Abs module SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1474 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-1 Body Electrical Control System:

Control Systems

Body Electrical Control System

Precautions

Precautions in Diagnosing TroubleS6RW0DA200001

• Diagnostic information stored in BCM memory can be cleared as well as checked by using SUZUKI scan tool.

Before using scan tool, read its Operator’s (Instruction) Manual carefully to have good understanding as to what

functions are available and how to use it.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection and observe what is

written there.

• Communication of ECM, TCM (A/T model), ABS control module, 4WD control module (if equipped), keyless start

control module (if equipped), combination meter and BCM is established by CAN (Controller Area Network). For

detail of CAN communication for BCM, refer to “CAN Communication System Description”. Therefore, handle CAN

communication line with care referring to “Precaution for CAN Communication System in Section 00”.

General Description

BCM General DescriptionS6RW0DA201001

The Body electrical Control Module (BCM) is

incorporated in junction block. Do not attempt removal of

BCM from junction block as it may cause contact failure.

The BCM incorporates relays and controllers which are

used for the following systems and controls them.

• Power door lock (if equipped)

• Keyless entry (if equipped)

• Door lock function of keyless start system (if

equipped)

• Rear wiper

• Combination meter

• Interior light• Warning buzzer

• Rear end door window defogger and door mirror

heater (if equipped)

• Rear end door opener (if equipped)

• Theft deterrent light

Also, the BCM has a function to cause the interior light

and open door warning light in the combination meter to

turn off when any door is left open for longer than 15

minutes to reduce wasteful battery consumption.

In addition, it is possible to check operation of actuator

which is controlled by BCM by using the output test

function of SUZUKI scan tool to operate actuator

simulatively.

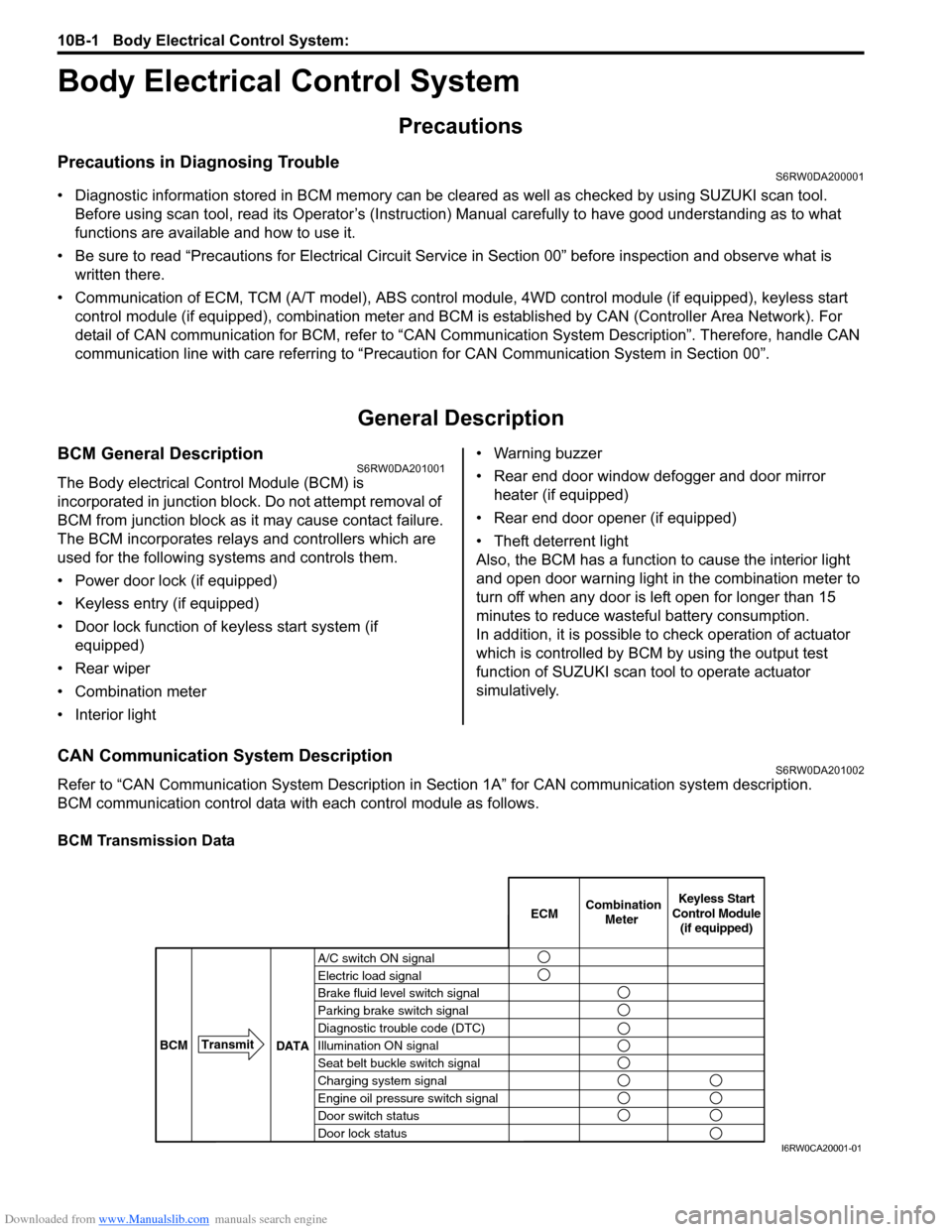

CAN Communication System DescriptionS6RW0DA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

BCM communication control data with each control module as follows.

