head SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1348 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-29 Lighting Systems:

Height Sensor Removal and Installation (If

Equipped)

S6RW0D9206027

Removal

CAUTION!

• Do not remove bracket (4) and link (3) from

height sensor (2). Removal will spoil its

original function. If faulty condition is

found, replace it with new one in a set.

• If height sensor was dropped from a height

of 30 cm (0.9 ft) or more, replace it with

new one.

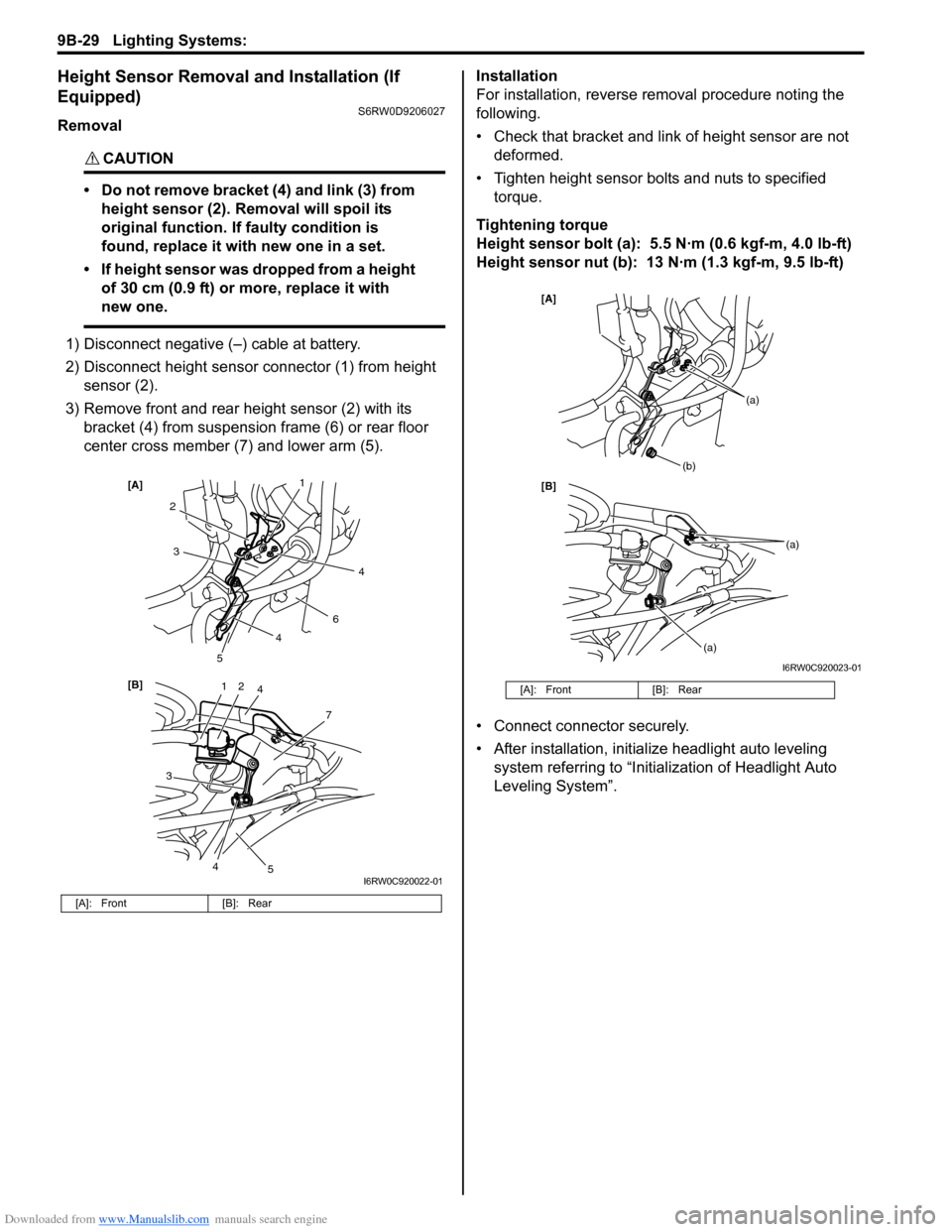

1) Disconnect negative (–) cable at battery.

2) Disconnect height sensor connector (1) from height

sensor (2).

