4WD SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 218 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-168 Engine General Information and Diagnosis:

Troubleshooting

Step Action Yes No

1DTC Check

1) Turn ignition switch to OFF position.

2) Connect scan tool to DLC.

3) Check DTC in the following control modules.

•ECM

•TCM

•BCM

• Keyless start control module

• 4WD control module

Is there any DTC other than CAN-DTC?Go to applicable

troubleshooting of DTC

other than CAN-DTC.Go to Step 2.

2Control module connector check

1) Turn ignition switch to OFF position.

2) Be sure to disconnect scan tool from DLC.

3) Disconnect all the following control module connectors.

• Control modules communicated by CAN

–ECM

–TCM

– ABS control module

–BCM

– Combination meter

– Keyless start control module

– 4WD control module

4) Check for proper connection to terminal of each CAN

line of all control module (communicated by CAN)

connectors.

5) If OK, connect all connectors of control module

communicated by CAN securely.

6) Recheck DTC for all control modules communicated by

CAN.

Is there any CAN-DTC?Go to Step 3. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

Page 219 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-169

3CAN line check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control module

communicated by CAN.

3) Check all the following CAN lines for open, short to

power circuit, short to ground circuit, short to other CAN

line and high resistance.

• Between BCM connector and DLC

• Between BCM connector and ABS control module

connector

• Between ABS control module connector and ECM

connector

• Between ECM connector and TCM connector

• Between BCM connector and keyless start control

module connector

• Between combination meter connector and 4WD

control module connector

• Between BCM connector and combination meter

connector

Are all CAN lines in good condition?Go to Step 4. Repair CAN line.

4Power and ground circuits check of BCM, ECM, ABS

control module and combination meter

1) Check power and ground circuits of the following control

module.

•ECM:

Refer to “ECM Power and Ground Circuit Check”.

•BCM:

Refer to “BCM Power Circuit and Ground Circuit

Check in Section 10B”.

• Combination meter:

Refer to “Combination Meter Circuit Diagram in

Section 9C”.

• ABS control module:

Refer to “ABS Hydraulic Unit / Control Module

Assembly Power and Ground Circuit Check in Section

4E”.

Are they in good condition?Go to Step 5. Repair power and/or

ground circuit.

5CAN communication check of BCM, ECM, ABS control

module and combination meter

1) Turn ignition switch to OFF position.

2) Connect BCM, ECM, ABS control module and

combination meter connectors.

3) Perform “Communication Bus Check” under “Bus

Check” using SUZUKI-SDT with ignition switch turned

ON.

Are all of BCM, ECM, ABS control module and combination

meter normally displayed?Go to Step 12. Go to Step 6. Step Action Yes No

Page 221 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-171

12CAN communication check of TCM

1) Turn ignition switch to OFF position.

2) Connect TCM connectors.

3) Perform “Communication Bus Check” under “Bus

Check” using SUZUKI-SDT with ignition switch turned

ON.

Are all of BCM, ECM, ABS control module, combination

meter and TCM normally displayed?Go to Step 13. Check power and

ground circuits of TCM

referring to “TCM Power

and Ground Circuit

Check in Section 5A”. If

OK, substitute a known-

good TCM.

13CAN communication check of keyless start control

module

1) Turn ignition switch to OFF position.

2) Connect keyless start control module connector.

3) Perform “Communication Bus Check” under “Bus

Check” using SUZUKI-SDT with ignition switch turned

ON.

Are all of BCM, ECM, ABS control module, combination

meter, TCM and keyless start control module normally

displayed?Go to Step 14. Check power and

ground circuits of

keyless start control

module referring to

“Keyless Start Control

Module Power and

Ground Circuit Check in

Section 10E”. If OK,

substitute a known-

good keyless start

control module.

14CAN communication check of 4WD control module

1) Turn ignition switch to OFF position.

2) Connect combination meter connector and 4WD control

module.

3) Perform “Communication Bus Check” under “Bus

Check” on SUZUKI-SDT with ignition switch turned ON.

Are all of BCM, ECM, ABS control module, combination

meter, TCM, keyless start control module, combination

meter and 4WD control module normally displayed?Recheck DTC. Check power and

ground circuits of 4WD

control module referring

to “Step 2” and “Step 3”

under “DTC C1240:

4WD Control Module

Power Supply Circuit

Malfunction in Section

3B”. If OK, substitute a

known-good 4WD

control module. Step Action Yes No

Page 298 of 1556

![SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 1D-16 Engine Mechanical:

Engine Mountings ComponentsS6RW0D1406012

I6RW0D140002-01

[A]: For 4WD model 4. Engine left mounting

: Be sure to dire SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 1D-16 Engine Mechanical:

Engine Mountings ComponentsS6RW0D1406012

I6RW0D140002-01

[A]: For 4WD model 4. Engine left mounting

: Be sure to dire](/img/20/7612/w960_7612-297.png)

