle ........................ 5A-1

Manual Transmission/Transaxle ............................ 5B-1

Clutch .....................................................................5C-1

Steering ....................................................................... 6-i Precautions .............................................................. 6-1

Steering General Diagnosis ................................... 6A-1

Steering Wheel and Column .................................. 6B-1

Power Assisted Steering System ...........................6C-1

HVAC ........................................................................... 7-i Precautions .............................................................. 7-1

Heater and Ventilation............................................ 7A-1

Air Conditioning System ......................................... 7B-1

Restraint ...................................................................... 8-i Precautions .............................................................. 8-1

Seat Belts ............................................................... 8A-1

Air Bag System ...................................................... 8B-1

Body, Cab and Accessories .... .................................. 9-i

Precautions .............................................................. 9-1

Wiring Systems ...................................................... 9A-1

Lighting Systems .................................................... 9B-1

Instrumentation / Driver Info. / Horn .......................9C-1

Wipers / Washers ...................................................9D-1

Glass / Windows / Mirrors ...................................... 9E-1

Security and Locks ................................................. 9F-1

Seats ..................................................................... 9G-1

Interior Trim ............................................................9H-1

Hood / Fenders / Doors .......................................... 9J-1

Body Structure ....................................................... 9K-1

Paint / Coatings ...................................................... 9L-1

Exterior Trim .......................................................... 9M-1

Control Systems ....................................................... 10-i Precautions ............................................................ 10-1

Body Electrical Control Sy stem ............................ 10B-1

Immobilizer Control System .................................10C-1

Keyless Start System ........................................... 10E-1

TABLE OF CONTENTS

Page 5 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 00- i

00

Section 00

CONTENTS

Precautions

Precautions ............................................... 00-1

Precautions........................................................... 00-1

Precautions for Vehicles Equipped with a Supplemental Restraint (A ir Bag) System ........ 00-1

General Precautions ........... ................................ 00-4

Warning for Wheel (with tire) Removal ............... 00-7

Warning for Handling Emergency Flat Tire Repair Kit .......................................................... 00-7

Precautions for Catalytic Converter .................... 00-7

Precautions for Installing Mobile Communication Equipment ............................... 00-7

Precaution for CAN Communication System ...... 00-7 Precautions for Electrical Circuit Service ............ 00-8

Air Bag Warning ................................................ 00-10

Air Bag System Service Warning ...................... 00-10

Fastener Caution............................................... 00-10

Suspension Caution .......................................... 00-10

Wheels and Tires Caution ................................. 00-10

Precaution for Vehicle Equipped with ESP

®

System ............................................................ 00-11

Brake Caution ................................................... 00-11

Repair Instructions ........ .................................... 00-11

Electrical Circuit Inspection Procedure ............. 00-11

Intermittent and Poor Co nnection Inspection .... 00-13

Page 12 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-7 Precautions:

Warning for Wheel (with tire) RemovalS7RS0B0000003

WARNING!

When removing any of these wheels installed

with wheel bolts, never remove all wheel

bolts at the same time. Leave at least 1 bolt

for each wheel as it is to prevent wheel from

dropping. When removing this remaining 1

bolt, hold wheel and tire so as not to allow

them to come off.

Warning for Handling Emergency Flat Tire

Repair Kit

S7RS0B0000004

WARNING!

If vehicle is equipped with Emergency Flat

Tire Repair Kit instead of spare tire, be sure

to observe “Precaution for Emergency Flat

Tire Repair Kit in Section 2D” when handling

Emergency Flat Tire Repair Kit and repairing

flat tire.

Otherwise, your health may be ruined or it

will be impossible to repair flat tire.

Precautions for Catalytic ConverterS7RS0B0000005

For vehicles equipped with a catalytic converter, use

only unleaded gasoline and be careful not to let a large

amount of unburned gasoline enter the converter or it

can be damaged.

• Conduct a spark jump test only when necessary, make it as short as possible, and do not open the

throttle.

• Conduct engine compression checks within the shortest possible time.

• Avoid situations which can result in engine misfire (e.g. starting the engine when the fuel tank is nearly

empty.)

Precautions for Installing Mobile

Communication Equipment

S7RS0B0000006

When installing mobile communication equipment such

as CB (Citizens-Band)-radi o or cellular-telephone, be

sure to observe the following precautions.

Failure to follow cautions may adversely affect electronic

control system.

• Keep the antenna as far away as possible from the vehicle’s electronic control unit.

• Keep the antenna feeder more than 20 cm (7.9 in.) away from electronic control unit and its wire

harnesses.

• Do not run the antenna feeder parallel with other wire harnesses.

• Confirm that the antenna and feeder are correctly adjusted.