3) Remove front and rear height sensor (2) with its

bracket (4) from suspension frame (6) or rear floor

center cross member (7) and lower arm (5).Installation

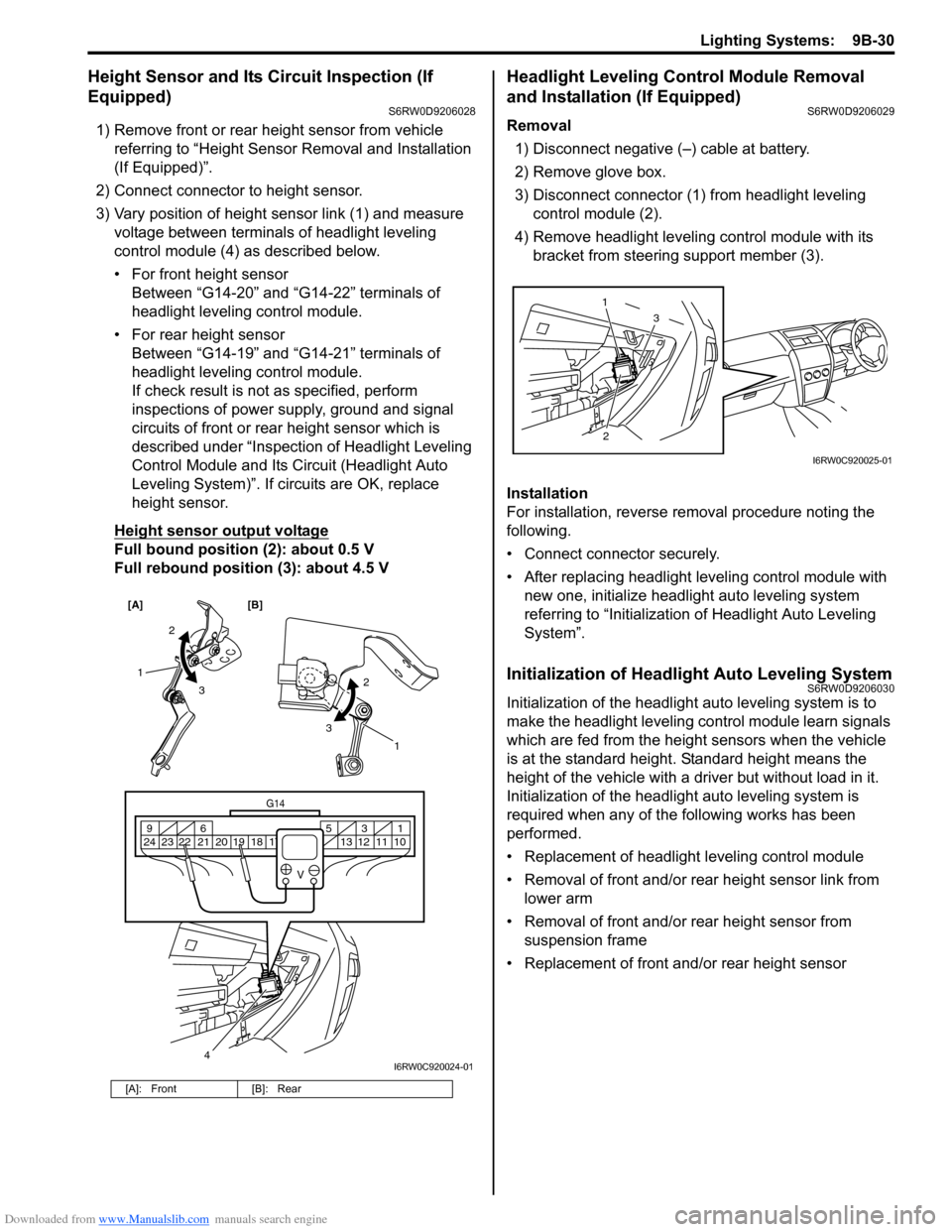

For installation, reverse removal procedure noting the

following.

• Check that bracket and link of height sensor are not

deformed.

• Tighten height sensor bolts and nuts to specified

torque.

Tightening torque

Height sensor bolt (a): 5.5 N·m (0.6 kgf-m, 4.0 lb-ft)

Height sensor nut (b): 13 N·m (1.3 kgf-m, 9.5 lb-ft)

• Connect connector securely.

• After installation, initialize headlight auto leveling

system referring to “Initialization of Headlight Auto

Leveling System”.

[A]: Front [B]: Rear

12

7

[B] [A]

4

3

2

6

3

5

5

1

4

4

4

I6RW0C920022-01

[A]: Front [B]: Rear

[B] [A]

(b)

(a)

(a)

(a)

I6RW0C920023-01

Page 1349 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-30

Height Sensor and Its Circuit Inspection (If

Equipped)

