Oil ring SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1156 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-117 Air Bag System:

21) Disconnect adapter cable (special tool) from air bag

(inflator) module or seat belt pretensioner as soon as

possible. This will prevent adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

22) Check adapter cable connector as follows.

Adapter cable connector (special tool) is designed to

be reused. However it should be inspected for

damage after deployment and replaced if necessary.

23) With air bag (inflator) modules deployed and seat

belt pretensioners activated, vehicle may be

scrapped in the same manner as non-air bag system

/ seat belt pretensioner equipped vehicle.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

24) Remove undeployed air bag (inflator) module(s) and/

or inactivated seat belt pretensioner(s) from vehicle.

For driver air bag (inflator) module, refer to “Driver

Air Bag (Inflator) Module Removal and Installation”.

For passenger air bag (inflator) module, refer to

“Passenger Air Bag (Inflator) Module Removal and

Installation”. For side air bag (inflator) module, refer

to “Side-Air Bag (Inflator) Module Removal and

Installation”. For side curtain-air bag (inflator)

module, refer to “Side Curtain-Air Bag (Inflator)

Module Removal and Installation”. For seat belt

pretensioner, refer to “Front Seat Belt Removal and

Installation in Section 8A”.

25) Temporarily store undeployed air bag (inflator)

module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

26) Contact your local distributor for further assistance.

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal

S6RW0D8206019

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. The undeployed air bag

(inflator) module and the inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

the inactivated seat belt pretensioner

contains substances that can cause severe

illness or personal injury if the sealed

container is damaged during disposal.

Deployed air bag (inflator) module and the activated seat

belt pretensioner can be disposed of through normal

refuse channels just like any other parts. For their

disposal, however, the following points should be noted.

• The air bag (inflator) module and the seat belt

pretensioner immediately after deployment / activation

is very hot. Wait for 30 minutes to cool it off before

handling it.