BCM Transmission Data

A/C switch ON signal

Electric load signal

Brake fluid level switch signal

Parking brake switch signal

Diagnostic trouble code (DTC)

Illumination ON signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Door switch status

Door lock statusECMKeyless Start

Control Module

(if equipped) Combination

Meter

BCMTransmit

DATA

I6RW0CA20001-01

Page 1478 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-5 Body Electrical Control System:

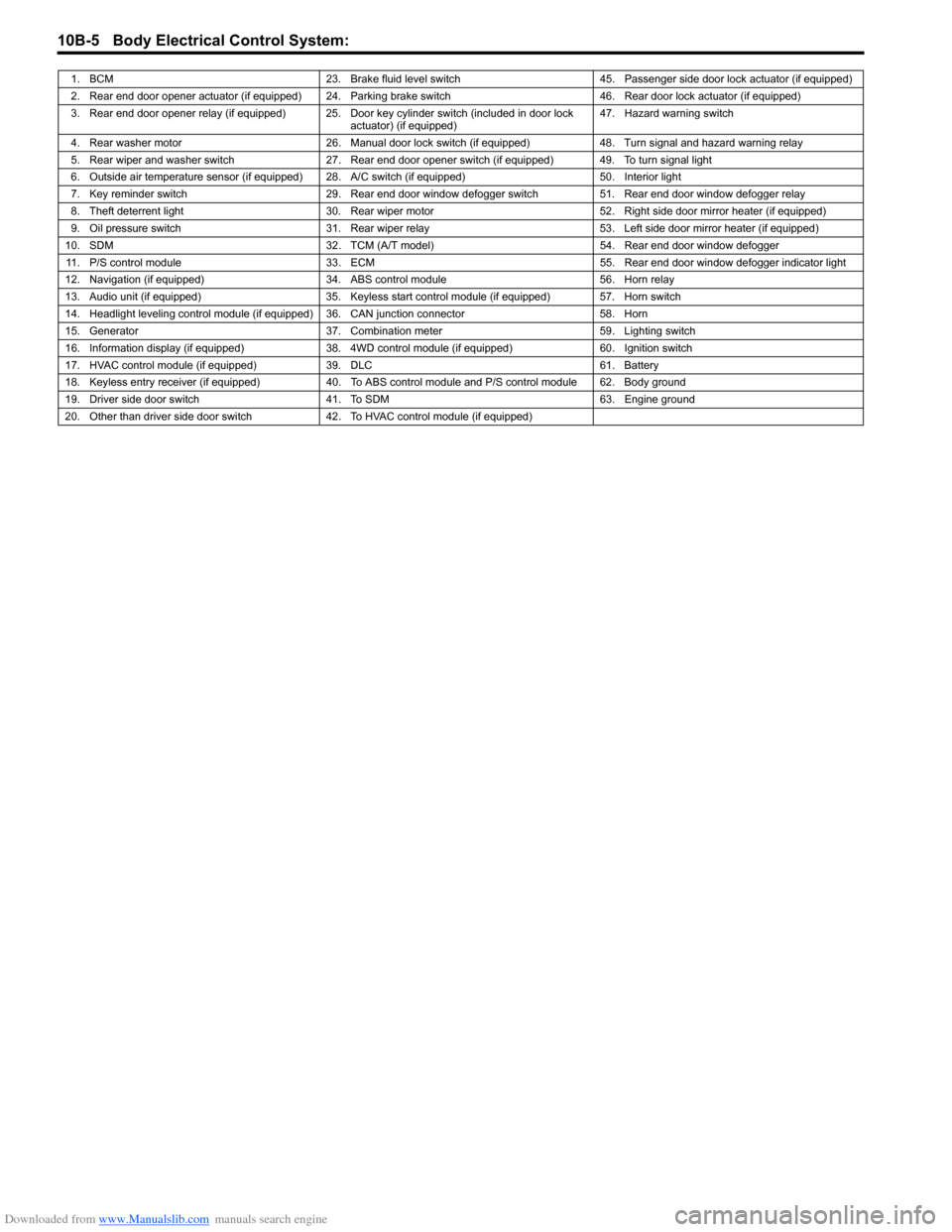

1. BCM 23. Brake fluid level switch 45. Passenger side door lock actuator (if equipped)

2. Rear end door opener actuator (if equipped) 24. Parking brake switch 46. Rear door lock actuator (if equipped)

3. Rear end door opener relay (if equipped) 25. Door key cylinder switch (included in door lock

actuator) (if equipped)47. Hazard warning switch

4. Rear washer motor 26. Manual door lock switch (if equipped) 48. Turn signal and hazard warning relay

5. Rear wiper and washer switch 27. Rear end door opener switch (if equipped) 49. To turn signal light

6. Outside air temperature sensor (if equipped) 28. A/C switch (if equipped) 50. Interior light

7. Key reminder switch 29. Rear end door window defogger switch 51. Rear end door window defogger relay

8. Theft deterrent light 30. Rear wiper motor 52. Right side door mirror heater (if equipped)

9. Oil pressure switch 31. Rear wiper relay 53. Left side door mirror heater (if equipped)

10. SDM 32. TCM (A/T model) 54. Rear end door window defogger

11. P/S control module 33. ECM 55. Rear end door window defogger indicator light

12. Navigation (if equipped) 34. ABS control module 56. Horn relay

13. Audio unit (if equipped) 35. Keyless start control module (if equipped) 57. Horn switch

14. Headlight leveling control module (if equipped) 36. CAN junction connector 58. Horn

15. Generator 37. Combination meter 59. Lighting switch

16. Information display (if equipped) 38. 4WD control module (if equipped) 60. Ignition switch

17. HVAC control module (if equipped) 39. DLC 61. Battery

18. Keyless entry receiver (if equipped) 40. To ABS control module and P/S control module 62. Body ground

19. Driver side door switch 41. To SDM 63. Engine ground

20. Other than driver side door switch 42. To HVAC control module (if equipped)

Page 1495 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-22

BCM connector “E04”L01-10Driver side door lock

actuator control (Unlock) (if

equipped)10 – 14 VUnlock signal is output for driver side door

lock actuator

0 VUnlock signal is not output for driver side

door lock actuator

L01-11Rear end door opener

actuator control (if equipped)0 VRear end door actuator motor is not in

operation

10 – 14 V Rear end door actuator motor is in operation

L01-12Manual door lock switch

(Lock) (if equipped)10 – 14 VManual door lock switch is at any position

other than lock position

0 V Manual door lock switch is at lock position

L01-13 — — —

L01-14 Driver side seat belt switch*0 – 3 V

↑↓

10 – 14 VRefer to “Reference waveform No. 2: ”

0 VIgnition switch is at ON position and driver

side seat belt is unfastened

L01-15Door switch (other than

driver side door and rear end

door)10 – 14 VRear right and left side door and passenger

side door are closed

0 VAny one of the door is opened (except driver

side door and rear end door)

