200 SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 884 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11](/img/20/7612/w960_7612-883.png)

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11

10 12 13

141516

17 18 19201

2

[B]

1

2

[C] [D]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[F][E]

12

BRN RED/

BLU GRY LT GRN/

BLK

BLK

RED

WHT GRN

BLK

E11-1

E11-5

E11-14

E11-12

[J]:E01-44E01-4

[J]:E01-27E01-26

E12-1

E12-2

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

G241-25G241-31

RED/BLK

11

12

1314 3 18

20

21

7 19

4 12

22

12V

E13-2BLK

9V

REDE11-20

12V

12V

E61-2

E61-1

610

55

5V

8

E11-115V

PPL

E11-4

9

23

+BB

BLU/

WHTE04-9

1524YELE11-18E31-5

E31-2

E31-39V

3V

E31-4

E31-1IG11617

C07-25

[H]

[G]

G04-15

[I]:G04-22

25L313-3

[I]

I6RW0D630001-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 15. BCM

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 16. Output shaft speed sensor

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 5. Front (left/right) wheel speed sensor 17. TCM

[D]: Combination meter connector “G241” (viewed from harness side) 6. ABS control module 18. Individual circuit fuse box No.1

[E]: Torque sensor connector “E31” (viewed from harness side) 7. Combination meter 19. “IGN” fuse

[F]: Motor connector “E61” (viewed from harness side) 8. “EPS” warning light 20. “P/S” fuse

[G]: M/T model 9. Data link connector (DLC) 21. “IG1 SIG” fuse

[H]: A/T model 10. ECM 22. “MTR” fuse

[I]: Junction block without BCM model (Taiwan model) 11. P/S control module 23. To ABS control module

[J]: M15A engine with 4A/T equipped with slip control model (Hong Kong

model)12. P/S motor 24. To HVAC control module

1. Main fuse box 13. Shield 25. To SDM

2. Ignition switch 14. Torque sensor (built into steering gear case)

Page 887 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-7

Step 1: Customer Complaint Analysis

Record details of the problem (failure, complaint) and how it occurred as described by the customer. For this purpose,

use of such an inspection form will facilitate collecting information to the point required for proper analysis and

diagnosis. Check if the problem described in “Customer questionnaire” actually occurs in the vehicle if necessary.

(This step should be performed with the customer if possible)

Customer questionnaire (Example)

NOTE

This form is a standard sample. It should be modified according to conditions characteristic of each

market.

Step 2: DTC check, record and clearance

First, referring to “DTC Check”, check DTC (including

pending DTC). If DTC exists, print or write down DTC

and then clear them by referring to “DTC Clearance”.

DTC indicates malfunction in the system but it is not

possible to know from it whether the malfunction is

occurring now or it occurred in the past and normal

condition has been restored. In order to know that, check

symptom in question according to Step 5 and then

recheck DTC according to Step 6 and 7.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.Step 3 and Step 4: Visual inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the P/S system

referring to “Visual Inspection”.

Step 5: Trouble Symptom Confirmation

Based on information obtained in “Step 1: Customer

Complaint Analysis:” and “Step 2: DTC Check, Record

and Clearance:”, confirm trouble symptoms. Also,

reconfirm trouble symptom by performing test drive and

turning steering wheel fully to right and left at stopped

vehicle.

Step 6 and 7: Rechecking and Record of DTC

Refer to “DTC Check” for checking procedure.

