ECU SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1437 of 1556

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-1

Body, Cab and Accessories

Hood / Fenders / Doors

Repair Instructions

Hood Removal and InstallationS6RW0D9A06001

Removal

CAUTION!

Place cloth to prevent body from any

damage.

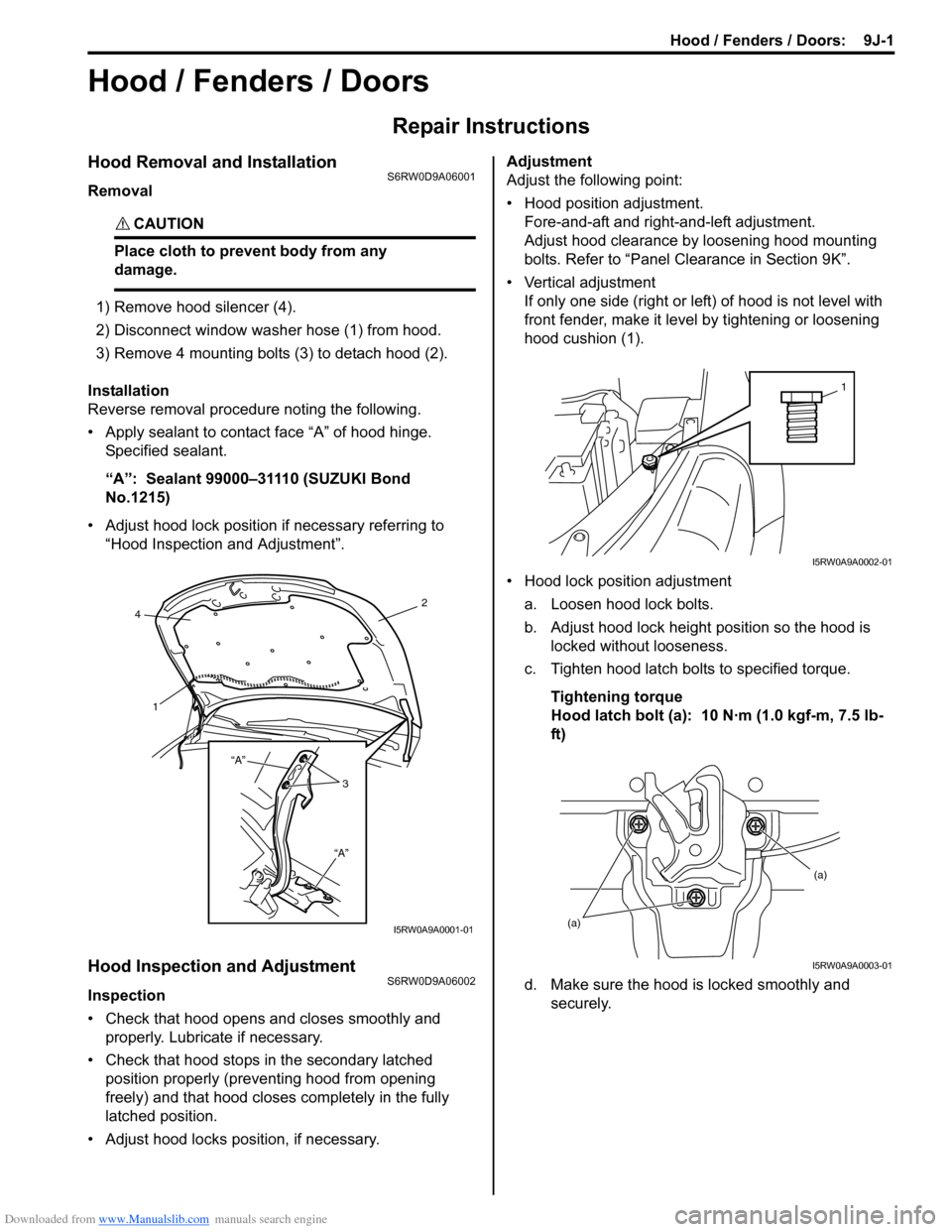

1) Remove hood silencer (4).

2) Disconnect window washer hose (1) from hood.

3) Remove 4 mounting bolts (3) to detach hood (2).

Installation

Reverse removal procedure noting the following.

• Apply sealant to contact face “A” of hood hinge.

Specified sealant.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

• Adjust hood lock position if necessary referring to

“Hood Inspection and Adjustment”.

Hood Inspection and AdjustmentS6RW0D9A06002

Inspection

• Check that hood opens and closes smoothly and

properly. Lubricate if necessary.

• Check that hood stops in the secondary latched

position properly (preventing hood from opening

freely) and that hood closes completely in the fully

latched position.

• Adjust hood locks position, if necessary.Adjustment

Adjust the following point:

• Hood position adjustment.

Fore-and-aft and right-and-left adjustment.

Adjust hood clearance by loosening hood mounting

bolts. Refer to “Panel Clearance in Section 9K”.

• Vertical adjustment

If only one side (right or left) of hood is not level with

front fender, make it level by tightening or loosening

hood cushion (1).

• Hood lock position adjustment

a. Loosen hood lock bolts.

b. Adjust hood lock height position so the hood is

locked without looseness.

c. Tighten hood latch bolts to specified torque.

Tightening torque

Hood latch bolt (a): 10 N·m (1.0 kgf-m, 7.5 lb-

ft)

d. Make sure the hood is locked smoothly and

securely.

