Oil ring SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 892 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-12 Power Assisted Steering System:

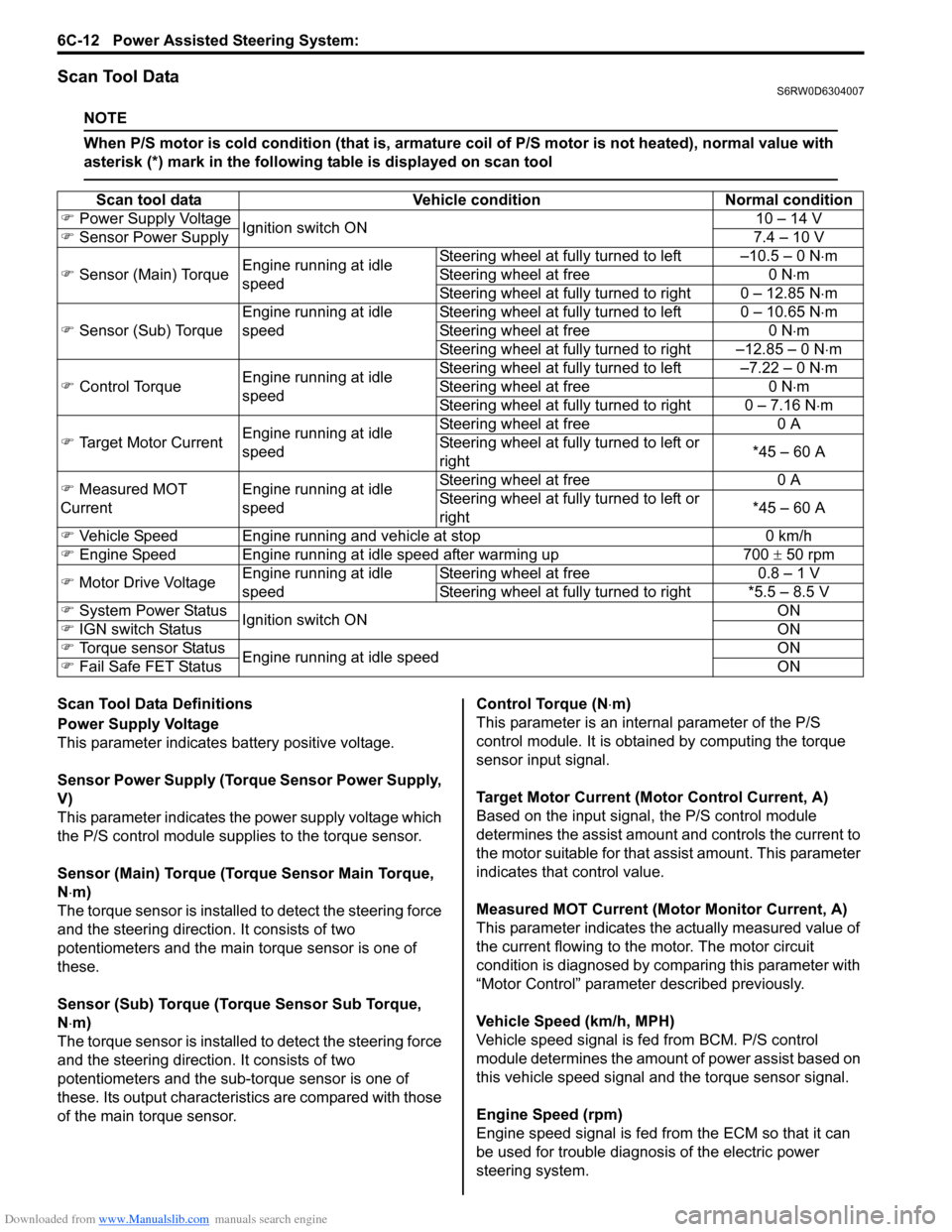

Scan Tool DataS6RW0D6304007

NOTE

When P/S motor is cold condition (that is, armature coil of P/S motor is not heated), normal value with

asterisk (*) mark in the following table is displayed on scan tool

Scan Tool Data Definitions

Power Supply Voltage

This parameter indicates battery positive voltage.

Sensor Power Supply (Torque Sensor Power Supply,

V)

This parameter indicates the power supply voltage which

the P/S control module supplies to the torque sensor.

Sensor (Main) Torque (Torque Sensor Main Torque,

N⋅m)

The torque sensor is installed to detect the steering force

and the steering direction. It consists of two

potentiometers and the main torque sensor is one of

these.

Sensor (Sub) Torque (Torque Sensor Sub Torque,

N⋅m)

The torque sensor is installed to detect the steering force

and the steering direction. It consists of two

potentiometers and the sub-torque sensor is one of

these. Its output characteristics are compared with those

of the main torque sensor.Control Torque (N⋅m)

This parameter is an internal parameter of the P/S

control module. It is obtained by computing the torque

sensor input signal.

