heat SUZUKI SX4 2006 1.G Service Owners Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 940 of 1556

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

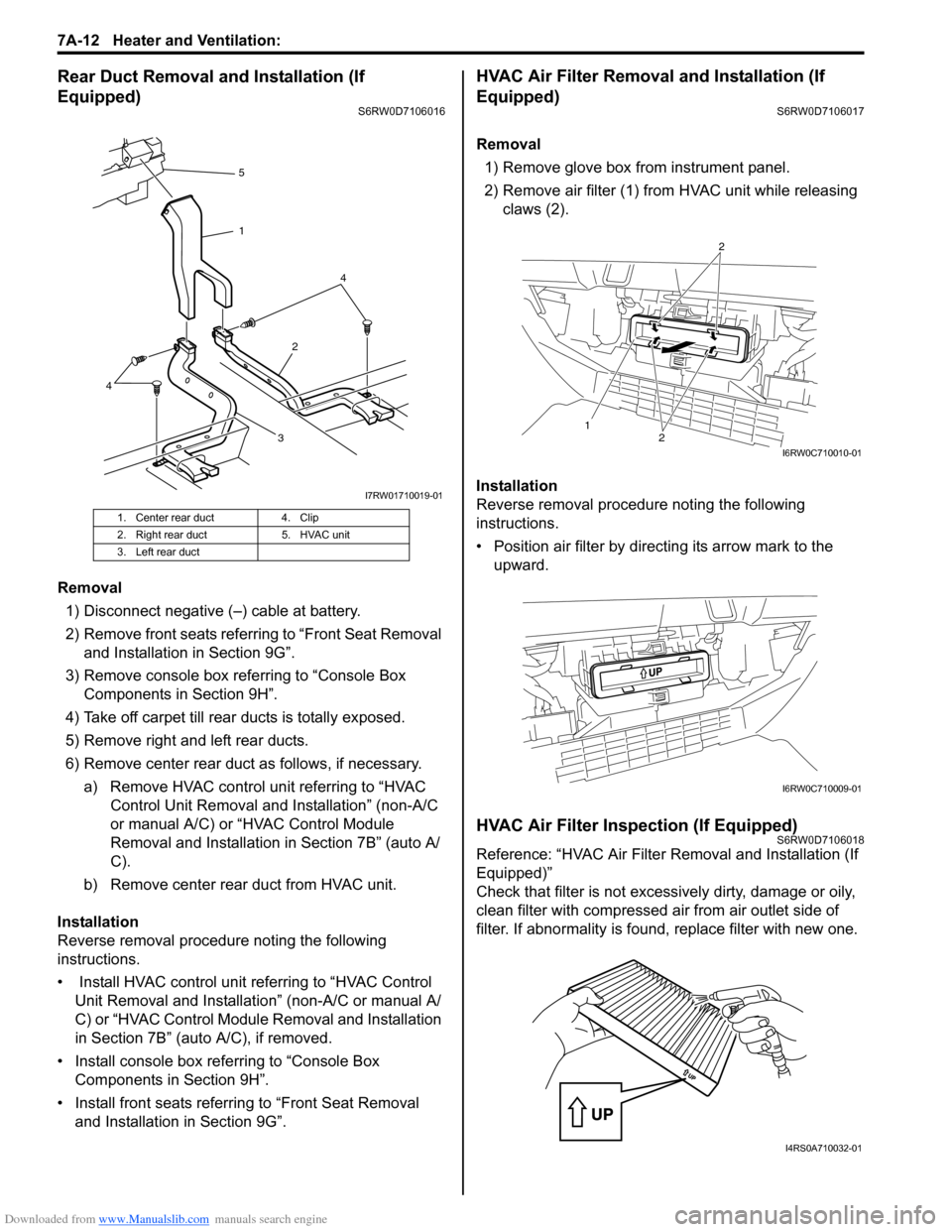

Rear Duct Removal and Installation (If

Equipped)

S6RW0D7106016

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front seats referring to “Front Seat Removal

and Installation in Section 9G”.

3) Remove console box referring to “Console Box

Components in Section 9H”.

4) Take off carpet till rear ducts is totally exposed.

5) Remove right and left rear ducts.

6) Remove center rear duct as follows, if necessary.

a) Remove HVAC control unit referring to “HVAC

Control Unit Removal and Installation” (non-A/C

or manual A/C) or “HVAC Control Module

Removal and Installation in Section 7B” (auto A/

C).

b) Remove center rear duct from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Install HVAC control unit referring to “HVAC Control

Unit Removal and Installation” (non-A/C or manual A/

C) or “HVAC Control Module Removal and Installation

in Section 7B” (auto A/C), if removed.

• Install console box referring to “Console Box

Components in Section 9H”.

• Install front seats referring to “Front Seat Removal

and Installation in Section 9G”.

