4WD SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 54 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-4 Engine General Information and Diagnosis:

Outline of troubleshooting

When there is a trouble with CAN, perform “Troubleshooting for Communication Error with Scan Tool Using CAN” and/

or “Troubleshooting for CAN-DTC”. Not using this procedure or performing troubleshooting in any other way may skip

some check points resulting in misdiagnosis or take a longer time than necessary.

1) Checking connector related to CAN

2) Checking CAN line

3) Checking each control module/sensor using “DTC check” or “Bus Check”

4) Checking power and ground connection of each control module/sensor

CAN-DTC

Even when DTC related to CAN (= CAN-DTC) as described below is detected, it is not possible to point out the

specific trouble point by CAN-DTC itself. Be sure to troubleshoot according to “Troubleshooting for CAN-DTC”.

CAN-DTC table

Communication with scan tool

• K line or CAN line is used for communication between each control module and scan tool.

Refer to “CAN schematic and routing diagram: ” to determine which line is used for communication between each

control module and scan tool.

• ECM and TCM use CAN line for communication with scan tool. Even if CAN has a trouble other than between DLC

and BCM, communication may also fail between scan tool and these control modules. In such case, perform

troubleshooting according to “Troubleshooting for Communication Error with Scan Tool Using CAN”.

• BCM, ABS control module and 4WD control module use K-line for communication with scan tool. Even if CAN has a

trouble, it is possible to communicate between scan tool and these control modules.

Bus check with SUZUKI scan tool

SUZUKI scan tool (SUZUKI-SDT) efficiently diagnoses a CAN bus malfunction by “Communication Bus Check” and

“Communication Malfunction DTC” under “Bus check”.

“Communication Bus Check” can display all control modules/sensors name communicated by CAN.

Also, “Communication Malfunction DTC” can display only CAN-DTC which is detected by the control modules (ECM

and TCM) communicating with scan tool using CAN line.

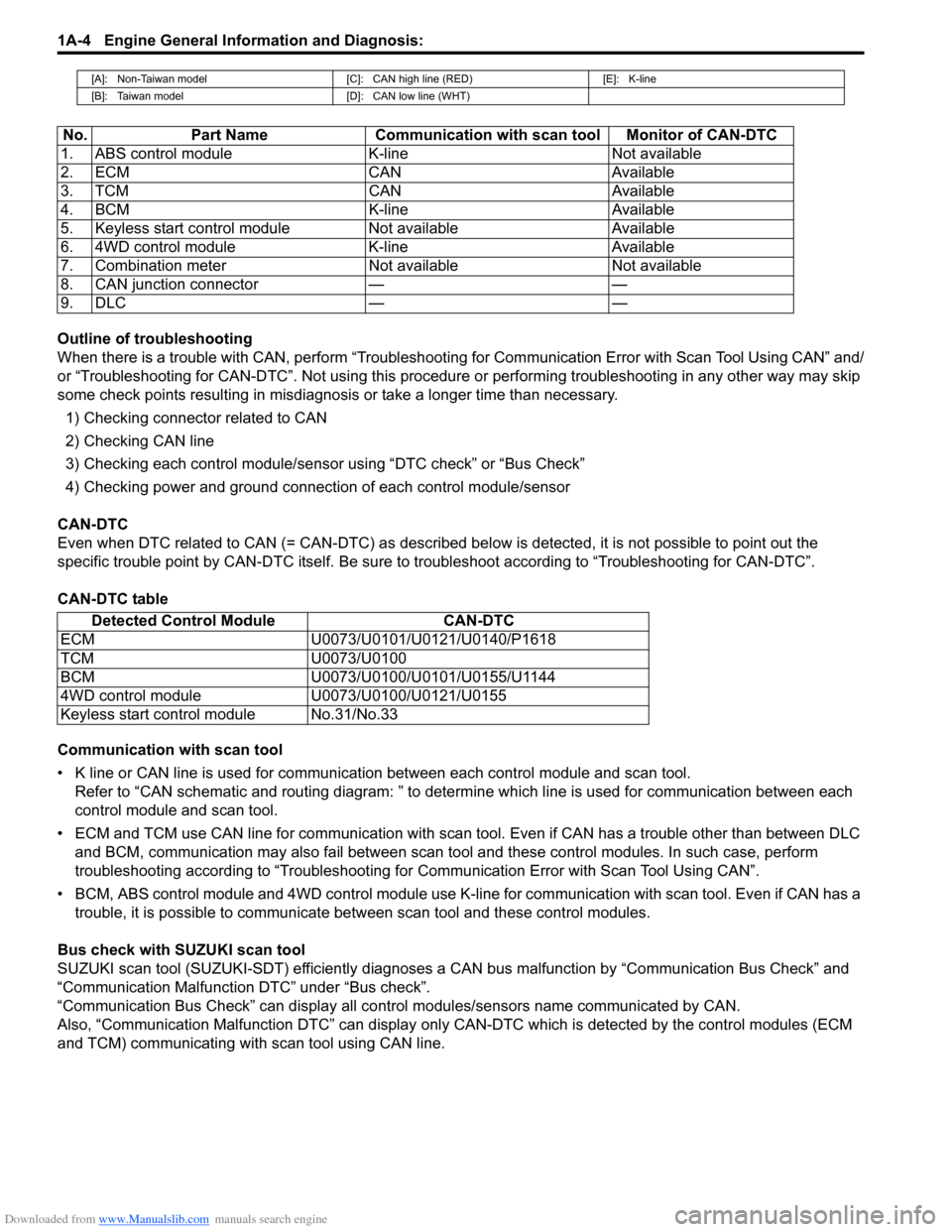

[A]: Non-Taiwan model [C]: CAN high line (RED) [E]: K-line

[B]: Taiwan model [D]: CAN low line (WHT)