S6RW0D9206028

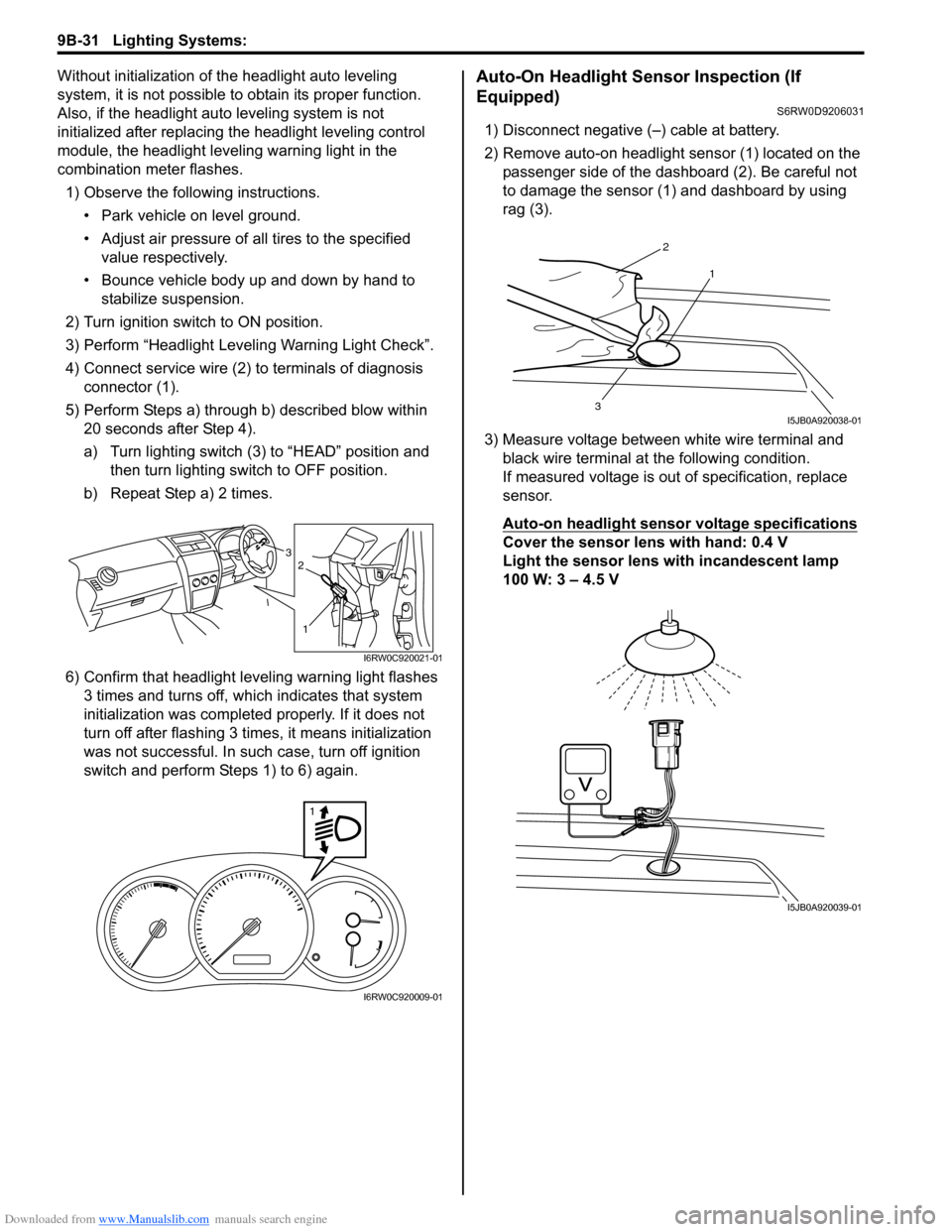

1) Remove front or rear height sensor from vehicle

referring to “Height Sensor Removal and Installation

(If Equipped)”.

2) Connect connector to height sensor.

3) Vary position of height sensor link (1) and measure

voltage between terminals of headlight leveling

control module (4) as described below.

• For front height sensor

Between “G14-20” and “G14-22” terminals of

headlight leveling control module.

• For rear height sensor

Between “G14-19” and “G14-21” terminals of

headlight leveling control module.

If check result is not as specified, perform

inspections of power supply, ground and signal

circuits of front or rear height sensor which is

described under “Inspection of Headlight Leveling

Control Module and Its Circuit (Headlight Auto

Leveling System)”. If circuits are OK, replace

height sensor.

Height sensor output voltage

Full bound position (2): about 0.5 V

Full rebound position (3): about 4.5 V

Headlight Leveling Control Module Removal

and Installation (If Equipped)

S6RW0D9206029

Removal

1) Disconnect negative (–) cable at battery.

2) Remove glove box.

3) Disconnect connector (1) from headlight leveling

control module (2).

4) Remove headlight leveling control module with its

bracket from steering support member (3).

Installation

For installation, reverse removal procedure noting the

following.

• Connect connector securely.

• After replacing headlight leveling control module with

new one, initialize headlight auto leveling system

referring to “Initialization of Headlight Auto Leveling

System”.