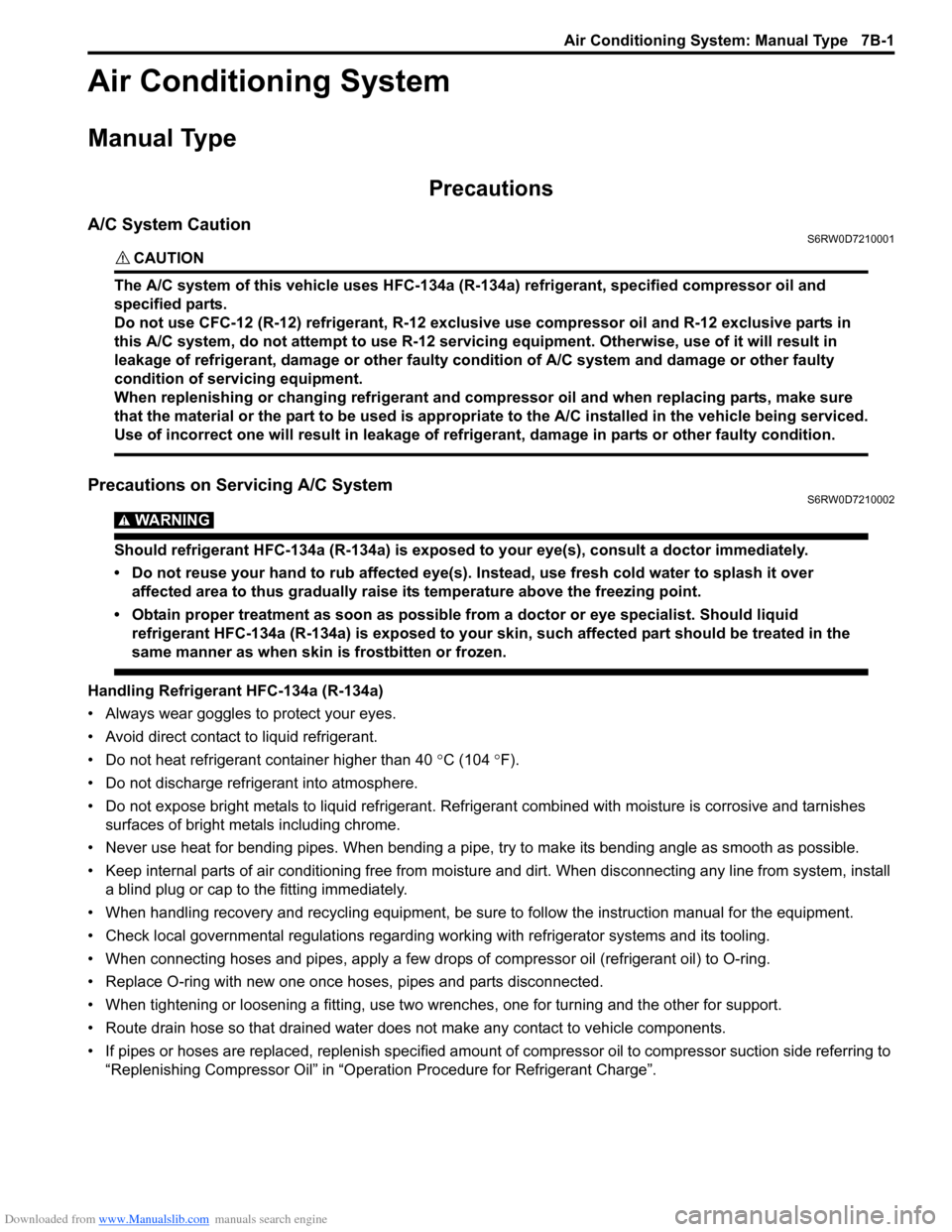

HVAC Air Filter Removal and Installation (If

Equipped)

S6RW0D7106017

Removal

1) Remove glove box from instrument panel.

2) Remove air filter (1) from HVAC unit while releasing

claws (2).

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the

upward.

HVAC Air Filter Inspection (If Equipped)S6RW0D7106018

Reference: “HVAC Air Filter Removal and Installation (If

Equipped)”

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1. Center rear duct 4. Clip

2. Right rear duct 5. HVAC unit

3. Left rear duct

324 5

1

4

I7RW01710019-01

12

2

I6RW0C710010-01

I6RW0C710009-01

I4RS0A710032-01

Page 941 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS6RW0D7210001

CAUTION!

The A/C system of this vehicle uses HFC-134a (R-134a) refrigerant, specified compressor oil and

specified parts.

Do not use CFC-12 (R-12) refrigerant, R-12 exclusive use compressor oil and R-12 exclusive parts in

this A/C system, do not attempt to use R-12 servicing equipment. Otherwise, use of it will result in

leakage of refrigerant, damage or other faulty condition of A/C system and damage or other faulty

condition of servicing equipment.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

Precautions on Servicing A/C SystemS6RW0D7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not reuse your hand to rub affected eye(s). Instead, use fresh cold water to splash it over

affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid

refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 °F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrigerant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

• Never use heat for bending pipes. When bending a pipe, try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• Replace O-ring with new one once hoses, pipes and parts disconnected.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compressor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Page 942 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-134a) into atmosphere would cause adverse effect to

environments referring to “Recovery” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Charge

After performing compressor oil replenishment and evacuation, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

General Description

Sub-Cool A/C System DescriptionS6RW0D7211001

In the sub-cool A/C system (condenser integrated with receiver / dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver / dryer is located between those. In the receiver / dryer,

the refrigerant is separated into the vapor refrigerant and the liquid refrigerant. Only the liquid refrigerant is delivered to

the sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

I5RW0A721003-02

[A]: Liquid 2. Magnet clutch 6. Expansion valve 10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator 11. Filter

[C]: Superheated vapor 4. Receiver/dryer 8. Condensation part 12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant

Page 944 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

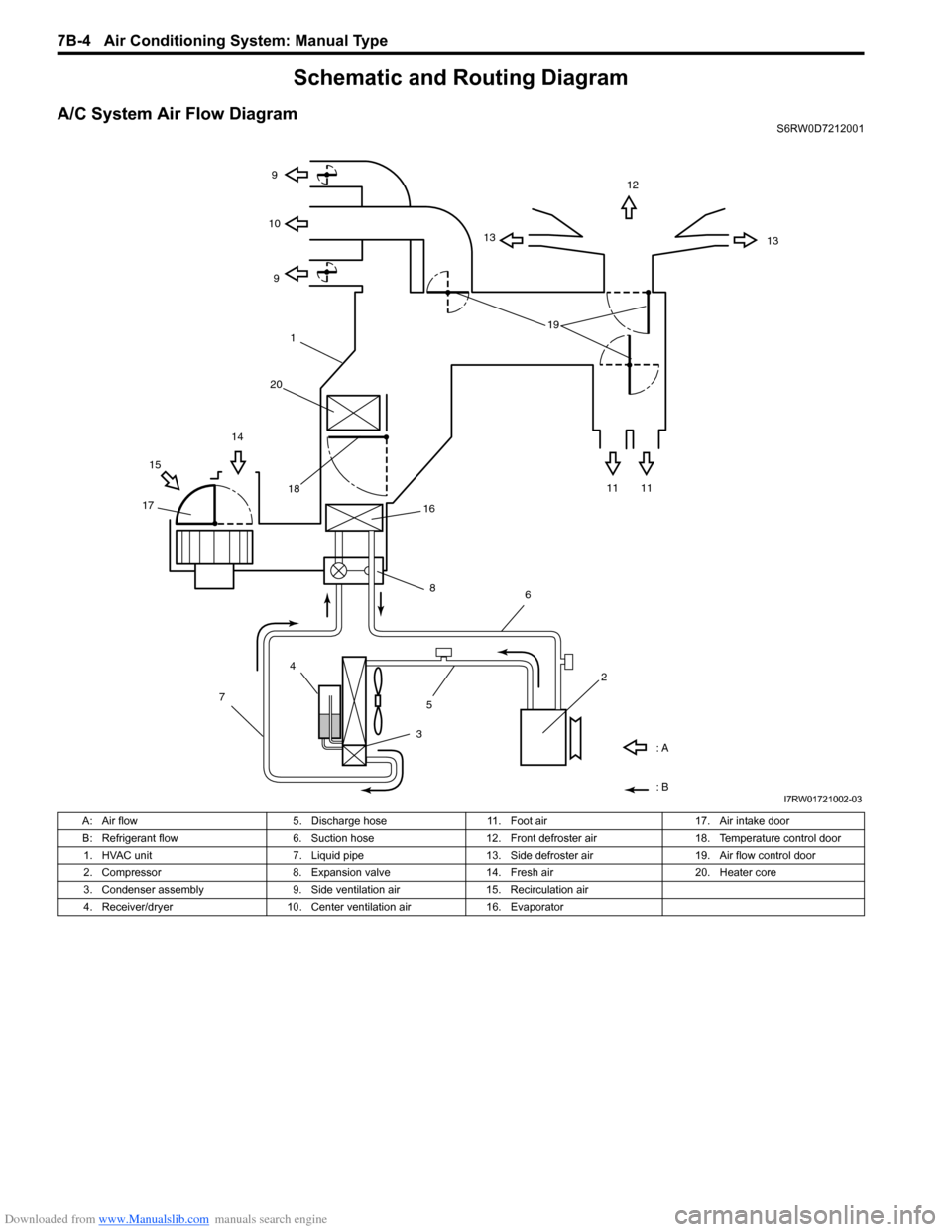

Schematic and Routing Diagram

A/C System Air Flow DiagramS6RW0D7212001

1312

13 9

9 10

11 11 1514

1718

: A

: B

4

7

356

2 16

8

191

20

I7RW01721002-03

A: Air flow 5. Discharge hose 11. Foot air 17. Air intake door

B: Refrigerant flow 6. Suction hose 12. Front defroster air 18. Temperature control door