No. Part Name Communication with scan tool Monitor of CAN-DTC

1. ABS control module K-line Not available

2. ECM CAN Available

3. TCM CAN Available

4. BCM K-line Available

5. Keyless start control module Not available Available

6. 4WD control module K-line Available

7. Combination meter Not available Not available

8. CAN junction connector — —

9. DLC — —

Detected Control Module CAN-DTC

ECM U0073/U0101/U0121/U0140/P1618

TCM U0073/U0100

BCM U0073/U0100/U0101/U0155/U1144

4WD control module U0073/U0100/U0121/U0155

Keyless start control module No.31/No.33

Page 59 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-9

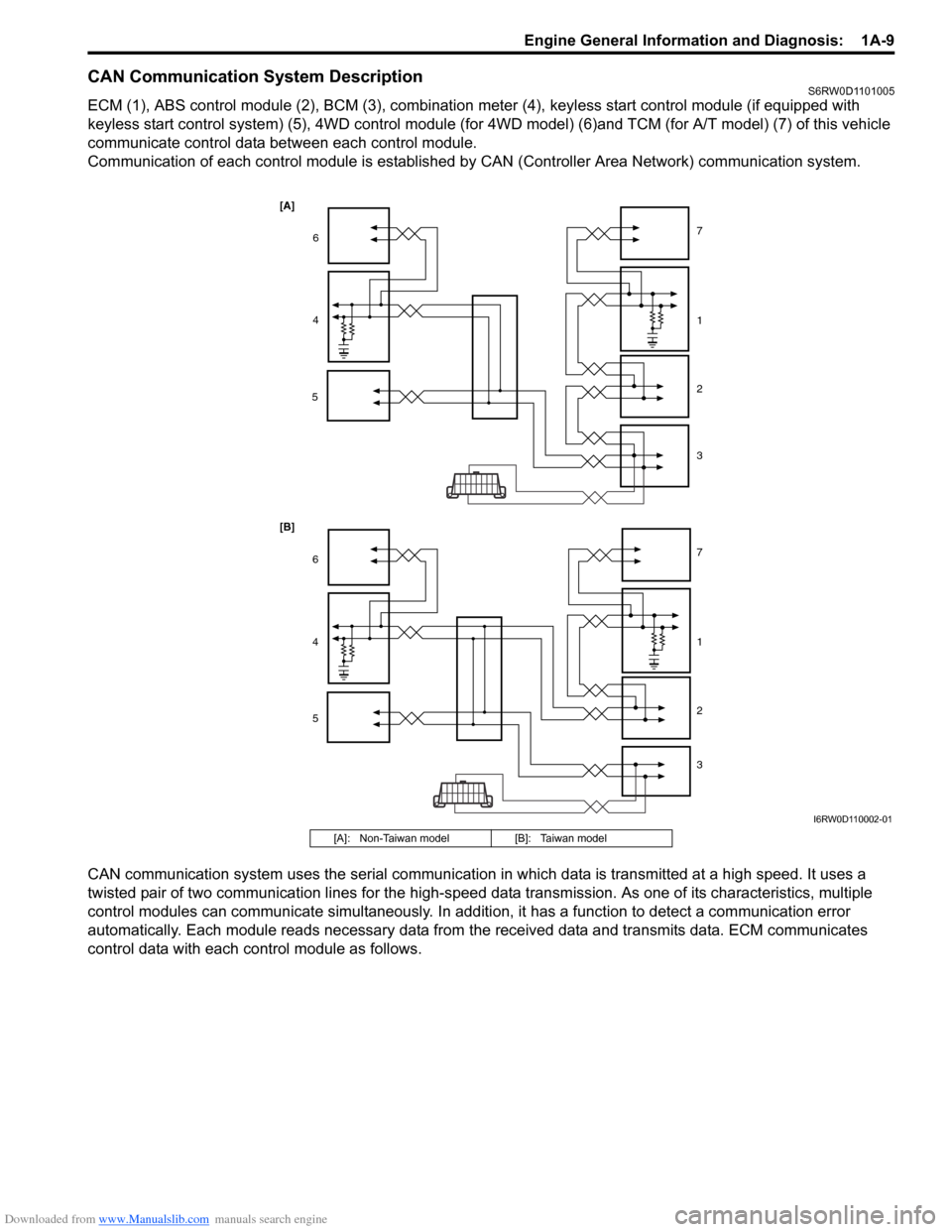

CAN Communication System DescriptionS6RW0D1101005

ECM (1), ABS control module (2), BCM (3), combination meter (4), keyless start control module (if equipped with

keyless start control system) (5), 4WD control module (for 4WD model) (6)and TCM (for A/T model) (7) of this vehicle

communicate control data between each control module.

Communication of each control module is established by CAN (Controller Area Network) communication system.

CAN communication system uses the serial communication in which data is transmitted at a high speed. It uses a

twisted pair of two communication lines for the high-speed data transmission. As one of its characteristics, multiple

control modules can communicate simultaneously. In addition, it has a function to detect a communication error

automatically. Each module reads necessary data from the received data and transmits data. ECM communicates

control data with each control module as follows.

[A]

[B]

6

4

51 7

2

3

6

4

51 7

2

3

I6RW0D110002-01

[A]: Non-Taiwan model [B]: Taiwan model

Page 60 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-10 Engine General Information and Diagnosis:

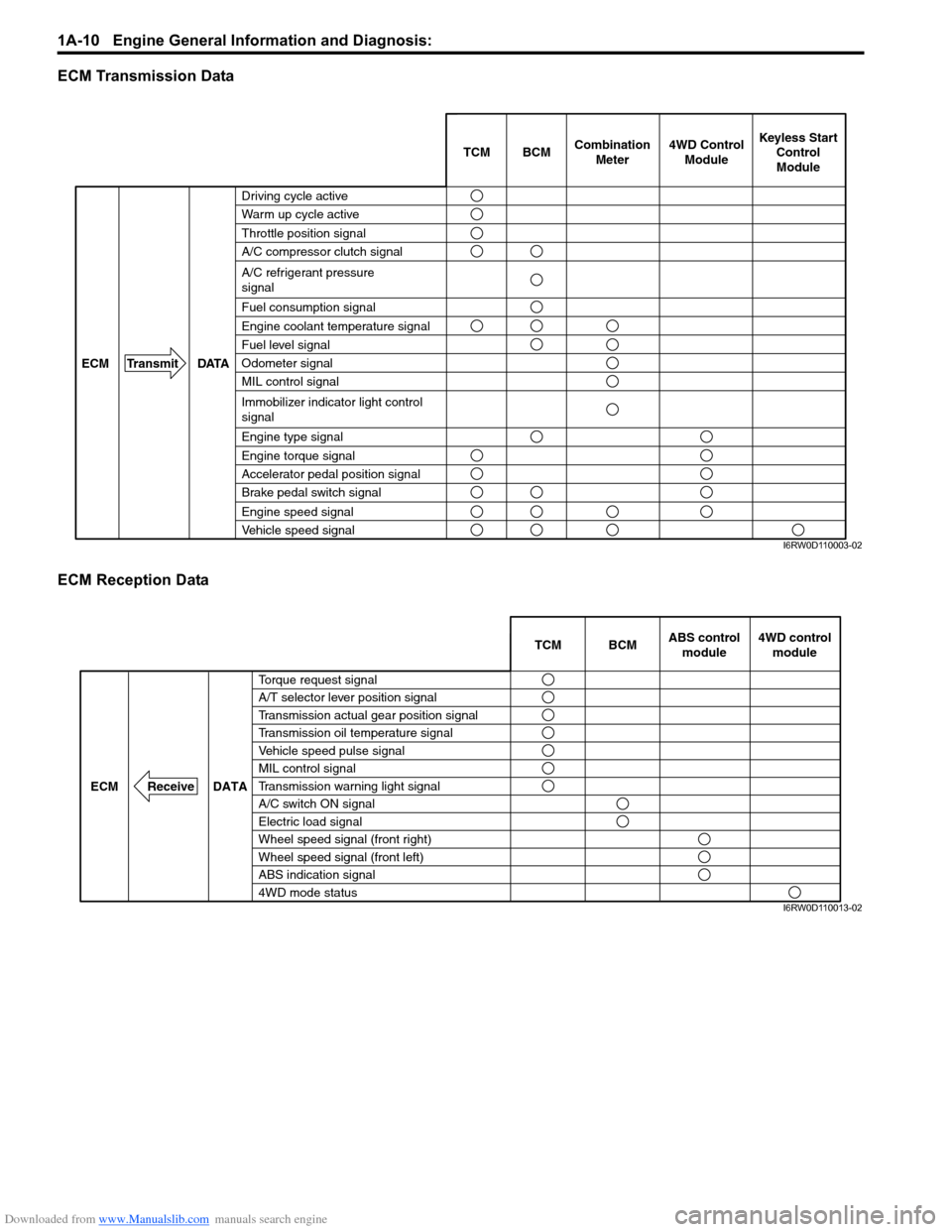

ECM Transmission Data

ECM Reception Data

BCM TCMCombination

Meter

DATA ECM Transmit

Brake pedal switch signal

Vehicle speed signal

Engine speed signal

Engine torque signal

Accelerator pedal position signal

4WD Control

ModuleKeyless Start

Control

Module

A/C refrigerant pressure

signal

A/C compressor clutch signal

Engine type signal

Immobilizer indicator light control

signal

MIL control signal

Engine coolant temperature signal

Fuel level signal

Fuel consumption signal

Throttle position signal

Driving cycle active

Warm up cycle active

Odometer signal

I6RW0D110003-02

DATA ECM Receive

ABS control

module

Transmission oil temperature signal

Transmission warning light signal Vehicle speed pulse signal A/T selector lever position signal

Transmission actual gear position signal

Wheel speed signal (front right)

Wheel speed signal (front left)

ABS indication signal

A/C switch ON signal

Electric load signalBCM

4WD mode status

Torque request signalTCM

MIL control signal4WD control

module

I6RW0D110013-02

Page 62 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-12 Engine General Information and Diagnosis:

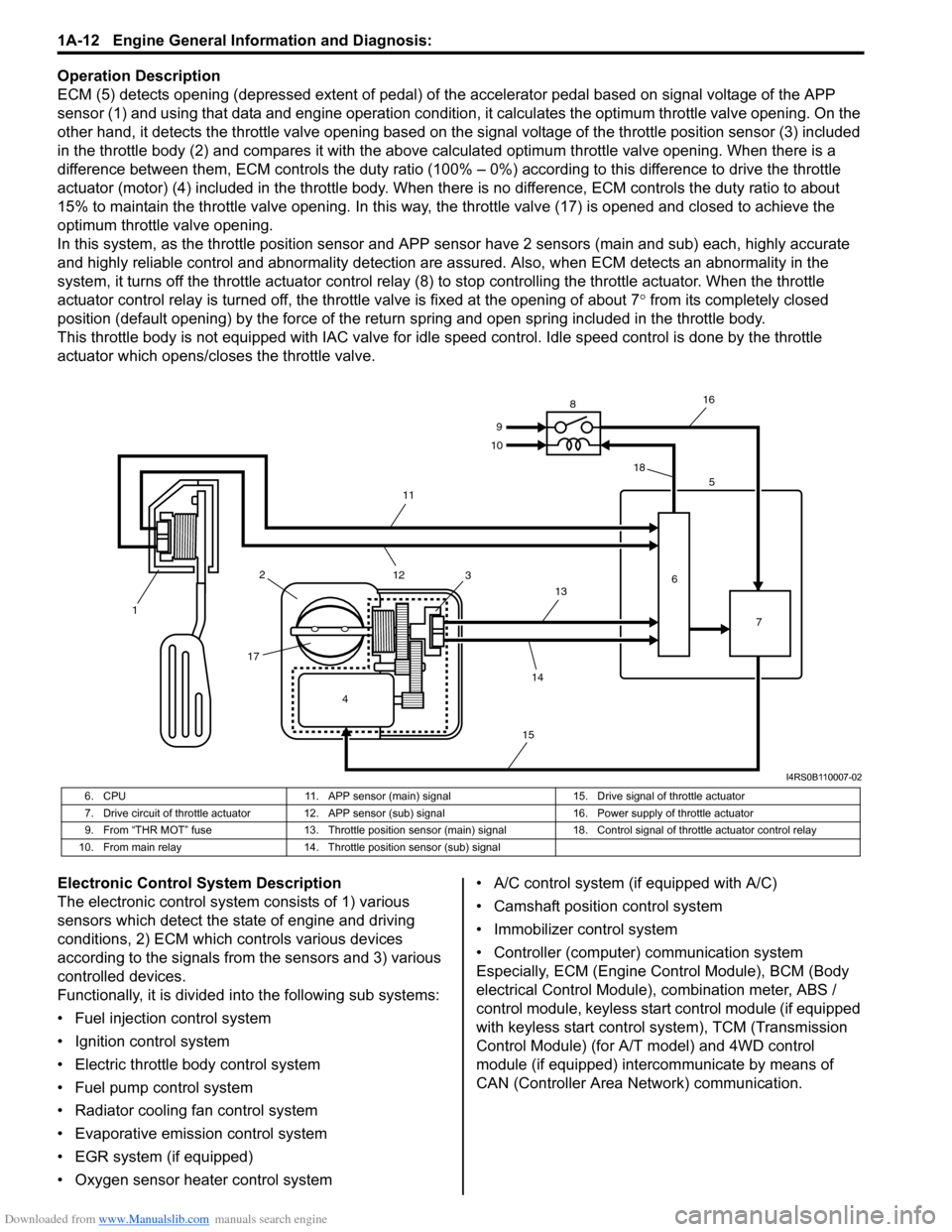

Operation Description

ECM (5) detects opening (depressed extent of pedal) of the accelerator pedal based on signal voltage of the APP

sensor (1) and using that data and engine operation condition, it calculates the optimum throttle valve opening. On the

other hand, it detects the throttle valve opening based on the signal voltage of the throttle position sensor (3) included

in the throttle body (2) and compares it with the above calculated optimum throttle valve opening. When there is a

difference between them, ECM controls the duty ratio (100% – 0%) according to this difference to drive the throttle

actuator (motor) (4) included in the throttle body. When there is no difference, ECM controls the duty ratio to about

15% to maintain the throttle valve opening. In this way, the throttle valve (17) is opened and closed to achieve the

optimum throttle valve opening.

In this system, as the throttle position sensor and APP sensor have 2 sensors (main and sub) each, highly accurate

and highly reliable control and abnormality detection are assured. Also, when ECM detects an abnormality in the

system, it turns off the throttle actuator control relay (8) to stop controlling the throttle actuator. When the throttle

actuator control relay is turned off, the throttle valve is fixed at the opening of about 7° from its completely closed

position (default opening) by the force of the return spring and open spring included in the throttle body.

