fuse type SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 51 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-1

Engine

Engine General Information and Diagnosis

Precautions

Precautions on Engine ServiceS6RW0D1100001

CAUTION!

The following information on engine service

should be noted carefully, as it is important in

preventing damage, and in contributing to

reliable engine performance.

• When raising or supporting engine for any reason, do

not use a jack under oil pan. Due to small clearance

between oil pan and oil pump strainer, jacking against

oil pan may cause it to be bent against strainer,

resulting in damaged oil pick-up unit.

• It should be kept in mind, while working on engine,

that 12-volt electrical system is capable of violent and

damaging short circuits.

When performing any work where electrical terminals

can be grounded, ground cable of the battery should

be disconnected at battery.

• Any time the air cleaner, throttle body or intake

manifold is removed, the intake opening should be

covered. This will protect against accidental entrance

of foreign material which could follow intake passage

into cylinder and cause extensive damage when

engine is started.

Precaution on On-Board Diagnostic (OBD)

System

S6RW0D1100006

There are two types of On-Board Diagnostic (OBD)

system, Euro OBD system and non-Euro-OBD system,

depending on the vehicle specification.

It is possible to identify each OBD system by checking if

it is equipped with the HO2S-2 or not.

• Euro OBD model is equipped with HO2S-2.

• Non-Euro-OBD model is not equipped with HO2S-2.

NOTE

For Taiwan model, bear in mind that it is non-

Euro-OBD model which is equipped with

HO2S-2.

As the diagnosis function is different between these two

types, be sure to fully understand the OBD system

referring to “On-Board Diagnostic System Description”.

OBD System Summary Table

Precautions in Diagnosing TroubleS6RW0D1100002

NOTE

There are two types of OBD system

depending on the vehicle specification.

For identification, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

• Don’t disconnect ECM couplers from ECM, battery

cable from battery, ECM ground wire harness from

engine or main fuse before confirming diagnostic

information (DTC, freeze frame data, etc.) stored in

ECM memory. Such disconnection will erase

memorized information in ECM memory.

• Diagnostic information stored in ECM memory can be

cleared as well as checked by using SUZUKI scan

tool or CAN communication OBD generic scan tool.

Before using scan tool, read its Operator’s

(Instruction) Manual carefully to have good

understanding as to what functions are available and

how to use it.

For Euro OBD model, it is indistinguishable which

module turns on MIL because not only ECM but also

TCM (for A/T model) turns on MIL (for details of on-

board diagnostic system for A/T model, refer to “On-

Board Diagnostic System Description in Section 5A”

for A/T).

Therefore, check both ECM and TCM (for A/T model)

for DTC when MIL lights on.

IYSQ01110001-01

Euro OBD

model (with

HO2S-2)Non-Euro-OBD

model (without

HO2S-2)

Quantity of DTC

related to engine

controlApprox. 100 Approx. 50 to 80

Freeze frame

dataAvailable Not available

SUZUKI scan tool

(SUZUKI- SDT)Available Available

CAN

communication

OBD generic

scan toolAvailable Not available

Page 76 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

• The MIL is turned on when the ECM and/or

TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs the DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the scan tool because the

DTC stored in ECM and TCM is not read

and displayed at a time. However, each of

the ECM and TCM needs not to be checked

with the generic scan tool because the

DTC stored in ECM and TCM is read and

displayed at a time.

