acc SUZUKI SWIFT 2017 5.G Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2017, Model line: SWIFT, Model: SUZUKI SWIFT 2017 5.GPages: 336, PDF Size: 6.24 MB

Page 192 of 336

7-1INSPECTION AND MAINTENANCE

74LH0-74E

60B128S

WA R N I N G

You should take extreme care when

working on your vehicle to prevent

accidental injury. Here are a few pre-

cautions that you should be espe-

cially careful to observe:

To prevent damage or unintended

activation of the air bag system or

seat belt pretensioner system, be

sure the battery is disconnected and

the ignition switch has been in the

“LOCK” position for at least 90 sec-

onds before performing any electri-

cal service work on your vehicle. Do

not touch air bag system compo-

nents, seat belt pretensioner system

components or wires.

The wires are wrapped with yellow

tape or yellow tubing, and the cou-

plers are yellow for easy identifica-

tion.

Do not leave the engine running in

garages or other confined areas.

(Continued)

WA R N I N G

(Continued)

When the engine is running, keep

hands, clothing, tools, and other

objects away from the fan and drive

belt. Even though the fan may not

be moving, it can automatically

turn on without warning.

When it is necessary to do service

work with the engine running, make

sure that the parking brake is set

fully and the transmission is in

Neutral.

Do not touch ignition wires or other

ignition system parts when starting

the engine or when the engine is

running, or you could receive an

electric shock.

Be careful not to touch a hot

engine, exhaust manifold and

pipes, muffler, radiator and water

hoses.

Do not allow smoking, sparks, or

flames around fuel or the battery.

Flammable fumes are present.

Do not get under your vehicle if it is

supported only with the portable

jack provided in your vehicle.

Be careful not to cause accidental

short circuits between the positive

and negative battery terminals.

(Continued)

WA R N I N G

(Continued)

Keep used oil, coolant, and other

fluids away from children and pets.

Dispose of used fluids properly;

never pour them on the ground,

into sewers, etc.

Page 197 of 336

7-6

INSPECTION AND MAINTENANCE

74LH0-74E

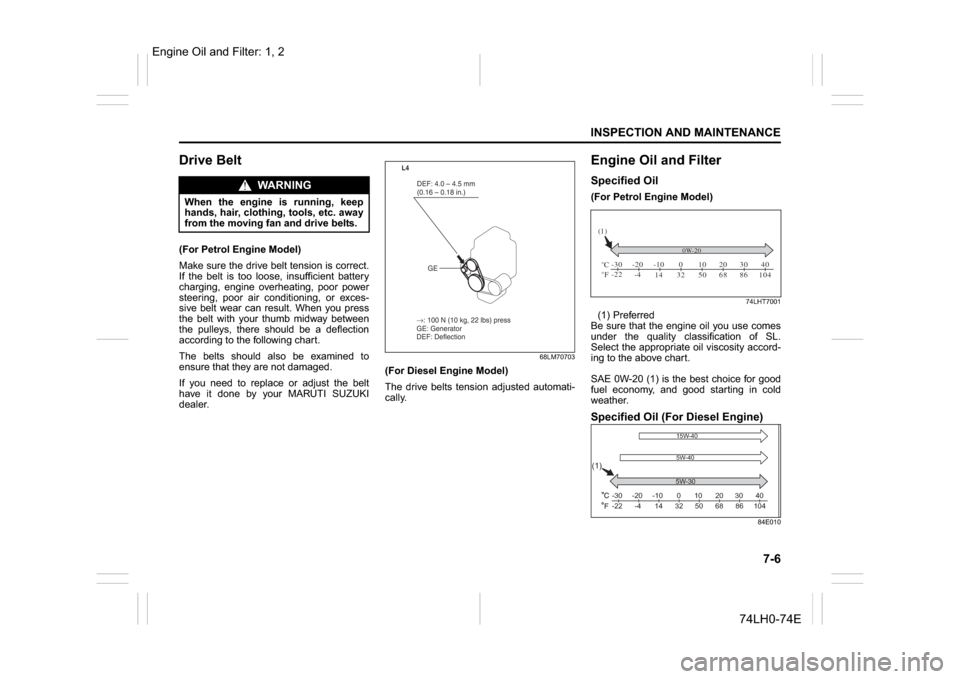

Drive Belt(For Petrol Engine Model)

Make sure the drive belt tension is correct.

If the belt is too loose, insufficient battery

charging, engine overheating, poor power

steering, poor air conditioning, or exces-

sive belt wear can result. When you press

the belt with your thumb midway between

the pulleys, there should be a deflection

according to the following chart.

The belts should also be examined to

ensure that they are not damaged.

If you need to replace or adjust the belt

have it done by your MARUTI SUZUKI

dealer.