L01-16Driver side door key cylinder

switch (Lock) (if equipped)10 – 14 VDriver side door key cylinder switch is at any

position other than lock position

0 VDriver side door key cylinder switch is at lock

position

L01-17Driver side door key cylinder

switch (Unlock) (if equipped)10 – 14 VDriver side door key cylinder switch is at any

position other than unlock position

0 VDriver side door key cylinder switch is at

unlock position

L01-18 — — —

Terminal Circuit Normal voltage Condition

E04-1CAN communication line (high)

for ABS control module*2.5 – 3.6 V

Refer to “Reference waveform No. 3: ”

E04-2CAN communication line (low)

for ABS control module*1.6 – 2.5 V

E04-3 — — —

E04-4 Generator “L” terminal10 – 14 V Engine is running

0 V Ignition switch is at ON position

E04-5 Brake fluid level switch*0 – 3 V

↑↓

10 – 14 VRefer to “Reference waveform No. 1: ”

0 VIgnition switch is at ON position, parking brake

lever is released and brake fluid level is lower

than MIN level

E04-6 — — —

E04-7 — — —

E04-8Sensor ground for outside air

temperature sensor (if

equipped)0 V —

E04-9Serial communication line of

data link connector for ABS

control module7 – 12 V Ignition switch is at ON position

E04-10Outside air temperature sensor

(if equipped)About 1.5 VIgnition switch is at ON position and outside

air temperature approx. 20 °C (68

°F)

E04-11 Oil pressure switch*3 – 14 V Refer to “Reference waveform No. 4: ”

0 VIgnition switch is at ON position and engine is

at stop

E04-12 — — — Terminal Circuit Normal voltage Condition

Page 1499 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-26

Reference waveform No. 1

Parking brake or brake fluid level switch signal (1)

Reference waveform No. 2

Driver seat belt switch signal (1)Reference waveform No. 3

CAN communication signal

Reference waveform No. 4

Oil pressure switch signal (1) Measurement terminal Parking brake switch

CH2: “L01-6” to “G271-3”

Brake fluid level switch

CH2: “E04-5” to “G271-3”

Oscilloscope setting CH1: 5 V / DIV

TIME: 10 ms / DIV

Measurement

conditionParking brake switch:

• Ignition switch is at ON

position, parking brake lever

is released

Brake fluid level switch

• Ignition switch is at ON

position, brake fluid level is in

normal

Measurement terminal CH2: “L01-14” to “G271-3”

Oscilloscope setting CH2: 5 V/DIV

TIME: 4 ms/DIV

Measurement

conditionIgnition switch is at ON position

and driver side seat belt is

fastened

I4RS0AA20018-02

I4RS0AA20016-02

Measurement terminal CAN communication signal for

ABS control module

CH2: “E04-1” to “G271-3”

CH3: “E04-2” to “G271-3”

CAN communication signal for

DLC

CH2: “G04-3” to “G271-3”

CH3: “G04-1” to “G271-3”

CAN communication signal for

each control module

CH2: “G04-4” to “G271-3”

CH3: “G04-2” to “G271-3”

Oscilloscope setting CH2: 1 V/DIV

CH3: 1 V/DIV

TIME: 40 µs/ DIV

Measurement

conditionIgnition switch is at ON position

1. CAN communication line signal (High)

2. CAN communication line signal (Low)

Measurement terminal CH2: “E04-11” to “G271-3”

Oscilloscope setting CH2: 5 V / DIV

TIME: 10 ms / DIV

Measurement

conditionEngine is running and oil

pressure is in normal condition

I4RS0AA20017-02

I4RS0AA20018-02

Page 1503 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-1

Control Systems

Immobilizer Control System

Precautions

Precautions in Diagnosing TroublesS6RW0DA300001

• Before confirming the diagnostic trouble code (DTC),

do not disconnect connector from ECM, battery cable

from battery, ground wire harness, or main fuse. Such

disconnection will erase DTC stored in ECM.

• DTC stored in ECM memory can be checked as well

as cleared by using SUZUKI scan tool. Before using

SUZUKI scan tool, read its operator’s manual

carefully to know how to use it and what functions are

available.

• Be sure to read “Precautions for Electrical Circuit

Service in Section 00” before inspection.

• Communication of ECM, BCM, ABS control module,

TCM (if equipped), 4WD control module (if equipped),

keyless start control module (if equipped),

combination meter and DLC is established by CAN

(Controller Area Network). Therefore, handle CAN

communication lines with care referring to “Precaution

for CAN Communication System in Section 00”.

For CAN communication system, refer to description

on “CAN Communication System Description in

Section 1A”.

Precaution in Replacing ECMS6RW0DA300002

• If ECM is replaced with new or used one without

Immobilizer control function, the engine will not be

started. In case of the above, check if the newly

installed ECM has Immobilizer control function.

• After ECM is replaced with new one or used one, the

transponder code in the transponder built in the

ignition key has to be registered with ECM. Or, the

engine cannot be started up. For the registration

procedure, refer to “Procedure after ECM

Replacement”.

Precaution in Replacing Ignition KeyS6RW0DA300003

To register ignition key in case of replacing key(s) and/or

making spare key(s), the transponder code in the ignition

key is registered with ECM. Or the engine can not be

started up. For the registration procedure, refer to

“Registration of the Ignition Key”.

