clock SUZUKI SWIFT 2017 5.G User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: SWIFT, Model: SUZUKI SWIFT 2017 5.GPages: 336, PDF Size: 6.24 MB

Page 174 of 336

5-47OTHER CONTROLS AND EQUIPMENT

74LH0-74E

Fuel Filler CapSwift

68LM522

Dzire

74LHT0511

The fuel filler cap is located on the left rear

side of the vehicle. The fuel filler door can

be unlocked by pulling up the opener lever

located on the outboard side of the driver’s

seat and locked by simply closing the door.

57l51093

To remove the fuel filler cap:

1) Open the fuel filler door.

2) Remove the cap by turning it counter

clockwise.

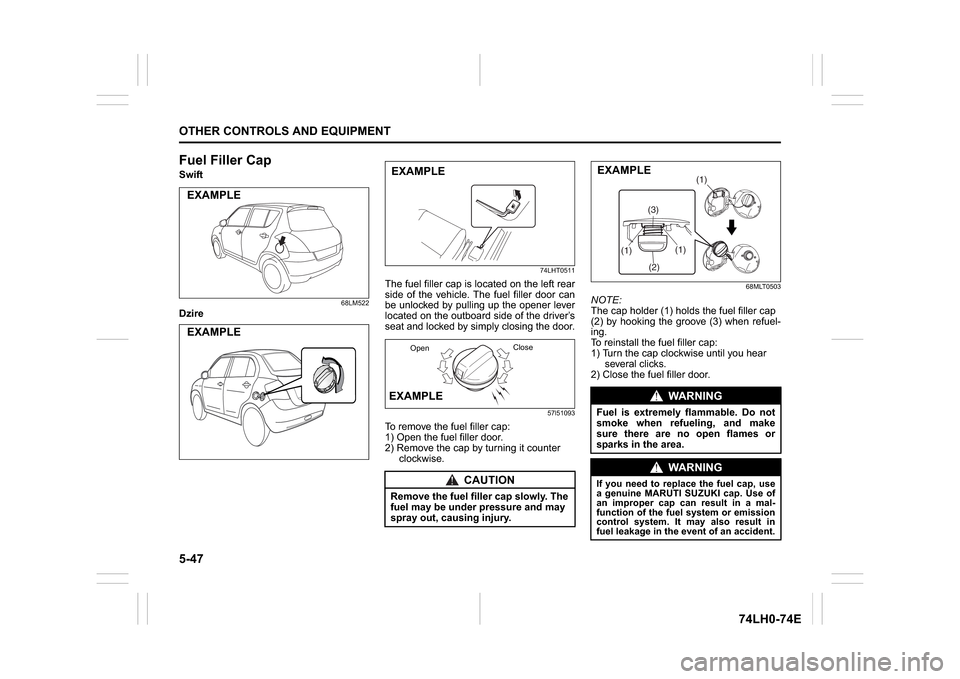

68MLT0503

NOTE:

The cap holder (1) holds the fuel filler cap

(2) by hooking the groove (3) when refuel-

ing.

To reinstall the fuel filler cap:

1) Turn the cap clockwise until you hear

several clicks.

2) Close the fuel filler door.

EXAMPLEEXAMPLE

CAUTION

Remove the fuel filler cap slowly. The

fuel may be under pressure and may

spray out, causing injury.EXAMPLEEXAMPLE

OpenClose

WA R N I N G

Fuel is extremely flammable. Do not

smoke when refueling, and make

sure there are no open flames or

sparks in the area.

WA R N I N G

If you need to replace the fuel cap, use

a genuine MARUTI SUZUKI cap. Use of

an improper cap can result in a mal-

function of the fuel system or emission

control system. It may also result in

fuel leakage in the event of an accident.