Initialization of Headlight Auto Leveling SystemS6RW0D9206030

Initialization of the headlight auto leveling system is to

make the headlight leveling control module learn signals

which are fed from the height sensors when the vehicle

is at the standard height. Standard height means the

height of the vehicle with a driver but without load in it.

Initialization of the headlight auto leveling system is

required when any of the following works has been

performed.

• Replacement of headlight leveling control module

• Removal of front and/or rear height sensor link from

lower arm

• Removal of front and/or rear height sensor from

suspension frame

• Replacement of front and/or rear height sensor

[A]: Front [B]: Rear

[A] [B]

4

G14

10 11 12 13 16 17 18 19 2031 5 6 9

21 22 23 24

V

2

3 1

2

3

1

I6RW0C920024-01

23 1

I6RW0C920025-01

Page 1350 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-31 Lighting Systems:

Without initialization of the headlight auto leveling

system, it is not possible to obtain its proper function.

Also, if the headlight auto leveling system is not

initialized after replacing the headlight leveling control

module, the headlight leveling warning light in the

combination meter flashes.

1) Observe the following instructions.

• Park vehicle on level ground.

• Adjust air pressure of all tires to the specified

value respectively.

• Bounce vehicle body up and down by hand to

stabilize suspension.

2) Turn ignition switch to ON position.

3) Perform “Headlight Leveling Warning Light Check”.

4) Connect service wire (2) to terminals of diagnosis

connector (1).

5) Perform Steps a) through b) described blow within

20 seconds after Step 4).

a) Turn lighting switch (3) to “HEAD” position and

then turn lighting switch to OFF position.

b) Repeat Step a) 2 times.

6) Confirm that headlight leveling warning light flashes

3 times and turns off, which indicates that system

initialization was completed properly. If it does not

turn off after flashing 3 times, it means initialization

was not successful. In such case, turn off ignition

switch and perform Steps 1) to 6) again.Auto-On Headlight Sensor Inspection (If

Equipped)

S6RW0D9206031

1) Disconnect negative (–) cable at battery.

2) Remove auto-on headlight sensor (1) located on the

passenger side of the dashboard (2). Be careful not

to damage the sensor (1) and dashboard by using

rag (3).

3) Measure voltage between white wire terminal and

black wire terminal at the following condition.

If measured voltage is out of specification, replace

sensor.

Auto-on headlight sensor voltage specifications

Cover the sensor lens with hand: 0.4 V

Light the sensor lens with incandescent lamp

100 W: 3 – 4.5 V3

1

2

I6RW0C920021-01

1

I6RW0C920009-01

2

1

3I5JB0A920038-01

I5JB0A920039-01

Page 1351 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-32

Illumination Cancel Switch Inspection (If

Equipped)

S6RW0D9206022

Check for continuity between terminals at each switch

position.

If check result is not as specified, replace switch.

Tail Light Relay, Headlight Relay, Front Fog

Light Relay Inspection (If Equipped)

S6RW0D9206032

1) Remove tail light relay (1), headlight relay and/or

front fog light relay (2).

2) Check that there is no continuity between terminal

“3” and “4”. If there is continuity, replace relay.

3) Connect battery positive (+) terminal to terminal “2”

of relay.

4) Connect battery negative (–) terminal to terminal “A”

of relay.

5) Check continuity between terminal “3” and “4”. If

there is no continuity when relay is connected to the

battery, replace relay.

1

2

3

Switch PositionTerminal

ON (PUSH IN)123

OFF

I5RW0A920015-01

8

[B] [A]

3

4

1

5 62

2

I6RW0C920027-02

[A]: Junction block with BCM type (other than discharge headlight model)

[B]: Junction block with BCM type (discharge headlight model)

[C]: Junction block without BCM type

3. Headlight low beam relay (left side)

4. Headlight low beam relay (right side)

5. Headlight high beam relay (left side)

6. Headlight high beam relay (right side)

7. Junction block

8. Battery

7

7

5 6

1

8

3

42 [C]

I6RW0C920028-01

“4” “2”“1”“3”

I4RS0A920022-01

Page 1353 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-1

Body, Cab and Accessories

Instrumentation / Driver Info. / Horn

Precautions

Precautions in Diagnosing Troubles for Combination MeterS6RW0D9300001

Combination meter uses signals (information) from each control module by CAN communication to control

speedometer, tachometer, fuel meter, engine coolant temp meter, warning light and indicator light (other than air bag

warning light, EPS warning light, headlight leveling warning light (if equipped), rear fog light indicator light (if

equipped), high beam indicator light and turn signal indicator light). Therefor, check that no DTC is detected in each

module before performing combination meter symptom diagnosis. If any DTC is detected, correct trouble indicated by

that DTC troubleshooting first.