2

4

1

3 “A”

“A”

I5RW0A9A0001-01

1

I5RW0A9A0002-01

(a)(a)

I5RW0A9A0003-01

Page 1443 of 1556

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-7

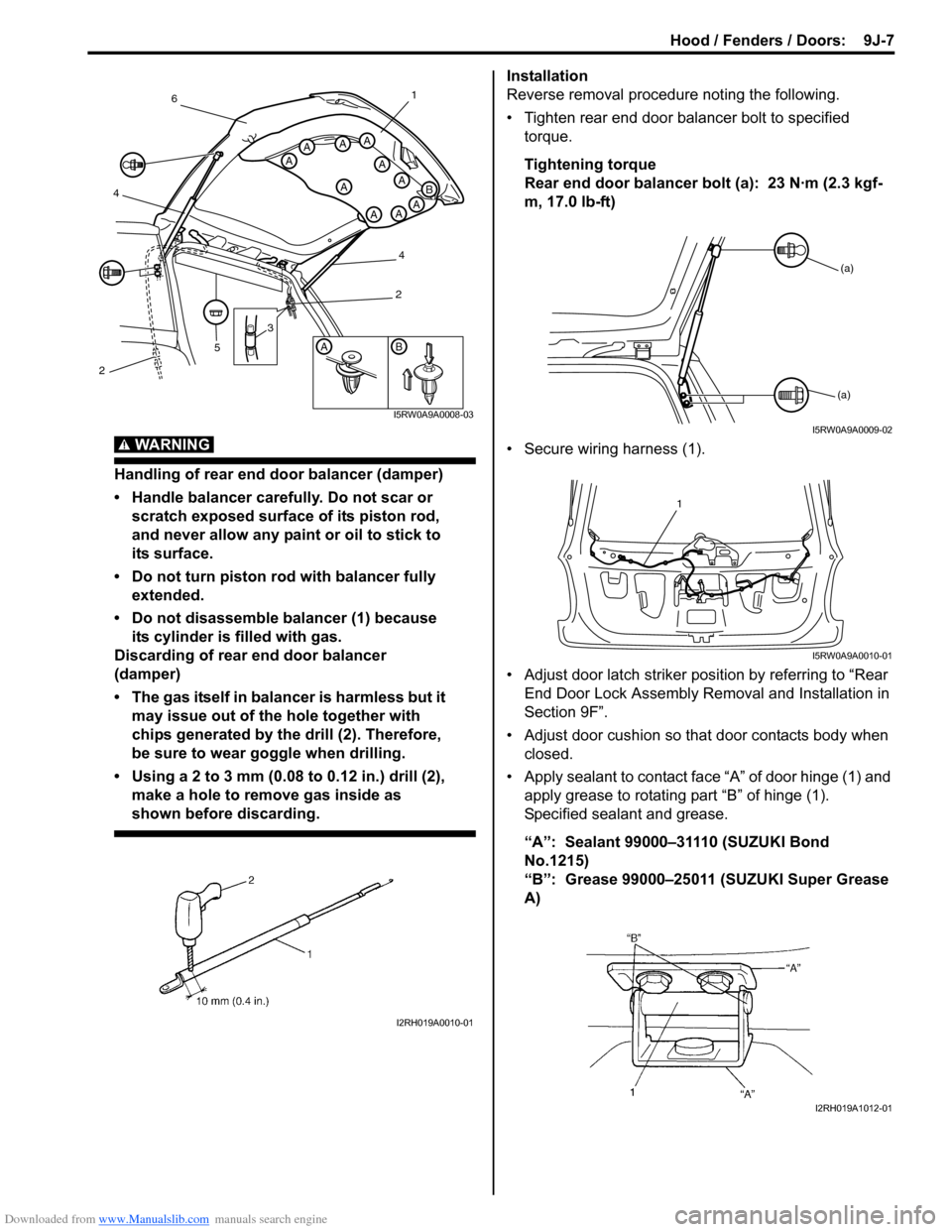

WARNING!

Handling of rear end door balancer (damper)

• Handle balancer carefully. Do not scar or

scratch exposed surface of its piston rod,

and never allow any paint or oil to stick to

its surface.

• Do not turn piston rod with balancer fully

extended.

• Do not disassemble balancer (1) because

its cylinder is filled with gas.

Discarding of rear end door balancer

(damper)

• The gas itself in balancer is harmless but it

may issue out of the hole together with

chips generated by the drill (2). Therefore,

be sure to wear goggle when drilling.

• Using a 2 to 3 mm (0.08 to 0.12 in.) drill (2),

make a hole to remove gas inside as

shown before discarding.

Installation

Reverse removal procedure noting the following.

• Tighten rear end door balancer bolt to specified

torque.

Tightening torque

Rear end door balancer bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

• Secure wiring harness (1).

• Adjust door latch striker position by referring to “Rear

End Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust door cushion so that door contacts body when

closed.

