Motor SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1007 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-67

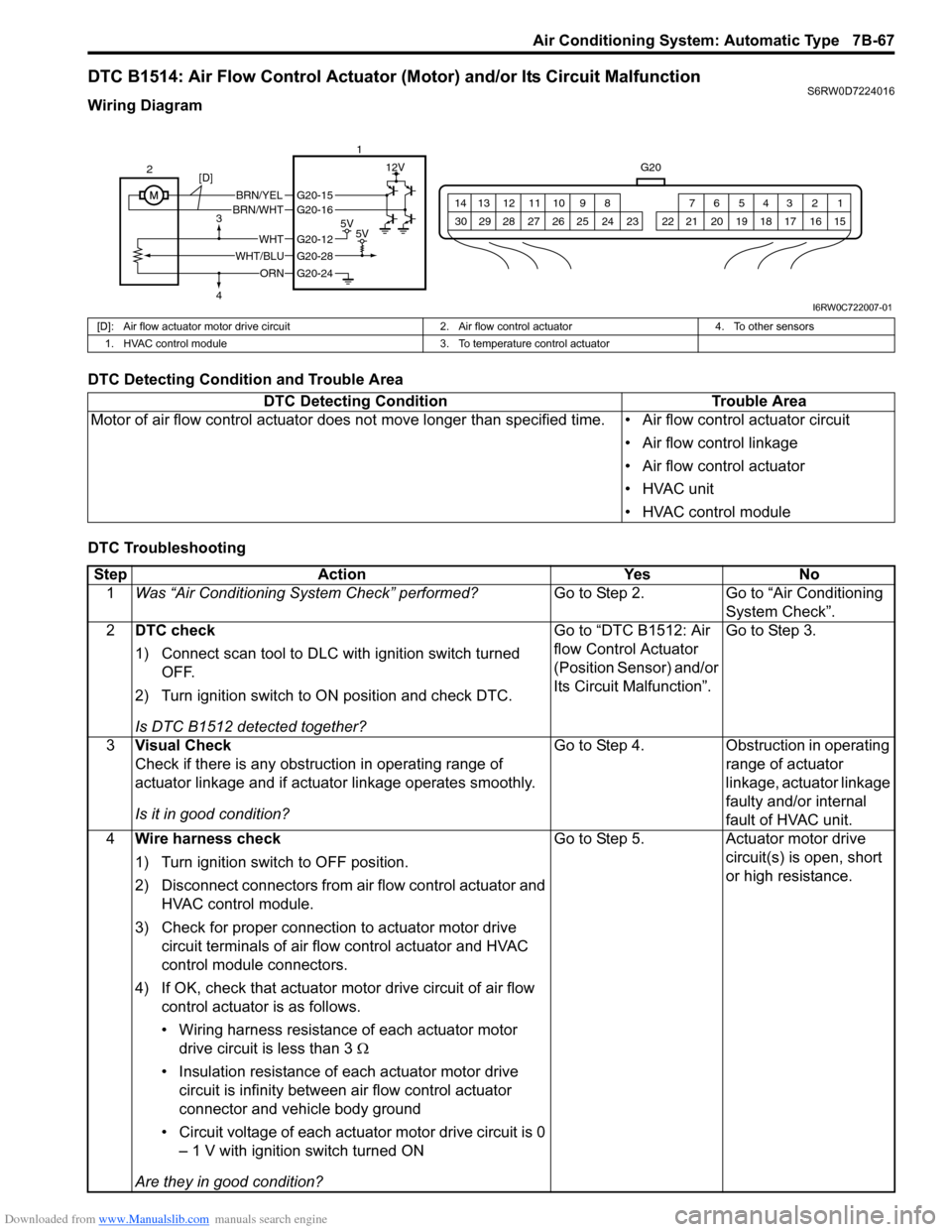

DTC B1514: Air Flow Control Actuator (Motor) and/or Its Circuit MalfunctionS6RW0D7224016

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

G20

1 2 3 4 5 6 7 8 9 10 11 12 13 14

15 16 17 18 19 20 21 24 23 22 25 26 27 28 29 30

BRN/YELBRN/WHT

5V5V

12V

ORN

WHTG20-12

G20-28

G20-24

G20-15G20-16

WHT/BLU 2

3

41

[D]

I6RW0C722007-01

[D]: Air flow actuator motor drive circuit 2. Air flow control actuator 4. To other sensors

1. HVAC control module 3. To temperature control actuator

DTC Detecting Condition Trouble Area

Motor of air flow control actuator does not move longer than specified time. • Air flow control actuator circuit

• Air flow control linkage

• Air flow control actuator

• HVAC unit

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ignition switch to ON position and check DTC.

Is DTC B1512 detected together?Go to “DTC B1512: Air

flow Control Actuator

(Position Sensor) and/or

Its Circuit Malfunction”.Go to Step 3.

3Visual Check

Check if there is any obstruction in operating range of

actuator linkage and if actuator linkage operates smoothly.

Is it in good condition?Go to Step 4. Obstruction in operating

range of actuator

linkage, actuator linkage

faulty and/or internal

fault of HVAC unit.

4Wire harness check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from air flow control actuator and

HVAC control module.

3) Check for proper connection to actuator motor drive

circuit terminals of air flow control actuator and HVAC

control module connectors.

4) If OK, check that actuator motor drive circuit of air flow

control actuator is as follows.

• Wiring harness resistance of each actuator motor

drive circuit is less than 3 Ω

• Insulation resistance of each actuator motor drive

circuit is infinity between air flow control actuator

connector and vehicle body ground

• Circuit voltage of each actuator motor drive circuit is 0

– 1 V with ignition switch turned ON

Are they in good condition?Go to Step 5. Actuator motor drive

circuit(s) is open, short

or high resistance.