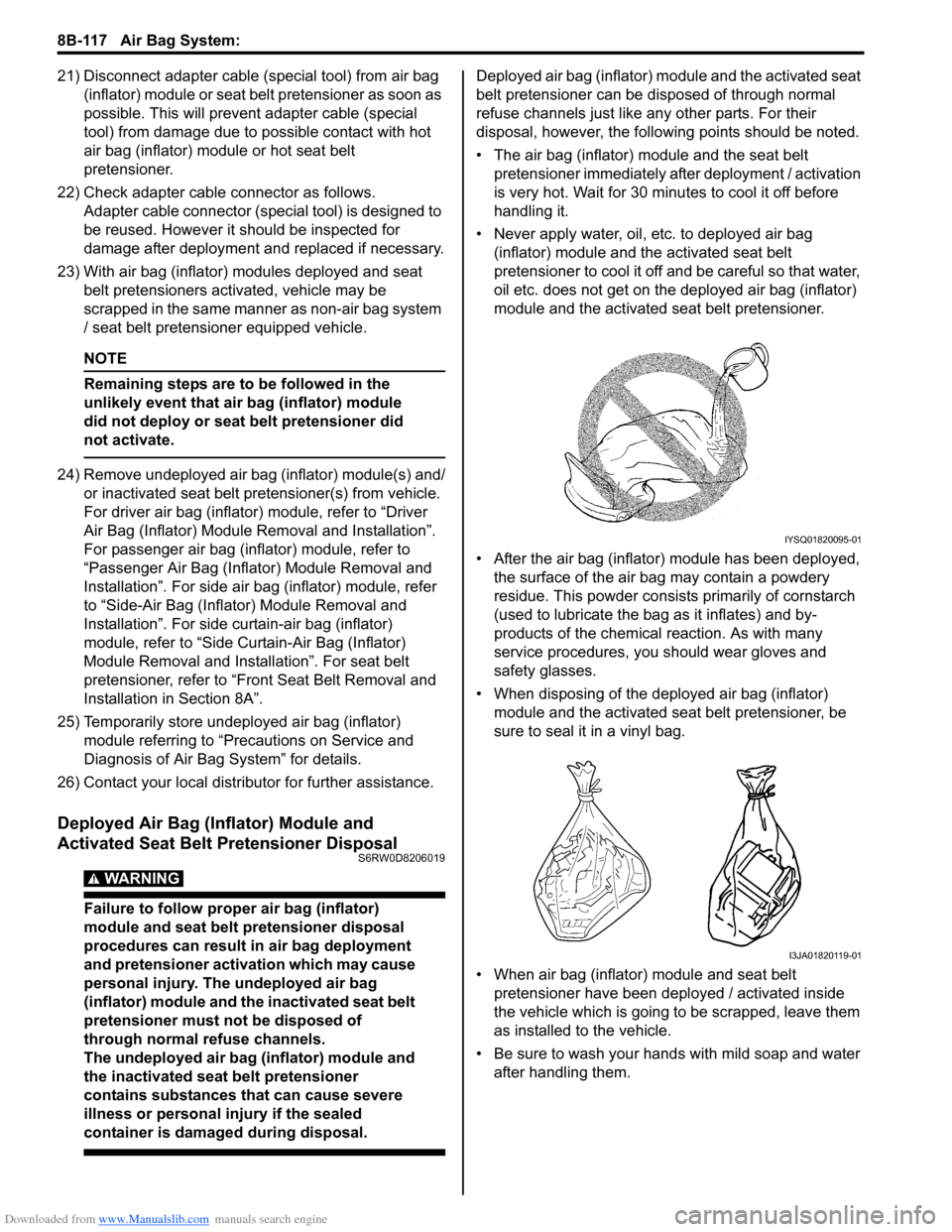

• Never apply water, oil, etc. to deployed air bag

(inflator) module and the activated seat belt

pretensioner to cool it off and be careful so that water,

oil etc. does not get on the deployed air bag (inflator)

module and the activated seat belt pretensioner.

• After the air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery

residue. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-

products of the chemical reaction. As with many

service procedures, you should wear gloves and

safety glasses.