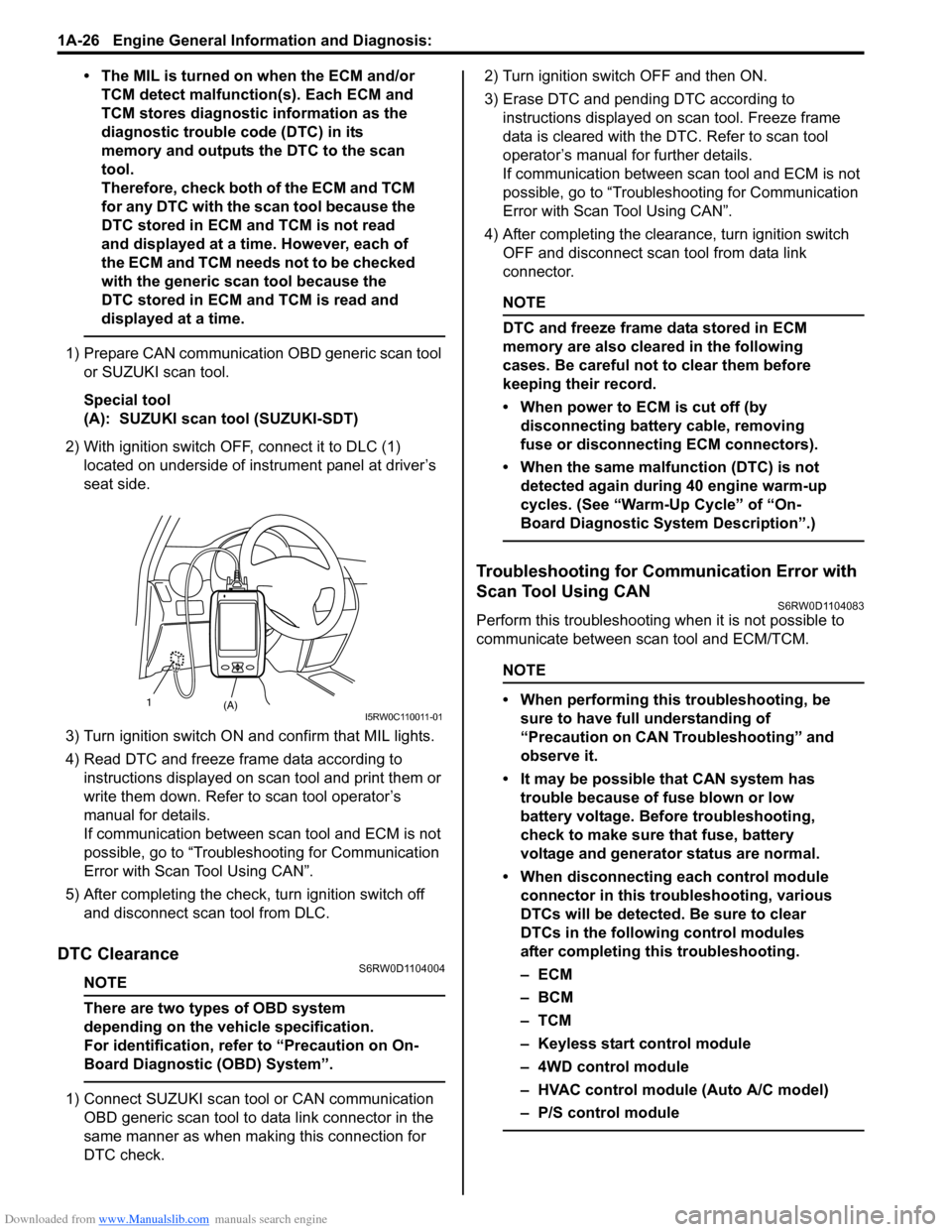

1) Prepare CAN communication OBD generic scan tool

or SUZUKI scan tool.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

2) With ignition switch OFF, connect it to DLC (1)

located on underside of instrument panel at driver’s

seat side.

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC and freeze frame data according to

instructions displayed on scan tool and print them or

write them down. Refer to scan tool operator’s

manual for details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN”.

5) After completing the check, turn ignition switch off

and disconnect scan tool from DLC.

DTC ClearanceS6RW0D1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For identification, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

1) Connect SUZUKI scan tool or CAN communication

OBD generic scan tool to data link connector in the

same manner as when making this connection for

DTC check.2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to

instructions displayed on scan tool. Freeze frame

data is cleared with the DTC. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN”.

4) After completing the clearance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by

disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

Troubleshooting for Communication Error with

Scan Tool Using CAN

S6RW0D1104083

Perform this troubleshooting when it is not possible to

communicate between scan tool and ECM/TCM.

NOTE

• When performing this troubleshooting, be

sure to have full understanding of

“Precaution on CAN Troubleshooting” and

observe it.

• It may be possible that CAN system has

trouble because of fuse blown or low

battery voltage. Before troubleshooting,

check to make sure that fuse, battery

voltage and generator status are normal.

• When disconnecting each control module

connector in this troubleshooting, various

DTCs will be detected. Be sure to clear

DTCs in the following control modules

after completing this troubleshooting.

–ECM

–BCM

–TCM

– Keyless start control module

– 4WD control module

– HVAC control module (Auto A/C model)

– P/S control module

(A) 1I5RW0C110011-01

Page 384 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-7 Fuel System:

