Can SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 415 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-1

Engine

Charging System

General Description

Battery DescriptionS6RW0D1A01001

The battery has three major functions in the electrical

system.

• It is a source of electrical energy for cranking the

engine.

• It acts as a voltage stabilizer for the electrical system.

• It can, for a limited time, provide energy when the

electrical load exceeds the output of the generator.

Carrier and Hold-Down

The battery carrier should be in good condition so that it

will support the battery securely and keep it level. Before

installing the battery, the battery carrier and hold-down

clamp should be clean and free from corrosion and

make certain there are no parts in carrier.

To prevent the battery from shaking in its carrier, the

hold-down bolts should be tight enough but not over-

tightened.

Electrolyte Freezing

The freezing point of electrolyte depends on its specific

gravity. Since freezing may ruin a battery, it should be

protected against freezing by keeping it in a fully

charged condition. If a battery is frozen accidentally, it

should not be charged until it is warmed.

Sulfation

If the battery is allowed to stand for a long period in

discharged condition, the lead sulfate becomes

converted into a hard, crystalline substance, which will

not easily turn back to the active material again during

the subsequent recharging. “Sulfation” means the result

as well as the process of that reaction. Such a battery

can be revived by very slow charging and may be

restored to usable condition but its capacity is lower than

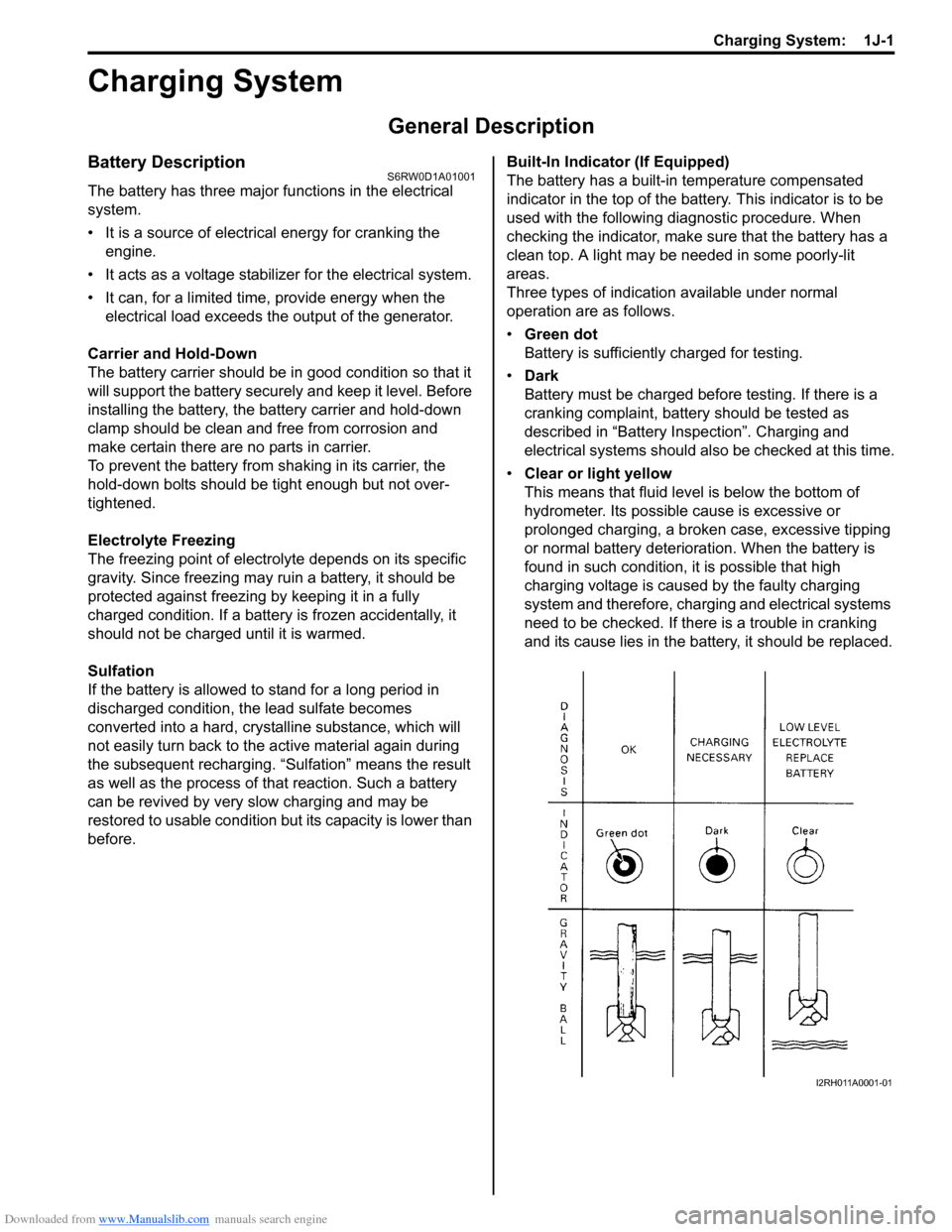

before.Built-In Indicator (If Equipped)

The battery has a built-in temperature compensated

indicator in the top of the battery. This indicator is to be

used with the following diagnostic procedure. When

checking the indicator, make sure that the battery has a

clean top. A light may be needed in some poorly-lit

areas.

Three types of indication available under normal

operation are as follows.

•Green dot

Battery is sufficiently charged for testing.

•Dark

Battery must be charged before testing. If there is a

cranking complaint, battery should be tested as

described in “Battery Inspection”. Charging and

electrical systems should also be checked at this time.

•Clear or light yellow

This means that fluid level is below the bottom of

hydrometer. Its possible cause is excessive or

prolonged charging, a broken case, excessive tipping

or normal battery deterioration. When the battery is

found in such condition, it is possible that high

charging voltage is caused by the faulty charging

system and therefore, charging and electrical systems

need to be checked. If there is a trouble in cranking

and its cause lies in the battery, it should be replaced.

I2RH011A0001-01

Page 416 of 1556

Downloaded from www.Manualslib.com manuals search engine 1J-2 Charging System:

Care of battery

WARNING!

