speed SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 639 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-34

Installation

1) Install hydraulic unit / control module assembly by

reversing removal procedure noting the following.

Install ABS hydraulic unit / control module assembly

bracket bolt as follows.

a) Tighten bracket bolt (1) and (2) by hand.

b) Then tighten bracket bolt to specified torque.

Tightening order (1) → (2)

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

ABS hydraulic unit / control module assembly

bolt (b): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ABS hydraulic unit / control module assembly

bracket bolt (c): 26 N·m (2.6 kgf-m, 19.0 lb-ft)2) Bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage and

perform “ABS Hydraulic Unit Operation Check”.

NOTE

For new ABS hydraulic unit / control module

assembly, if “ABS Hydraulic Unit Operation

Check” has not been performed, ABS

warning light may flash when ignition switch

is turned ON position.

Accordingly preform “ABS Hydraulic Unit

Operation Check” to stop flashing of ABS

warning light.

Front and Rear Wheel Speed Sensor On-Vehicle

Inspection

S6RW0D4506005

Output Voltage Inspection

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Set up measuring device as shown in figure, the

resistance to 115 Ω and the power supply voltage to

12 V.

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

I6RW0C450011-01

1. Wheel speed sensor connector 4. “BLK” wire terminal

2. Resistance (115Ω) 5. Power supply (12 V)

3. “WHT” wire terminal

V

41

3

2

5

I5JB0A450026-03

Page 640 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-35 ABS:

5) Measure voltage at resistance without wheel

rotation.If voltage is out of specification, check

sensor, mating encoder and their installation

conditions.

Voltage at the resistance (115

Ω) without wheel

rotation

680 – 960 mV

6) Measure voltage at resistance with wheel rotation

and confirm voltage alternately changes between

high and low voltages.If voltage does not change

with wheel rotation, check sensor, mating encoder

and their installation conditions.

Voltage at the resistance (115

Ω) with wheel

rotation

High voltage “a”: 1360 – 1930 mV

Low voltage “b”: 680 – 960 mV

Reference

When using oscilloscope for this check, check if peak-to-

peak voltage and waveform meet specification.

Peak-to-peak voltage at the resistance (115

Ω) with

wheel rotation

High voltage “a”: 1360 to 1930 mV

Low voltage “b”: 680 to 960 mV

Front Wheel Speed Sensor Removal and

Installation

S6RW0D4506006

CAUTION!

• Do not pull wire harness when removing

and installing front wheel speed sensor.

• Do not cause damage to surface of front

wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Removal

1) Disconnect negative (–) cable from battery.

2) Disconnect front wheel speed sensor connector (1).

3) Hoist vehicle and remove wheel.

4) Remove harness clamp, clamp bolt (2).

5) Remove front wheel speed sensor (3) from knuckle.

[A]: Voltage [B]: Time

I5JB0A450027-01

I5JB0A450028-02

3

1

2

I5RW0A450023-01

Page 641 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-36

Installation

1) Check that no foreign material is attached to sensor

(1) and wheel speed sensor encoder (included in

wheel hub assembly).

2) Install it by reversing removal procedure.

NOTE

Before fitting wheel speed sensor, be sure to

silicon grease to its O-ring.

Tightening torque

Front wheel speed sensor bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

Front wheel speed sensor harness clamp bolt

(b): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Check that there is no clearance between sensor

and knuckle.

Front and Rear Wheel Speed Sensor InspectionS6RW0D4506007

Check sensor for damage.

If any malcondition is found, replace.

Rear Wheel Speed Sensor Removal and

Installation (4WD Model)

S6RW0D4506008

CAUTION!

Rear wheel speed sensor is included in rear

wheel hub assembly. If rear wheel speed

sensor needs to be replaced, replace it as a

rear wheel hub assembly.

For removal and Installation of rear wheel speed sensor

(included in rear wheel hub), refer to “Rear Wheel Hub

Assembly Removal and Installation in Section 2C”.

Rear Wheel Speed Sensor Removal and

Installation (2WD Model)

S6RW0D4506009

CAUTION!

• Do not pull wire harness when removing

and installing rear wheel speed sensor.

• Do not cause damage to surface of rear

wheel speed sensor and do not allow dust,

etc. to enter its installation hole.

Removal

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle, and remove wheel.

3) Disconnect rear wheel speed sensor connector.

4) Remove harness clamp.

