diagram SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 712 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-64 Automatic Transmission/Transaxle:

DTC P0973 / P0976: Shift Solenoid-A (No.1) Control Circuit Low / Shift Solenoid-B (No.2) Control

Circuit Low

S6RW0D5104032

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine shift select lever to “D” range.

4) Start vehicle and increase vehicle speed until gear position reaches 3rd or 4th gear.

5) Decrease vehicle speed and stop vehicle.

6) Check DTC.

12V

12VBRNC06-16

C06-15BLK/YEL

41

2

3

16 15

C06C07

[A]

I6RW0B510014-01

1. TCM 3. Shift solenoid valve-B (No.2)

2. Shift solenoid valve-A (No.1) [A]: Terminal arrangement of TCM connector (Viewed from harness side)

DTC detecting condition Trouble area

Voltage of shift solenoid valve TCM terminal is low although

TCM is commanding shift solenoid to turn ON• Shift solenoid valve circuit shorted to ground

• Malfunction of shift solenoid valve

•TCM

Page 714 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-66 Automatic Transmission/Transaxle:

DTC P0974 / P0977: Shift Solenoid-A (No.1) / Shift Solenoid-B (No.2) Control Circuit HighS6RW0D5104033

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine and shift select lever to “D” range.

4) Start vehicle and increase vehicle speed until gear position reaches 3rd or 4th gear.

5) Decrease vehicle speed and stop vehicle.

6) Check DTC.

1. TCM 3. Shift solenoid valve-B (No.2) [A]: Terminal arrangement of TCM connector (viewed from harness side)

2. Shift solenoid valve-A (No.1) 4. A/T

DTC detecting condition Trouble area

Voltage of shift solenoid valve TCM terminal is high although

TCM is commanding shift solenoid to turn OFF• Shift solenoid valve circuit open or shorted to power

circuit

• Malfunction of shift solenoid valve

•TCM

12V

12VBRNC06-16

C06-15BLK/YEL

41

2

3

16 15

C06C07

[A]

I6RW0B510014-01

Page 716 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-68 Automatic Transmission/Transaxle:

DTC P1702: Internal Control Module Memory Check Sum ErrorS6RW0D5104034

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTC in TCM memory.

3) After 10 seconds passed from turning ignition switch ON, check DTC.

DTC Troubleshooting

DTC P1723: Range Select Switch MalfunctionS6RW0D5104036

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF.

2) Clear DTCs in TCM and ECM memories by using scan tool and turn ignition switch ON.

3) Shift select lever to each of “L”, “2”, “3”, “D”, “N”, “R” and “P” ranges for 20 seconds each.

4) Check DTC, pending DTC and freeze-frame data.DTC detecting condition Trouble area

Calculation of current data stored in TCM is not correct

comparing with pre-stored checking data in TCM.TCM

Step Action Yes No

1Is DTC P1702 detected after performing “DTC Confirmation

Procedure”?Faulty TCM.

Replace TCM.Could be a temporary

malfunction of TCM.

1. “3” position switch 2. TCM [A]: TCM connector (viewed from harness side)

DTC detecting condition Trouble area

“3” position switch ON signal is inputted although

transmission range switch signal is inputted P, R, N or L.

range.• “3” position switch or its circuit malfunction

•TCM

C06

9 C07

[A]

12V

C07-9YEL

12

I6RW0B510015-01

Page 718 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-70 Automatic Transmission/Transaxle:

DTC P2762: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit Range /

Performance

S6RW0D5104050

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed for 30 seconds or more.

5) Stop vehicle and check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Difference between actual current of TCC solenoid valve

circuit and current of TCC solenoid valve circuit calculated by

ECM is more than specification.• TCC solenoid valve or its circuit malfunction

•TCM

Page 720 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-72 Automatic Transmission/Transaxle:

DTC P2763: Torque Converter Clutch (TCC) Pressure Control Solenoid Control Circuit HighS6RW0D5104042

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 10 seconds or more.