(1)

(2)(3)(1)

(1)

EXAMPLE

Page 181 of 336

5-54

OTHER CONTROLS AND EQUIPMENT

74LH0-74E

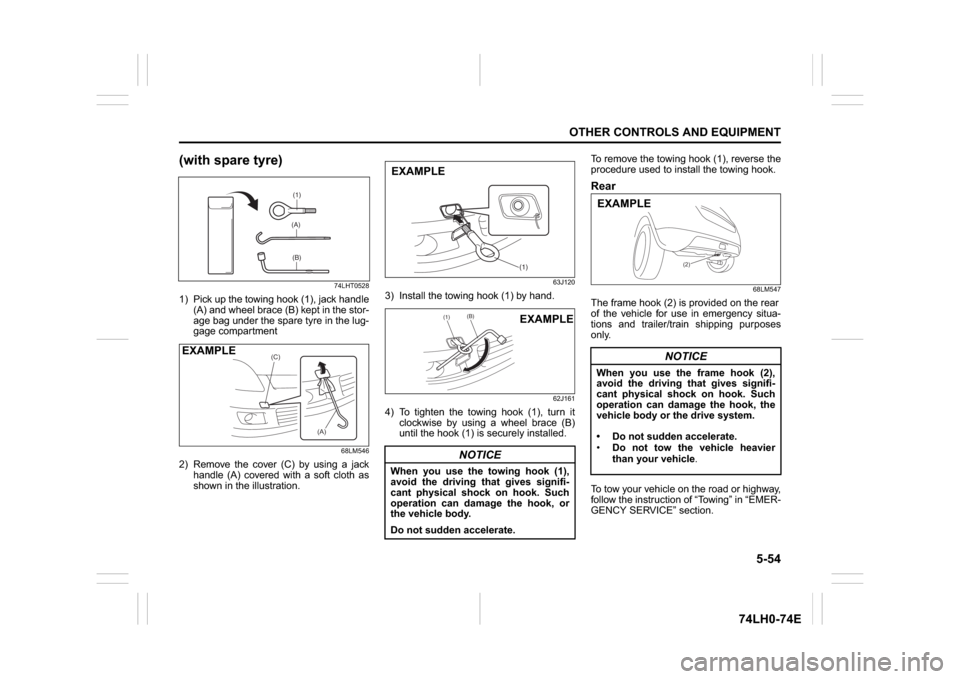

(with spare tyre)

74LHT0528

1) Pick up the towing hook (1), jack handle

(A) and wheel brace (B) kept in the stor-

age bag under the spare tyre in the lug-

gage compartment

68LM546

2) Remove the cover (C) by using a jack

handle (A) covered with a soft cloth as

shown in the illustration.

63J120

3) Install the towing hook (1) by hand.

62J161

4) To tighten the towing hook (1), turn it

clockwise by using a wheel brace (B)

until the hook (1) is securely installed.To remove the towing hook (1), reverse the

procedure used to install the towing hook.

Rear

68LM547

The frame hook (2) is provided on the rear

of the vehicle for use in emergency situa-

tions and trailer/train shipping purposes

only.

To tow your vehicle on the road or highway,

follow the instruction of “Towing” in “EMER-

GENCY SERVICE” section.

(1)(A)(B)

(C)

(A)

EXAMPLE

NOTICE

When you use the towing hook (1),

avoid the driving that gives signifi-

cant physical shock on hook. Such

operation can damage the hook, or

the vehicle body.

Do not sudden accelerate.

(1)

EXAMPLE

(1)

(B)

EXAMPLE

NOTICE

When you use the frame hook (2),

avoid the driving that gives signifi-

cant physical shock on hook. Such

operation can damage the hook, the

vehicle body or the drive system.

Do not sudden accelerate.

Do not tow the vehicle heavier

than your vehicle.

(2)

EXAMPLE

Page 200 of 336

7-9INSPECTION AND MAINTENANCE

74LH0-74E

Replace the Oil Filter(For Petrol Engine Model)

1) Using an oil filter wrench, turn the oil fil-

ter counterclockwise and remove it.

2) Using a clean rag, wipe off the mount-

ing surface on the engine where the

new filter will be seated.

3) Smear a little engine oil around the rub-

ber gasket of the new oil filter.

4) Screw on the new filter by hand until the

filter gasket contacts the mounting sur-

face.