This throttle body is not equipped with IAC valve for idle speed control. Idle speed control is done by the throttle

actuator which opens/closes the throttle valve.

Electronic Control System Description

The electronic control system consists of 1) various

sensors which detect the state of engine and driving

conditions, 2) ECM which controls various devices

according to the signals from the sensors and 3) various

controlled devices.

Functionally, it is divided into the following sub systems:

• Fuel injection control system

• Ignition control system

• Electric throttle body control system

• Fuel pump control system

• Radiator cooling fan control system

• Evaporative emission control system

• EGR system (if equipped)

• Oxygen sensor heater control system• A/C control system (if equipped with A/C)

• Camshaft position control system

• Immobilizer control system

• Controller (computer) communication system

Especially, ECM (Engine Control Module), BCM (Body

electrical Control Module), combination meter, ABS /

control module, keyless start control module (if equipped

with keyless start control system), TCM (Transmission

Control Module) (for A/T model) and 4WD control

module (if equipped) intercommunicate by means of

CAN (Controller Area Network) communication.

4 12

1735

6

7 8

9

10

11

12

13

14

1516

18

I4RS0B110007-02

6. CPU 11. APP sensor (main) signal 15. Drive signal of throttle actuator

7. Drive circuit of throttle actuator 12. APP sensor (sub) signal 16. Power supply of throttle actuator

9. From “THR MOT” fuse 13. Throttle position sensor (main) signal 18. Control signal of throttle actuator control relay

10. From main relay 14. Throttle position sensor (sub) signal

Page 63 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-13

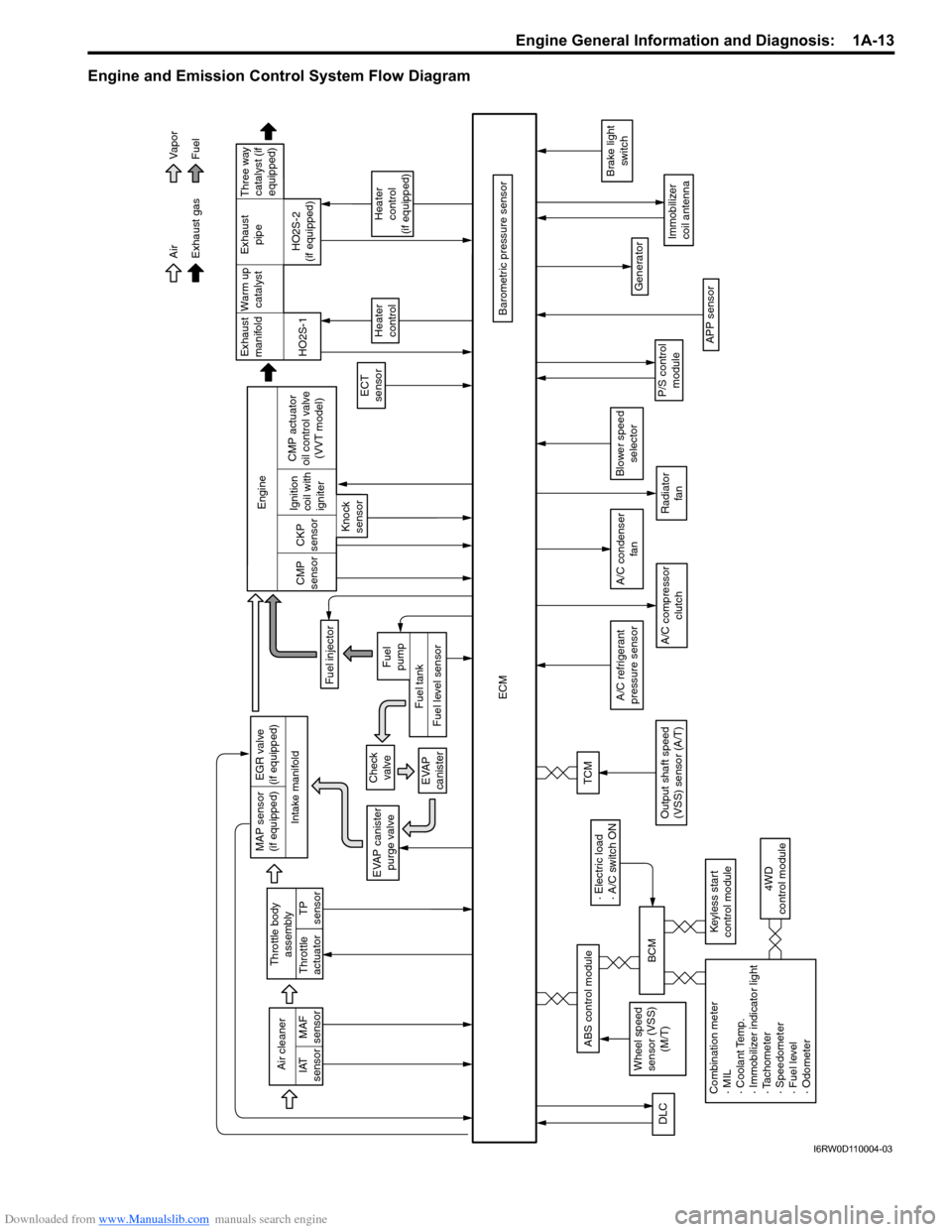

Engine and Emission Control System Flow Diagram

Intake manifoldExhaust

manifold

Exhaust gas Air

Fuel Vapor

War m up

catalystExhaust

pipe

EVAP canister

purge valve

Fuel injector

ECT

sensor

ECM

Heater

control

Heater

control

(if equipped)

Barometric pressure sensor HO2S-1HO2S-2

(if equipped) Engine

CMP

sensorCKP

sensor

Knock

sensorIgnition

coil with

igniter

APP sensor

A/C compressor

clutch

Generator

Immobilizer

coil antenna

P/S control

module

Brake light

switch

Air cleaner

IAT

sensorMAF

sensor

A/C refrigerant

pressure sensor

TP

sensor Throttle body

assembly

Throttle

actuator

A/C condenser

fan

DLC

Radiator

fan

Combination meter

· MIL

· Coolant Temp.

· Immobilizer indicator light

· Tachometer

· Speedometer

· Fuel level

· Odometer4WD

control module

Wheel speed

sensor (VSS)

(M/T)

· Electric load

· A/C switch ON

BCM

Keyless start

control module

ABS control module

Blower speed

selector

MAP sensor

(if equipped)EGR valve

(if equipped)

Check

valve

EVAP

canister

Fuel level sensorFuel tankFuel

pump

CMP actuator

oil control valve

(VVT model)

TCM

Output shaft speed

(VSS) sensor (A/T)

Three way

catalyst (if

equipped)

I6RW0D110004-03

Page 76 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-26 Engine General Information and Diagnosis:

• The MIL is turned on when the ECM and/or

TCM detect malfunction(s). Each ECM and

TCM stores diagnostic information as the

diagnostic trouble code (DTC) in its

memory and outputs the DTC to the scan

tool.