Downloaded from www.Manualslib.com manuals search engine 1D-16 Engine Mechanical:

Engine Mountings ComponentsS6RW0D1406012

I6RW0D140002-01

[A]: For 4WD model 4. Engine left mounting

: Be sure to direct paint mark to forward.12. Dynamic damper

[B]: For 2WD model 5. Engine rear mounting

: Be sure to direct paint mark to forward.13. Mounting member cushion

[C]: For M/T model 6. Engine rear mounting No.1 bracket 14. Yellow mark

[D]: For A/T model 7. Engine rear mounting No.2 bracket 15. Mounting member

Page 300 of 1556

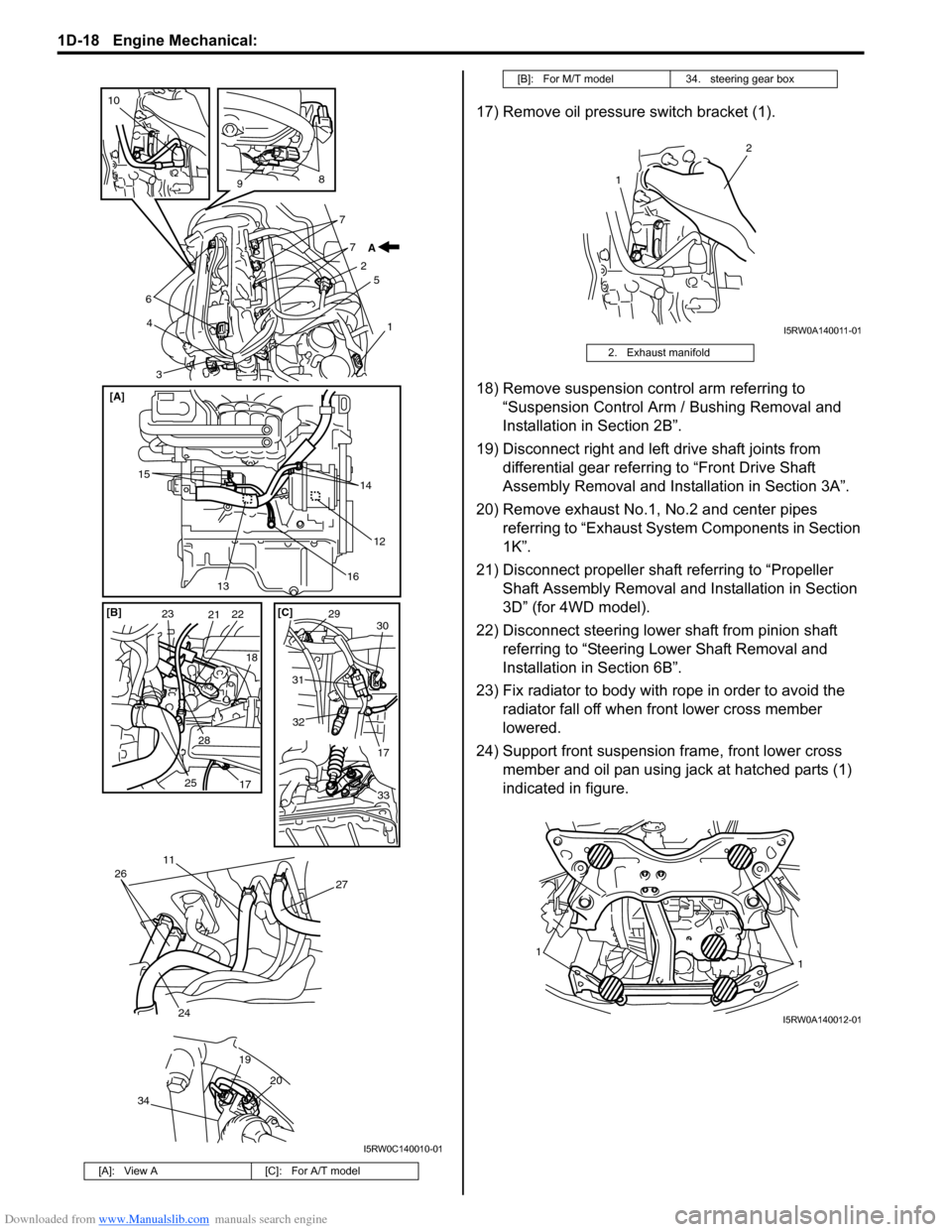

Downloaded from www.Manualslib.com manuals search engine 1D-18 Engine Mechanical:

17) Remove oil pressure switch bracket (1).

18) Remove suspension control arm referring to

“Suspension Control Arm / Bushing Removal and

Installation in Section 2B”.

