ECU SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1142 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-103 Air Bag System:

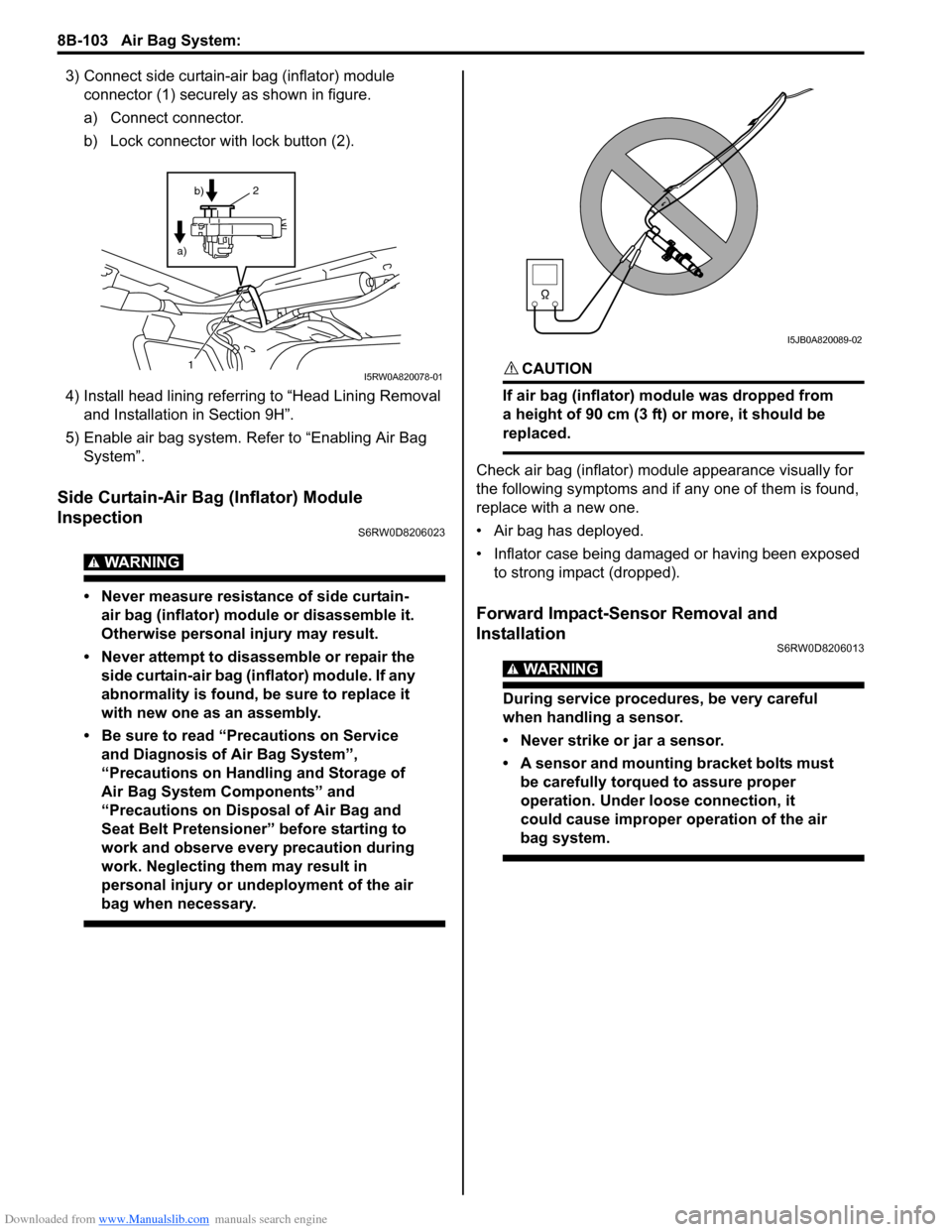

3) Connect side curtain-air bag (inflator) module

connector (1) securely as shown in figure.

a) Connect connector.

b) Lock connector with lock button (2).

4) Install head lining referring to “Head Lining Removal

and Installation in Section 9H”.

5) Enable air bag system. Refer to “Enabling Air Bag

System”.

Side Curtain-Air Bag (Inflator) Module

Inspection

S6RW0D8206023

WARNING!

• Never measure resistance of side curtain-

air bag (inflator) module or disassemble it.

Otherwise personal injury may result.

• Never attempt to disassemble or repair the

side curtain-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System”,

“Precautions on Handling and Storage of

Air Bag System Components” and

“Precautions on Disposal of Air Bag and

Seat Belt Pretensioner” before starting to

work and observe every precaution during

work. Neglecting them may result in

personal injury or undeployment of the air

bag when necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• Inflator case being damaged or having been exposed

to strong impact (dropped).

Forward Impact-Sensor Removal and

Installation

S6RW0D8206013

WARNING!

During service procedures, be very careful

when handling a sensor.

• Never strike or jar a sensor.

• A sensor and mounting bracket bolts must

be carefully torqued to assure proper

operation. Under loose connection, it

could cause improper operation of the air

bag system.

1

2

b)

a)