1. HVAC unit 7. Liquid pipe 13. Side defroster air 19. Air flow control door

2. Compressor 8. Expansion valve 14. Fresh air 20. Heater core

3. Condenser assembly 9. Side ventilation air 15. Recirculation air

4. Receiver/dryer 10. Center ventilation air 16. Evaporator

Page 949 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

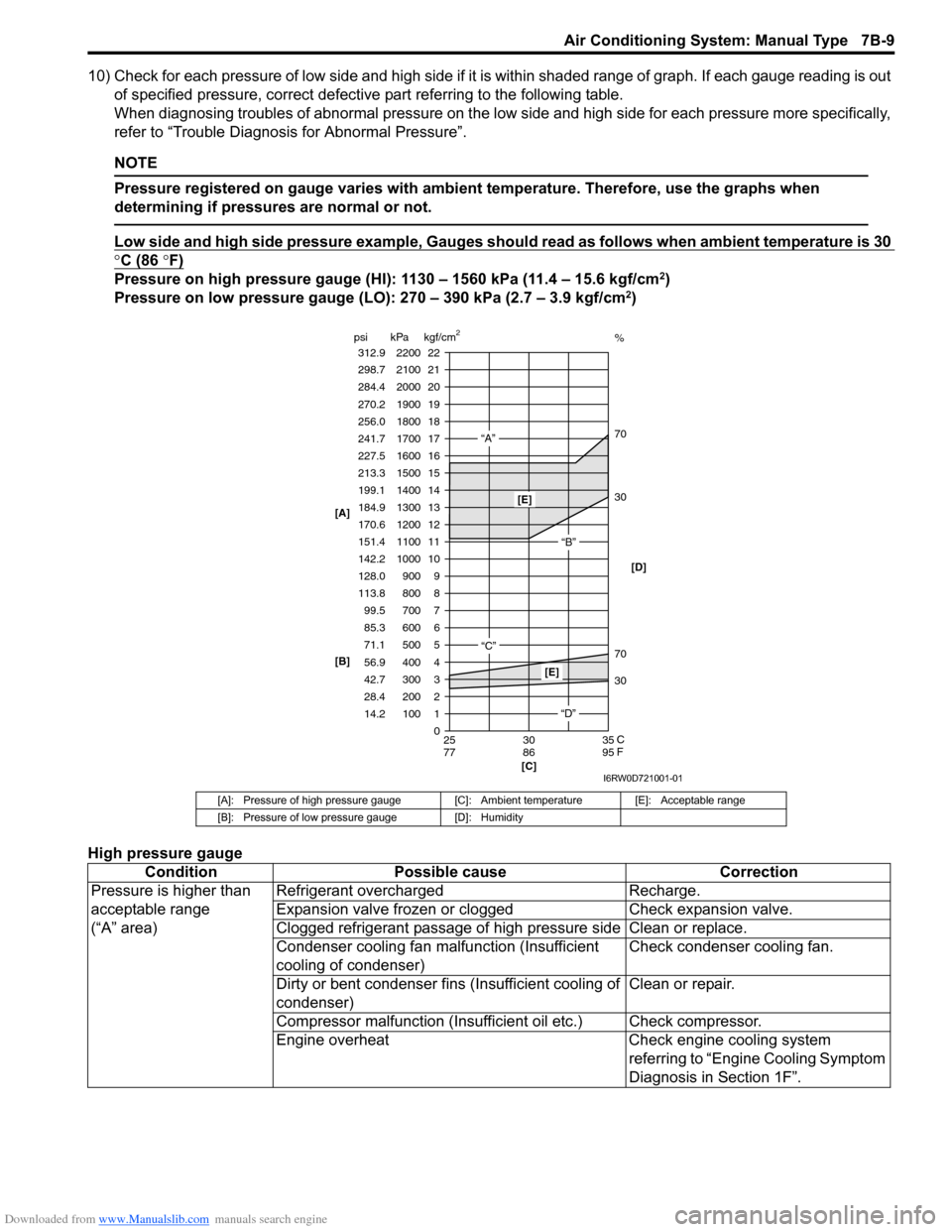

10) Check for each pressure of low side and high side if it is within shaded range of graph. If each gauge reading is out

of specified pressure, correct defective part referring to the following table.

When diagnosing troubles of abnormal pressure on the low side and high side for each pressure more specifically,

refer to “Trouble Diagnosis for Abnormal Pressure”.

NOTE

Pressure registered on gauge varies with ambient temperature. Therefore, use the graphs when

determining if pressures are normal or not.

Low side and high side pressure example, Gauges should read as follows when ambient temperature is 30

°C (86 °F)

Pressure on high pressure gauge (HI): 1130 – 1560 kPa (11.4 – 15.6 kgf/cm2)

Pressure on low pressure gauge (LO): 270 – 390 kPa (2.7 – 3.9 kgf/cm2)

High pressure gauge

[A]: Pressure of high pressure gauge [C]: Ambient temperature [E]: Acceptable range

[B]: Pressure of low pressure gauge [D]: Humidity

Condition Possible cause Correction

Pressure is higher than

acceptable range

(“A” area)Refrigerant overcharged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage of high pressure side Clean or replace.

Condenser cooling fan malfunction (Insufficient

cooling of condenser)Check condenser cooling fan.

Dirty or bent condenser fins (Insufficient cooling of

condenser)Clean or repair.

Compressor malfunction (Insufficient oil etc.) Check compressor.

Engine overheat Check engine cooling system

referring to “Engine Cooling Symptom

Diagnosis in Section 1F”.

22 312.9 2200

0 1 2 3

30 70 30 70%

4 5 6 7 8 9 10

11 12 13

14

15

16

17

18

19 21 298.7 2100

20

14.2 28.4 42.7 56.9 71.1 85.3 99.5 113.8 128.0

142.2

151.4 170.6 184.9

199.1

213.3

227.5

241.7

256.0

270.2

284.4

100 200 300 400 500 600 700 800 900 1000

1100 1200 1300

1400

1500

1600

1700

1800

1900

2000

25 30 35

77 86 95 psi kPa kgf/cm

2

[C] [B] [A]

C

F

“A”

“B”

“C”

[E]

[E]

“D”[D]