Target Motor Current (Motor Control Current, A)

Based on the input signal, the P/S control module

determines the assist amount and controls the current to

the motor suitable for that assist amount. This parameter

indicates that control value.

Measured MOT Current (Motor Monitor Current, A)

This parameter indicates the actually measured value of

the current flowing to the motor. The motor circuit

condition is diagnosed by comparing this parameter with

“Motor Control” parameter described previously.

Vehicle Speed (km/h, MPH)

Vehicle speed signal is fed from BCM. P/S control

module determines the amount of power assist based on

this vehicle speed signal and the torque sensor signal.

Engine Speed (rpm)

Engine speed signal is fed from the ECM so that it can

be used for trouble diagnosis of the electric power

steering system. Scan tool data Vehicle condition Normal condition

�) Power Supply Voltage

Ignition switch ON10 – 14 V

�) Sensor Power Supply7.4 – 10 V

�) Sensor (Main) TorqueEngine running at idle

speedSteering wheel at fully turned to left –10.5 – 0 N⋅m

Steering wheel at free 0 N⋅m

Steering wheel at fully turned to right 0 – 12.85 N⋅m

�) Sensor (Sub) Torque Engine running at idle

speedSteering wheel at fully turned to left 0 – 10.65 N⋅m

Steering wheel at free 0 N⋅m

Steering wheel at fully turned to right –12.85 – 0 N⋅m

�) Control TorqueEngine running at idle

speedSteering wheel at fully turned to left –7.22 – 0 N⋅m

Steering wheel at free 0 N⋅m

Steering wheel at fully turned to right 0 – 7.16 N⋅m

�) Target Motor CurrentEngine running at idle

speedSteering wheel at free 0 A

Steering wheel at fully turned to left or

right*45 – 60 A

�) Measured MOT

Current

Engine running at idle

speedSteering wheel at free 0 A

Steering wheel at fully turned to left or

right*45 – 60 A

�) Vehicle Speed Engine running and vehicle at stop 0 km/h

�) Engine Speed Engine running at idle speed after warming up 700 ± 50 rpm

�) Motor Drive VoltageEngine running at idle

speedSteering wheel at free 0.8 – 1 V

Steering wheel at fully turned to right *5.5 – 8.5 V

�) System Power Status

Ignition switch ONON

�) IGN switch StatusON

�) Torque sensor Status

Engine running at idle speedON

�) Fail Safe FET StatusON

Page 917 of 1556

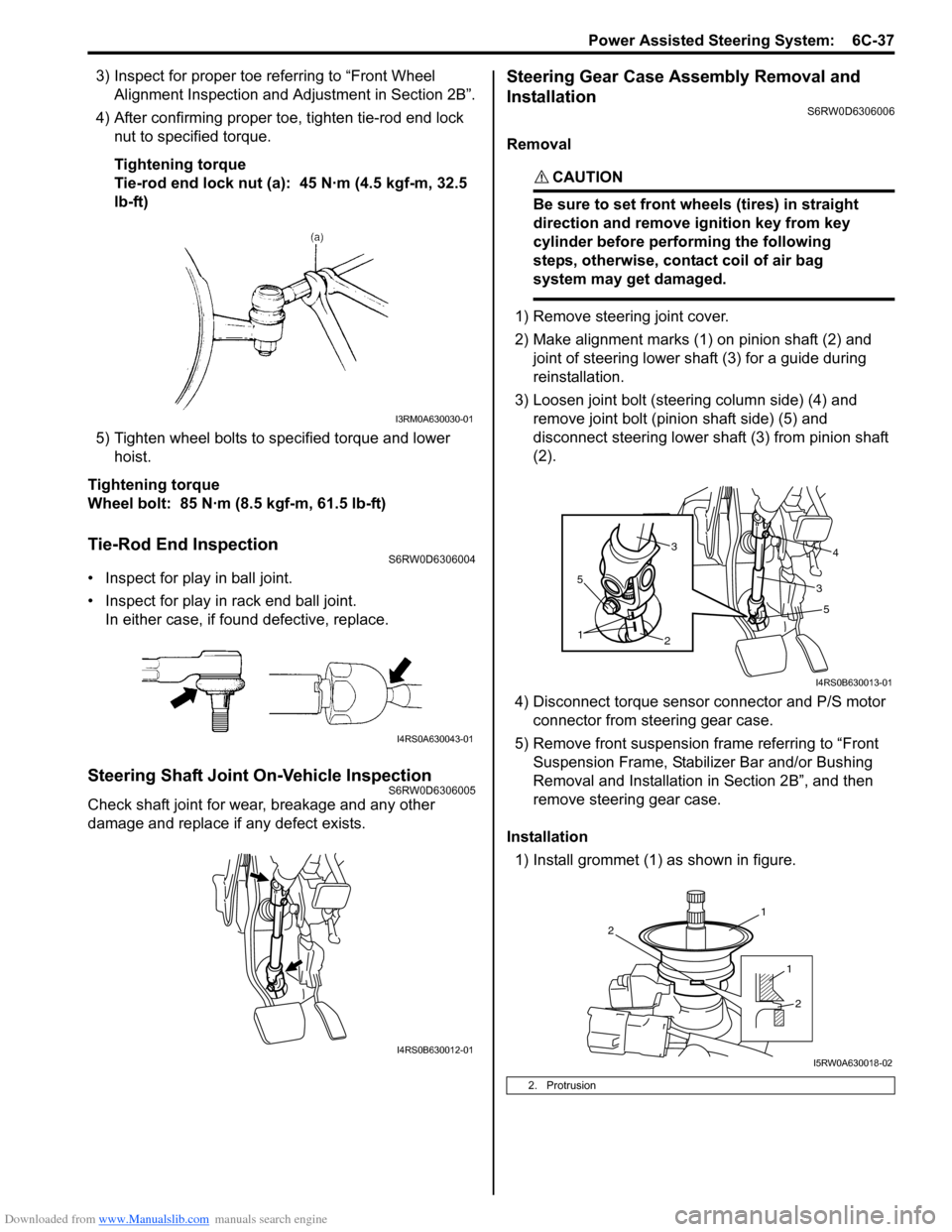

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-37

3) Inspect for proper toe referring to “Front Wheel

Alignment Inspection and Adjustment in Section 2B”.

4) After confirming proper toe, tighten tie-rod end lock

nut to specified torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

5) Tighten wheel bolts to specified torque and lower

hoist.

Tightening torque

Wheel bolt: 85 N·m (8.5 kgf-m, 61.5 lb-ft)

Tie-Rod End InspectionS6RW0D6306004

• Inspect for play in ball joint.

• Inspect for play in rack end ball joint.

In either case, if found defective, replace.

Steering Shaft Joint On-Vehicle InspectionS6RW0D6306005