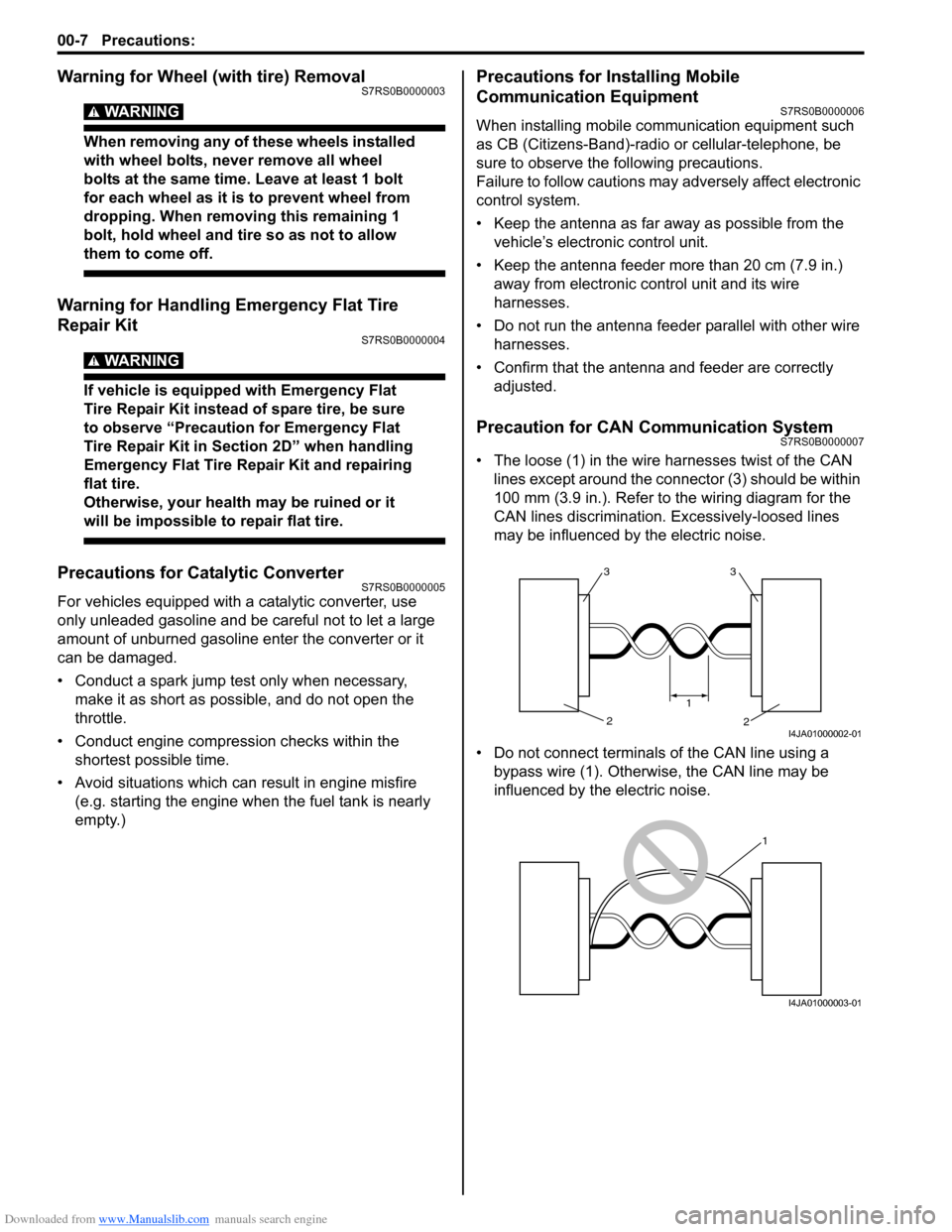

Precaution for CAN Communication SystemS7RS0B0000007

• The loose (1) in the wire harnesses twist of the CAN lines except around the connector (3) should be within

100 mm (3.9 in.). Refer to the wiring diagram for the

CAN lines discrimination. Excessively-loosed lines

may be influenced by the electric noise.

• Do not connect terminals of the CAN line using a bypass wire (1). Otherwise, the CAN line may be

influenced by the electric noise.

33

2

2

1

I4JA01000002-01

1

I4JA01000003-01

Page 15 of 1496

Downloaded from www.Manualslib.com manuals search engine Precautions: 00-10

Air Bag WarningS7RS0B0000009

WARNING!

For vehicles equipped with Supplemental

Restraint (Air Bag) System:

• Service on and around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer. Refer

to “Air Bag System Components, Wiring

and Connectors Location in Section 8B” in

order to confirm whether you are

performing service on or near the air bag

system components or wiring. Please

observe all WARNINGS in Air Bag System

section and “Precautions on Service and

Diagnosis of Air Bag System in Section

8B” before performing service on or

around the air bag system components or

wiring. Failure to follow WARNINGS could

result in unintentional activation of the

system or could render the system

inoperative. Either of these two conditions

may result in severe injury.

• Technical service work must be started at least 90 seconds after the ignition switch is

turned to the LOCK position and the

negative cable is disconnected from the

battery. Otherwise, the system may be

activated by reserve energy in the Sensing

and Diagnostic Module (SDM).

Air Bag System Service WarningS7RS0B0000010

WARNING!

• Service on or around the air bag system components or wiring must be performed

only by an authorized SUZUKI dealer.