• Apply sealant to contact face “A” of door hinge (1) and

apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25011 (SUZUKI Super Grease

A)

AB

A

A

A

A

AAA

AAA

B

3

5

461

4

2

2

I5RW0A9A0008-03

I2RH019A0010-01

(a)

(a)

I5RW0A9A0009-02

1

I5RW0A9A0010-01

I2RH019A1012-01

Page 1471 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 10- i

10

Section 10

CONTENTS

Control Systems

Precautions ............................................... 10-1

Precautions........................................................... 10-1

Precautions for Control Systems......................... 10-1

Body Electrical Control System ........... 10B-1

Precautions......................................................... 10B-1

Precautions in Diagnosing Trouble ................... 10B-1

General Description ........................................... 10B-1

BCM General Description ................................. 10B-1

CAN Communication System Description......... 10B-1

Theft Deterrent Light ......................................... 10B-2

Security Alarm Description (If Equipped) .......... 10B-2

Schematic and Routing Diagram ...................... 10B-3

Body Electrical Control System Wiring Circuit

Diagram .......................................................... 10B-3

Connector Layout Diagram of BCM and

Junction Block ................................................. 10B-6

Component Location ......................................... 10B-7

BCM and Related System Component

Location .......................................................... 10B-7

Diagnostic Information and Procedures .......... 10B-8

BCM Self-Diagnosis Function ........................... 10B-8

Body Electrical Control System Check.............. 10B-9

Scan Tool Data ............................................... 10B-11

DTC Table ....................................................... 10B-13

DTC Check ..................................................... 10B-14

DTC Clearance ............................................... 10B-15

BCM Power Circuit and Ground Circuit Check 10B-16

DTC B1133 (DTC No. 1133): Battery Voltage

Too High ....................................................... 10B-17

DTC B1141 / DTC B1142 (No. 1141 / No.

1142) Outside Air Temperature (Ambient

Temp.) Sensor Circuit Malfunction ................ 10B-18

DTC B1150 (No. 1150): Air Bag

Communication Circuit Malfunction .............. 10B-19

DTC B1157 (No. 1157) Air Bag Deployment

Signal Input ................................................... 10B-20

DTC B1170 (No. 1170): EEPROM Access

Error .............................................................. 10B-20

DTC U0073 (No. 0073): Control Module

Communication Bus Off ................................ 10B-20

DTC U0100 (No. 0100): Lost Communication

with ECM....................................................... 10B-20DTC U0101 (No. 0101): Lost Communication