I7RW01632004-02

Page 888 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

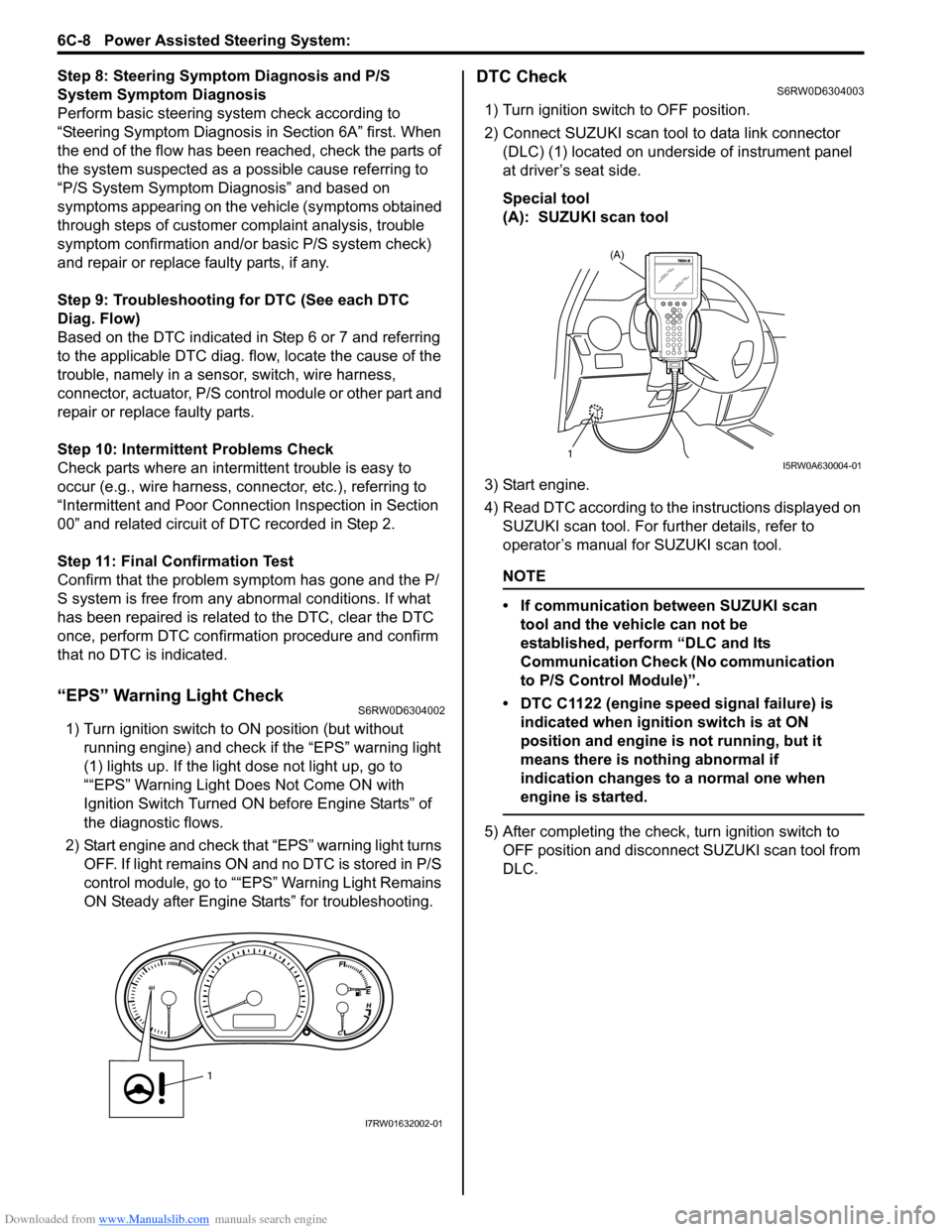

“EPS” Warning Light CheckS6RW0D6304002

1) Turn ignition switch to ON position (but without

running engine) and check if the “EPS” warning light

(1) lights up. If the light dose not light up, go to

““EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine Starts” of

the diagnostic flows.

2) Start engine and check that “EPS” warning light turns

OFF. If light remains ON and no DTC is stored in P/S

control module, go to ““EPS” Warning Light Remains

ON Steady after Engine Starts” for troubleshooting.

DTC CheckS6RW0D6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan

tool and the vehicle can not be

established, perform “DLC and Its

Communication Check (No communication

to P/S Control Module)”.

• DTC C1122 (engine speed signal failure) is

indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

1

I7RW01632002-01

(A)

1I5RW0A630004-01

Page 918 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-38 Power Assisted Steering System:

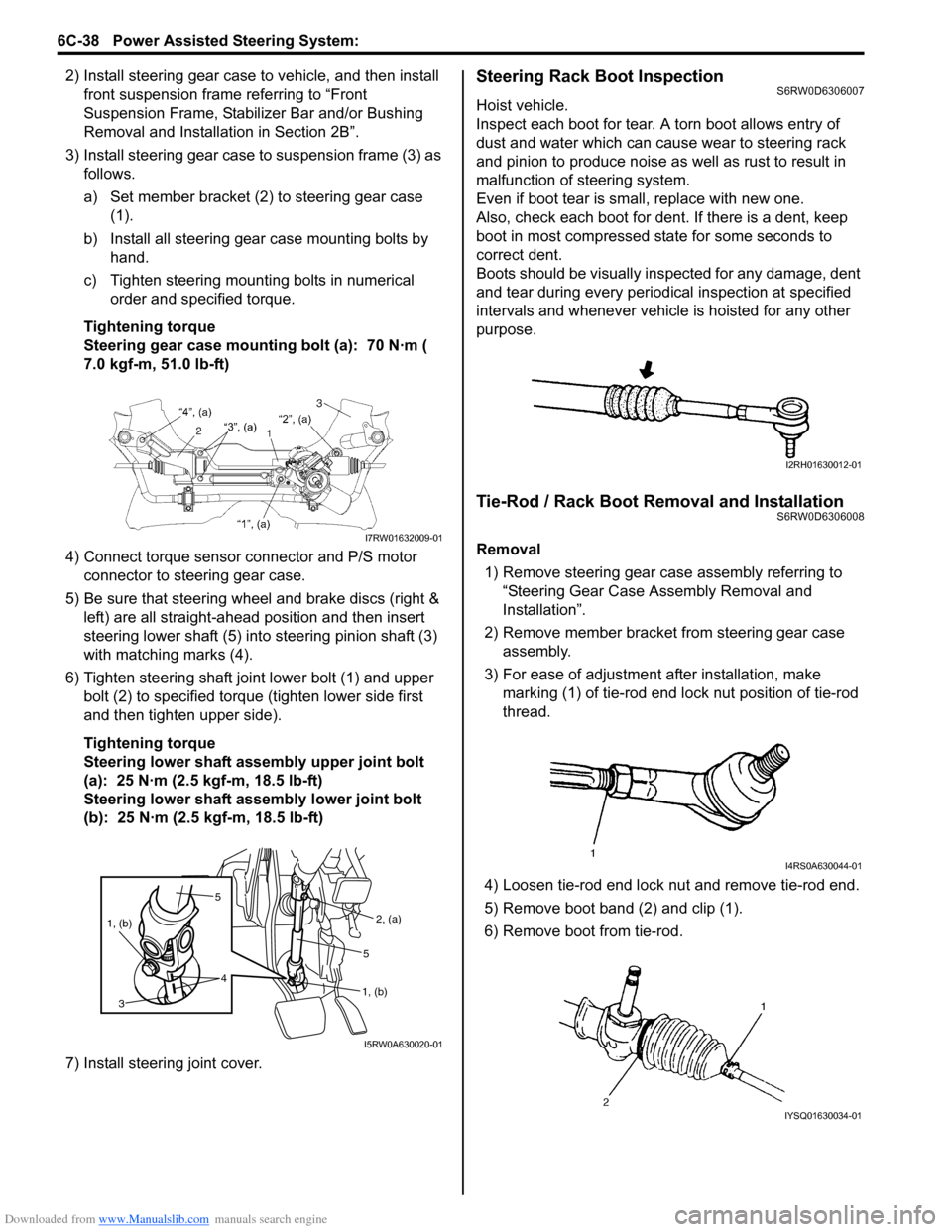

2) Install steering gear case to vehicle, and then install

front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”.