Please observe all WARNINGS in Air Bag

System section and “Precautions on

Service and Diagnosis of Air Bag System

in Section 8B” before performing service

on or around the air bag system

components or wiring. Failure to follow

WARNINGS could result in unintended

activation of the system or could render

the system inoperative. Either of these two

conditions may result in severe injury.

• The procedures in the air bag system section must be followed in the order

listed to disable the air bag system

temporarily and prevent false DTCs from

setting. Failure to follow procedures could

result in possible activation of the air bag

system, personal injury or otherwise

unneeded air bag system repairs.

Fastener CautionS7RS0B0000011

CAUTION!

When fasteners are removed, always reinstall

them at the same location from which they

were removed. If a fastener needs to be

replaced, use the correct part number

fastener for that application. If the correct

part number fastener is not available, a

fastener of equal size and strength (or

stronger) may be used. Fasteners that are not

reused, and those requiring thread-locking

compound, will be called out. The correct

torque value must be used when installing

fasteners that require it. If the conditions are

not followed, parts or system damage could

result.

Suspension CautionS7RS0B0000012

CAUTION!

• All suspension fasteners are an important attaching part in that it could affect the

performance of vital parts and systems,

and/or could result in major repair

expense. They must be replaced with one

of the same part number or with an

equivalent part if replacement becomes

necessary. Do not use a replacement part

of lesser quality or substitute design.

Torque values must be used as specified

during reassembly to assure proper

retention of this part.

• Never attempt to heat, quench or straighten any suspension part. Replace it

with a new part or damage to the part may

result.

Wheels and Tires CautionS7RS0B0000013

CAUTION!

All wheel fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of the same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts.

There is to be no welding as it may result in

extensive damage and weakening of the

metal.

Page 16 of 1496

Downloaded from www.Manualslib.com manuals search engine 00-11 Precautions:

Precaution for Vehicle Equipped with ESP®

System

S7RS0B0000015

• When testing with any of the following equipments

(when vehicle is tested by rotating wheels (tires)

under vehicle stop), be sure to deactivate ESP ®

system referring to “Precautions in Speedometer Test

or Other Tests in Section 4F” to obtain correct data.

– 2 or 4-wheel chassis dynamometer

– Speedometer tester

– Brake tester

–Etc.

ESP ® control module

• When ESP ® control module is removed / installed, do

not use impact wrenches which generate shock or

impact to avoid damaging sensors in ESP ® control

module.

• When any of the following operation is done, calibrate steering angle sensor referring to “Sensor Calibration

in Section 4F”.

– When battery or dome fuse is removed.

– When steering angle sensor is replaced.

Brake CautionS7RS0B0000014

CAUTION!

All brake fasteners are important attaching

parts in that they could affect the

performance of vital parts and systems, and/

or could result in major repair expense. They

must be replaced with one of same part

number or with an eq uivalent part if

replacement becomes necessary. Do not use

a replacement part of lesser quality or

substitute design. Torque values must be

used as specified during reassembly to

assure proper retention of all parts. There is

to be no welding as it may result in extensive

damage and weakening of the metal.