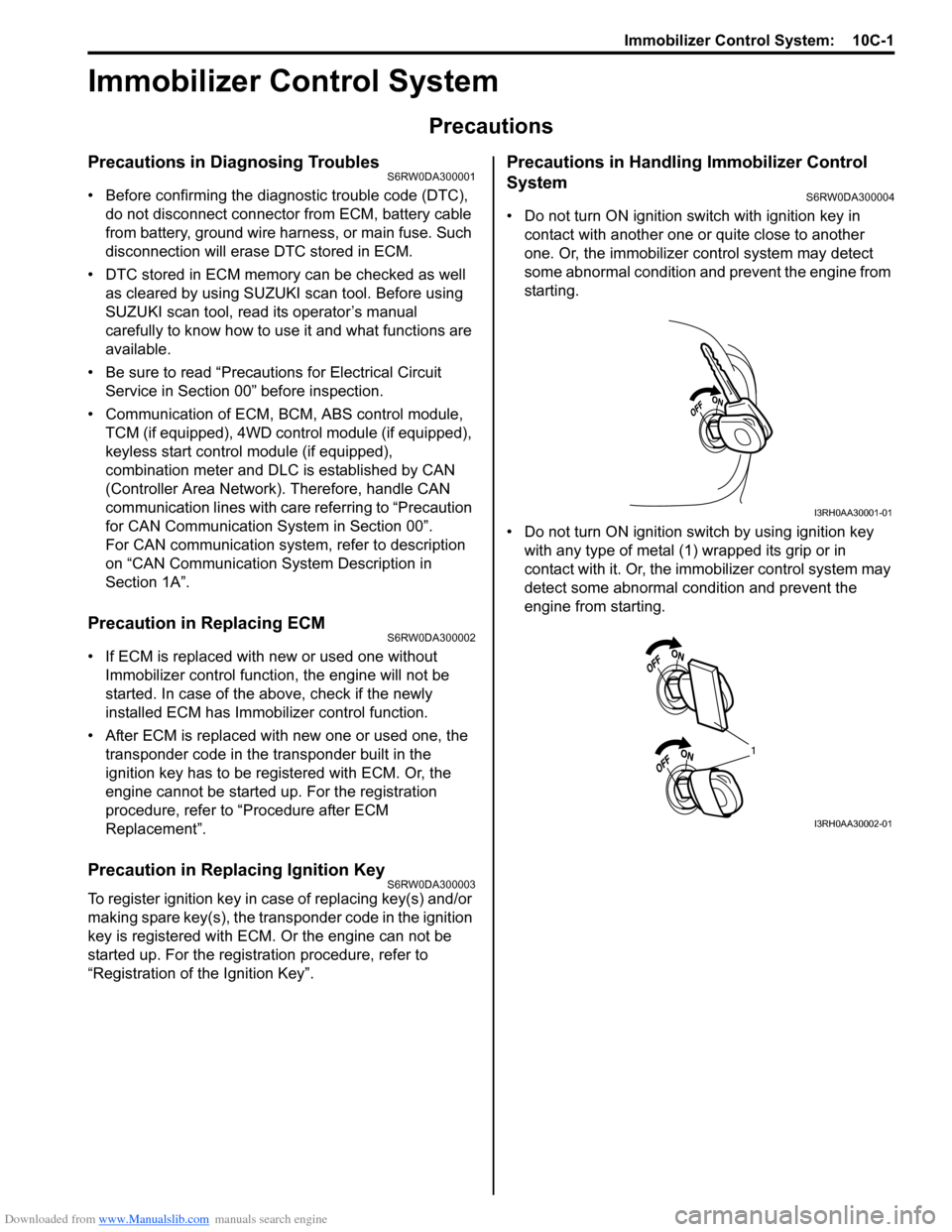

Precautions in Handling Immobilizer Control

System

S6RW0DA300004

• Do not turn ON ignition switch with ignition key in

contact with another one or quite close to another

one. Or, the immobilizer control system may detect

some abnormal condition and prevent the engine from

starting.

• Do not turn ON ignition switch by using ignition key

with any type of metal (1) wrapped its grip or in

contact with it. Or, the immobilizer control system may

detect some abnormal condition and prevent the

engine from starting.