54G092

(1) Loosen

(2) Tighten

Tightening (viewed from filter top)

54G093

(1) Oil filter

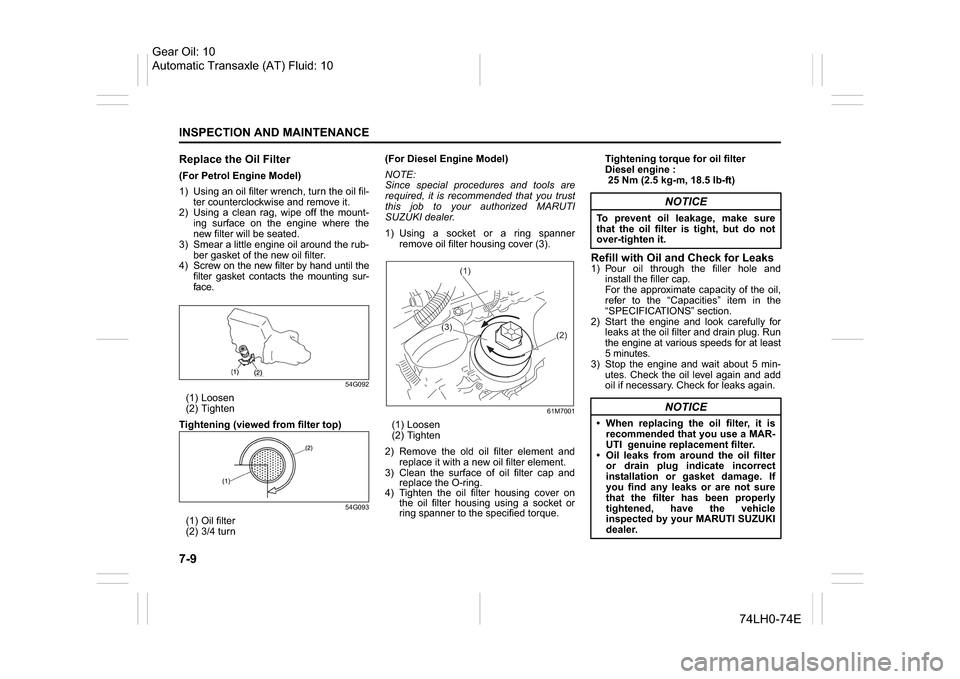

(2) 3/4 turn(For Diesel Engine Model)

NOTE:

Since special procedures and tools are

required, it is recommended that you trust

this job to your authorized MARUTI

SUZUKI dealer.

1) Using a socket or a ring spanner

remove oil filter housing cover (3).

61M7001

(1) Loosen

(2) Tighten

2) Remove the old oil filter element and

replace it with a new oil filter element.

3) Clean the surface of oil filter cap and

replace the O-ring.

4) Tighten the oil filter housing cover on

the oil filter housing using a socket or

ring spanner to the specified torque.Tightening torque for oil filter

Diesel engine :

25 Nm (2.5 kg-m, 18.5 lb-ft)

Refill with Oil and Check for Leaks1) Pour oil through the filler hole and

install the filler cap.

For the approximate capacity of the oil,

refer to the “Capacities” item in the

“SPECIFICATIONS” section.

2) Start the engine and look carefully for

leaks at the oil filter and drain plug. Run

the engine at various speeds for at least

5 minutes.

3) Stop the engine and wait about 5 min-

utes. Check the oil level again and add

oil if necessary. Check for leaks again.

(1)

(3)

(2)

NOTICE

To prevent oil leakage, make sure

that the oil filter is tight, but do not

over-tighten it.

NOTICE

When replacing the oil filter, it is

recommended that you use a MAR-

UTI genuine replacement filter.

Oil leaks from around the oil filter

or drain plug indicate incorrect

installation or gasket damage. If

you find any leaks or are not sure

that the filter has been properly

tightened, have the vehicle

inspected by your MARUTI SUZUKI

dealer.

Gear Oil: 10

Automatic Transaxle (AT) Fluid: 10

Page 202 of 336

7-11INSPECTION AND MAINTENANCE

74LH0-74E

reaches the “FULL” mark. Never fill the res-

ervoir tank above the “FULL” mark.

(For Diesel Engine Model)

LHT0705

If the coolant level is below the “LOW”

mark, more coolant should be added.