68LM70703

(For Diesel Engine Model)

The drive belts tension adjusted automati-

cally.

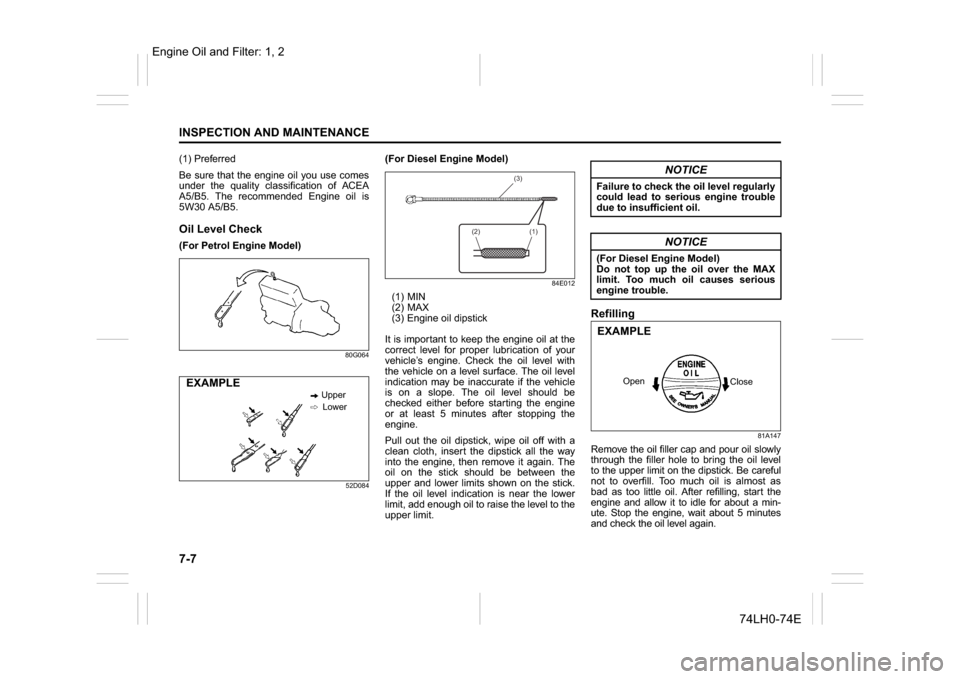

Engine Oil and FilterSpecified Oil (For Petrol Engine Model)

74LHT7001

(1) Preferred

Be sure that the engine oil you use comes

under the quality classification of SL.

Select the appropriate oil viscosity accord-

ing to the above chart.

SAE 0W-20 (1) is the best choice for good

fuel economy, and good starting in cold

weather. Specified Oil (For Diesel Engine)

84E010

When the engine is running, keep

hands, hair, clothing, tools, etc. away

from the moving fan and drive belts.

→ : 100 N (10 kg, 22 lbs) press

GE: Generator

DEF: Deflection DEF: 4.0 – 4.5 mm

(0.16 – 0.18 in.)

GE

L4

CFo o-30

-22 -20

-4 -10

14 32 50 68 86 104 010203040

(1)

0W-205W-30

(1)

-30

-22 -4 14

32506886 104

-20 -10 10 20

3040

0

15W-40

5W-40

Engine Oil and Filter: 1, 2

WA R N I N G

Page 198 of 336

7-7INSPECTION AND MAINTENANCE

74LH0-74E

(1) Preferred

Be sure that the engine oil you use comes

under the quality classification of ACEA

A5/B5. The recommended Engine oil is

5W30 A5/B5. Oil Level Check(For Petrol Engine Model)

80G064

52D084

(For Diesel Engine Model)

84E012

(1) MIN

(2) MAX

(3) Engine oil dipstick

It is important to keep the engine oil at the

correct level for proper lubrication of your

vehicle’s engine. Check the oil level with

the vehicle on a level surface. The oil level

indication may be inaccurate if the vehicle

is on a slope. The oil level should be

checked either before starting the engine

or at least 5 minutes after stopping the

engine.

Pull out the oil dipstick, wipe oil off with a

clean cloth, insert the dipstick all the way

into the engine, then remove it again. The

oil on the stick should be between the

upper and lower limits shown on the stick.

If the oil level indication is near the lower

limit, add enough oil to raise the level to the

upper limit.

Refilling

81A147

Remove the oil filler cap and pour oil slowly

through the filler hole to bring the oil level

to the upper limit on the dipstick. Be careful

not to overfill. Too much oil is almost as

bad as too little oil. After refilling, start the

engine and allow it to idle for about a min-

ute. Stop the engine, wait about 5 minutes

and check the oil level again.

Upper

Lower

EXAMPLE

(3)

(2) (1)

NOTICE

Failure to check the oil level regularly

could lead to serious engine trouble

due to insufficient oil.