19) Disconnect right and left drive shaft joints from

differential gear referring to “Front Drive Shaft

Assembly Removal and Installation in Section 3A”.

20) Remove exhaust No.1, No.2 and center pipes

referring to “Exhaust System Components in Section

1K”.

21) Disconnect propeller shaft referring to “Propeller

Shaft Assembly Removal and Installation in Section

3D” (for 4WD model).

22) Disconnect steering lower shaft from pinion shaft

referring to “Steering Lower Shaft Removal and

Installation in Section 6B”.

23) Fix radiator to body with rope in order to avoid the

radiator fall off when front lower cross member

lowered.

24) Support front suspension frame, front lower cross

member and oil pan using jack at hatched parts (1)

indicated in figure.

[A]: View A [C]: For A/T model

6

3 45

1 7 7

2

8

9

10

A

15

14

16

20 19

26

24

27

12

13 [A]

11

34

232122

25

17 2818 [B] [C]

2930

31

32

17

33

I5RW0C140010-01

[B]: For M/T model 34. steering gear box

2. Exhaust manifold

1

2

I5RW0A140011-01

11

I5RW0A140012-01

Page 301 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-19

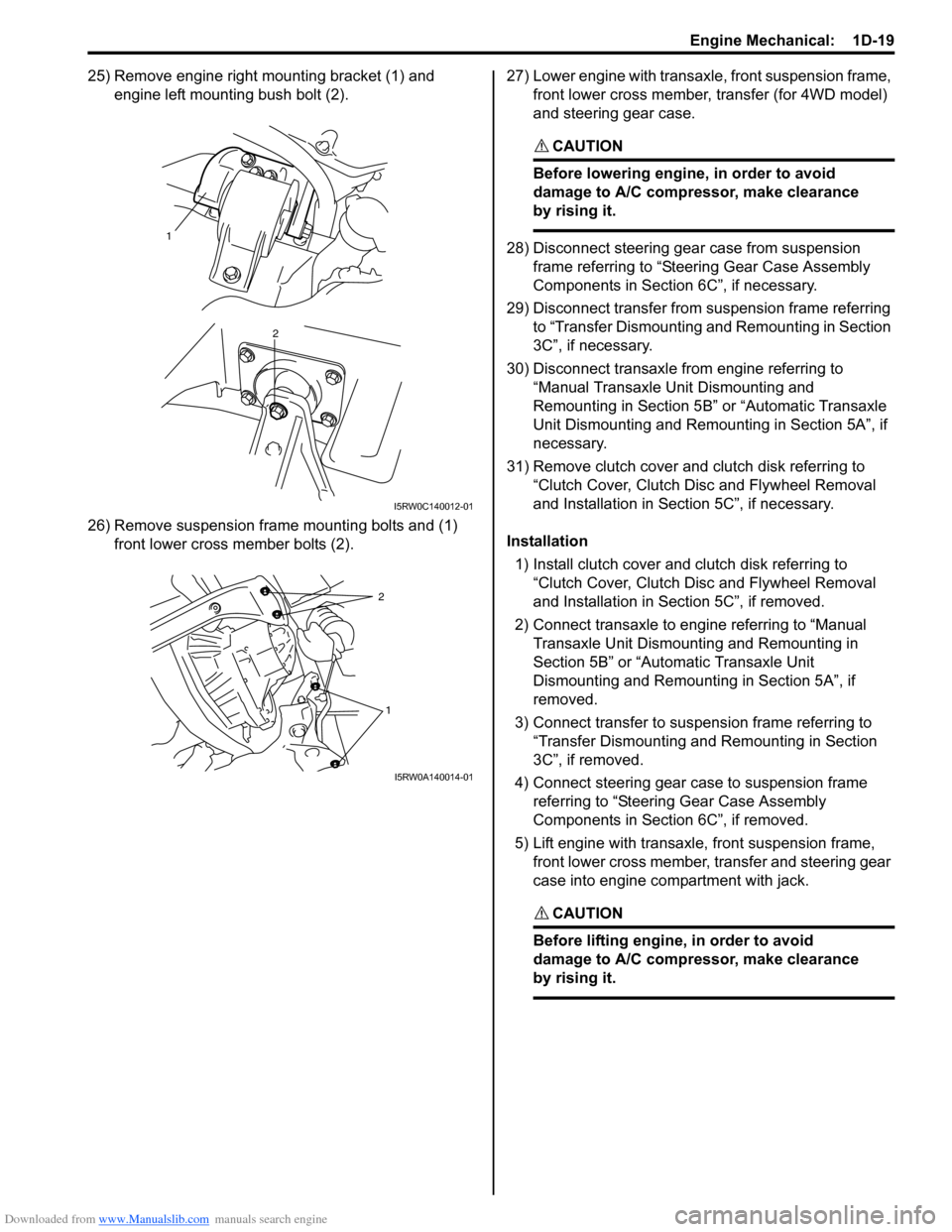

25) Remove engine right mounting bracket (1) and

engine left mounting bush bolt (2).