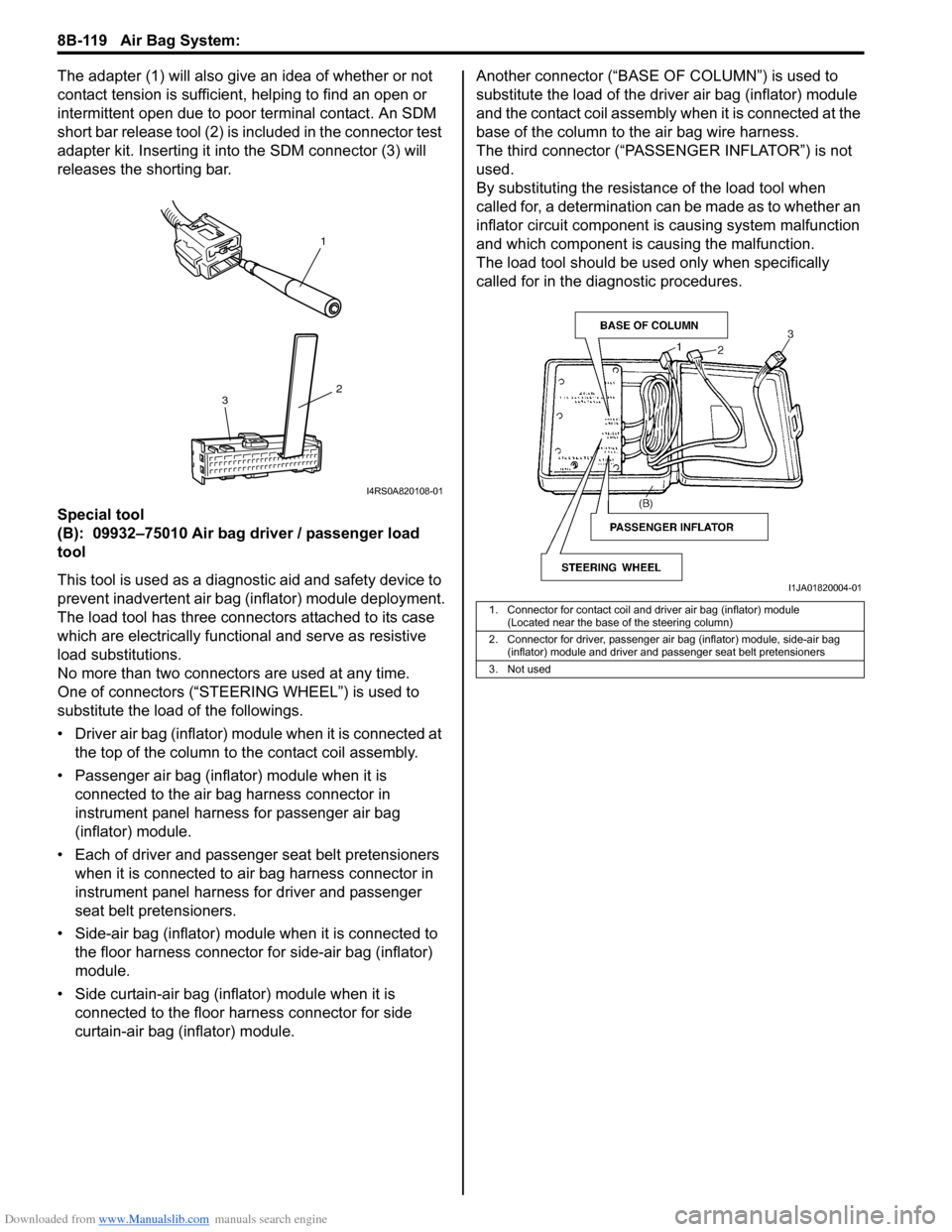

• When disposing of the deployed air bag (inflator)

module and the activated seat belt pretensioner, be

sure to seal it in a vinyl bag.

• When air bag (inflator) module and seat belt

pretensioner have been deployed / activated inside

the vehicle which is going to be scrapped, leave them

as installed to the vehicle.

• Be sure to wash your hands with mild soap and water

after handling them.

IYSQ01820095-01

I3JA01820119-01

Page 1158 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-119 Air Bag System:

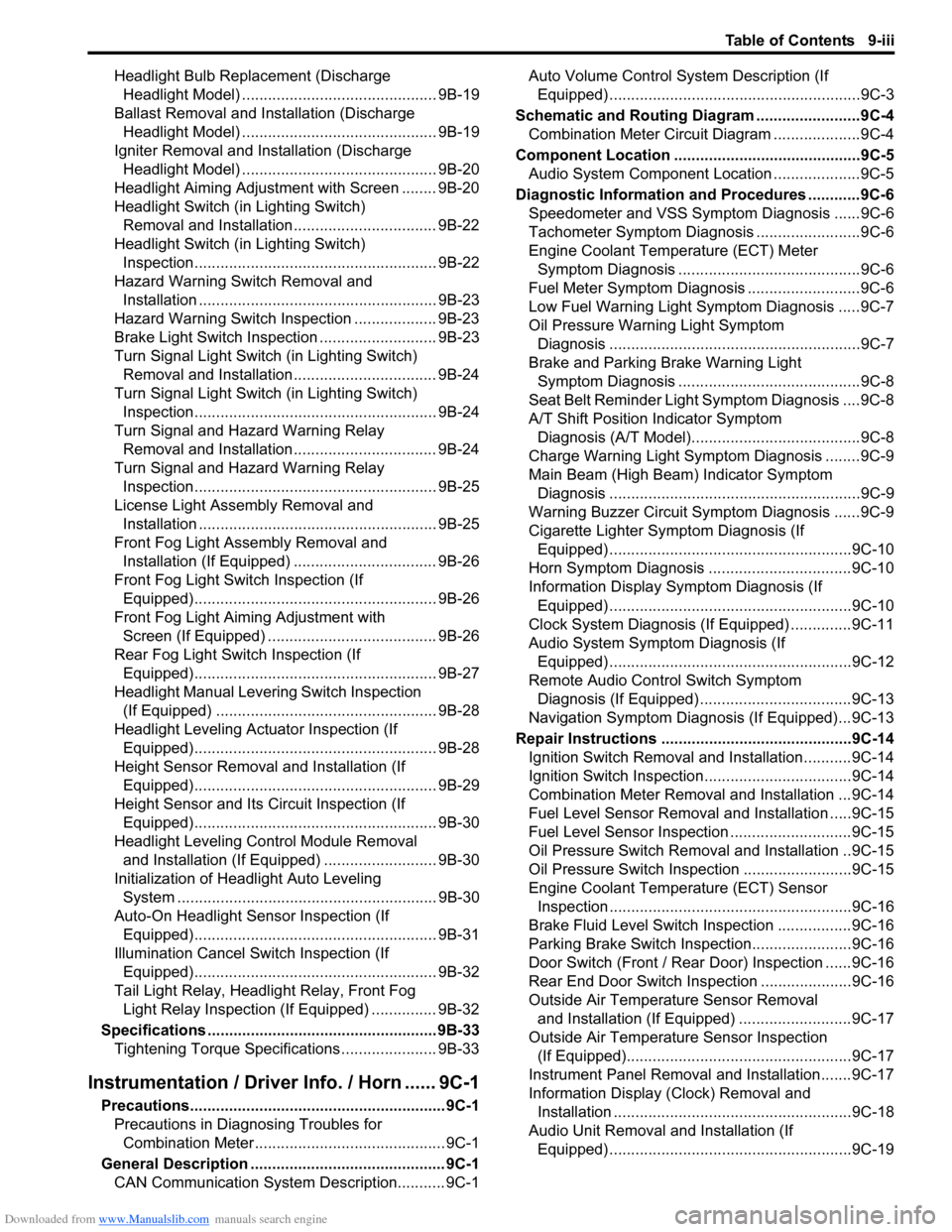

The adapter (1) will also give an idea of whether or not

contact tension is sufficient, helping to find an open or

intermittent open due to poor terminal contact. An SDM

short bar release tool (2) is included in the connector test

adapter kit. Inserting it into the SDM connector (3) will

releases the shorting bar.

Special tool

(B): 09932–75010 Air bag driver / passenger load

tool

This tool is used as a diagnostic aid and safety device to

prevent inadvertent air bag (inflator) module deployment.

The load tool has three connectors attached to its case

which are electrically functional and serve as resistive

load substitutions.

No more than two connectors are used at any time.

One of connectors (“STEERING WHEEL”) is used to

substitute the load of the followings.

• Driver air bag (inflator) module when it is connected at

the top of the column to the contact coil assembly.

• Passenger air bag (inflator) module when it is

connected to the air bag harness connector in

instrument panel harness for passenger air bag

(inflator) module.

• Each of driver and passenger seat belt pretensioners

when it is connected to air bag harness connector in

instrument panel harness for driver and passenger

seat belt pretensioners.

• Side-air bag (inflator) module when it is connected to

the floor harness connector for side-air bag (inflator)

module.

• Side curtain-air bag (inflator) module when it is

connected to the floor harness connector for side

curtain-air bag (inflator) module.Another connector (“BASE OF COLUMN”) is used to

substitute the load of the driver air bag (inflator) module

and the contact coil assembly when it is connected at the

base of the column to the air bag wire harness.

The third connector (“PASSENGER INFLATOR”) is not

used.

By substituting the resistance of the load tool when

called for, a determination can be made as to whether an

inflator circuit component is causing system malfunction

and which component is causing the malfunction.

The load tool should be used only when specifically

called for in the diagnostic procedures.