3) Install steering gear case to suspension frame (3) as

follows.

a) Set member bracket (2) to steering gear case

(1).

b) Install all steering gear case mounting bolts by

hand.

c) Tighten steering mounting bolts in numerical

order and specified torque.

Tightening torque

Steering gear case mounting bolt (a): 70 N·m (

7.0 kgf-m, 51.0 lb-ft)

4) Connect torque sensor connector and P/S motor

connector to steering gear case.

5) Be sure that steering wheel and brake discs (right &

left) are all straight-ahead position and then insert

steering lower shaft (5) into steering pinion shaft (3)

with matching marks (4).

6) Tighten steering shaft joint lower bolt (1) and upper

bolt (2) to specified torque (tighten lower side first

and then tighten upper side).

Tightening torque

Steering lower shaft assembly upper joint bolt

(a): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

Steering lower shaft assembly lower joint bolt

(b): 25 N·m (2.5 kgf-m, 18.5 lb-ft)

7) Install steering joint cover.Steering Rack Boot InspectionS6RW0D6306007

Hoist vehicle.

Inspect each boot for tear. A torn boot allows entry of

dust and water which can cause wear to steering rack

and pinion to produce noise as well as rust to result in

malfunction of steering system.

Even if boot tear is small, replace with new one.

Also, check each boot for dent. If there is a dent, keep

boot in most compressed state for some seconds to

correct dent.

Boots should be visually inspected for any damage, dent

and tear during every periodical inspection at specified

intervals and whenever vehicle is hoisted for any other

purpose.

Tie-Rod / Rack Boot Removal and InstallationS6RW0D6306008

Removal

1) Remove steering gear case assembly referring to

“Steering Gear Case Assembly Removal and

Installation”.

2) Remove member bracket from steering gear case

assembly.

3) For ease of adjustment after installation, make

marking (1) of tie-rod end lock nut position of tie-rod

thread.

4) Loosen tie-rod end lock nut and remove tie-rod end.

5) Remove boot band (2) and clip (1).

6) Remove boot from tie-rod.I7RW01632009-01

5

4 1, (b)

3

2, (a)