I5RW0A820078-01

I5JB0A820089-02

Page 1145 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-106

Passenger Air Bag (Inflator) Module Repair

Harness Installation

S6RW0D8206017

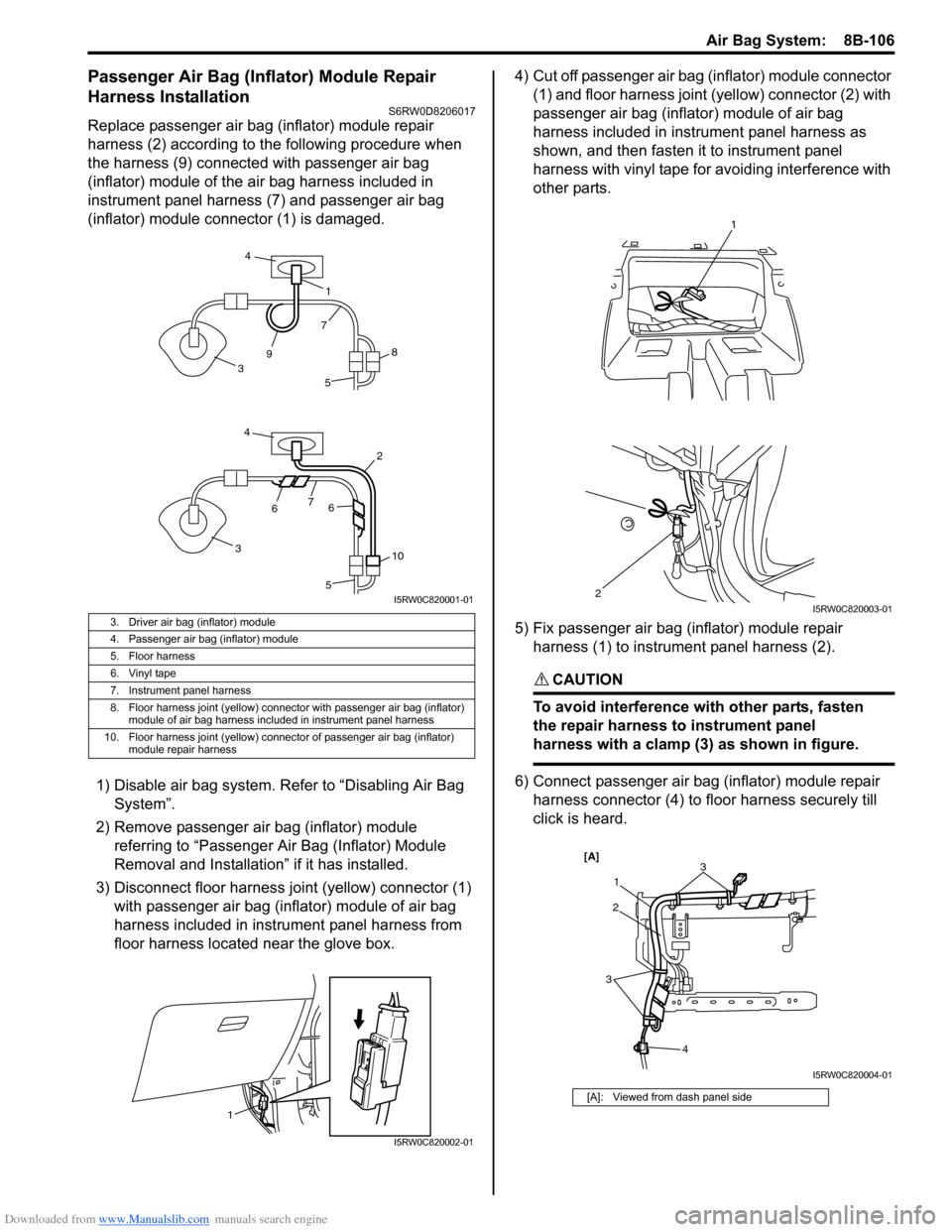

Replace passenger air bag (inflator) module repair

harness (2) according to the following procedure when

the harness (9) connected with passenger air bag

(inflator) module of the air bag harness included in

instrument panel harness (7) and passenger air bag

(inflator) module connector (1) is damaged.

1) Disable air bag system. Refer to “Disabling Air Bag

System”.

2) Remove passenger air bag (inflator) module

referring to “Passenger Air Bag (Inflator) Module

Removal and Installation” if it has installed.

3) Disconnect floor harness joint (yellow) connector (1)

with passenger air bag (inflator) module of air bag

harness included in instrument panel harness from

floor harness located near the glove box.4) Cut off passenger air bag (inflator) module connector

(1) and floor harness joint (yellow) connector (2) with

passenger air bag (inflator) module of air bag

harness included in instrument panel harness as

shown, and then fasten it to instrument panel

harness with vinyl tape for avoiding interference with

other parts.

5) Fix passenger air bag (inflator) module repair

harness (1) to instrument panel harness (2).

CAUTION!

To avoid interference with other parts, fasten

the repair harness to instrument panel

harness with a clamp (3) as shown in figure.

6) Connect passenger air bag (inflator) module repair

harness connector (4) to floor harness securely till

click is heard.

3. Driver air bag (inflator) module

4. Passenger air bag (inflator) module

5. Floor harness

6. Vinyl tape

7. Instrument panel harness

8. Floor harness joint (yellow) connector with passenger air bag (inflator)

module of air bag harness included in instrument panel harness

10. Floor harness joint (yellow) connector of passenger air bag (inflator)

module repair harness

5

2

4

4

7

7

1

3

3

5

66

8

10

9

I5RW0C820001-01

1

I5RW0C820002-01

[A]: Viewed from dash panel side

1

2

I5RW0C820003-01

3

4 213

[A]

I5RW0C820004-01

Page 1148 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-109 Air Bag System:

WARNING!

• For handling and storage of seat belt

pretensioner, select place where ambient

temperature is below 65 °C (150 °F),

without high humidity and away from

electric noise.

• Never carry seat belt pretensioner by

webbing.

• When placing seat belt pretensioner on

workbench or other surface, be sure to lay

it with its exhaust hole (1) side facing up. It

is also prohibited to put something on seat

belt pretensioner.

Otherwise, personal injury may result.