Page 1017 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-77

G20-8 BLU/WHTElectric load signal for

blower motor10 – 14 V• Ignition switch turned ON, blower speed selector

OFF or 1st position

• Ignition switch turned ON, blower speed selector

from 1st to 2nd position

0 – 2 V• Ignition switch turned ON, blower speed selector

between 3rd and HIGH position

• Ignition switch turned ON, blower speed selector

from 3rd to 2nd position

G20-9 WHT/BLKEvaporator temperature

sensor signalApprox. 2.6 VIgnition switch turned ON, evaporator temperature 0

°C (32 °F)

Approx. 1.7 VIgnition switch turned ON, evaporator temperature

15 °C (59 °F)

Approx. 1.0 VIgnition switch turned ON, evaporator temperature

30 °C (86 °F)

G20-10 PNK/BLKInside air temperature

sensor signalApprox. 2.5 VIgnition switch turned ON, room temperature 25 °C

(77 °F)

Approx. 3.7 VIgnition switch turned ON, room temperature 0 °C

(32 °F)

G20-11 — — —

G20-12 WHTOutput of 5 V power

source for air flow control

actuator position sensor

and temperature control

actuator position sensor4 – 6 V Ignition switch turned ON

G20-13 YELSerial communication line

of BCMRefer to “Reference waveform No. 2: Automatic Type”.

G20-14 — — — —

G20-15 BRN/YELAir flow control actuator

(FACE)10 – 14 VIgnition switch turned ON, air flow control actuator is

working in operation from “DEF” to “FACE” position

0 – 1 VIgnition switch turned ON, except the above

condition

G20-16 BRN/WHTAir flow control actuator

(DEF)10 – 14 VIgnition switch turned ON, air flow control actuator is

working in operation from “FACE” to “DEF” position

0 – 1 VIgnition switch turned ON, except the above

condition

G20-17 GRNAir intake actuator

(FRESH AIR)0 – 1 VIgnition switch turned ON, air intake selector “FRE”

position

10 – 14 VIgnition switch turned ON, air intake selector “REC”

position

G20-18 REDAir intake actuator

(RECIRCULATION AIR)0 – 1 VIgnition switch turned ON, air intake selector “REC”

position

10 – 14 VIgnition switch turned ON, air intake selector “FRE”

position

G20-19 GRN/REDAir intake actuator (MIX

AIR)10 – 14 VIgnition switch turned ON, air intake selector “FRE”

or “REC” position

0 – 1 VIgnition switch turned ON, air intake selector is

working in operation from “FRE” to “REC” or “REC”

to “FRE” position

G20-20 — — — —

G20-21 GRN/WHT A/C switch signal Refer to “Reference waveform No. 1: Automatic Type”.

G20-22 RED/BLK Electric power source 10 – 14 V Ignition switch turned ON

G20-23 BLK/ORNGround for HVAC control

moduleBelow 0.5 V Ignition switch turned ON

G20-24 ORN Ground for sensors Below 0.5 V Ignition switch turned ON Terminal Wire Color CircuitNormal