1, (b)5

I5RW0A630020-01

I2RH01630012-01

I4RS0A630044-01

IYSQ01630034-01

Page 930 of 1556

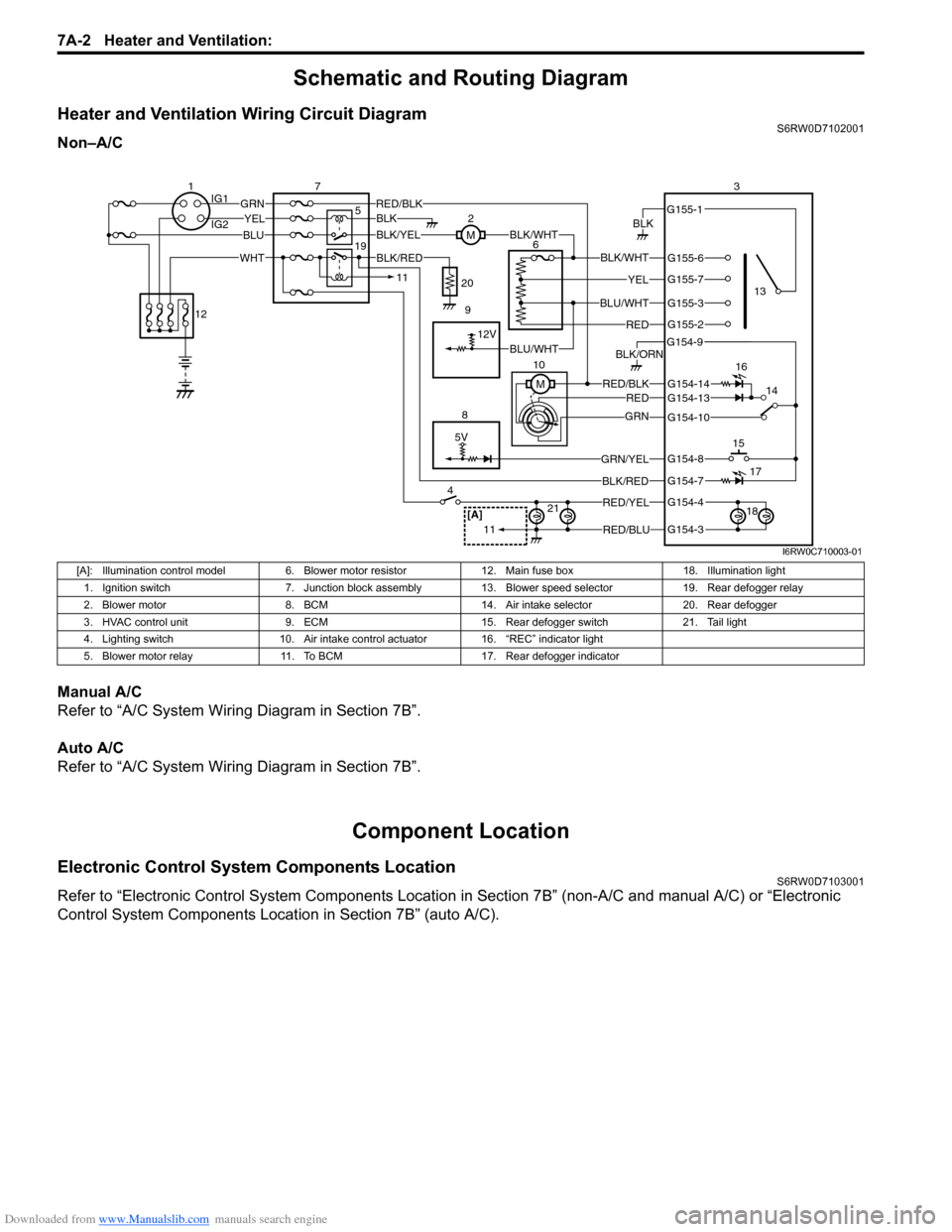

Downloaded from www.Manualslib.com manuals search engine 7A-2 Heater and Ventilation:

Schematic and Routing Diagram

Heater and Ventilation Wiring Circuit DiagramS6RW0D7102001

Non–A/C

Manual A/C

Refer to “A/C System Wiring Diagram in Section 7B”.

Auto A/C

Refer to “A/C System Wiring Diagram in Section 7B”.

Component Location

Electronic Control System Components LocationS6RW0D7103001

Refer to “Electronic Control System Components Location in Section 7B” (non-A/C and manual A/C) or “Electronic

Control System Components Location in Section 7B” (auto A/C).

5V

BLK

RED/BLK3

5 72

G154-3

G154-4

G154-7

G154-8

G154-10

G154-13

G155-2

G155-3

G155-7

G155-6

G155-1

G154-9

G154-14

BLK/WHT

YEL

BLU/WHT

RED

RED/BLKRED

GRN

GRN/YEL

RED/YEL

RED/BLU

BLK/ORN

46

8

BLU

YELGRN

WHT

13

1514

[A]21

BLK/RED

12V

BLK/YELBLK/WHTM

BLK

1IG1

IG2

12

BLK/RED

M 10

11

11

BLU/WHT 19

16

17

18 9 20

I6RW0C710003-01

[A]: Illumination control model 6. Blower motor resistor 12. Main fuse box 18. Illumination light