NOTICE

(For Diesel Engine Model)

Do not top up the oil over the MAX

limit. Too much oil causes serious

engine trouble.

Close Open

EXAMPLE

Engine Oil and Filter: 1, 2

Page 201 of 336

7-10

INSPECTION AND MAINTENANCE

74LH0-74E

Engine CoolantSelection of CoolantTo maintain optimum performance and

durability of your engine, use MARUTI

SUZUKI Genuine Coolant or equivalent.

This type of coolant is best for your cooling

system as it:

Helps maintain proper engine tempera-

ture.

Gives proper protection against freezing

and boiling.

Gives proper protection against corro-

sion and rust.

Failure to use the proper coolant can dam-

age your cooling system. Your authorized

MARUTI SUZUKI dealer can help you

select the proper coolant.

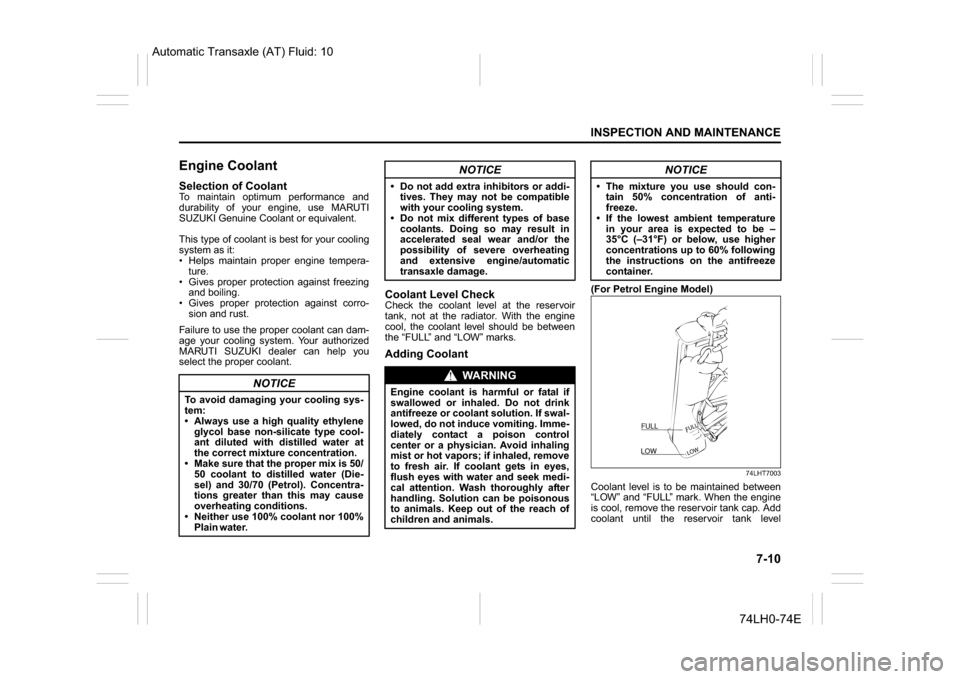

Coolant Level CheckCheck the coolant level at the reservoir

tank, not at the radiator. With the engine

cool, the coolant level should be between

the “FULL” and “LOW” marks.Adding Coolant

(For Petrol Engine Model)

74LHT7003

Coolant level is to be maintained between

“LOW” and “FULL” mark. When the engine

is cool, remove the reservoir tank cap. Add

coolant until the reservoir tank level

NOTICE

To avoid damaging your cooling sys-

tem:

Always use a high quality ethylene

glycol base non-silicate type cool-

ant diluted with distilled water at

the correct mixture concentration.

Make sure that the proper mix is 50/

50 coolant to distilled water (Die-

sel) and 30/70 (Petrol). Concentra-

tions greater than this may cause

overheating conditions.

Neither use 100% coolant nor 100%

Plain water.

NOTICE

Do not add extra inhibitors or addi-

tives. They may not be compatible

with your cooling system.

Do not mix different types of base

coolants. Doing so may result in

accelerated seal wear and/or the

possibility of severe overheating

and extensive engine/automatic

transaxle damage.

WA R N I N G

Engine coolant is harmful or fatal if

swallowed or inhaled. Do not drink

antifreeze or coolant solution. If swal-

lowed, do not induce vomiting. Imme-

diately contact a poison control

center or a physician. Avoid inhaling

mist or hot vapors; if inhaled, remove

to fresh air. If coolant gets in eyes,

flush eyes with water and seek medi-

cal attention. Wash thoroughly after

handling. Solution can be poisonous

to animals. Keep out of the reach of

children and animals.

NOTICE

The mixture you use should con-

tain 50% concentration of anti-

freeze.