I3RH0AA30001-01

1

I3RH0AA30002-01

Page 1505 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-3

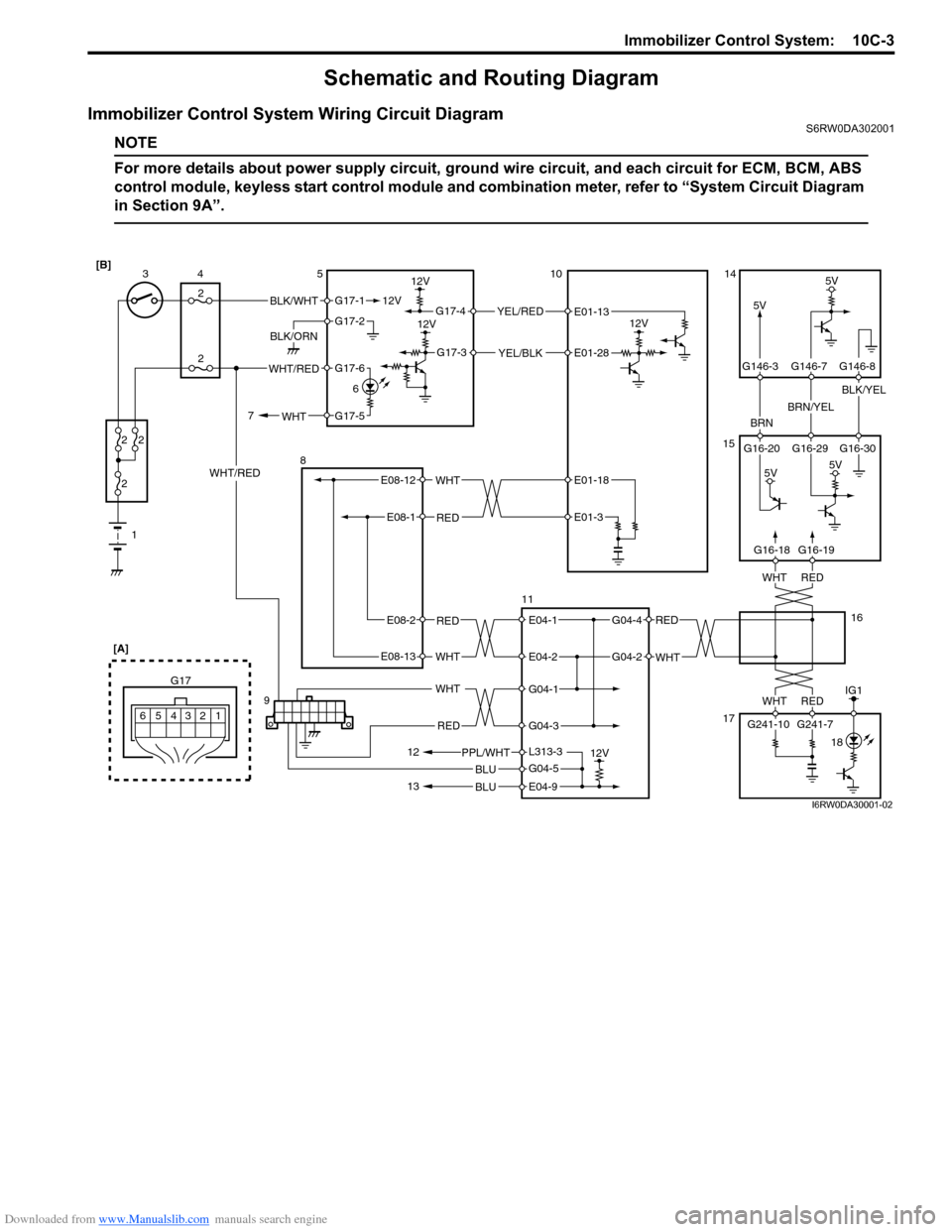

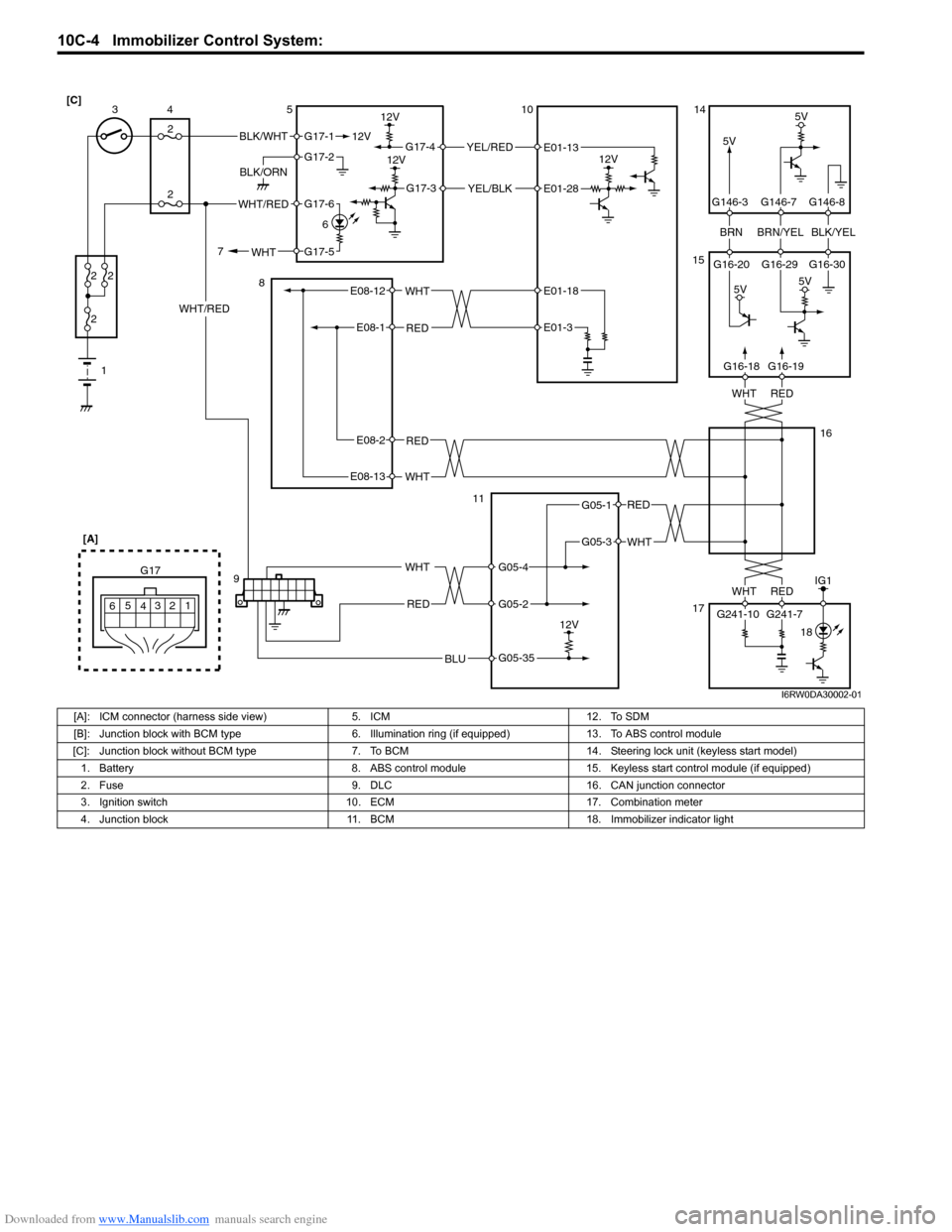

Schematic and Routing Diagram

Immobilizer Control System Wiring Circuit DiagramS6RW0DA302001

NOTE

For more details about power supply circuit, ground wire circuit, and each circuit for ECM, BCM, ABS

control module, keyless start control module and combination meter, refer to “System Circuit Diagram

in Section 9A”.

BLK/WHT

BLK/ORN12V

G17-1

G17-2

12V

5V

12V

12VYEL/RED

YEL/BLK

G17-4

G17-3

5V

BRN

BRN/YEL

BLK/YEL

1 2

22

2 34

251014

15

1 2 3

4 G17

[A]

5

6

G16-20 G16-29 G16-30 G146-3 G146-7 G146-8

WHT/RED

5V

5V

9

G16-18G16-19 E01-13

E01-28

BLU

BLU

RED

WHTE08-12

E08-1E01-18

E01-3

RED

WHTE08-13

E08-2E04-1

E04-2

WHT

RED

G04-1

G04-3

12V

E04-9

G04-5

PPL/WHTL313-3 8

11

12

13

G17-5WHT 76

G17-6WHT/RED

17

REDWHT

REDWHT

G241-10 G241-7

IG1

18

WHT

REDG04-4

G04-2

16 [B]