5) Remove rear wheel speed sensor from wheel hub.

Installation

1) Check that no foreign material is attached to sensor

and encoder (included in wheel hub assembly).

2) Install it by reversing removal procedure.

NOTE

Before fitting wheel speed sensor, be sure to

silicon grease to its O-ring.

Tightening torque

Rear wheel speed sensor bolt: 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

3) Check that there is no clearance between sensor

and wheel hub.[A]: OK [B]: NG

1

2

(b)

(a)

I5RW0A450025-01

[A][B]

11

I5RW0A450024-01

I5JB0A450031-01

[A]: OK [B]: NG

[A][B]

11

I5RW0A450024-01

Page 642 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-37 ABS:

Front Wheel Speed Sensor Encoder On-Vehicle

Inspection

S6RW0D4506010

Before inspecting front wheel speed sensor encoder,

remove front drive shaft referring to “Front Drive Shaft

Assembly Removal and Installation in Section 3A”.

• Check sensor encoder (1) for crack, damage or

deformation.

• Turn wheel and check if sensor encoder rotation is

free from eccentricity and looseness.

• Check that no foreign material is attached.

If any faulty is found, clean or replace. Refer to “Front

Wheel Hub, Steering Knuckle and Wheel Bearing

Removal and Installation in Section 2B”.

Front Wheel Speed Sensor Encoder Removal

and Installation

S6RW0D4506011

CAUTION!

Front wheel speed sensor encoder is

included in front wheel hub assembly. If front

wheel speed sensor encoder needs to be

replaced, replace it as a front wheel hub

assembly.

For removal and installation of front wheel hub

assembly, referring to “Front Wheel Hub, Steering

Knuckle and Wheel Bearing Removal and Installation in

Section 2B”.

Rear Wheel Speed Sensor Encoder On-Vehicle

Inspection

S6RW0D4506012

For 4WD model

Refer to “Rear Wheel Speed Sensor On-Vehicle

Inspection”.

For 2WD model

Before inspecting rear wheel speed sensor encoder,

remove rear wheel speed sensor referring to “Rear

Wheel Speed Sensor Removal and Installation (2WD

Model)”.

• Check encoder (1) for crack, damage or deformation.

• Turn wheel and check if encoder rotation is free from

eccentricity and looseness.

• Check that no foreign material is attached.

If any faulty is found, clean or replace. Refer to “Rear

Wheel Hub Assembly Removal and Installation in

Section 2C”.

Rear Wheel Speed Sensor Encoder Removal

and Installation

S6RW0D4506013

CAUTION!

Rear wheel speed sensor encoder is included

in rear wheel hub assembly. If rear wheel

speed sensor encoder needs to be replaced,

replace it as a rear wheel hub assembly.

For removal and installation of front wheel hub

assembly, referring to “Rear Wheel Hub Assembly

Removal and Installation in Section 2C”.

1

I5RW0A450026-01

Page 644 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-39 ABS:

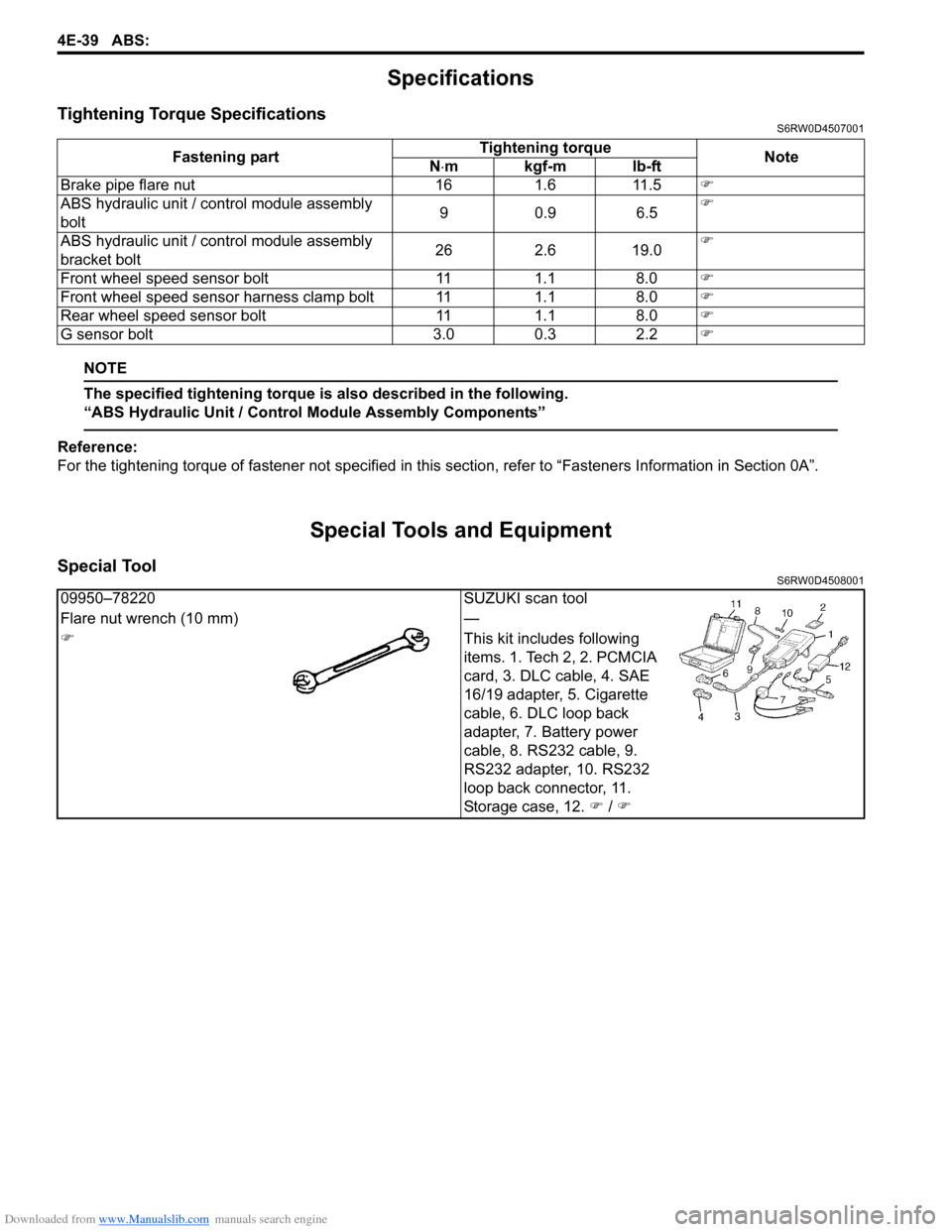

Specifications

Tightening Torque SpecificationsS6RW0D4507001

NOTE

The specified tightening torque is also described in the following.

“ABS Hydraulic Unit / Control Module Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Special ToolS6RW0D4508001

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Brake pipe flare nut 16 1.6 11.5�)

ABS hydraulic unit / control module assembly

bolt90.9 6.5�)

ABS hydraulic unit / control module assembly

bracket bolt26 2.6 19.0�)

Front wheel speed sensor bolt 11 1.1 8.0�)

Front wheel speed sensor harness clamp bolt 11 1.1 8.0�)

Rear wheel speed sensor bolt 11 1.1 8.0�)

G sensor bolt 3.0 0.3 2.2�)