Repair Instructions

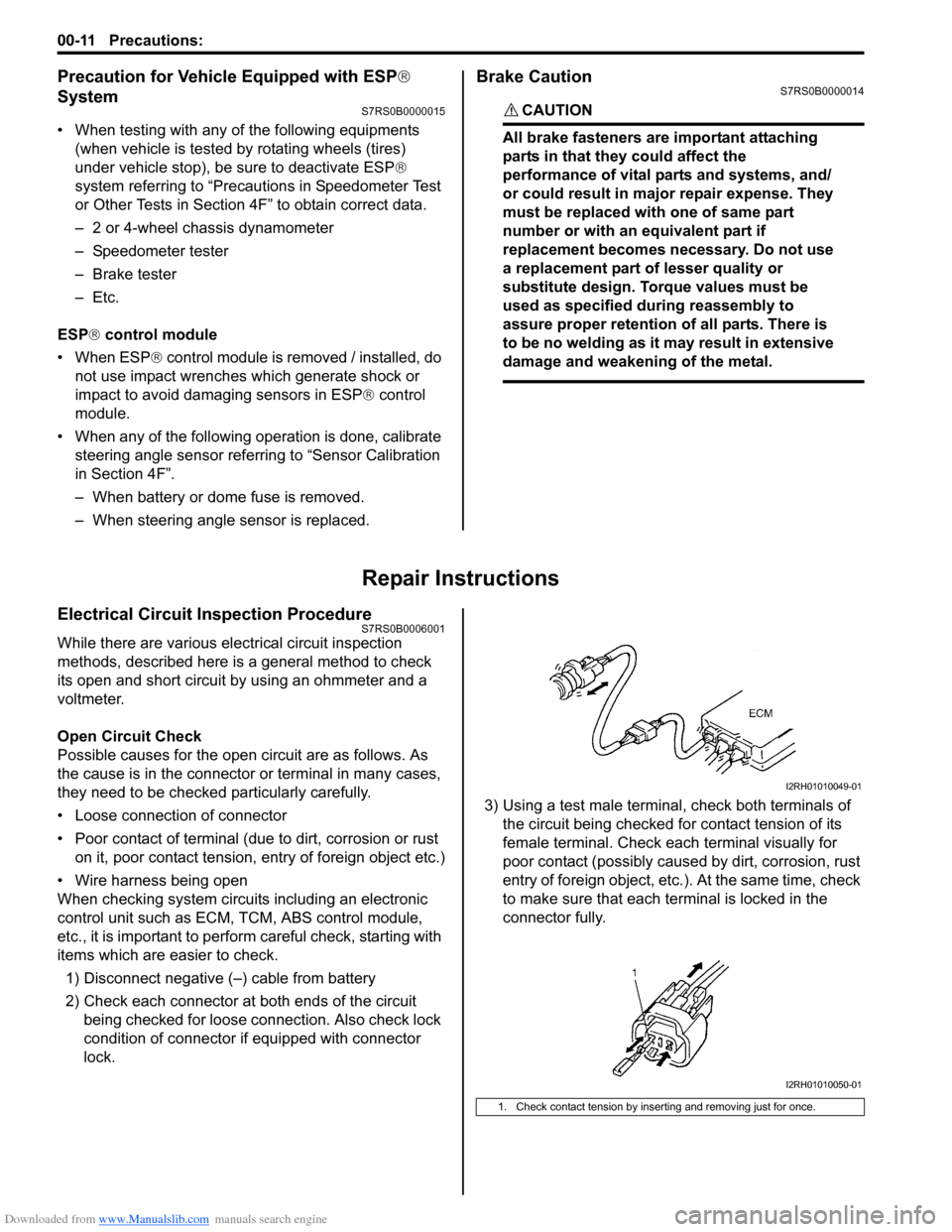

Electrical Circuit Inspection ProcedureS7RS0B0006001

While there are various electrical circuit inspection

methods, described here is a general method to check

its open and short circuit by using an ohmmeter and a

voltmeter.

Open Circuit Check

Possible causes for the open circuit are as follows. As

the cause is in the connector or terminal in many cases,

they need to be checked particularly carefully.

• Loose connection of connector

• Poor contact of terminal (due to dirt, corrosion or rust

on it, poor contact tension, entry of foreign object etc.)

• Wire harness being open

When checking system circuits including an electronic

control unit such as ECM, TCM, ABS control module,

etc., it is important to perfor m careful check, starting with

items which are easier to check.

1) Disconnect negative (–) cable from battery

2) Check each connector at both ends of the circuit being checked for loose connection. Also check lock

condition of connector if equipped with connector

lock. 3) Using a test male terminal

, check both terminals of

the circuit being checked for contact tension of its

female terminal. Check each terminal visually for

poor contact (possibly caused by dirt, corrosion, rust

entry of foreign object, etc.). At the same time, check

to make sure that each te rminal is locked in the

connector fully.

1. Check contact tension by inserting and removing just for once.

I2RH01010049-01

I2RH01010050-01

Page 21 of 1496

Downloaded from www.Manualslib.com manuals search engine Table of Contents 0- i

0

Section 0

CONTENTS

General Information

General Information ................................ 0A-1

General Description ............................................. 0A-1

Abbreviations ...................................................... 0A-1

Symbols .............................................................. 0A-2

Wire Color Symbols ............................................ 0A-2

Fasteners Information ......................................... 0A-3

Vehicle Lifting Points ........................................... 0A-5

Engine Supporting Points ................................... 0A-7

Vehicle Identification Number ............................. 0A-7

Engine Identification Number .............................. 0A-7

Transmission Identification Number .................... 0A-7

Component Locatio n ........................................... 0A-8

Warning, Caution and Information Labels Location ............................................................ 0A-8

Maintenance and Lubricat ion ................. 0B-1

Precautions........................................................... 0B-1

Precautions for Maintenance and Lubrication ..... 0B-1

Scheduled Maintenance ...................................... 0B-1 Maintenance Schedule under Normal Driving Conditions ......................................................... 0B-1

Maintenance Recommended under Severe Driving Conditions ............................................. 0B-2

Repair Instructions .............................................. 0B-3 Accessory Drive Belt Inspection.......................... 0B-3

Accessory Drive Belt Repl acement ..................... 0B-4

Valve Lash (Clearance) Inspection ..................... 0B-4

Engine Oil and Filter Change .............................. 0B-4

Engine Coolant Change ...... ................................ 0B-5

Exhaust System Inspection ................................. 0B-6

Spark Plug Replacement .................................... 0B-6

Air Cleaner Filter Inspection ................................ 0B-6

Air Cleaner Filter Replac ement ........................... 0B-6 Fuel Lines and Connections Inspection .............. 0B-6