Therefore, check both of the ECM and TCM

for any DTC with the scan tool because the

DTC stored in ECM and TCM is not read

and displayed at a time. However, each of

the ECM and TCM needs not to be checked

with the generic scan tool because the

DTC stored in ECM and TCM is read and

displayed at a time.

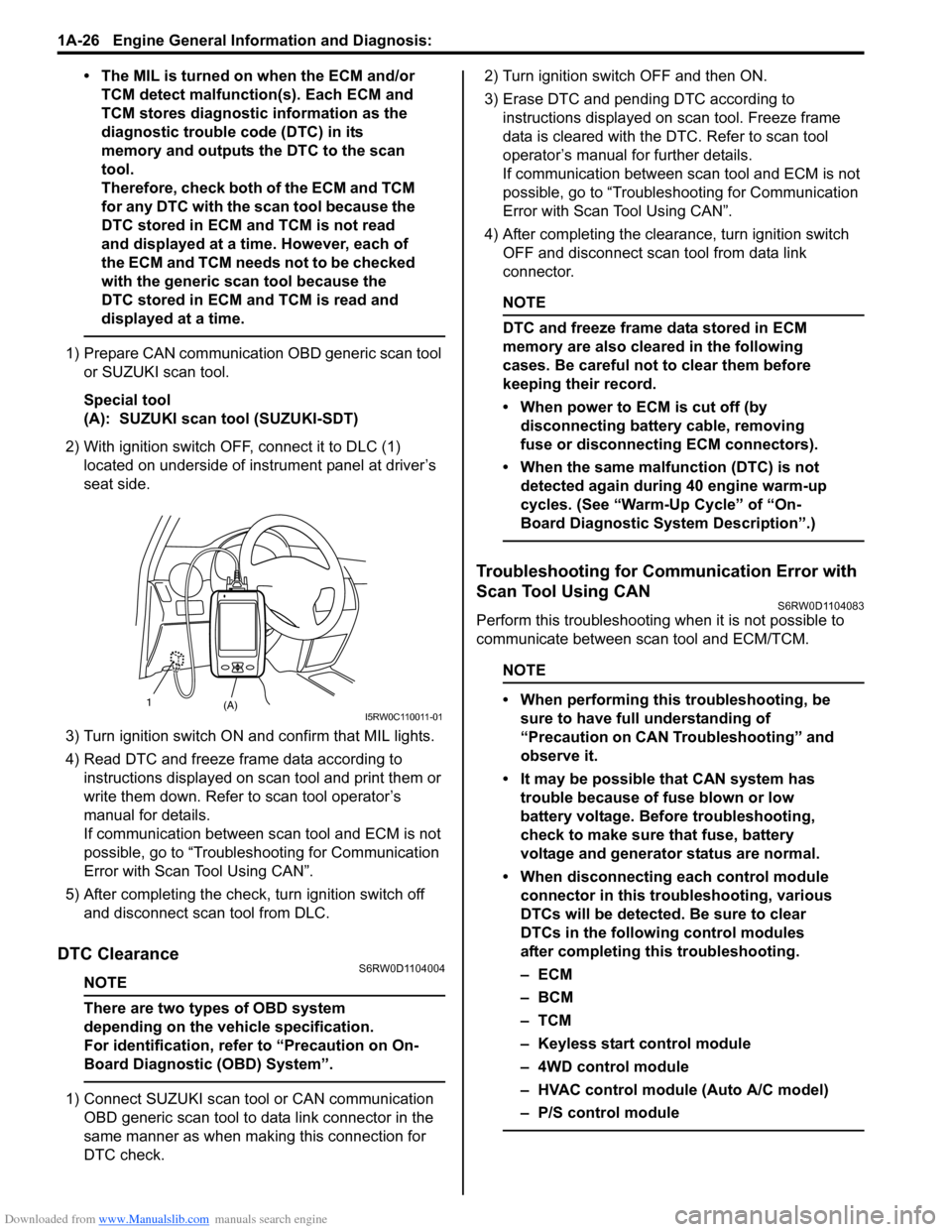

1) Prepare CAN communication OBD generic scan tool

or SUZUKI scan tool.

Special tool

(A): SUZUKI scan tool (SUZUKI-SDT)

2) With ignition switch OFF, connect it to DLC (1)

located on underside of instrument panel at driver’s

seat side.

3) Turn ignition switch ON and confirm that MIL lights.

4) Read DTC and freeze frame data according to

instructions displayed on scan tool and print them or

write them down. Refer to scan tool operator’s

manual for details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN”.

5) After completing the check, turn ignition switch off

and disconnect scan tool from DLC.

DTC ClearanceS6RW0D1104004

NOTE

There are two types of OBD system

depending on the vehicle specification.

For identification, refer to “Precaution on On-

Board Diagnostic (OBD) System”.

1) Connect SUZUKI scan tool or CAN communication

OBD generic scan tool to data link connector in the

same manner as when making this connection for

DTC check.2) Turn ignition switch OFF and then ON.

3) Erase DTC and pending DTC according to

instructions displayed on scan tool. Freeze frame

data is cleared with the DTC. Refer to scan tool

operator’s manual for further details.

If communication between scan tool and ECM is not

possible, go to “Troubleshooting for Communication

Error with Scan Tool Using CAN”.

4) After completing the clearance, turn ignition switch

OFF and disconnect scan tool from data link

connector.

NOTE

DTC and freeze frame data stored in ECM

memory are also cleared in the following

cases. Be careful not to clear them before

keeping their record.

• When power to ECM is cut off (by

disconnecting battery cable, removing

fuse or disconnecting ECM connectors).

• When the same malfunction (DTC) is not

detected again during 40 engine warm-up

cycles. (See “Warm-Up Cycle” of “On-

Board Diagnostic System Description”.)

Troubleshooting for Communication Error with

Scan Tool Using CAN

S6RW0D1104083

Perform this troubleshooting when it is not possible to

communicate between scan tool and ECM/TCM.

NOTE

• When performing this troubleshooting, be

sure to have full understanding of

“Precaution on CAN Troubleshooting” and

observe it.

• It may be possible that CAN system has

trouble because of fuse blown or low

battery voltage. Before troubleshooting,

check to make sure that fuse, battery

voltage and generator status are normal.

• When disconnecting each control module

connector in this troubleshooting, various

DTCs will be detected. Be sure to clear

DTCs in the following control modules

after completing this troubleshooting.