General Description

CAN Communication System DescriptionS6RW0D9301001

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

Combination meter communicates control data with each control module as follows.

Combination Meter Transmission Data

BCM

Combination

meterDATA

TransmitCombination meter spec signal

I5RW0A930001-02

Page 1356 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-4 Instrumentation / Driver Info. / Horn:

Schematic and Routing Diagram

Combination Meter Circuit DiagramS6RW0D9302001

7

6

5

4G241-99

G241-5

1

2

11

G241-1323

G241-31

G241-263

G241-16

G241-2212

G241-2513

G241-13

8 17

1514

20

G241-32

G241-69

16

18

19

G241-2121

G241-7 G241-10 10

10

G241-1922

I6RW0D930002-01

1. DOME fuse 9. 4WD control module (if equipped) 17. CAN driver

2. METER fuse 10. CAN junction connector 18. Stepper motor and LED output driver

3. Combination switch 11. SDM 19. A/T shift position indicator (“P”, “R”, “N”, “D”, “3”, “2” and “L”)

4. Tachometer 12. Combination switch (high beam) 20. Combination meter

5. Speedometer 13. P/S control module 21. Combination switch (rear fog light)

6. Fuel meter 14. CPU 22. Headlight leveling control module (if equipped)

7. ECT meter 15. Power supply 23. Illumination cancel switch (if equipped)

8. ODO-TRIP 16. Interface circuit

Page 1357 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-5

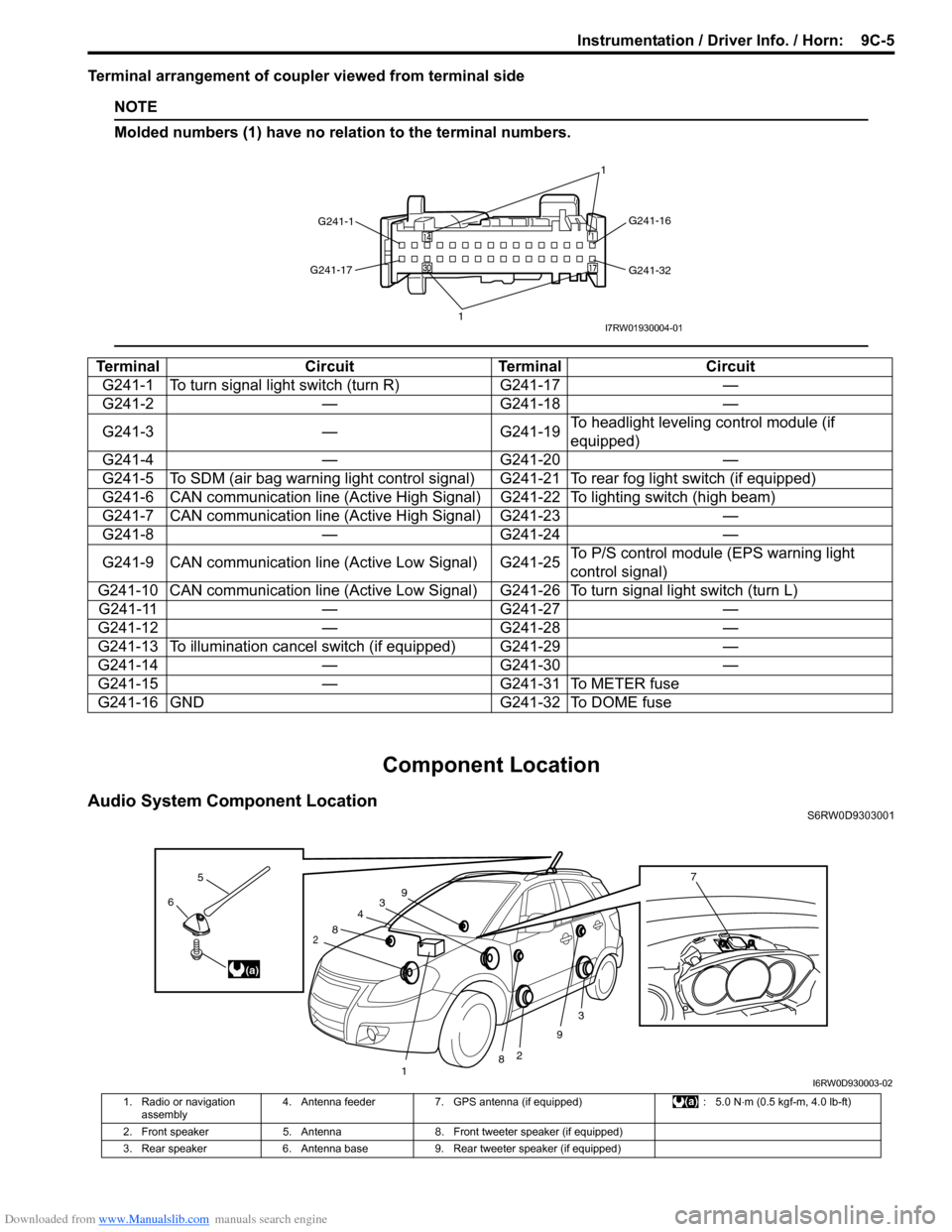

Terminal arrangement of coupler viewed from terminal side

NOTE

Molded numbers (1) have no relation to the terminal numbers.