• Never expose battery to open flame or electric spark because of battery generate gas which is

flammable and explosive.

• Do not allow battery fluid to contact eyes, skin, fabrics, or painted surfaces as fluid is a corrosive

acid. Flush any contacted area with water immediately and thoroughly.

• Batteries should always be kept out of reach of children.

1) The battery is a very reliable component, but needs periodical attentions.

• Keep the battery carrier clean.

• Prevent rust formation on the terminal posts.

• Keep the electrolyte up to the upper level uniformly in all cells.

• When keeping battery on vehicle over a long period of time, follow instructions given below.

– Weekly, start the engine and run it until it reaches normal operating temperature with engine speed of 2000 to

3000 rpm. Make sure all electric switches are off before storing the vehicle.

– Recharge the battery twice a month to prevent it from discharging excessively. This is especially important

when ambient temperature is low.

The battery discharges even when it is not used, while vehicles are being stored. Battery electrolyte can

freeze and battery case can crack at cold ambient condition if battery is not properly charged.

2) Keep the battery cable connections clean.

The cable connections, particularly at the positive (+) terminal post, tend to become corroded. The product of

corrosion, or rust, on the mating faces of conductors resists the flow of current.

Clean the terminals and fittings periodically to ensure good metal-to-metal contact, and grease the connections

after each cleaning to protect them against rusting.

3) Be always in the know as to the state of charge of the battery. The simplest way to tell the state of charge is to

carry out a hydrometer test. The hydrometer is an instrument for measuring the specific gravity (S.G.) of the

battery electrolyte. The S.G. of the electrolyte is indicative of the state of charge. Refer to “Battery Inspection”.

Page 417 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-3

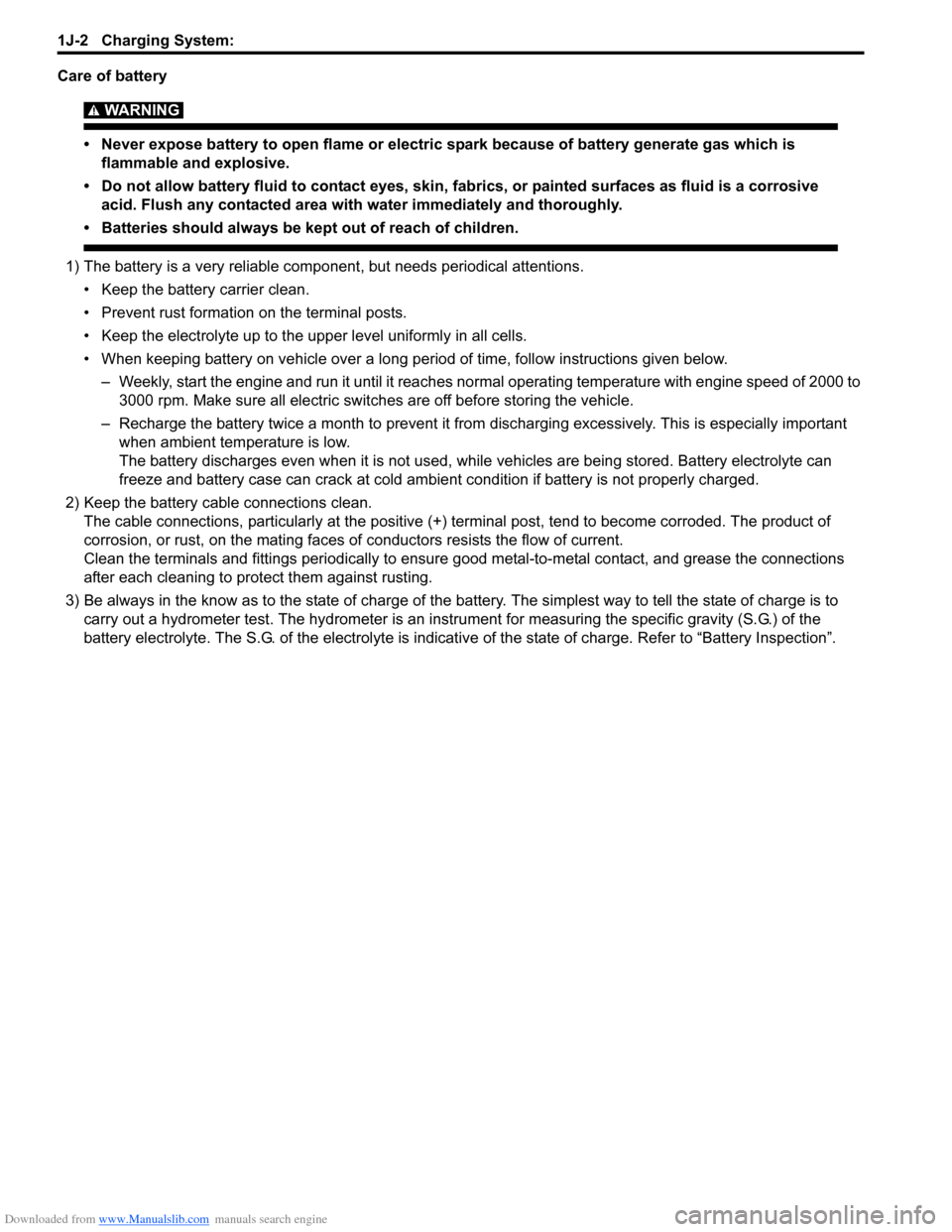

Generator DescriptionS6RW0D1A01002

The basic charging system is the IC integral regulator charging system. The internal components are connected

electrically as shown below.

Charging System Circuit

The generator features a solid state regulator that is mounted inside the generator. All regulator components are

enclosed into a solid mold, and this unit along with the brush holder assembly is attached to the rear housing. The

regulator voltage is being controlled by ECM under some conditions while driving. Refer to “Generator Control System

Description in Section 1A” in related manual.

The generator rotor bearings contain enough grease to eliminate the need for periodic lubrication.

Two brushes carry current through the two slip rings to the field coil mounted on the rotor, and under normal conditions

will provide long period of attention-free service.

The stator windings are assembled inside a laminated core that forms part of the generator frame.

