Tcm SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 722 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

DTC P2764: Torque Converter Clutch (TCC) Circuit Pressure Control Solenoid Control Circuit LowS6RW0D5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC solenoid valve TCM terminal is low although

TCM is commanding TCC solenoid valve to turn ON.• TCC solenoid valve circuit shorted to ground

• Malfunction of TCC solenoid valve

•TCM

Page 723 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-75

DTC Troubleshooting

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Check TCC solenoid valve resistance

1) Turn ignition switch OFF.

2) Disconnect valve body harness connector (1), (2) on

automatic transaxle.

3) Check for proper connection to solenoid at “WHT/BLU”

and “WHT/BLK” circuits.

4) Check resistance of TCC solenoid valve.

TCC solenoid valve resistance

Between shift terminals of transaxle side valve body

harness connector: 5.0 – 5.6 Ω at 20 °C (68 °F)

Between shift terminals of transaxle side valve body

harness connector and transaxle: Infinity

Is check results satisfactory?Go to Step 3. Replace TCC solenoid

valve or valve body

harness.

3Check TCC solenoid valve circuit for ground short

1) Disconnect TCM connectors.

2) Check for proper connection to TCM at terminals “C06-

3” and “C06-5”.

3) If connection is OK, check continuity between terminal

“C06-5” of disconnected harness side TCM connector

and ground, between terminal “C06-3” of disconnected

harness side TCM connector and ground.

Are continuity indicated?“WHT/BLU” or “WHT/

BLK” circuit shorted to

ground.Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

1

6 7 8 9

1054

32

2

1

I5RW0C510023-01

Page 724 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-76 Automatic Transmission/Transaxle:

DTC U0073: Control Module Communication Bus OffS6RW0D5104051

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

DTC U0100: Lost Communication with ECM / PCM “A”S6RW0D5104052

Refer to “Troubleshooting for CAN-DTC in Section 1A”.

Inspection of TCM and Its CircuitsS6RW0D5104044

TCM and its circuits can be checked at TCM wiring connectors by measuring voltage, pulse signal and resistance.

CAUTION!

TCM cannot be checked by itself, it is strictly prohibited to connect voltmeter or ohmmeter to TCM with

connector disconnected from it.

1) Remove TCM (1) from vehicle referring to “Transmission Control Module (TCM) Removal and Installation”.

2) Connect TCM connectors (2) to TCM.

3) Check voltage and/or pulse signal at each terminal of connectors connected using voltmeter (3) and oscilloscope

(4).

NOTE

• As each terminal voltage is affected by battery voltage, confirm that it is 11 V or more when ignition

switch is ON.

• Voltage with asterisk(*) cannot be measured by voltmeter because it is pulse signal. Check it with

oscilloscope if necessary.

Terminal arrangement of TCM coupler (Viewed from harness side)

3

4

12

I4RS0A510021-02

65

16 15 14 13 12 1143

24 23 212210 9 8 721

19 20 18 17 C06

17 16

26 2515 14 65 342

13 12

23 22 2411 10 9

21 20 1987

18 1 C07

I6RW0B510018-01

Page 728 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-80 Automatic Transmission/Transaxle:

Reference waveform No. 5

Output shaft speed sensor (VSS) signal at vehicle speed

60 km/h (37 mile/h).

TCM Power and Ground Circuit CheckS6RW0D5104045

Wiring DiagramMeasurement

terminalCH1: “C07-25” to “C06-1”

Oscilloscope

settingCH1: 5 V/DIV

TIME: 20 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Drive vehicle at 60 km/h (37

mile/h).

I3RM0B510028-01

BLK

BLK

BLK

C06-1

C06-23

C06-6YEL/BLKYEL/BLU

LT GRN/BLK

+BB

C06-24WHT/RED1

23

6

24 231

C06C07

[A]

I6RW0B510019-01

1. TCM 3. Ignition switch

2. A/T relay [A]: Terminal arrangement of TCM connector (viewed from harness side)

Page 729 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-81

Troubleshooting

Brake Interlock System InspectionS6RW0D5104046

1) Check that select lever cannot be moved to any

other range from “P” range position when ignition

switch key is at ACC position, at LOCK position or it

is removed from keyhole of ignition switch, or brake

pedal is not depressed.2) Shift select lever to “P” range position, check for the

following.

