fuse type SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 997 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-57

SUN LOAD (W/m2): This parameter indicates the

amount of sunlight detected by sunload sensor.

MODE CONT SWITCH (Air flow selector position,

AUTO, FACE, B/L, FOOT, D/F, DEF): This

parameter indicates the selected position of air flow

selector.

FAN CONT SWITCH (Blower speed selector, AUTO,

OFF, 1st – 8th): This parameter indicates the

selected position of blower speed selector.

FAN DESIRE VOLT (Fan desired voltage, V): This

parameter indicates the consumption voltage of

blower motor.

AIR MIX POS SENSOR (Temperature control

actuator position sensor, V): This parameter

indicates the input signal from position sensor in

temperature control actuator.

MODE POS SENSOR (Air flow control actuator

position sensor, V): This parameter indicates the

input signal from position sensor in air flow control

actuator.

A/C CONT SIG (A/C control signal, ON, OFF): This

parameter indicates the state of A/C switch.BLOWER LOAD SIG (Blower fan load signal, ON,

OFF): ON: Position of blower speed selector is 1st

position or more.

OFF: Position of blower speed selector is OFF

position.

AIR INTAKE MODE (Air intake selector position,

AUTO, FRE, REC): This parameter indicates the

selected position of air intake selector.

REFRIGERANT PRESSURE (A/C refrigerant absolute

pressure, kPa): This parameter indicates the A/C

refrigerant absolute pressure calculated by ECM

A/C COMP CLUCH (A/C compressor magnet clutch,

ON, OFF): This parameter indicates the state of the

A/C compressor magnet clutch.

VEHICLE SPEED (km/h, mph): This parameter

indicates the vehicle speed calculated by ECM.

ENGINE TYPE (Engine type signal, J20, M16 or

M15): This parameter indicates the engine type

signal transmitted by ECM.

METER SPEC (Combination meter spec signal, EU,

UK, US, Canada, DOM): This parameter indicates

the combination meter spec signal transmitted by

combination meter.

Visual InspectionS6RW0D7224009

Check visually the following parts and systems.