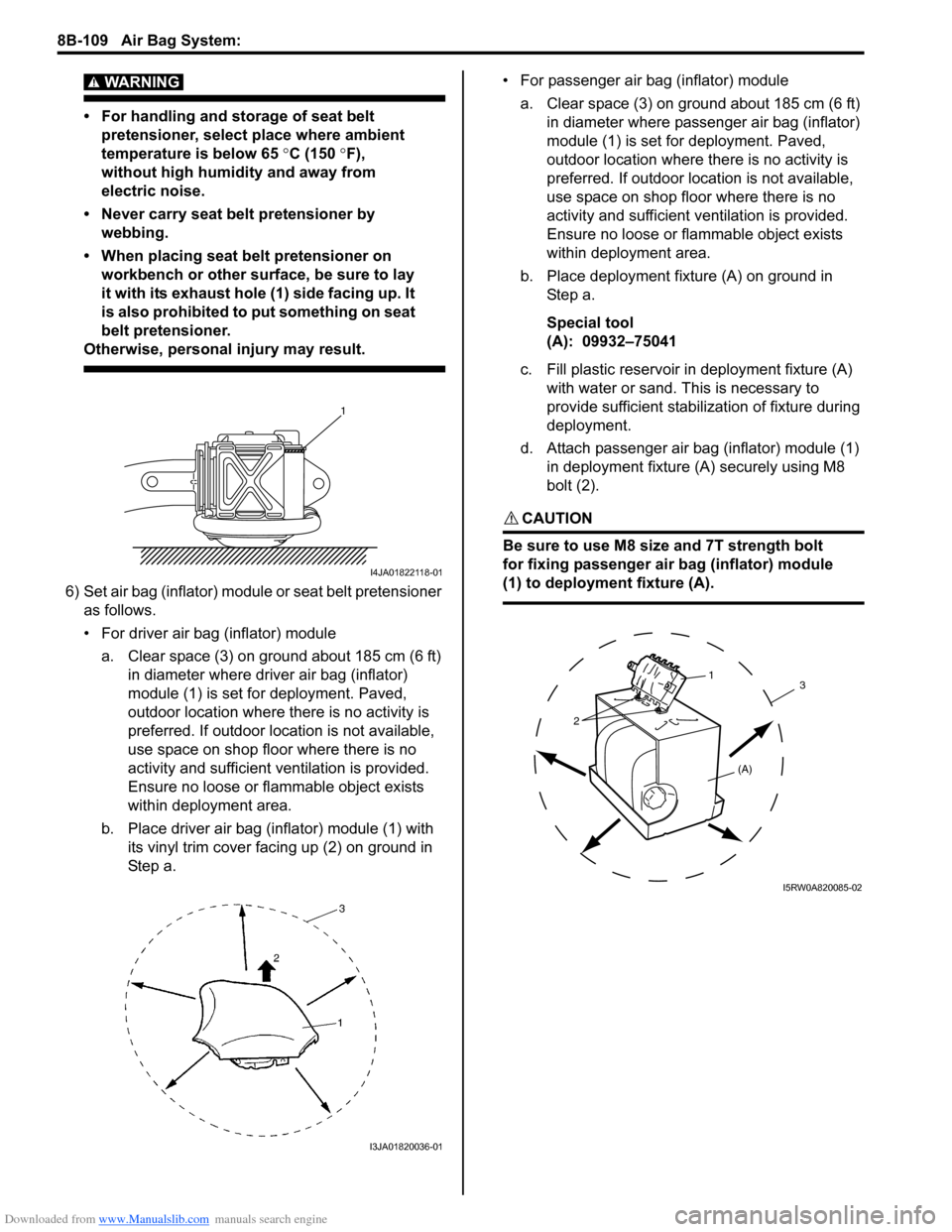

6) Set air bag (inflator) module or seat belt pretensioner

as follows.

• For driver air bag (inflator) module

a. Clear space (3) on ground about 185 cm (6 ft)

in diameter where driver air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place driver air bag (inflator) module (1) with

its vinyl trim cover facing up (2) on ground in

St ep a .• For passenger air bag (inflator) module

a. Clear space (3) on ground about 185 cm (6 ft)

in diameter where passenger air bag (inflator)

module (1) is set for deployment. Paved,

outdoor location where there is no activity is

preferred. If outdoor location is not available,

use space on shop floor where there is no

activity and sufficient ventilation is provided.

Ensure no loose or flammable object exists

within deployment area.

b. Place deployment fixture (A) on ground in

Step a.

Special tool

(A): 09932–75041

c. Fill plastic reservoir in deployment fixture (A)

with water or sand. This is necessary to

provide sufficient stabilization of fixture during

deployment.

d. Attach passenger air bag (inflator) module (1)

in deployment fixture (A) securely using M8

bolt (2).

CAUTION!

Be sure to use M8 size and 7T strength bolt

for fixing passenger air bag (inflator) module

(1) to deployment fixture (A).

1

I4JA01822118-01

I3JA01820036-01

31

2

(A)

I5RW0A820085-02

Page 1151 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-112

10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A] SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-112

10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]](/img/20/7612/w960_7612-1150.png)

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-112

10) Connect adapter cable (B) as follows.

Special tool

(B): 09932–76510

• For driver air bag (inflator) module [A]:

Check that driver air bag (inflator) module is

placed with its vinyl trim cover facing up, and

connect adapter cable (B) to driver air bag

(inflator) module.

• For passenger air bag (inflator) module [B]:

Check that passenger air bag (inflator) module is

firmly and properly secured on deployment fixture

(special tool), and connect adapter cable (B) to

passenger air bag (inflator) module.

NOTE

Wind wire harness (5) around at least 2 times.

• For side-air bag (inflator) module [C]:

Verify that side-air bag (inflator) module is firmly

and properly on deployment fixture (special tool),

and connect adapter cable (B) to side-air bag

(inflator) module.

• For side curtain-air bag (inflator) module [D]:

a. Connect adapter cable (B) to side curtain-air

bag (inflator) module.

b. Pile 2 tires (2) and wheel-installed tire (3) on

top of tire with side curtain-air bag (inflator)

(4), and tie them with wire harness (5) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

• For seat belt pretensioner [E]:

a. Connect adapter cable (B) to seat belt

pretensioner.

b. Pile 2 wheel-installed tires (3) on top of tire

with seat belt pretensioner (6), and tie them

with wire harness (5) as shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (5) around at least 2 times.

c. Drape blanket (7) over those tires.

11) Connect adapter cable (B) to deployment harness

(A) connector and lock connectors with lock lever.

[A]

10 m (33 ft)

(A)

(B)

1

10 m (33 ft)

(A)

(B)1

5

3

2

4

(A)

[B]

[C]

[D]

[E]

7

3

6

5 (A)(B)

1

10 m (33 ft)

10 m (33 ft) (A)

(B)

1

1

10 m (33 ft)

I5JB0A820102-01

Page 1153 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-114

21) Wash your hands with mild soap and water

afterward.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

22) Ensure that deployment harness has been

disconnected from 12 volts vehicle battery and that

its two banana plugs have been shorted together by

fully seating one banana plug into the other.

23) Disconnect deployment harness and adapter cable

from air bag (inflator) module or seat belt

pretensioner.

24) Temporarily store undeployed air bag (inflator)

module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

25) Contact your local distributor for further assistance.