Component Location

Audio System Component LocationS6RW0D9303001

Terminal Circuit Terminal Circuit

G241-1 To turn signal light switch (turn R) G241-17 —

G241-2 — G241-18 —

G241-3 — G241-19To headlight leveling control module (if

equipped)

G241-4 — G241-20 —

G241-5 To SDM (air bag warning light control signal) G241-21 To rear fog light switch (if equipped)

G241-6 CAN communication line (Active High Signal) G241-22 To lighting switch (high beam)

G241-7 CAN communication line (Active High Signal) G241-23 —

G241-8 — G241-24 —

G241-9 CAN communication line (Active Low Signal) G241-25To P/S control module (EPS warning light

control signal)

G241-10 CAN communication line (Active Low Signal) G241-26 To turn signal light switch (turn L)

G241-11 — G241-27 —

G241-12 — G241-28 —

G241-13 To illumination cancel switch (if equipped) G241-29 —

G241-14 — G241-30 —

G241-15 — G241-31 To METER fuse

G241-16 GND G241-32 To DOME fuse

G241-1G241-16

G241-32 G241-17

11I7RW01930004-01

3

2

3

2

1

4

8

8

9

96

5

(a)

7

I6RW0D930003-02

1. Radio or navigation

assembly4. Antenna feeder 7. GPS antenna (if equipped) : 5.0 N⋅m (0.5 kgf-m, 4.0 lb-ft)

2. Front speaker 5. Antenna 8. Front tweeter speaker (if equipped)

3. Rear speaker 6. Antenna base 9. Rear tweeter speaker (if equipped)

Page 1361 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-9

Charge Warning Light Symptom DiagnosisS6RW0D9304010

Main Beam (High Beam) Indicator Symptom DiagnosisS6RW0D9304011

Warning Buzzer Circuit Symptom DiagnosisS6RW0D9304012

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

Charge warning light

does not come ONCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faulty Replace after making sure that none of above

parts is faulty.

Charge warning light stay

ONCharging system faultyCheck charging system.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faulty Replace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Main beam (high beam)

indicator does not come

ONCircuit fuse blownReplace fuse and check for short circuit.

Combination switch faultyCheck combination switch referring to

“Headlight Switch (in Lighting Switch)

Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

Main beam (high beam)

indicator stay ONCombination switch faultyCheck combination switch referring to

“Headlight Switch (in Lighting Switch)

Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

Condition Possible cause Correction / Reference Item

Warning buzzer shows no

soundingCircuit fuse blownReplace fuse and check for short circuit.

Driver side door switch faultyCheck driver side door switch referring to

“Door Switch (Front / Rear Door) Inspection”.

Lighting switch faultyCheck lighting switch referring to “Headlight

Switch (in Lighting Switch) Inspection in

Section 9B”.

Key reminder switch faultyCheck key reminder switch referring to

“Ignition Switch Inspection”.

Seat belt switch faultyCheck seat belt switch referring to “Front Seat

Belt Inspection in Section 8A”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1373 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-21