I6RW0DA30001-02

Page 1506 of 1556

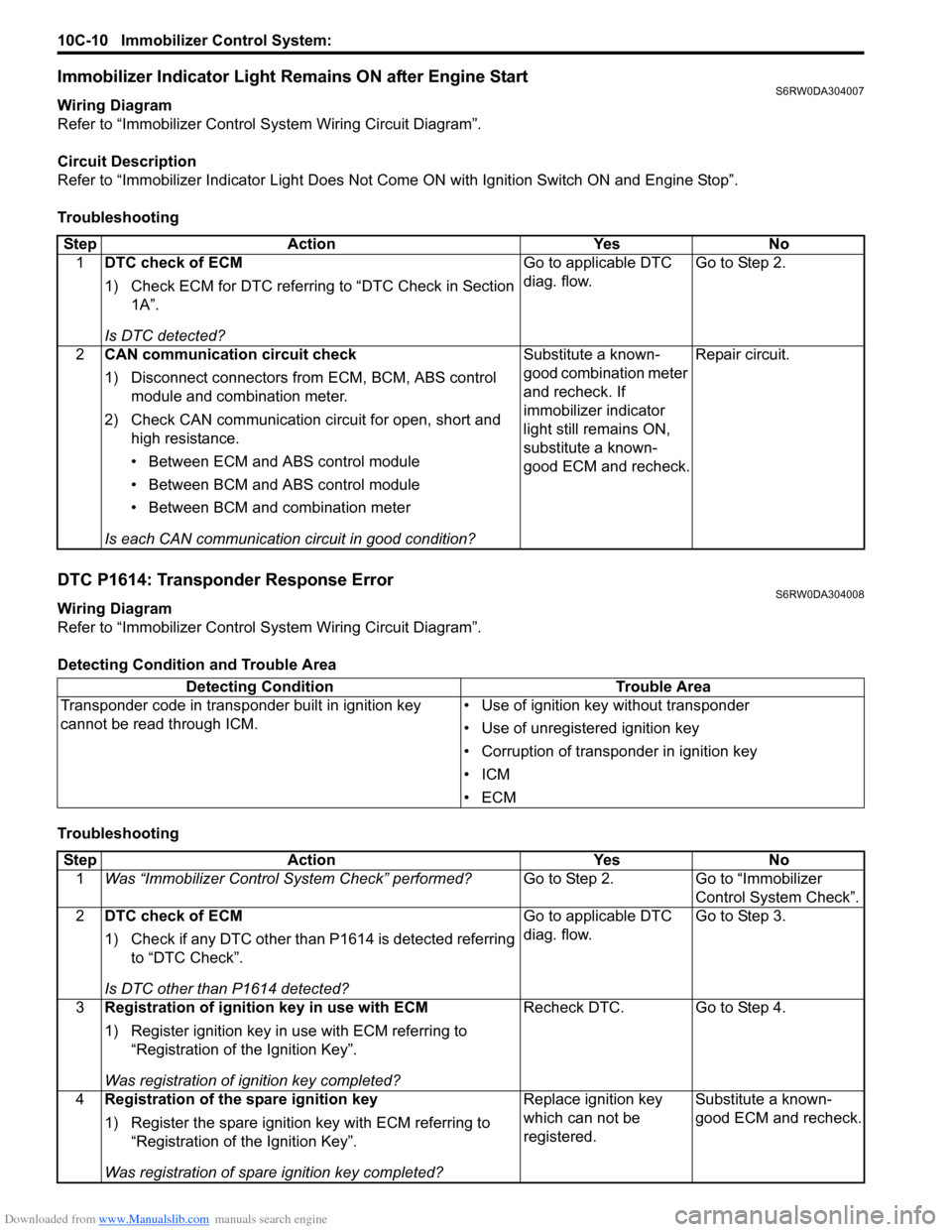

Downloaded from www.Manualslib.com manuals search engine 10C-4 Immobilizer Control System:

BLK/WHT

BLK/ORN12V

G17-1

G17-2

12V

5V

12V

12VYEL/RED

YEL/BLK

G17-4

G17-3

5V

BRNBRN/YELBLK/YEL

1 2

22

2 34

251014

15

1 2 3

4 G17

[A]

5

6

G16-20 G16-29 G16-30 G146-3 G146-7 G146-8

WHT/RED

5V

5V

9

G16-18G16-19 E01-13

E01-28

BLU

RED

WHTE08-12

E08-1E01-18

E01-3

RED

WHTE08-13

E08-2

WHT

RED

G05-4

G05-2

12V

G05-35 8

11

G17-5WHT 76

G17-6WHT/RED

17

REDWHT

REDWHT

G241-10 G241-7

IG1

18

WHT

REDG05-1

G05-3

16 [C]

I6RW0DA30002-01

[A]: ICM connector (harness side view) 5. ICM 12. To SDM

[B]: Junction block with BCM type 6. Illumination ring (if equipped) 13. To ABS control module

[C]: Junction block without BCM type 7. To BCM 14. Steering lock unit (keyless start model)