I6RW0D721001-01

Page 951 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-11

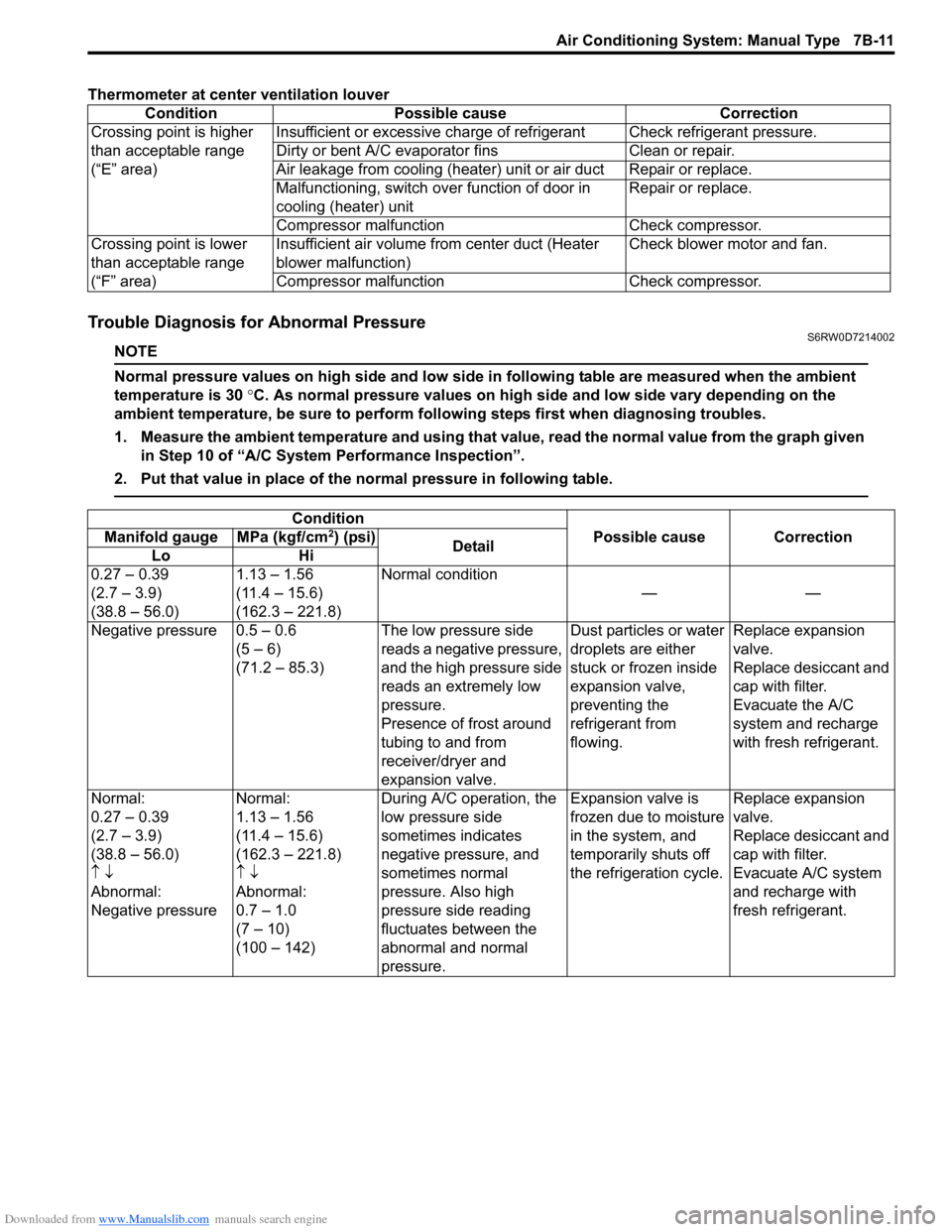

Thermometer at center ventilation louver

Trouble Diagnosis for Abnormal PressureS6RW0D7214002

NOTE

Normal pressure values on high side and low side in following table are measured when the ambient

temperature is 30 °C. As normal pressure values on high side and low side vary depending on the

ambient temperature, be sure to perform following steps first when diagnosing troubles.

1. Measure the ambient temperature and using that value, read the normal value from the graph given

in Step 10 of “A/C System Performance Inspection”.

2. Put that value in place of the normal pressure in following table.

Condition Possible cause Correction

Crossing point is higher

than acceptable range

(“E” area)Insufficient or excessive charge of refrigerant Check refrigerant pressure.

Dirty or bent A/C evaporator fins Clean or repair.

Air leakage from cooling (heater) unit or air duct Repair or replace.

Malfunctioning, switch over function of door in

cooling (heater) unitRepair or replace.

Compressor malfunction Check compressor.

Crossing point is lower

than acceptable range

(“F” area)Insufficient air volume from center duct (Heater

blower malfunction)Check blower motor and fan.

Compressor malfunction Check compressor.

Condition

Possible cause Correction Manifold gauge MPa (kgf/cm2) (psi)

Detail

Lo Hi

0.27 – 0.39

(2.7 – 3.9)

(38.8 – 56.0)1.13 – 1.56

(11.4 – 15.6)

(162.3 – 221.8)Normal condition

——

Negative pressure 0.5 – 0.6

(5 – 6)

(71.2 – 85.3)The low pressure side

reads a negative pressure,

and the high pressure side

reads an extremely low

pressure.

Presence of frost around

tubing to and from

receiver/dryer and

expansion valve.Dust particles or water

droplets are either

stuck or frozen inside

expansion valve,

preventing the

refrigerant from

flowing.Replace expansion

valve.

Replace desiccant and

cap with filter.

Evacuate the A/C

system and recharge

with fresh refrigerant.

Normal:

0.27 – 0.39

(2.7 – 3.9)

(38.8 – 56.0)

↑ ↓

Abnormal:

Negative pressureNormal:

1.13 – 1.56

(11.4 – 15.6)

(162.3 – 221.8)

↑ ↓

Abnormal:

0.7 – 1.0

(7 – 10)

(100 – 142)During A/C operation, the

low pressure side

sometimes indicates

negative pressure, and

sometimes normal

pressure. Also high

pressure side reading

fluctuates between the

abnormal and normal

pressure.Expansion valve is

frozen due to moisture

in the system, and

temporarily shuts off

the refrigeration cycle.Replace expansion

valve.

Replace desiccant and

cap with filter.

Evacuate A/C system

and recharge with

fresh refrigerant.