Vo l ta g eCondition

Page 1018 of 1556

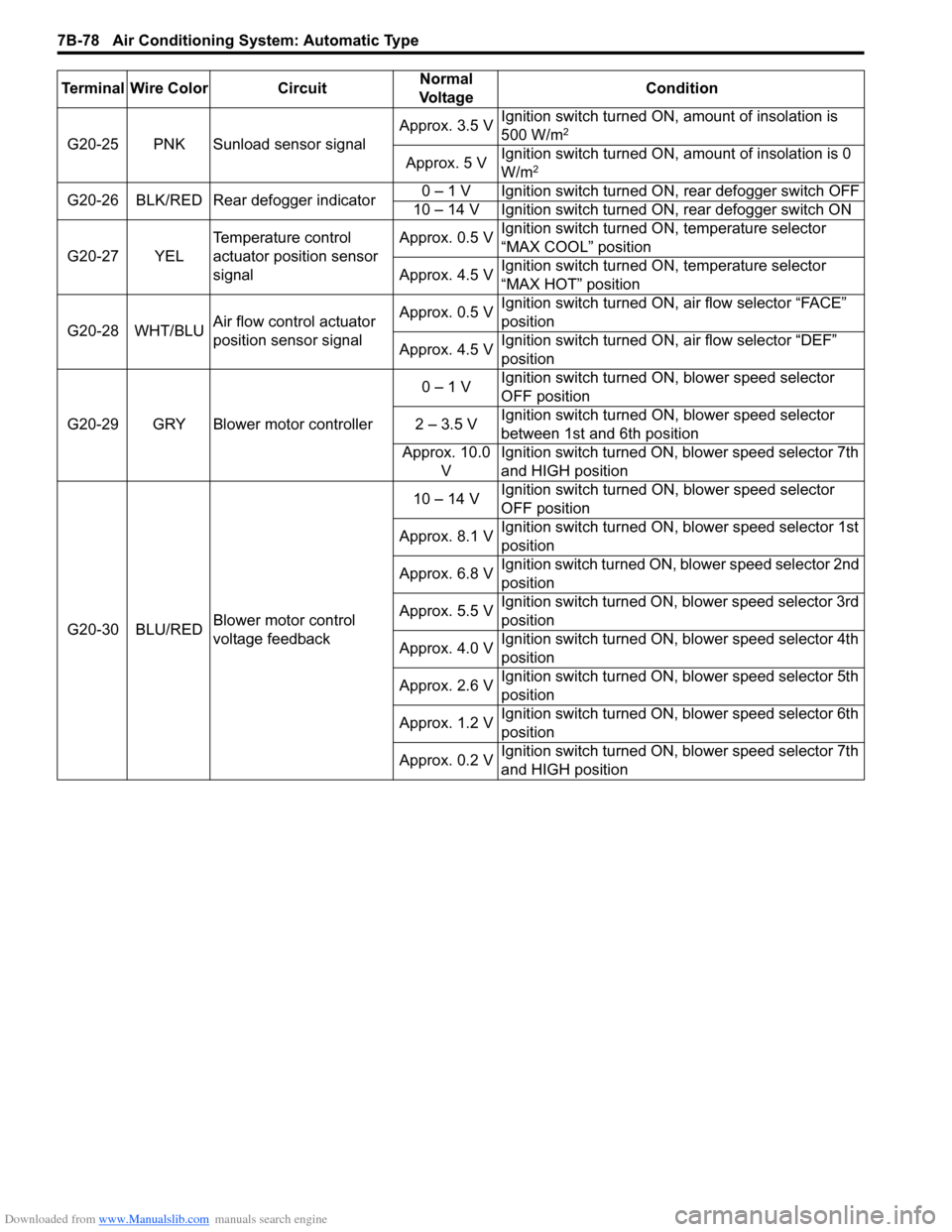

Downloaded from www.Manualslib.com manuals search engine 7B-78 Air Conditioning System: Automatic Type

G20-25 PNK Sunload sensor signalApprox. 3.5 VIgnition switch turned ON, amount of insolation is

500 W/m2

Approx. 5 VIgnition switch turned ON, amount of insolation is 0

W/m2

G20-26 BLK/RED Rear defogger indicator0 – 1 V Ignition switch turned ON, rear defogger switch OFF

10 – 14 V Ignition switch turned ON, rear defogger switch ON

G20-27 YELTemperature control

actuator position sensor

signalApprox. 0.5 VIgnition switch turned ON, temperature selector

“MAX COOL” position

Approx. 4.5 VIgnition switch turned ON, temperature selector

“MAX HOT” position

G20-28 WHT/BLUAir flow control actuator

position sensor signalApprox. 0.5 VIgnition switch turned ON, air flow selector “FACE”

position

Approx. 4.5 VIgnition switch turned ON, air flow selector “DEF”

position

G20-29 GRY Blower motor controller0 – 1 VIgnition switch turned ON, blower speed selector

OFF position

2 – 3.5 VIgnition switch turned ON, blower speed selector

between 1st and 6th position

Approx. 10.0

VIgnition switch turned ON, blower speed selector 7th

and HIGH position

G20-30 BLU/REDBlower motor control

voltage feedback10 – 14 VIgnition switch turned ON, blower speed selector

OFF position

Approx. 8.1 VIgnition switch turned ON, blower speed selector 1st

position

Approx. 6.8 VIgnition switch turned ON, blower speed selector 2nd

position

Approx. 5.5 VIgnition switch turned ON, blower speed selector 3rd

position

Approx. 4.0 VIgnition switch turned ON, blower speed selector 4th

position

Approx. 2.6 VIgnition switch turned ON, blower speed selector 5th

position

Approx. 1.2 VIgnition switch turned ON, blower speed selector 6th

position

Approx. 0.2 VIgnition switch turned ON, blower speed selector 7th

and HIGH position Terminal Wire Color CircuitNormal

Vo l ta g eCondition

Page 1020 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-80 Air Conditioning System: Automatic Type