1. Battery 8. ABS control module 15. Keyless start control module (if equipped)

2. Fuse 9. DLC 16. CAN junction connector

3. Ignition switch 10. ECM 17. Combination meter

4. Junction block 11. BCM 18. Immobilizer indicator light

Page 1512 of 1556

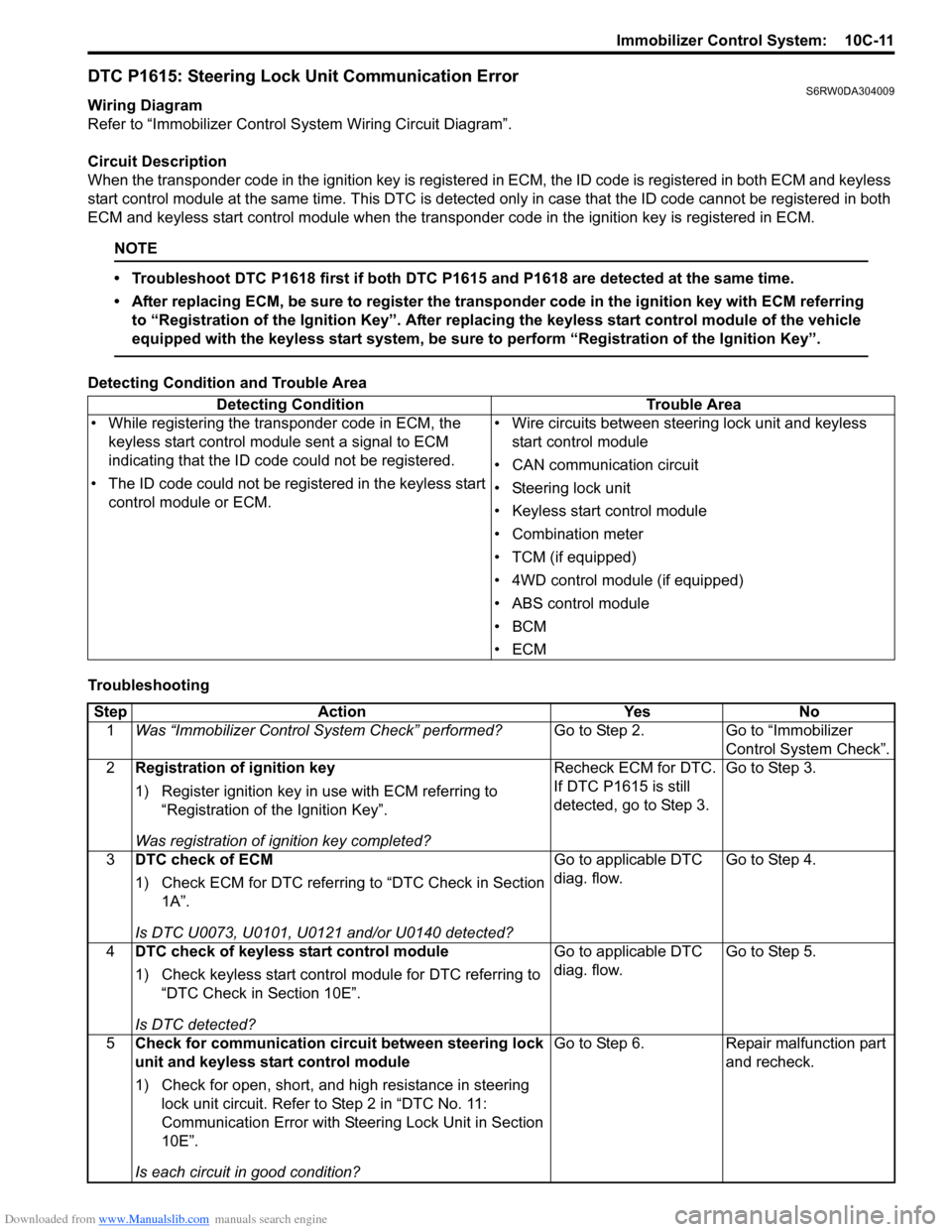

Downloaded from www.Manualslib.com manuals search engine 10C-10 Immobilizer Control System:

Immobilizer Indicator Light Remains ON after Engine StartS6RW0DA304007

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

Refer to “Immobilizer Indicator Light Does Not Come ON with Ignition Switch ON and Engine Stop”.

Troubleshooting

DTC P1614: Transponder Response ErrorS6RW0DA304008

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Detecting Condition and Trouble Area

TroubleshootingStep Action Yes No

1DTC check of ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is DTC detected?Go to applicable DTC

diag. flow.Go to Step 2.

2CAN communication circuit check

1) Disconnect connectors from ECM, BCM, ABS control

module and combination meter.

2) Check CAN communication circuit for open, short and

high resistance.

• Between ECM and ABS control module

• Between BCM and ABS control module

• Between BCM and combination meter

Is each CAN communication circuit in good condition?Substitute a known-

good combination meter

and recheck. If

immobilizer indicator

light still remains ON,

substitute a known-

good ECM and recheck.Repair circuit.

Detecting Condition Trouble Area

Transponder code in transponder built in ignition key

cannot be read through ICM.• Use of ignition key without transponder

• Use of unregistered ignition key

• Corruption of transponder in ignition key

•ICM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2DTC check of ECM

1) Check if any DTC other than P1614 is detected referring

to “DTC Check”.

Is DTC other than P1614 detected?Go to applicable DTC

diag. flow.Go to Step 3.

3Registration of ignition key in use with ECM

1) Register ignition key in use with ECM referring to

“Registration of the Ignition Key”.

Was registration of ignition key completed?Recheck DTC. Go to Step 4.

4Registration of the spare ignition key

1) Register the spare ignition key with ECM referring to

“Registration of the Ignition Key”.

Was registration of spare ignition key completed?Replace ignition key

which can not be

registered.Substitute a known-

good ECM and recheck.

Page 1513 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-11

DTC P1615: Steering Lock Unit Communication ErrorS6RW0DA304009

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Circuit Description

When the transponder code in the ignition key is registered in ECM, the ID code is registered in both ECM and keyless

start control module at the same time. This DTC is detected only in case that the ID code cannot be registered in both

ECM and keyless start control module when the transponder code in the ignition key is registered in ECM.

NOTE

• Troubleshoot DTC P1618 first if both DTC P1615 and P1618 are detected at the same time.

• After replacing ECM, be sure to register the transponder code in the ignition key with ECM referring

to “Registration of the Ignition Key”. After replacing the keyless start control module of the vehicle

equipped with the keyless start system, be sure to perform “Registration of the Ignition Key”.

Detecting Condition and Trouble Area

TroubleshootingDetecting Condition Trouble Area

• While registering the transponder code in ECM, the

keyless start control module sent a signal to ECM

indicating that the ID code could not be registered.

• The ID code could not be registered in the keyless start

control module or ECM.• Wire circuits between steering lock unit and keyless

start control module

• CAN communication circuit

• Steering lock unit

• Keyless start control module

• Combination meter

• TCM (if equipped)

• 4WD control module (if equipped)

• ABS control module

•BCM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2Registration of ignition key

1) Register ignition key in use with ECM referring to

“Registration of the Ignition Key”.

Was registration of ignition key completed?Recheck ECM for DTC.

If DTC P1615 is still

detected, go to Step 3.Go to Step 3.