26) Remove suspension frame mounting bolts and (1)

front lower cross member bolts (2).27) Lower engine with transaxle, front suspension frame,

front lower cross member, transfer (for 4WD model)

and steering gear case.

CAUTION!

Before lowering engine, in order to avoid

damage to A/C compressor, make clearance

by rising it.

28) Disconnect steering gear case from suspension

frame referring to “Steering Gear Case Assembly

Components in Section 6C”, if necessary.

29) Disconnect transfer from suspension frame referring

to “Transfer Dismounting and Remounting in Section

3C”, if necessary.

30) Disconnect transaxle from engine referring to

“Manual Transaxle Unit Dismounting and

Remounting in Section 5B” or “Automatic Transaxle

Unit Dismounting and Remounting in Section 5A”, if

necessary.

31) Remove clutch cover and clutch disk referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if necessary.

Installation

1) Install clutch cover and clutch disk referring to

“Clutch Cover, Clutch Disc and Flywheel Removal

and Installation in Section 5C”, if removed.

2) Connect transaxle to engine referring to “Manual

Transaxle Unit Dismounting and Remounting in

Section 5B” or “Automatic Transaxle Unit

Dismounting and Remounting in Section 5A”, if

removed.

3) Connect transfer to suspension frame referring to

“Transfer Dismounting and Remounting in Section

3C”, if removed.

4) Connect steering gear case to suspension frame

referring to “Steering Gear Case Assembly

Components in Section 6C”, if removed.

5) Lift engine with transaxle, front suspension frame,

front lower cross member, transfer and steering gear

case into engine compartment with jack.

CAUTION!

Before lifting engine, in order to avoid

damage to A/C compressor, make clearance

by rising it.

1

2

I5RW0C140012-01

2

1

I5RW0A140014-01

Page 302 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-20 Engine Mechanical:

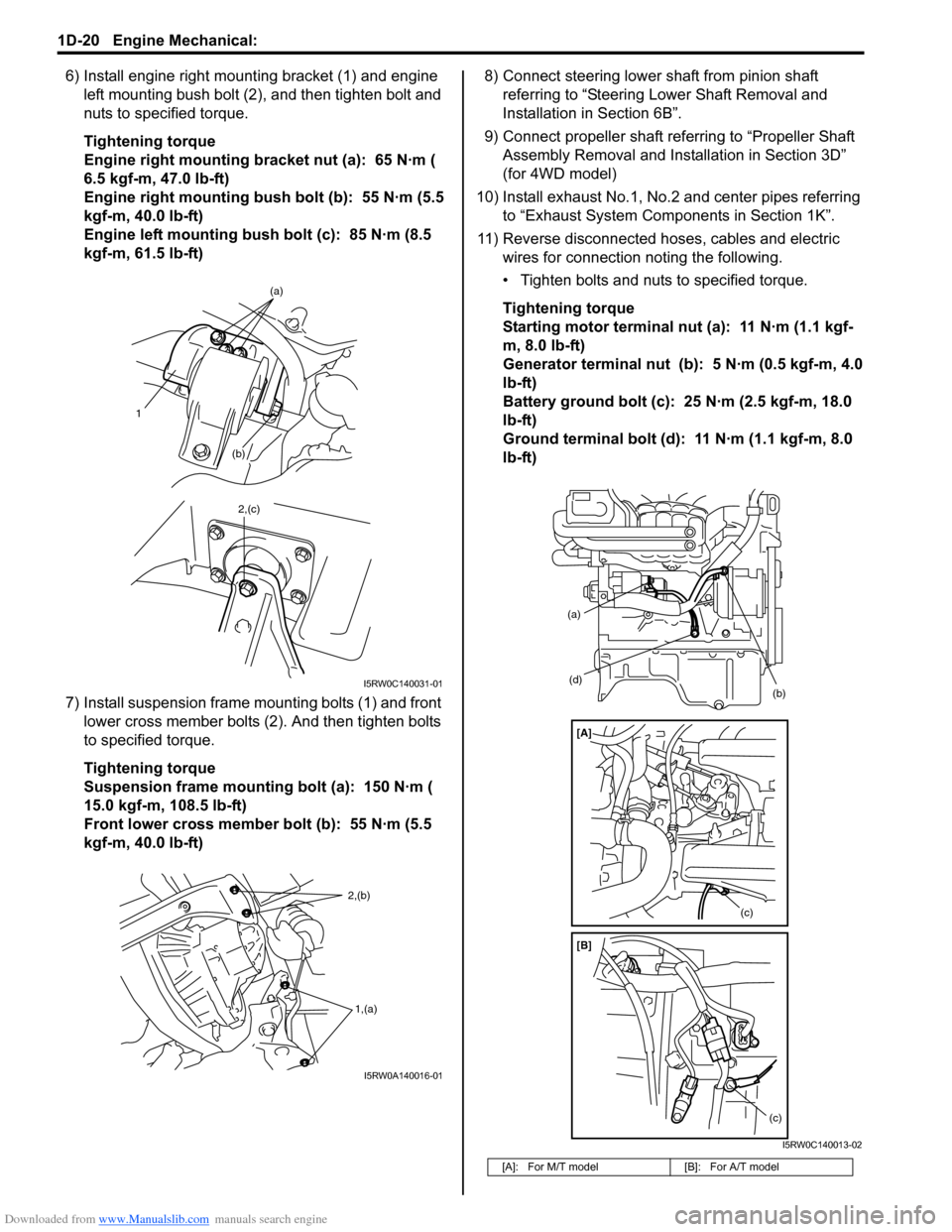

6) Install engine right mounting bracket (1) and engine

left mounting bush bolt (2), and then tighten bolt and

nuts to specified torque.

Tightening torque

Engine right mounting bracket nut (a): 65 N·m (

6.5 kgf-m, 47.0 lb-ft)

Engine right mounting bush bolt (b): 55 N·m (5.5

kgf-m, 40.0 lb-ft)

Engine left mounting bush bolt (c): 85 N·m (8.5

kgf-m, 61.5 lb-ft)

7) Install suspension frame mounting bolts (1) and front

lower cross member bolts (2). And then tighten bolts

to specified torque.

Tightening torque

Suspension frame mounting bolt (a): 150 N·m (

15.0 kgf-m, 108.5 lb-ft)

Front lower cross member bolt (b): 55 N·m (5.5

kgf-m, 40.0 lb-ft)8) Connect steering lower shaft from pinion shaft

referring to “Steering Lower Shaft Removal and

Installation in Section 6B”.

9) Connect propeller shaft referring to “Propeller Shaft

Assembly Removal and Installation in Section 3D”

(for 4WD model)

10) Install exhaust No.1, No.2 and center pipes referring

to “Exhaust System Components in Section 1K”.

11) Reverse disconnected hoses, cables and electric

wires for connection noting the following.

• Tighten bolts and nuts to specified torque.

Tightening torque

Starting motor terminal nut (a): 11 N·m (1.1 kgf-

m, 8.0 lb-ft)

Generator terminal nut (b): 5 N·m (0.5 kgf-m, 4.0

lb-ft)

Battery ground bolt (c): 25 N·m (2.5 kgf-m, 18.0

lb-ft)

Ground terminal bolt (d): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

1

(b)(a)

2,(c)

I5RW0C140031-01

2,(b)

1,(a)

I5RW0A140016-01

[A]: For M/T model [B]: For A/T model

(d)

(a)

(b)

(c)

(c)

[A]

[B]

I5RW0C140013-02

Page 360 of 1556

Downloaded from www.Manualslib.com manuals search engine 1E-4 Engine Lubrication System:

Oil Pan and Oil Pump Strainer Removal and

Installation

S6RW0D1506002

Removal

1) Remove oil level gauge.

2) Drain engine oil by removing drain plug.

3) For 4WD model, dismount transfer referring to

“Transfer Dismounting and Remounting in Section

3C”.

4) Remove clutch housing lower plate (1).

5) Remove oil pan and then oil pump strainer (1) from

cylinder block.