1. Ignition switch 7. Junction block assembly 13. Blower speed selector 19. Rear defogger relay

2. Blower motor 8. BCM 14. Air intake selector 20. Rear defogger

3. HVAC control unit 9. ECM 15. Rear defogger switch 21. Tail light

4. Lighting switch 10. Air intake control actuator 16. “REC” indicator light

5. Blower motor relay 11. To BCM 17. Rear defogger indicator

Page 944 of 1556

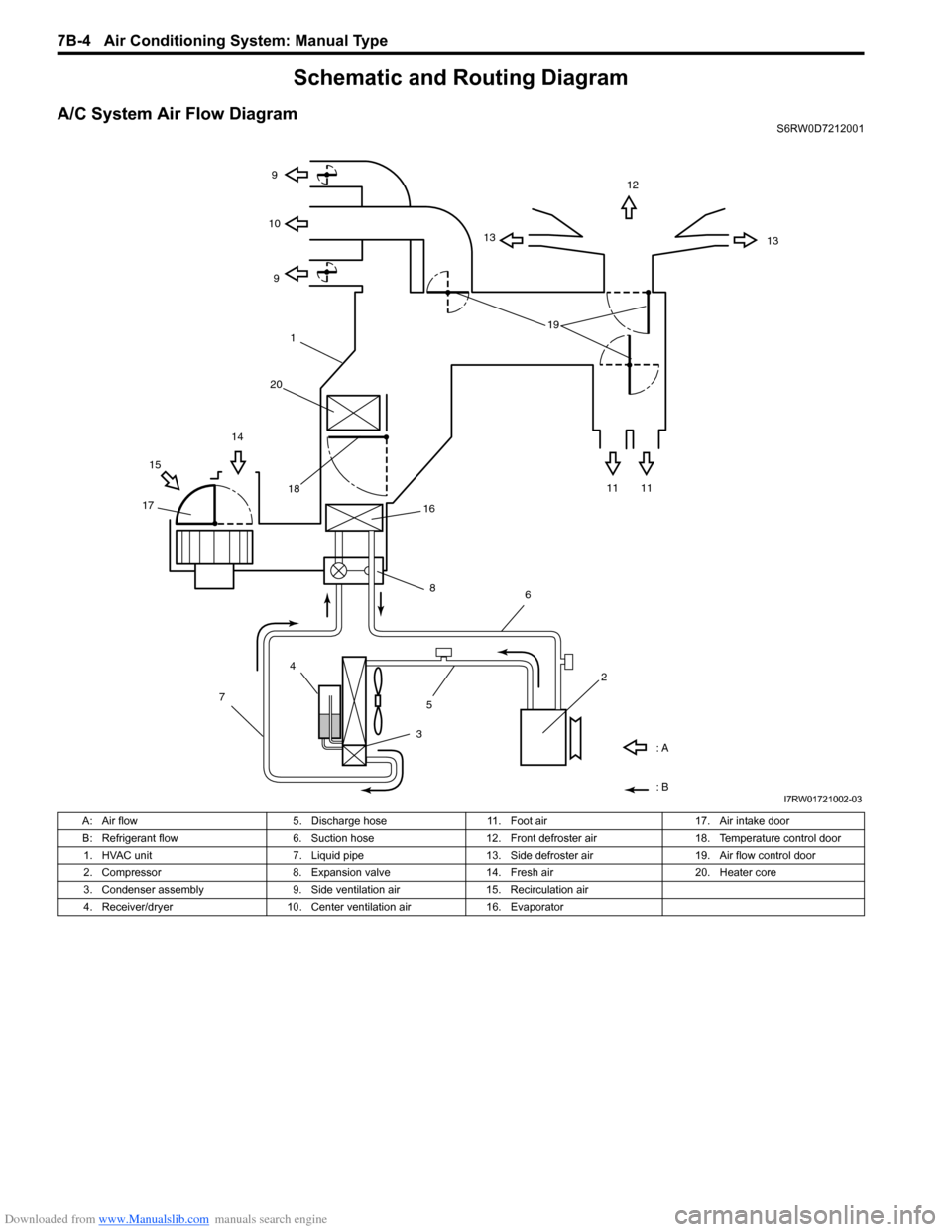

Downloaded from www.Manualslib.com manuals search engine 7B-4 Air Conditioning System: Manual Type

Schematic and Routing Diagram

A/C System Air Flow DiagramS6RW0D7212001

1312

13 9

9 10

11 11 1514

1718

: A

: B

4

7

356

2 16

8

191

20

I7RW01721002-03

A: Air flow 5. Discharge hose 11. Foot air 17. Air intake door

B: Refrigerant flow 6. Suction hose 12. Front defroster air 18. Temperature control door

1. HVAC unit 7. Liquid pipe 13. Side defroster air 19. Air flow control door

2. Compressor 8. Expansion valve 14. Fresh air 20. Heater core

3. Condenser assembly 9. Side ventilation air 15. Recirculation air

4. Receiver/dryer 10. Center ventilation air 16. Evaporator

Page 945 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G15 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G15](/img/20/7612/w960_7612-944.png)

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-5

A/C System Wiring DiagramS6RW0D7212002

[A]