A rectifier bridge connected to the stator windings contains diodes, and electrically changes that stator AC. voltages to

a D.C. voltage which appears at the generator output terminal.

1 26345

4

3B

7

8

9

10E FFRCIG

L

I6RW0D1A0002-01

1. Pulley 6. Field coil B: Generator output (Battery terminal) L: Lamp terminal

2. Pulley nut 7. Regulator C: Generator cut FR: Field duty monitor

3. Rotor fan 8. Brush E: Ground

4. Stator coil 9. Rear end frame F: Field coil terminal

5. Stator core 10. Drive end frame IG: Ignition terminal

B

IG

L

C

E

7

2 4

3

5

FR

610

11

12 13 1

[A]

IG1 9

14

8

I6RW0D1A0001-03

[A]: If equipped with electric load current sensor 4. Diode 8. Battery 12. Combination meter

1. Generator with regulator assembly 5. Field coil (rotor coil) 9. Electric load current sensor (if equipped) 13. CAN driver

2. I.C. regulator 6. Charge indicator light 10. ECM 14. Main fuse box

3. Stator coil 7. Main switch 11. BCM

Page 419 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-5

Charging Indicator Lamp Operation

Generator Test (Undercharged Battery Check)S6RW0D1A04003

This condition, as evidenced by slow cranking or low

specific gravity can be caused by one or more of the

following conditions even though indicator lamp may be

operating normal. The following procedure also applies

to cars with voltmeter and ammeter.

• Make sure that undercharged condition has not been

caused by accessories left on for extended period of

time.

• Check drive belt for proper tension.

• If battery defect is suspected, refer to “Battery

Description”.

• Inspect wiring for defects. Check all connections for

tightness and cleanliness, battery cable connections

at battery, starting motor and ignition ground cable.

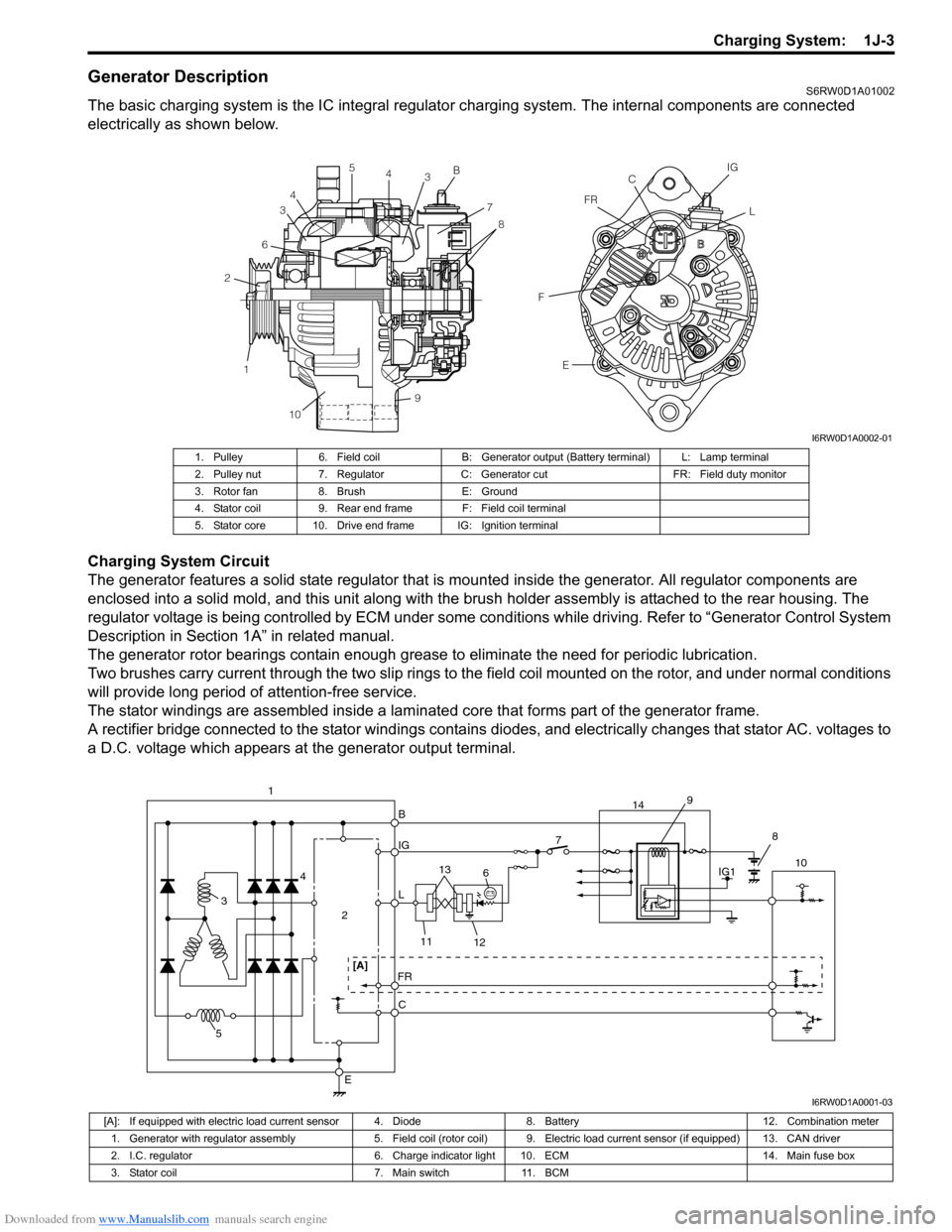

No-Load Check

1) Connect voltmeter and ammeter as shown in figure.

NOTE

Use fully charged battery.

2) Run engine from idling up to 2,000 rpm with all

accessories turned off and read meters.

If voltage is higher than standard value, check

ground of brushes.

If brushes are not grounded, replace IC regulator.

If voltage is lower than standard value, proceed to

the following check.

Specification for undercharged battery (No-load

check)

Current: 10 A

Voltage: 14.2 – 14.8 V at Hi (H) (at 25 °C, 77 °F)

Voltage: 12.5 – 13.1 V at Lo (L) (at 25 °C, 77 °F)

NOTE

Consideration should be taken that voltage

will differ somewhat with regulator case

temperature as shown in figure.