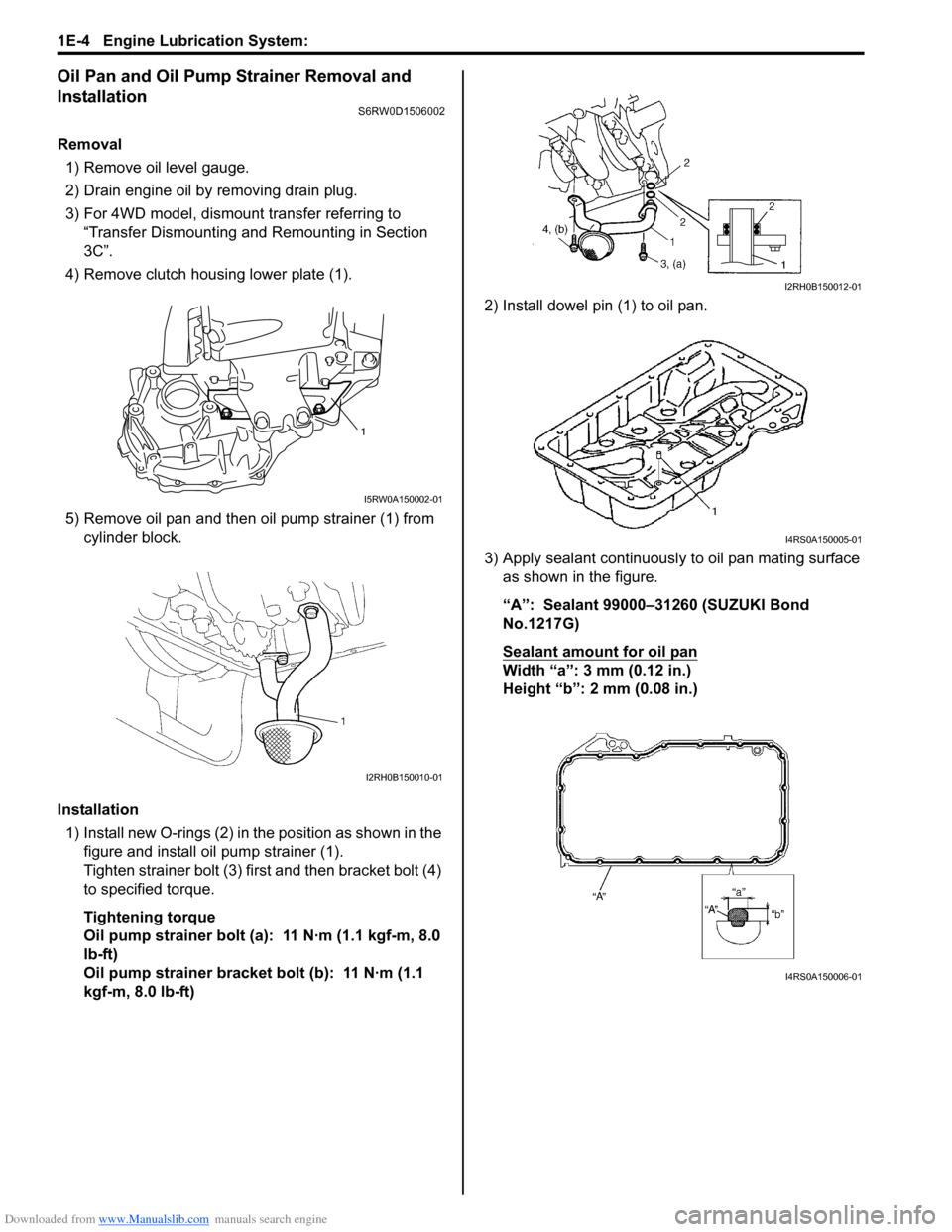

Installation

1) Install new O-rings (2) in the position as shown in the

figure and install oil pump strainer (1).

Tighten strainer bolt (3) first and then bracket bolt (4)

to specified torque.

Tightening torque

Oil pump strainer bolt (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Oil pump strainer bracket bolt (b): 11 N·m (1.1

kgf-m, 8.0 lb-ft)2) Install dowel pin (1) to oil pan.

3) Apply sealant continuously to oil pan mating surface

as shown in the figure.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for oil pan