7

WHT

GRN5YELBLK

3

G154-3

G154-4

G154-7

G154-8

G154-10

G154-13

G154-5

G154-6

G155-5

G155-2

G155-3

G155-7

G155-6

G155-1

G154-9

G154-14

BLK/WHT

YEL

BLU/WHT

RED

BRN

GRN/WHT

RED/BLK

RED

GRN

GRN/YEL

RED/YEL

RED/BLU

20

21

23 22

BLK/RED

6 2

MBLK/WHTBLK/YEL

M

11

4RED/YEL 1

E01-49

12

E01-16

GRY 13

12V

BLU/WHTE01-3510

E01-48

18

19RED/BLK

BLK/RED

BLK/RED

BRN/WHTE01-60

E01-1

E01-29BLK/WHT

M

BLU/YELBLK/YEL

5V5V 5V

WHT/BLK

9

ORN

14E01-36

C01-12C01-14GRY/REDRED/BLU

E01-41

RED/BLK

RED

WHT

8

BLK

BLK/ORN

BLU IG1

IG2

5V

17

28

29

31

2726 2524

16

16

30

34

33E01-4 E01-19WHTRED

C01-50C01-49WHTRED

32

LT GRN

C01-57

C01-2415

GRY/BLU5V

I6RW0C721002-01

[A]: Illumination control model 9. A/C refrigerant pressure

sensor18. Condenser cooling fan relay 27. Illumination light

1. Ignition switch 10. ECM 19. Condenser cooling fan motor 28. Rear defogger relay

2. Blower motor 11. Air intake control actuator 20. Blower speed selector 29. Rear defogger

3. HVAC control unit 12. Compressor relay 21. A/C switch 30. Main relay

4. Lighting switch 13. Compressor 22. Air intake selector 31. Tail light

5. Blower motor relay 14. Evaporator temperature

sensor23. Rear defogger switch 32. TCM

6. Blower motor resistor 15. ECT sensor 24. “A/C” indicator light 33. To other control module and DLC

7. Junction block assembly 16. To BCM 25. “REC” indicator light 34. ABS control module

8. BCM 17. Main fuse box 26. Rear defogger indicator

Page 949 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

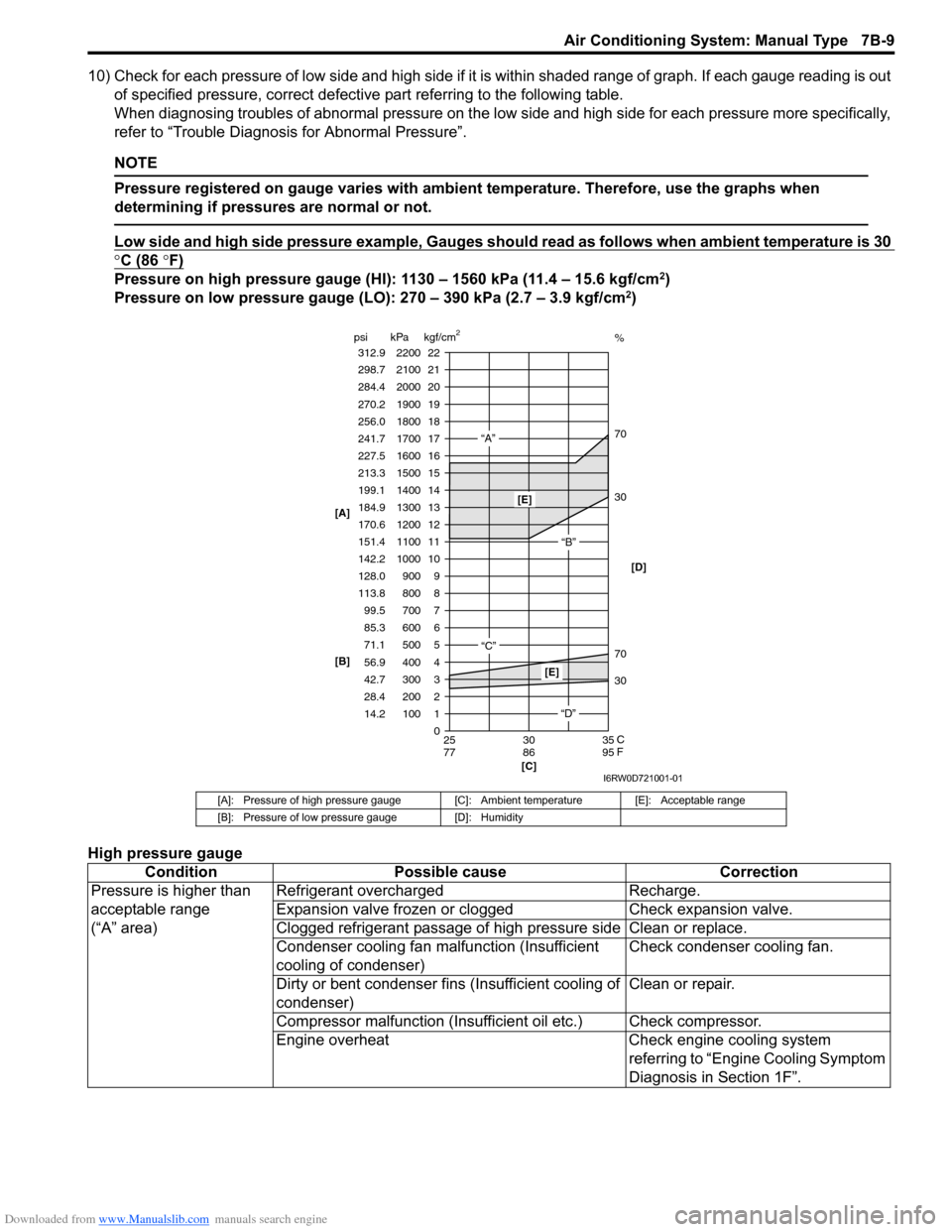

10) Check for each pressure of low side and high side if it is within shaded range of graph. If each gauge reading is out

of specified pressure, correct defective part referring to the following table.

When diagnosing troubles of abnormal pressure on the low side and high side for each pressure more specifically,

refer to “Trouble Diagnosis for Abnormal Pressure”.

NOTE

Pressure registered on gauge varies with ambient temperature. Therefore, use the graphs when

determining if pressures are normal or not.

Low side and high side pressure example, Gauges should read as follows when ambient temperature is 30

°C (86 °F)

Pressure on high pressure gauge (HI): 1130 – 1560 kPa (11.4 – 15.6 kgf/cm2)

Pressure on low pressure gauge (LO): 270 – 390 kPa (2.7 – 3.9 kgf/cm2)

High pressure gauge

[A]: Pressure of high pressure gauge [C]: Ambient temperature [E]: Acceptable range

[B]: Pressure of low pressure gauge [D]: Humidity

Condition Possible cause Correction

Pressure is higher than

acceptable range

(“A” area)Refrigerant overcharged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage of high pressure side Clean or replace.

Condenser cooling fan malfunction (Insufficient

cooling of condenser)Check condenser cooling fan.

Dirty or bent condenser fins (Insufficient cooling of

condenser)Clean or repair.

Compressor malfunction (Insufficient oil etc.) Check compressor.

Engine overheat Check engine cooling system

referring to “Engine Cooling Symptom

Diagnosis in Section 1F”.

22 312.9 2200

0 1 2 3

30 70 30 70%

4 5 6 7 8 9 10

11 12 13

14

15

16

17

18

19 21 298.7 2100

20

14.2 28.4 42.7 56.9 71.1 85.3 99.5 113.8 128.0

142.2

151.4 170.6 184.9

199.1

213.3

227.5

241.7

256.0

270.2

284.4

100 200 300 400 500 600 700 800 900 1000

1100 1200 1300

1400

1500

1600

1700

1800

1900

2000

25 30 35

77 86 95 psi kPa kgf/cm

2

[C] [B] [A]

C

F

“A”

“B”

“C”

[E]

[E]

“D”[D]

I6RW0D721001-01

Page 958 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-18 Air Conditioning System: Manual Type