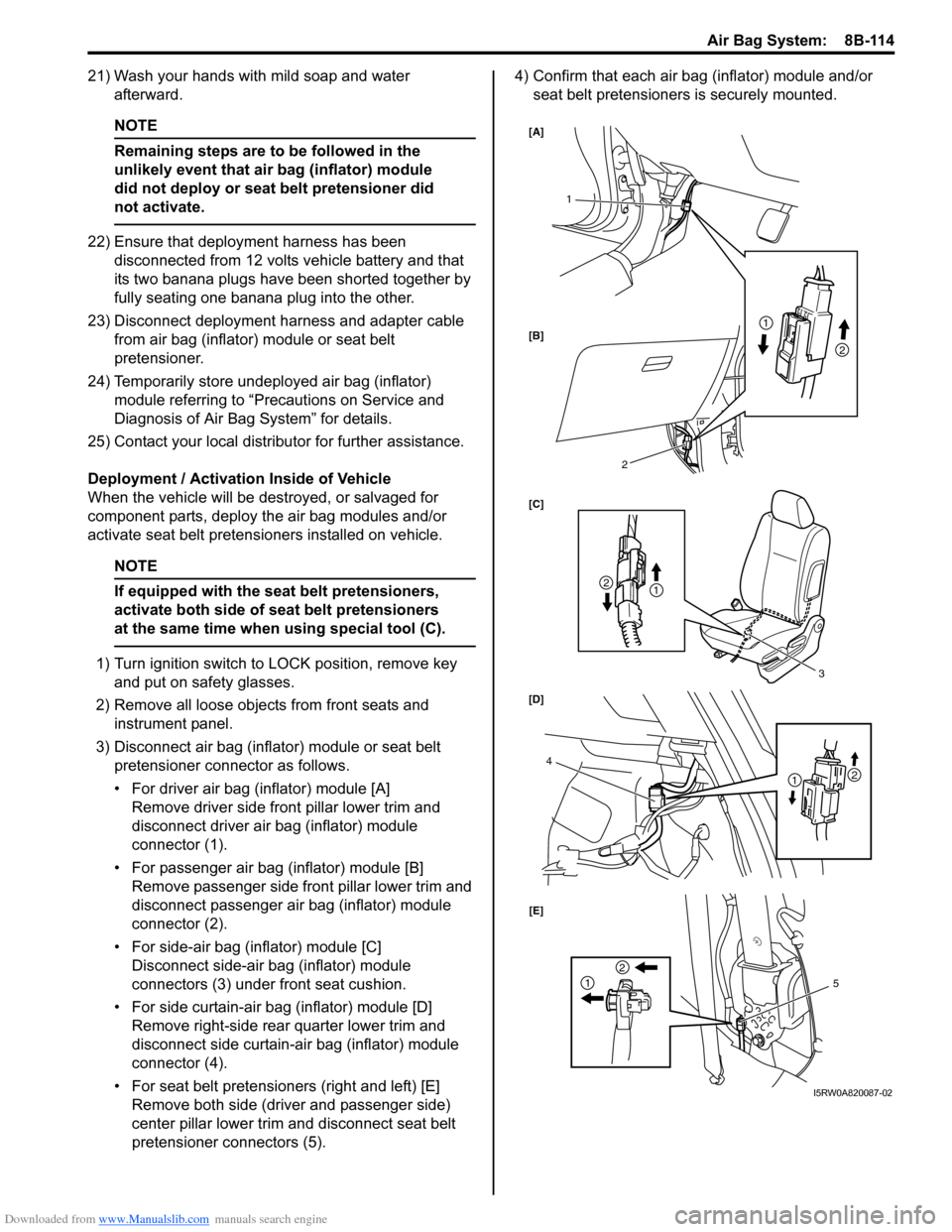

Deployment / Activation Inside of Vehicle

When the vehicle will be destroyed, or salvaged for

component parts, deploy the air bag modules and/or

activate seat belt pretensioners installed on vehicle.

NOTE

If equipped with the seat belt pretensioners,

activate both side of seat belt pretensioners

at the same time when using special tool (C).

1) Turn ignition switch to LOCK position, remove key

and put on safety glasses.

2) Remove all loose objects from front seats and

instrument panel.

3) Disconnect air bag (inflator) module or seat belt

pretensioner connector as follows.

• For driver air bag (inflator) module [A]

Remove driver side front pillar lower trim and

disconnect driver air bag (inflator) module

connector (1).

• For passenger air bag (inflator) module [B]

Remove passenger side front pillar lower trim and

disconnect passenger air bag (inflator) module

connector (2).

• For side-air bag (inflator) module [C]

Disconnect side-air bag (inflator) module

connectors (3) under front seat cushion.

• For side curtain-air bag (inflator) module [D]

Remove right-side rear quarter lower trim and

disconnect side curtain-air bag (inflator) module

connector (4).

• For seat belt pretensioners (right and left) [E]

Remove both side (driver and passenger side)

center pillar lower trim and disconnect seat belt

pretensioner connectors (5).4) Confirm that each air bag (inflator) module and/or

seat belt pretensioners is securely mounted.

1

3

4

2

1

21

2

21

2

15 [A]

[B]

[C]

[D]

[E]

I5RW0A820087-02

Page 1164 of 1556

Downloaded from www.Manualslib.com manuals search engine 9-iv Table of Contents

Front Speaker Removal and Installation (If

Equipped) ........................................................9C-19

Rear Speaker Removal and Installation (If

Equipped) ........................................................9C-19

GPS Antenna Removal and Installation (If

Equipped) ........................................................9C-20

Horn Removal and Installation ..........................9C-20

Horn Inspection .................................................9C-20

Horn Relay Inspection .......................................9C-20

Antenna Base Removal and Installation ...........9C-21

Remote Audio Control Switch Removal and

Installation (If Equipped) .................................9C-21

Remote Audio Control Switch Inspection (If

Equipped) ........................................................9C-22

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped) ...........................................9C-22

Specifications .....................................................9C-22

Tightening Torque Specifications ......................9C-22

Wipers / Washers .................................... 9D-1

Diagnostic Information and Procedures ............ 9D-1

Front Wiper and Washer Symptom Diagnosis ....9D-1

Rear Wiper and Washer Symptom Diagnosis..... 9D-1

Repair Instructions ..............................................9D-2

Wipers and Washers Components .....................9D-2

Washer Tank and Washer Pump Removal

and Installation ..................................................9D-3

Washer Pump Inspection ....................................9D-3

Windshield Wiper Removal and Installation ........9D-3

Windshield Wiper Motor Inspection.....................9D-4

Rear Wiper Removal and Installation.................. 9D-6

Rear Wiper Motor Inspection ..............................9D-7

Windshield Wiper and Washer Switch

Removal and Installation ................................... 9D-8

Windshield Wiper and Washer Switch

Inspection .......................................................... 9D-8

Rear Wiper and Washer Switch Removal and

Installation .......................................................9D-10

Rear Wiper and Washer Switch Inspection.......9D-10

Rear Wiper Relay Removal and Installation .....9D-10

Rear Wiper Relay Inspection ............................9D-10

Specifications .....................................................9D-11

Tightening Torque Specifications ......................9D-11

Glass / Windows / Mirrors .......................9E-1

Precautions........................................................... 9E-1

Precautions for Power Window Service

(Pinching Prevention Function Model) .............. 9E-1

General Description ............................................. 9E-1

Rear End Door Window Defogger System

Description ........................................................ 9E-1

Schematic and Routing Diagram ........................ 9E-2

Power Window Circuit Diagram (Pinching

Prevention Function Model) .............................. 9E-2

Diagnostic Information and Procedures ............ 9E-3

Rear End door Window Defogger Symptom

Diagnosis .......................................................... 9E-3

Power Window Control System Symptom

Diagnosis .......................................................... 9E-3Inspection of Pinching Prevention Function