Check shaft joint for wear, breakage and any other

damage and replace if any defect exists.

Steering Gear Case Assembly Removal and

Installation

S6RW0D6306006

Removal

CAUTION!

Be sure to set front wheels (tires) in straight

direction and remove ignition key from key

cylinder before performing the following

steps, otherwise, contact coil of air bag

system may get damaged.

1) Remove steering joint cover.

2) Make alignment marks (1) on pinion shaft (2) and

joint of steering lower shaft (3) for a guide during

reinstallation.

3) Loosen joint bolt (steering column side) (4) and

remove joint bolt (pinion shaft side) (5) and

disconnect steering lower shaft (3) from pinion shaft

(2).

4) Disconnect torque sensor connector and P/S motor

connector from steering gear case.

5) Remove front suspension frame referring to “Front

Suspension Frame, Stabilizer Bar and/or Bushing

Removal and Installation in Section 2B”, and then

remove steering gear case.

Installation

1) Install grommet (1) as shown in figure.

I3RM0A630030-01

I4RS0A630043-01

I4RS0B630012-01

2. Protrusion

5

2

1

5

34

3

I4RS0B630013-01

1

2

1

2

I5RW0A630018-02

Page 923 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-43

8) Using ammeter (2), check that P/S motor current (1)

is as following table with idling engine. If check result

is not satisfactory, check P/S control module for

torque sensor signal and P/S motor output referring

to “Inspection of P/S Control Module and Its

Circuits”. If they are OK, replace steering gear case

assembly.

NOTE

When P/S motor is cold condition (that is,

armature coil of P/S motor is not heated),

motor current in the following table can be

measured

Motor current at hoisted vehicle (reference

value)

Specifications

Tightening Torque SpecificationsS6RW0D6307001

NOTE

The specified tightening torque is also described in the following.

“Steering Gear Case Assembly Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. ConditionWhen

steering

wheel is left

at straight

position: [A]When steering

wheel is turned

left or right by

turning speed

with 90° /sec:

[B]When

steering

wheel is

kept fully

turned left

or right

until it

stops.: [C]

Motor

currentApprox. 0 A Approx. 0 – 5 AApprox.

45 – 60 A

3. P/S control module

1

32

E12-1

E12-2

[C][A]

[B] [B]

I7RW01632012-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Tie-rod end nut 45 4.5 32.5�)

Tie-rod end lock nut 45 4.5 32.5�)

Wheel bolt 85 8.5 61.5�)

Steering gear case mounting bolt 70 7.0 51.0�)

Steering lower shaft assembly upper joint bolt 25 2.5 18.5�)

Steering lower shaft assembly lower joint bolt 25 2.5 18.5�)

Tie-rod 75 7.5 54.5�)

Earth cable bolt 4.0 0.4 2.8�)

Rack damper screw Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) and

loosen 180° and then tighten 3.9 N⋅m (0.39

kgf-m, 3.0 lb-ft) and turn it back by 10° or

less by the specified procedure.�)