If the lowest ambient temperature

in your area is expected to be –

35°C (–31°F) or below, use higher

concentrations up to 60% following

the instructions on the antifreeze

container.

FULLLOWFULLLOW

Automatic Transaxle (AT) Fluid: 10

Page 203 of 336

7-12

INSPECTION AND MAINTENANCE

74LH0-74E

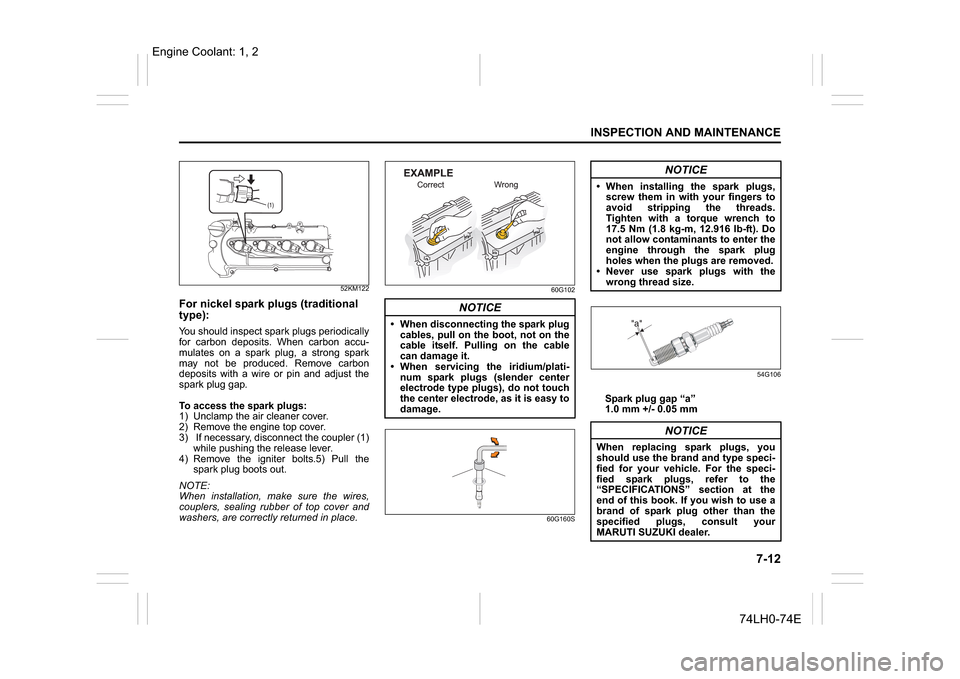

52KM122

For nickel spark plugs (traditional

type):You should inspect spark plugs periodically

for carbon deposits. When carbon accu-

mulates on a spark plug, a strong spark

may not be produced. Remove carbon

deposits with a wire or pin and adjust the

spark plug gap.

To access the spark plugs:

1) Unclamp the air cleaner cover.

2) Remove the engine top cover.

3) If necessary, disconnect the coupler (1)

while pushing the release lever.

4) Remove the igniter bolts.5) Pull the

spark plug boots out.

NOTE:

When installation, make sure the wires,

couplers, sealing rubber of top cover and

washers, are correctly returned in place.

60G102

60G160S54G106

Spark plug gap “a”

1.0 mm +/- 0.05 mm

NOTICE

When disconnecting the spark plug

cables, pull on the boot, not on the

cable itself. Pulling on the cable

can damage it.

When servicing the iridium/plati-

num spark plugs (slender center

electrode type plugs), do not touch

the center electrode, as it is easy to

damage.

NOTICE

When installing the spark plugs,

screw them in with your fingers to

avoid stripping the threads.

Tighten with a torque wrench to

17.5 Nm (1.8 kg-m, 12.916 lb-ft). Do

not allow contaminants to enter the

engine through the spark plug

holes when the plugs are removed.

Never use spark plugs with the

wrong thread size.

NOTICE

When replacing spark plugs, you

should use the brand and type speci-

fied for your vehicle. For the speci-

fied spark plugs, refer to the

“SPECIFICATIONS” section at the

end of this book. If you wish to use a

brand of spark plug other than the

specified plugs, consult your

MARUTI SUZUKI dealer.