with TCM ....................................................... 10B-20

DTC U0155 (No. 0155): Lost Communication

with Instrument Panel Cluster (IPC) Control

Module .......................................................... 10B-20

DTC U1144 (No. 1144): Lost Communication

with Keyless Start Control Module ................ 10B-20

Inspection of BCM and Its Circuits .................. 10B-21

Repair Instructions ..........................................10B-28

BCM (Included in Junction Block) Removal

and Installation .............................................. 10B-28

Security Alarm Mode Selection Procedure (If

Equipped) ...................................................... 10B-29

Outside Air Temperature Sensor Removal

and Installation .............................................. 10B-29

Outside Air Temperature Sensor Inspection ... 10B-29

Special Tools and Equipment .........................10B-29

Special Tool .................................................... 10B-29

Immobilizer Control System ................. 10C-1

Precautions.........................................................10C-1

Precautions in Diagnosing Troubles .................10C-1

Precaution in Replacing ECM ...........................10C-1

Precaution in Replacing Ignition Key ................10C-1

Precautions in Handling Immobilizer Control

System ............................................................10C-1

General Description ...........................................10C-2

Immobilizer Control System Introduction ..........10C-2

On-Board Diagnostic System Description

(Self-diagnosis Function)................................10C-2

Schematic and Routing Diagram ......................10C-3

Immobilizer Control System Wiring Circuit

Diagram...........................................................10C-3

Component Location .........................................10C-5

Immobilizer Control System Components

Location...........................................................10C-5

Diagnostic Information and Procedures ..........10C-5

Immobilizer Control System Check ...................10C-5

DTC Check........................................................10C-6

DTC Clearance .................................................10C-6

DTC Table .........................................................10C-7

Scan Tool Data .................................................10C-8

Immobilizer Indicator Light Does Not Come

ON with Ignition Switch ON and Engine Stop ..10C-9

Page 1475 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-2

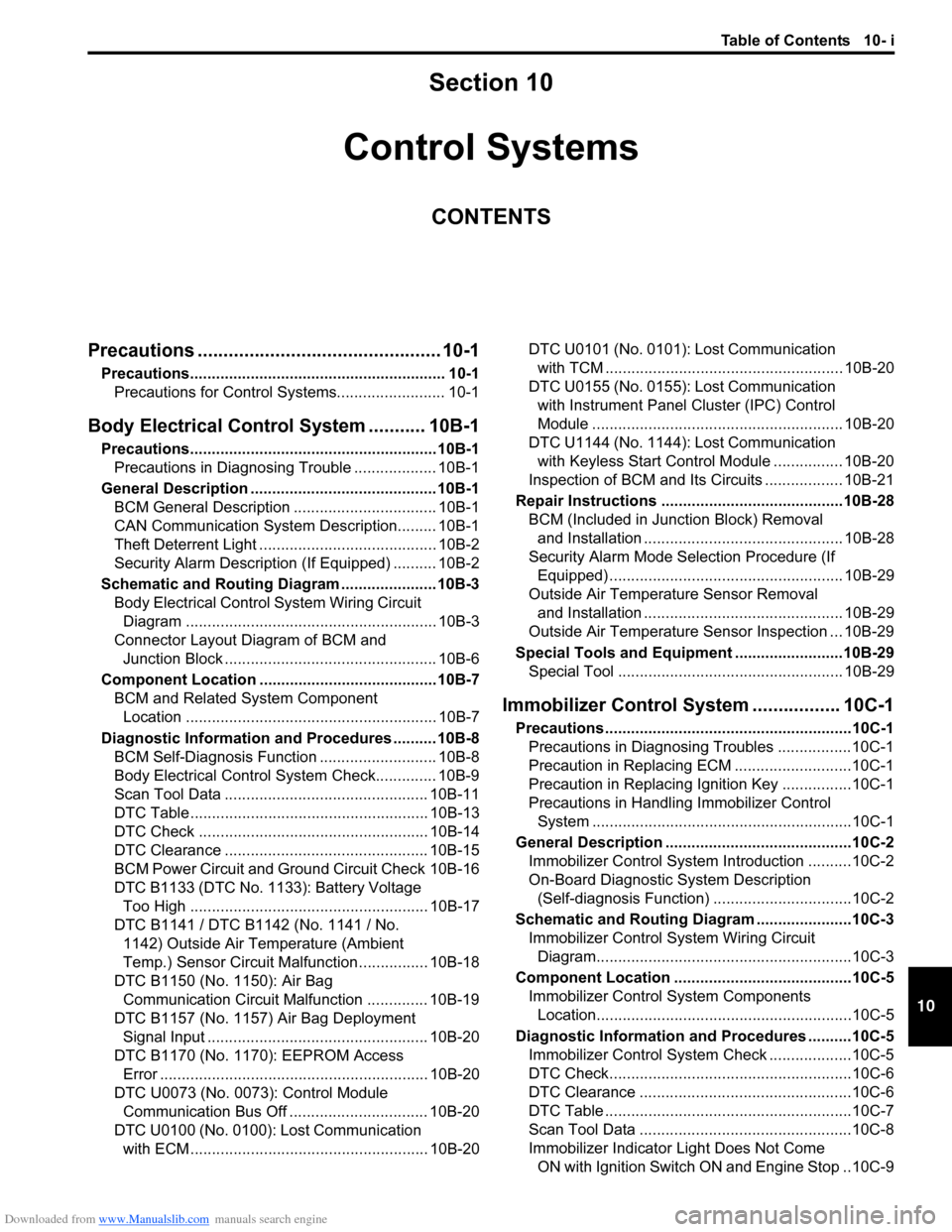

BCM Reception Data

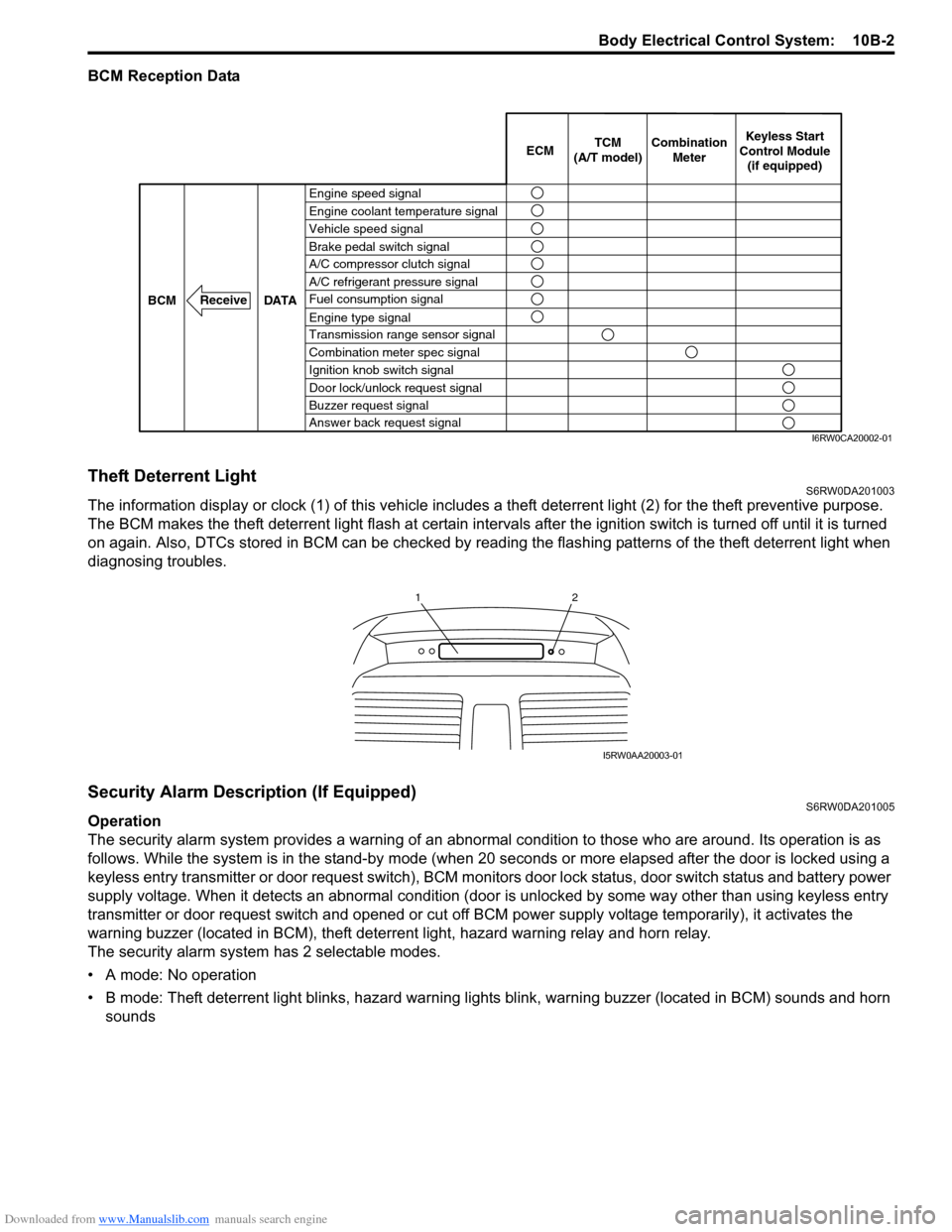

Theft Deterrent LightS6RW0DA201003

The information display or clock (1) of this vehicle includes a theft deterrent light (2) for the theft preventive purpose.

The BCM makes the theft deterrent light flash at certain intervals after the ignition switch is turned off until it is turned

on again. Also, DTCs stored in BCM can be checked by reading the flashing patterns of the theft deterrent light when

diagnosing troubles.

Security Alarm Description (If Equipped)S6RW0DA201005