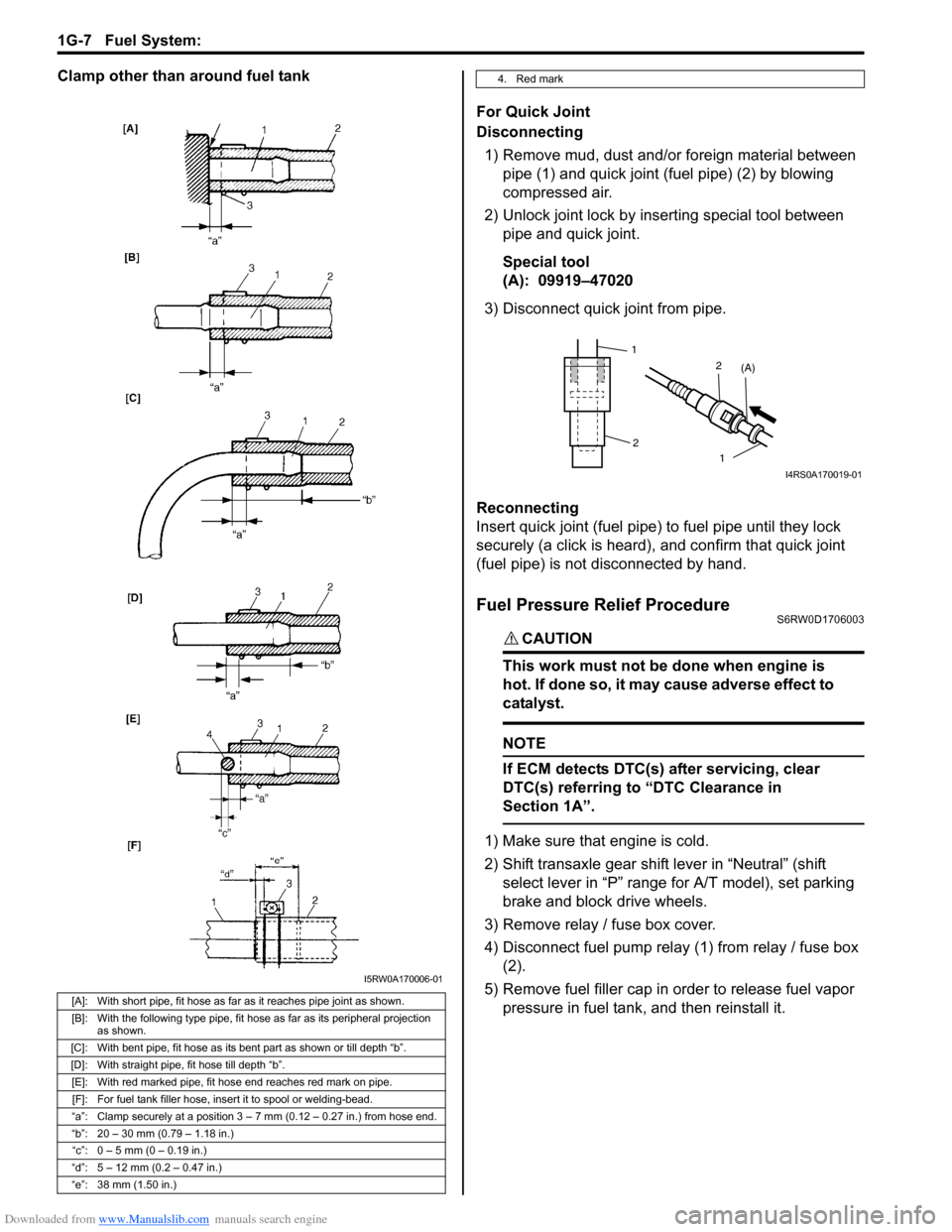

Clamp other than around fuel tank

For Quick Joint

Disconnecting

1) Remove mud, dust and/or foreign material between

pipe (1) and quick joint (fuel pipe) (2) by blowing

compressed air.

2) Unlock joint lock by inserting special tool between

pipe and quick joint.

Special tool

(A): 09919–47020

3) Disconnect quick joint from pipe.

Reconnecting

Insert quick joint (fuel pipe) to fuel pipe until they lock

securely (a click is heard), and confirm that quick joint

(fuel pipe) is not disconnected by hand.

Fuel Pressure Relief ProcedureS6RW0D1706003

CAUTION!

This work must not be done when engine is

hot. If done so, it may cause adverse effect to

catalyst.

NOTE

If ECM detects DTC(s) after servicing, clear

DTC(s) referring to “DTC Clearance in

Section 1A”.

1) Make sure that engine is cold.

2) Shift transaxle gear shift lever in “Neutral” (shift

select lever in “P” range for A/T model), set parking

brake and block drive wheels.

3) Remove relay / fuse box cover.

4) Disconnect fuel pump relay (1) from relay / fuse box

(2).

5) Remove fuel filler cap in order to release fuel vapor

pressure in fuel tank, and then reinstall it.

[A]: With short pipe, fit hose as far as it reaches pipe joint as shown.

[B]: With the following type pipe, fit hose as far as its peripheral projection

as shown.

[C]: With bent pipe, fit hose as its bent part as shown or till depth “b”.

[D]: With straight pipe, fit hose till depth “b”.

[E]: With red marked pipe, fit hose end reaches red mark on pipe.

[F]: For fuel tank filler hose, insert it to spool or welding-bead.

“a”: Clamp securely at a position 3 – 7 mm (0.12 – 0.27 in.) from hose end.

“b”: 20 – 30 mm (0.79 – 1.18 in.)

“c”: 0 – 5 mm (0 – 0.19 in.)

“d”: 5 – 12 mm (0.2 – 0.47 in.)

“e”: 38 mm (1.50 in.)

I5RW0A170006-01

4. Red mark

1

2

1 2

(A)

I4RS0A170019-01

Page 399 of 1556

Downloaded from www.Manualslib.com manuals search engine Ignition System: 1H-4

Diagnostic Information and Procedures

Ignition System Symptom DiagnosisS6RW0D1804001

Reference Waveform of Ignition SystemS6RW0D1804002

Refer to “Reference waveform No.5”, “Reference waveform No.6” and “Reference waveform No.7” under “Inspection

of ECM and Its Circuits in Section 1A” for waveform of Ignition trigger signal.

Ignition System CheckS6RW0D1804003

Condition Possible cause Correction / Reference Item

Engine cranks, but will

not start or hard to start

(No spark)Blown fuse for ignition coilReplace.

Loose connection or disconnection of

lead wire or high-tension cord(s)Connect securely.

Faulty high-tension cord(s)Replace.

Faulty spark plug(s)Replace.

Faulty ignition coilReplace ignition coil assembly.

Faulty CKP sensor or CKP sensor plateClean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaftClean, tighten or replace.

Faulty ECMReplace.

Poor fuel economy or

engine performanceIncorrect ignition timingCheck related sensors and CKP sensor plate.

Faulty spark plug(s) or high-tension

cord(s)Adjust, clean or replace.

Faulty ignition coil assemblyReplace.