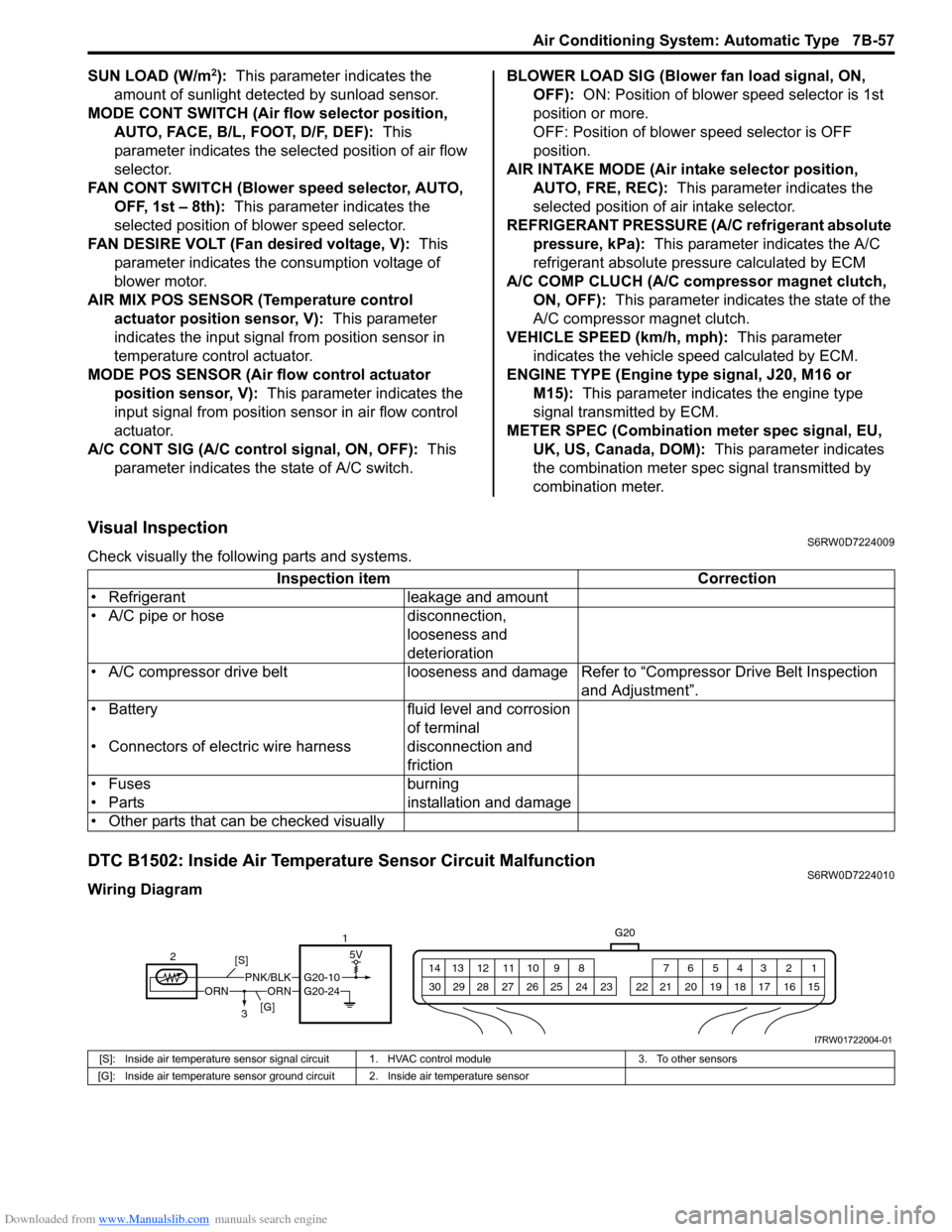

DTC B1502: Inside Air Temperature Sensor Circuit MalfunctionS6RW0D7224010

Wiring DiagramInspection item Correction

• Refrigerant leakage and amount

• A/C pipe or hose disconnection,

looseness and

deterioration

• A/C compressor drive belt looseness and damageRefer to “Compressor Drive Belt Inspection

and Adjustment”.

• Battery fluid level and corrosion

of terminal

• Connectors of electric wire harness disconnection and

friction

• Fuses burning

• Parts installation and damage

• Other parts that can be checked visually

5V

G20

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 24 23 22 25 26 27 28 29 30

ORNORNPNK/BLKG20-10

21

3 [S]

[G]

G20-24

I7RW01722004-01

[S]: Inside air temperature sensor signal circuit 1. HVAC control module 3. To other sensors

[G]: Inside air temperature sensor ground circuit 2. Inside air temperature sensor

Page 1009 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-69

DTC B1541: Back-Up Power Supply Circuit MalfunctionS6RW0D7224018

Wiring Diagram

DTC Detecting Condition and Trouble Area

NOTE

When checking DTC after connecting battery cable, be sure to turn ignition switch from OFF to ON and

from ON to OFF at least once, or DTC B1541 will be detected.

DTC Troubleshooting

12V5V

WHTG20-7 2

31G201 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 24 23 22 25 26 27 28 29 30WHT/RED [B]

I7RW01722011-01

[B]: Back-up power supply circuit 2. Main fuse

1. HVAC control module 3. Circuit fuse

DTC Detecting Condition Trouble Area

• Back-up power supply voltage is lower than specified value continuously.

• When connect battery with vehicle and then, turn ignition switch to ON

position for first time.• Battery voltage supply circuit

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Turn ignition switch to ON position for 20 sec. or more.

2) Ignition switch turned OFF and connect scan tool to

DLC.

3) Turn ON ignition switch and check DTC.

Is there DTC B1541?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

3Battery voltage supply circuit check

1) Disconnect connector from HVAC control module with

ignition switch turned OFF.

2) Check for proper connection to back-up power supply

circuit terminal of HVAC control module connector.

3) If OK, measure voltage between back-up power supply

circuit terminal of HVAC control module connector and

vehicle body ground.

Is voltage 10 – 14 V?Substitute a known-

good HVAC control

module and recheck.Back-up power supply

circuit is open or

shorted to ground.