Condition Possible cause Correction / Reference Item

Charge light does not

light with ignition ON and

engine offFuse blownCheck fuse.

Indicator lamp (LED) faultyCheck BCM, combination meter and/or CAN

communication line.

Wiring connection looseTighten loose connection.

IC regulator or field coil faultyCheck generator.

Poor contact between brush and slip

ringRepair or replace.

Charge light does not go

out with engine running

(battery requires frequent

recharging)Drive belt loose or wornAdjust or replace drive belt.

IC regulator or generator faultyCheck charging system.

Wiring faultyRepair wiring.

1. Generator

2. Ammeter (between generator “B” terminal and battery (+) terminal)

3. Voltmeter (between generator “B” terminal and ground)

4. Battery

5. Load

6. Switch

I2RH011A0006-01

[A]: Regulated voltage (V)

[B]: Heatsink temperature (°C)

16.0

12.0

14.2 15.3

14.8

14.2

13.3 14.8

15.0

11.0 14.0

13.0 [A]

12.5 13.6

13.1

12.5

11.613.1

[B] -30 0 25 135

H

L

I2RH0B1A0005-01

Page 421 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-7

1) Set parking brake and place automatic transaxle in

PARK (NEUTRAL on manual transaxle). Turn off

ignition, turn off lights and all other electrical loads.

2) Check electrolyte level. If it is below low level line,

add distilled water.

3) Attach end of one jumper cable to positive terminal

of booster battery and the other end of the same

cable to positive terminal of discharged battery. (Use

12-volt battery only to jump start engine).

4) Attach one end of the remaining negative cable to

negative terminal of booster battery, and the other

end to a solid engine ground (such as exhaust

manifold) at least 45 cm (18 in.) away from battery of

vehicle being started.

5) Start engine of vehicle with booster battery and turn

off electrical accessories. Then start engine of the

vehicle with discharged battery.

6) Disconnect jumper cables in the exact reverse order.

With Charging Equipment

CAUTION!

When jump starting engine with charging

equipment, be sure equipment used is 12-

volt and negative ground. Do not use 24-volt

charging equipment. Using such equipment

can cause serious damage to electrical

system or electronic parts.

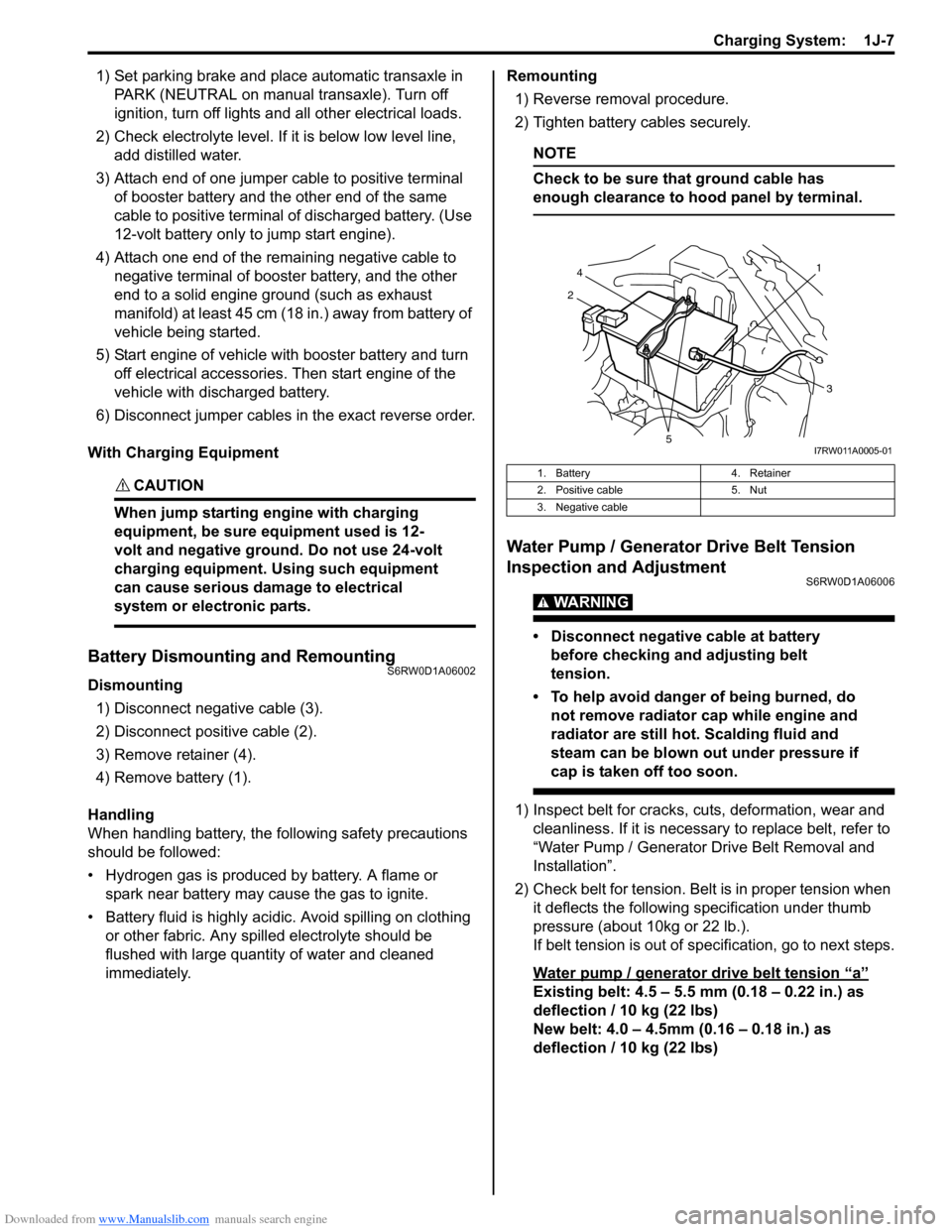

Battery Dismounting and RemountingS6RW0D1A06002

Dismounting

1) Disconnect negative cable (3).

2) Disconnect positive cable (2).

3) Remove retainer (4).

4) Remove battery (1).

