Shift switch SUZUKI SX4 2006 1.G Service User Guide

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 407 of 1556

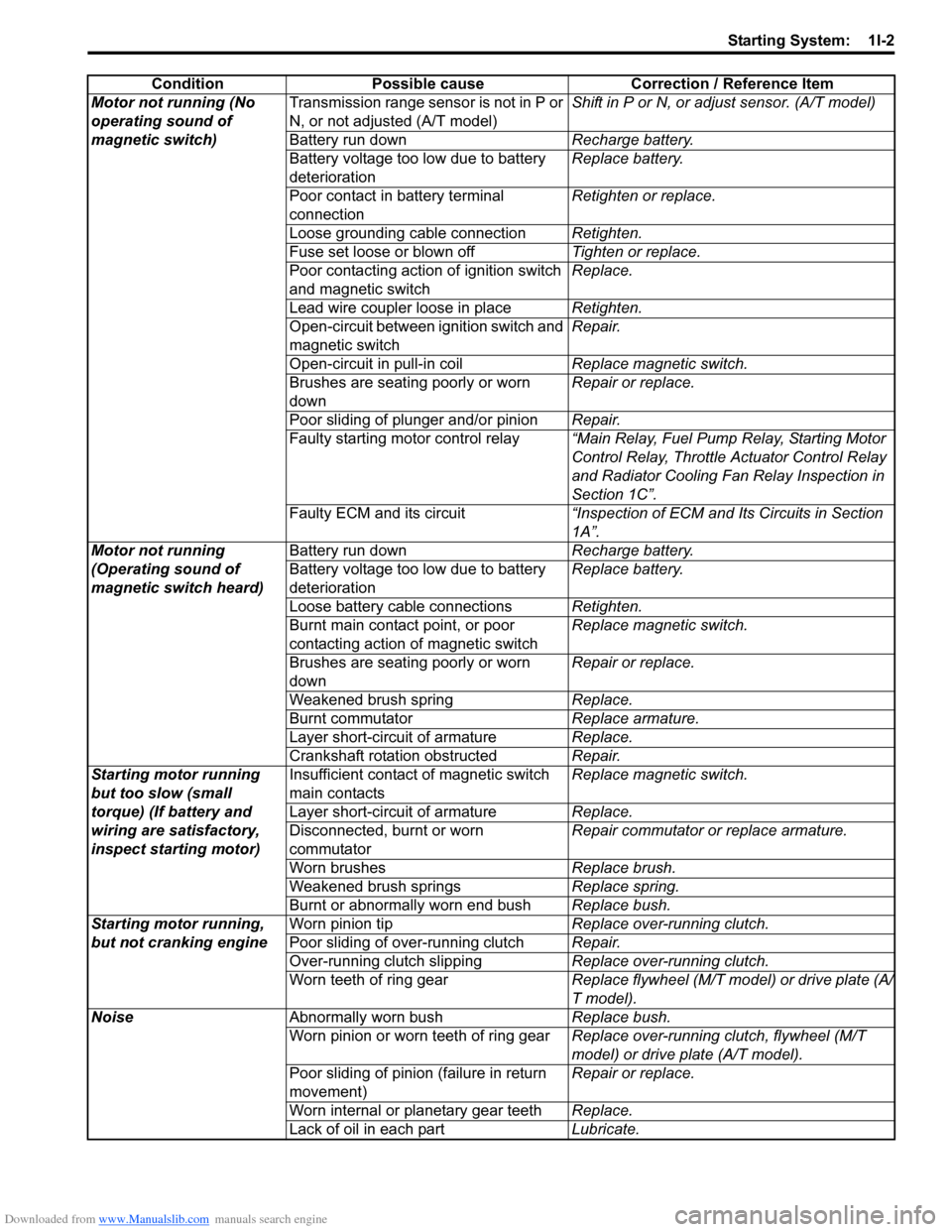

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-2

Condition Possible cause Correction / Reference Item

Motor not running (No

operating sound of

magnetic switch)Transmission range sensor is not in P or

N, or not adjusted (A/T model)Shift in P or N, or adjust sensor. (A/T model)

Battery run downRecharge battery.

Battery voltage too low due to battery

deteriorationReplace battery.

Poor contact in battery terminal

connectionRetighten or replace.

Loose grounding cable connectionRetighten.

Fuse set loose or blown offTighten or replace.

Poor contacting action of ignition switch

and magnetic switchReplace.

Lead wire coupler loose in placeRetighten.

Open-circuit between ignition switch and

magnetic switchRepair.

Open-circuit in pull-in coilReplace magnetic switch.

Brushes are seating poorly or worn

downRepair or replace.

Poor sliding of plunger and/or pinionRepair.

Faulty starting motor control relay“Main Relay, Fuel Pump Relay, Starting Motor

Control Relay, Throttle Actuator Control Relay

and Radiator Cooling Fan Relay Inspection in

Section 1C”.

Faulty ECM and its circuit“Inspection of ECM and Its Circuits in Section

1A”.

Motor not running

(Operating sound of

magnetic switch heard)Battery run downRecharge battery.

Battery voltage too low due to battery

deteriorationReplace battery.

Loose battery cable connectionsRetighten.

Burnt main contact point, or poor

contacting action of magnetic switchReplace magnetic switch.

Brushes are seating poorly or worn

downRepair or replace.

Weakened brush springReplace.

Burnt commutatorReplace armature.

Layer short-circuit of armatureReplace.

Crankshaft rotation obstructedRepair.

Starting motor running

but too slow (small

torque) (If battery and

wiring are satisfactory,

inspect starting motor)Insufficient contact of magnetic switch

main contactsReplace magnetic switch.

Layer short-circuit of armatureReplace.

Disconnected, burnt or worn

commutatorRepair commutator or replace armature.

Worn brushesReplace brush.

Weakened brush springsReplace spring.

Burnt or abnormally worn end bushReplace bush.

Starting motor running,

but not cranking engineWorn pinion tipReplace over-running clutch.

Poor sliding of over-running clutchRepair.

Over-running clutch slippingReplace over-running clutch.

Worn teeth of ring gearReplace flywheel (M/T model) or drive plate (A/

T model).