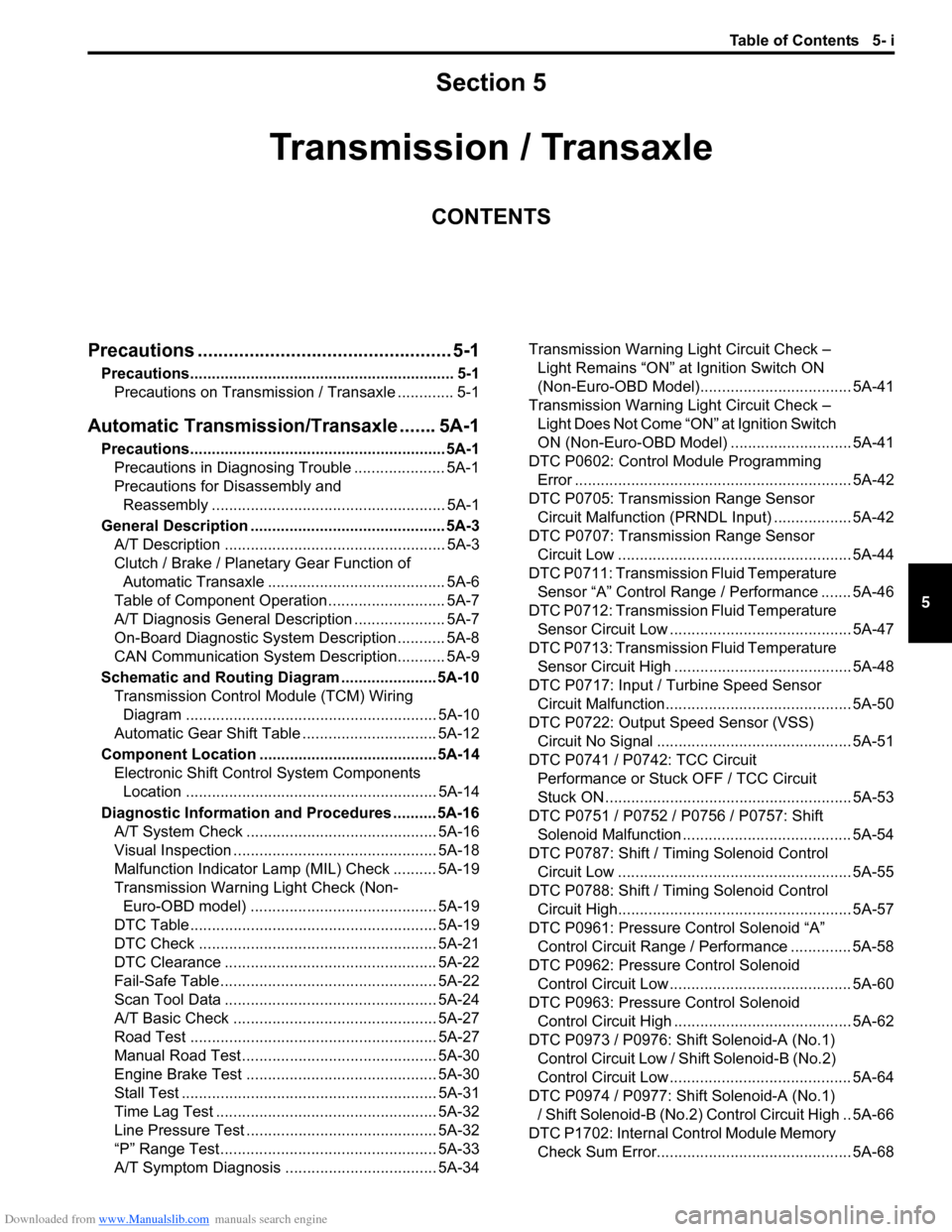

09950–78220 SUZUKI scan tool

Flare nut wrench (10 mm) —

�)This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �) / �)

Page 645 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1

Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and

Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3

A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of

Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

A/T Diagnosis General Description ..................... 5A-7

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10

Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Location ......................................... 5A-14

Electronic Shift Control System Components

Location .......................................................... 5A-14

Diagnostic Information and Procedures .......... 5A-16

A/T System Check ............................................ 5A-16

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-19

Transmission Warning Light Check (Non-

Euro-OBD model) ........................................... 5A-19

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-21

DTC Clearance ................................................. 5A-22

Fail-Safe Table .................................................. 5A-22

Scan Tool Data ................................................. 5A-24

A/T Basic Check ............................................... 5A-27

Road Test ......................................................... 5A-27

Manual Road Test ............................................. 5A-30

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-31

Time Lag Test ................................................... 5A-32

Line Pressure Test ............................................ 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ................................... 5A-34Transmission Warning Light Circuit Check –

Light Remains “ON” at Ignition Switch ON

(Non-Euro-OBD Model)................................... 5A-41

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON (Non-Euro-OBD Model)............................ 5A-41

DTC P0602: Control Module Programming

Error ................................................................ 5A-42

DTC P0705: Transmission Range Sensor

Circuit Malfunction (PRNDL Input) .................. 5A-42

DTC P0707: Transmission Range Sensor

Circuit Low ...................................................... 5A-44

DTC P0711: Transmission Fluid Temperature

Sensor “A” Control Range / Performance ....... 5A-46

DTC P0712: Transmission Fluid Temperature

Sensor Circuit Low .......................................... 5A-47

DTC P0713: Transmission Fluid Temperature

Sensor Circuit High ......................................... 5A-48

DTC P0717: Input / Turbine Speed Sensor

Circuit Malfunction........................................... 5A-50

DTC P0722: Output Speed Sensor (VSS)