• Ignition key can be turned between LOCK and

ACC positions back and forth and also it can be

removed from ignition switch. Step Action Yes No

1Check TCM back-up power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C06-24”

terminal.

3) If OK, check voltage at terminal “C06-24” of

disconnected TCM connector.

Is it 10 – 14 V?Go to Step 2. “WHT/RED” circuit open

or shorted to ground.

2Check TCM power circuit

1) Disconnect TCM connector with ignition switch OFF.

2) Check for proper connection to TCM at “C06-6” terminal.

3) If OK, turn ignition switch ON and check voltage at

terminal “C06-6” of disconnected TCM connector.

Is it 10 – 14 V?Go to Step 4. Go to Step 3.

3Check A/T relay operation

1) Check A/T relay operation referring to “A/T Relay

Inspection”.

Is check result satisfactory?“YEL/BLK”, “YEL/BLU”,

“LT GRN/BLK” or “BLK”

circuit for power supply

open.Replace A/T relay.

4Check TCM ground circuit

1) Turn ignition switch OFF.

2) With TCM connectors disconnected, check for proper

connection to TCM at “C06-1” / “C06-23” terminal.

3) If OK, check resistance between “C06-1” / “C06-23”

terminal of disconnected TCM connector and body

ground.

Is continuity indicated?TCM power and ground

circuits are in good

condition.“BLK” circuit for TCM

ground open.