–ECM

–BCM

–TCM

– Keyless start control module

– 4WD control module

– HVAC control module (Auto A/C model)

– P/S control module

(A) 1I5RW0C110011-01

Page 78 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-28 Engine General Information and Diagnosis:

Trouble area

• Scan tool

• Connector related to CAN line (included in DLC)

• CAN line

• Power or ground circuit of DLC

• Control module communicated by CAN

–ECM

–TCM

– ABS control module

–BCM

– Combination meter

– Keyless start control module

– 4WD control module

• Power or ground circuit of control module communicated by CAN

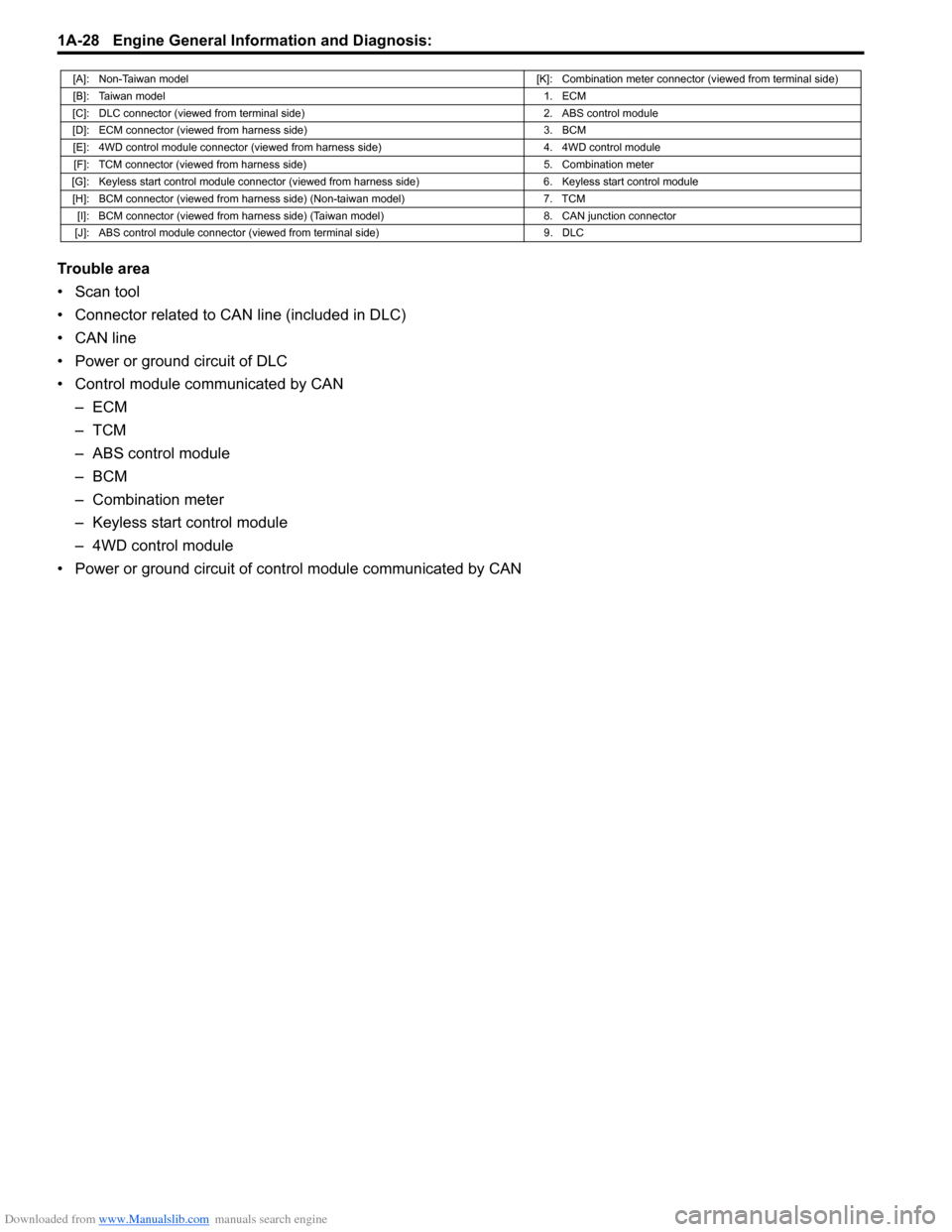

[A]: Non-Taiwan model[K]: Combination meter connector (viewed from terminal side)

[B]: Taiwan model1. ECM

[C]: DLC connector (viewed from terminal side) 2. ABS control module

[D]: ECM connector (viewed from harness side) 3. BCM

[E]: 4WD control module connector (viewed from harness side) 4. 4WD control module

[F]: TCM connector (viewed from harness side) 5. Combination meter

[G]: Keyless start control module connector (viewed from harness side) 6. Keyless start control module

[H]: BCM connector (viewed from harness side) (Non-taiwan model) 7. TCM

[I]: BCM connector (viewed from harness side) (Taiwan model) 8. CAN junction connector