Engine Coolant: 1, 2

Page 206 of 336

7-15

INSPECTION AND MAINTENANCE

74LH0-74E

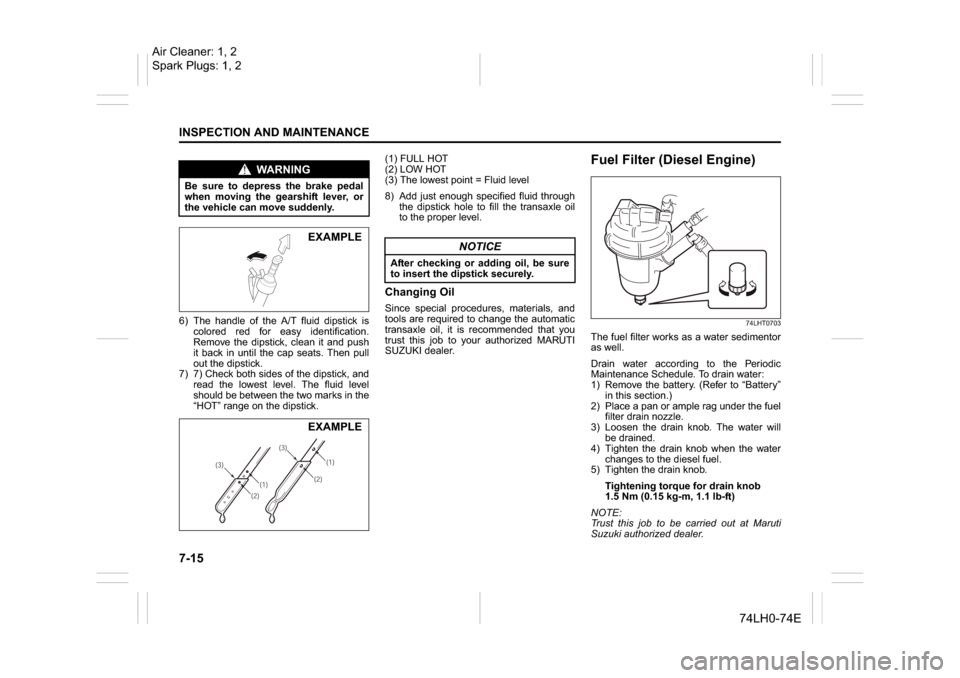

6) The handle of the A/T fluid dipstick is

colored red for easy identification.

Remove the dipstick, clean it and push

it back in until the cap seats. Then pull

out the dipstick.

7) 7) Check both sides of the dipstick, and

read the lowest level. The fluid level

should be between the two marks in the

“HOT” range on the dipstick.(1) FULL HOT

(2) LOW HOT

(3) The lowest point = Fluid level

8) Add just enough specified fluid through

the dipstick hole to fill the transaxle oil

to the proper level.

Changing Oil

Since special procedures, materials, and

tools are required to change the automatic

transaxle oil, it is recommended that you

trust this job to your authorized MARUTI

SUZUKI dealer.

Fuel Filter (Diesel Engine)

74LHT0703

The fuel filter works as a water sedimentor

as well.

Drain water according to the Periodic

Maintenance Schedule. To drain water:

1) Remove the battery. (Refer to “Battery”

in this section.)

2) Place a pan or ample rag under the fuel

filter drain nozzle.

3) Loosen the drain knob. The water will

be drained.

4) Tighten the drain knob when the water

changes to the diesel fuel.

5) Tighten the drain knob.

Tightening torque for drain knob

1.5 Nm (0.15 kg-m, 1.1 lb-ft)

NOTE:

Trust this job to be carried out at Maruti

Suzuki authorized dealer.

WA R N I N G

Be sure to depress the brake pedal

when moving the gearshift lever, or

the vehicle can move suddenly.

EXAMPLE

(1)(2) (3)(1)

(2)(3)

EXAMPLE

NOTICE

After checking or adding oil, be sure

to insert the dipstick securely.