(Pinching Prevention Function Model) .............. 9E-4

Power Door Mirror Control System Symptom

Diagnosis .......................................................... 9E-4

Door Mirror Heater Symptom Diagnosis (If

Equipped) .......................................................... 9E-5

Repair Instructions .............................................. 9E-5

Windshield Components ..................................... 9E-5

Windshield Removal and Installation .................. 9E-6

Front Pillar Window Components...................... 9E-10

Front Pillar Window Removal and Installation... 9E-10

Rear Quarter Window Components .................. 9E-11

Rear Quarter Window Removal and

Installation ....................................................... 9E-11

Rear End Door Window Components ............... 9E-12

Rear End Door Glass Removal and

Installation ....................................................... 9E-12

Front Door Window Components ...................... 9E-13

Front Door Glass Removal and Installation ...... 9E-14

Front Door Window Regulator Removal and

Installation ....................................................... 9E-15

Front Door Window Regulator Inspection ......... 9E-15

Rear Door Window Components ...................... 9E-16

Rear Door Glass Removal and Installation ....... 9E-16

Rear Door Window Regulator Removal and

Installation ....................................................... 9E-18

Rear Door Window Regulator Inspection .......... 9E-18

Rear End Door Window Defogger Switch

Inspection ........................................................ 9E-18

Rear End Door Window Defogger Relay

Inspection ........................................................ 9E-19

Rear End Door Window Defogger Wire

Inspection ........................................................ 9E-19

Rear End Door Window Defogger Wire

Repair.............................................................. 9E-20

Power Window Main Switch Inspection ............ 9E-20

Power Window Sub Switch Inspection .............. 9E-22

Pulse Sensor and Its Circuit Inspection

(Pinching Prevention Function Model) ............ 9E-23

Power Window Main Switch Initialization

(Pinching Prevention Function Model) ............ 9E-24

Door Mirror Components................................... 9E-24

Door Mirror Removal and Installation................ 9E-25

Power Door Mirror Switch Inspection ................ 9E-25

Power Door Mirror Actuator Inspection ............. 9E-25

Door Mirror Heater Inspection (If Equipped) ..... 9E-26

Door Mirror Heater Switch Inspection (If

Equipped) ........................................................ 9E-26

Special Tools and Equipment ........................... 9E-26

Recommended Service Material ....................... 9E-26

Security and Locks...................................9F-1

General Description ............................................. 9F-1

Key Coding Construction .................................... 9F-1

Rear End Door Opener System Description ....... 9F-1

Component Location ........................................... 9F-2

Power Door Lock and Keyless Entry System

Component Location (If Equipped) ................... 9F-2

Diagnostic Information and Procedures ............ 9F-3

Page 1190 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-23 Wiring Systems:

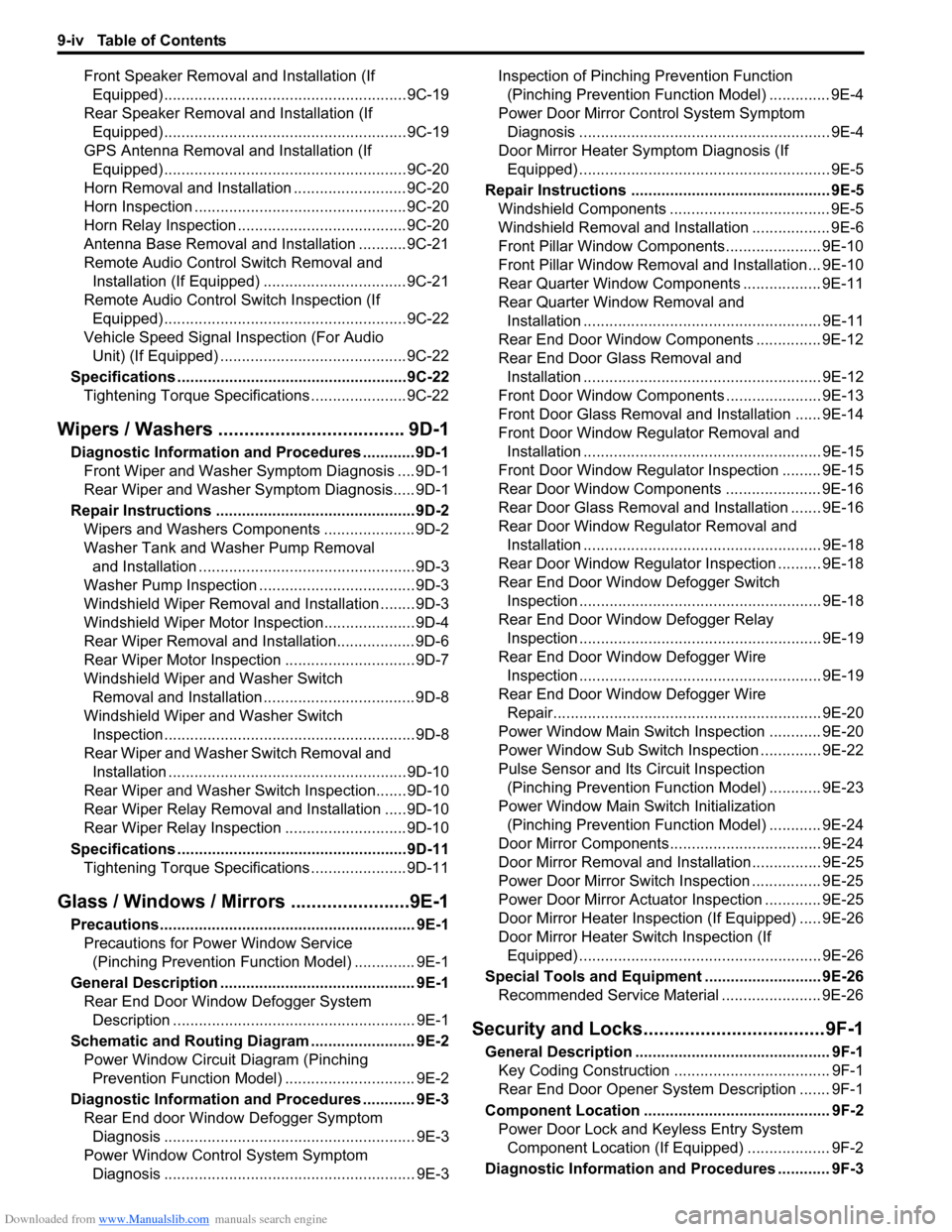

G: Instrument panel harness, Instrument panel antenna wire / S: Contact coil (LHD)