5) Check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC solenoid valve TCM terminal is high although

TCM is commanding TCC solenoid valve to turn OFF.• TCC solenoid valve circuit shorted to ground

• Malfunction of TCC solenoid valve

•TCM

Page 722 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-74 Automatic Transmission/Transaxle:

DTC P2764: Torque Converter Clutch (TCC) Circuit Pressure Control Solenoid Control Circuit LowS6RW0D5104043

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory.

3) Start engine.

4) Keep engine running at idle speed in “P” range for 20 seconds or more.

5) Check DTC.

12V

C06-5

C06-3

WHT/BLU

WHT/BLK

3

1

2

53

C06C07

[A]

I6RW0D510007-01

1. TCM 3. A/T

2. TCC solenoid valve [A]: Terminal arrangement of TCM connector (viewed from harness side)

DTC detecting condition Trouble area

Voltage of TCC solenoid valve TCM terminal is low although

TCM is commanding TCC solenoid valve to turn ON.• TCC solenoid valve circuit shorted to ground

• Malfunction of TCC solenoid valve

•TCM

Page 728 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-80 Automatic Transmission/Transaxle:

Reference waveform No. 5

Output shaft speed sensor (VSS) signal at vehicle speed

60 km/h (37 mile/h).

TCM Power and Ground Circuit CheckS6RW0D5104045

Wiring DiagramMeasurement

terminalCH1: “C07-25” to “C06-1”

Oscilloscope

settingCH1: 5 V/DIV

TIME: 20 ms/DIV

Measurement

condition• After warmed up to normal

operating temperature

• Drive vehicle at 60 km/h (37

mile/h).

I3RM0B510028-01

BLK

BLK

BLK

C06-1

C06-23

C06-6YEL/BLKYEL/BLU

LT GRN/BLK

+BB

C06-24WHT/RED1

23

6

24 231

C06C07

[A]

I6RW0B510019-01

1. TCM 3. Ignition switch

2. A/T relay [A]: Terminal arrangement of TCM connector (viewed from harness side)

Page 865 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosis.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-1

Steering Symptom Diagnosis .............................. 6A-1

Steering System Inspection ................................ 6A-2

Steering Wheel and Column................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and

Column.............................................................. 6B-1

General Description ............................................. 6B-1

Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2

Checking Steering Column for Accident

Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3

Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and

Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Column Removal and Installation ......... 6B-6

Steering Column Inspection ................................ 6B-8

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)...... 6B-8

Steering Lock Assembly (Ignition Switch)

Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and

Installation ....................................................... 6B-10

Specifications..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipment ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1

P/S System Note ................................................. 6C-1

Precautions in Diagnosing Troubles ................... 6C-1General Description .............................................6C-2

P/S System Description ......................................6C-2

EPS Diagnosis General Description ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4

EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5

EPS System Check .............................................6C-5

“EPS” Warning Light Check ................................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Visual Inspection ...............................................6C-11

Scan Tool Data .................................................6C-12

P/S System Symptom Diagnosis ......................6C-13

DLC and Its Communication Check (No

communication to P/S Control Module)...........6C-14

“EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine

Starts ...............................................................6C-16

“EPS” Warning Light Remains ON Steady

after Engine Starts ..........................................6C-18

DTC C1111 / C1113 / C1115: Torque Sensor

Circuit Failure ..................................................6C-19

DTC C1116: Steering Torque Sensor Power

Supply Circuit ..................................................6C-21

DTC C1121 / C1123 / C1124: Vehicle Speed

Signal Circuit Failure .......................................6C-22

DTC C1122: Engine Speed Signal....................6C-24

DTC C1141 / C1142 / C1143 / C1145: Motor

Circuit Failure ..................................................6C-26

DTC C1153: P/S Control Module Power

Supply Circuit ..................................................6C-27

DTC C1155: P/S Control Module Internal

Failure .............................................................6C-28

P/S Control Module Power Supply and

Ground Circuit Check ......................................6C-29

Inspection of P/S Control Module and Its

Circuits ............................................................6C-30

Steering Wheel Play Check ..............................6C-34

Steering Force Check .......................................6C-34

Repair Instructions ............................................6C-35

Steering Gear Case Assembly Components ....6C-35

Tie-Rod End Boot On-Vehicle Inspection .........6C-36

Tie-Rod End Removal and Installation..............6C-36

Page 884 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11](/img/20/7612/w960_7612-883.png)