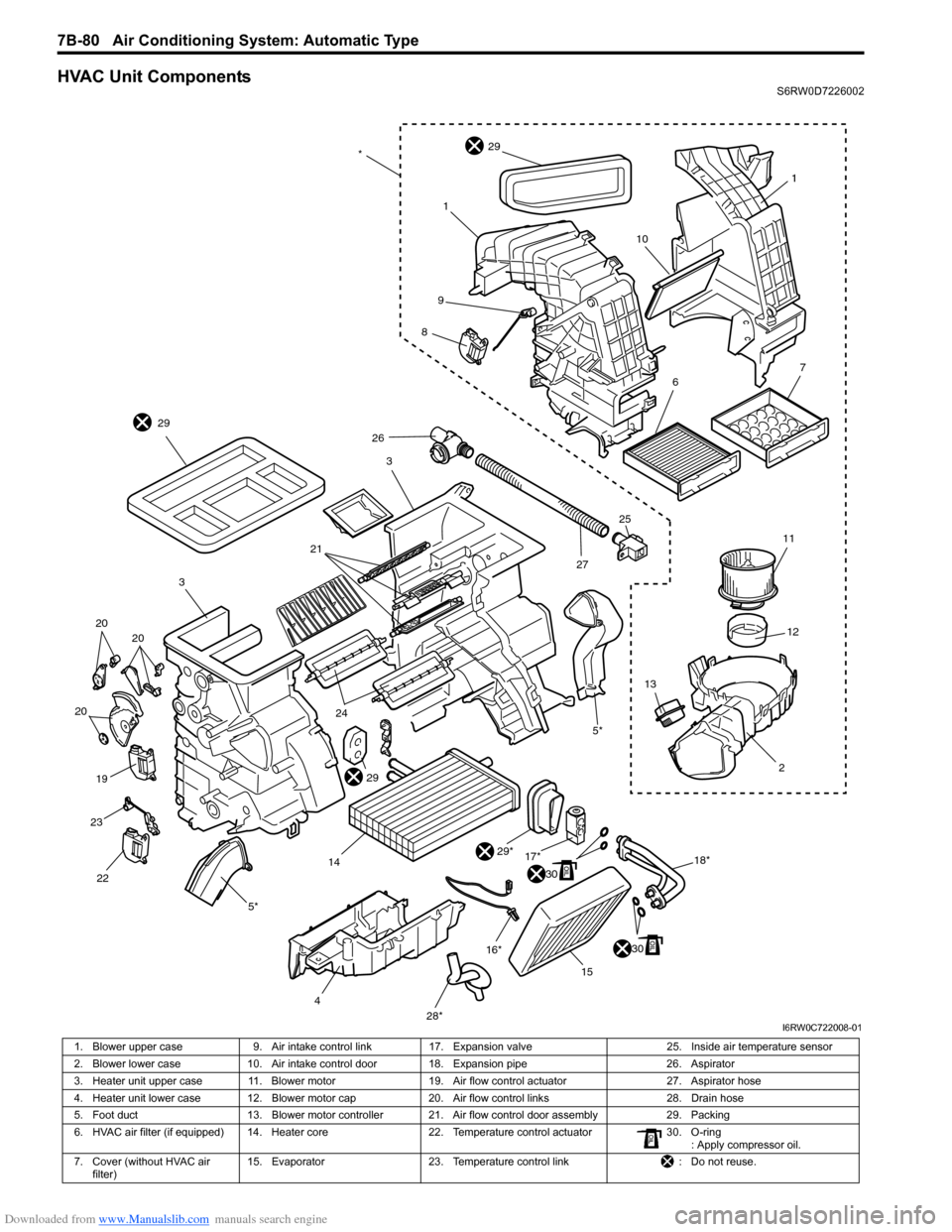

HVAC Unit ComponentsS6RW0D7226002

1

10

1

29

9

8

3

29

21

3

20 20

20

19

23

22

5*

4

28*15 16*

30

29*

30

17*

18*2 1312 11

5*

26

2725

1424

29

67

*

I6RW0C722008-01

1. Blower upper case 9. Air intake control link 17. Expansion valve 25. Inside air temperature sensor

2. Blower lower case 10. Air intake control door 18. Expansion pipe 26. Aspirator

3. Heater unit upper case 11. Blower motor 19.Air flow control actuator 27. Aspirator hose

4. Heater unit lower case 12. Blower motor cap 20. Air flow control links 28. Drain hose

5. Foot duct 13. Blower motor controller 21. Air flow control door assembly 29. Packing

6. HVAC air filter (if equipped) 14. Heater core 22. Temperature control actuator 30. O-ring

: Apply compressor oil.

7. Cover (without HVAC air

filter)15. Evaporator 23. Temperature control link : Do not reuse.

Page 1024 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-84 Air Conditioning System: Automatic Type

7) Set air flow selector of HVAC control module to

“DEF” position with ignition switch turned ON, and

make sure if the position of actuator lever is “DEF”

position (A).

8) Turn ignition switch to OFF position, and then

disconnect connector from air flow control actuator.

9) Measure resistance between terminal “1” and “2”.

Air flow control actuator resistance between

terminal “1” and “2” (DEF position) (Reference

value)

Approx. 0.45 kΩ at 25 °C (77 °F)

10) Connect connector to air flow control actuator.

11) Set air flow selector of HVAC control module to

“VENT” position with ignition switch turned ON, and

make sure if the position of actuator lever is “VENT”

position (B).

12) Turn ignition switch to OFF position, and then

disconnect connector from air flow control actuator.13) Measure resistance between terminal “1” and “2”.

Air flow control actuator resistance between

terminal “1” and “2” (VENT position) (Reference

value)

Approx. 4.3 kΩ at 25 °C (77 °F)

If measure resistance is out of specification, replace the

actuator with new one.

Air Intake Actuator Removal and InstallationS6RW0D7226008

Remove and install air intake actuator referring to “Air

Intake Control Actuator Removal and Installation in

Section 7A”.

Air Intake Actuator InspectionS6RW0D7226009

For inspection, refer to “Air Intake Control Actuator

Inspection in Section 7A”.

Actuator Linkage InspectionS6RW0D7226010

• Check if each actuator linkage operates smoothly.

• Check actuator rod for bend.

• Check each actuator linkage for breakage.

• Make sure if there is not any obstruction in operating

range of actuator linkage.

If any malfunction is found, repair or replace faulty

part(s).

Blower Motor Controller Removal and

Installation

S6RW0D7226011

Refer to “Blower Motor Resistor Removal and

Installation in Section 7A”.