G: Instrument panel harness

G146G141

G309

G34

G253

G266G255

G144

G241

G17G311

G153 G63

G248

G310

G61

G259G243

G267

G355

(TO L409)

1311

14

G16

G341

(TO L374)

G354

(TO K154)

G342

(TO L375)

G348

(TO K153)

G352

(TO L402)

G254

G04

G271

G272

G307

12

G211

G343

(TO L376)G349

(TO L399)

G344

(TO L377)G147G345

(TO L378)

G334

(TO E382)

G333

(TO E381)

G20

S121S61

G32 G155 G154 G64

G62G214

G65 G273

G151

G152 G150

G05 G06

G308

G306 G265

G35

G251

G347

S172

G346

S171

G S S

Instrument panel

antenna wire

I6RW0D910902-01

No./Color Connective position No./Color Connective position

G04/N or BLU BCM G248/BLU Audio (Navigation)

G05/N (Taiwan) BCM G251/N ACC socket

G06/BLK

(Taiwan)BCM G253/GRN Multi information display

G16/N (IF

EQPD)KLS ECMG254/N (IF

EQPD)Keyless receiver

G17/BLK ICMG255/BLK

(Auto A/C)Diode #1

G20/GRN

(Auto A/C)Auto A/C unit G259/ORN Passenger inflator

G32/N EVAP thermistorG265/N

(Taiwan)Security option

G34/N (Auto A/

C)Room temperature sensor G271/N J/B

G35/N (Auto A/

C)Sunlight sensor G272/N J/B

G61/N Heater fan motor G273/N J/B

G62/BLK Fresh/Recircle actuator G306/N J/C

G63/BLK (Auto

A/C)Mode selecting actuatorG307/N (IF

EQPD)J/C

G64/BLK (Auto

A/C)Temperature control actuator G308/N J/C

G65/N Fan driver G309/GRY J/C

G141/BLK COMB switchG310/N (Auto

A/C)J/C

G144/N COMB switch G311/GRY J/C

G146/N Main switch (key) G333/GRY or N Main harness (To E381)

G147/N IG switch G334/BRN Main harness (To E382)

Page 1251 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-84

38 39

"D-5""D-1"

BLK/BLU

3 AA BBG042

BLU/YEL

BLU/YEL

J/C

G307

1G265

J/C

G308

G146

1 4

Main switch

(Key switch)

DOME

G2715 15A

37ACC

G2725 15A

23

WHT/REDWHT/BLK

WHT/RED

YEL/RED

YEL/RED

YEL/BLK

YEL/BLK

1E37

2

Ambient

temperature

sensor

"B-5" Switch

840

37362726

RED/BLUBRN/YELLT GRN/BLKBRNGRY/WHTGRY/RED

Parking

brake

switchSeat

belt

switch

"C-3"

RBBY

97

RED/BLK

BB

GR

Oil

pressure

switchBrake

fluid

level

switch

Security

option

GRB

G05G0617

PNK

G04

24

GRY/RED

9G0521

LgBBGWGR

Main switch

"B-5"

Sub switch

"B-5"

Front door

switch

"D-3"Switch

Front door

switch

"D-5"

BRBR

BLK/RED

R

12

RED

BLK/BLUBLK/RED

BLK/REDBLK/REDBLK/RED

J/B

FF

Rear door

switch

"D-5"

BR

DD

J/CJ/C

L346

L347

BCM

GRY

E381

G33334

G343

L3761511

I6RW0C910956-01

Page 1338 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-19 Lighting Systems:

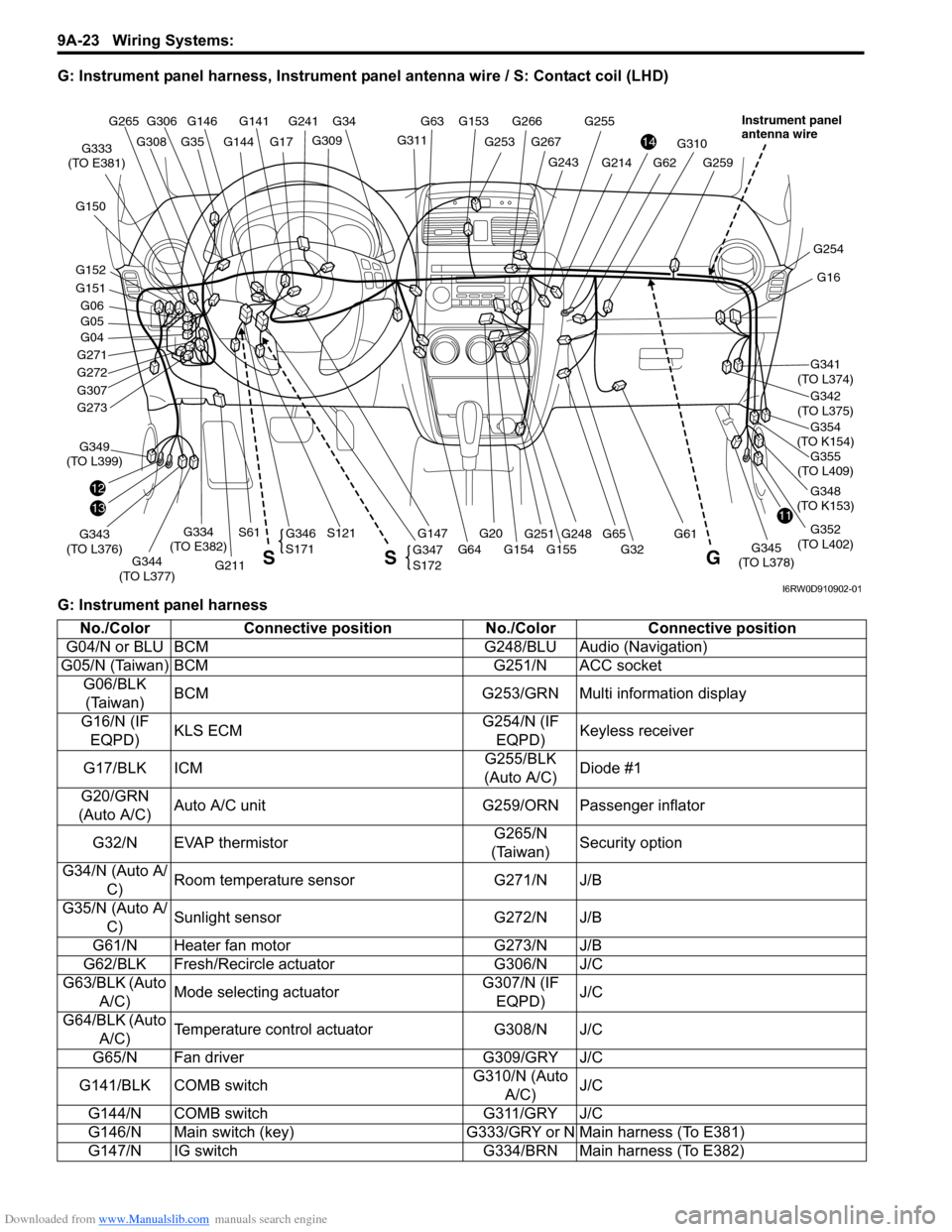

Headlight Bulb Replacement (Discharge

Headlight Model)

S6RW0D9206002

WARNING!

• To avoid danger of being burned, don’t

touch when the bulb is hot.

• Don’t touch glass surface of bulb, to avoid

deteriorate as the case may be unclear

when bulb light on at dirty condition.

• Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” before

starting to service work.

1) Check to ensure that lighting switch is at OFF

position.

2) Disconnect negative (–) cable at battery.

3) Remove headlight housing referring to “Headlight

Housing Removal and Installation”.

4) Remove cover (1) from headlight housing by turning

it counterclockwise.

5) Remove igniter (2) from discharge headlight bulb by

turning it counterclockwise.

6) Replace bulb (1) from headlight housing.

7) Install igniter to discharge headlight bulb by turning it

clockwise.

8) Install cover to headlight housing by turning it

clockwise.

9) Install headlight housing to vehicle body referring to

“Headlight Housing Removal and Installation”.

10) Connect negative (–) cable at battery.

11) After installation, be sure to inspect and adjust

aiming referring to “Headlight Aiming Adjustment

with Screen”.

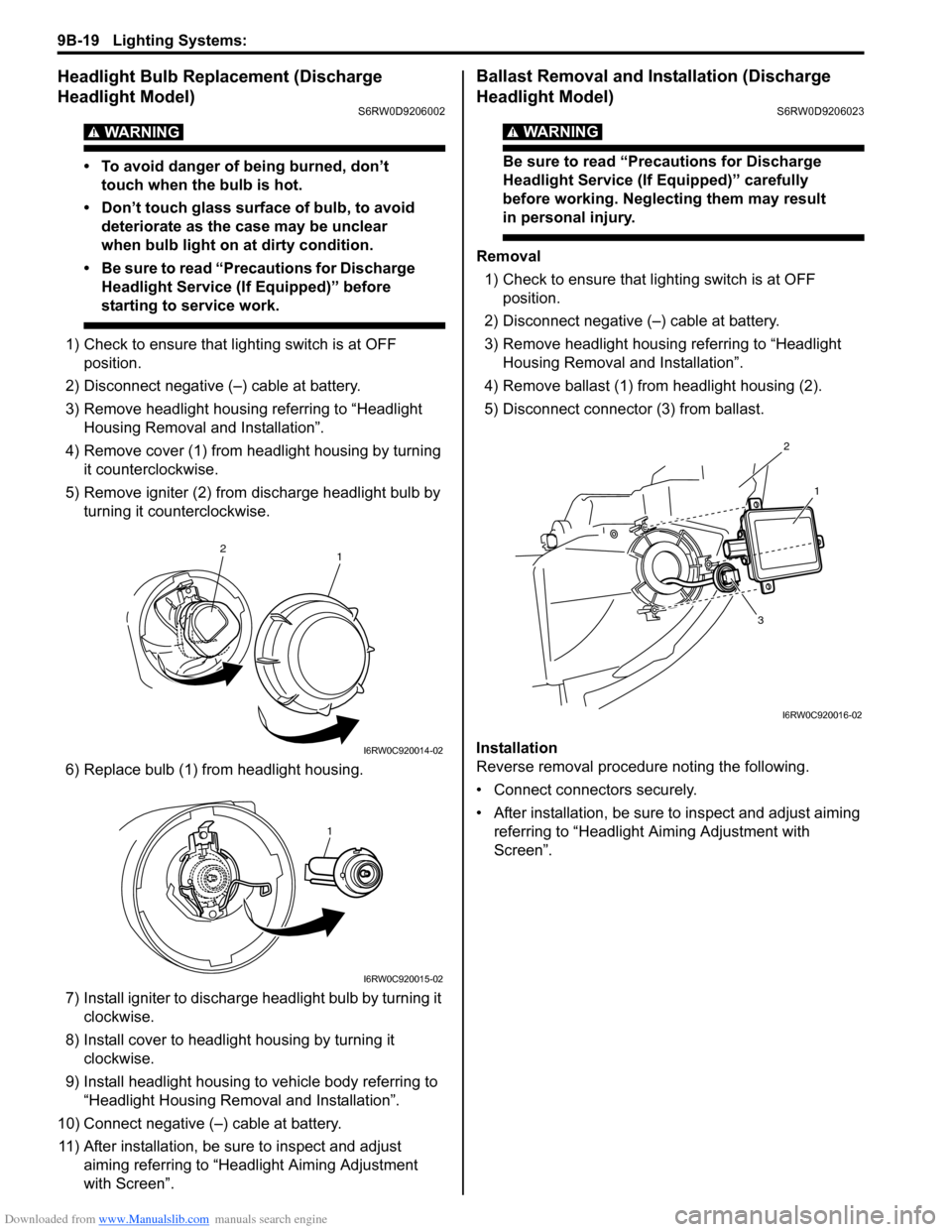

Ballast Removal and Installation (Discharge

Headlight Model)

S6RW0D9206023

WARNING!

Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” carefully

before working. Neglecting them may result

in personal injury.

Removal

1) Check to ensure that lighting switch is at OFF

position.

2) Disconnect negative (–) cable at battery.

3) Remove headlight housing referring to “Headlight

Housing Removal and Installation”.

4) Remove ballast (1) from headlight housing (2).

5) Disconnect connector (3) from ballast.

Installation

Reverse removal procedure noting the following.

• Connect connectors securely.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”.

1 2

I6RW0C920014-02

1

I6RW0C920015-02

2

1

3

I6RW0C920016-02

Page 1339 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-20

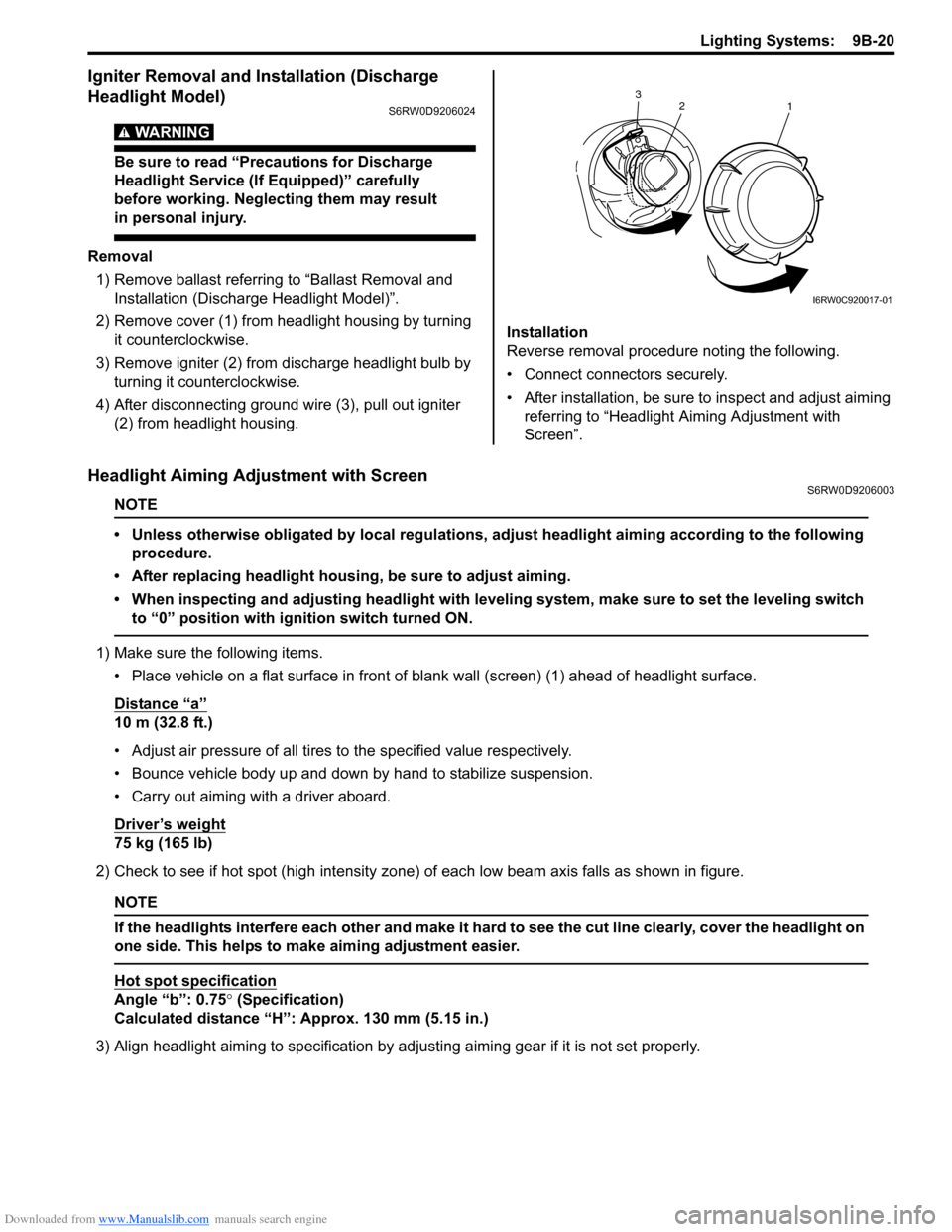

Igniter Removal and Installation (Discharge

Headlight Model)

S6RW0D9206024

WARNING!

Be sure to read “Precautions for Discharge

Headlight Service (If Equipped)” carefully

before working. Neglecting them may result

in personal injury.

Removal

1) Remove ballast referring to “Ballast Removal and

Installation (Discharge Headlight Model)”.

2) Remove cover (1) from headlight housing by turning

it counterclockwise.

3) Remove igniter (2) from discharge headlight bulb by

turning it counterclockwise.

4) After disconnecting ground wire (3), pull out igniter

(2) from headlight housing.Installation

Reverse removal procedure noting the following.

• Connect connectors securely.

• After installation, be sure to inspect and adjust aiming

referring to “Headlight Aiming Adjustment with

Screen”.

Headlight Aiming Adjustment with ScreenS6RW0D9206003

NOTE

• Unless otherwise obligated by local regulations, adjust headlight aiming according to the following

procedure.

• After replacing headlight housing, be sure to adjust aiming.

• When inspecting and adjusting headlight with leveling system, make sure to set the leveling switch

to “0” position with ignition switch turned ON.

1) Make sure the following items.

• Place vehicle on a flat surface in front of blank wall (screen) (1) ahead of headlight surface.

Distance “a”

10 m (32.8 ft.)

• Adjust air pressure of all tires to the specified value respectively.

• Bounce vehicle body up and down by hand to stabilize suspension.

• Carry out aiming with a driver aboard.

Driver’s weight

75 kg (165 lb)

2) Check to see if hot spot (high intensity zone) of each low beam axis falls as shown in figure.

NOTE

If the headlights interfere each other and make it hard to see the cut line clearly, cover the headlight on

one side. This helps to make aiming adjustment easier.

Hot spot specification

Angle “b”: 0.75° (Specification)

Calculated distance “H”: Approx. 130 mm (5.15 in.)

3) Align headlight aiming to specification by adjusting aiming gear if it is not set properly.

2

1 3

I6RW0C920017-01