Page 1010 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-70 Air Conditioning System: Automatic Type

DTC B1546: A/C Refrigerant Pressure MalfunctionS6RW0D7224019

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1551: Serial Communication Circuit MalfunctionS6RW0D7224020

Wiring DiagramDTC detecting condition Trouble area

• A/C refrigerant pressure sensor signal voltage is lower than specified value

even though outside air temperature is higher than specified value for

specified time continuously.

• Insufficient refrigerant in A/C system• Insufficient of refrigerant

• A/C refrigerant pressure sensor

• Outside air temperature sensor

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch to ON position and check DTC in

BCM.

Is DTC B1141 or B1142 (BCM) detected?Go to applicable DTC

diag. flow.Go to Step 3.

3DTC check

Check DTC in ECM.

Is DTC P0532 or P0533 detected?Go to applicable DTC

diag. flow.Go to Step 4.

4A/C refrigerant pressure and outside air temperature

data check

1) Start engine and select “DATA LIST” mode on scan tool.

2) Check “Refrigerant Pressure” and “Outside Air Temp”

displayed on scan tool.

Are values of A/C refrigerant pressure sensor and outside air

temperature within specified ranges indicated in “Scan Tool

Data”?Substitute a known-

good HVAC control

module and recheck.Check the amount of

refrigerant and system

for leaks.

12V

G20

G20-13YEL

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 24 23 22 25 26 27 28 29 30

1

2 3

[S]WHT/REDWHTG20-7

12V5V

[B]4 4

I7RW01722012-02

[B]: Back-up power supply circuit 1. HVAC control module 3. Information display

[S]: Serial communication circuit 2. BCM 4. Circuit fuse

Page 1011 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously.• Back-up power supply circuit

• Serial communication circuit

•BCM

• Information display

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2Back-up power supply circuit fuse check

1) Check back-up power supply circuit fuse for blowing.

Is fuse(s) blown?Replace blown fuse and

check for short in back-

up power supply circuit.Go to Step 3.

3Wire harness check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, information display

and HVAC control module.

3) Check for proper connection to serial communication

circuit terminal of BCM, information display and HVAC

control module connectors.

4) If OK, check that serial communication circuit is as

follows.

• Wiring harness resistance of serial communication

circuit is less than 3 Ω

• Insulation resistance between serial communication

circuit terminal and vehicle body ground is Infinity

• Circuit voltage of serial communication circuit is 0 - 1

V with ignition switch turned ON

Are they in good condition?Go to Step 4. Serial communication

circuit is open, short or

high resistance.

4Serial communication signal check

1) Connect connectors to BCM and HVAC control module

with ignition switch turned OFF.

2) Turn ignition switch to ON position.

3) Check that serial communication signal is outputted from

BCM referring to “Voltage Check” under “Inspection of

BCM and Its Circuits in Section 10B”.

Is serial communication signal outputted?Replace information

display.Go to Step 5.

5Communication data check

1) Connect connector to information display with ignition

switch turned OFF.

2) Check that serial communication signal is outputted from

BCM referring to “Voltage Check” under “Inspection of

BCM and Its Circuits in Section 10B”.

Is serial communication signal outputted?Substitute a known-

good HVAC control

module and recheck.Substitute a known-

good BCM and recheck.

Page 1044 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-5 Air Bag System:

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner

S6RW0D8200003

Do not dispose of the live (undeployed) air bag (inflator)

modules and the live (inactivated) seat belt

pretensioners.

When disposal is necessary, be sure to deploy / activate

the air bag and seat belt pretensioner according to

deployment / activation procedure described in “Air Bag

(Inflator) Module and Seat Belt Pretensioner Disposal”.

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which could

cause personal injury. Undeployed air bag

(inflator) module and inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

inactivated seat belt pretensioner contain

substances that can cause severe illness or

personal injury if the sealed container is

damaged during disposal.