Air Cleaner: 1, 2

Spark Plugs: 1, 2

Page 209 of 336

7-18

INSPECTION AND MAINTENANCE

74LH0-74E

Check that the steering wheel turns easily

and smoothly without rattling by turning it

all the way to the right and to the left while

driving very slowly in an open area. If the

amount of free play is outside the specifi-

cation or you find anything else to be

wrong, an inspection must be performed

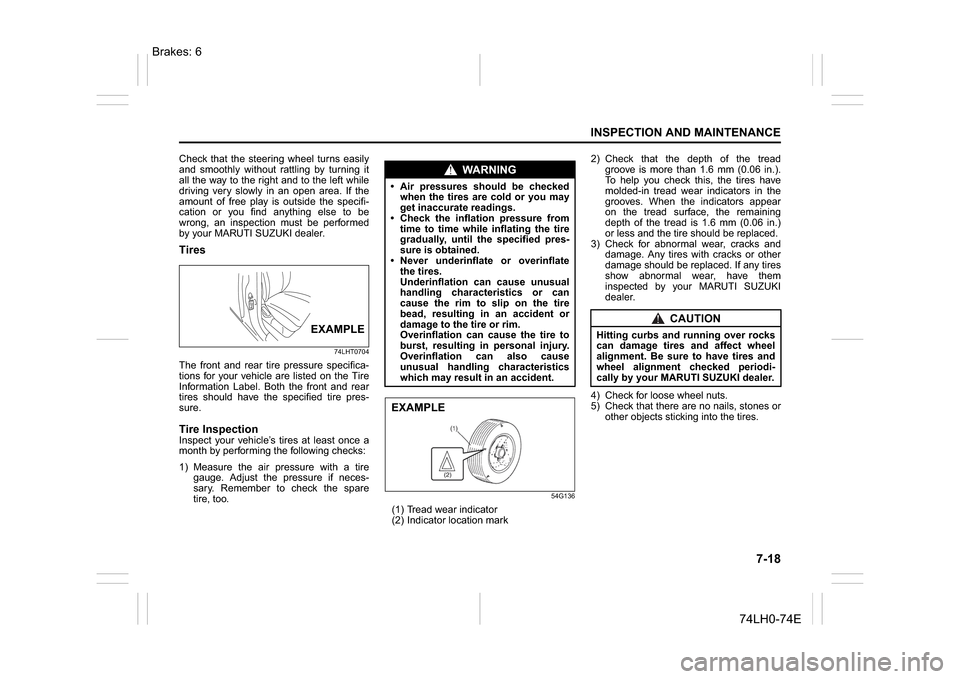

by your MARUTI SUZUKI dealer.Tires

74LHT0704

The front and rear tire pressure specifica-

tions for your vehicle are listed on the Tire

Information Label. Both the front and rear

tires should have the specified tire pres-

sure.Tire InspectionInspect your vehicle’s tires at least once a

month by performing the following checks:

1) Measure the air pressure with a tire

gauge. Adjust the pressure if neces-

sary. Remember to check the spare

tire, too.

54G136

(1) Tread wear indicator

(2) Indicator location mark2) Check that the depth of the tread

groove is more than 1.6 mm (0.06 in.).

To help you check this, the tires have

molded-in tread wear indicators in the

grooves. When the indicators appear

on the tread surface, the remaining

depth of the tread is 1.6 mm (0.06 in.)

or less and the tire should be replaced.

3) Check for abnormal wear, cracks and

damage. Any tires with cracks or other

damage should be replaced. If any tires

show abnormal wear, have them

inspected by your MARUTI SUZUKI

dealer.

4) Check for loose wheel nuts.

5) Check that there are no nails, stones or

other objects sticking into the tires.

EXAMPLE

WA R N I N G

Air pressures should be checked

when the tires are cold or you may

get inaccurate readings.

Check the inflation pressure from

time to time while inflating the tire

gradually, until the specified pres-

sure is obtained.

Never underinflate or overinflate

the tires.

Underinflation can cause unusual

handling characteristics or can

cause the rim to slip on the tire

bead, resulting in an accident or

damage to the tire or rim.

Overinflation can cause the tire to

burst, resulting in personal injury.

Overinflation can also cause

unusual handling characteristics

which may result in an accident.EXAMPLE

CAUTION

Hitting curbs and running over rocks

can damage tires and affect wheel

alignment. Be sure to have tires and

wheel alignment checked periodi-

cally by your MARUTI SUZUKI dealer.