NoiseAbnormally worn bushReplace bush.

Worn pinion or worn teeth of ring gearReplace over-running clutch, flywheel (M/T

model) or drive plate (A/T model).

Poor sliding of pinion (failure in return

movement)Repair or replace.

Worn internal or planetary gear teethReplace.

Lack of oil in each partLubricate.

Page 409 of 1556

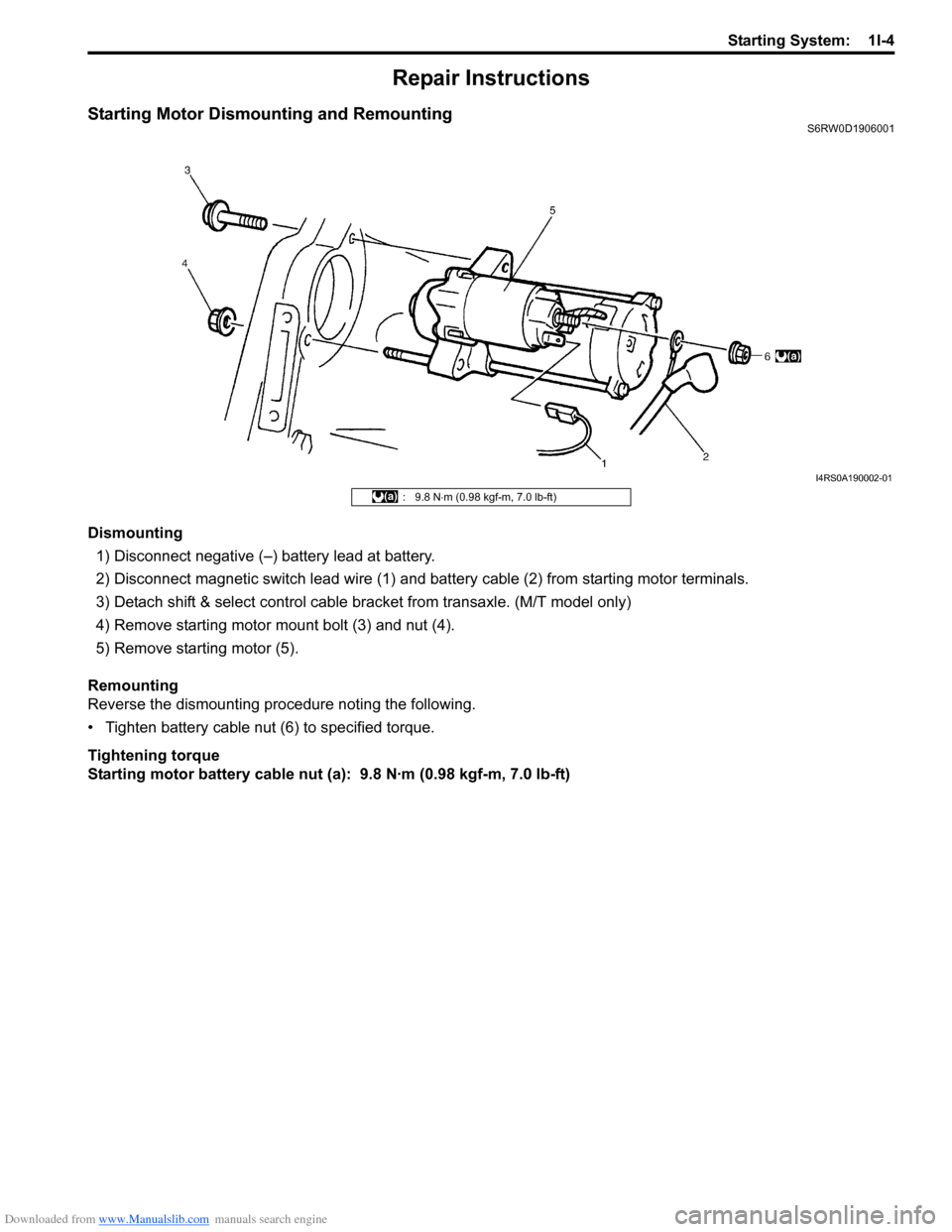

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-4

Repair Instructions

Starting Motor Dismounting and RemountingS6RW0D1906001

Dismounting

1) Disconnect negative (–) battery lead at battery.

2) Disconnect magnetic switch lead wire (1) and battery cable (2) from starting motor terminals.

3) Detach shift & select control cable bracket from transaxle. (M/T model only)

4) Remove starting motor mount bolt (3) and nut (4).

5) Remove starting motor (5).

Remounting

Reverse the dismounting procedure noting the following.

• Tighten battery cable nut (6) to specified torque.

Tightening torque

Starting motor battery cable nut (a): 9.8 N·m (0.98 kgf-m, 7.0 lb-ft)

I4RS0A190002-01

: 9.8 N⋅m (0.98 kgf-m, 7.0 lb-ft)