General Description

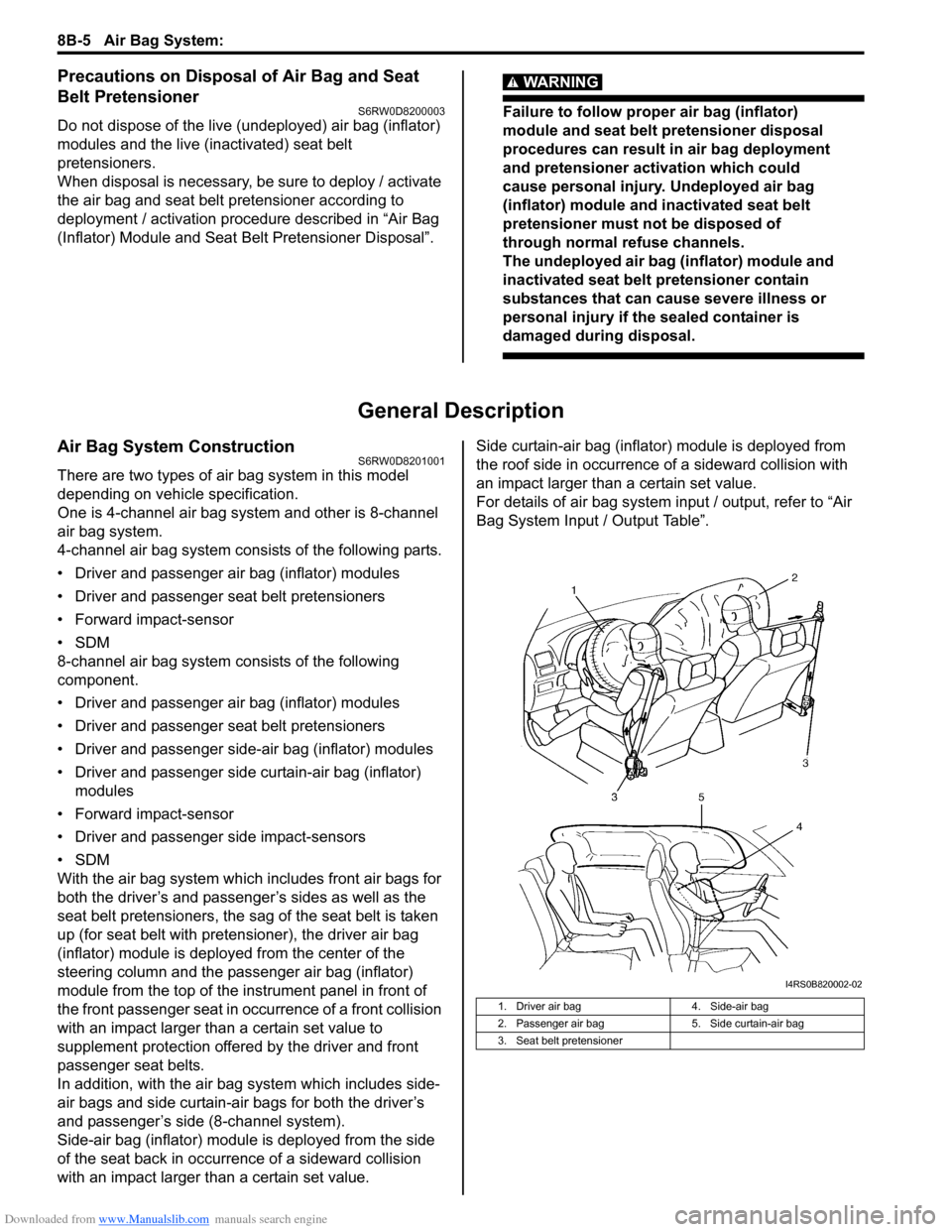

Air Bag System ConstructionS6RW0D8201001

There are two types of air bag system in this model

depending on vehicle specification.

One is 4-channel air bag system and other is 8-channel

air bag system.

4-channel air bag system consists of the following parts.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• Forward impact-sensor

•SDM

8-channel air bag system consists of the following

component.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• Driver and passenger side-air bag (inflator) modules

• Driver and passenger side curtain-air bag (inflator)

modules

• Forward impact-sensor

• Driver and passenger side impact-sensors

•SDM

With the air bag system which includes front air bags for

both the driver’s and passenger’s sides as well as the

seat belt pretensioners, the sag of the seat belt is taken

up (for seat belt with pretensioner), the driver air bag

(inflator) module is deployed from the center of the

steering column and the passenger air bag (inflator)

module from the top of the instrument panel in front of

the front passenger seat in occurrence of a front collision

with an impact larger than a certain set value to

supplement protection offered by the driver and front

passenger seat belts.