When the engine is cool, remove the

degassing tank cap by turning it anticlock-

wise slowly to release any pressure. And

add coolant until the degassing tank level

reaches the “FULL” mark. Never fill the

degassing tank above the “FULL” mark.Coolant ReplacementCoolant replacement work requires techni-

cal skill. Do not replace the coolant by

yourself. Trust this job to Maruti Suzuki

Authorised Dealer workshop or service

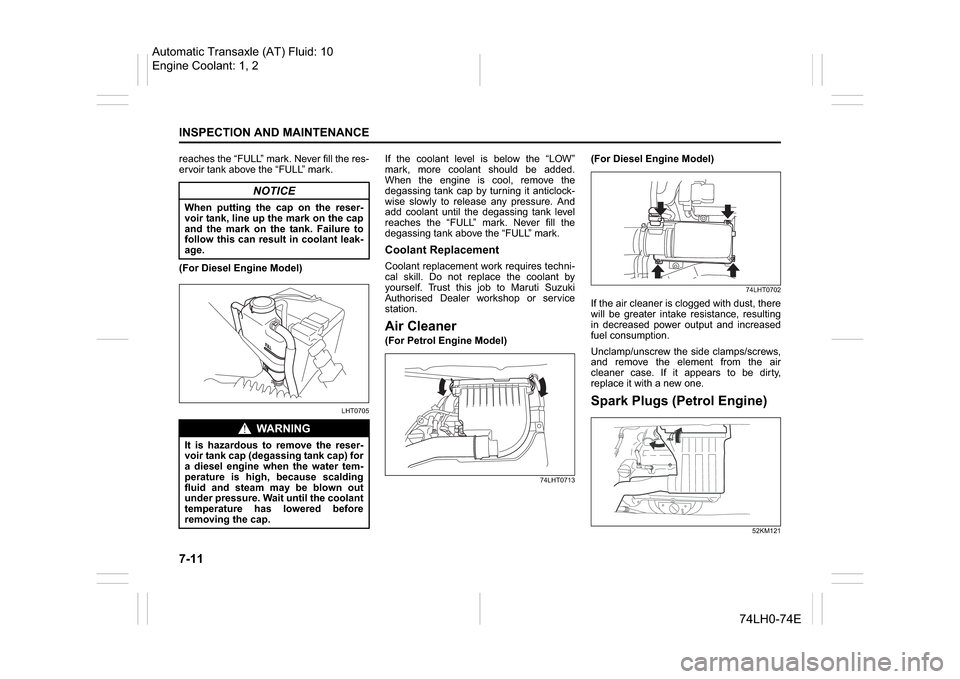

station.Air Cleaner(For Petrol Engine Model)

74LHT0713

(For Diesel Engine Model)

74LHT0702

If the air cleaner is clogged with dust, there

will be greater intake resistance, resulting

in decreased power output and increased

fuel consumption.

Unclamp/unscrew the side clamps/screws,

and remove the element from the air

cleaner case. If it appears to be dirty,

replace it with a new one.Spark Plugs (Petrol Engine)

52KM121

NOTICE

When putting the cap on the reser-

voir tank, line up the mark on the cap

and the mark on the tank. Failure to

follow this can result in coolant leak-

age.

WA R N I N G

It is hazardous to remove the reser-

voir tank cap (degassing tank cap) for

a diesel engine when the water tem-

perature is high, because scalding

fluid and steam may be blown out

under pressure. Wait until the coolant

temperature has lowered before

removing the cap.