Brakes: 6

Page 214 of 336

7-23INSPECTION AND MAINTENANCE

74LH0-74E

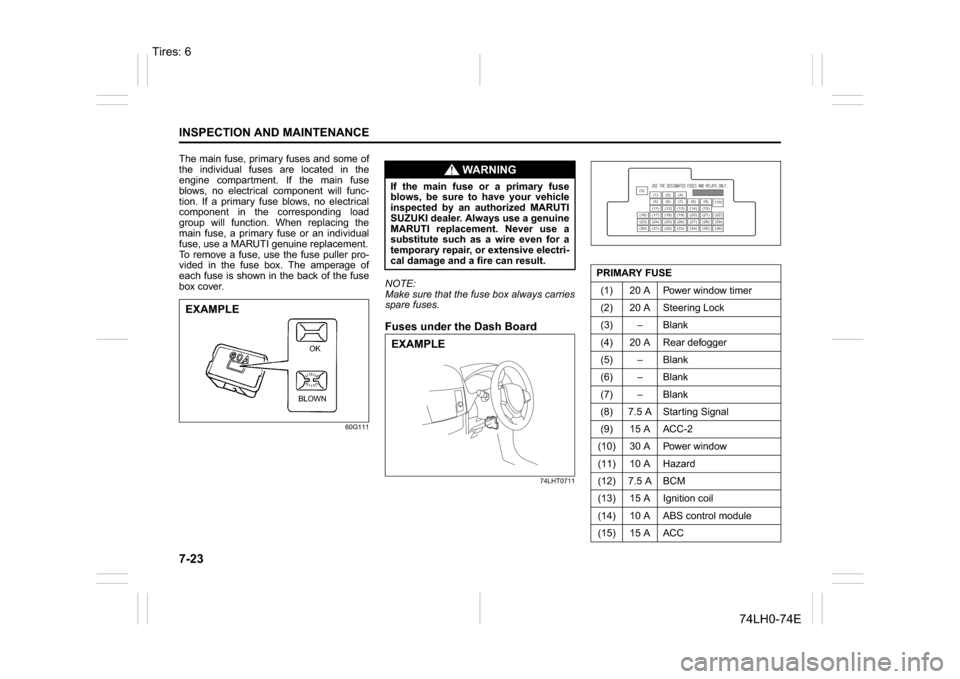

The main fuse, primary fuses and some of

the individual fuses are located in the

engine compartment. If the main fuse

blows, no electrical component will func-

tion. If a primary fuse blows, no electrical

component in the corresponding load

group will function. When replacing the

main fuse, a primary fuse or an individual

fuse, use a MARUTI genuine replacement.

To remove a fuse, use the fuse puller pro-

vided in the fuse box. The amperage of

each fuse is shown in the back of the fuse

box cover.

60G111

NOTE:

Make sure that the fuse box always carries

spare fuses.Fuses under the Dash Board

74LHT0711

EXAMPLE

BLOWNOK

WA R N I N G

If the main fuse or a primary fuse

blows, be sure to have your vehicle

inspected by an authorized MARUTI

SUZUKI dealer. Always use a genuine

MARUTI replacement. Never use a

substitute such as a wire even for a

temporary repair, or extensive electri-

cal damage and a fire can result.EXAMPLE

PRIMARY FUSE

(1) 20 A Power window timer

(2) 20 A Steering Lock

(3) – Blank

(4) 20 A Rear defogger

(5) – Blank

(6) – Blank

(7) – Blank

(8) 7.5 A Starting Signal

(9) 15 A ACC-2

(10) 30 A Power window

(11) 10 A Hazard

(12) 7.5 A BCM

(13) 15 A Ignition coil

(14) 10 A ABS control module

(15) 15 A ACC

(3)

(12)(10)

(13)

(36) (1) (2) (4)

(5)(6)

(7) (8)(9)

(11) (14) (15)

(16) (17) (18) (19) (20) (21) (22)

(23) (24) (25) (26) (27) (28) (29)

(30) (31) (32) (33) (34) (35)

Tires: 6

Page 217 of 336

7-26

INSPECTION AND MAINTENANCE

74LH0-74E

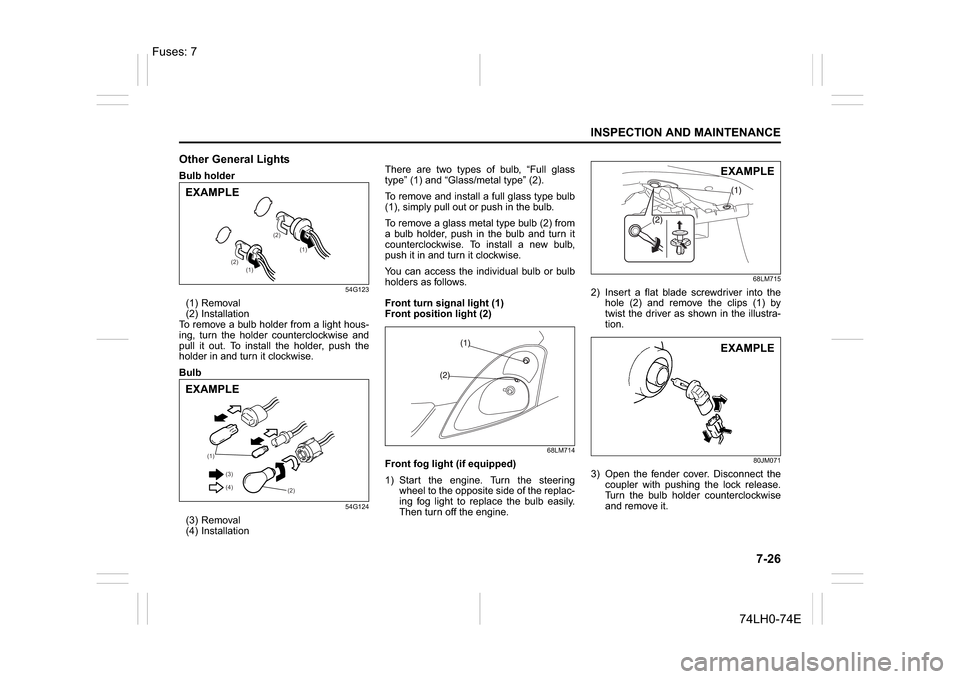

Other General LightsBulb holder

54G123

(1) Removal

(2) Installation

To remove a bulb holder from a light hous-

ing, turn the holder counterclockwise and

pull it out. To install the holder, push the

holder in and turn it clockwise.