Handling

When handling battery, the following safety precautions

should be followed:

• Hydrogen gas is produced by battery. A flame or

spark near battery may cause the gas to ignite.

• Battery fluid is highly acidic. Avoid spilling on clothing

or other fabric. Any spilled electrolyte should be

flushed with large quantity of water and cleaned

immediately.Remounting

1) Reverse removal procedure.

2) Tighten battery cables securely.

NOTE

Check to be sure that ground cable has

enough clearance to hood panel by terminal.

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S6RW0D1A06006

WARNING!

• Disconnect negative cable at battery

before checking and adjusting belt

tension.

• To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

cap is taken off too soon.

1) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

2) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 10kg or 22 lb.).

If belt tension is out of specification, go to next steps.

Water pump / generator drive belt tension

“a”

Existing belt: 4.5 – 5.5 mm (0.18 – 0.22 in.) as

deflection / 10 kg (22 lbs)

New belt: 4.0 – 4.5mm (0.16 – 0.18 in.) as

deflection / 10 kg (22 lbs)

1. Battery 4. Retainer

2. Positive cable 5. Nut

3. Negative cable

21

4

3

5I7RW011A0005-01

Page 439 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-2

Front Wheel Alignment ConstructionS6RW0D2201002

Among factors for front wheel alignment, only toe setting

can be adjusted. Camber and caster are not adjustable.

Therefore, should camber or caster be out of

specification due to the damage caused by hazardous

road conditions or collision, whether the damage is in

body or in suspension should be determined and

damaged body should be repaired or damaged

suspension should be replaced.

Preliminary Checks Prior to Adjustment Front Wheel

Alignment

Steering and vibration complaints are not always the

result of improper wheel alignment. An additional item to

be checked is the possibility of tire lead due to worn or

improperly manufactured tires. “Lead” is the vehicle

deviation from a straight path on a level road without

hand pressure on the steering wheel. Refer to “Radial

Tire Lead / Pull Description in Section 2D” in order to

determine if the vehicle has a tire lead problem. Before

making any adjustment affecting wheel alignment, the

following checks and inspections should be made to

ensure correctness of alignment readings and alignment

adjustments:• Check all tires for proper inflation pressures and

approximately the same tread wear.

• Check for loose of ball joints. Check tie-rod ends; if

excessive looseness is noted, it must be corrected

before adjusting.

• Check for run-out of wheels and tires.

• Check vehicle trim heights; if it is out of limit and a

correction is needed, it must be done before adjusting

toe.

• Check for loose of suspension control arms.

• Check for loose or missing stabilizer bar attachments.

• Consideration must be given to excess loads, such as

tool boxes. If this excess load is normally carried in

vehicle, it should remain in vehicle during alignment

checks.

• Consider condition of equipment being used to check

alignment and follow manufacturer’s instructions.

• Regardless of equipment used to check alignment,

vehicle must be placed on a level surface.

NOTE

To prevent possible incorrect reading of toe,

camber or caster, vehicle front and rear end

must be moved up and down a few times

before inspection.

Repair Instructions

Front Wheel Alignment Inspection and

Adjustment

S6RW0D2206001

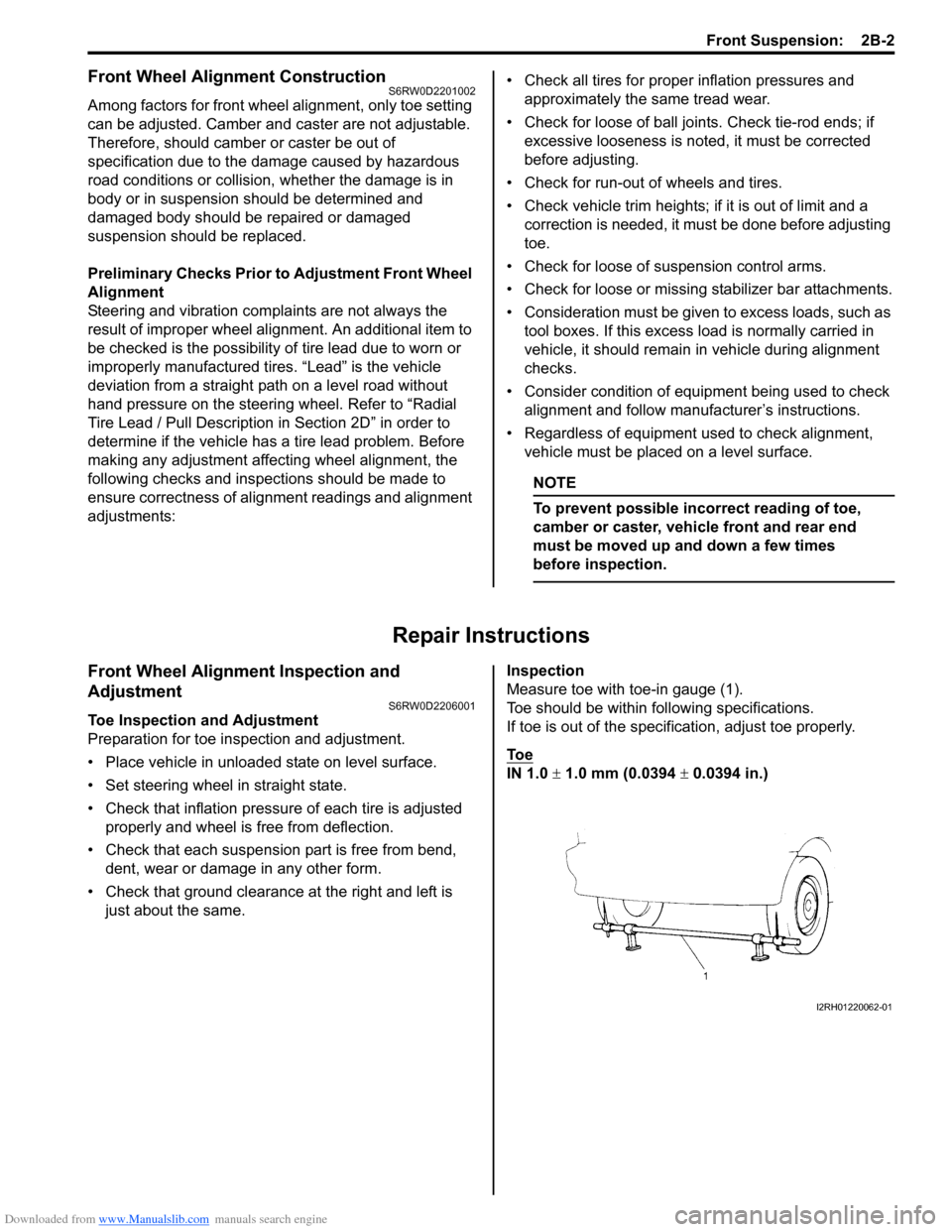

Toe Inspection and Adjustment

Preparation for toe inspection and adjustment.