Operation

The security alarm system provides a warning of an abnormal condition to those who are around. Its operation is as

follows. While the system is in the stand-by mode (when 20 seconds or more elapsed after the door is locked using a

keyless entry transmitter or door request switch), BCM monitors door lock status, door switch status and battery power

supply voltage. When it detects an abnormal condition (door is unlocked by some way other than using keyless entry

transmitter or door request switch and opened or cut off BCM power supply voltage temporarily), it activates the

warning buzzer (located in BCM), theft deterrent light, hazard warning relay and horn relay.

The security alarm system has 2 selectable modes.

• A mode: No operation

• B mode: Theft deterrent light blinks, hazard warning lights blink, warning buzzer (located in BCM) sounds and horn

sounds

Engine speed signal

Vehicle speed signal Engine coolant temperature signal

Brake pedal switch signal

A/C refrigerant pressure signal

Fuel consumption signal A/C compressor clutch signal

Engine type signal

Transmission range sensor signal

Combination meter spec signal

Ignition knob switch signal

Door lock/unlock request signal

Buzzer request signal

Answer back request signal DATA BCM

Receive

Combination

Meter TCM

(A/T model)Keyless Start

Control Module

(if equipped) ECM

I6RW0CA20002-01

12

I5RW0AA20003-01

Page 1476 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-3 Body Electrical Control System:

When “B” mode is selected and the door is locked using keyless entry transmitter or door request switch, the theft

deterrent light (1) flashes at 0.1 second interval for 20 seconds and the security alarm system is set to the stand-by

mode (2). Once it is set to the stand-by mode, the theft deterrent light blinks at 2 second intervals.

When the system is set to stand-by mode and the door is unlocked by some way other than using keyless entry

transmitter or door request switch and opened or cut off BCM power supply voltage temporarily, the alarm devices

operate according to the selected mode as described above.

The alarm stops under either of the following conditions.

• Ignition switch is turned ON

• A certain time has elapsed since the alarm started

For selection of the mode of the security alarm system, refer to “Security Alarm Mode Selection Procedure (If

Equipped)”.

Input / Output Table

Schematic and Routing Diagram

Body Electrical Control System Wiring Circuit DiagramS6RW0DA202001

NOTE

This wiring diagram shows circuits related to only BCM, not the entire circuits of BCM and junction

block. Refer to “Power Supply Diagram in Section 9A” for wiring circuits other than the figure below.

B AT3

T1

T2 2 C

1

I7RW01A20015-01

A: Indicator light turned ON T1: 0.1 seconds

B: Indicator light turned OFF T2: 20 seconds

C: When door is locked using keyless entry transmitter or door request switch T3: 2 seconds

Input Output

Keyless entry transmitter

Door switch status

Door lock statusBCMHorn relay

Theft deterrent light

(in information display)

Warning buzzer

(located in BCM)