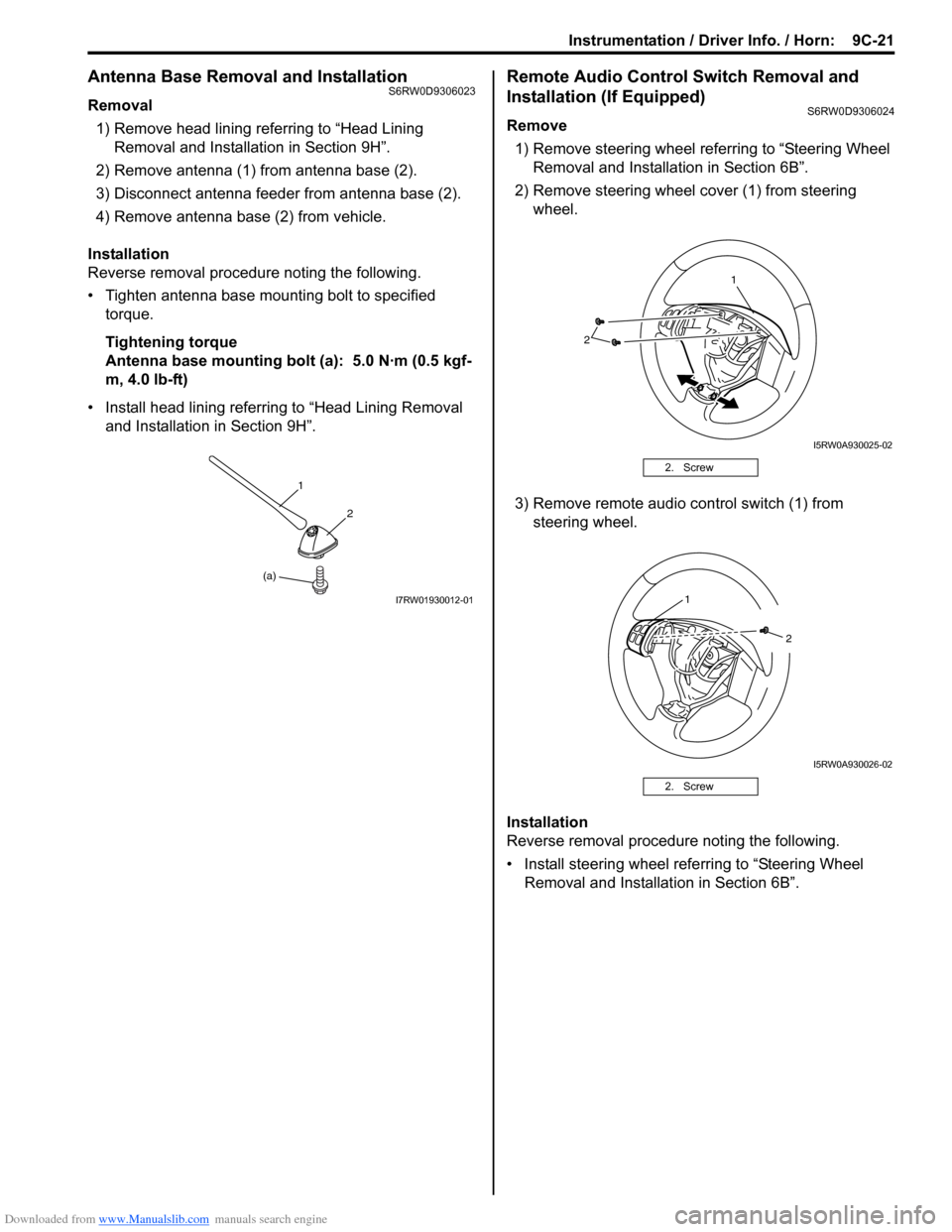

Antenna Base Removal and InstallationS6RW0D9306023

Removal

1) Remove head lining referring to “Head Lining

Removal and Installation in Section 9H”.

2) Remove antenna (1) from antenna base (2).

3) Disconnect antenna feeder from antenna base (2).

4) Remove antenna base (2) from vehicle.

Installation

Reverse removal procedure noting the following.

• Tighten antenna base mounting bolt to specified

torque.

Tightening torque

Antenna base mounting bolt (a): 5.0 N·m (0.5 kgf-

m, 4.0 lb-ft)

• Install head lining referring to “Head Lining Removal

and Installation in Section 9H”.

Remote Audio Control Switch Removal and

Installation (If Equipped)

S6RW0D9306024

Remove

1) Remove steering wheel referring to “Steering Wheel

Removal and Installation in Section 6B”.

2) Remove steering wheel cover (1) from steering

wheel.

3) Remove remote audio control switch (1) from

steering wheel.

Installation

Reverse removal procedure noting the following.

• Install steering wheel referring to “Steering Wheel

Removal and Installation in Section 6B”.