• Place vehicle in unloaded state on level surface.

• Set steering wheel in straight state.

• Check that inflation pressure of each tire is adjusted

properly and wheel is free from deflection.

• Check that each suspension part is free from bend,

dent, wear or damage in any other form.

• Check that ground clearance at the right and left is

just about the same.Inspection

Measure toe with toe-in gauge (1).

Toe should be within following specifications.

If toe is out of the specification, adjust toe properly.

To e

IN 1.0 ± 1.0 mm (0.0394 ± 0.0394 in.)

I2RH01220062-01

Page 445 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-8

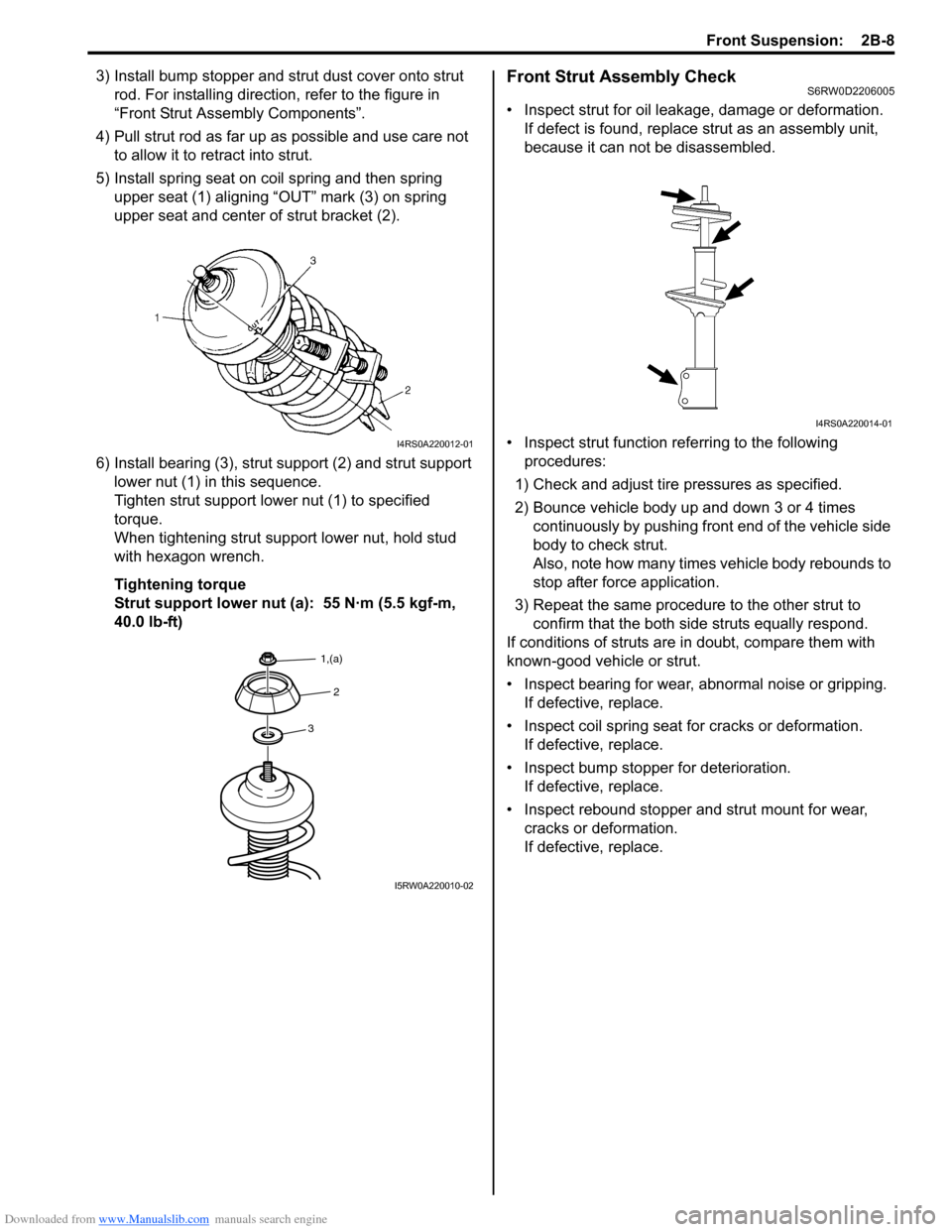

3) Install bump stopper and strut dust cover onto strut

rod. For installing direction, refer to the figure in

“Front Strut Assembly Components”.

4) Pull strut rod as far up as possible and use care not

to allow it to retract into strut.

5) Install spring seat on coil spring and then spring

upper seat (1) aligning “OUT” mark (3) on spring

upper seat and center of strut bracket (2).

6) Install bearing (3), strut support (2) and strut support

lower nut (1) in this sequence.

Tighten strut support lower nut (1) to specified

torque.

When tightening strut support lower nut, hold stud

with hexagon wrench.

Tightening torque

Strut support lower nut (a): 55 N·m (5.5 kgf-m,

40.0 lb-ft)Front Strut Assembly CheckS6RW0D2206005

• Inspect strut for oil leakage, damage or deformation.

If defect is found, replace strut as an assembly unit,

because it can not be disassembled.

• Inspect strut function referring to the following

procedures:

1) Check and adjust tire pressures as specified.

2) Bounce vehicle body up and down 3 or 4 times

continuously by pushing front end of the vehicle side

body to check strut.

Also, note how many times vehicle body rebounds to

stop after force application.