123456

6

M5

3

2

1 A

I7RW01722025-01

123456

6

M5

3

2

1 B

I7RW01722026-01

Page 1025 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-85

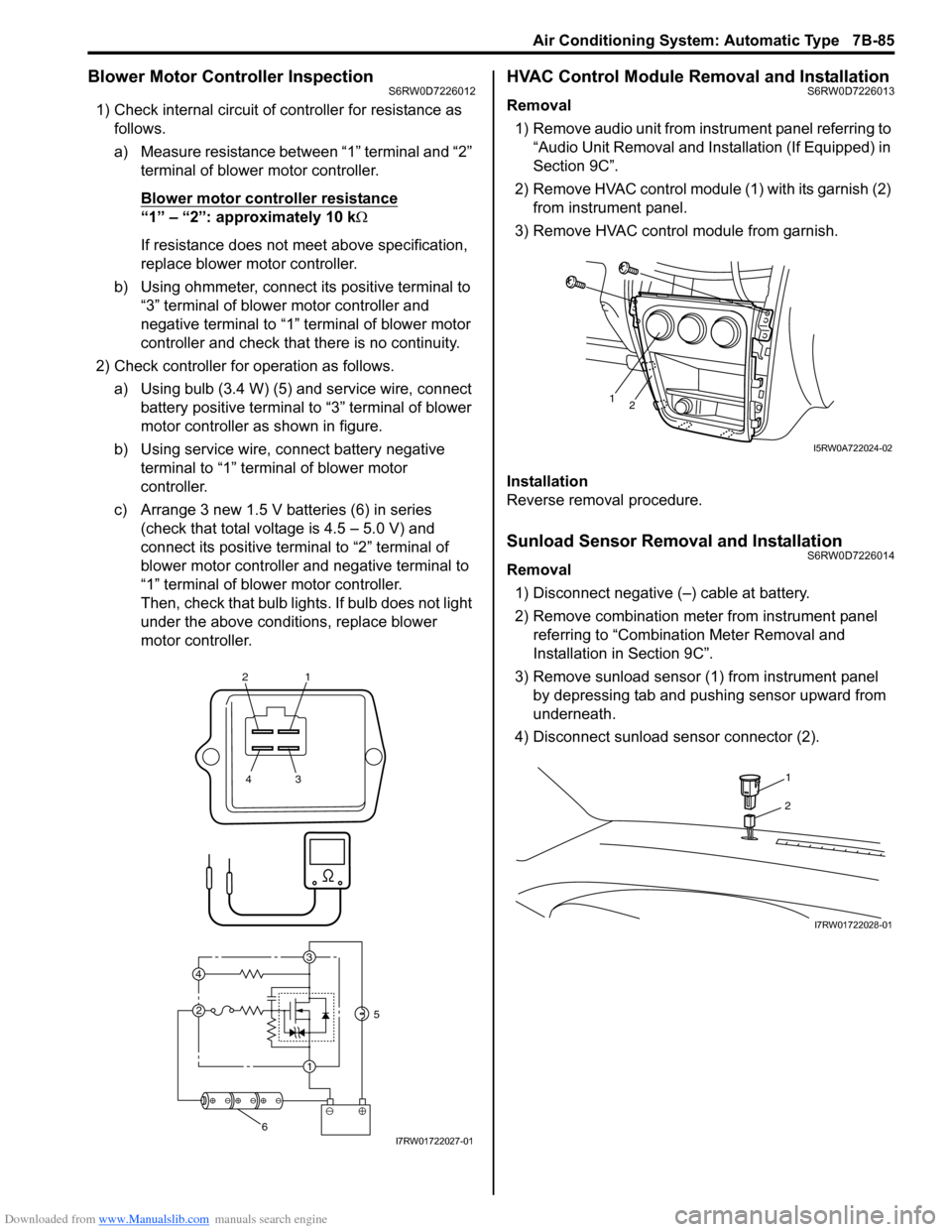

Blower Motor Controller InspectionS6RW0D7226012

1) Check internal circuit of controller for resistance as

follows.

a) Measure resistance between “1” terminal and “2”

terminal of blower motor controller.

Blower motor controller resistance

“1” – “2”: approximately 10 kΩ

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to

“3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows.

a) Using bulb (3.4 W) (5) and service wire, connect

battery positive terminal to “3” terminal of blower

motor controller as shown in figure.

b) Using service wire, connect battery negative

terminal to “1” terminal of blower motor

controller.

c) Arrange 3 new 1.5 V batteries (6) in series

(check that total voltage is 4.5 – 5.0 V) and

connect its positive terminal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

HVAC Control Module Removal and InstallationS6RW0D7226013

Removal

1) Remove audio unit from instrument panel referring to

“Audio Unit Removal and Installation (If Equipped) in

Section 9C”.

2) Remove HVAC control module (1) with its garnish (2)

from instrument panel.

3) Remove HVAC control module from garnish.

Installation

Reverse removal procedure.

Sunload Sensor Removal and InstallationS6RW0D7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter from instrument panel

referring to “Combination Meter Removal and

Installation in Section 9C”.

3) Remove sunload sensor (1) from instrument panel

by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2).