Page 501 of 1556

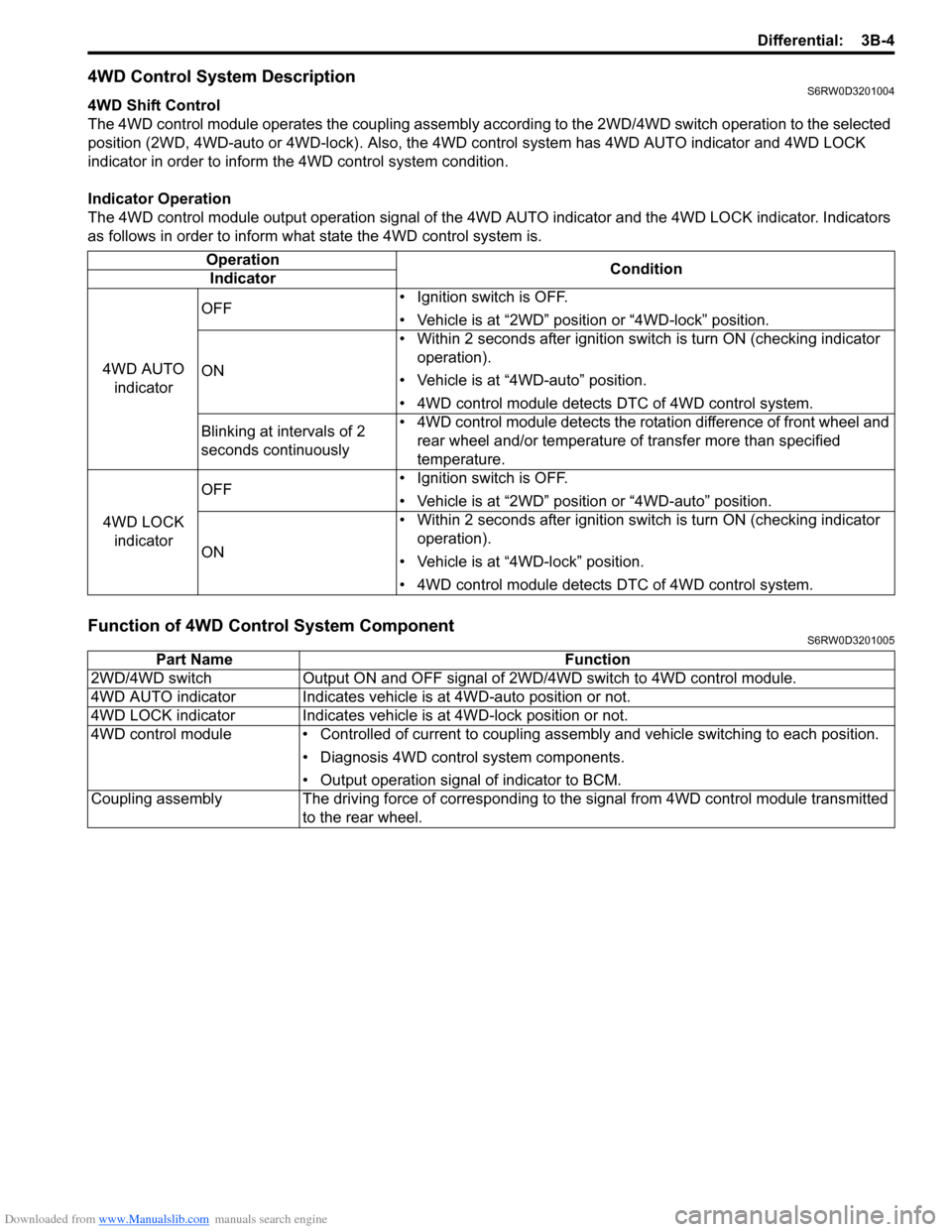

Downloaded from www.Manualslib.com manuals search engine Differential: 3B-4

4WD Control System DescriptionS6RW0D3201004

4WD Shift Control

The 4WD control module operates the coupling assembly according to the 2WD/4WD switch operation to the selected

position (2WD, 4WD-auto or 4WD-lock). Also, the 4WD control system has 4WD AUTO indicator and 4WD LOCK

indicator in order to inform the 4WD control system condition.

Indicator Operation

The 4WD control module output operation signal of the 4WD AUTO indicator and the 4WD LOCK indicator. Indicators

as follows in order to inform what state the 4WD control system is.

Function of 4WD Control System ComponentS6RW0D3201005

Operation

Condition

Indicator

4WD AUTO

indicatorOFF• Ignition switch is OFF.

• Vehicle is at “2WD” position or “4WD-lock” position.

ON• Within 2 seconds after ignition switch is turn ON (checking indicator

operation).

• Vehicle is at “4WD-auto” position.

• 4WD control module detects DTC of 4WD control system.

Blinking at intervals of 2

seconds continuously• 4WD control module detects the rotation difference of front wheel and

rear wheel and/or temperature of transfer more than specified

temperature.

4WD LOCK

indicatorOFF• Ignition switch is OFF.

• Vehicle is at “2WD” position or “4WD-auto” position.

ON• Within 2 seconds after ignition switch is turn ON (checking indicator

operation).

• Vehicle is at “4WD-lock” position.

• 4WD control module detects DTC of 4WD control system.

Part Name Function

2WD/4WD switch Output ON and OFF signal of 2WD/4WD switch to 4WD control module.

4WD AUTO indicator Indicates vehicle is at 4WD-auto position or not.

4WD LOCK indicator Indicates vehicle is at 4WD-lock position or not.

4WD control module • Controlled of current to coupling assembly and vehicle switching to each position.

• Diagnosis 4WD control system components.

• Output operation signal of indicator to BCM.

Coupling assembly The driving force of corresponding to the signal from 4WD control module transmitted

to the rear wheel.