Rotation torque of pinion 2.2 0.22 1.5�)

Steering rack damper lock nut 60 6.0 43.5�)

Page 940 of 1556

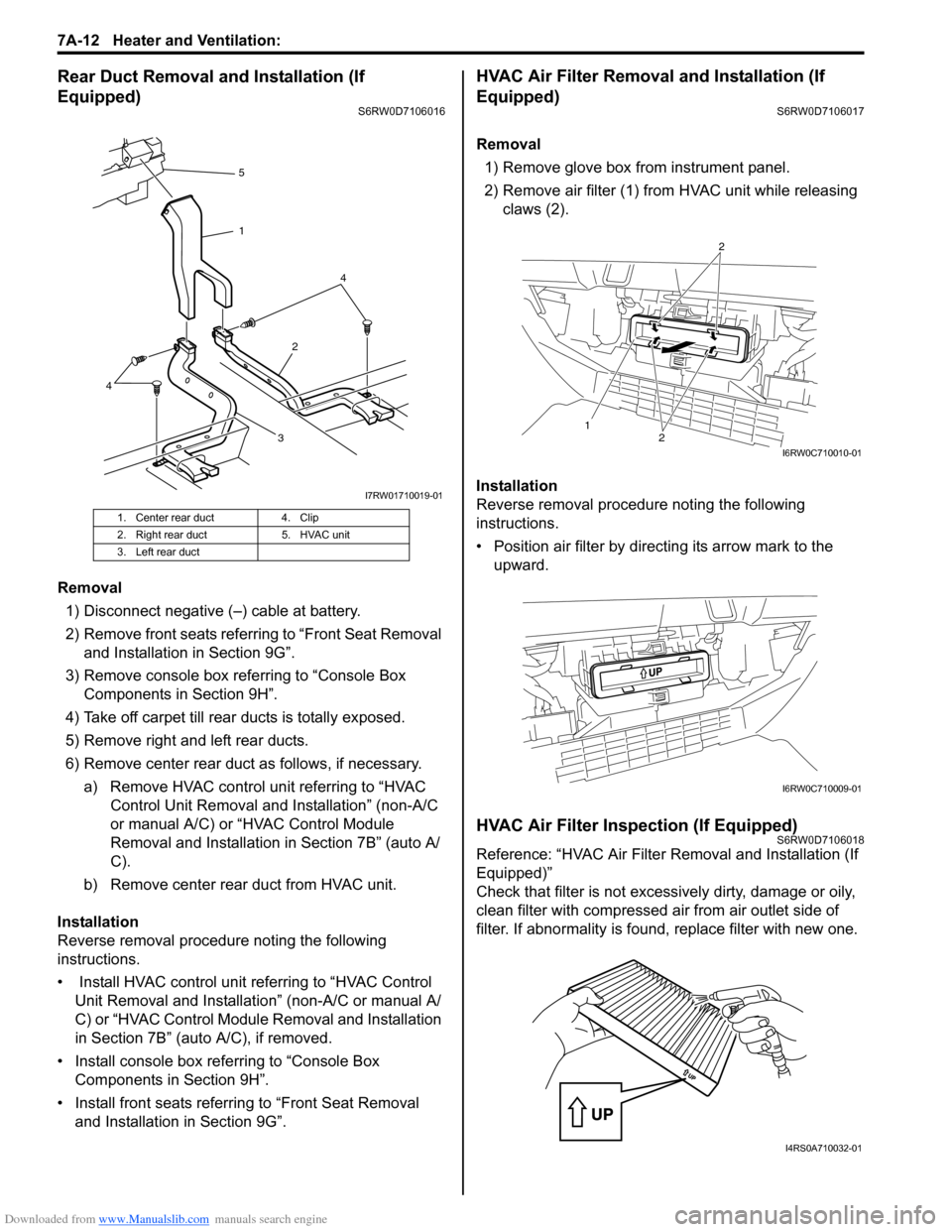

Downloaded from www.Manualslib.com manuals search engine 7A-12 Heater and Ventilation:

Rear Duct Removal and Installation (If

Equipped)

S6RW0D7106016

Removal

1) Disconnect negative (–) cable at battery.

2) Remove front seats referring to “Front Seat Removal

and Installation in Section 9G”.

3) Remove console box referring to “Console Box

Components in Section 9H”.

4) Take off carpet till rear ducts is totally exposed.

5) Remove right and left rear ducts.

6) Remove center rear duct as follows, if necessary.

a) Remove HVAC control unit referring to “HVAC

Control Unit Removal and Installation” (non-A/C

or manual A/C) or “HVAC Control Module

Removal and Installation in Section 7B” (auto A/

C).

b) Remove center rear duct from HVAC unit.

Installation

Reverse removal procedure noting the following

instructions.