Faulty CKP sensor or CKP sensor plateClean, tighten or replace.

Faulty CMP sensor or sensor rotor tooth

of camshaftClean, tighten or replace.

Faulty knock sensorReplace.

Faulty ECMReplace.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check in

Section 1A”.

2Ignition spark test

1) Check all spark plugs for condition and type referring to

“Spark Plug Inspection”.

2) If OK, perform ignition spark test referring to “Ignition

Spar k Tes t”.

Is spark emitted from all spark plugs?Go to Step 12. Go to Step 3.

3DTC check

1) Perform DTC check referring to “DTC Check in Section

1A”.

Is DTC stored in ECM?Go to applicable DTC

diag. flow.Go to Step 4.

4Electrical connection check

1) Check ignition coil assemblies and high-tension cords

for electrical connection.

Are they connected securely?Go to Step 5. Connect securely.

5High-tension cords check

1) Check high-tension cord for resistance referring to

“High-Tension Cord Inspection”.

Is check result satisfactory?Go to Step 6. Replace high-tension

cord(s).

Page 945 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G15 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G15](/img/20/7612/w960_7612-944.png)

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G154-13

G154-5

G154-6

G155-5

G155-2

G155-3

G155-7

G155-6

G155-1

G154-9

G154-14

BLK/WHT

YEL

BLU/WHT

RED

BRN

GRN/WHT

RED/BLK

RED

GRN

GRN/YEL

RED/YEL

RED/BLU

20

21

23 22

BLK/RED

6 2

MBLK/WHTBLK/YEL

M

11

4RED/YEL 1

E01-49

12

E01-16

GRY 13

12V

BLU/WHTE01-3510

E01-48

18

19RED/BLK

BLK/RED

BLK/RED

BRN/WHTE01-60

E01-1

E01-29BLK/WHT

M

BLU/YELBLK/YEL

5V5V 5V

WHT/BLK

9

ORN

14E01-36

C01-12C01-14GRY/REDRED/BLU

E01-41

RED/BLK

RED

WHT

8

BLK

BLK/ORN

BLU IG1

IG2

5V

17

28

29

31

2726 2524

16

16

30

34

33E01-4 E01-19WHTRED

C01-50C01-49WHTRED

32

LT GRN

C01-57

C01-2415

GRY/BLU5V

I6RW0C721002-01

[A]: Illumination control model 9. A/C refrigerant pressure

sensor18. Condenser cooling fan relay 27. Illumination light

1. Ignition switch 10. ECM 19. Condenser cooling fan motor 28. Rear defogger relay

2. Blower motor 11. Air intake control actuator 20. Blower speed selector 29. Rear defogger

3. HVAC control unit 12. Compressor relay 21. A/C switch 30. Main relay

4. Lighting switch 13. Compressor 22. Air intake selector 31. Tail light

5. Blower motor relay 14. Evaporator temperature

sensor23. Rear defogger switch 32. TCM

6. Blower motor resistor 15. ECT sensor 24. “A/C” indicator light 33. To other control module and DLC

7. Junction block assembly 16. To BCM 25. “REC” indicator light 34. ABS control module

8. BCM 17. Main fuse box 26. Rear defogger indicator

Page 953 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-13

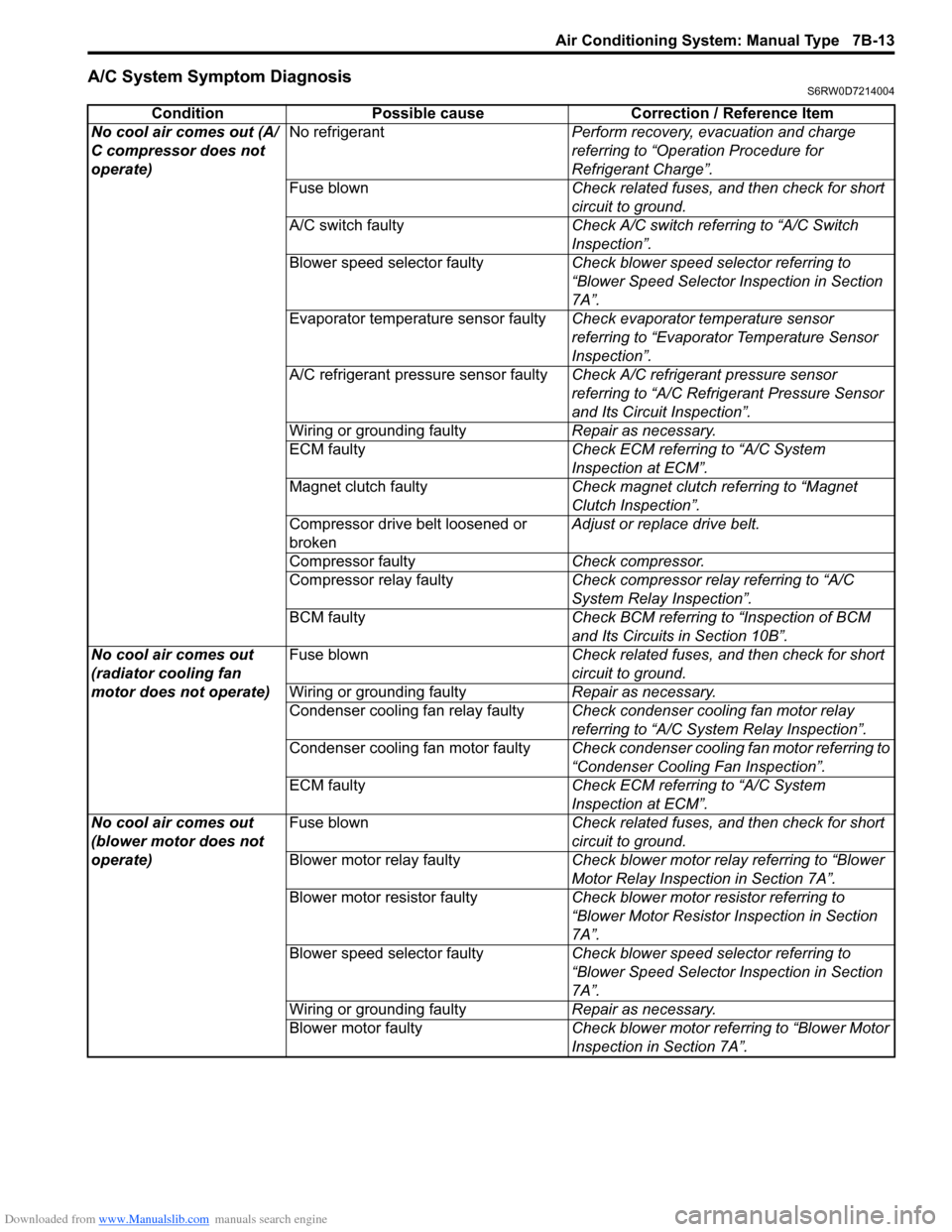

A/C System Symptom DiagnosisS6RW0D7214004

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C compressor does not

operate)No refrigerantPerform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blownCheck related fuses, and then check for short

circuit to ground.

A/C switch faultyCheck A/C switch referring to “A/C Switch

Inspection”.

Blower speed selector faultyCheck blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