Page 611 of 1556

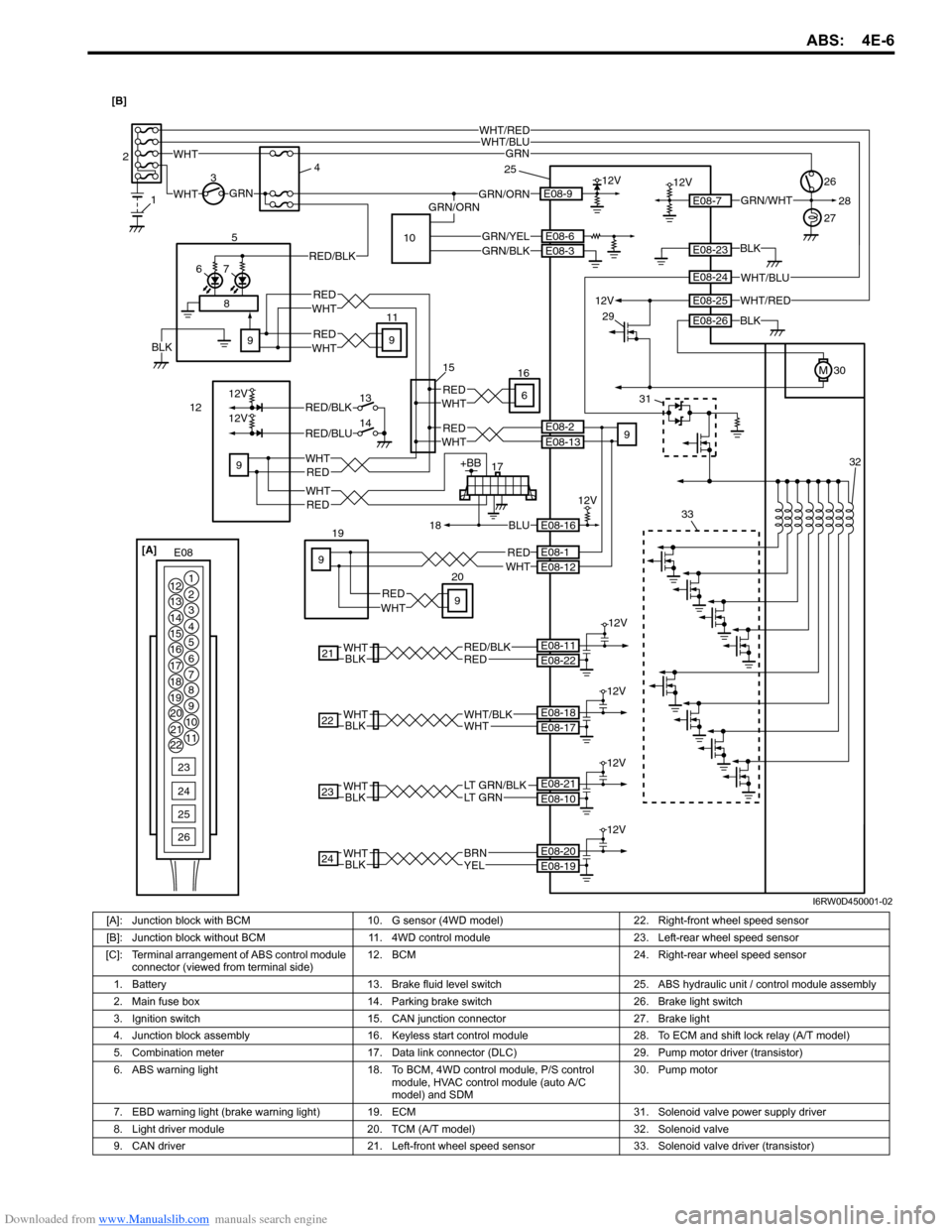

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-6

17+BB

18BLU

WHT12VGRN/ORN 34

30E08-9

RED

WHT 1226

WHT/RED

12V

E08-7

19GRN

GRN

E08-16

12V

5

76

21REDRED/BLK

12V

BLKWHTE08-22 E08-11

23BLKWHTLT GRN/BLKLT GRN

12V

E08-10 E08-21

E08-23

E08-26

E08-1E08-12

24BLKWHT

12V

YELBRNE08-19 E08-20

27

1 2

RED/BLK

WHTRED

WHTRED

WHTRED9

E08-2E08-13WHT

E08-6

RED

9

9

11

9

9

9

REDWHT

WHTRED

12VE08-25

M

BLK

BLK

WHT/BLUWHT/RED

WHT/BLUE08-24

WHT

E08 [A]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

GRN/WHT

22

12V

BLKWHTWHTWHT/BLKE08-17 E08-18

GRN/ORN28

2033

31

29

25

15

32

GRN/YELE08-3GRN/BLK

8

12V

12V

13

14RED/BLK

RED/BLU

WHTRED6

16

10

BLK [B]

I6RW0D450001-02

[A]: Junction block with BCM 10. G sensor (4WD model) 22. Right-front wheel speed sensor

[B]: Junction block without BCM 11. 4WD control module 23. Left-rear wheel speed sensor