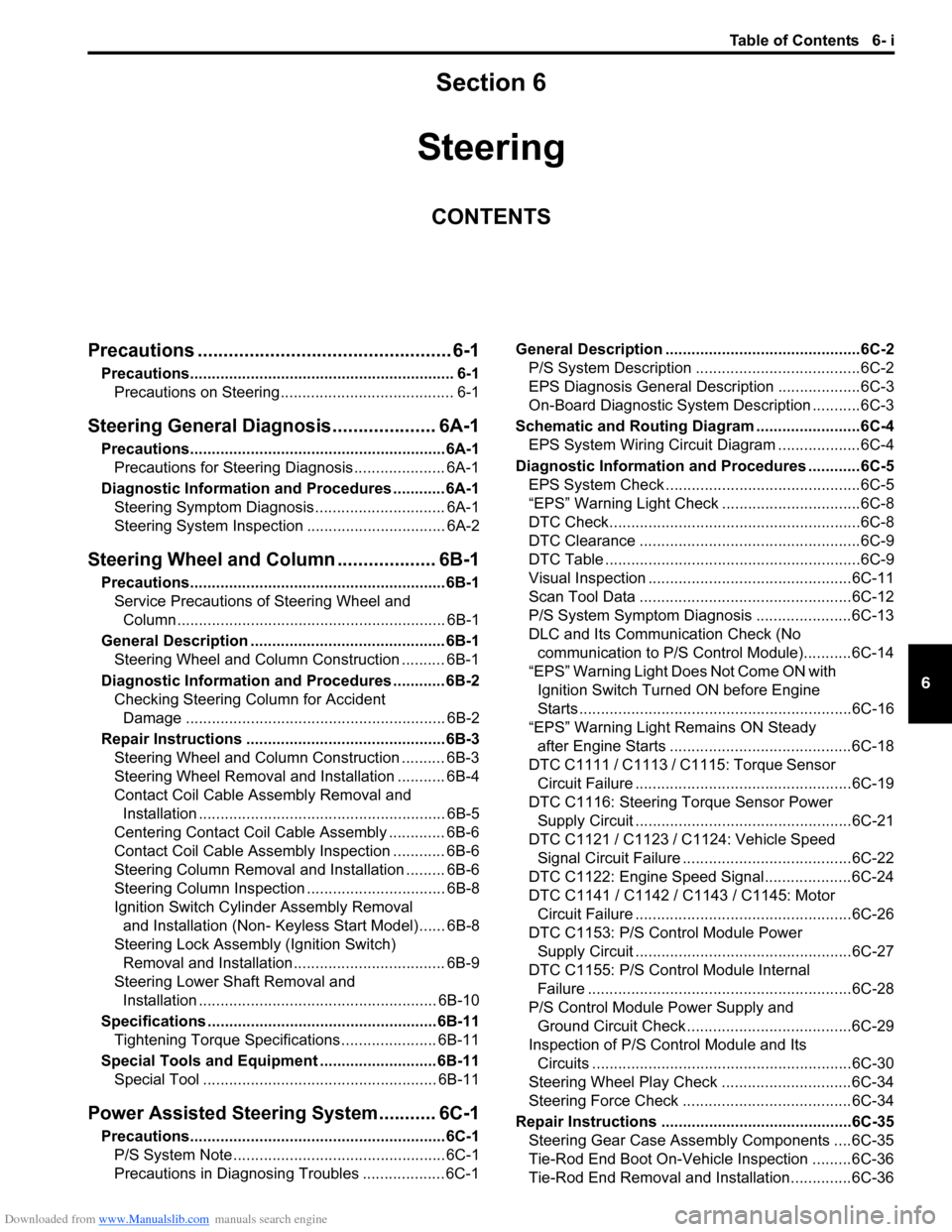

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11

10 12 13

141516

17 18 19201

2

[B]