A/C refrigerant pressure sensor faultyCheck A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck ECM referring to “A/C System

Inspection at ECM”.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Compressor faultyCheck compressor.

Compressor relay faultyCheck compressor relay referring to “A/C

System Relay Inspection”.

BCM faultyCheck BCM referring to “Inspection of BCM

and Its Circuits in Section 10B”.

No cool air comes out

(radiator cooling fan

motor does not operate)Fuse blownCheck related fuses, and then check for short

circuit to ground.

Wiring or grounding faultyRepair as necessary.

Condenser cooling fan relay faultyCheck condenser cooling fan motor relay

referring to “A/C System Relay Inspection”.

Condenser cooling fan motor faultyCheck condenser cooling fan motor referring to

“Condenser Cooling Fan Inspection”.

ECM faultyCheck ECM referring to “A/C System

Inspection at ECM”.

No cool air comes out

(blower motor does not

operate)Fuse blownCheck related fuses, and then check for short

circuit to ground.

Blower motor relay faultyCheck blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.

Blower motor resistor faultyCheck blower motor resistor referring to

“Blower Motor Resistor Inspection in Section

7A”.

Blower speed selector faultyCheck blower speed selector referring to

“Blower Speed Selector Inspection in Section

7A”.

Wiring or grounding faultyRepair as necessary.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Page 970 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-30 Air Conditioning System: Manual Type

A/C System Relay InspectionS6RW0D7216017

NOTE

Do not use blue relay for the substitute of

white relay because internal durability of a

blue relay is different from the durability of a

white relay.

1) Disconnect negative (–) cable from battery.

2) Remove compressor relay (1) or condenser cooling

fan relay (2) from main fuse box (3).

3) Check that there is no continuity between terminal

“c” and “d”. If there is continuity, replace relay.

4) Connect battery positive (+) terminal to terminal “b”

of relay and battery negative (–) terminal to terminal

“a” of relay, and then check continuity between

terminal “c” and “d”. If there is no continuity, replace

relay.

Compressor Drive Belt Inspection and

Adjustment

S6RW0D7216018

Inspection

• Check compressor drive belt (1) for wear, crack,

deformation and cleanliness. If any defect is found,

replace the belt with new one referring to

“Compressor Drive Belt Removal and Installation”.

• Check compressor drive belt tension by measuring

how much it deflects when pushed intermediate point

between magnet clutch pulley (6) and crankshaft

pulley (3) with about 100 N (10 kg) force after rotating

crankshaft pulley 360°. If belt tension is out of

specification, adjust belt tension referring to

“Adjustment”.

Compressor drive belt tension

“a”

: 7 – 8 mm (0.28 – 0.31 in.)

NOTE

When replacing drive belt, adjust drive belt

tension to the following specifications.

New compressor drive belt tension “a”

: 6 – 7 mm (0.24 – 0.28 in.)

Adjustment

1) Loosen tension pulley nut (4).

2) Adjust belt tension by tighten or loosen tension

pulley adjusting bolt (5).

3) Tighten tension pulley nut.

4) Rotate the crankshaft pulley 360°, and then recheck

belt tension.