3) Repeat the same procedure to the other strut to

confirm that the both side struts equally respond.

If conditions of struts are in doubt, compare them with

known-good vehicle or strut.

• Inspect bearing for wear, abnormal noise or gripping.

If defective, replace.

• Inspect coil spring seat for cracks or deformation.

If defective, replace.

• Inspect bump stopper for deterioration.

If defective, replace.

• Inspect rebound stopper and strut mount for wear,

cracks or deformation.

If defective, replace.

I4RS0A220012-01

3

2

1,(a)

I5RW0A220010-02

I4RS0A220014-01

Page 453 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-16

Assembly

1) Front bushing

Press-fit front bushing (1) by using special tools and

press (2).

Special tool

(A): 09943–76310

(B): 09913–75821

CAUTION!

Be sure to use new bushing.

NOTE

• Before installing bushing, apply soap

water on its circumference to facilitate

bushing installation.

2) Press-fit bushing (1) so that dimensions “A” and “B”

in figure become equal.

Suspension Control Arm / Steering Knuckle

Check

S6RW0D2206011

Inspect for cracks, deformation or damage.

If defective, replace.

Suspension Control Arm Bushing CheckS6RW0D2206012

Inspect for damage, wear or deterioration.

If defective, replace.

Suspension Control Arm Joint CheckS6RW0D2206013

• Check smooth rotation of ball stud.

• Check damages of ball stud.

• Check damages of dust cover.

NOTE

Suspension control arm and arm joint cannot

be separated.

If there is any damage to either parts, control arm must

be replaced as a complete unit.

12

(A) (B)

I4RS0B220021-01

I4RS0A220033-01

I4RS0B220022-01

I4RS0B220023-01

Page 457 of 1556

Downloaded from www.Manualslib.com manuals search engine Front Suspension: 2B-20

12) Install exhaust No.1, No.2 and center pipe referring

to “Exhaust System Components in Section 1K”.

13) Install wheel and tighten nut to specified torque.

Tightening torque

Wheel nut: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

14) Install air cleaner assembly referring to “Air Cleaner

Assembly Removal and Installation in Section 1D”.

15) Install hood referring to “Hood Removal and

Installation in Section 9J”.

16) Lower hoist and vehicle in unloaded condition,

tighten suspension control arm bolts to specified

torque.

Tightening torque

Suspension control arm bolt: 95 N·m (9.5 kgf-m,

69.0 lb-ft)

17) Connect negative (–) cable at battery.

18) Confirm front wheel alignment referring to “Front

Wheel Alignment Inspection and Adjustment”.

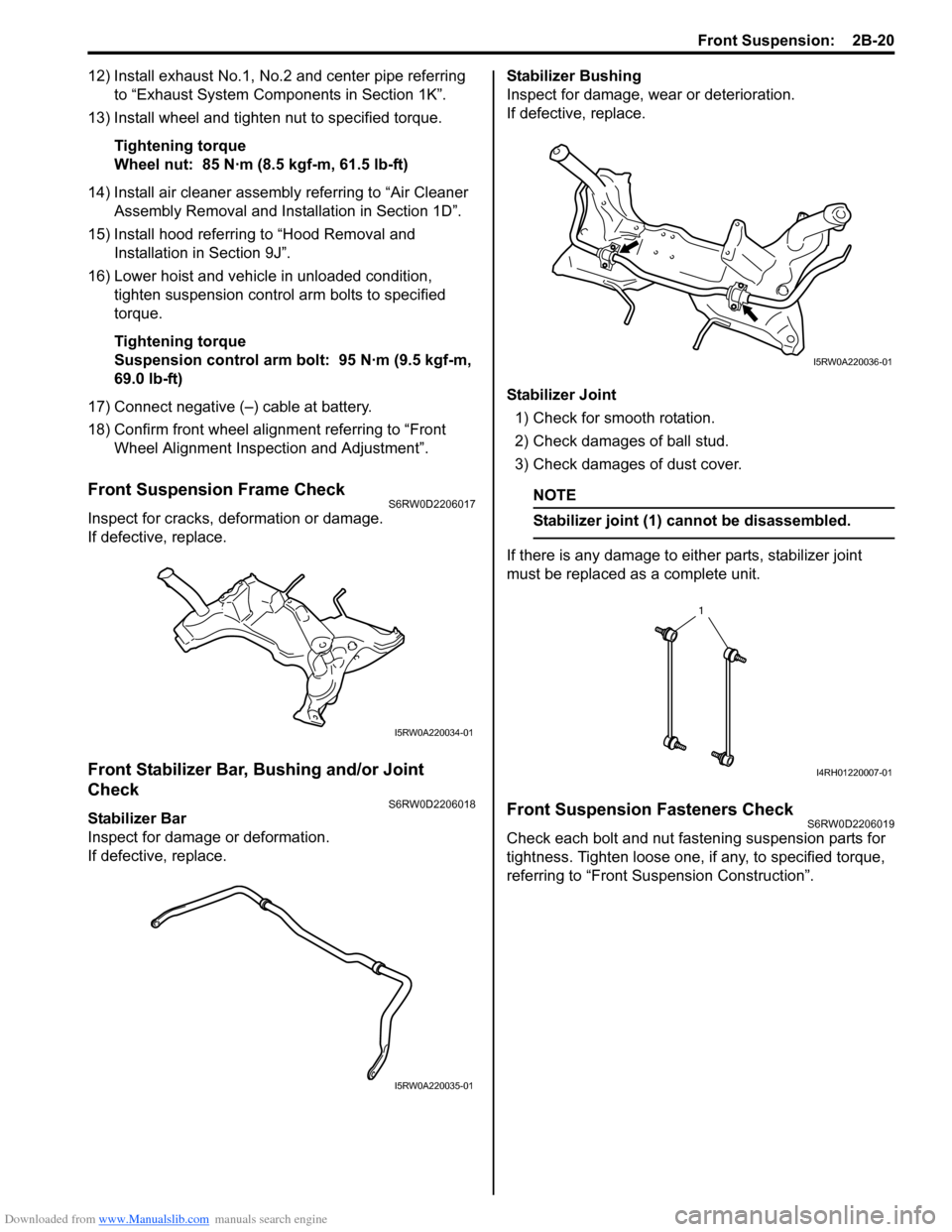

Front Suspension Frame CheckS6RW0D2206017

Inspect for cracks, deformation or damage.