Page 954 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-14 Air Conditioning System: Manual Type

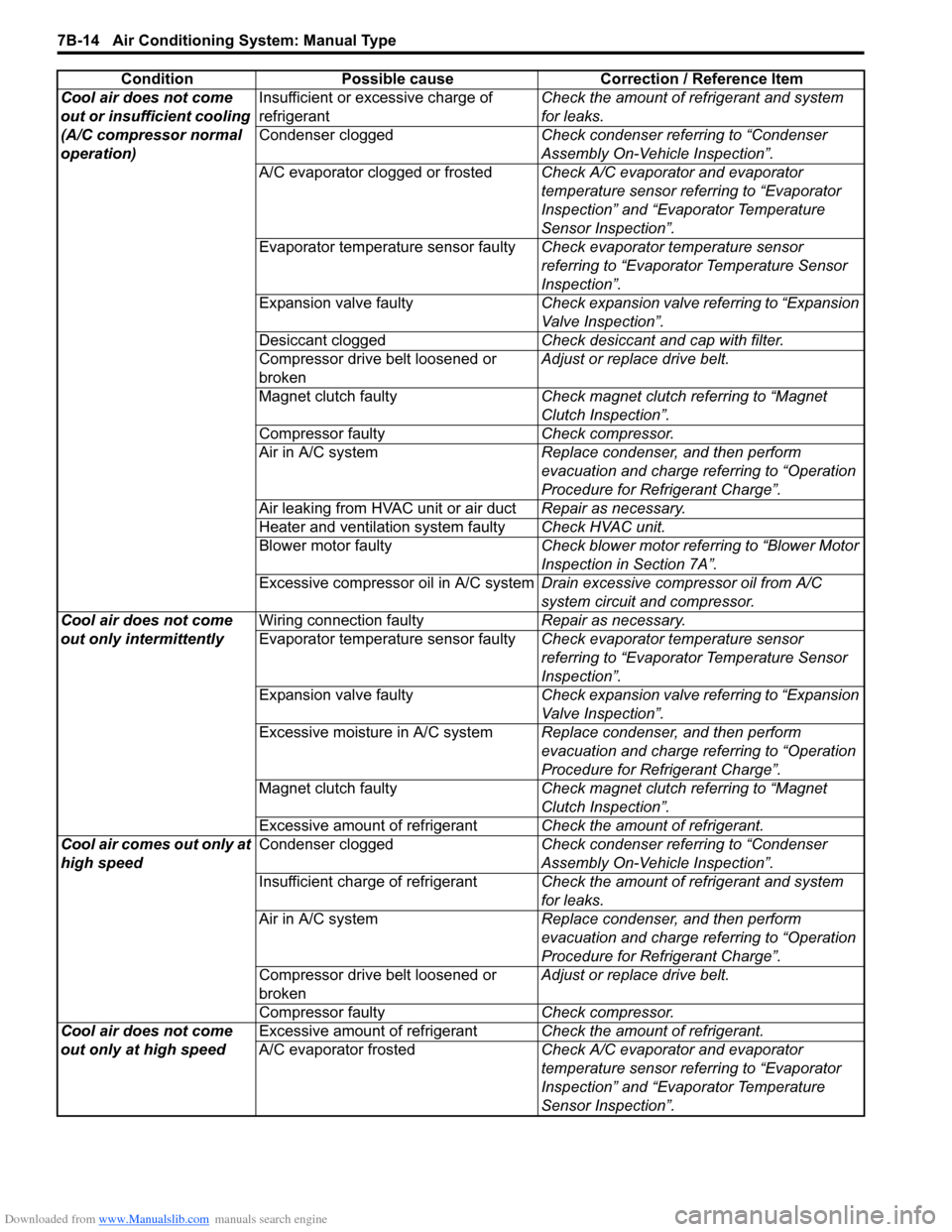

Cool air does not come

out or insufficient cooling

(A/C compressor normal

operation)Insufficient or excessive charge of

refrigerantCheck the amount of refrigerant and system

for leaks.

Condenser cloggedCheck condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

Expansion valve faultyCheck expansion valve referring to “Expansion

Valve Inspection”.

Desiccant cloggedCheck desiccant and cap with filter.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faultyCheck compressor.

Air in A/C systemReplace condenser, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air ductRepair as necessary.

Heater and ventilation system faultyCheck HVAC unit.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C systemDrain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittentlyWiring connection faultyRepair as necessary.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

Expansion valve faultyCheck expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C systemReplace condenser, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerantCheck the amount of refrigerant.

Cool air comes out only at

high speedCondenser cloggedCheck condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerantCheck the amount of refrigerant and system

for leaks.

Air in A/C systemReplace condenser, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Compressor faultyCheck compressor.

Cool air does not come

out only at high speedExcessive amount of refrigerantCheck the amount of refrigerant.