Automatic Transaxle (AT) Fluid: 10

Engine Coolant: 1, 2

Page 217 of 336

7-26

INSPECTION AND MAINTENANCE

74LH0-74E

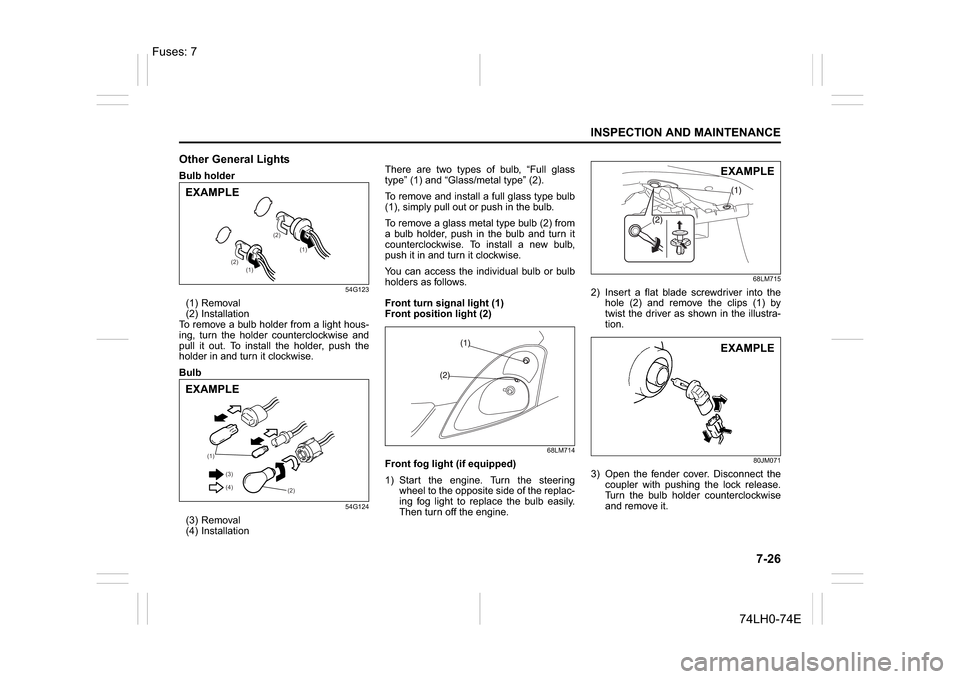

Other General LightsBulb holder

54G123

(1) Removal

(2) Installation

To remove a bulb holder from a light hous-

ing, turn the holder counterclockwise and

pull it out. To install the holder, push the

holder in and turn it clockwise.

Bulb

54G124

(3) Removal

(4) InstallationThere are two types of bulb, “Full glass

type” (1) and “Glass/metal type” (2).

To remove and install a full glass type bulb

(1), simply pull out or push in the bulb.

To remove a glass metal type bulb (2) from

a bulb holder, push in the bulb and turn it

counterclockwise. To install a new bulb,

push it in and turn it clockwise.

You can access the individual bulb or bulb

holders as follows.

Front turn signal light (1)

Front position light (2)

68LM714

Front fog light (if equipped)

1) Start the engine. Turn the steering

wheel to the opposite side of the replac-

ing fog light to replace the bulb easily.

Then turn off the engine.

68LM715

2) Insert a flat blade screwdriver into the

hole (2) and remove the clips (1) by

twist the driver as shown in the illustra-

tion.

80JM071

3) Open the fender cover. Disconnect the

coupler with pushing the lock release.

Turn the bulb holder counterclockwise

and remove it.

(1)

(1) (2)(2)

EXAMPLE

(1)

(2) (3)

(4)