1

2

[C] [D]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[F][E]

12

BRN RED/

BLU GRY LT GRN/

BLK

BLK

RED

WHT GRN

BLK

E11-1

E11-5

E11-14

E11-12

[J]:E01-44E01-4

[J]:E01-27E01-26

E12-1

E12-2

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

G241-25G241-31

RED/BLK

11

12

1314 3 18

20

21

7 19

4 12

22

12V

E13-2BLK

9V

REDE11-20

12V

12V

E61-2

E61-1

610

55

5V

8

E11-115V

PPL

E11-4

9

23

+BB

BLU/

WHTE04-9

1524YELE11-18E31-5

E31-2

E31-39V

3V

E31-4

E31-1IG11617

C07-25

[H]

[G]

G04-15

[I]:G04-22

25L313-3

[I]

I6RW0D630001-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 15. BCM

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 16. Output shaft speed sensor

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 5. Front (left/right) wheel speed sensor 17. TCM

[D]: Combination meter connector “G241” (viewed from harness side) 6. ABS control module 18. Individual circuit fuse box No.1

[E]: Torque sensor connector “E31” (viewed from harness side) 7. Combination meter 19. “IGN” fuse

[F]: Motor connector “E61” (viewed from harness side) 8. “EPS” warning light 20. “P/S” fuse

[G]: M/T model 9. Data link connector (DLC) 21. “IG1 SIG” fuse

[H]: A/T model 10. ECM 22. “MTR” fuse

[I]: Junction block without BCM model (Taiwan model) 11. P/S control module 23. To ABS control module