A/C evaporator frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”. Condition Possible cause Correction / Reference Item

Page 960 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-20 Air Conditioning System: Manual Type

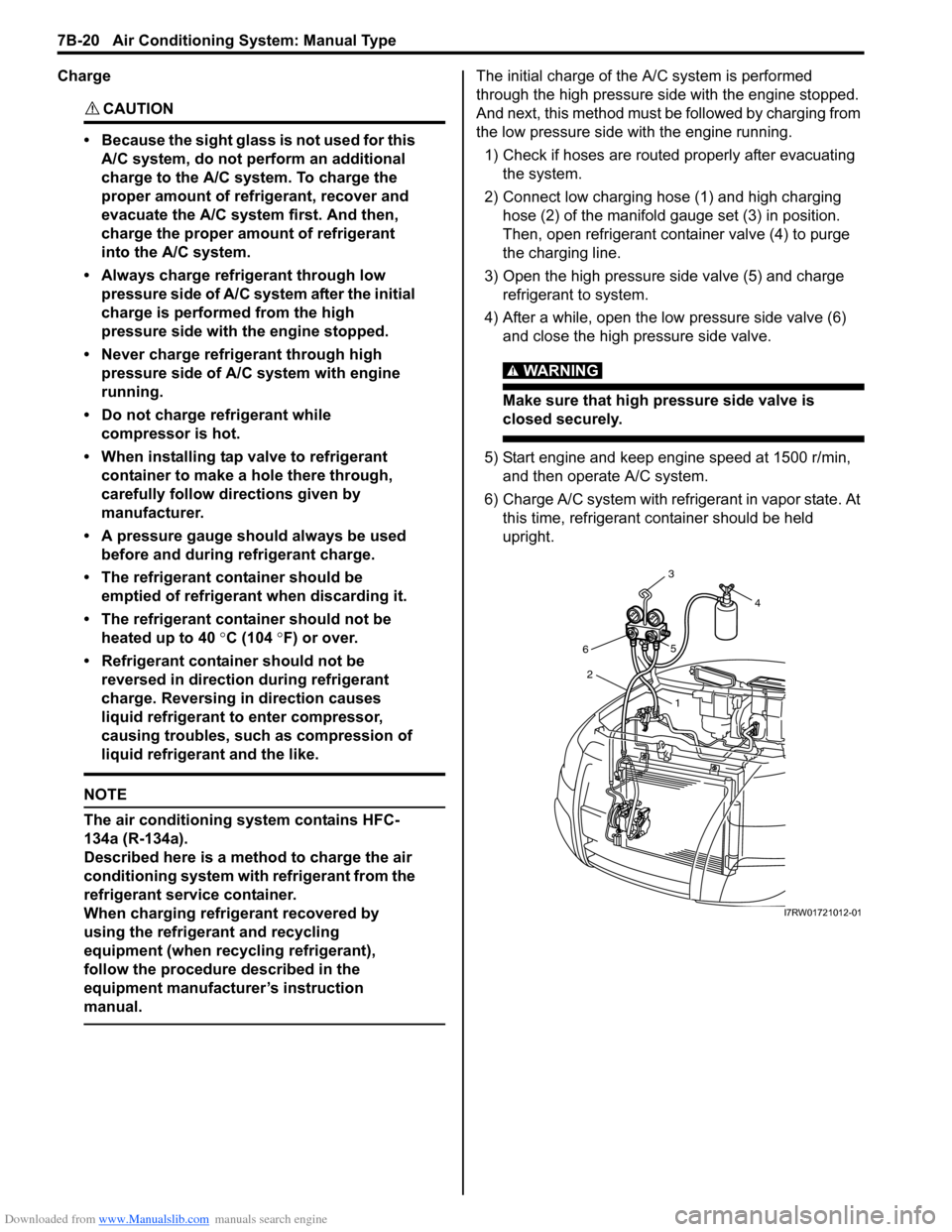

Charge

CAUTION!

• Because the sight glass is not used for this

A/C system, do not perform an additional

charge to the A/C system. To charge the

proper amount of refrigerant, recover and

evacuate the A/C system first. And then,

charge the proper amount of refrigerant

into the A/C system.

• Always charge refrigerant through low

pressure side of A/C system after the initial

charge is performed from the high

pressure side with the engine stopped.

• Never charge refrigerant through high

pressure side of A/C system with engine

running.

• Do not charge refrigerant while

compressor is hot.

• When installing tap valve to refrigerant

container to make a hole there through,

carefully follow directions given by

manufacturer.

• A pressure gauge should always be used

before and during refrigerant charge.

• The refrigerant container should be

emptied of refrigerant when discarding it.

• The refrigerant container should not be

heated up to 40 °C (104 °F) or over.

• Refrigerant container should not be

reversed in direction during refrigerant

charge. Reversing in direction causes

liquid refrigerant to enter compressor,

causing troubles, such as compression of

liquid refrigerant and the like.

NOTE

The air conditioning system contains HFC-

134a (R-134a).

Described here is a method to charge the air

conditioning system with refrigerant from the

refrigerant service container.

When charging refrigerant recovered by

using the refrigerant and recycling

equipment (when recycling refrigerant),

follow the procedure described in the

equipment manufacturer’s instruction

manual.

The initial charge of the A/C system is performed

through the high pressure side with the engine stopped.

And next, this method must be followed by charging from

the low pressure side with the engine running.

1) Check if hoses are routed properly after evacuating

the system.

2) Connect low charging hose (1) and high charging

hose (2) of the manifold gauge set (3) in position.

Then, open refrigerant container valve (4) to purge

the charging line.

3) Open the high pressure side valve (5) and charge

refrigerant to system.

4) After a while, open the low pressure side valve (6)

and close the high pressure side valve.

WARNING!

Make sure that high pressure side valve is

closed securely.

5) Start engine and keep engine speed at 1500 r/min,

and then operate A/C system.

6) Charge A/C system with refrigerant in vapor state. At

this time, refrigerant container should be held

upright.