If defective, replace.

Front Stabilizer Bar, Bushing and/or Joint

Check

S6RW0D2206018

Stabilizer Bar

Inspect for damage or deformation.

If defective, replace.Stabilizer Bushing

Inspect for damage, wear or deterioration.

If defective, replace.

Stabilizer Joint

1) Check for smooth rotation.

2) Check damages of ball stud.

3) Check damages of dust cover.

NOTE

Stabilizer joint (1) cannot be disassembled.

If there is any damage to either parts, stabilizer joint

must be replaced as a complete unit.

Front Suspension Fasteners CheckS6RW0D2206019

Check each bolt and nut fastening suspension parts for

tightness. Tighten loose one, if any, to specified torque,

referring to “Front Suspension Construction”.

I5RW0A220034-01

I5RW0A220035-01

I5RW0A220036-01

1

I4RH01220007-01

Page 463 of 1556

Downloaded from www.Manualslib.com manuals search engine Rear Suspension: 2C-4

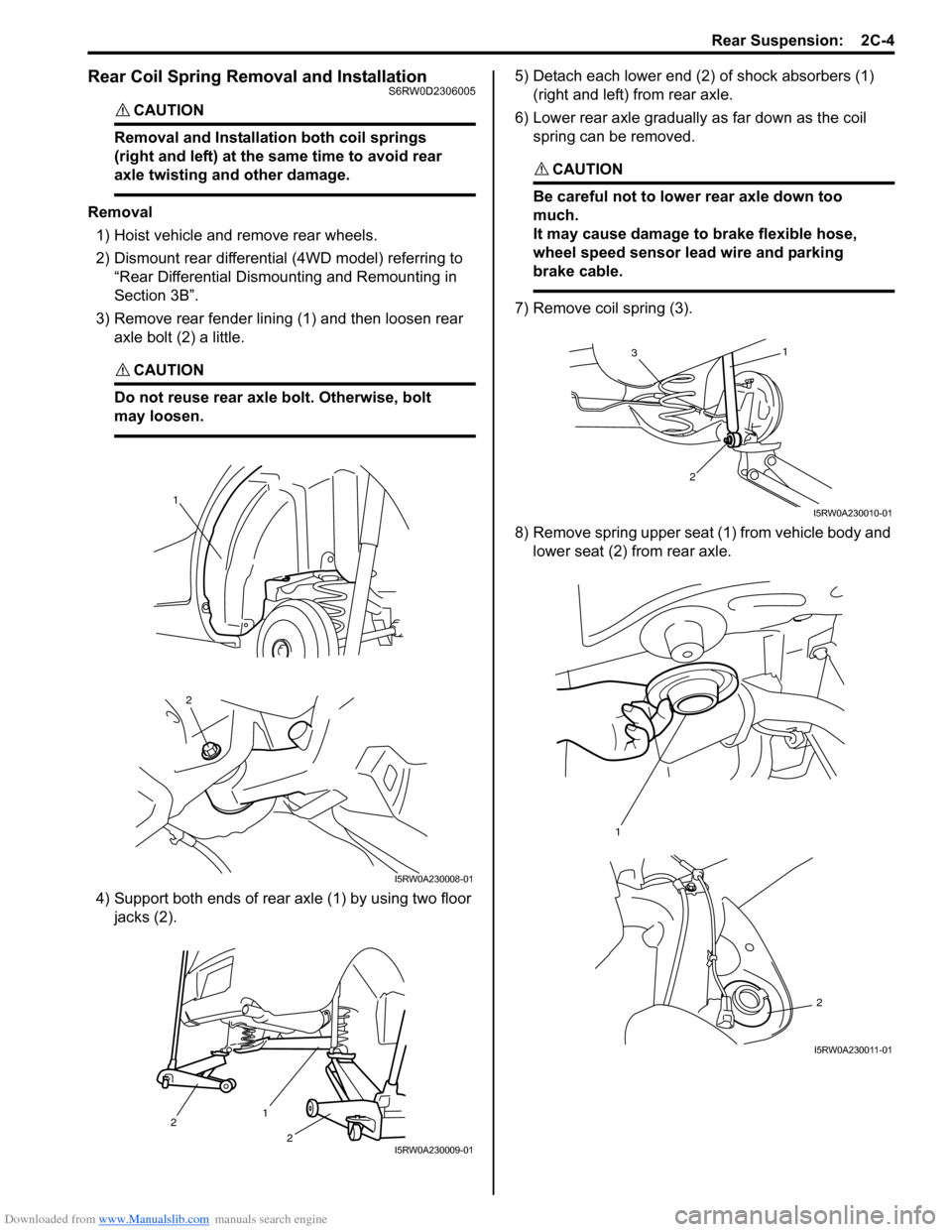

Rear Coil Spring Removal and InstallationS6RW0D2306005

CAUTION!

Removal and Installation both coil springs

(right and left) at the same time to avoid rear

axle twisting and other damage.

Removal

1) Hoist vehicle and remove rear wheels.

2) Dismount rear differential (4WD model) referring to

“Rear Differential Dismounting and Remounting in

Section 3B”.

3) Remove rear fender lining (1) and then loosen rear

axle bolt (2) a little.

CAUTION!

Do not reuse rear axle bolt. Otherwise, bolt

may loosen.

4) Support both ends of rear axle (1) by using two floor

jacks (2).5) Detach each lower end (2) of shock absorbers (1)

(right and left) from rear axle.

6) Lower rear axle gradually as far down as the coil

spring can be removed.

CAUTION!

Be careful not to lower rear axle down too

much.

It may cause damage to brake flexible hose,

wheel speed sensor lead wire and parking

brake cable.

7) Remove coil spring (3).

8) Remove spring upper seat (1) from vehicle body and

lower seat (2) from rear axle.

2

1

I5RW0A230008-01

1

2

2

I5RW0A230009-01

1

2

3

I5RW0A230010-01

1

2

I5RW0A230011-01