Fuel Filter Replacement ...................................... 0B-7

Fuel Tank Inspection ........................................... 0B-7

PCV Valve Inspection ......................................... 0B-7

Fuel Evaporative Emission Control System

Inspection .......................................................... 0B-7

Brake Discs and Pads Inspection ....................... 0B-7

Brake Hoses and Pipes Inspection ..................... 0B-7

Brake Fluid Inspection......................................... 0B-8

Brake Fluid Replacement .................................... 0B-8

Brake Lever and Cable Inspection ...................... 0B-8

Clutch Fluid Inspection ........................................ 0B-8

Tires Inspection ................................................... 0B-9

Wheel Discs Inspection ....................................... 0B-9

Wheel Bearing Inspection ................................... 0B-9

Suspension System Inspection ........................... 0B-9

Steering System Inspection .............................. 0B-10

Drive Shaft (Axle) Boots Inspection .................. 0B-10

Manual Transaxle Oil Inspection ....................... 0B-10

Manual Transaxle Oil Replacement .................. 0B-10

Automatic Transaxle Fluid Level Inspection...... 0B-11

Automatic Transaxle Fluid Replacement .......... 0B-11

Automatic Transaxle Fluid Cooler Hose Inspection ........................................................ 0B-11

All Latches, Hinges and Locks Inspection......... 0B-11

HVAC Air Filter (If Equipped) Inspection ........... 0B-12

HVAC Air Filter (If Equipped) Replacement ...... 0B-12

Final Inspection for Maint enance Service ......... 0B-12

Specifications .................... .................................0B-13

Tightening Torque Specifications ...................... 0B-13

Special Tools and Equipmen t ...........................0B-13

Recommended Fluids and Lubricants............... 0B-13

Special Tool ...................................................... 0B-14

Page 26 of 1496

Downloaded from www.Manualslib.com manuals search engine 0A-5 General Information:

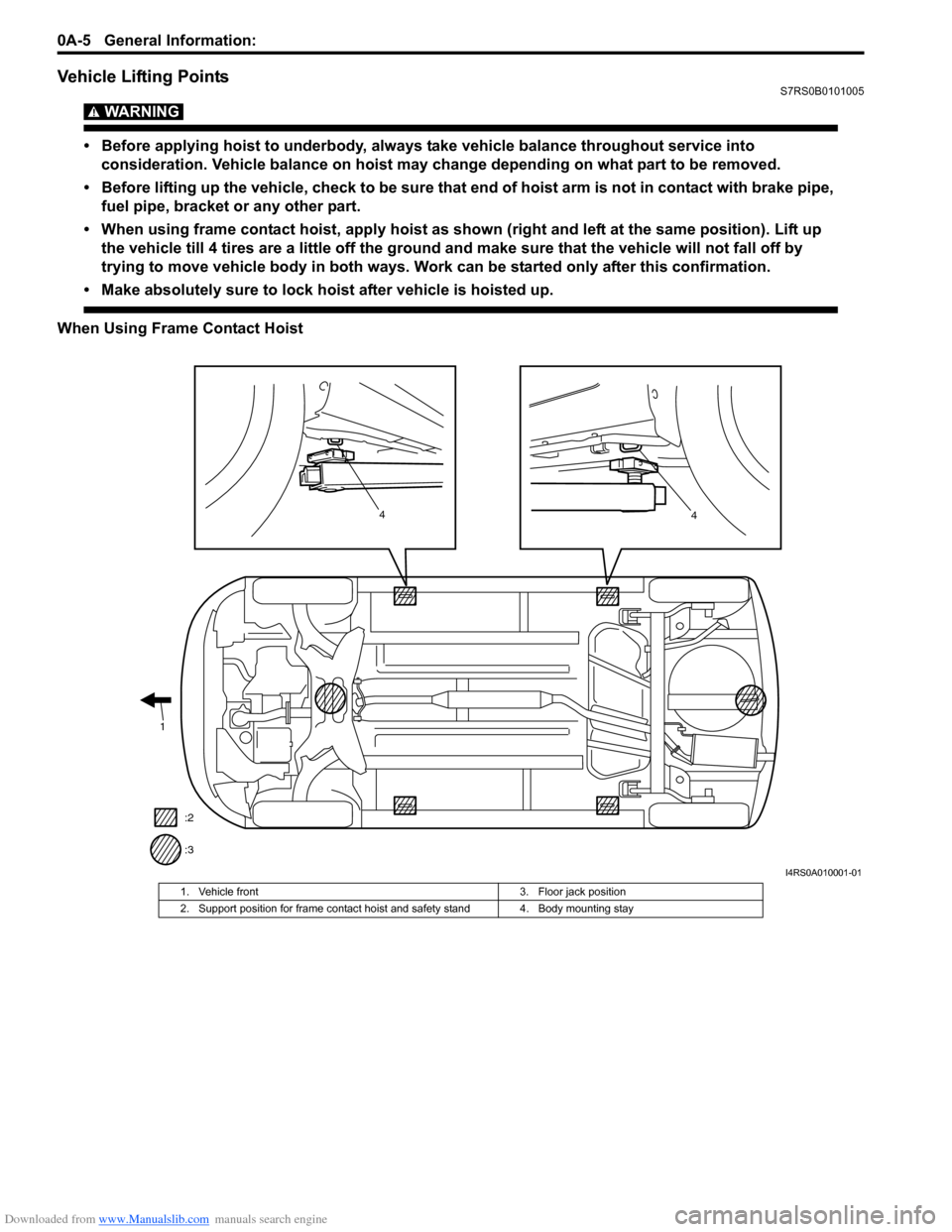

Vehicle Lifting PointsS7RS0B0101005

WARNING!