4

3

6

2

1 5

I7RW01721012-01

Page 965 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-25

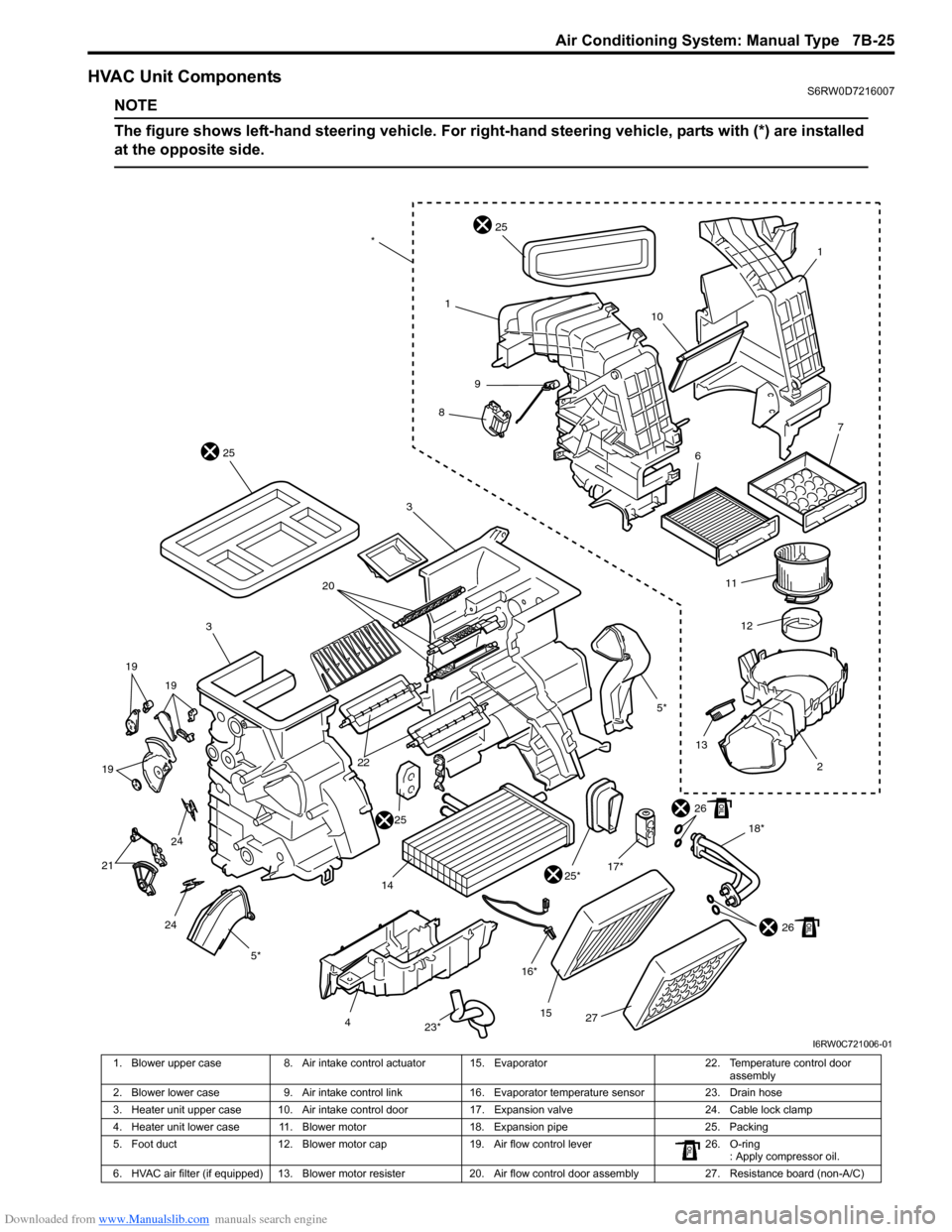

HVAC Unit ComponentsS6RW0D7216007

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

1

10

1

9

8

25

25

3

20

3

19 19

19

24

24 21

4

23*27 15 16* 14

25*18*2

2526

17*1312 11

5*22

67

*

26

5*

I6RW0C721006-01

1. Blower upper case 8. Air intake control actuator 15. Evaporator 22. Temperature control door

assembly

2. Blower lower case 9. Air intake control link 16. Evaporator temperature sensor 23. Drain hose

3. Heater unit upper case 10. Air intake control door 17. Expansion valve 24. Cable lock clamp

4. Heater unit lower case 11. Blower motor 18. Expansion pipe 25. Packing

5. Foot duct 12. Blower motor cap 19. Air flow control lever 26. O-ring

: Apply compressor oil.

6. HVAC air filter (if equipped) 13. Blower motor resister 20. Air flow control door assembly 27. Resistance board (non-A/C)

Page 966 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-26 Air Conditioning System: Manual Type

HVAC Unit Removal and InstallationS6RW0D7216008

Removal

1) Recover refrigerant from A/C system with recovery

and recycling equipment referring to “Recovery” in

“Operation Procedure for Refrigerant Charge”.

2) Drain engine coolant referring to “Cooling System

Draining in Section 1F”, and then disconnect heater

hoses from HVAC unit.

3) Remove cowl top cover from vehicle body referring

to “Cowl Top and Front Lower Crossmember

Components in Section 9K”

4) Remove instrument panel from vehicle body

referring to “Instrument Panel Removal and

Installation in Section 9C”.

5) Loosen a bolt (1) and remove pipes from expansion

valve (2).6) Remove HVAC unit (1) from vehicle body by

removing nuts (2).

7. Cover (without HVAC air

filter)14. Heater core 21. Temperature control lever : Do not reuse.

1

2

I7RW01721016-01

2

2

2

1

I7RW01710003-01