EXAMPLE

EXAMPLEEXAMPLE

Fuses: 7

Page 224 of 336

8-1EMERGENCY SERVICE

74LH0-74E

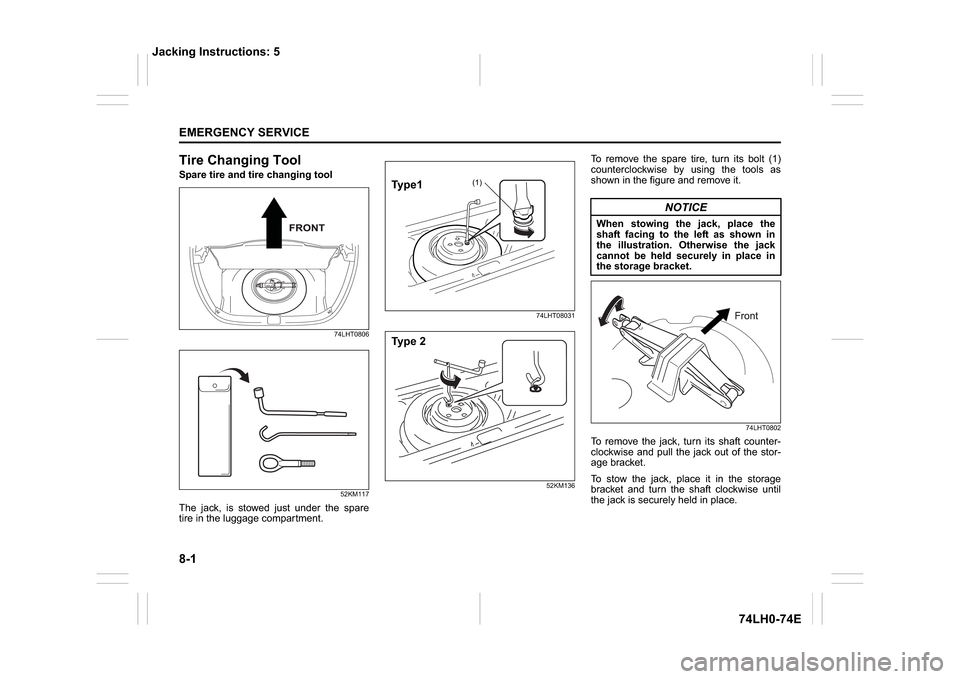

Tire Changing ToolSpare tire and tire changing tool

74LHT0806

52KM117

The jack, is stowed just under the spare

tire in the luggage compartment.

74LHT08031

52KM136

To remove the spare tire, turn its bolt (1)

counterclockwise by using the tools as

shown in the figure and remove it.

74LHT0802

To remove the jack, turn its shaft counter-

clockwise and pull the jack out of the stor-

age bracket.

To stow the jack, place it in the storage

bracket and turn the shaft clockwise until

the jack is securely held in place.

(1)

Ty p e 1Ty p e 2

NOTICE

When stowing the jack, place the

shaft facing to the left as shown in

the illustration. Otherwise the jack

cannot be held securely in place in

the storage bracket.

Jacking Instructions: 5

Page 225 of 336

8-2

EMERGENCY SERVICE

74LH0-74E

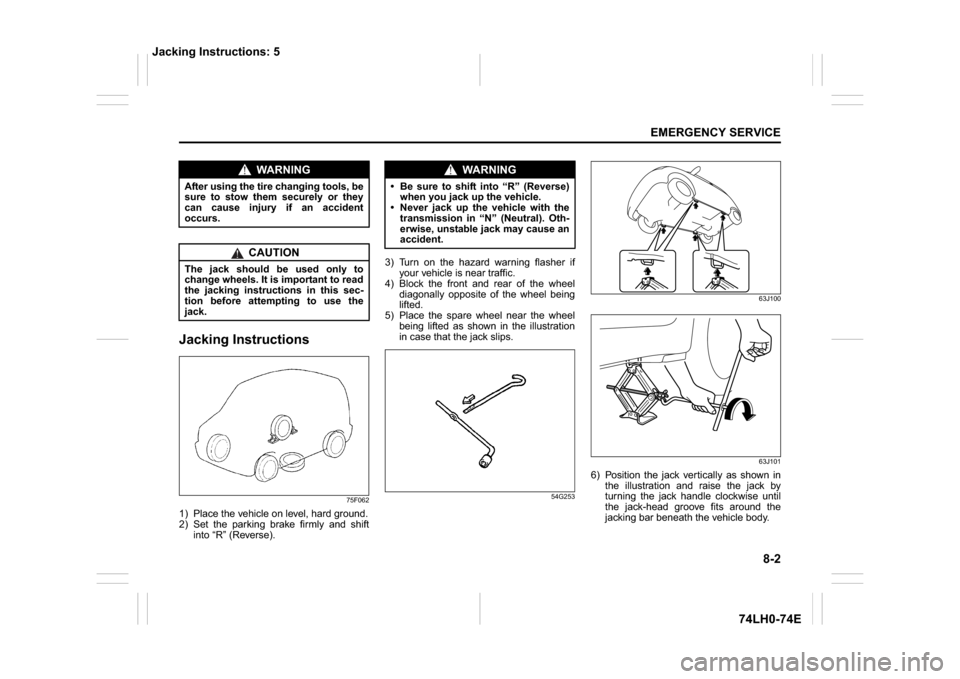

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G25363J100

63J101

6) Position the jack vertically as shown in

the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

WA R N I N G

After using the tire changing tools, be

sure to stow them securely or they

can cause injury if an accident

occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

WA R N I N G

Be sure to shift into “R” (Reverse)

when you jack up the vehicle.