Circuit No Signal ............................................. 5A-51

DTC P0741 / P0742: TCC Circuit

Performance or Stuck OFF / TCC Circuit

Stuck ON ......................................................... 5A-53

DTC P0751 / P0752 / P0756 / P0757: Shift

Solenoid Malfunction ....................................... 5A-54

DTC P0787: Shift / Timing Solenoid Control

Circuit Low ...................................................... 5A-55

DTC P0788: Shift / Timing Solenoid Control

Circuit High...................................................... 5A-57

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid-A (No.1)

Control Circuit Low / Shift Solenoid-B (No.2)

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid-A (No.1)

/ Shift Solenoid-B (No.2) Control Circuit High .. 5A-66

DTC P1702: Internal Control Module Memory

Check Sum Error............................................. 5A-68

Page 646 of 1556

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1723: Range Select Switch

Malfunction ...................................................... 5A-68

DTC P1878: Torque Converter Clutch

Shudder .......................................................... 5A-69

DTC P2762: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

Range / Performance ...................................... 5A-70

DTC P2763: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

High ................................................................. 5A-72

DTC P2764: Torque Converter Clutch (TCC)

Circuit Pressure Control Solenoid Control

Circuit Low ...................................................... 5A-74

DTC U0073: Control Module Communication

Bus Off ............................................................ 5A-76

DTC U0100: Lost Communication with ECM /

PCM “A” .......................................................... 5A-76

Inspection of TCM and Its Circuits .................... 5A-76

TCM Power and Ground Circuit Check ............. 5A-80

Brake Interlock System Inspection .................... 5A-81

Repair Instructions ............................................5A-82

Learning Control Initialization ............................ 5A-82

A/T Fluid Level Check ....................................... 5A-82

A/T Fluid Change .............................................. 5A-83

Select Lever Components ................................. 5A-84

Select Lever Assembly Removal and

Installation ....................................................... 5A-84

Select Lever Knob Installation........................... 5A-84

Select Lever Inspection ..................................... 5A-85

“3” Position Switch Inspection ........................... 5A-85

Shift Lock Solenoid Inspection .......................... 5A-85

Shift Lock Solenoid Replacement ..................... 5A-85

Select Cable Components ................................ 5A-86

Select Cable Removal and Installation ............. 5A-86

Select Cable Adjustment ................................... 5A-86

Key Interlock Cable Removal and Installation... 5A-87

Transmission Range Sensor Inspection and

Adjustment ...................................................... 5A-89

Output Shaft Speed Sensor (VSS) Removal

and Installation ................................................ 5A-90

Output Shaft Speed Sensor (VSS) Inspection .. 5A-90

Input Shaft Speed Sensor Removal and

Installation ....................................................... 5A-91

Input Shaft Speed Sensor Inspection................ 5A-91

Transmission Fluid Temperature Sensor

Removal and Installation ................................. 5A-91

Transmission Fluid Temperature Sensor

Inspection ........................................................ 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Inspection .................. 5A-94

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Solenoid)

Removal and Installation ................................. 5A-95

Pressure Control Solenoid Valves Inspection ... 5A-96

Transmission Control Module (TCM)

Removal and Installation ................................. 5A-97

A/T Relay Inspection ......................................... 5A-97Differential Side Oil Seal Replacement ............. 5A-98

A/T Fluid Cooler Hoses Replacement ............... 5A-98

Automatic Transaxle Unit Components............. 5A-99

Automatic Transaxle Unit Dismounting and

Remounting ................................................... 5A-100

Automatic Transaxle Assembly Components . 5A-102

Automatic Transaxle Unit Disassembly........... 5A-104

Oil Pump Assembly Components ................... 5A-116

Oil Pump Assembly Disassembly and

Reassembly .................................................. 5A-116

Oil Pump Assembly Inspection ....................... 5A-117

Direct Clutch Assembly Components.............. 5A-119

Direct Clutch Assembly Preliminary Check ..... 5A-119

Direct Clutch Assembly Disassembly and

Reassembly .................................................. 5A-120

Direct Clutch Assembly Inspection.................. 5A-122

Forward and Reverse Clutch Assembly

Components .................................................. 5A-123

Forward and Reverse Clutch Assembly

Preliminary Check ......................................... 5A-123

Forward and Reverse Clutch Assembly

Disassembly and Reassembly ...................... 5A-124

Forward and Reverse Clutch Assembly

Inspection ...................................................... 5A-127

2nd Brake Piston Assembly Components ....... 5A-128

2nd Brake Piston Assembly Disassembly and

Reassembly .................................................. 5A-128

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Components........... 5A-129