21

43

3

1 2 4

5

6I7RW01722027-01

12

I5RW0A722024-02

1

2

I7RW01722028-01

Page 1164 of 1556

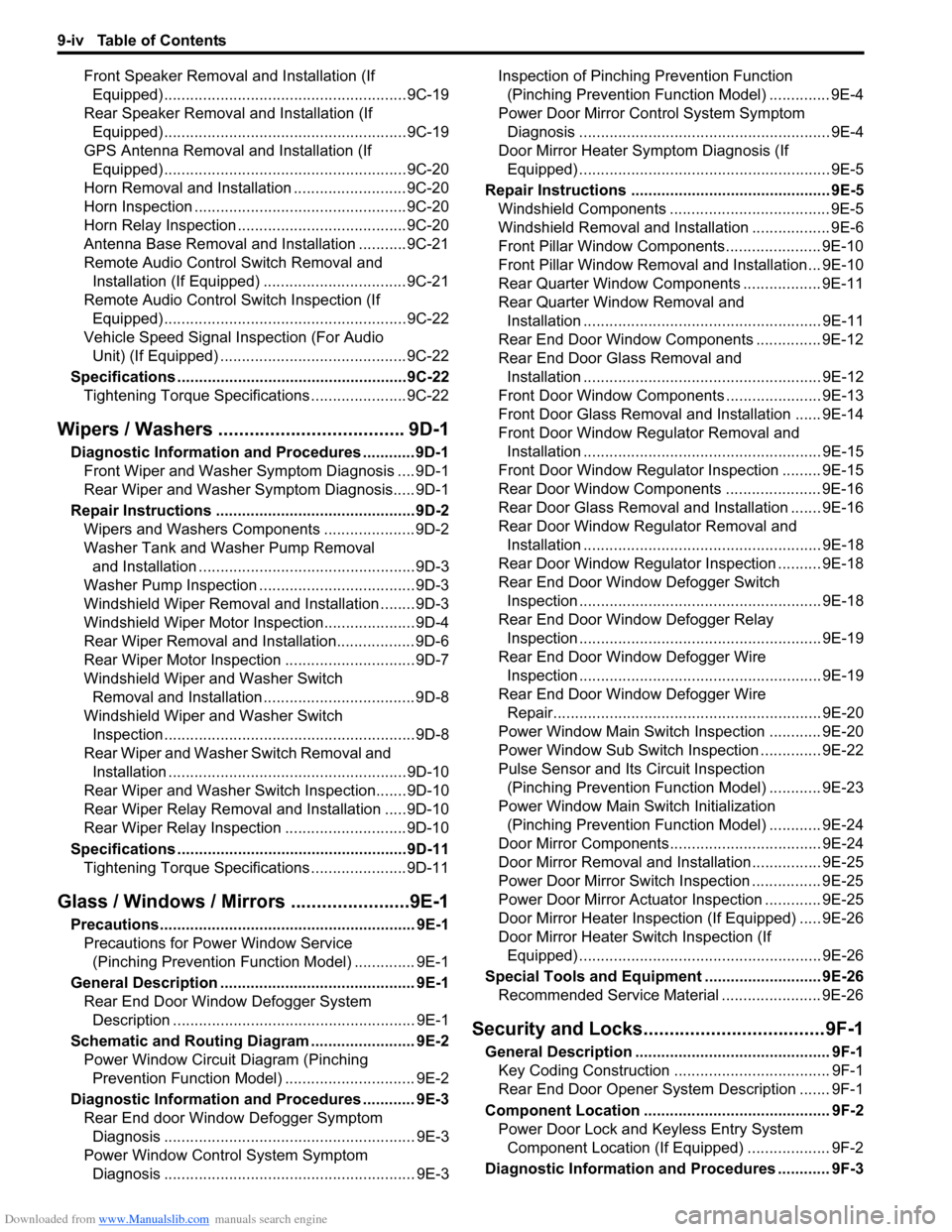

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Front Speaker Removal and Installation (If

Equipped) ........................................................9C-19

Rear Speaker Removal and Installation (If

Equipped) ........................................................9C-19

GPS Antenna Removal and Installation (If

Equipped) ........................................................9C-20

Horn Removal and Installation ..........................9C-20

Horn Inspection .................................................9C-20

Horn Relay Inspection .......................................9C-20

Antenna Base Removal and Installation ...........9C-21

Remote Audio Control Switch Removal and

Installation (If Equipped) .................................9C-21

Remote Audio Control Switch Inspection (If

Equipped) ........................................................9C-22

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped) ...........................................9C-22

Specifications .....................................................9C-22

Tightening Torque Specifications ......................9C-22

Wipers / Washers .................................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis ....9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions ..............................................9D-2

Wipers and Washers Components .....................9D-2

Washer Tank and Washer Pump Removal

and Installation ..................................................9D-3

Washer Pump Inspection ....................................9D-3

Windshield Wiper Removal and Installation ........9D-3

Windshield Wiper Motor Inspection.....................9D-4

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection ..............................9D-7

Windshield Wiper and Washer Switch

Removal and Installation ................................... 9D-8

Windshield Wiper and Washer Switch

Inspection .......................................................... 9D-8

Rear Wiper and Washer Switch Removal and

Installation .......................................................9D-10

Rear Wiper and Washer Switch Inspection.......9D-10

Rear Wiper Relay Removal and Installation .....9D-10

Rear Wiper Relay Inspection ............................9D-10

Specifications .....................................................9D-11

Tightening Torque Specifications ......................9D-11

Glass / Windows / Mirrors .......................9E-1

Precautions........................................................... 9E-1

Precautions for Power Window Service

(Pinching Prevention Function Model) .............. 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System

Description ........................................................ 9E-1

Schematic and Routing Diagram ........................ 9E-2

Power Window Circuit Diagram (Pinching

Prevention Function Model) .............................. 9E-2

Diagnostic Information and Procedures ............ 9E-3

Rear End door Window Defogger Symptom

Diagnosis .......................................................... 9E-3

Power Window Control System Symptom

Diagnosis .......................................................... 9E-3Inspection of Pinching Prevention Function

(Pinching Prevention Function Model) .............. 9E-4

Power Door Mirror Control System Symptom

Diagnosis .......................................................... 9E-4

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-5

Repair Instructions .............................................. 9E-5

Windshield Components ..................................... 9E-5

Windshield Removal and Installation .................. 9E-6

Front Pillar Window Components...................... 9E-10

Front Pillar Window Removal and Installation... 9E-10

Rear Quarter Window Components .................. 9E-11

Rear Quarter Window Removal and

Installation ....................................................... 9E-11

Rear End Door Window Components ............... 9E-12

Rear End Door Glass Removal and

Installation ....................................................... 9E-12

Front Door Window Components ...................... 9E-13

Front Door Glass Removal and Installation ...... 9E-14

Front Door Window Regulator Removal and

Installation ....................................................... 9E-15

Front Door Window Regulator Inspection ......... 9E-15

Rear Door Window Components ...................... 9E-16

Rear Door Glass Removal and Installation ....... 9E-16

Rear Door Window Regulator Removal and

Installation ....................................................... 9E-18

Rear Door Window Regulator Inspection .......... 9E-18

Rear End Door Window Defogger Switch

Inspection ........................................................ 9E-18

Rear End Door Window Defogger Relay

Inspection ........................................................ 9E-19

Rear End Door Window Defogger Wire

Inspection ........................................................ 9E-19

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-20

Power Window Main Switch Inspection ............ 9E-20

Power Window Sub Switch Inspection .............. 9E-22

Pulse Sensor and Its Circuit Inspection

(Pinching Prevention Function Model) ............ 9E-23

Power Window Main Switch Initialization

(Pinching Prevention Function Model) ............ 9E-24

Door Mirror Components................................... 9E-24

Door Mirror Removal and Installation................ 9E-25

Power Door Mirror Switch Inspection ................ 9E-25

Power Door Mirror Actuator Inspection ............. 9E-25

Door Mirror Heater Inspection (If Equipped) ..... 9E-26

Door Mirror Heater Switch Inspection (If

Equipped) ........................................................ 9E-26

Special Tools and Equipment ........................... 9E-26

Recommended Service Material ....................... 9E-26

Security and Locks...................................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ........................................... 9F-2