I4RS0A510047-01

I4RS0A510048-01

Page 745 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

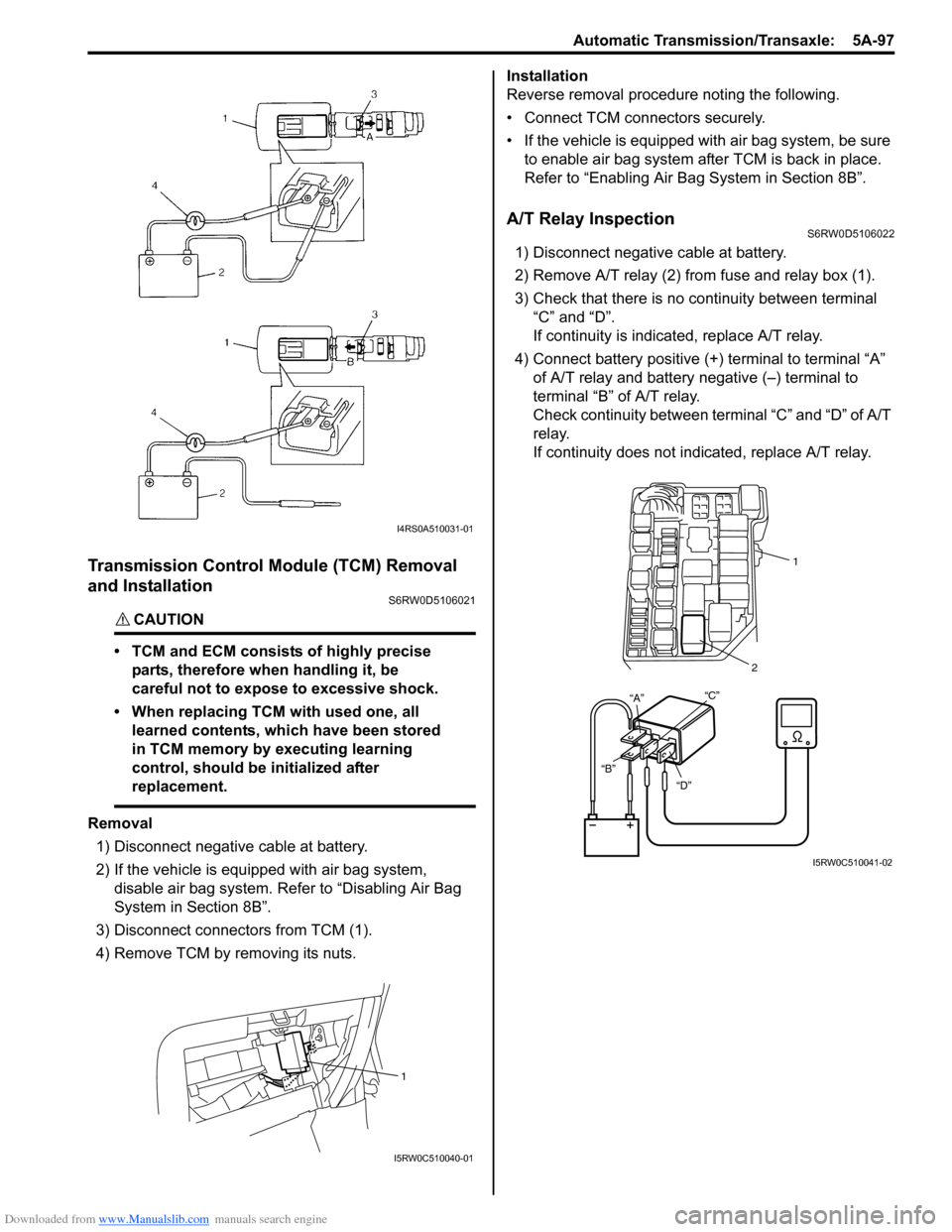

Transmission Control Module (TCM) Removal

and Installation

S6RW0D5106021

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all

learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system,

disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its nuts.Installation

Reverse removal procedure noting the following.

• Connect TCM connectors securely.

• If the vehicle is equipped with air bag system, be sure

to enable air bag system after TCM is back in place.

Refer to “Enabling Air Bag System in Section 8B”.

A/T Relay InspectionS6RW0D5106022

1) Disconnect negative cable at battery.

2) Remove A/T relay (2) from fuse and relay box (1).

3) Check that there is no continuity between terminal

“C” and “D”.

If continuity is indicated, replace A/T relay.

4) Connect battery positive (+) terminal to terminal “A”

of A/T relay and battery negative (–) terminal to

terminal “B” of A/T relay.

Check continuity between terminal “C” and “D” of A/T

relay.

If continuity does not indicated, replace A/T relay.

I4RS0A510031-01

1

I5RW0C510040-01

“D” “B”“C”21

“A”

I5RW0C510041-02

Page 757 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-109

36) Remove 2nd brake gasket (1).

37) Measure O/D and 2nd coast brake piston stroke.

If piston stroke exceeds specification, inspect and

replace plates and discs.

• Measure dimension “a” from mating surface of

transaxle case to O/D and 2nd coast brake rear

plate (1) using straightedge and micrometer

caliper.

• Measure dimension “b” from O/D and 2nd coast

brake piston (2) to rear cover assembly mating

surface using straightedge and micrometer

caliper.

• Calculate piston stroke from measured value of

dimensions “a” and “b”.

• Piston stroke = “a” – “b”

O/D and 2nd coast brake piston stroke

Standard: 0.65 – 1.05 mm (0.026 – 0.041 in.)

CAUTION!

When brake disc, retaining plate, separator

plate and/or rear plate of O/D and 2nd coast

brake have been replaced, all learned

contents, which have been stored in TCM

memory by executing learning control,

should be initialized referring to “Learning

Control Initialization”.

Neglecting this initialization may cause

excessive shift shock.

38) Remove forward and reverse clutch assembly (1).

39) Remove intermediate shaft thrust bearing front race

(1), thrust bearing (2) and rear race (3) from forward

and reverse clutch assembly (4).

NOTE

If intermediate shaft thrust bearing and/or

races are not found on forward and reverse

clutch assembly, they may have been left in

transaxle.

I2RH0B510109-01

I2RH0B510110-01

I2RH0B510111-01

I2RH0B510112-01

Page 759 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-111

48) Remove O/D and 2nd coast brake retaining plate

snap ring (1).