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-130

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Inspection............... 5A-131

Countershaft Assembly Components.............. 5A-132

Countershaft Assembly Disassembly and

Reassembly .................................................. 5A-132

Valve Body Assembly Components ................ 5A-133

Valve Body Assembly Disassembly and

Reassembly .................................................. 5A-134

Differential Assembly Components ................. 5A-135

Differential Assembly Disassembly and

Reassembly .................................................. 5A-136

Differential Assembly Inspection ..................... 5A-137

Torque Converter Housing Disassembly and

Reassembly .................................................. 5A-138

Transaxle Case Disassembly and

Reassembly .................................................. 5A-140

Automatic Transaxle Unit Inspection and

Adjustment .................................................... 5A-141

Automatic Transaxle Unit Assembly ............... 5A-144

Specifications ...................................................5A-161

Tightening Torque Specifications .................... 5A-161

Special Tools and Equipment .........................5A-162

Recommended Service Material ..................... 5A-162

Special Tool .................................................... 5A-162

Manual Transmission/Transaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction .......................... 5B-1

Page 651 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-3

General Description

A/T DescriptionS6RW0D5101001

This automatic transaxle is electronic control full automatic transaxle with forward 3-speed plus overdrive (O/D) and

reverse 1-speed.

The torque converter is a 3-element, 1-step and 2-phase type and is equipped with an automatically controlled lock-up

mechanism.

The gear change device consists of a ravigneau type planetary gear unit, 3 multiple disc type clutches, 3 multiple disc

type brakes and 2 one-way clutches.

The hydraulic pressure control device consists of a valve body assembly, pressure control solenoid valve (linear

solenoid), 2 shift solenoid valves, TCC solenoid valve (TCC pressure control solenoid valve) (linear solenoid) and a

timing solenoid valve. Optimum line pressure complying with engine torque is produced by the pressure control

solenoid valve in dependence upon control signal from transmission control module (TCM). This makes it possible to

control the line pressure with high accuracy in accordance with the engine power and running conditions to achieve

smooth shifting characteristics and high efficiency.

A clutch-to-clutch control system is provided for shifting between 3rd gear and 4th gear. This clutch-to-clutch control

system is made to function optimally, so that hydraulic pressure controls such as shown below are conducted.

• When upshifting from 3rd gear to 4th gear, to adjust the drain hydraulic pressure at releasing the forward clutch, a

timing solenoid valve is used to switch a hydraulic passage with an orifice to another during shifting.

• When downshifting from 4th gear to 3rd gear, to adjust the line pressure applied to the forward clutch at engaging

the forward clutch, a timing solenoid valve is used to switch a hydraulic passage with an orifice to another during

shifting.

• When upshifting from 3rd gear to 4th gear with engine throttle opened, to optimize the line pressure applied to the

forward clutch at releasing the forward clutch, the learning control is processed to compensate the switching timing

of the timing solenoid at every shifting.

• When downshifting from 4th gear to 3rd gear with engine throttle opened, to optimize the line pressure applied to

the forward clutch at engaging the forward clutch, the learning control is processed to compensate the line pressure

at every shifting.

Employing the ravigneau type planetary gear unit and this clutch-to-clutch control system greatly simplifies the

construction to make possible a lightweight and compact transaxle.

A line pressure learning control is conducted to provide optimum shifting time at every upshifting with engine throttle

opened. If long upshifting time is detected, the subsequent line pressure applied during upshifting is intensified. On the

contrary, if short upshifting time is detected, the subsequent line pressure applied during upshifting is weakened.