Hazard warning relay

Door request switch signal

Ignition switch

I5RS0CA20003-01

Page 1477 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-4

BLK/BLU

BLK/YEL BLK/RED

12V

12V

+BB

BLU/YEL

WHT/BLU

+BB

RED/YEL G272-7

YEL/REDYEL/BLK

5V

IG1

IG2 IG2

L312-4

ORNL314-9YEL

BLUL313-3BLUPPL/WHT

+B +B

GRN/RED

GRN

GRN

RED/BLU

L315-9

L315-10

L01-10L01-1

ON DOOROFF+B

+B

IG1WHT

L312-5 12V

LT GRN

BLK

5V5V

5V

PNK

+BB

GRN G273-2BLKBLK/ORNG272-9

G271-3

BLK/ORNL314-4

BLU G273-5

WHTE324-2

WHTG272-11

+B

REDWHT

REDWHT

REDWHT

+BB

1

30

31

6

7

8

15

16

18

19

20 20 20

21

62 6339

40

42 41

43

4346 46 45 44

484947

50

51

56

5758

59

60

61

IG1

BRN/YEL23

25 22RED/BLK

24RED/BLU

IG128GRN/WHT33

34

12V 12VLT GRN/BLK

BRN12V

L01-1226GRY/WHT

GRY/RED

IG129GRN/YEL

12V27WHT/RED

+B

32

BLU/YEL

37

35

36

G04-16

IG1

IG1

IG1

IG1

12V

17IG2

WASH

OFF

INT

ON

WASH, ON WR EWON INTBLU/BLK

YELG272-20

GRN12V

12V 5

4

PPLG04-1511

12

13

14

GRNE325-3

G272-3BLU

GRY

IG19

+B

5V

L313-2YEL

10

REDWHT

REDWHT 32

L01-11

G04-21

G04-22

E04-10

E04-8

G04-8GRY

E04-11

E04-4

G04-11YEL

G04-13

G04-14G04-12

L01-7

L01-15

L01-3

L01-14

E04-5

L01-6

L01-16

L01-17

L01-5

L01-4

G04-18

G04-17G04-5

E04-9

G04-1G04-3

G04-2G04-4

E04-2 E04-1

38

REDWHT

REDWHT

REDWHT

YEL +BL315-143

BLK/RED

BLK/REDL314-6

G271-752

BLK/REDL314-7

53BLK/REDL314-8

54

55

46 46 45 44GRN

RED/BLU

L315-9

L315-10 +B

43

[A]

[B]

I6RW0DA20001-01

[A]: Without security alarm system 21. Rear end door switch 43. Door lock actuator relay (if equipped)

[B]: With security alarm system 22. Driver side seat belt switch 44. Driver side door lock actuator (if equipped)

Page 1482 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-9 Body Electrical Control System:

Body Electrical Control System CheckS6RW0DA204002

Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer.

For this purpose, use of such a questionnaire form as shown in the figure will facilitate collecting information to the

point required for proper analysis and diagnosis.Rear end door window

defogger• Rear end door window defogger switch

• Generator• Rear end door window defogger

relay

Rear end door opener• Manual door lock switch (unlock signal)

• Key cylinder switch (unlock signal)

• Keyless entry transmitter (unlock signal)

• Rear end door opener switch• Rear end door opener relay

Door lock canceller • SDM (air bag deployment signal) • Each door lock actuator

Theft deterrent light• Key reminder switch • Theft deterrent light (located in

information display or clock) Control Input Output

Step Action Yes No

1�) Customer complaint analysis

1) Perform customer complaint analysis.

Was customer complaint analysis performed?Go to Step 2. Perform customer

complaint analysis.

2�) Problem symptom confirmation

1) Perform problem symptom confirmation.

Does trouble recur?Go to Step 3. Go to Step 7.

3�) DTC check

1) Check DTC.

Is it malfunction code?Go to Step 4. Go to Step 5.

4�) Troubleshooting for DTC

1) Check and repair according to DTC diag. flow.

Are check and repair completed?Go to Step 7. Check and repair

malfunction part(s).

5�) Body electrical control system symptom diagnosis

1) Perform check and repair referring to “Symptom

Diagnosis” of system having a trouble.

Is there faulty condition?Repair or replace

malfunction part(s).Go to Step 6.

6�) Check for intermittent problem

1) Check for intermittent problem.

Is there faulty condition?Repair or replace

malfunction part(s).Go to Step 7.

7�) Final confirmation test

1) Clear DTC referring to “DTC Clearance”.

2) Check DTC referring to “DTC Check”.

Is there any DTC?Go to Step 4. End.

Page 1485 of 1556

Downloaded from www.Manualslib.com manuals search engine Body Electrical Control System: 10B-12