Power Door Lock and Keyless Entry System

Component Location (If Equipped) ................... 9F-2

Diagnostic Information and Procedures ............ 9F-3

Page 1169 of 1556

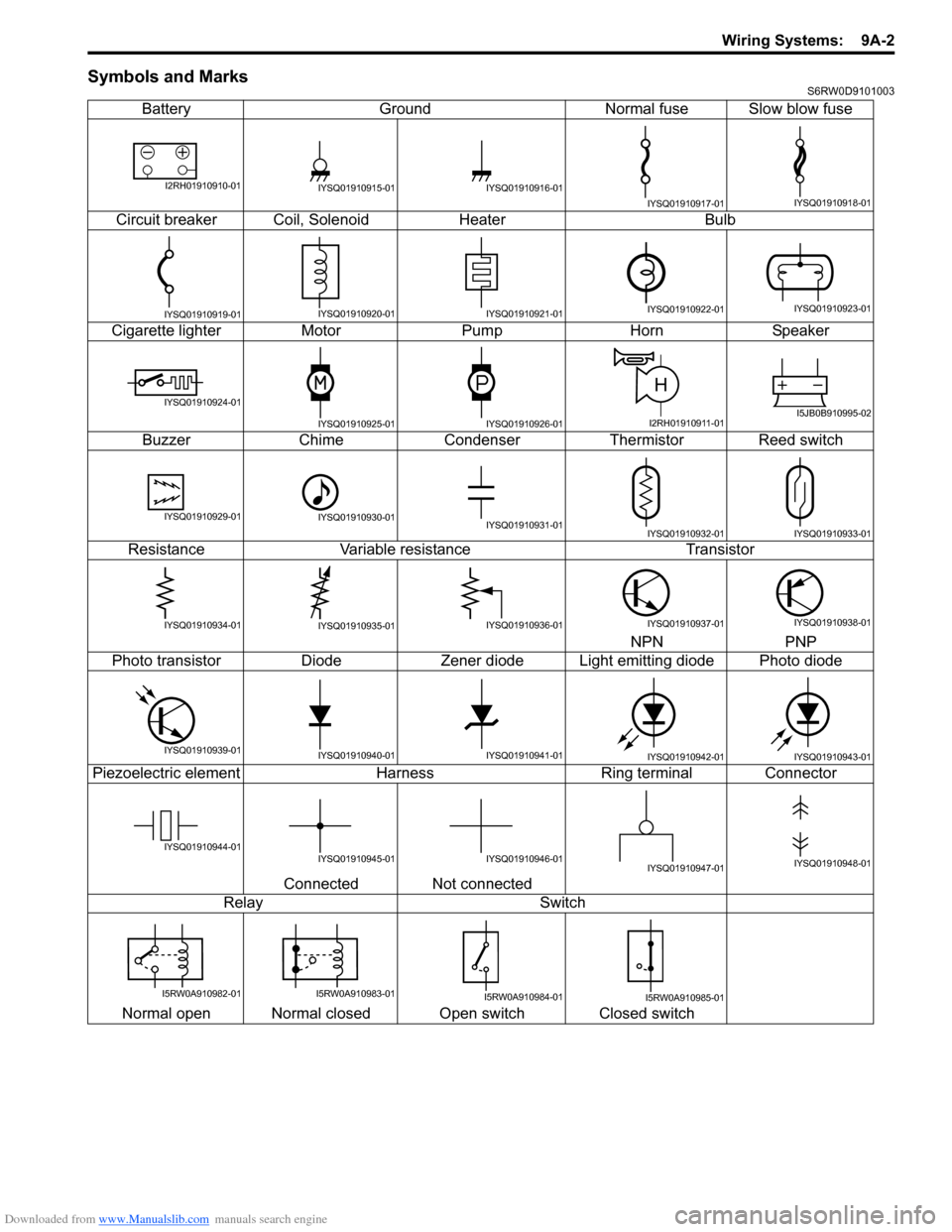

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-2

Symbols and MarksS6RW0D9101003

Battery Ground Normal fuse Slow blow fuse

Circuit breaker Coil, Solenoid Heater Bulb

Cigarette lighter Motor Pump Horn Speaker

Buzzer Chime Condenser Thermistor Reed switch

Resistance Variable resistance Transistor

NPN PNP

Photo transistor Diode Zener diode Light emitting diode Photo diode

Piezoelectric element Harness Ring terminal Connector

Connected Not connected

Relay Switch

Normal open Normal closed Open switch Closed switch

I2RH01910910-01IYSQ01910915-01IYSQ01910916-01

IYSQ01910917-01IYSQ01910918-01

IYSQ01910919-01IYSQ01910920-01IYSQ01910921-01IYSQ01910922-01IYSQ01910923-01

IYSQ01910924-01

IYSQ01910925-01IYSQ01910926-01

H

I2RH01910911-01I5JB0B910995-02

IYSQ01910929-01IYSQ01910930-01IYSQ01910931-01IYSQ01910932-01IYSQ01910933-01

IYSQ01910934-01IYSQ01910935-01IYSQ01910936-01IYSQ01910937-01IYSQ01910938-01

IYSQ01910939-01IYSQ01910940-01IYSQ01910941-01IYSQ01910942-01IYSQ01910943-01

IYSQ01910944-01IYSQ01910945-01IYSQ01910946-01IYSQ01910947-01IYSQ01910948-01

I5RW0A910982-01I5RW0A910983-01I5RW0A910984-01I5RW0A910985-01

Page 1175 of 1556

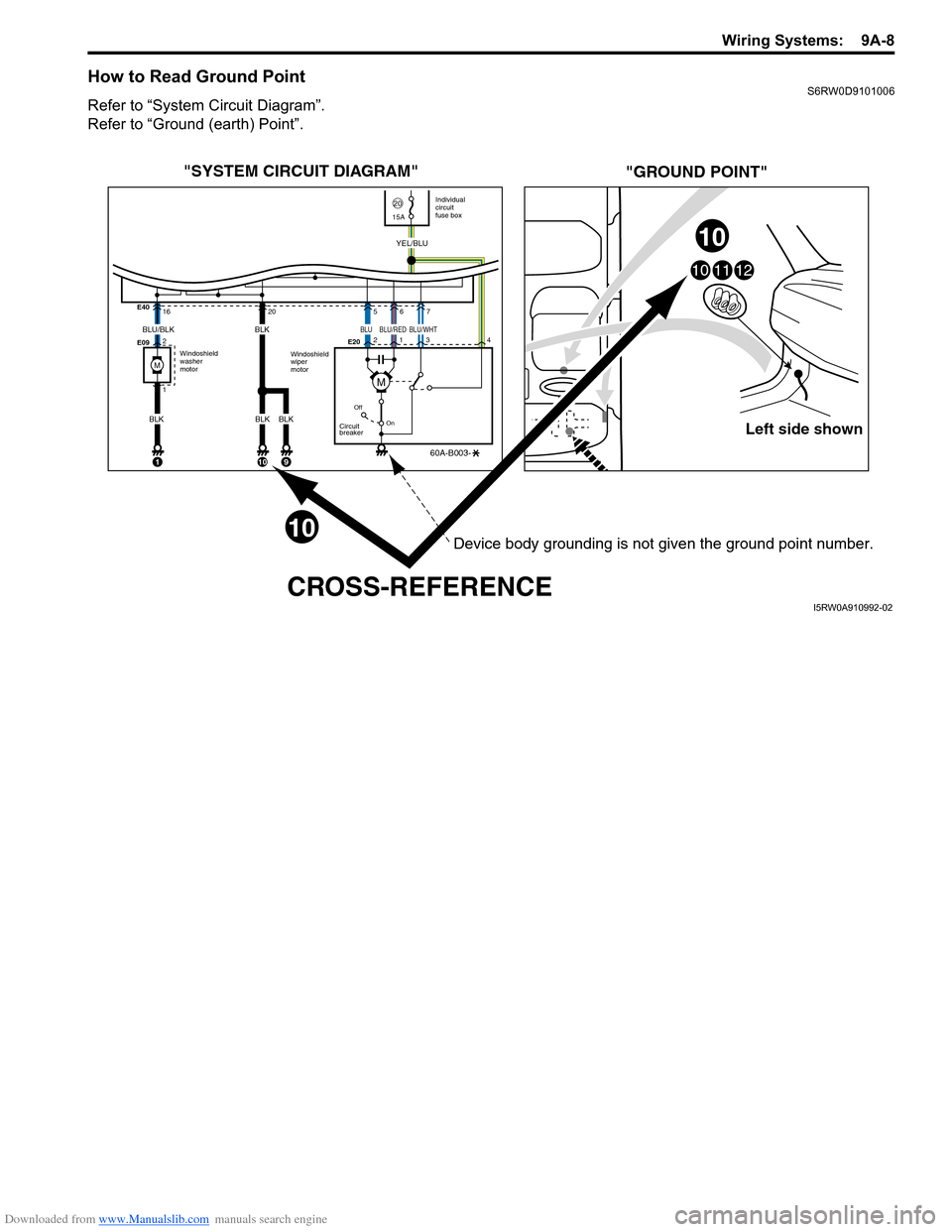

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-8

How to Read Ground PointS6RW0D9101006

Refer to “System Circuit Diagram”.

Refer to “Ground (earth) Point”.

Left side shown

101112

"SYSTEM CIRCUIT DIAGRAM"

"GROUND POINT"

CROSS-REFERENCE

Windoshield

washer