• Install HVAC control unit referring to “HVAC Control

Unit Removal and Installation” (non-A/C or manual A/

C) or “HVAC Control Module Removal and Installation

in Section 7B” (auto A/C), if removed.

• Install console box referring to “Console Box

Components in Section 9H”.

• Install front seats referring to “Front Seat Removal

and Installation in Section 9G”.

HVAC Air Filter Removal and Installation (If

Equipped)

S6RW0D7106017

Removal

1) Remove glove box from instrument panel.

2) Remove air filter (1) from HVAC unit while releasing

claws (2).

Installation

Reverse removal procedure noting the following

instructions.

• Position air filter by directing its arrow mark to the

upward.

HVAC Air Filter Inspection (If Equipped)S6RW0D7106018

Reference: “HVAC Air Filter Removal and Installation (If

Equipped)”

Check that filter is not excessively dirty, damage or oily,

clean filter with compressed air from air outlet side of

filter. If abnormality is found, replace filter with new one.

1. Center rear duct 4. Clip

2. Right rear duct 5. HVAC unit

3. Left rear duct

324 5

1

4

I7RW01710019-01

12

2

I6RW0C710010-01

I6RW0C710009-01

I4RS0A710032-01

Page 941 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-1

HVAC

Air Conditioning System

Manual Type

Precautions

A/C System CautionS6RW0D7210001

CAUTION!

The A/C system of this vehicle uses HFC-134a (R-134a) refrigerant, specified compressor oil and

specified parts.

Do not use CFC-12 (R-12) refrigerant, R-12 exclusive use compressor oil and R-12 exclusive parts in

this A/C system, do not attempt to use R-12 servicing equipment. Otherwise, use of it will result in

leakage of refrigerant, damage or other faulty condition of A/C system and damage or other faulty

condition of servicing equipment.

When replenishing or changing refrigerant and compressor oil and when replacing parts, make sure

that the material or the part to be used is appropriate to the A/C installed in the vehicle being serviced.

Use of incorrect one will result in leakage of refrigerant, damage in parts or other faulty condition.

Precautions on Servicing A/C SystemS6RW0D7210002

WARNING!

Should refrigerant HFC-134a (R-134a) is exposed to your eye(s), consult a doctor immediately.

• Do not reuse your hand to rub affected eye(s). Instead, use fresh cold water to splash it over

affected area to thus gradually raise its temperature above the freezing point.

• Obtain proper treatment as soon as possible from a doctor or eye specialist. Should liquid

refrigerant HFC-134a (R-134a) is exposed to your skin, such affected part should be treated in the

same manner as when skin is frostbitten or frozen.

Handling Refrigerant HFC-134a (R-134a)

• Always wear goggles to protect your eyes.

• Avoid direct contact to liquid refrigerant.

• Do not heat refrigerant container higher than 40 °C (104 °F).

• Do not discharge refrigerant into atmosphere.

• Do not expose bright metals to liquid refrigerant. Refrigerant combined with moisture is corrosive and tarnishes

surfaces of bright metals including chrome.

• Never use heat for bending pipes. When bending a pipe, try to make its bending angle as smooth as possible.

• Keep internal parts of air conditioning free from moisture and dirt. When disconnecting any line from system, install

a blind plug or cap to the fitting immediately.

• When handling recovery and recycling equipment, be sure to follow the instruction manual for the equipment.

• Check local governmental regulations regarding working with refrigerator systems and its tooling.

• When connecting hoses and pipes, apply a few drops of compressor oil (refrigerant oil) to O-ring.

• Replace O-ring with new one once hoses, pipes and parts disconnected.

• When tightening or loosening a fitting, use two wrenches, one for turning and the other for support.

• Route drain hose so that drained water does not make any contact to vehicle components.

• If pipes or hoses are replaced, replenish specified amount of compressor oil to compressor suction side referring to

“Replenishing Compressor Oil” in “Operation Procedure for Refrigerant Charge”.

Page 942 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-2 Air Conditioning System: Manual Type

Refrigerant Recovery

When discharging refrigerant out of A/C system, always recover it by using refrigerant recovery and recycling

equipment because discharging refrigerant HFC-134a (R-134a) into atmosphere would cause adverse effect to

environments referring to “Recovery” in “Operation Procedure for Refrigerant Charge”.

Refrigerant Charge

After performing compressor oil replenishment and evacuation, charge a proper amount of refrigerant to A/C system

referring to “Charge” in “Operation Procedure for Refrigerant Charge”.

General Description

Sub-Cool A/C System DescriptionS6RW0D7211001

In the sub-cool A/C system (condenser integrated with receiver / dryer), the inside of the condenser is divided into the

condensation part and the sub-cooler part, and the receiver / dryer is located between those. In the receiver / dryer,

the refrigerant is separated into the vapor refrigerant and the liquid refrigerant. Only the liquid refrigerant is delivered to

the sub-cooler part of the condenser. The refrigerant is supercooled by the sub-cooler part of the condenser.