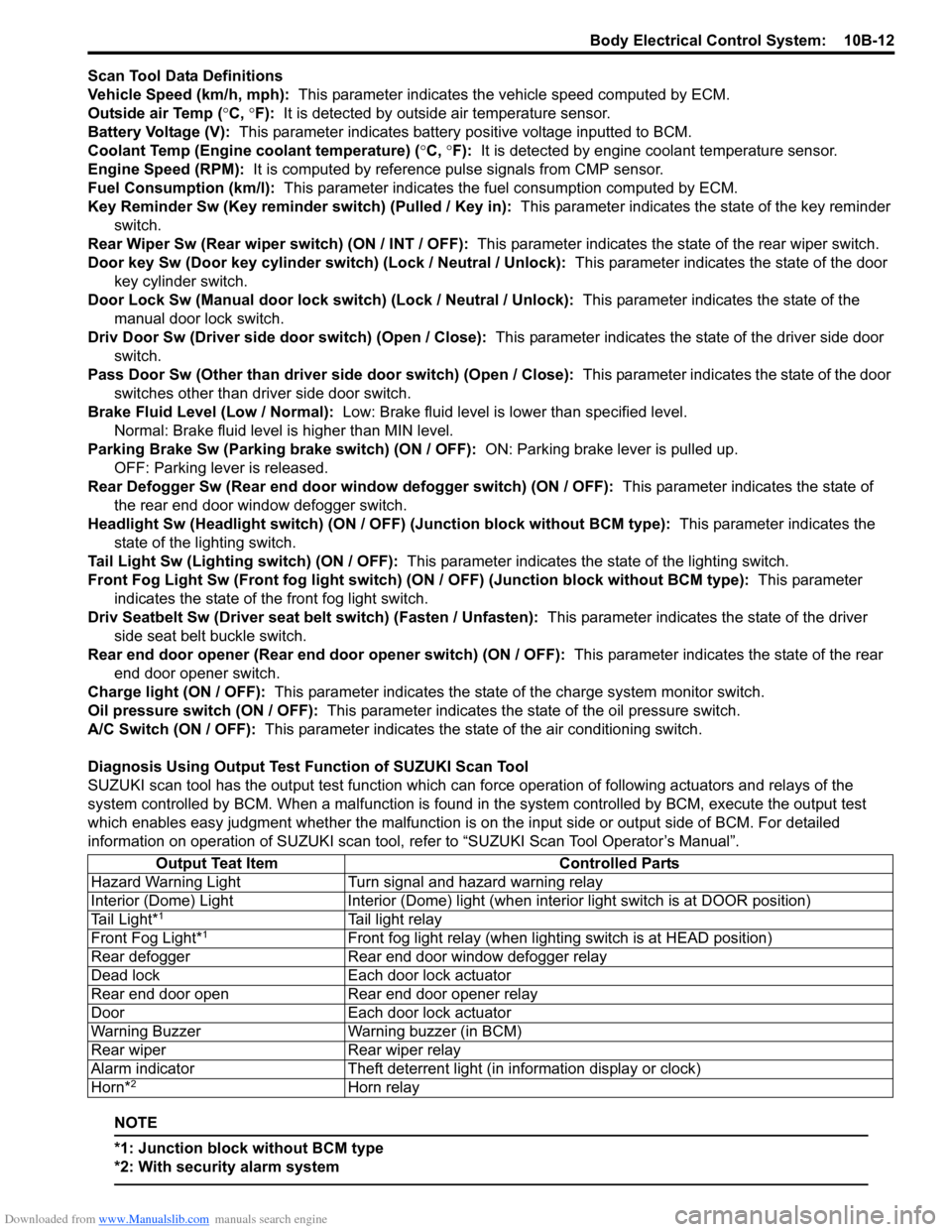

Scan Tool Data Definitions

Vehicle Speed (km/h, mph): This parameter indicates the vehicle speed computed by ECM.

Outside air Temp (°C, °F): It is detected by outside air temperature sensor.

Battery Voltage (V): This parameter indicates battery positive voltage inputted to BCM.

Coolant Temp (Engine coolant temperature) (°C, °F): It is detected by engine coolant temperature sensor.

Engine Speed (RPM): It is computed by reference pulse signals from CMP sensor.

Fuel Consumption (km/l): This parameter indicates the fuel consumption computed by ECM.

Key Reminder Sw (Key reminder switch) (Pulled / Key in): This parameter indicates the state of the key reminder

switch.

Rear Wiper Sw (Rear wiper switch) (ON / INT / OFF): This parameter indicates the state of the rear wiper switch.

Door key Sw (Door key cylinder switch) (Lock / Neutral / Unlock): This parameter indicates the state of the door

key cylinder switch.

Door Lock Sw (Manual door lock switch) (Lock / Neutral / Unlock): This parameter indicates the state of the

manual door lock switch.

Driv Door Sw (Driver side door switch) (Open / Close): This parameter indicates the state of the driver side door

switch.

Pass Door Sw (Other than driver side door switch) (Open / Close): This parameter indicates the state of the door

switches other than driver side door switch.

Brake Fluid Level (Low / Normal): Low: Brake fluid level is lower than specified level.

Normal: Brake fluid level is higher than MIN level.

Parking Brake Sw (Parking brake switch) (ON / OFF): ON: Parking brake lever is pulled up.

OFF: Parking lever is released.

Rear Defogger Sw (Rear end door window defogger switch) (ON / OFF): This parameter indicates the state of

the rear end door window defogger switch.

Headlight Sw (Headlight switch) (ON / OFF) (Junction block without BCM type): This parameter indicates the

state of the lighting switch.

Tail Light Sw (Lighting switch) (ON / OFF): This parameter indicates the state of the lighting switch.

Front Fog Light Sw (Front fog light switch) (ON / OFF) (Junction block without BCM type): This parameter

indicates the state of the front fog light switch.

Driv Seatbelt Sw (Driver seat belt switch) (Fasten / Unfasten): This parameter indicates the state of the driver

side seat belt buckle switch.

Rear end door opener (Rear end door opener switch) (ON / OFF): This parameter indicates the state of the rear

end door opener switch.

Charge light (ON / OFF): This parameter indicates the state of the charge system monitor switch.

Oil pressure switch (ON / OFF): This parameter indicates the state of the oil pressure switch.

A/C Switch (ON / OFF): This parameter indicates the state of the air conditioning switch.

Diagnosis Using Output Test Function of SUZUKI Scan Tool

SUZUKI scan tool has the output test function which can force operation of following actuators and relays of the

system controlled by BCM. When a malfunction is found in the system controlled by BCM, execute the output test

which enables easy judgment whether the malfunction is on the input side or output side of BCM. For detailed

information on operation of SUZUKI scan tool, refer to “SUZUKI Scan Tool Operator’s Manual”.

NOTE

*1: Junction block without BCM type

*2: With security alarm system

Output Teat Item Controlled Parts

Hazard Warning Light Turn signal and hazard warning relay

Interior (Dome) Light Interior (Dome) light (when interior light switch is at DOOR position)

Tail Light*

1Tail light relay

Front Fog Light*1Front fog light relay (when lighting switch is at HEAD position)

Rear defogger Rear end door window defogger relay

Dead lock Each door lock actuator

Rear end door open Rear end door opener relay

Door Each door lock actuator

Warning Buzzer Warning buzzer (in BCM)

Rear wiper Rear wiper relay

Alarm indicator Theft deterrent light (in information display or clock)

Horn*

2Horn relay

Page 1502 of 1556

Downloaded from www.Manualslib.com manuals search engine 10B-29 Body Electrical Control System:

5) Disconnect connectors from BCM and junction

block.