(a)1

2

I7RW01930012-01

2. Screw

2. Screw

2

1

I5RW0A930025-02

1

2

I5RW0A930026-02

Page 1377 of 1556

Downloaded from www.Manualslib.com manuals search engine Wipers / Washers: 9D-3

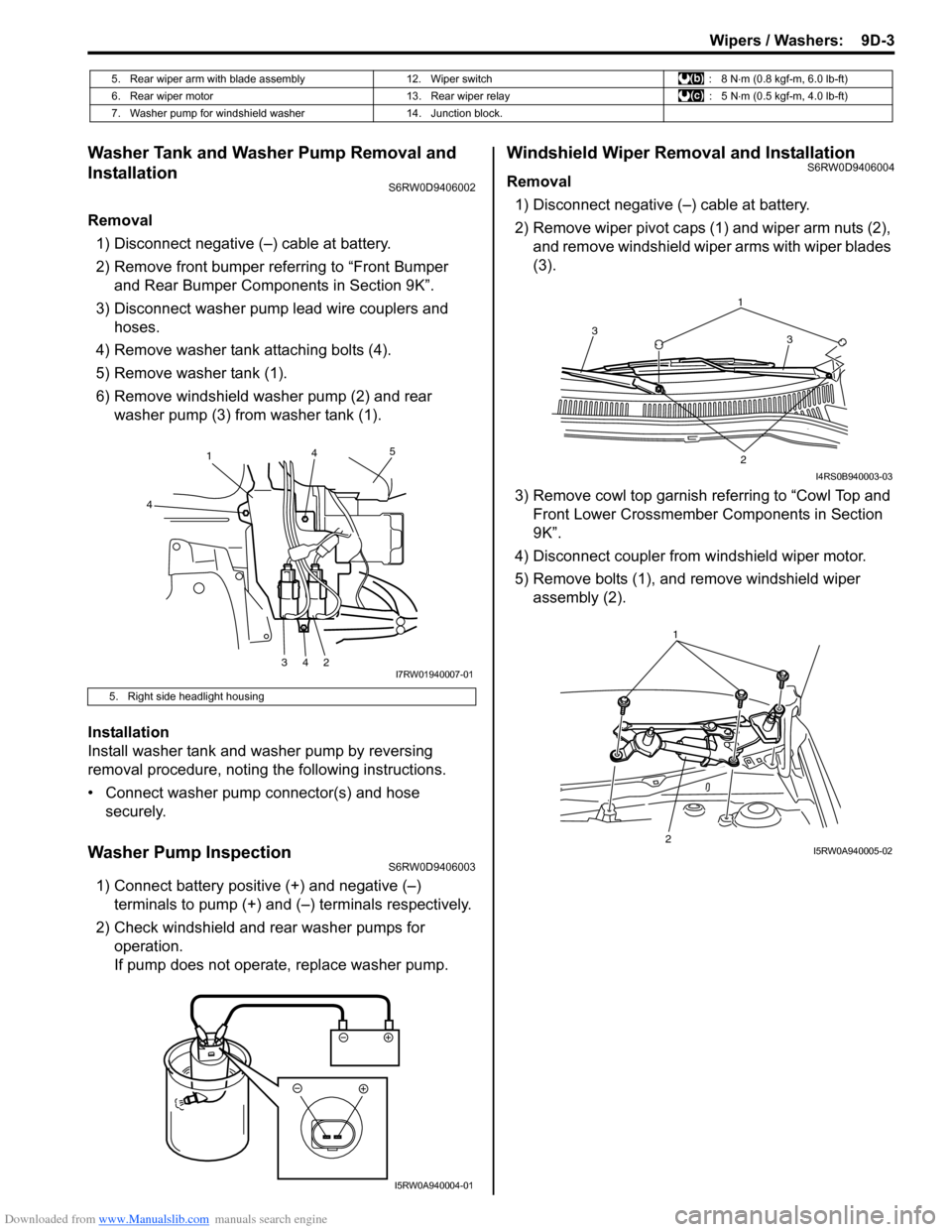

Washer Tank and Washer Pump Removal and

Installation

S6RW0D9406002

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

3) Disconnect washer pump lead wire couplers and

hoses.

4) Remove washer tank attaching bolts (4).

5) Remove washer tank (1).

6) Remove windshield washer pump (2) and rear

washer pump (3) from washer tank (1).

Installation

Install washer tank and washer pump by reversing

removal procedure, noting the following instructions.

• Connect washer pump connector(s) and hose

securely.

Washer Pump InspectionS6RW0D9406003

1) Connect battery positive (+) and negative (–)

terminals to pump (+) and (–) terminals respectively.

2) Check windshield and rear washer pumps for

operation.

If pump does not operate, replace washer pump.

Windshield Wiper Removal and InstallationS6RW0D9406004

Removal

1) Disconnect negative (–) cable at battery.

2) Remove wiper pivot caps (1) and wiper arm nuts (2),

and remove windshield wiper arms with wiper blades

(3).

3) Remove cowl top garnish referring to “Cowl Top and

Front Lower Crossmember Components in Section

9K”.

4) Disconnect coupler from windshield wiper motor.

5) Remove bolts (1), and remove windshield wiper

assembly (2).

5. Rear wiper arm with blade assembly 12. Wiper switch : 8 N⋅m (0.8 kgf-m, 6.0 lb-ft)

6. Rear wiper motor 13. Rear wiper relay : 5 N⋅m (0.5 kgf-m, 4.0 lb-ft)

7. Washer pump for windshield washer 14. Junction block.

5. Right side headlight housing

1

4

34245

I7RW01940007-01

I5RW0A940004-01

1

3 3

2

I4RS0B940003-03

21I5RW0A940005-02