Page 652 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-4 Automatic Transmission/Transaxle:

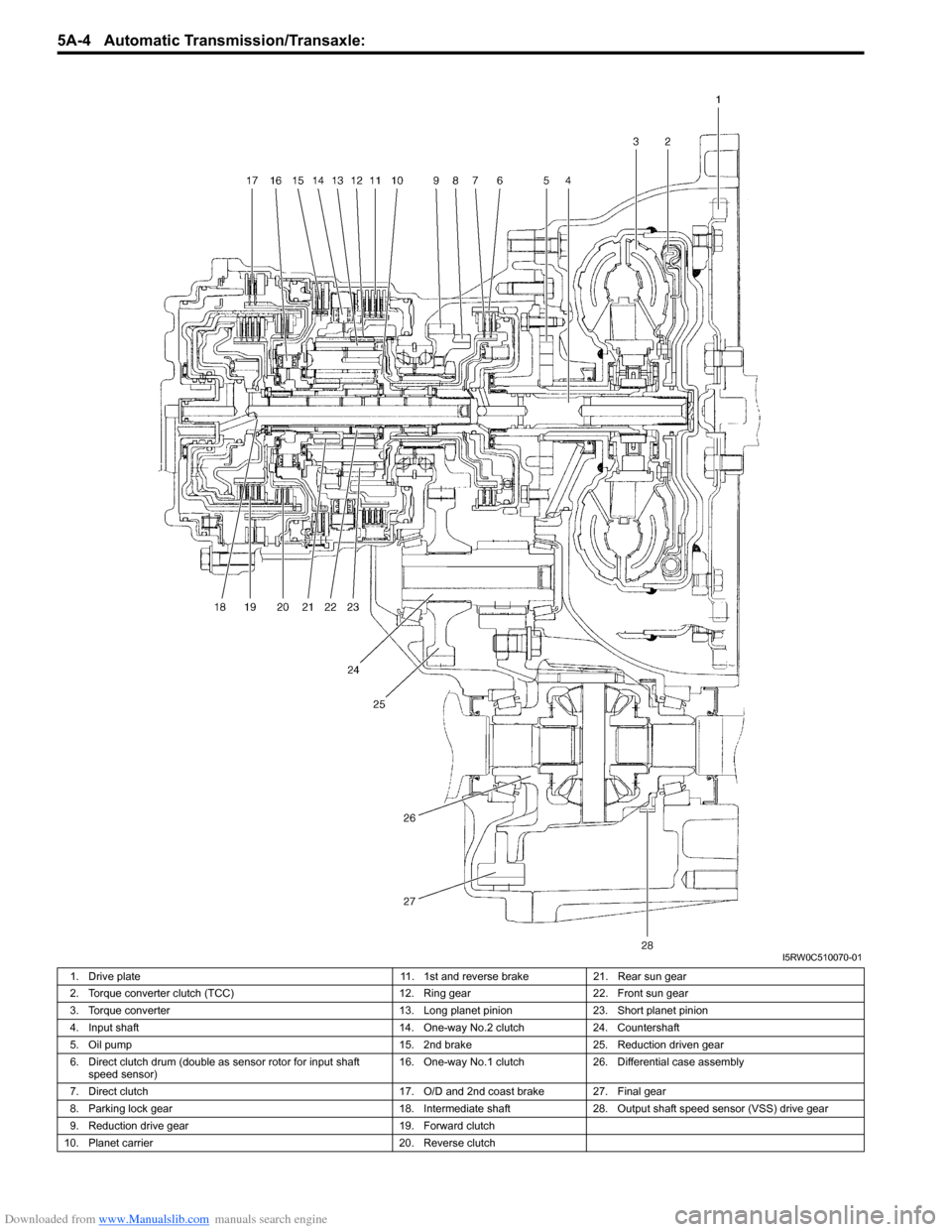

I5RW0C510070-01

1. Drive plate 11. 1st and reverse brake 21. Rear sun gear

2. Torque converter clutch (TCC) 12. Ring gear 22. Front sun gear

3. Torque converter 13. Long planet pinion 23. Short planet pinion

4. Input shaft 14. One-way No.2 clutch 24. Countershaft

5. Oil pump 15. 2nd brake 25. Reduction driven gear

6. Direct clutch drum (double as sensor rotor for input shaft

speed sensor)16. One-way No.1 clutch 26. Differential case assembly

7. Direct clutch 17. O/D and 2nd coast brake 27. Final gear

8. Parking lock gear 18. Intermediate shaft 28. Output shaft speed sensor (VSS) drive gear

9. Reduction drive gear 19. Forward clutch

10. Planet carrier 20. Reverse clutch

Page 657 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-9

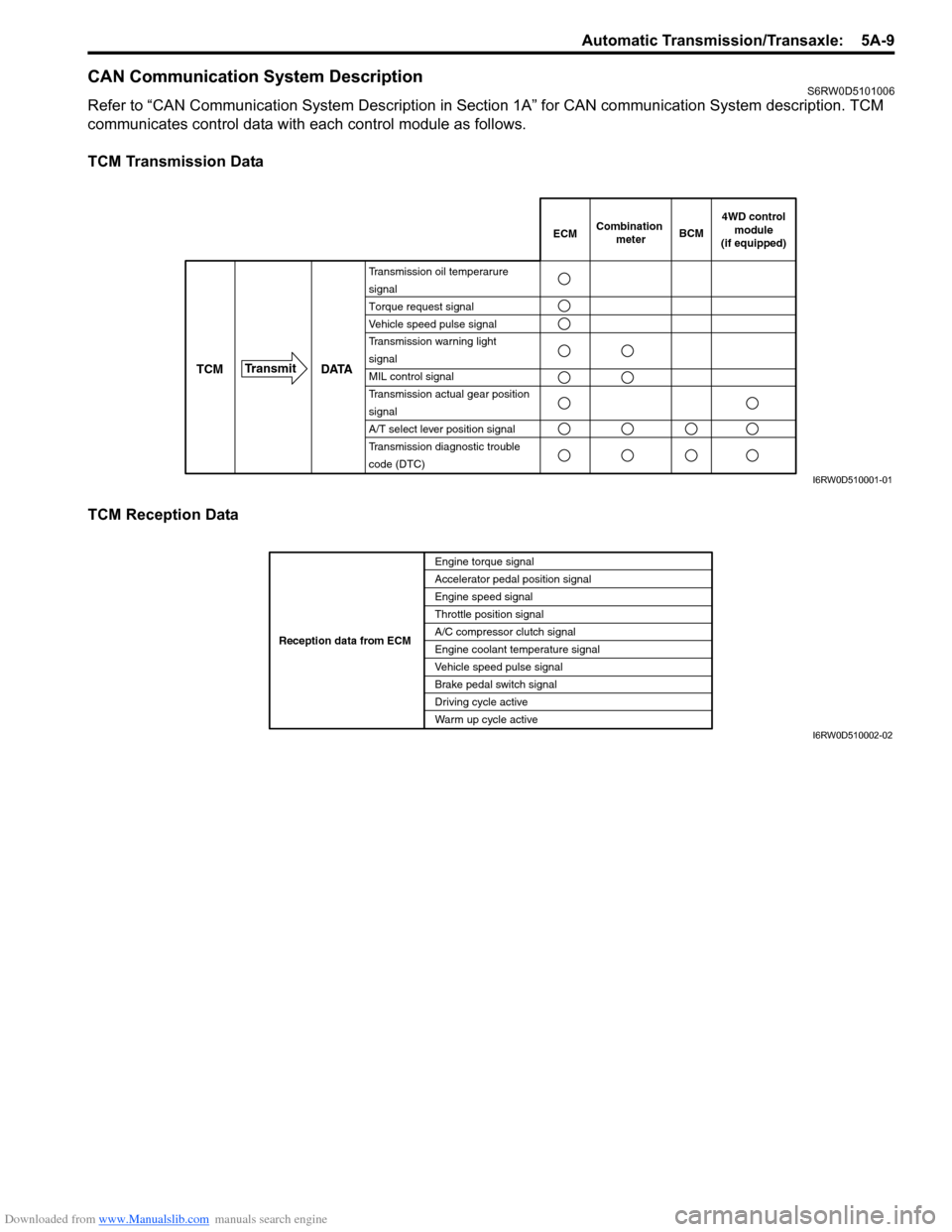

CAN Communication System DescriptionS6RW0D5101006

Refer to “CAN Communication System Description in Section 1A” for CAN communication System description. TCM

communicates control data with each control module as follows.

TCM Transmission Data

TCM Reception Data

DATA TCMTransmit

Transmission oil temperarure

signal

Torque request signal

Vehicle speed pulse signal

Transmission warning light

signal

MIL control signal

Transmission actual gear position

signal

A/T select lever position signal

Transmission diagnostic trouble

code (DTC)

ECMCombination

meterBCM

4WD control

module

(if equipped)

I6RW0D510001-01

Engine torque signal

Accelerator pedal position signal

Engine speed signal

Throttle position signal

A/C compressor clutch signal

Engine coolant temperature signal

Vehicle speed pulse signal

Brake pedal switch signal

Driving cycle active

Warm up cycle active Reception data from ECM

I6RW0D510002-02