Bulb

54G124

(3) Removal

(4) InstallationThere are two types of bulb, “Full glass

type” (1) and “Glass/metal type” (2).

To remove and install a full glass type bulb

(1), simply pull out or push in the bulb.

To remove a glass metal type bulb (2) from

a bulb holder, push in the bulb and turn it

counterclockwise. To install a new bulb,

push it in and turn it clockwise.

You can access the individual bulb or bulb

holders as follows.

Front turn signal light (1)

Front position light (2)

68LM714

Front fog light (if equipped)

1) Start the engine. Turn the steering

wheel to the opposite side of the replac-

ing fog light to replace the bulb easily.

Then turn off the engine.

68LM715

2) Insert a flat blade screwdriver into the

hole (2) and remove the clips (1) by

twist the driver as shown in the illustra-

tion.

80JM071

3) Open the fender cover. Disconnect the

coupler with pushing the lock release.

Turn the bulb holder counterclockwise

and remove it.

(1)

(1) (2)(2)

EXAMPLE

(1)

(2) (3)

(4)

EXAMPLE

EXAMPLEEXAMPLE

Fuses: 7

Page 225 of 336

8-2

EMERGENCY SERVICE

74LH0-74E

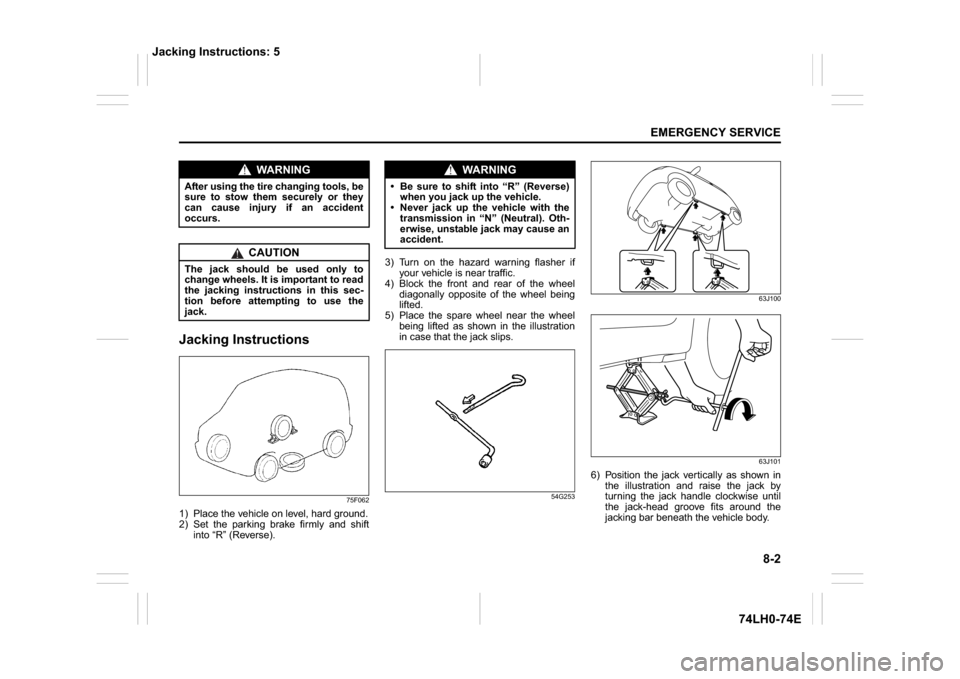

Jacking Instructions

75F062

1) Place the vehicle on level, hard ground.

2) Set the parking brake firmly and shift

into “R” (Reverse).3) Turn on the hazard warning flasher if

your vehicle is near traffic.

4) Block the front and rear of the wheel

diagonally opposite of the wheel being

lifted.

5) Place the spare wheel near the wheel

being lifted as shown in the illustration

in case that the jack slips.

54G25363J100

63J101

6) Position the jack vertically as shown in

the illustration and raise the jack by

turning the jack handle clockwise until

the jack-head groove fits around the

jacking bar beneath the vehicle body.

WA R N I N G

After using the tire changing tools, be

sure to stow them securely or they

can cause injury if an accident

occurs.

CAUTION

The jack should be used only to

change wheels. It is important to read

the jacking instructions in this sec-

tion before attempting to use the

jack.

WA R N I N G

Be sure to shift into “R” (Reverse)

when you jack up the vehicle.

Never jack up the vehicle with the

transmission in “N” (Neutral). Oth-

erwise, unstable jack may cause an

accident.

Jacking Instructions: 5