• Before applying hoist to underbody, always take vehicle balance throughout service into

consideration. Vehicle balance on hoist may change depending on what part to be removed.

• Before lifting up the vehicle, check to be sure that end of hoist arm is not in contact with brake pipe,

fuel pipe, bracket or any other part.

• When using frame contact hoist, apply hoist as shown (right and left at the same position). Lift up

the vehicle till 4 tires are a little off the ground and make sure that the vehicle will not fall off by

trying to move vehicle body in both ways. Work can be started only after this confirmation.

• Make absolutely sure to lock hoist after vehicle is hoisted up.

When Using Frame Contact Hoist

1

:2

:3

4

4

I4RS0A010001-01

1. Vehicle front

3. Floor jack position

2. Support position for frame contact hoist and safety stand 4. Body mounting stay

Page 31 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-1

General Information

Maintenance and Lubrication

Precautions

Precautions for Maintenance and LubricationS7RS0B0200001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Scheduled Maintenance

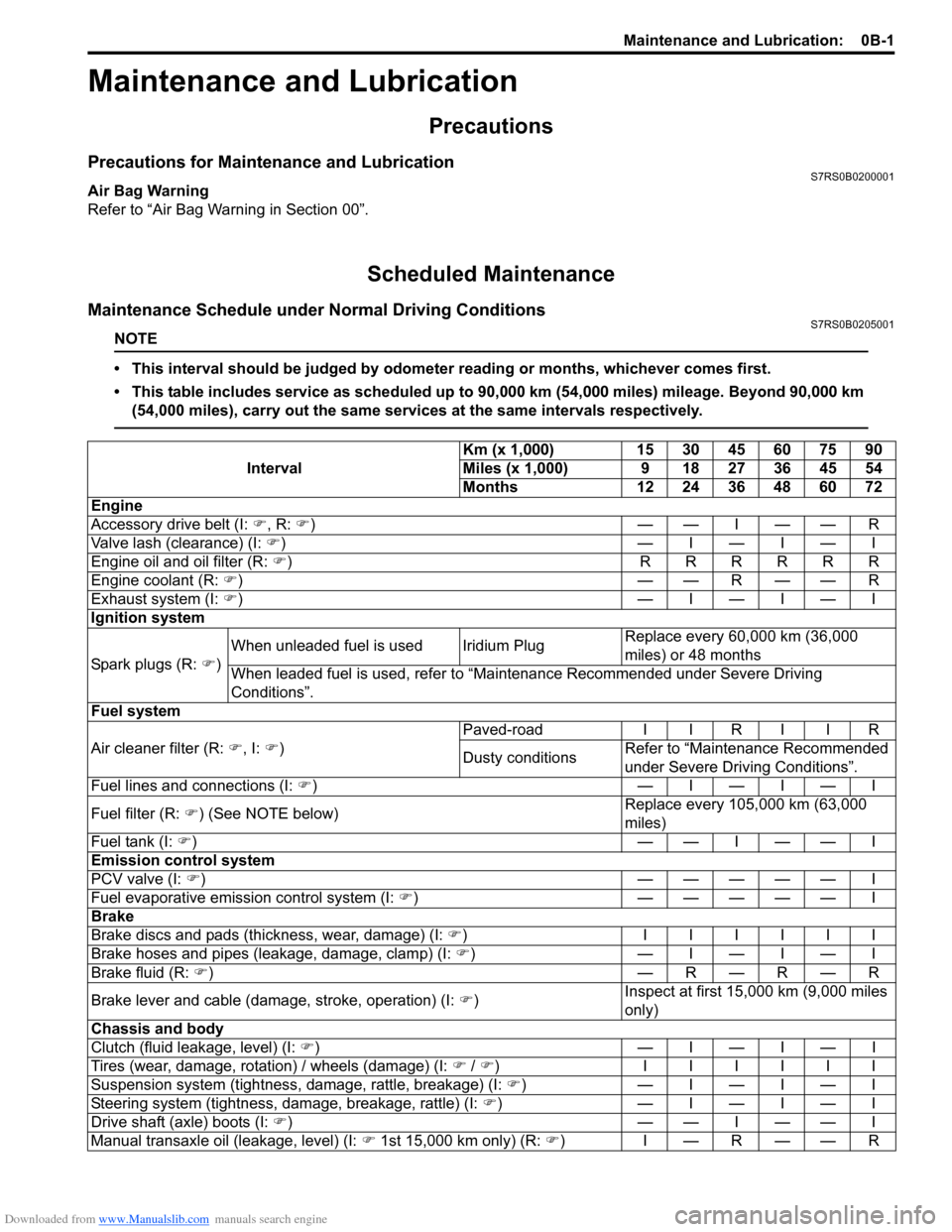

Maintenance Schedule under Normal Driving ConditionsS7RS0B0205001

NOTE

• This interval should be judged by odometer reading or months, whichever comes first.