[J]: M15A engine with 4A/T equipped with slip control model (Hong Kong

model)12. P/S motor 24. To HVAC control module

1. Main fuse box 13. Shield 25. To SDM

2. Ignition switch 14. Torque sensor (built into steering gear case)

Page 894 of 1556

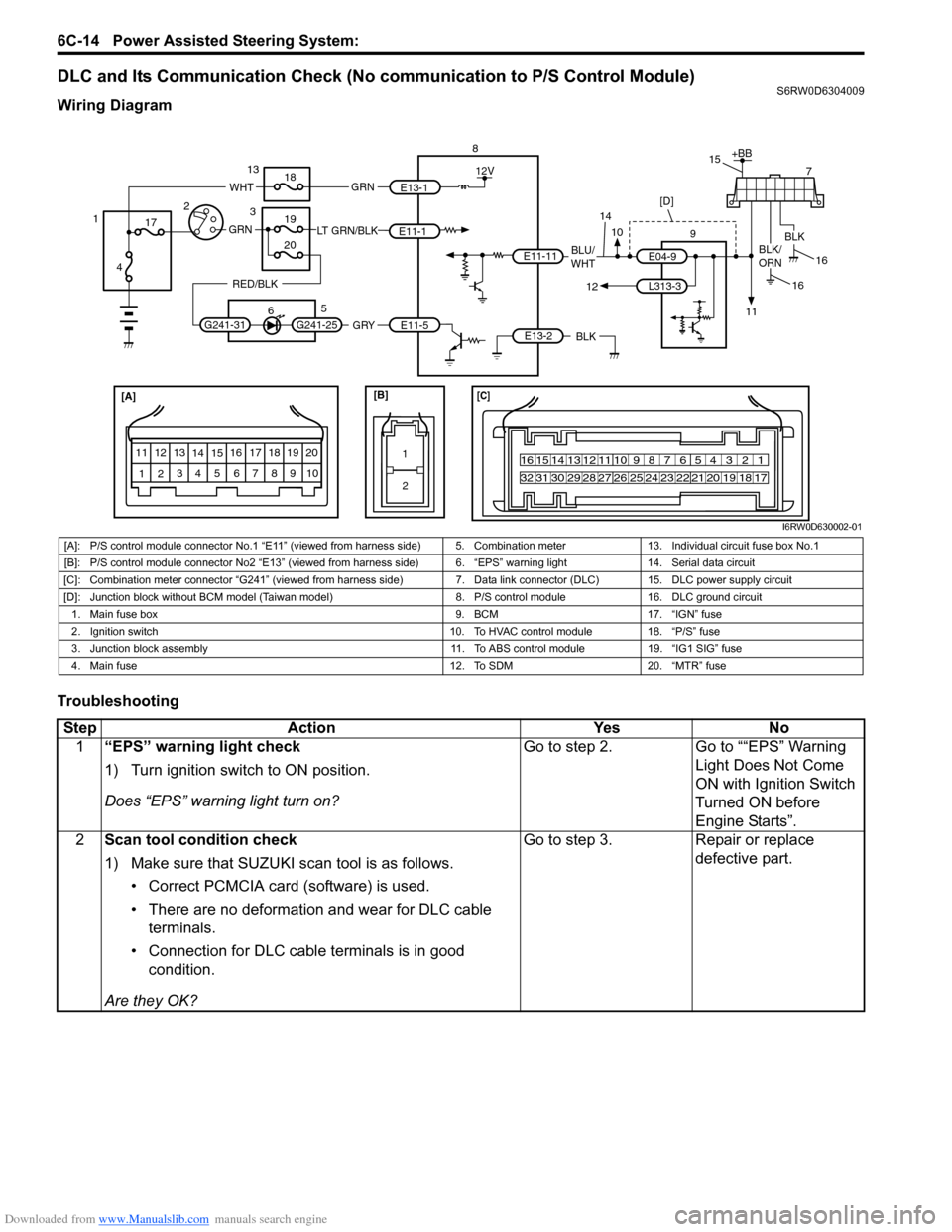

Downloaded from www.Manualslib.com manuals search engine 6C-14 Power Assisted Steering System:

DLC and Its Communication Check (No communication to P/S Control Module)S6RW0D6304009

Wiring Diagram

Troubleshooting

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

LT GRN/BLKE11-1

E11-11

E13-1 GRN

GRN

WHT

8

13

318

19

20

5

6 17

4

12

712V

E13-2BLK

9

G241-31

+BB

BLU/

WHTE04-9

10

11

RED/BLK

G241-25E11-5GRY

L313-312

BLKBLK/

ORN

16

16

15

14[D]

I6RW0D630002-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 5. Combination meter 13. Individual circuit fuse box No.1

[B]: P/S control module connector No2 “E13” (viewed from harness side) 6. “EPS” warning light 14. Serial data circuit

[C]: Combination meter connector “G241” (viewed from harness side) 7. Data link connector (DLC) 15. DLC power supply circuit

[D]: Junction block without BCM model (Taiwan model) 8. P/S control module 16. DLC ground circuit

1. Main fuse box 9. BCM 17. “IGN” fuse

2. Ignition switch 10. To HVAC control module 18. “P/S” fuse

3. Junction block assembly 11. To ABS control module 19. “IG1 SIG” fuse

4. Main fuse 12. To SDM 20. “MTR” fuse

Step Action Yes No

1“EPS” warning light check

1) Turn ignition switch to ON position.

Does “EPS” warning light turn on?Go to step 2. Go to ““EPS” Warning

Light Does Not Come

ON with Ignition Switch

Turned ON before

Engine Starts”.

2Scan tool condition check

1) Make sure that SUZUKI scan tool is as follows.

• Correct PCMCIA card (software) is used.

• There are no deformation and wear for DLC cable

terminals.

• Connection for DLC cable terminals is in good

condition.

Are they OK?Go to step 3. Repair or replace

defective part.