Never jack up the vehicle with the

transmission in “N” (Neutral). Oth-

erwise, unstable jack may cause an

accident.

Jacking Instructions: 5

Page 231 of 336

8-8

EMERGENCY SERVICE

74LH0-74E

For Diesel

65D350D

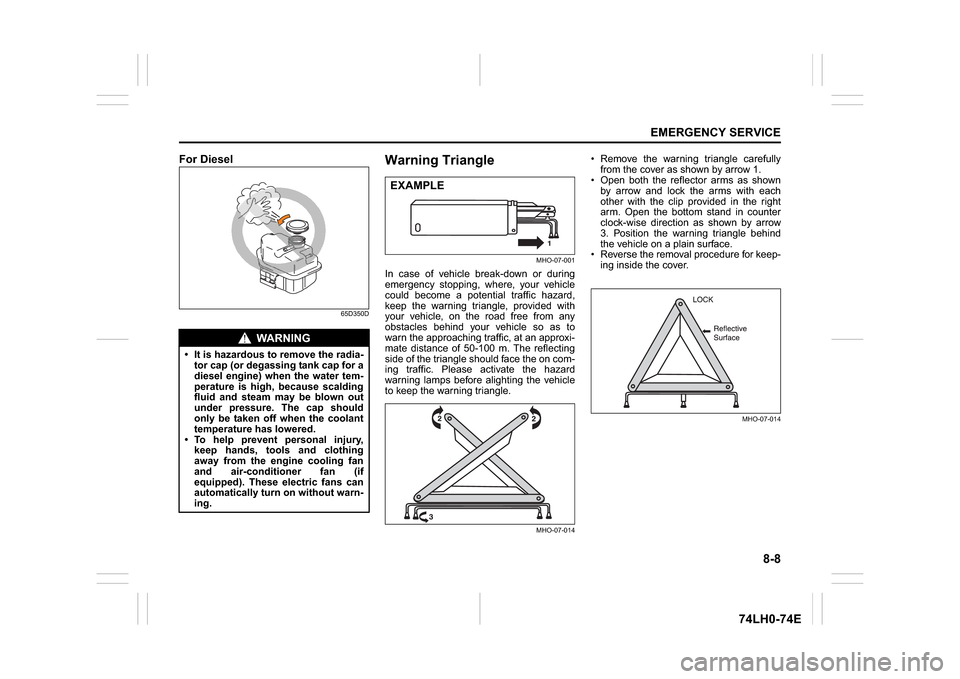

Warning Triangle

MHO-07-001

In case of vehicle break-down or during

emergency stopping, where, your vehicle

could become a potential traffic hazard,

keep the warning triangle, provided with

your vehicle, on the road free from any

obstacles behind your vehicle so as to

warn the approaching traffic, at an approxi-

mate distance of 50-100 m. The reflecting

side of the triangle should face the on com-

ing traffic. Please activate the hazard

warning lamps before alighting the vehicle

to keep the warning triangle.

MHO-07-014

Remove the warning triangle carefully

from the cover as shown by arrow 1.

Open both the reflector arms as shown

by arrow and lock the arms with each

other with the clip provided in the right

arm. Open the bottom stand in counter

clock-wise direction as shown by arrow

3. Position the warning triangle behind

the vehicle on a plain surface.

Reverse the removal procedure for keep-

ing inside the cover.

MHO-07-014

WA R N I N G

It is hazardous to remove the radia-

tor cap (or degassing tank cap for a

diesel engine) when the water tem-

perature is high, because scalding

fluid and steam may be blown out

under pressure. The cap should

only be taken off when the coolant

temperature has lowered.

To help prevent personal injury,

keep hands, tools and clothing

away from the engine cooling fan

and air-conditioner fan (if

equipped). These electric fans can

automatically turn on without warn-

ing.

EXAMPLE