motorIndividual

circuit

fuse box

2015A

Windoshield

wiper

motor E40

E09E20 16

2

1

Off

On

Circuit

breaker

60A-B003-

YEL/BLU

1

205

2

134

67

BLU/BLK

BLK

10

BLK

BLK

9

10

10

BLK

M

BLUBLU/WHTBLU/RED

M

Device body grounding is not given the ground point number.

I5RW0A910992-02

Page 1177 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-10

[D]: Terminals-in-one-connector mark

[E]: Wire color

[F]: Shield wire

[G]: Ground point

[H]: “From” or “To” (Wit SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-10

[D]: Terminals-in-one-connector mark

[E]: Wire color

[F]: Shield wire

[G]: Ground point

[H]: “From” or “To” (Wit](/img/20/7612/w960_7612-1176.png)

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-10

[D]: Terminals-in-one-connector mark

[E]: Wire color

[F]: Shield wire

[G]: Ground point

[H]: “From” or “To” (With ID letter (s))

[I]: Specification variation

The white arrow between A and B means “or”.

[J]: “From” (With ID letter (s))

[K] “To” (With ID letter (s))

[L]: Connector code

[M]: Terminal No.

[N]: Symbol mark

[O]: “SEE” mark

Switch

BLU

BLU

GRN/BLK

GRN/REDGRN/BLK

12

GRN

GRN

C262

1

BLK

5

BLK

2 1

C40

GRN/BLK

"XX"

Solenoid FuseFuse

3

15A

Main

relay

ON OFF

1

15A

6

20A

1

Sensor 1

2

8

BRN/RED

E521

2E521

BRN/RED

RED

2

BRN/REDBRN/RED

MotorM M

655

A

B

AB5

6

1

2

56464 4-DOOR

2-DOOR

2

C71

E03

E34

O06

C31

E19

[A]

[B]

[C]

[F]

[G]

[H] [D][I] [K] [L]

E3375E341

21

43E08

ORNWHTYEL

RED

YELYEL/REDGRN/RED

4

3

YEL

BLK/RED

ORN

GRN

GRN

BA

GRN

GRN

2

XX

Cont.M

[J]

[E]

[N] [O] [M]

GBGR

Y

Y

GB

P

3

4

2

3

L50 G20

1

GR

Y

BLK

BLK

GR

I5RW0A910994-02