I5RW0A721003-02

[A]: Liquid 2. Magnet clutch 6. Expansion valve 10. Desiccant

[B]: Vapor 3. Condenser 7. A/C evaporator 11. Filter

[C]: Superheated vapor 4. Receiver/dryer 8. Condensation part 12. Vapor refrigerant

1. Compressor 5. Refrigerant pressure sensor 9. Sub-cooler part 13. Liquid refrigerant

Page 946 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-6 Air Conditioning System: Manual Type

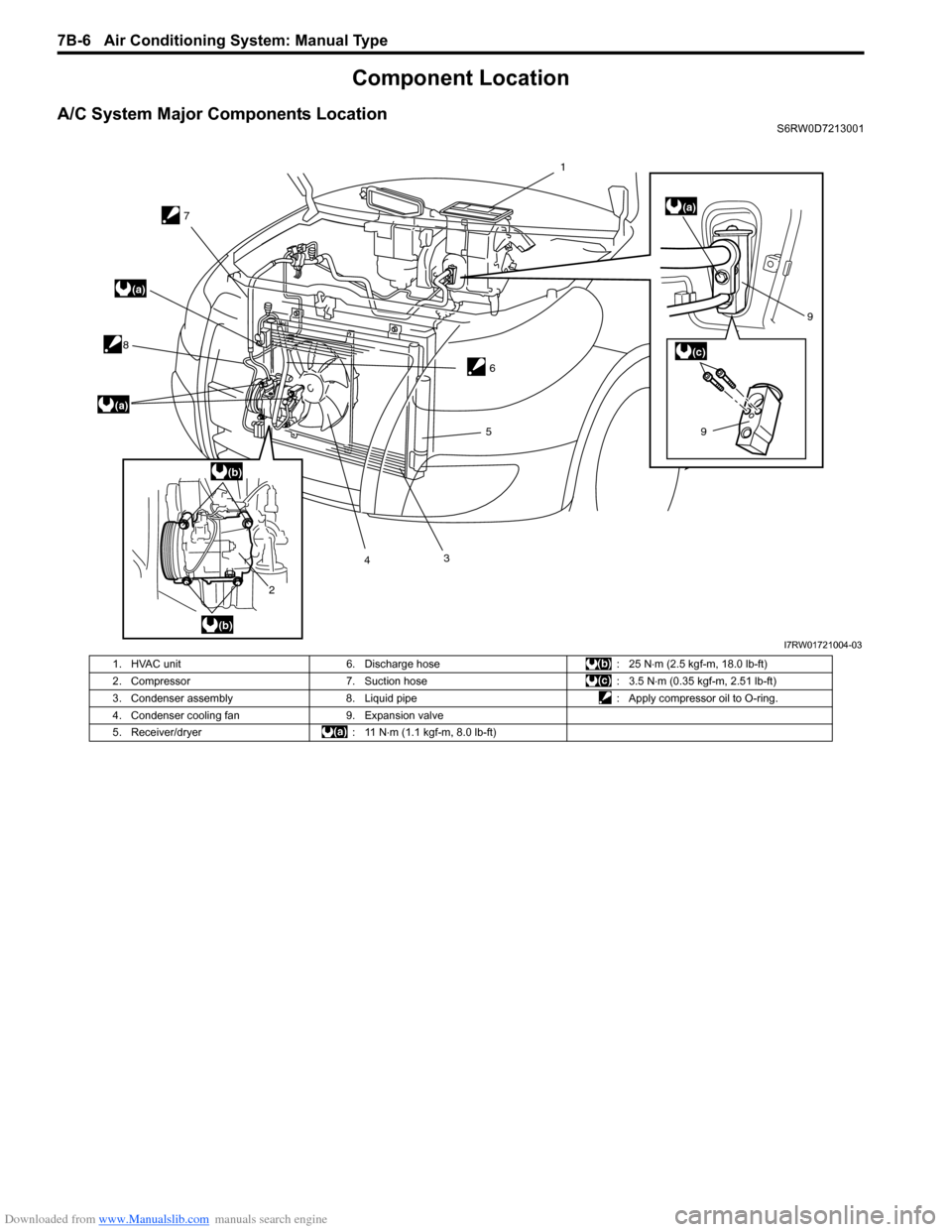

Component Location

A/C System Major Components LocationS6RW0D7213001

7

8

2435

69

9

(a)

(a)

(a)

(b)

(b)

(c)