• This table includes service as scheduled up to 90,000 km (54,000 miles) mileage. Beyond 90,000 km

(54,000 miles), carry out the same services at the same intervals respectively.

Interval Km (x 1,000) 15 30 45 60 75 90

Miles (x 1,000) 9 18 27 36 45 54

Months 12 24 36 48 60 72

Engine

Accessory drive belt (I: �), R: �))——I——R

Valve lash (clearance) (I: �)) —I—I—I

Engine oil and oil filter (R: �)) RRRRRR

Engine coolant (R: �))— —R— — R

Exhaust system (I: �)) —I—I—I

Ignition system

Spark plugs (R: �) )When unleaded fuel is used Iridium Plug

Replace every 60,000 km (36,000

miles) or 48 months

When leaded fuel is used, refer to “Maintenance Recommended under Severe Driving

Conditions”.

Fuel system

Air cleaner filter (R: �), I: �)) Paved-road

I I R I I R

Dusty conditions Refer to “Maintenance Recommended

under Severe Driv

ing Conditions”.

Fuel lines and connections (I: �)) —I—I—I

Fuel filter (R: �)) (See NOTE below) Replace every 105,000 km (63,000

miles)

Fuel tank (I: �))— —I— — I

Emission control system

PCV valve (I: �)) ————— I

Fuel evaporative emission control system (I: �)) ————— I

Brake

Brake discs and pads (thickness, wear, damage) (I: �)) IIIIII

Brake hoses and pipes (leakage, damage, clamp) (I: �)) —I—I—I

Brake fluid (R: �)) —R—R—R

Brake lever and cable (damage, stroke, operation) (I: �)) Inspect at first 15,000 km (9,000 miles

only)

Chassis and body

Clutch (fluid leakage, level) (I: �)) —I—I—I

Tires (wear, damage, rotation) / wheels (damage) (I: �) / �) ) IIIIII

Suspension system (tightness, damage, rattle, breakage) (I: �)) —I—I—I

Steering system (tightness, damage, breakage, rattle) (I: �)) —I—I—I

Drive shaft (axle) boots (I: �))— —I— — I

Manual transaxle oil (leakage, level) (I: �) 1st 15,000 km only) (R: �))I—R——R

Page 39 of 1496

Downloaded from www.Manualslib.com manuals search engine Maintenance and Lubrication: 0B-9

Tires InspectionS7RS0B0206020

1) Check tires for uneven or excessive wear, or damage. If defective, replace.

Refer to “Irregular and/or Premature Wear

Description in Section 2D” and “Wear Indicators

Description in Section 2D” for details.

2) Check inflating pressure of each tire and adjust pressure to specification as necessary.

NOTE

• Tire inflation pressure should be checked when tires are cool.

• Specified tire inflation pressure should be found on tire placard or in owner’s manual

which came with the vehicle.

3) Rotate tires. For details, refer to “Tire Rotation in Section 2D”.

Wheel Discs InspectionS7RS0B0206021

Inspect each wheel disc for de nts, distortion and cracks.

A disc in badly damaged condition must be replaced.

Wheel Bearing InspectionS7RS0B0206022

1) Check front wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to “Front

Wheel Hub, Disc, Nut and Bearing Check in Section

2B”.

2) Check rear wheel bearing for wear, damage, abnormal noise or rattles. For details, refer to“Rear

Wheel Disc, bolt and Bearing Inspection in Section

2C”.

Suspension System InspectionS7RS0B0206023

• Inspect front struts and rear shock absorbers for evidence of oil leakage, dents or any other damage on

sleeves; and inspect anchor ends for deterioration.

Replace defective parts, if any.

• Check front and rear suspension systems for damaged, loose or missing parts; also for parts

showing signs of wear or lack of lubrication.

Repair or replace defective parts, if any.

• Check front suspension arm ball joint stud dust seals for leakage, detachment, tear or any other damage.

Replace defective boot, if any.