[J]: ABS control module connector (viewed from terminal side) 9. DLC

Page 79 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-29

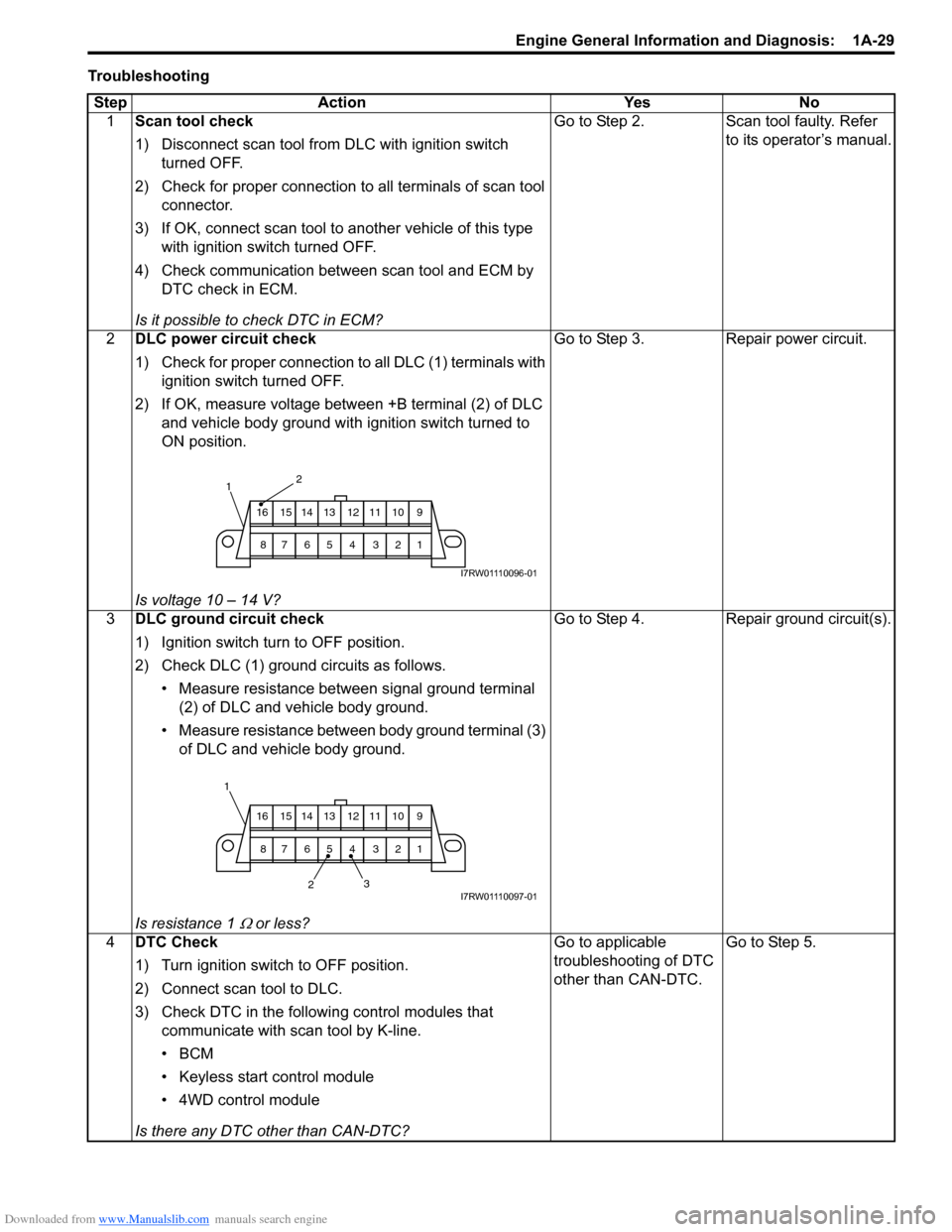

Troubleshooting

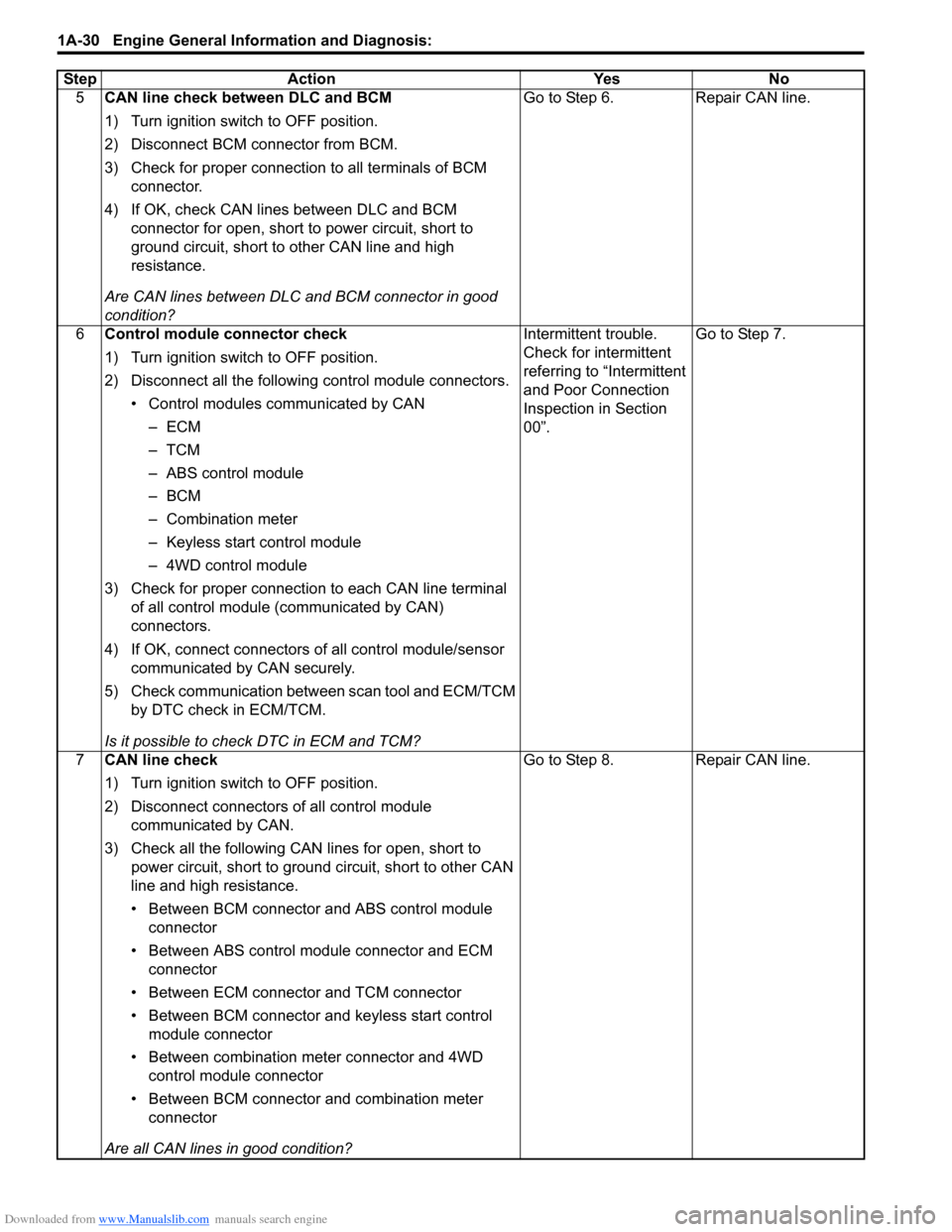

Step Action Yes No

1Scan tool check

1) Disconnect scan tool from DLC with ignition switch

turned OFF.

2) Check for proper connection to all terminals of scan tool

connector.

3) If OK, connect scan tool to another vehicle of this type

with ignition switch turned OFF.

4) Check communication between scan tool and ECM by

DTC check in ECM.

Is it possible to check DTC in ECM?Go to Step 2. Scan tool faulty. Refer

to its operator’s manual.

2DLC power circuit check

1) Check for proper connection to all DLC (1) terminals with

ignition switch turned OFF.

2) If OK, measure voltage between +B terminal (2) of DLC

and vehicle body ground with ignition switch turned to

ON position.

Is voltage 10 – 14 V?Go to Step 3. Repair power circuit.

3DLC ground circuit check

1) Ignition switch turn to OFF position.

2) Check DLC (1) ground circuits as follows.

• Measure resistance between signal ground terminal

(2) of DLC and vehicle body ground.

• Measure resistance between body ground terminal (3)

of DLC and vehicle body ground.

Is resistance 1

Ω or less?Go to Step 4. Repair ground circuit(s).

4DTC Check

1) Turn ignition switch to OFF position.

2) Connect scan tool to DLC.

3) Check DTC in the following control modules that

communicate with scan tool by K-line.

•BCM

• Keyless start control module

• 4WD control module

Is there any DTC other than CAN-DTC?Go to applicable

troubleshooting of DTC

other than CAN-DTC.Go to Step 5.

2

9 10 11 12 13 14 15 16

1 2 3 4 5 6 7 8

1

I7RW01110096-01

23 1

9 10 11 12 13 14 15 16

1 2 3 4 5 6 7 8

I7RW01110097-01

Page 80 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-30 Engine General Information and Diagnosis:

5CAN line check between DLC and BCM

1) Turn ignition switch to OFF position.