6) Detach wiring harness clamp from junction block.

Installation

Reverse removal procedure for installation, noting

following points.

• Connect connectors securely.

• Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

• With keyless entry system (other than keyless start

model), if BCM is replaced, register transmitter code

into BCM, referring to “Programming Transmitter

Code for Keyless Entry System (Other than Keyless

Start Model) in Section 9F”.

Security Alarm Mode Selection Procedure (If

Equipped)

S6RW0DA206005

Security alarm mode can be selected by performing the

following procedure.

1) Confirm that all doors are closed, all doors are

unlocked and ignition key is inserted in ignition key

cylinder.

2) Remove ignition key from ignition key cylinder.

3) Perform Step a) through e) described below within

15 seconds.

a) Insert ignition key (1) in ignition key cylinder (2).

b) Remove ignition key from ignition key cylinder.

c) Repeat Step a) and b) twice.

d) Insert ignition key in ignition key cylinder.

e) Push lock side (3) of driver side manual lock

switch (4) 3 times.4) When Step 3) is completed, the mode changes to

the next one automatically. The warning buzzer

(located in BCM) sounds by the number of specified

for each mode as follows.

• Changed from A mode to B mode: Buzzer sounds

4 times

• Changed from B mode to A mode: Buzzer sounds

once

Outside Air Temperature Sensor Removal and

Installation

S6RW0DA206002

For removal and installation, refer to “Outside Air

Temperature Sensor Removal and Installation (If

Equipped) in Section 9C”.

Outside Air Temperature Sensor InspectionS6RW0DA206003

For inspection, refer to “Outside Air Temperature Sensor

Inspection (If Equipped) in Section 9C”.

Special Tools and Equipment

Special ToolS6RW0DA208001

1 2

4

3

I7JB01A20007-01

SUZUKI scan tool

—

This kit includes following

items. 1. Tech 2, 2. PCMCIA

card, 3. DLC cable, 4. SAE

16/19 adapter, 5. Cigarette

cable, 6. DLC loop back

adapter, 7. Battery power

cable, 8. RS232 cable, 9.

RS232 adapter, 10. RS232

loop back connector, 11.

Storage case, 12. �)

Page 1530 of 1556

Downloaded from www.Manualslib.com manuals search engine 10E-8 Keyless Start System:

Diagnostic Information and Procedures

Precautions in Diagnosing TroublesS6RW0DA504001

• The keyless start system executes data transmission/

reception by means of the radio wave. Therefore,

proper operation may not be obtained if use of the

door lock function and engine start function of the

keyless start system is attempted near the place

where strong radio wave is emitted (TV and radio

broadcasting stations, etc.).

• Diagnostic information stored in keyless start control

module memory can be checked only by key indicator

light.

• Be sure to use the trouble diagnosis procedure as

described in “Keyless Start System Check”. Failure to

follow it may result in incorrect diagnosis. (Some other

DTC may be stored by mistake in the memory of

keyless start control module during inspection.)

• Be sure to read“Precautions for Electrical Circuit

Service in Section 00” before inspection and observe

what is written there.

• Communication of ECM, TCM (A/T model), BCM,

ABS control module, 4WD control module (if

equipped), keyless start control module and

combination meter is established by CAN (Controller

Area Network). (For detail of CAN communication for

keyless start control module, refer to “CAN

Communication System Description”). Therefore,

handle CAN communication line with care referring to

“Precaution for CAN Communication System in

Section 00”.

• Replacement of the keyless start control module

When keyless start control module is replaced with

new one, make sure that register remote controller ID

code to keyless start control module correctly

according to “Registration Procedure for Remote

Controller ID Code”.• Keyless start control module substitution

When the keyless start control module used in

another vehicle was installed in the vehicle being

serviced, register the ID code of the remote controller

to the keyless start control module first and then the

following code.

– With immobilizer control system, register the

ignition key transponder code for the immobilizer

control system in ECM. For registration procedure

of that, refer to “Registration of the Ignition Key in

Section 10C”.

– Without immobilizer control system, register the

steering lock unit ID code in keyless start control

module. For registration procedure of that, refer to

“Keyless Start Registration”.

Self-Diagnosis FunctionS6RW0DA504002

The keyless start control module has self-diagnosis

function to monitor the system components and circuits

while the keyless start system is at work. When the

keyless start control module detects an abnormality in

the system, it saves the area where such abnormality

has occurred as a DTC in its memory. The DTC stored in

memory of the keyless start control module is indicated

by the key indicator light in the combination meter

flashing in a specific pattern. For DTC indication, refer to

“DTC Check” and for the clearing procedure, to “DTC

Clearance”.

Keyless Start System Diagnosis IntroductionS6RW0DA504003

To ensure that the trouble diagnosis is done accurately

and smoothly, observe “Precautions in Diagnosing

Troubles” and follow “Keyless Start System Check”.

4. Ignition knob switch 13. Rear end door request switch 22. Ignition Switch

5. Key reminder switch 14. Driver side door lock switch

6. Driver side door antenna 15. Passenger side door lock switch