1. Wear indicator

I2RH01020022-01

I2RH01020023-01

I4RS0A020011-01

I4RS0A020012-01

Page 93 of 1496

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-43

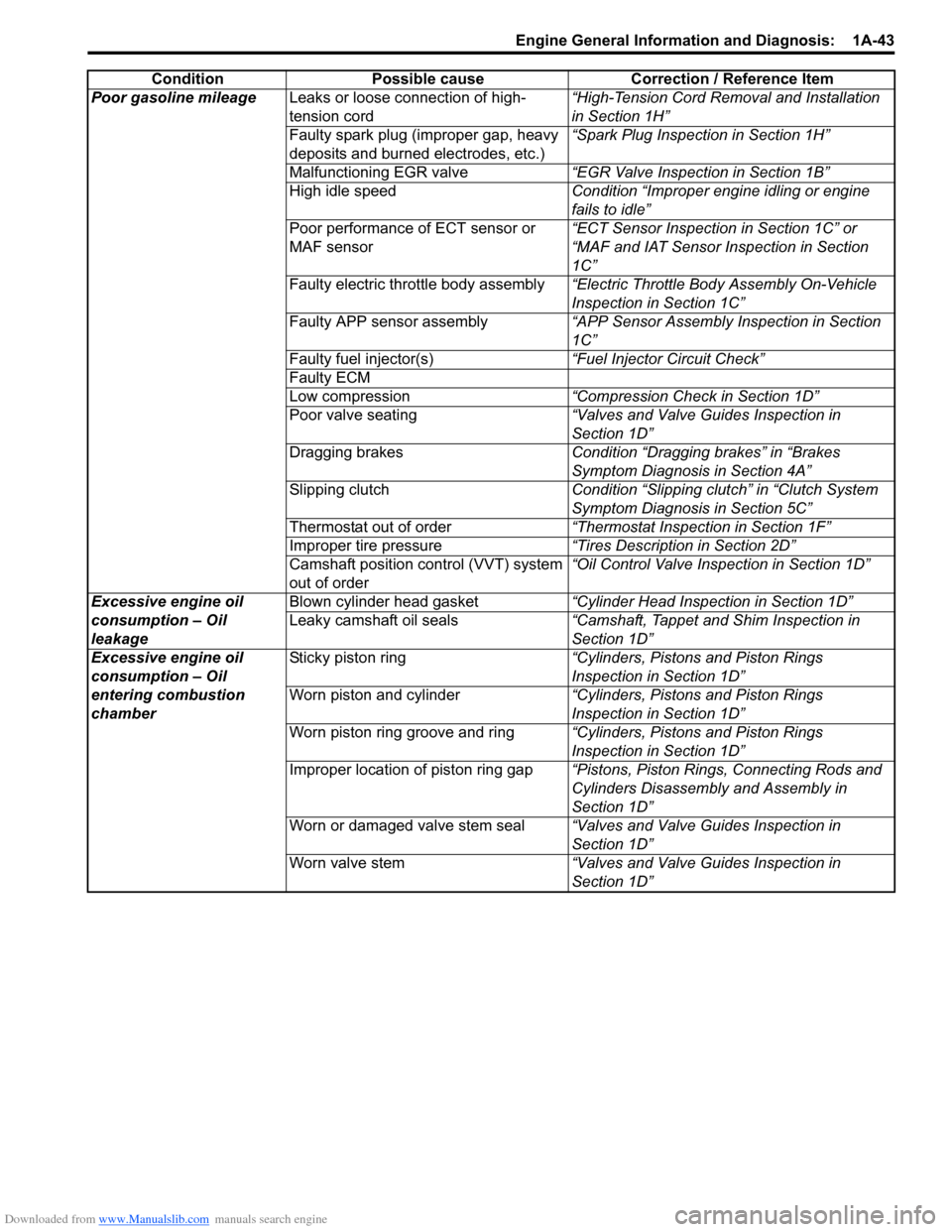

Poor gasoline mileageLeaks or loose connection of high-

tension cord “High-Tension Cord Removal and Installation

in Section 1H”

Faulty spark plug (improper gap, heavy

deposits and burned electrodes, etc.) “Spark Plug Inspection in Section 1H”

Malfunctioning EGR valve “EGR Valve Inspection in Section 1B”

High idle speed Condition “Improper engine idling or engine

fails to idle”

Poor performance of ECT sensor or

MAF sensor “ECT Sensor Inspection in Section 1C” or

“MAF and IAT Sensor Inspection in Section

1C”

Faulty electric throttle body assembly “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”

Faulty APP sensor assembly “APP Sensor Assembly Inspection in Section

1C”

Faulty fuel injector(s) “Fuel Injector Circuit Check”

Faulty ECM

Low compression “Compression Check in Section 1D”

Poor valve seating “Valves and Valve Guides Inspection in

Section 1D”

Dragging brakes Condition “Dragging brakes” in “Brakes

Symptom Diagnosis in Section 4A”

Slipping clutch Condition “Slipping clutch” in “Clutch System

Symptom Diagnosis in Section 5C”

Thermostat out of order “Thermostat Inspection in Section 1F”

Improper tire pressure “Tires Description in Section 2D”

Camshaft position control (VVT) system

out of order “Oil Control Valve Inspection in Section 1D”

Excessive engine oil

consumption – Oil

leakage Blown cylinder head gasket

“Cylinder Head Inspection in Section 1D”

Leaky camshaft oil seals “Camshaft, Tappet and Shim Inspection in

Section 1D”

Excessive engine oil

consumption – Oil

entering combustion

chamber Sticky piston ring

“Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston and cylinder “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Worn piston ring groove and ring “Cylinders, Pistons and Piston Rings

Inspection in Section 1D”

Improper location of piston ring gap “Pistons, Piston Rings, Connecting Rods and

Cylinders Disassembly and Assembly in

Section 1D”

Worn or damaged valve stem seal “Valves and Valve Guides Inspection in

Section 1D”

Worn valve stem “Valves and Valve Guides Inspection in

Section 1D”

Condition Possible cause Correction / Reference Item