[C]: Terminal arrangement of ABS control module

connector (viewed from terminal side)12. BCM 24. Right-rear wheel speed sensor

1. Battery 13. Brake fluid level switch 25. ABS hydraulic unit / control module assembly

2. Main fuse box 14. Parking brake switch 26. Brake light switch

3. Ignition switch 15. CAN junction connector 27. Brake light

4. Junction block assembly 16. Keyless start control module 28. To ECM and shift lock relay (A/T model)

5. Combination meter 17. Data link connector (DLC) 29. Pump motor driver (transistor)

6. ABS warning light 18. To BCM, 4WD control module, P/S control

module, HVAC control module (auto A/C

model) and SDM30. Pump motor

7. EBD warning light (brake warning light)19. ECM 31. Solenoid valve power supply driver

8. Light driver module 20. TCM (A/T model) 32. Solenoid valve

9. CAN driver 21. Left-front wheel speed sensor 33. Solenoid valve driver (transistor)

Page 627 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-22

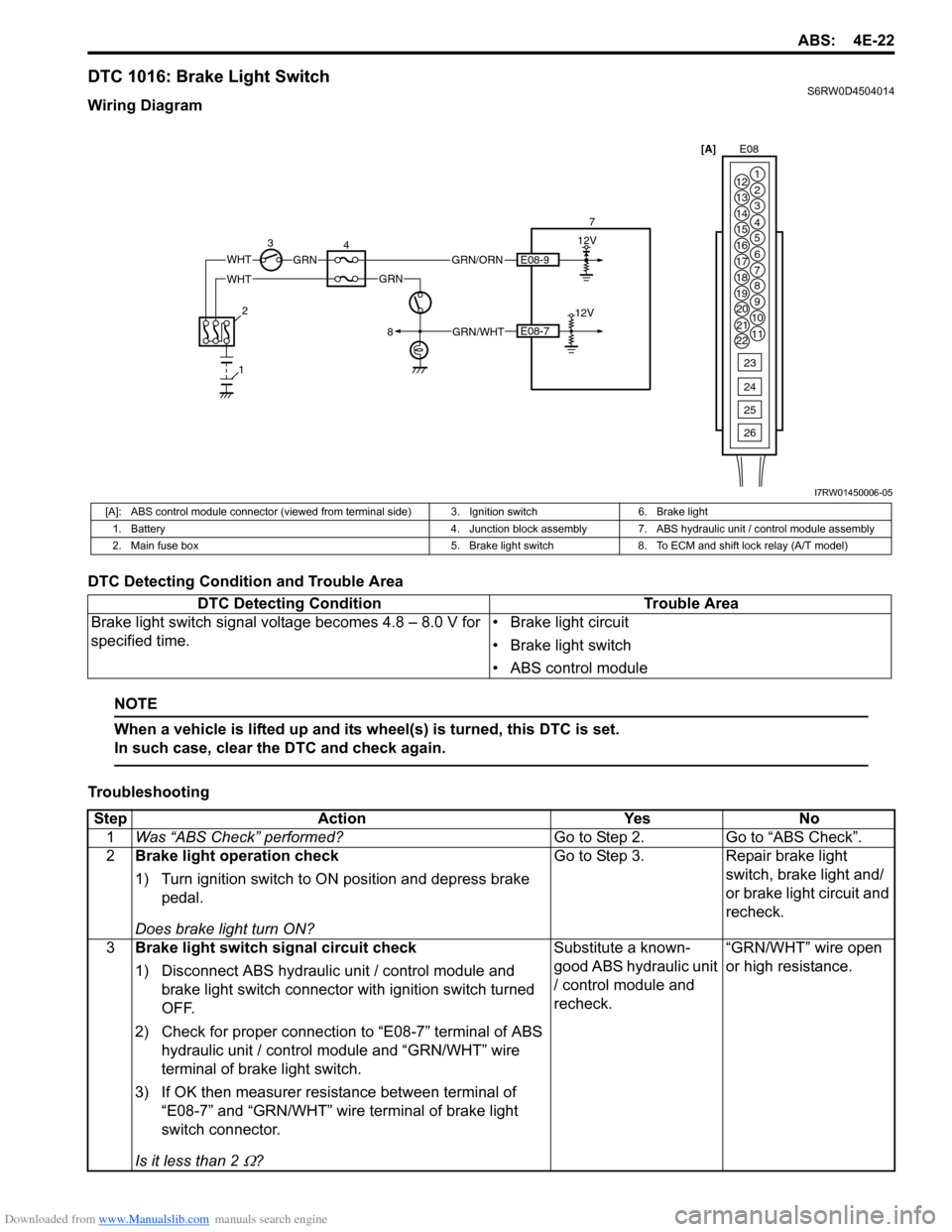

DTC 1016: Brake Light SwitchS6RW0D4504014

Wiring Diagram

DTC Detecting Condition and Trouble Area

NOTE

When a vehicle is lifted up and its wheel(s) is turned, this DTC is set.

In such case, clear the DTC and check again.

Troubleshooting

WHTGRN

34 712V

E08-7

E08-9GRN/ORN

2

8

112V

GRN/WHT

WHTGRN[A]E08

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

I7RW01450006-05

[A]: ABS control module connector (viewed from terminal side) 3. Ignition switch 6. Brake light

1. Battery 4. Junction block assembly 7. ABS hydraulic unit / control module assembly

2. Main fuse box 5. Brake light switch 8. To ECM and shift lock relay (A/T model)

DTC Detecting Condition Trouble Area

Brake light switch signal voltage becomes 4.8 – 8.0 V for

specified time.• Brake light circuit

• Brake light switch

• ABS control module

Step Action Yes No

1Was “ABS Check” performed?Go to Step 2. Go to “ABS Check”.

2Brake light operation check

1) Turn ignition switch to ON position and depress brake

pedal.

Does brake light turn ON?Go to Step 3. Repair brake light

switch, brake light and/

or brake light circuit and

recheck.

3Brake light switch signal circuit check

1) Disconnect ABS hydraulic unit / control module and

brake light switch connector with ignition switch turned

OFF.

2) Check for proper connection to “E08-7” terminal of ABS

hydraulic unit / control module and “GRN/WHT” wire

terminal of brake light switch.

3) If OK then measurer resistance between terminal of

“E08-7” and “GRN/WHT” wire terminal of brake light

switch connector.

Is it less than 2

Ω?Substitute a known-

good ABS hydraulic unit

/ control module and

recheck.“GRN/WHT” wire open

or high resistance.

Page 645 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1

Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and

Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3

A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of

Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

A/T Diagnosis General Description ..................... 5A-7

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10

Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Location ......................................... 5A-14

Electronic Shift Control System Components

Location .......................................................... 5A-14

Diagnostic Information and Procedures .......... 5A-16

A/T System Check ............................................ 5A-16

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-19

Transmission Warning Light Check (Non-

Euro-OBD model) ........................................... 5A-19

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-21

DTC Clearance ................................................. 5A-22

Fail-Safe Table .................................................. 5A-22

Scan Tool Data ................................................. 5A-24

A/T Basic Check ............................................... 5A-27

Road Test ......................................................... 5A-27

Manual Road Test ............................................. 5A-30

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-31

Time Lag Test ................................................... 5A-32

Line Pressure Test ............................................ 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ................................... 5A-34Transmission Warning Light Circuit Check –

Light Remains “ON” at Ignition Switch ON

(Non-Euro-OBD Model)................................... 5A-41

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON (Non-Euro-OBD Model)............................ 5A-41

DTC P0602: Control Module Programming

Error ................................................................ 5A-42

DTC P0705: Transmission Range Sensor

Circuit Malfunction (PRNDL Input) .................. 5A-42

DTC P0707: Transmission Range Sensor

Circuit Low ...................................................... 5A-44

DTC P0711: Transmission Fluid Temperature

Sensor “A” Control Range / Performance ....... 5A-46

DTC P0712: Transmission Fluid Temperature

Sensor Circuit Low .......................................... 5A-47

DTC P0713: Transmission Fluid Temperature

Sensor Circuit High ......................................... 5A-48

DTC P0717: Input / Turbine Speed Sensor

Circuit Malfunction........................................... 5A-50

DTC P0722: Output Speed Sensor (VSS)

Circuit No Signal ............................................. 5A-51

DTC P0741 / P0742: TCC Circuit

Performance or Stuck OFF / TCC Circuit

Stuck ON ......................................................... 5A-53

DTC P0751 / P0752 / P0756 / P0757: Shift

Solenoid Malfunction ....................................... 5A-54

DTC P0787: Shift / Timing Solenoid Control

Circuit Low ...................................................... 5A-55

DTC P0788: Shift / Timing Solenoid Control

Circuit High...................................................... 5A-57

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid-A (No.1)