1

I7RW01721004-03

1. HVAC unit 6. Discharge hose : 25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

2. Compressor 7. Suction hose : 3.5 N⋅m (0.35 kgf-m, 2.51 lb-ft)

3. Condenser assembly 8. Liquid pipe : Apply compressor oil to O-ring.

4. Condenser cooling fan 9. Expansion valve

5. Receiver/dryer : 11 N⋅m (1.1 kgf-m, 8.0 lb-ft)

Page 949 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-9

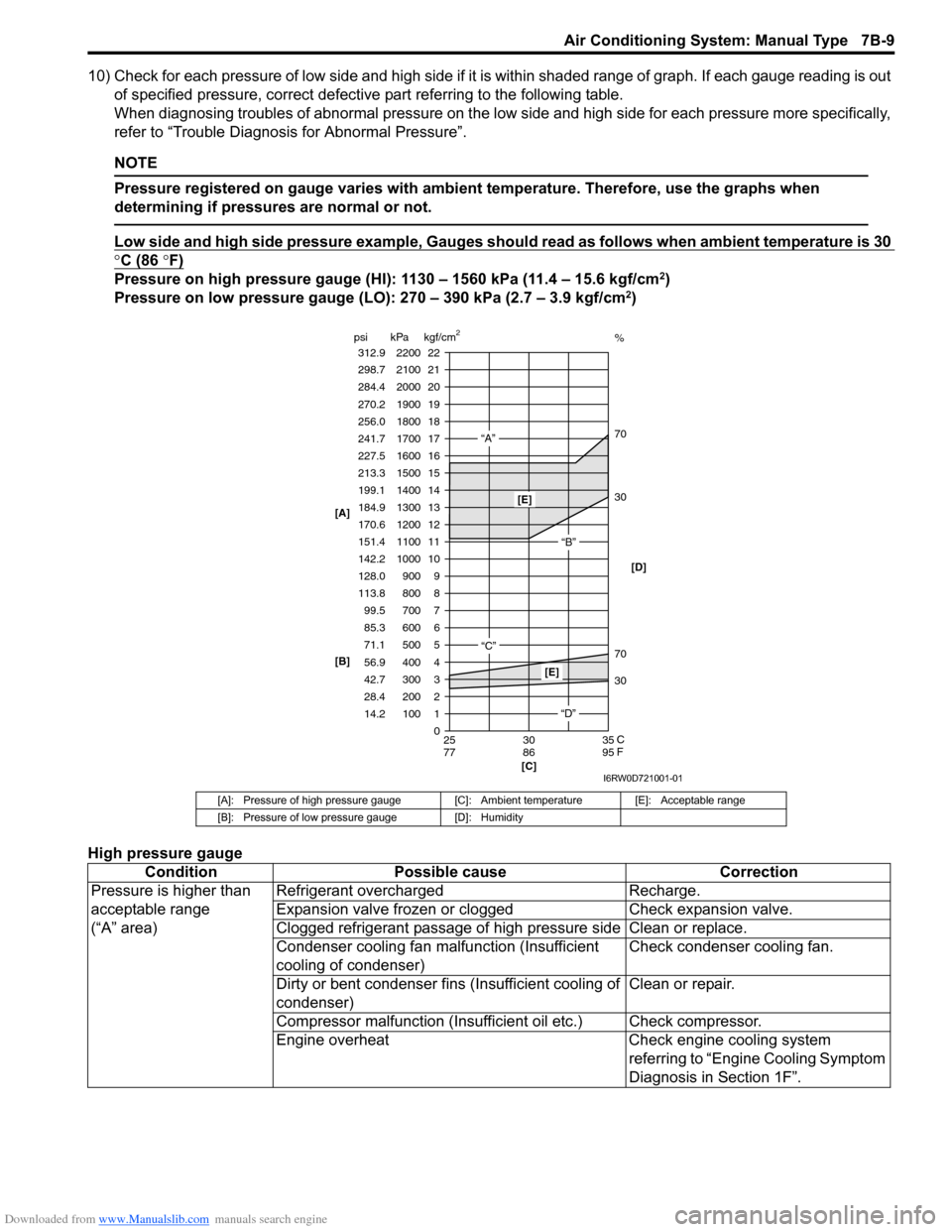

10) Check for each pressure of low side and high side if it is within shaded range of graph. If each gauge reading is out

of specified pressure, correct defective part referring to the following table.

When diagnosing troubles of abnormal pressure on the low side and high side for each pressure more specifically,

refer to “Trouble Diagnosis for Abnormal Pressure”.

NOTE

Pressure registered on gauge varies with ambient temperature. Therefore, use the graphs when

determining if pressures are normal or not.

Low side and high side pressure example, Gauges should read as follows when ambient temperature is 30

°C (86 °F)

Pressure on high pressure gauge (HI): 1130 – 1560 kPa (11.4 – 15.6 kgf/cm2)

Pressure on low pressure gauge (LO): 270 – 390 kPa (2.7 – 3.9 kgf/cm2)

High pressure gauge

[A]: Pressure of high pressure gauge [C]: Ambient temperature [E]: Acceptable range

[B]: Pressure of low pressure gauge [D]: Humidity

Condition Possible cause Correction

Pressure is higher than

acceptable range

(“A” area)Refrigerant overcharged Recharge.