3DTC check of ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is DTC U0073, U0101, U0121 and/or U0140 detected?Go to applicable DTC

diag. flow.Go to Step 4.

4DTC check of keyless start control module

1) Check keyless start control module for DTC referring to

“DTC Check in Section 10E”.

Is DTC detected?Go to applicable DTC

diag. flow.Go to Step 5.

5Check for communication circuit between steering lock

unit and keyless start control module

1) Check for open, short, and high resistance in steering

lock unit circuit. Refer to Step 2 in “DTC No. 11:

Communication Error with Steering Lock Unit in Section

10E”.

Is each circuit in good condition?Go to Step 6. Repair malfunction part

and recheck.

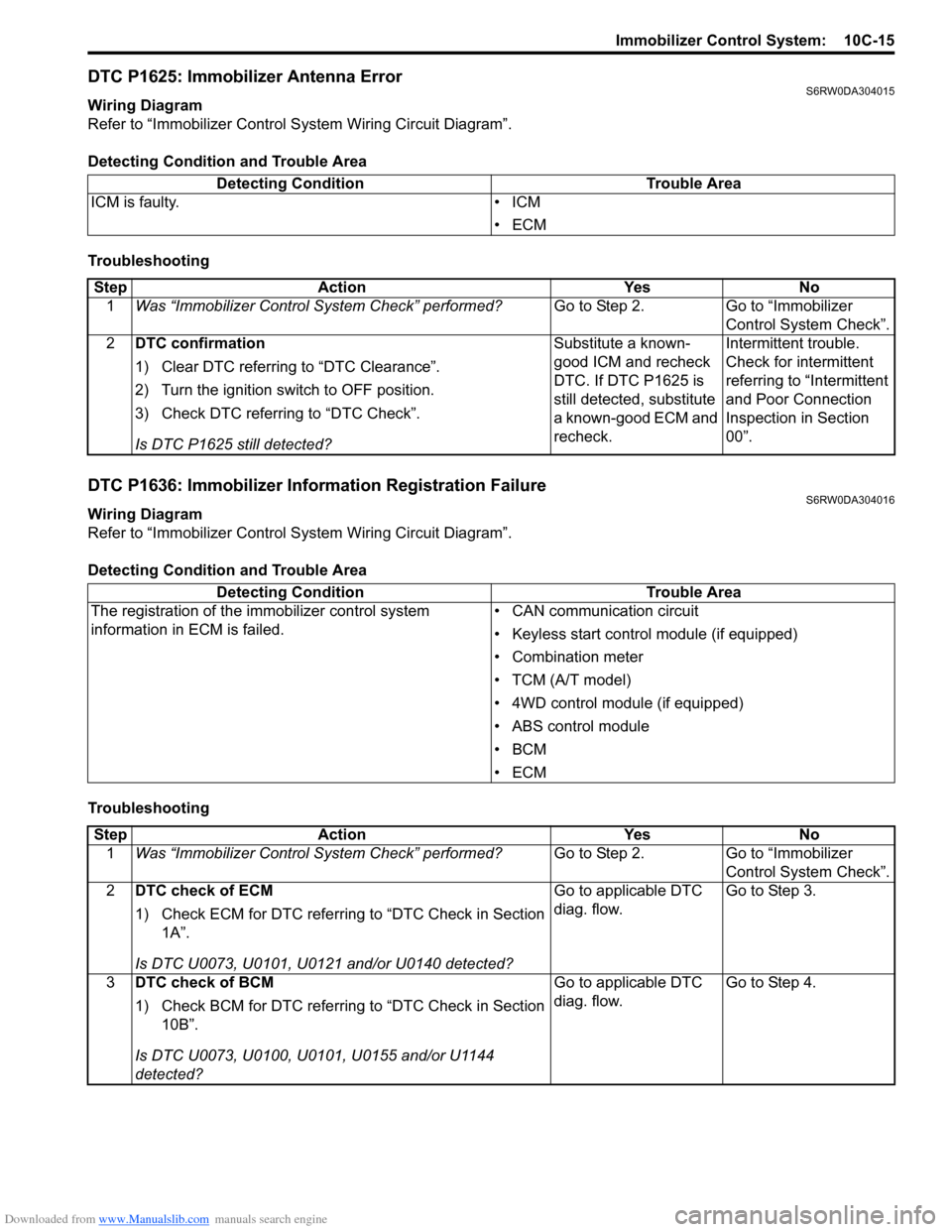

Page 1517 of 1556

Downloaded from www.Manualslib.com manuals search engine Immobilizer Control System: 10C-15

DTC P1625: Immobilizer Antenna ErrorS6RW0DA304015

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Detecting Condition and Trouble Area

Troubleshooting

DTC P1636: Immobilizer Information Registration FailureS6RW0DA304016

Wiring Diagram

Refer to “Immobilizer Control System Wiring Circuit Diagram”.

Detecting Condition and Trouble Area

TroubleshootingDetecting Condition Trouble Area

ICM is faulty. • ICM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2DTC confirmation

1) Clear DTC referring to “DTC Clearance”.

2) Turn the ignition switch to OFF position.

3) Check DTC referring to “DTC Check”.

Is DTC P1625 still detected?Substitute a known-

good ICM and recheck

DTC. If DTC P1625 is

still detected, substitute

a known-good ECM and

recheck.Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Detecting Condition Trouble Area

The registration of the immobilizer control system

information in ECM is failed.• CAN communication circuit

• Keyless start control module (if equipped)

• Combination meter

• TCM (A/T model)

• 4WD control module (if equipped)

• ABS control module

•BCM

•ECM

Step Action Yes No

1Was “Immobilizer Control System Check” performed?Go to Step 2. Go to “Immobilizer

Control System Check”.

2DTC check of ECM

1) Check ECM for DTC referring to “DTC Check in Section

1A”.

Is DTC U0073, U0101, U0121 and/or U0140 detected?Go to applicable DTC

diag. flow.Go to Step 3.

3DTC check of BCM

1) Check BCM for DTC referring to “DTC Check in Section

10B”.

Is DTC U0073, U0100, U0101, U0155 and/or U1144

detected?Go to applicable DTC

diag. flow.Go to Step 4.