Control Circuit Low / Shift Solenoid-B (No.2)

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid-A (No.1)

/ Shift Solenoid-B (No.2) Control Circuit High .. 5A-66

DTC P1702: Internal Control Module Memory

Check Sum Error............................................. 5A-68

Page 646 of 1556

Downloaded from www.Manualslib.com manuals search engine 5-ii Table of Contents

DTC P1723: Range Select Switch

Malfunction ...................................................... 5A-68

DTC P1878: Torque Converter Clutch

Shudder .......................................................... 5A-69

DTC P2762: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

Range / Performance ...................................... 5A-70

DTC P2763: Torque Converter Clutch (TCC)

Pressure Control Solenoid Control Circuit

High ................................................................. 5A-72

DTC P2764: Torque Converter Clutch (TCC)

Circuit Pressure Control Solenoid Control

Circuit Low ...................................................... 5A-74

DTC U0073: Control Module Communication

Bus Off ............................................................ 5A-76

DTC U0100: Lost Communication with ECM /

PCM “A” .......................................................... 5A-76

Inspection of TCM and Its Circuits .................... 5A-76

TCM Power and Ground Circuit Check ............. 5A-80

Brake Interlock System Inspection .................... 5A-81

Repair Instructions ............................................5A-82

Learning Control Initialization ............................ 5A-82

A/T Fluid Level Check ....................................... 5A-82

A/T Fluid Change .............................................. 5A-83

Select Lever Components ................................. 5A-84

Select Lever Assembly Removal and

Installation ....................................................... 5A-84

Select Lever Knob Installation........................... 5A-84

Select Lever Inspection ..................................... 5A-85

“3” Position Switch Inspection ........................... 5A-85

Shift Lock Solenoid Inspection .......................... 5A-85

Shift Lock Solenoid Replacement ..................... 5A-85

Select Cable Components ................................ 5A-86

Select Cable Removal and Installation ............. 5A-86

Select Cable Adjustment ................................... 5A-86

Key Interlock Cable Removal and Installation... 5A-87

Transmission Range Sensor Inspection and

Adjustment ...................................................... 5A-89

Output Shaft Speed Sensor (VSS) Removal

and Installation ................................................ 5A-90

Output Shaft Speed Sensor (VSS) Inspection .. 5A-90

Input Shaft Speed Sensor Removal and

Installation ....................................................... 5A-91

Input Shaft Speed Sensor Inspection................ 5A-91

Transmission Fluid Temperature Sensor

Removal and Installation ................................. 5A-91

Transmission Fluid Temperature Sensor

Inspection ........................................................ 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Removal and

Installation ....................................................... 5A-92

Solenoid Valves (Shift Solenoid Valves and

Timing Solenoid Valve) Inspection .................. 5A-94

Pressure Control Solenoid Valves (Pressure

Control Solenoid and TCC Solenoid)

Removal and Installation ................................. 5A-95

Pressure Control Solenoid Valves Inspection ... 5A-96

Transmission Control Module (TCM)

Removal and Installation ................................. 5A-97

A/T Relay Inspection ......................................... 5A-97Differential Side Oil Seal Replacement ............. 5A-98

A/T Fluid Cooler Hoses Replacement ............... 5A-98

Automatic Transaxle Unit Components............. 5A-99

Automatic Transaxle Unit Dismounting and

Remounting ................................................... 5A-100

Automatic Transaxle Assembly Components . 5A-102

Automatic Transaxle Unit Disassembly........... 5A-104

Oil Pump Assembly Components ................... 5A-116

Oil Pump Assembly Disassembly and

Reassembly .................................................. 5A-116

Oil Pump Assembly Inspection ....................... 5A-117

Direct Clutch Assembly Components.............. 5A-119

Direct Clutch Assembly Preliminary Check ..... 5A-119

Direct Clutch Assembly Disassembly and

Reassembly .................................................. 5A-120

Direct Clutch Assembly Inspection.................. 5A-122

Forward and Reverse Clutch Assembly

Components .................................................. 5A-123

Forward and Reverse Clutch Assembly

Preliminary Check ......................................... 5A-123

Forward and Reverse Clutch Assembly

Disassembly and Reassembly ...................... 5A-124

Forward and Reverse Clutch Assembly

Inspection ...................................................... 5A-127

2nd Brake Piston Assembly Components ....... 5A-128

2nd Brake Piston Assembly Disassembly and

Reassembly .................................................. 5A-128

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Components........... 5A-129