In addition, with the air bag system which includes side-

air bags and side curtain-air bags for both the driver’s

and passenger’s side (8-channel system).

Side-air bag (inflator) module is deployed from the side

of the seat back in occurrence of a sideward collision

with an impact larger than a certain set value.Side curtain-air bag (inflator) module is deployed from

the roof side in occurrence of a sideward collision with

an impact larger than a certain set value.

For details of air bag system input / output, refer to “Air

Bag System Input / Output Table”.

1. Driver air bag 4. Side-air bag

2. Passenger air bag 5. Side curtain-air bag

3. Seat belt pretensioner

I4RS0B820002-02

Page 1051 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-12

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS6RW0D8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

• The order in which DTCs are diagnosed is

very important. Failure to diagnose the

DTCs in the order specified may result in

extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.

• When measurement of resistance or

voltage is required in the flow, use a tester

along with a correct terminal adapter from

special tool (Connector test adapter kit).

• When a check for proper connection is

required, refer to “Inspection of

Intermittent and Poor Connections”.

• If an open circuit in the air bag wire

harness damaged, connector or terminal is

found, replace the wire harness,

connectors and terminals as an assembly.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.

1) Perform the “Air Bag Diagnostic System Check

Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning light operation through

“AIR BAG” warning light and whether air bag DTCs

exist.)

2) Refer to the proper diagnostic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow”

after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

A: Combination meter 6. Side curtain-air bag (inflator) module (8-

channel system)14. “A/B” fuse in junction block assembly

B: Steering wheel 7. Contact coil assembly 15. Air bag harness in main harness

C: Seat 8. Forward impact-sensor 16. Air bag harness in instrument panel harness

1. “AIR BAG” warning light 9. Apron-side-member (driver side) 17. Air bag harness in floor harness

2. Driver air bag (inflator) module 10. Side impact-sensor (8-channel system) 18. Side-air bag harness (8-channel system)

3. Passenger air bag facing cover 11. Side sill inner panel 19. Side curtain-air bag harness (8-channel

system)

4. Passenger air bag (inflator) module 12. SDM 20. Ground for air bag system

5. Side-air bag (inflator) module (8-channel

system)13. Seat belt pretensioner

Page 1503 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS6RW0DA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, ABS control module,

TCM (if equipped), 4WD control module (if equipped),

keyless start control module (if equipped),

combination meter and DLC is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”.

For CAN communication system, refer to description

on “CAN Communication System Description in

Section 1A”.

Precaution in Replacing ECMS6RW0DA300002

• If ECM is replaced with new or used one without

Immobilizer control function, the engine will not be

started. In case of the above, check if the newly

installed ECM has Immobilizer control function.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precaution in Replacing Ignition KeyS6RW0DA300003

To register ignition key in case of replacing key(s) and/or

making spare key(s), the transponder code in the ignition

key is registered with ECM. Or the engine can not be

started up. For the registration procedure, refer to

“Registration of the Ignition Key”.