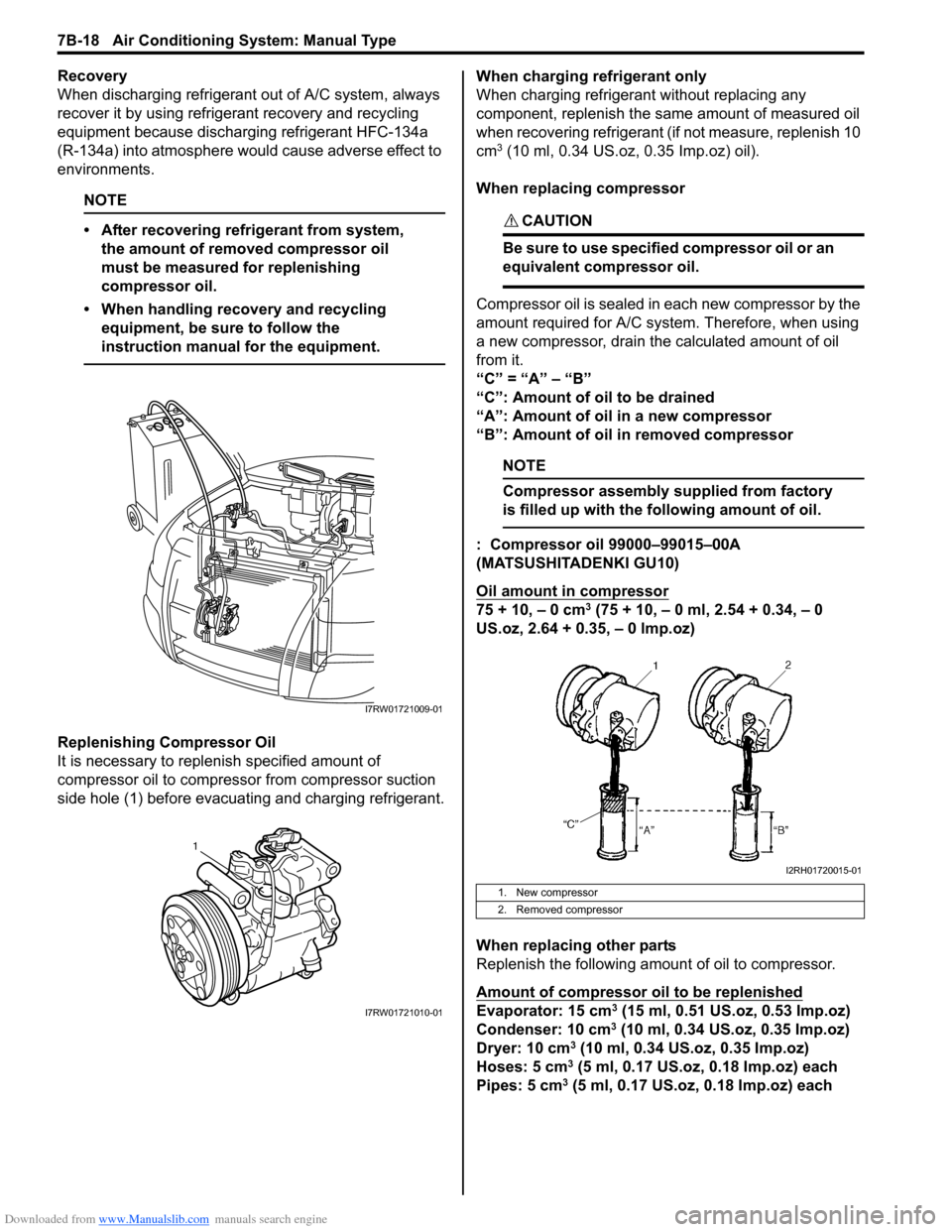

Recovery

When discharging refrigerant out of A/C system, always

recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a

(R-134a) into atmosphere would cause adverse effect to

environments.

NOTE

• After recovering refrigerant from system,

the amount of removed compressor oil

must be measured for replenishing

compressor oil.

• When handling recovery and recycling

equipment, be sure to follow the

instruction manual for the equipment.

Replenishing Compressor Oil

It is necessary to replenish specified amount of

compressor oil to compressor from compressor suction

side hole (1) before evacuating and charging refrigerant.When charging refrigerant only

When charging refrigerant without replacing any

component, replenish the same amount of measured oil

when recovering refrigerant (if not measure, replenish 10

cm

3 (10 ml, 0.34 US.oz, 0.35 Imp.oz) oil).

When replacing compressor

CAUTION!

Be sure to use specified compressor oil or an

equivalent compressor oil.

Compressor oil is sealed in each new compressor by the

amount required for A/C system. Therefore, when using

a new compressor, drain the calculated amount of oil

from it.

“C” = “A” – “B”

“C”: Amount of oil to be drained

“A”: Amount of oil in a new compressor

“B”: Amount of oil in removed compressor

NOTE

Compressor assembly supplied from factory

is filled up with the following amount of oil.

: Compressor oil 99000–99015–00A

(MATSUSHITADENKI GU10)

Oil amount in compressor

75 + 10, – 0 cm3 (75 + 10, – 0 ml, 2.54 + 0.34, – 0

US.oz, 2.64 + 0.35, – 0 lmp.oz)

When replacing other parts

Replenish the following amount of oil to compressor.

Amount of compressor oil to be replenished

Evaporator: 15 cm3 (15 ml, 0.51 US.oz, 0.53 Imp.oz)

Condenser: 10 cm3 (10 ml, 0.34 US.oz, 0.35 Imp.oz)

Dryer: 10 cm3 (10 ml, 0.34 US.oz, 0.35 Imp.oz)