3

1

2

“a”

“b”“c”

“d”

I5RW0B721023-01

2. Tension pulley

I5RW0A721033-01

Page 978 of 1556

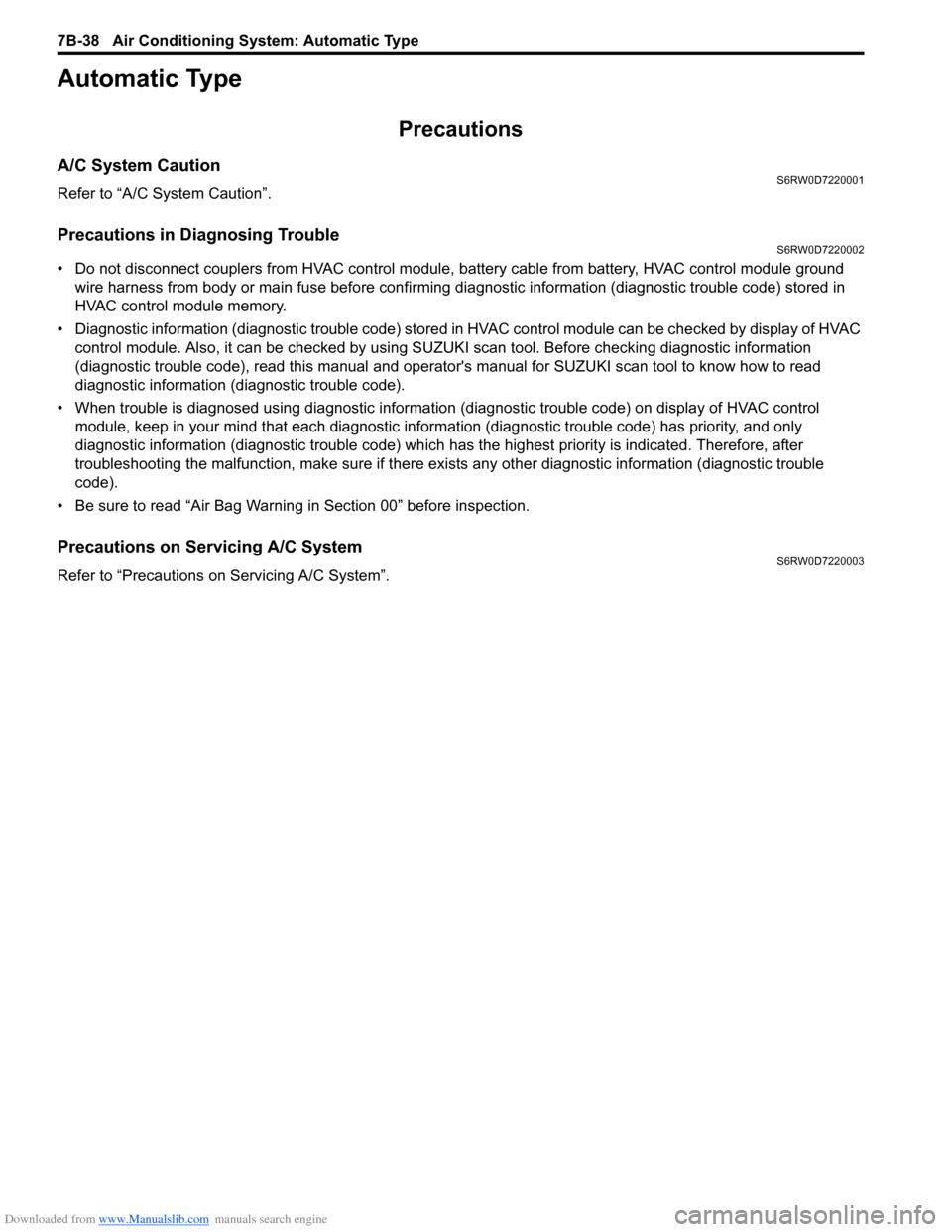

Downloaded from www.Manualslib.com manuals search engine 7B-38 Air Conditioning System: Automatic Type

Automatic Type

Precautions

A/C System CautionS6RW0D7220001

Refer to “A/C System Caution”.

Precautions in Diagnosing TroubleS6RW0D7220002

• Do not disconnect couplers from HVAC control module, battery cable from battery, HVAC control module ground

wire harness from body or main fuse before confirming diagnostic information (diagnostic trouble code) stored in

HVAC control module memory.

• Diagnostic information (diagnostic trouble code) stored in HVAC control module can be checked by display of HVAC

control module. Also, it can be checked by using SUZUKI scan tool. Before checking diagnostic information

(diagnostic trouble code), read this manual and operator's manual for SUZUKI scan tool to know how to read

diagnostic information (diagnostic trouble code).

• When trouble is diagnosed using diagnostic information (diagnostic trouble code) on display of HVAC control

module, keep in your mind that each diagnostic information (diagnostic trouble code) has priority, and only

diagnostic information (diagnostic trouble code) which has the highest priority is indicated. Therefore, after

troubleshooting the malfunction, make sure if there exists any other diagnostic information (diagnostic trouble

code).

• Be sure to read “Air Bag Warning in Section 00” before inspection.

Precautions on Servicing A/C SystemS6RW0D7220003

Refer to “Precautions on Servicing A/C System”.