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

1

I5RW0A150002-01

I2RH0B150010-01

I2RH0B150012-01

I4RS0A150005-01

I4RS0A150006-01

Page 361 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-5

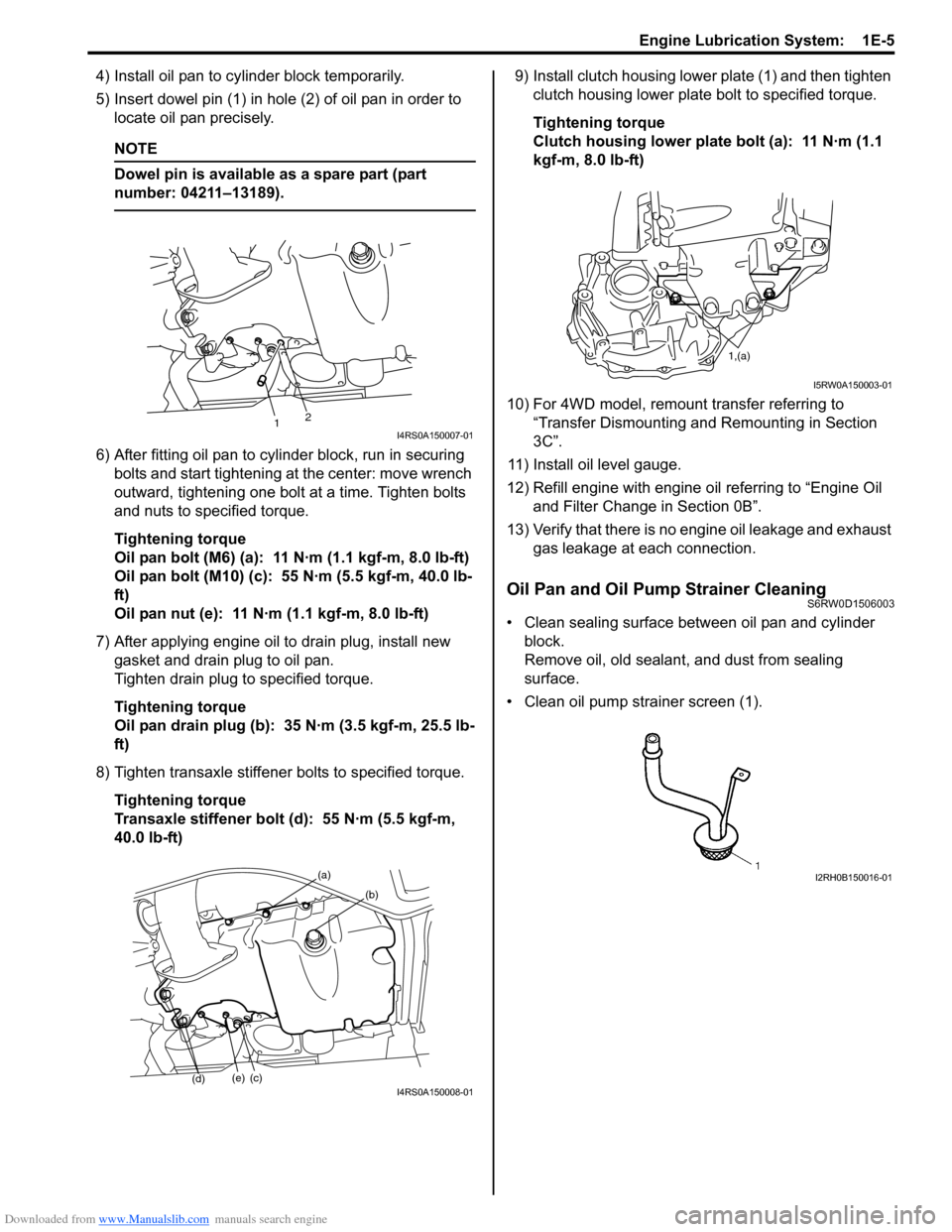

4) Install oil pan to cylinder block temporarily.

5) Insert dowel pin (1) in hole (2) of oil pan in order to

locate oil pan precisely.

NOTE

Dowel pin is available as a spare part (part

number: 04211–13189).

6) After fitting oil pan to cylinder block, run in securing

bolts and start tightening at the center: move wrench

outward, tightening one bolt at a time. Tighten bolts

and nuts to specified torque.

Tightening torque

Oil pan bolt (M6) (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Oil pan bolt (M10) (c): 55 N·m (5.5 kgf-m, 40.0 lb-

ft)

Oil pan nut (e): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

7) After applying engine oil to drain plug, install new

gasket and drain plug to oil pan.

Tighten drain plug to specified torque.

Tightening torque

Oil pan drain plug (b): 35 N·m (3.5 kgf-m, 25.5 lb-

ft)

8) Tighten transaxle stiffener bolts to specified torque.

Tightening torque

Transaxle stiffener bolt (d): 55 N·m (5.5 kgf-m,

40.0 lb-ft)9) Install clutch housing lower plate (1) and then tighten

clutch housing lower plate bolt to specified torque.

Tightening torque

Clutch housing lower plate bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

10) For 4WD model, remount transfer referring to

“Transfer Dismounting and Remounting in Section

3C”.

11) Install oil level gauge.

12) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

13) Verify that there is no engine oil leakage and exhaust

gas leakage at each connection.

Oil Pan and Oil Pump Strainer CleaningS6RW0D1506003

• Clean sealing surface between oil pan and cylinder

block.

Remove oil, old sealant, and dust from sealing

surface.

• Clean oil pump strainer screen (1).

21I4RS0A150007-01

(a)

(b)

(c)(e)

(d)I4RS0A150008-01

1,(a)

I5RW0A150003-01

I2RH0B150016-01

Page 390 of 1556

Downloaded from www.Manualslib.com manuals search engine 1G-13 Fuel System:

Fuel Tank Removal and InstallationS6RW0D1706011

WARNING!

Before starting the following procedure, be

sure to observe “Precautions on Fuel System

Service” in order to reduce the risk of fire and

personal injury.