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Disassembly and

Reassembly .................................................. 5A-130

Transaxle Rear Cover (O/D and 2nd Coast

Brake Piston) Assembly Inspection............... 5A-131

Countershaft Assembly Components.............. 5A-132

Countershaft Assembly Disassembly and

Reassembly .................................................. 5A-132

Valve Body Assembly Components ................ 5A-133

Valve Body Assembly Disassembly and

Reassembly .................................................. 5A-134

Differential Assembly Components ................. 5A-135

Differential Assembly Disassembly and

Reassembly .................................................. 5A-136

Differential Assembly Inspection ..................... 5A-137

Torque Converter Housing Disassembly and

Reassembly .................................................. 5A-138

Transaxle Case Disassembly and

Reassembly .................................................. 5A-140

Automatic Transaxle Unit Inspection and

Adjustment .................................................... 5A-141

Automatic Transaxle Unit Assembly ............... 5A-144

Specifications ...................................................5A-161

Tightening Torque Specifications .................... 5A-161

Special Tools and Equipment .........................5A-162

Recommended Service Material ..................... 5A-162

Special Tool .................................................... 5A-162

Manual Transmission/Transaxle ............ 5B-1

General Description .............................................5B-1

Manual Transaxle Construction .......................... 5B-1

Page 647 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5-iii

Diagnostic Information and Procedures ............ 5B-5

Manual Transaxle Symptom Diagnosis............... 5B-5

Repair Instructions .............................................. 5B-5

Manual Transaxle Oil Level Check ..................... 5B-5

Manual Transaxle Oil Change ............................ 5B-6

Differential Side Oil Seal Replacement ............... 5B-7

Gear Shift Control Lever and Cable

Components...................................................... 5B-8

Gear Shift Control Lever and Cable Removal

and Installation .................................................. 5B-9

Gear Select Control Cable Adjustment ............... 5B-9

Back Up Light Switch Removal and

Installation ....................................................... 5B-10

Back Up Light Switch Inspection ....................... 5B-10

Manual Transaxle Unit Components ................. 5B-11

Manual Transaxle Unit Dismounting and

Remounting..................................................... 5B-12

Gear Shift and Select Shaft Assembly

Components.................................................... 5B-13

Gear Shift and Select Shaft Assembly

Removal and Installation................................. 5B-14

Gear Shift and Select Shaft Assembly

Disassembly and Reassembly ........................ 5B-15

Manual Transaxle Assembly Components........ 5B-16

Fifth Gear Disassembly and Reassembly ......... 5B-17

Manual Transaxle Assembly Disassembly

and Reassembly ............................................. 5B-19

Right Case Disassembly and Reassembly ....... 5B-24

Left Case Disassembly and Reassembly.......... 5B-25

Input Shaft and Countershaft Components....... 5B-27

Input Shaft Disassembly and Reassembly........ 5B-28

Countershaft Disassembly and Reassembly .... 5B-31

Gear Shift Shaft Components ........................... 5B-35

5th and Reverse Gear Shift Shafts

Disassembly and Reassembly ........................ 5B-35

Gear Shift Shaft and Fork Inspection ................ 5B-35

Differential Components ................................... 5B-36Differential Disassembly and Reassembly ........ 5B-36

Specifications .....................................................5B-38

Tightening Torque Specifications ...................... 5B-38

Special Tools and Equipment ...........................5B-39

Recommended Service Material ....................... 5B-39

Special Tool ...................................................... 5B-39

Clutch ....................................................... 5C-1

General Description .............................................5C-1

Clutch (Hydraulic Type) Construction .................5C-1

Diagnostic Information and Procedures ............5C-2

Clutch System Symptom Diagnosis ....................5C-2

Repair Instructions ..............................................5C-3

Clutch Pedal Inspection ......................................5C-3

Clutch Fluid Level Inspection ..............................5C-3

Air Bleeding of Clutch System.............................5C-3

Clutch Fluid Pipe and Hose Location ..................5C-4

Clutch Fluid Pipe Removal and Installation.........5C-4

Clutch Fluid Pipe Inspection................................5C-4

Clutch Master Cylinder Removal and

Installation .........................................................5C-5

Clutch Operating Cylinder Assembly

Removal and Installation ...................................5C-5

Clutch Operating Cylinder Assembly

Inspection ..........................................................5C-6

Clutch Cover, Clutch Disc and Flywheel

Components ......................................................5C-6

Clutch Cover, Clutch Disc and Flywheel

Removal and Installation ...................................5C-7

Clutch Cover, Clutch Disc and Flywheel

Inspection ..........................................................5C-8

Specifications .......................................................5C-9

Tightening Torque Specifications ........................5C-9

Special Tools and Equipment ...........................5C-10

Recommended Service Material .......................5C-10

Special Tool ......................................................5C-10

Page 651 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-3

General Description

A/T DescriptionS6RW0D5101001

This automatic transaxle is electronic control full automatic transaxle with forward 3-speed plus overdrive (O/D) and

reverse 1-speed.

The torque converter is a 3-element, 1-step and 2-phase type and is equipped with an automatically controlled lock-up

mechanism.

The gear change device consists of a ravigneau type planetary gear unit, 3 multiple disc type clutches, 3 multiple disc

type brakes and 2 one-way clutches.

The hydraulic pressure control device consists of a valve body assembly, pressure control solenoid valve (linear

solenoid), 2 shift solenoid valves, TCC solenoid valve (TCC pressure control solenoid valve) (linear solenoid) and a

timing solenoid valve. Optimum line pressure complying with engine torque is produced by the pressure control

solenoid valve in dependence upon control signal from transmission control module (TCM). This makes it possible to

control the line pressure with high accuracy in accordance with the engine power and running conditions to achieve

smooth shifting characteristics and high efficiency.

A clutch-to-clutch control system is provided for shifting between 3rd gear and 4th gear. This clutch-to-clutch control

system is made to function optimally, so that hydraulic pressure controls such as shown below are conducted.

• When upshifting from 3rd gear to 4th gear, to adjust the drain hydraulic pressure at releasing the forward clutch, a

timing solenoid valve is used to switch a hydraulic passage with an orifice to another during shifting.

• When downshifting from 4th gear to 3rd gear, to adjust the line pressure applied to the forward clutch at engaging

the forward clutch, a timing solenoid valve is used to switch a hydraulic passage with an orifice to another during

shifting.

• When upshifting from 3rd gear to 4th gear with engine throttle opened, to optimize the line pressure applied to the

forward clutch at releasing the forward clutch, the learning control is processed to compensate the switching timing

of the timing solenoid at every shifting.

• When downshifting from 4th gear to 3rd gear with engine throttle opened, to optimize the line pressure applied to

the forward clutch at engaging the forward clutch, the learning control is processed to compensate the line pressure

at every shifting.

Employing the ravigneau type planetary gear unit and this clutch-to-clutch control system greatly simplifies the

construction to make possible a lightweight and compact transaxle.

A line pressure learning control is conducted to provide optimum shifting time at every upshifting with engine throttle

opened. If long upshifting time is detected, the subsequent line pressure applied during upshifting is intensified. On the

contrary, if short upshifting time is detected, the subsequent line pressure applied during upshifting is weakened.