2) Disconnect BCM connector from BCM.

3) Check for proper connection to all terminals of BCM

connector.

4) If OK, check CAN lines between DLC and BCM

connector for open, short to power circuit, short to

ground circuit, short to other CAN line and high

resistance.

Are CAN lines between DLC and BCM connector in good

condition?Go to Step 6. Repair CAN line.

6Control module connector check

1) Turn ignition switch to OFF position.

2) Disconnect all the following control module connectors.

• Control modules communicated by CAN

–ECM

–TCM

– ABS control module

–BCM

– Combination meter

– Keyless start control module

– 4WD control module

3) Check for proper connection to each CAN line terminal

of all control module (communicated by CAN)

connectors.

4) If OK, connect connectors of all control module/sensor

communicated by CAN securely.

5) Check communication between scan tool and ECM/TCM

by DTC check in ECM/TCM.

Is it possible to check DTC in ECM and TCM?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 7.

7CAN line check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control module

communicated by CAN.

3) Check all the following CAN lines for open, short to

power circuit, short to ground circuit, short to other CAN

line and high resistance.

• Between BCM connector and ABS control module

connector

• Between ABS control module connector and ECM

connector

• Between ECM connector and TCM connector

• Between BCM connector and keyless start control

module connector

• Between combination meter connector and 4WD

control module connector

• Between BCM connector and combination meter

connector

Are all CAN lines in good condition?Go to Step 8. Repair CAN line. Step Action Yes No

Page 217 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-167

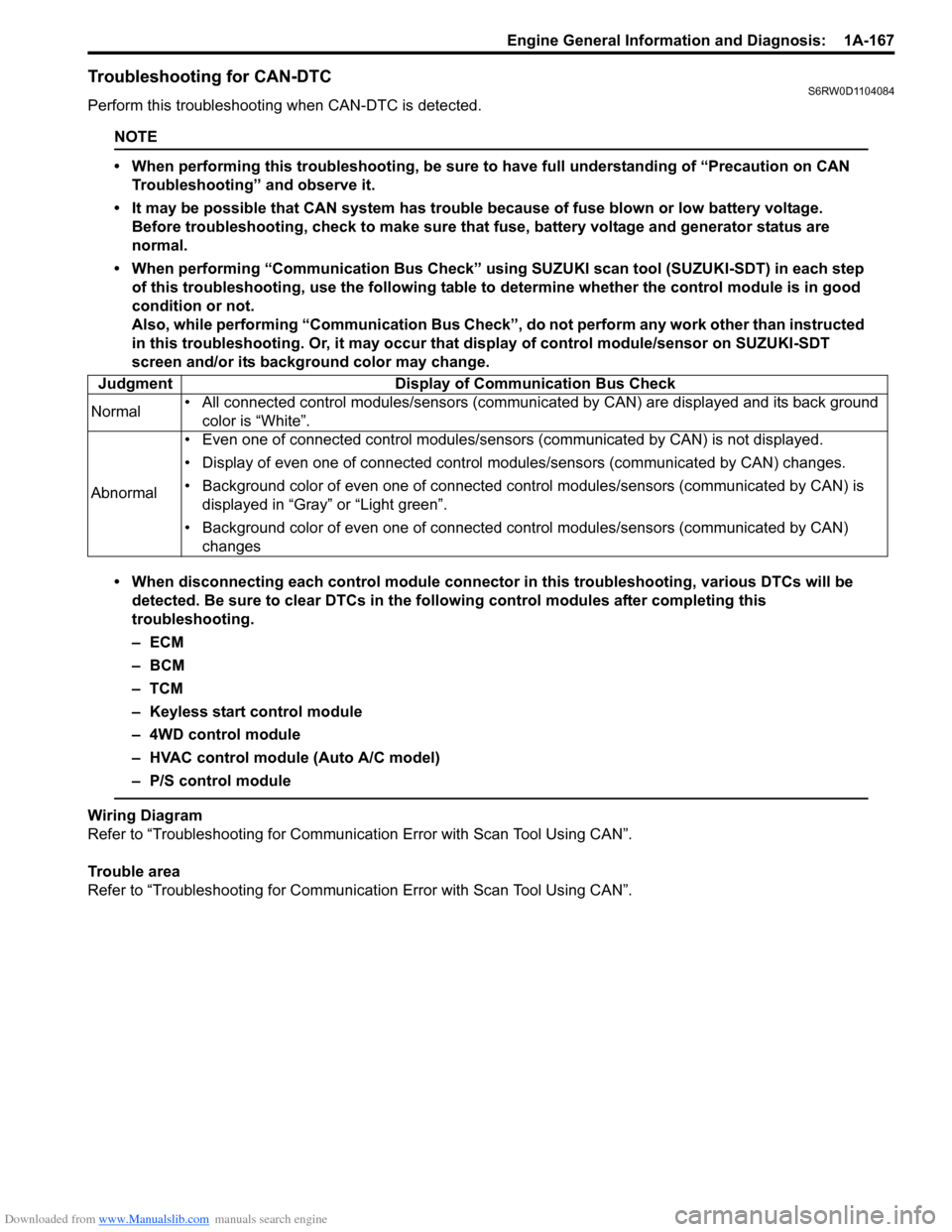

Troubleshooting for CAN-DTCS6RW0D1104084

Perform this troubleshooting when CAN-DTC is detected.

NOTE

• When performing this troubleshooting, be sure to have full understanding of “Precaution on CAN

Troubleshooting” and observe it.

• It may be possible that CAN system has trouble because of fuse blown or low battery voltage.

Before troubleshooting, check to make sure that fuse, battery voltage and generator status are

normal.

• When performing “Communication Bus Check” using SUZUKI scan tool (SUZUKI-SDT) in each step

of this troubleshooting, use the following table to determine whether the control module is in good

condition or not.

Also, while performing “Communication Bus Check”, do not perform any work other than instructed

in this troubleshooting. Or, it may occur that display of control module/sensor on SUZUKI-SDT

screen and/or its background color may change.

• When disconnecting each control module connector in this troubleshooting, various DTCs will be

detected. Be sure to clear DTCs in the following control modules after completing this

troubleshooting.

–ECM

– BCM

–TCM

– Keyless start control module

– 4WD control module

– HVAC control module (Auto A/C model)

– P/S control module

Wiring Diagram

Refer to “Troubleshooting for Communication Error with Scan Tool Using CAN”.

Trouble area

Refer to “Troubleshooting for Communication Error with Scan Tool Using CAN”. Judgment Display of Communication Bus Check

Normal• All connected control modules/sensors (communicated by CAN) are displayed and its back ground

color is “White”.

Abnormal• Even one of connected control modules/sensors (communicated by CAN) is not displayed.

• Display of even one of connected control modules/sensors (communicated by CAN) changes.

• Background color of even one of connected control modules/sensors (communicated by CAN) is

displayed in “Gray” or “Light green”.

• Background color of even one of connected control modules/sensors (communicated by CAN)

changes