Page 983 of 1556

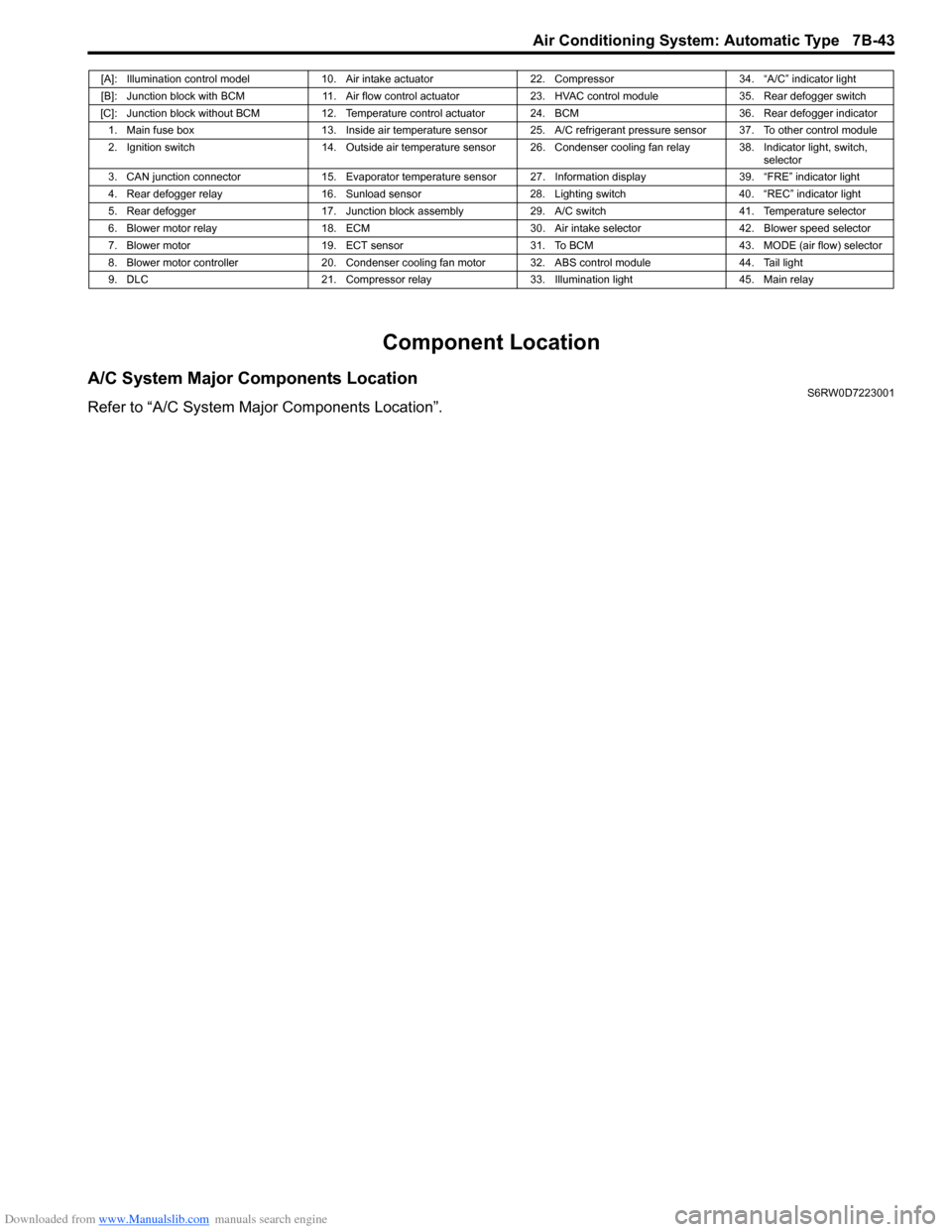

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-43

Component Location

A/C System Major Components LocationS6RW0D7223001

Refer to “A/C System Major Components Location”.

[A]: Illumination control model 10. Air intake actuator 22. Compressor 34. “A/C” indicator light

[B]: Junction block with BCM 11. Air flow control actuator 23. HVAC control module 35. Rear defogger switch

[C]: Junction block without BCM 12. Temperature control actuator 24. BCM 36. Rear defogger indicator