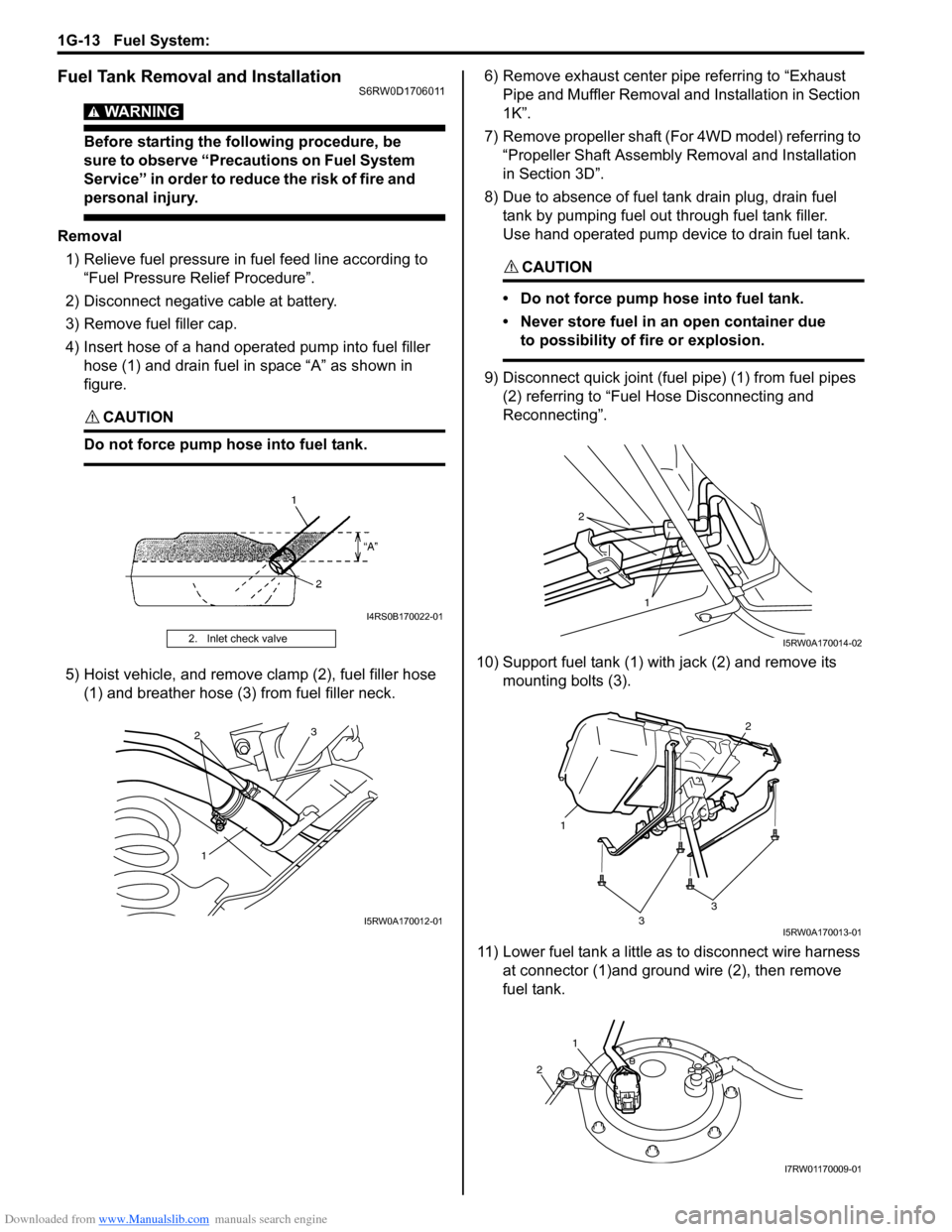

Removal

1) Relieve fuel pressure in fuel feed line according to

“Fuel Pressure Relief Procedure”.

2) Disconnect negative cable at battery.

3) Remove fuel filler cap.

4) Insert hose of a hand operated pump into fuel filler

hose (1) and drain fuel in space “A” as shown in

figure.

CAUTION!

Do not force pump hose into fuel tank.

5) Hoist vehicle, and remove clamp (2), fuel filler hose

(1) and breather hose (3) from fuel filler neck.6) Remove exhaust center pipe referring to “Exhaust

Pipe and Muffler Removal and Installation in Section

1K”.

7) Remove propeller shaft (For 4WD model) referring to

“Propeller Shaft Assembly Removal and Installation

in Section 3D”.

8) Due to absence of fuel tank drain plug, drain fuel

tank by pumping fuel out through fuel tank filler.

Use hand operated pump device to drain fuel tank.

CAUTION!

• Do not force pump hose into fuel tank.

• Never store fuel in an open container due

to possibility of fire or explosion.

9) Disconnect quick joint (fuel pipe) (1) from fuel pipes

(2) referring to “Fuel Hose Disconnecting and

Reconnecting”.

10) Support fuel tank (1) with jack (2) and remove its

mounting bolts (3).

11) Lower fuel tank a little as to disconnect wire harness

at connector (1)and ground wire (2), then remove

fuel tank.

2. Inlet check valve

I4RS0B170022-01

1 23

I5RW0A170012-01

2

1

I5RW0A170014-02

1

2

33

I5RW0A170013-01

1

2

I7RW01170009-01