Hoses: 5 cm3 (5 ml, 0.17 US.oz, 0.18 Imp.oz) each

Pipes: 5 cm3 (5 ml, 0.17 US.oz, 0.18 Imp.oz) each

I7RW01721009-01

1

I7RW01721010-01

1. New compressor

2. Removed compressor

I2RH01720015-01

Page 961 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-21

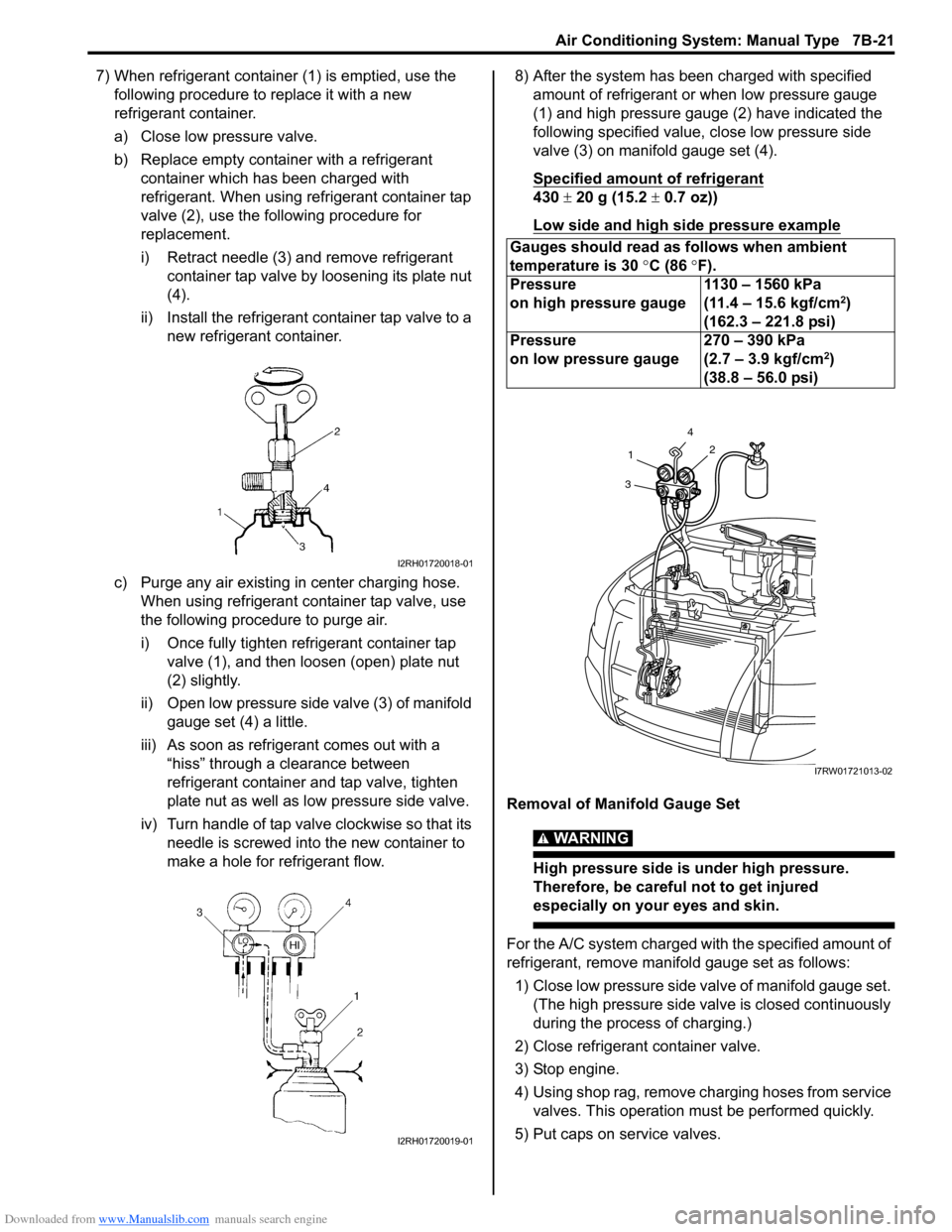

7) When refrigerant container (1) is emptied, use the

following procedure to replace it with a new

refrigerant container.

a) Close low pressure valve.

b) Replace empty container with a refrigerant

container which has been charged with

refrigerant. When using refrigerant container tap

valve (2), use the following procedure for

replacement.

i) Retract needle (3) and remove refrigerant

container tap valve by loosening its plate nut

(4).

ii) Install the refrigerant container tap valve to a

new refrigerant container.

c) Purge any air existing in center charging hose.

When using refrigerant container tap valve, use

the following procedure to purge air.

i) Once fully tighten refrigerant container tap

valve (1), and then loosen (open) plate nut

(2) slightly.

ii) Open low pressure side valve (3) of manifold

gauge set (4) a little.

iii) As soon as refrigerant comes out with a

“hiss” through a clearance between

refrigerant container and tap valve, tighten

plate nut as well as low pressure side valve.

iv) Turn handle of tap valve clockwise so that its

needle is screwed into the new container to

make a hole for refrigerant flow.8) After the system has been charged with specified

amount of refrigerant or when low pressure gauge

(1) and high pressure gauge (2) have indicated the

following specified value, close low pressure side

valve (3) on manifold gauge set (4).

Specified amount of refrigerant

430 ± 20 g (15.2 ± 0.7 oz))

Low side and high side pressure example

Removal of Manifold Gauge Set

WARNING!

High pressure side is under high pressure.

Therefore, be careful not to get injured

especially on your eyes and skin.

For the A/C system charged with the specified amount of

refrigerant, remove manifold gauge set as follows:

1) Close low pressure side valve of manifold gauge set.

(The high pressure side valve is closed continuously

during the process of charging.)

2) Close refrigerant container valve.

3) Stop engine.

4) Using shop rag, remove charging hoses from service

valves. This operation must be performed quickly.

5) Put caps on service valves.

I2RH01720018-01

I2RH01720019-01

Gauges should read as follows when ambient

temperature is 30 °C (86 °F).

Pressure

on high pressure gauge1130 – 1560 kPa

(11.4 – 15.6 kgf/cm

2)

(162.3 – 221.8 psi)

Pressure

on low pressure gauge270 – 390 kPa

(2.7 – 3.9 kgf/cm

2)

(38.8 – 56.0 psi)

4

2

1

3

I7RW01721013-02