1. Main fuse box 13. Inside air temperature sensor 25. A/C refrigerant pressure sensor 37. To other control module

2. Ignition switch 14. Outside air temperature sensor 26. Condenser cooling fan relay 38. Indicator light, switch,

selector

3. CAN junction connector 15. Evaporator temperature sensor 27. Information display 39. “FRE” indicator light

4. Rear defogger relay 16. Sunload sensor 28. Lighting switch 40. “REC” indicator light

5. Rear defogger 17. Junction block assembly 29. A/C switch 41. Temperature selector

6. Blower motor relay 18. ECM 30. Air intake selector 42. Blower speed selector

7. Blower motor 19. ECT sensor 31. To BCM 43. MODE (air flow) selector

8. Blower motor controller 20. Condenser cooling fan motor 32. ABS control module 44. Tail light

9. DLC 21. Compressor relay 33. Illumination light 45. Main relay

Page 987 of 1556

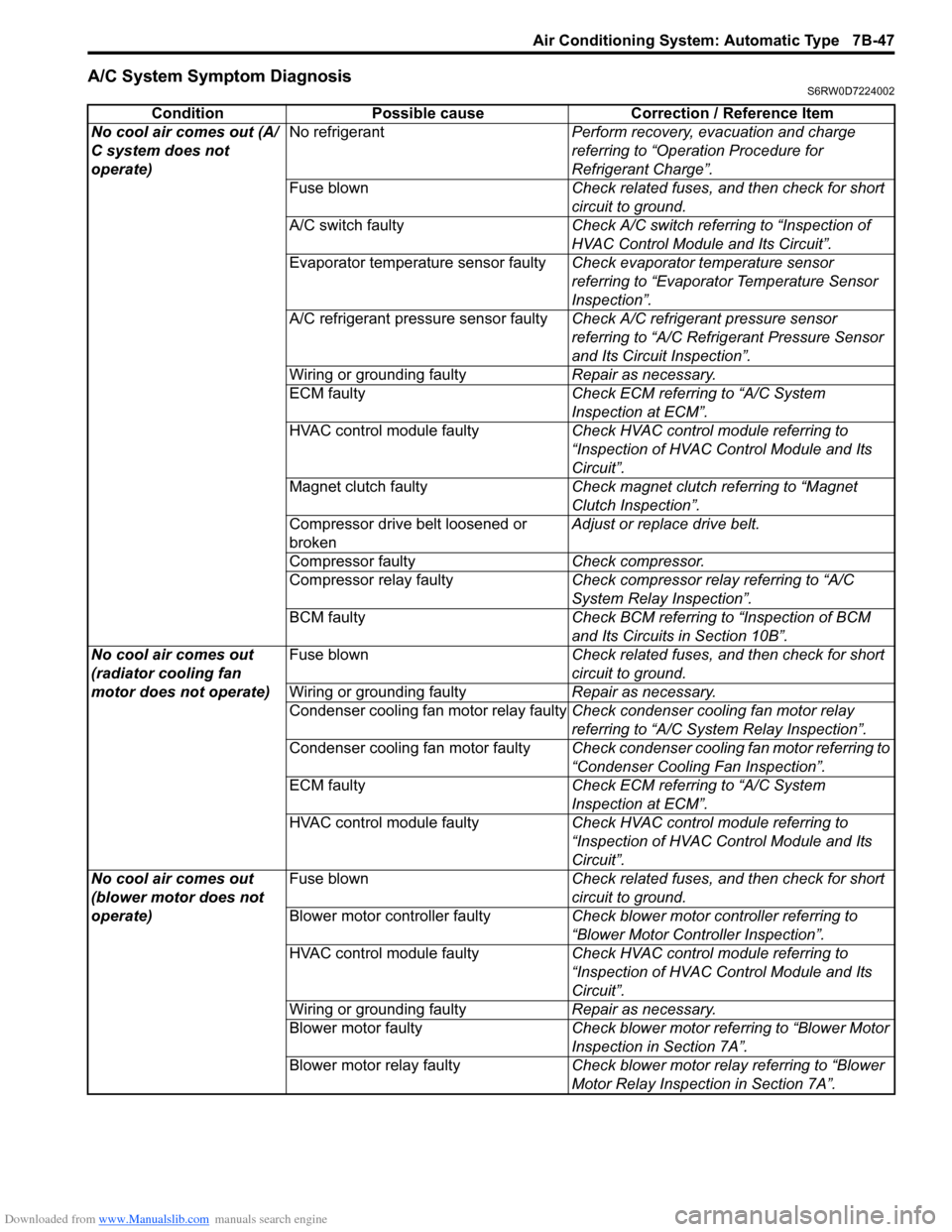

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-47

A/C System Symptom DiagnosisS6RW0D7224002

Condition Possible cause Correction / Reference Item

No cool air comes out (A/

C system does not

operate)No refrigerantPerform recovery, evacuation and charge

referring to “Operation Procedure for

Refrigerant Charge”.

Fuse blownCheck related fuses, and then check for short

circuit to ground.

A/C switch faultyCheck A/C switch referring to “Inspection of

HVAC Control Module and Its Circuit”.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

A/C refrigerant pressure sensor faultyCheck A/C refrigerant pressure sensor

referring to “A/C Refrigerant Pressure Sensor

and Its Circuit Inspection”.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faultyCheck HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Compressor faultyCheck compressor.

Compressor relay faultyCheck compressor relay referring to “A/C

System Relay Inspection”.

BCM faultyCheck BCM referring to “Inspection of BCM

and Its Circuits in Section 10B”.

No cool air comes out

(radiator cooling fan

motor does not operate)Fuse blownCheck related fuses, and then check for short

circuit to ground.

Wiring or grounding faultyRepair as necessary.

Condenser cooling fan motor relay faultyCheck condenser cooling fan motor relay

referring to “A/C System Relay Inspection”.

Condenser cooling fan motor faultyCheck condenser cooling fan motor referring to

“Condenser Cooling Fan Inspection”.

ECM faultyCheck ECM referring to “A/C System

Inspection at ECM”.

HVAC control module faultyCheck HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

No cool air comes out

(blower motor does not

operate)Fuse blownCheck related fuses, and then check for short

circuit to ground.

Blower motor controller faultyCheck blower motor controller referring to

“Blower Motor Controller Inspection”.

HVAC control module faultyCheck HVAC control module referring to

“Inspection of HVAC Control Module and Its

Circuit”.

Wiring or grounding faultyRepair as necessary.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Blower motor relay faultyCheck blower motor relay referring to “Blower

Motor Relay Inspection in Section 7A”.