49) Remove front planetary sun gear (1).

50) Remove front sun gear thrust bearing race (2) from

front planetary sun gear (1).

51) Before disassembling 2nd brake piston assembly

(4), check 2nd brake piston stroke by measuring

clearance between 2nd brake separator plate (1)

and piston (2) with feeler gauge (3).

If clearance, that is, piston stroke is out of

specification, replace brake discs and plates with

new ones.

CAUTION!

When brake disc, retaining plate and/or

separator plate of 2nd brake have been

replaced, all learned contents, which have

been stored in TCM memory by executing

learning control, should be initialized

referring to “Learning Control Initialization”.

Neglecting this initialization may cause

excessive shift shock.

2nd brake piston stroke

“a”: 0.40 – 1.25 mm (0.016 – 0.049 in.)

52) Using special tool and hydraulic press, remove 2nd

brake piston snap ring (1).

CAUTION!

Do not press 2nd brake piston assembly in

over 0.4 mm (0.016 in.).

Excessive compression may cause damage

to piston assembly, return spring, plates and/

or discs.

Special tool

(A): 09926–96050

I2RH0B510120-01

I2RH0B510121-01

I2RH0B510122-01

3

4 1 2

“a”4

I2RH0B510123-01

I2RH0B510124-01

Page 768 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-120 Automatic Transmission/Transaxle:

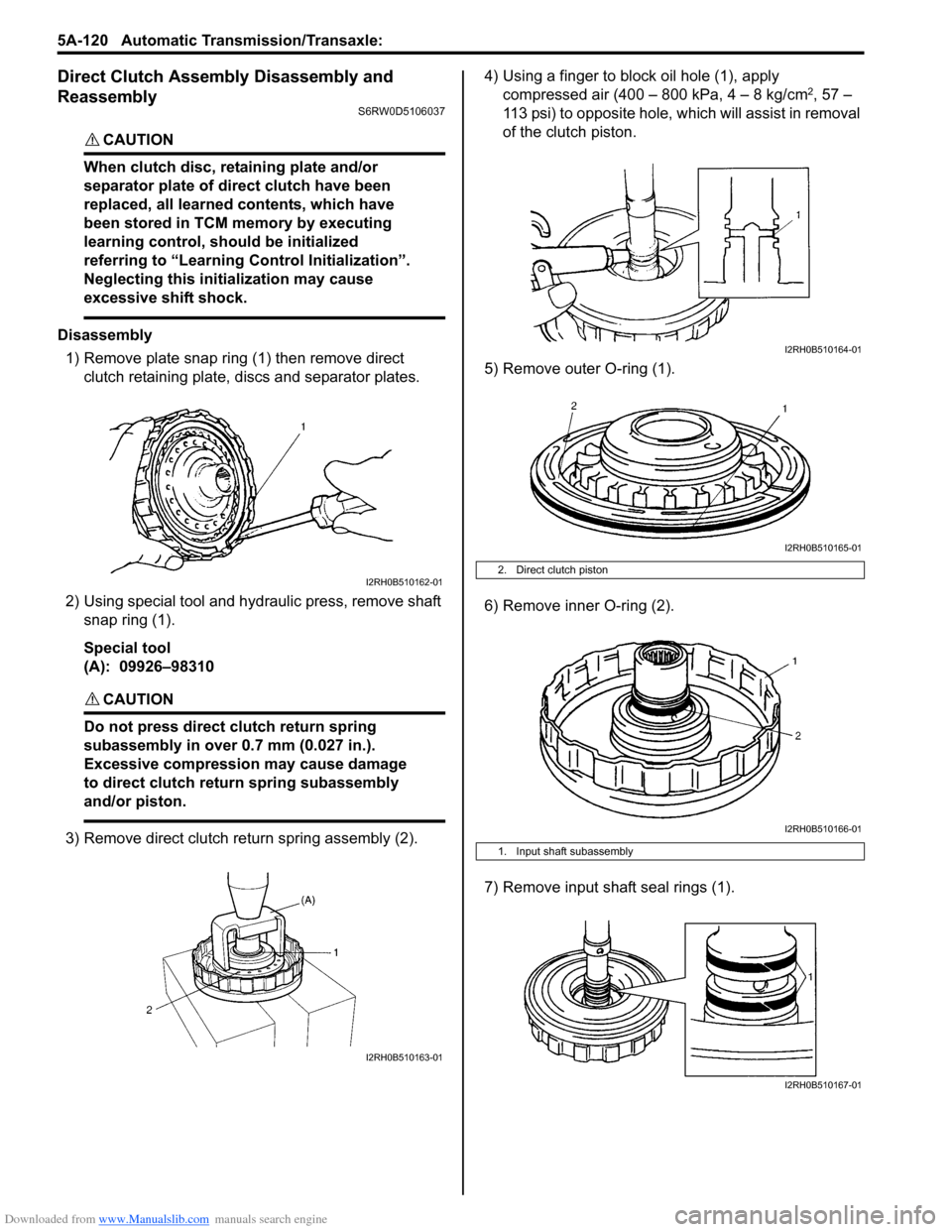

Direct Clutch Assembly Disassembly and

Reassembly

S6RW0D5106037

CAUTION!

When clutch disc, retaining plate and/or

separator plate of direct clutch have been

replaced, all learned contents, which have

been stored in TCM memory by executing

learning control, should be initialized

referring to “Learning Control Initialization”.

Neglecting this initialization may cause

excessive shift shock.

Disassembly

1) Remove plate snap ring (1) then remove direct

clutch retaining plate, discs and separator plates.

2) Using special tool and hydraulic press, remove shaft

snap ring (1).

Special tool

(A): 09926–98310

CAUTION!

Do not press direct clutch return spring

subassembly in over 0.7 mm (0.027 in.).

Excessive compression may cause damage

to direct clutch return spring subassembly

and/or piston.

3) Remove direct clutch return spring assembly (2).4) Using a finger to block oil hole (1), apply

compressed air (400 – 800 kPa, 4 – 8 kg/cm

2, 57 –

113 psi) to opposite hole, which will assist in removal

of the clutch piston.

5) Remove outer O-ring (1).

6) Remove inner O-ring (2).

7) Remove input shaft seal rings (1).

I2RH0B510162-01

I2RH0B510163-01

2. Direct clutch piston

1. Input shaft subassembly

I2RH0B510164-01

I2RH0B510165-01

I2RH0B510166-01

I2RH0B510167-01

Page 772 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-124 Automatic Transmission/Transaxle:

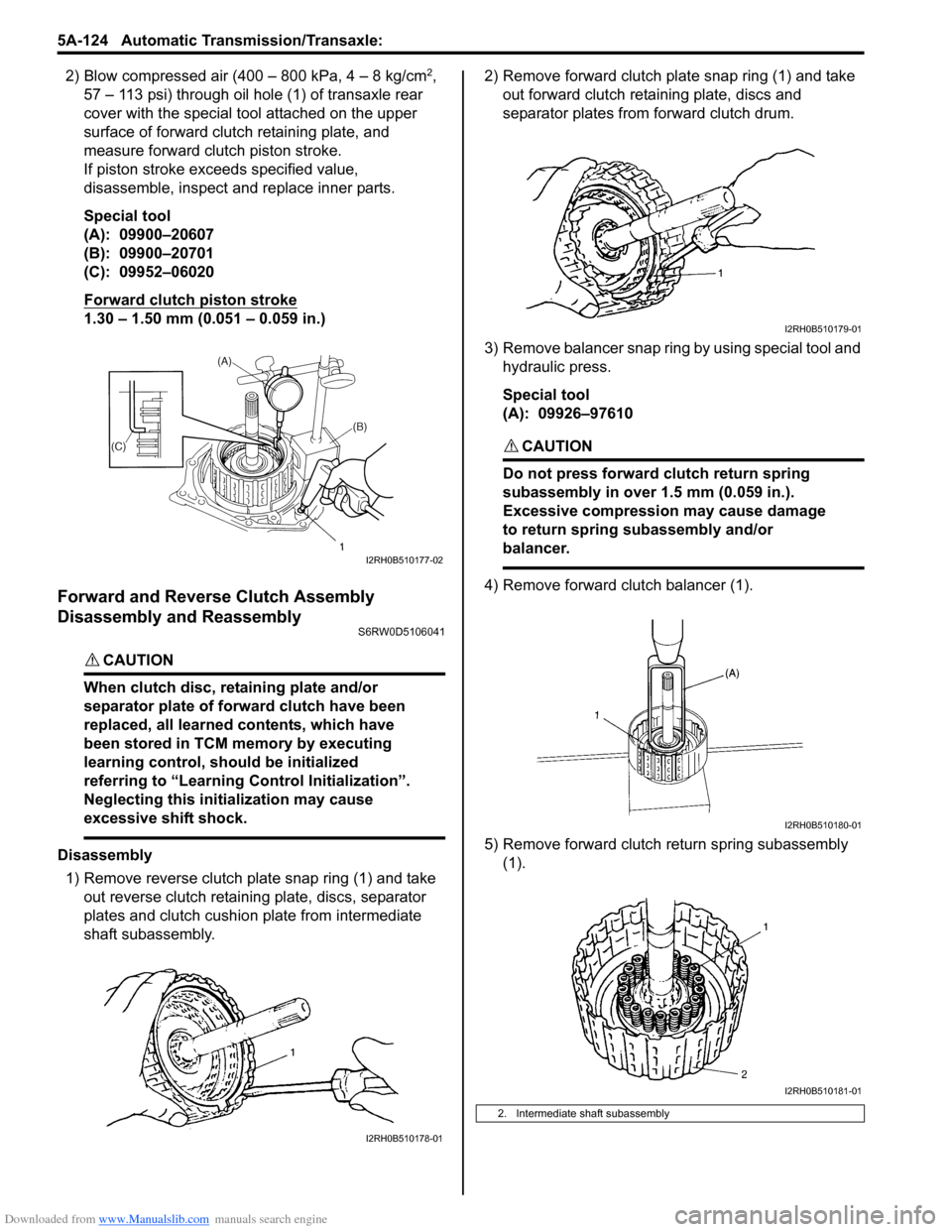

2) Blow compressed air (400 – 800 kPa, 4 – 8 kg/cm2,

57 – 113 psi) through oil hole (1) of transaxle rear

cover with the special tool attached on the upper

surface of forward clutch retaining plate, and

measure forward clutch piston stroke.

If piston stroke exceeds specified value,

disassemble, inspect and replace inner parts.

Special tool

(A): 09900–20607

(B): 09900–20701

(C): 09952–06020

Forward clutch piston stroke

1.30 – 1.50 mm (0.051 – 0.059 in.)

Forward and Reverse Clutch Assembly

Disassembly and Reassembly

S6RW0D5106041

CAUTION!

When clutch disc, retaining plate and/or

separator plate of forward clutch have been

replaced, all learned contents, which have

been stored in TCM memory by executing

learning control, should be initialized

referring to “Learning Control Initialization”.

Neglecting this initialization may cause

excessive shift shock.

Disassembly

1) Remove reverse clutch plate snap ring (1) and take

out reverse clutch retaining plate, discs, separator

plates and clutch cushion plate from intermediate

shaft subassembly.2) Remove forward clutch plate snap ring (1) and take

out forward clutch retaining plate, discs and

separator plates from forward clutch drum.

3) Remove balancer snap ring by using special tool and

hydraulic press.

Special tool

(A): 09926–97610

CAUTION!

Do not press forward clutch return spring

subassembly in over 1.5 mm (0.059 in.).

Excessive compression may cause damage

to return spring subassembly and/or

balancer.

4) Remove forward clutch balancer (1).

5) Remove forward clutch return spring subassembly

(1).

I2RH0B510177-02

I2RH0B510178-01

2. Intermediate shaft subassembly

I2RH0B510179-01

I2RH0B510180-01

I2RH0B510181-01