Page 658 of 1556

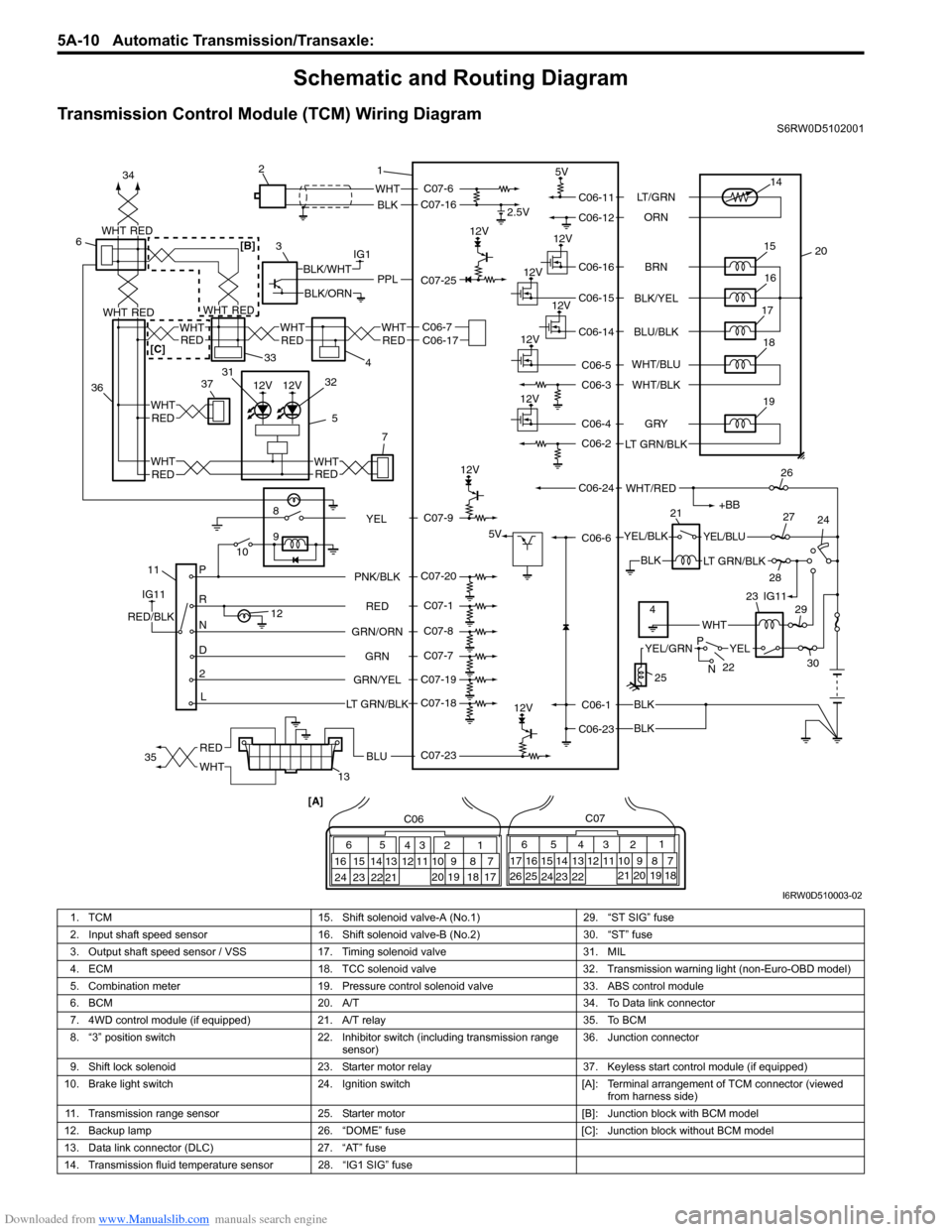

Downloaded from www.Manualslib.com manuals search engine 5A-10 Automatic Transmission/Transaxle:

Schematic and Routing Diagram

Transmission Control Module (TCM) Wiring DiagramS6RW0D5102001

12V

12V

12V

IG1

118

9

10

P

R

N

D

2

L12

2.5V

5V

12V

5V

12V

12V

12V

WHT

BLK

BLK

BLK

BLK

PPLBLK/WHT

BLK/ORN

IG11

RED/BLK

YEL/BLKYEL/BLU

LT GRN/BLK

+BB

WHT/RED

14

20 15

16

17

19

12V18

1 2

3

132126

24 27

28

29

30

65

16 15 14 13 12 1143

24 23 212210 9 8 721

19 20 18 17 C06

17 16

26 2515 14 65 342

13 12

23 22 2411 10 9

21 20 1987

18 1 C07

[A]

22

25

YELYEL/GRN

WHT

P

N

BRN LT/GRN

ORN

BLK/YEL

BLU/BLK

GRY

LT GRN/BLKWHT/BLU

WHT/BLK

C06-11

C06-12

C06-16

C06-15

C06-14

C06-4

C06-2

C06-1

C06-23C06-6 C06-24C06-5

C06-3

RED

GRN GRN/ORNPNK/BLK

GRN/YEL

LT GRN/BLKC07-6

C07-16

C07-23 C07-25

C07-20

C07-1

C07-8

C07-7

C07-19

C07-18

4IG11 23

C07-9

YEL

RED

WHTBLU35 34

3637

5REDWHT

7

WHT

RED

33

4

6

C06-7C06-17WHT

REDREDWHT

WHT

12V12V

WHTRED

WHTREDREDWHT

31

32

RED

WHTRED[B]

[C]

I6RW0D510003-02

1. TCM 15. Shift solenoid valve-A (No.1) 29. “ST SIG” fuse

2. Input shaft speed sensor 16. Shift solenoid valve-B (No.2) 30. “ST” fuse

3. Output shaft speed sensor / VSS 17. Timing solenoid valve 31. MIL

4. ECM 18. TCC solenoid valve 32. Transmission warning light (non-Euro-OBD model)

5. Combination meter 19. Pressure control solenoid valve 33. ABS control module

6. BCM 20. A/T 34. To Data link connector

7. 4WD control module (if equipped) 21. A/T relay 35. To BCM

8. “3” position switch 22. Inhibitor switch (including transmission range

sensor)36. Junction connector

9. Shift lock solenoid 23. Starter motor relay 37. Keyless start control module (if equipped)

10. Brake light switch 24. Ignition switch [A]: Terminal arrangement of TCM connector (viewed

from harness side)

11. Transmission range sensor 25. Starter motor [B]: Junction block with BCM model

12. Backup lamp 26. “DOME” fuse [C]: Junction block without BCM model

13. Data link connector (DLC) 27. “AT” fuse

14. Transmission fluid temperature sensor 28. “IG1 SIG” fuse