Expansion valve frozen or clogged Check expansion valve.

Clogged refrigerant passage of high pressure side Clean or replace.

Condenser cooling fan malfunction (Insufficient

cooling of condenser)Check condenser cooling fan.

Dirty or bent condenser fins (Insufficient cooling of

condenser)Clean or repair.

Compressor malfunction (Insufficient oil etc.) Check compressor.

Engine overheat Check engine cooling system

referring to “Engine Cooling Symptom

Diagnosis in Section 1F”.

22 312.9 2200

0 1 2 3

30 70 30 70%

4 5 6 7 8 9 10

11 12 13

14

15

16

17

18

19 21 298.7 2100

20

14.2 28.4 42.7 56.9 71.1 85.3 99.5 113.8 128.0

142.2

151.4 170.6 184.9

199.1

213.3

227.5

241.7

256.0

270.2

284.4

100 200 300 400 500 600 700 800 900 1000

1100 1200 1300

1400

1500

1600

1700

1800

1900

2000

25 30 35

77 86 95 psi kPa kgf/cm

2

[C] [B] [A]

C

F

“A”

“B”

“C”

[E]

[E]

“D”[D]

I6RW0D721001-01

Page 954 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-14 Air Conditioning System: Manual Type

Cool air does not come

out or insufficient cooling

(A/C compressor normal

operation)Insufficient or excessive charge of

refrigerantCheck the amount of refrigerant and system

for leaks.

Condenser cloggedCheck condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

A/C evaporator clogged or frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

Expansion valve faultyCheck expansion valve referring to “Expansion

Valve Inspection”.

Desiccant cloggedCheck desiccant and cap with filter.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Compressor faultyCheck compressor.

Air in A/C systemReplace condenser, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Air leaking from HVAC unit or air ductRepair as necessary.

Heater and ventilation system faultyCheck HVAC unit.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Excessive compressor oil in A/C systemDrain excessive compressor oil from A/C

system circuit and compressor.

Cool air does not come

out only intermittentlyWiring connection faultyRepair as necessary.

Evaporator temperature sensor faultyCheck evaporator temperature sensor

referring to “Evaporator Temperature Sensor

Inspection”.

Expansion valve faultyCheck expansion valve referring to “Expansion

Valve Inspection”.

Excessive moisture in A/C systemReplace condenser, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Magnet clutch faultyCheck magnet clutch referring to “Magnet

Clutch Inspection”.

Excessive amount of refrigerantCheck the amount of refrigerant.

Cool air comes out only at

high speedCondenser cloggedCheck condenser referring to “Condenser

Assembly On-Vehicle Inspection”.

Insufficient charge of refrigerantCheck the amount of refrigerant and system

for leaks.

Air in A/C systemReplace condenser, and then perform

evacuation and charge referring to “Operation

Procedure for Refrigerant Charge”.

Compressor drive belt loosened or

brokenAdjust or replace drive belt.

Compressor faultyCheck compressor.

Cool air does not come

out only at high speedExcessive amount of refrigerantCheck the amount of refrigerant.

A/C evaporator frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”. Condition Possible cause Correction / Reference Item

Page 955 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Manual Type 7B-15

Abnormal Noise Symptom Diagnosis of A/C SystemS6RW0D7214005

Abnormal Noise from Compressor

Abnormal Noise from Magnetic ClutchInsufficient air flow of

cooled airA/C evaporator clogged or frostedCheck A/C evaporator and evaporator

temperature sensor referring to “Evaporator

Inspection” and “Evaporator Temperature

Sensor Inspection”.

Air leaking from HVAC unit or air ductRepair as necessary.

Blower motor faultyCheck blower motor referring to “Blower Motor

Inspection in Section 7A”.

Wiring or grounding faultyRepair as necessary. Condition Possible cause Correction / Reference Item

Condition Possible cause Correction / Reference Item

During compressor

operation, a rumbling

noise is heard

proportional to engine

revolutionsInadequate clearance in scroll areaReplace compressor.

A loud noise is heard at a

certain rpm,

disproportionately to

engine revolutionLoose or faulty compressor drive beltAdjust drive belt tension or replace drive belt.

Loose compressor mounting boltsRetighten mounting bolts.

A loud rattle is heard at

low engine rpmLoose compressor clutch plate boltRetighten clutch plate bolt.

Replace compressor if it was operated in this

condition for a long time.

Condition Possible cause Correction / Reference Item

A rumbling noise is heard

when compressor is not

in operationWorn or damaged bearingsReplace magnet clutch assembly.

A chattering noise is

heard when compressor

is in operationFaulty magnet clutch clearance

(excessive clearance)Adjust magnet clutch clearance.

Worn magnet clutch friction surfaceReplace magnet clutch assembly.

Compressor oil leaked from shaft seal,

contaminating the friction surfaceReplace compressor body assembly.