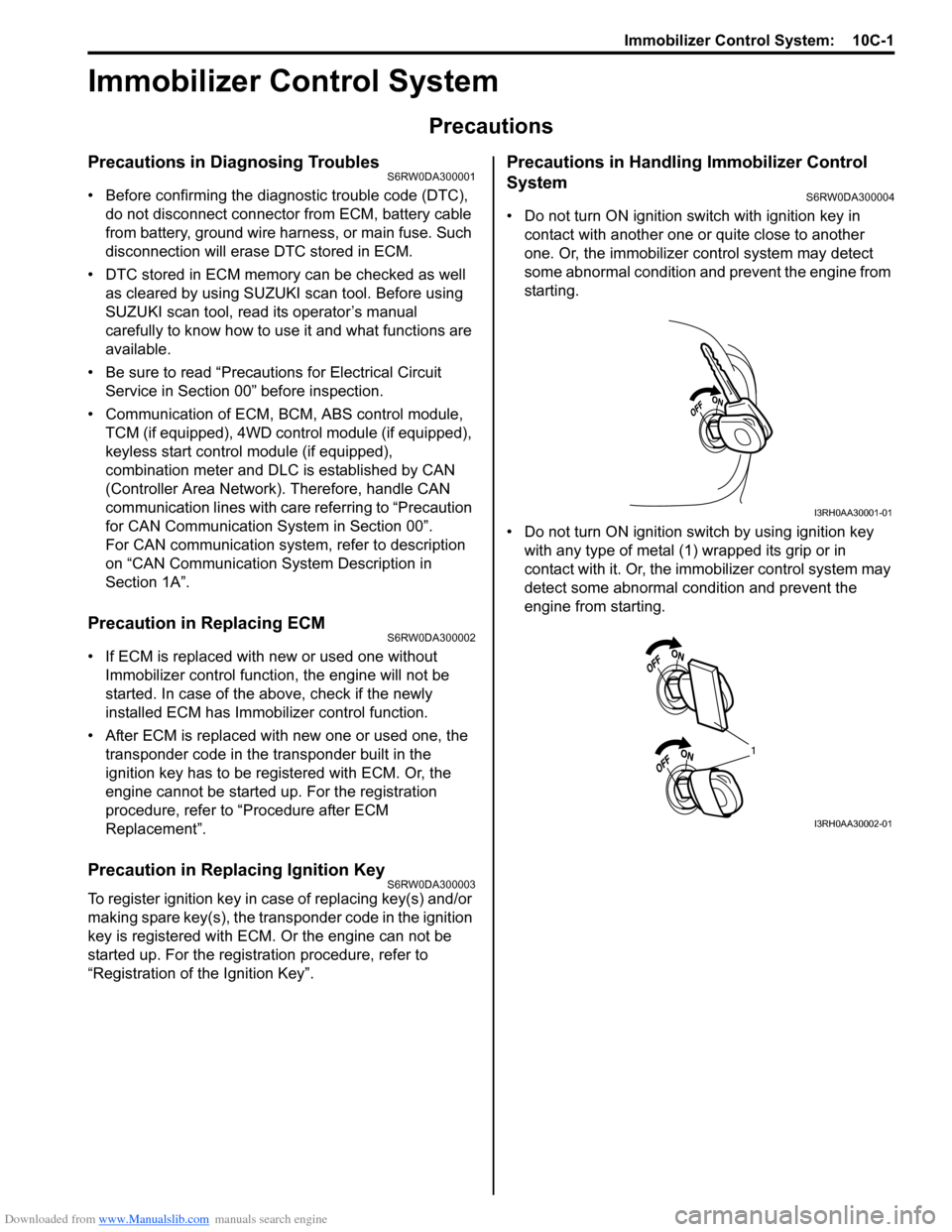

Precautions in Handling Immobilizer Control

System

S6RW0DA300004

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1506 of 1556

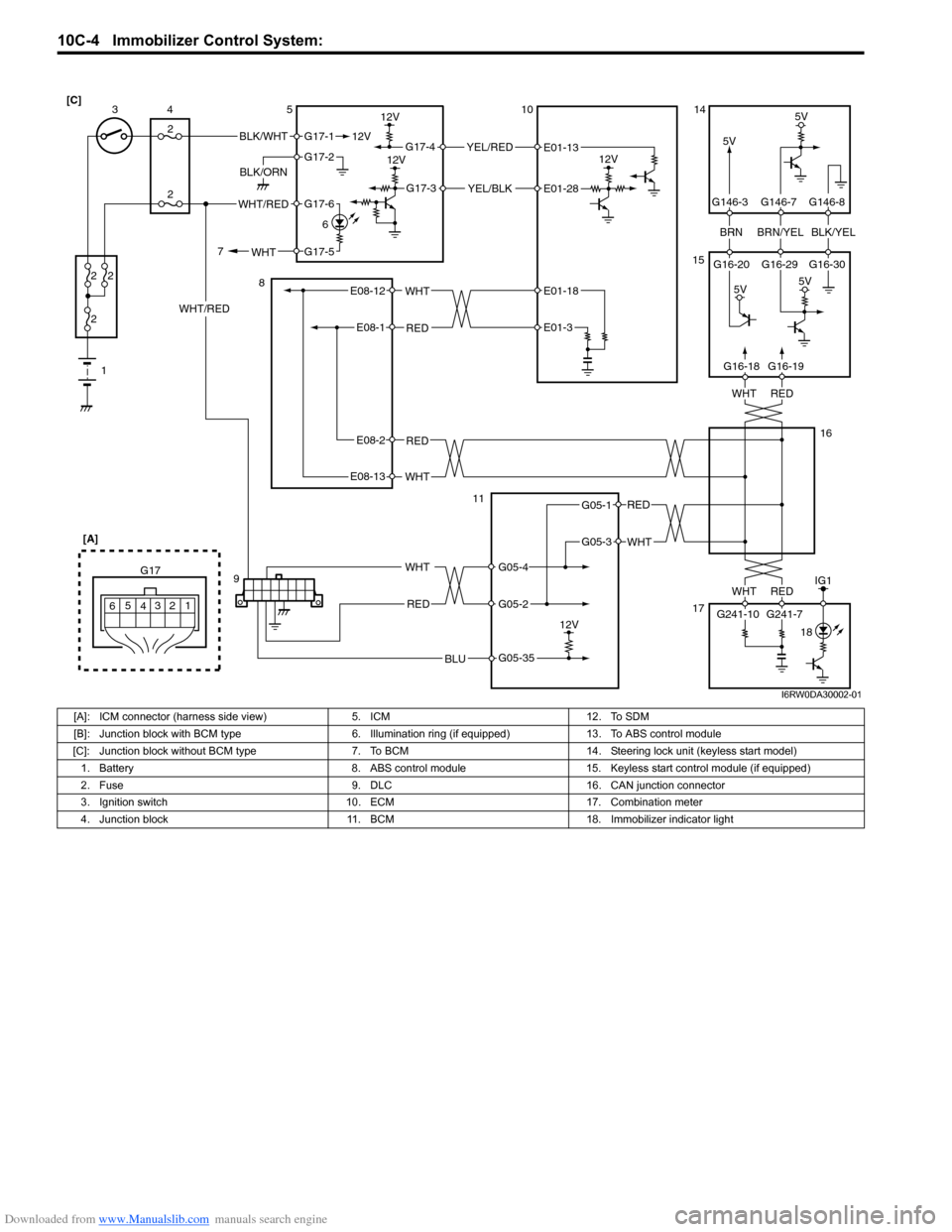

Downloaded from www.Manualslib.com manuals search engine 10C-4 Immobilizer Control System:

BLK/WHT

BLK/ORN12V

G17-1

G17-2

12V

5V

12V

12VYEL/RED

YEL/BLK

G17-4

G17-3

5V

BRNBRN/YELBLK/YEL

1 2

22

2 34

251014

15

1 2 3

4 G17

[A]

5

6

G16-20 G16-29 G16-30 G146-3 G146-7 G146-8

WHT/RED

5V

5V

9

G16-18G16-19 E01-13

E01-28

BLU

RED

WHTE08-12

E08-1E01-18

E01-3

RED

WHTE08-13

E08-2

WHT

RED

G05-4

G05-2

12V

G05-35 8

11

G17-5WHT 76

G17-6WHT/RED

17

REDWHT

REDWHT

G241-10 G241-7

IG1

18

WHT

REDG05-1

G05-3

16 [C]

I6RW0DA30002-01

[A]: ICM connector (harness side view) 5. ICM 12. To SDM

[B]: Junction block with BCM type 6. Illumination ring (if equipped) 13. To ABS control module

[C]: Junction block without BCM type 7. To BCM 14. Steering lock unit (keyless start model)

1. Battery 8. ABS control module 15. Keyless start control module (if equipped)

2. Fuse 9. DLC 16. CAN junction connector

3. Ignition switch 10. ECM 17. Combination meter

4. Junction block 11. BCM 18. Immobilizer indicator light