1

2

3

I4RS0A820108-01

1. Connector for contact coil and driver air bag (inflator) module

(Located near the base of the steering column)

2. Connector for driver, passenger air bag (inflator) module, side-air bag

(inflator) module and driver and passenger seat belt pretensioners

3. Not used

I1JA01820004-01

Page 1163 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-iii

Headlight Bulb Replacement (Discharge

Headlight Model) ............................................. 9B-19

Ballast Removal and Installation (Discharge

Headlight Model) ............................................. 9B-19

Igniter Removal and Installation (Discharge

Headlight Model) ............................................. 9B-20

Headlight Aiming Adjustment with Screen ........ 9B-20

Headlight Switch (in Lighting Switch)

Removal and Installation................................. 9B-22

Headlight Switch (in Lighting Switch)

Inspection........................................................ 9B-22

Hazard Warning Switch Removal and

Installation ....................................................... 9B-23

Hazard Warning Switch Inspection ................... 9B-23

Brake Light Switch Inspection ........................... 9B-23

Turn Signal Light Switch (in Lighting Switch)

Removal and Installation................................. 9B-24

Turn Signal Light Switch (in Lighting Switch)

Inspection........................................................ 9B-24

Turn Signal and Hazard Warning Relay

Removal and Installation................................. 9B-24

Turn Signal and Hazard Warning Relay

Inspection........................................................ 9B-25

License Light Assembly Removal and

Installation ....................................................... 9B-25

Front Fog Light Assembly Removal and

Installation (If Equipped) ................................. 9B-26

Front Fog Light Switch Inspection (If

Equipped)........................................................ 9B-26

Front Fog Light Aiming Adjustment with

Screen (If Equipped) ....................................... 9B-26

Rear Fog Light Switch Inspection (If

Equipped)........................................................ 9B-27

Headlight Manual Levering Switch Inspection

(If Equipped) ................................................... 9B-28

Headlight Leveling Actuator Inspection (If

Equipped)........................................................ 9B-28

Height Sensor Removal and Installation (If

Equipped)........................................................ 9B-29

Height Sensor and Its Circuit Inspection (If

Equipped)........................................................ 9B-30

Headlight Leveling Control Module Removal

and Installation (If Equipped) .......................... 9B-30

Initialization of Headlight Auto Leveling

System ............................................................ 9B-30

Auto-On Headlight Sensor Inspection (If

Equipped)........................................................ 9B-31

Illumination Cancel Switch Inspection (If

Equipped)........................................................ 9B-32

Tail Light Relay, Headlight Relay, Front Fog

Light Relay Inspection (If Equipped) ............... 9B-32

Specifications..................................................... 9B-33

Tightening Torque Specifications ...................... 9B-33

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions........................................................... 9C-1

Precautions in Diagnosing Troubles for

Combination Meter............................................ 9C-1

General Description ............................................. 9C-1

CAN Communication System Description........... 9C-1Auto Volume Control System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4

Combination Meter Circuit Diagram ....................9C-4

Component Location ...........................................9C-5

Audio System Component Location ....................9C-5

Diagnostic Information and Procedures ............9C-6

Speedometer and VSS Symptom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis ..........................................9C-6

Fuel Meter Symptom Diagnosis ..........................9C-6

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom

Diagnosis ..........................................................9C-7

Brake and Parking Brake Warning Light

Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis ....9C-8

A/T Shift Position Indicator Symptom

Diagnosis (A/T Model).......................................9C-8

Charge Warning Light Symptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom

Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Symptom Diagnosis ......9C-9

Cigarette Lighter Symptom Diagnosis (If

Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If

Equipped) ........................................................9C-10

Clock System Diagnosis (If Equipped) ..............9C-11

Audio System Symptom Diagnosis (If

Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom

Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-13

Repair Instructions ............................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-14

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Removal and Installation ..9C-15

Oil Pressure Switch Inspection .........................9C-15

Engine Coolant Temperature (ECT) Sensor

Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspection.......................9C-16

Door Switch (Front / Rear Door) Inspection ......9C-16

Rear End Door Switch Inspection .....................9C-16

Outside Air Temperature Sensor Removal

and Installation (If Equipped) ..........................9C-17

Outside Air Temperature Sensor Inspection

(If Equipped)....................................................9C-17

Instrument Panel Removal and Installation.......9C-17

Information Display (Clock) Removal and

Installation .......................................................9C-18

Audio Unit Removal and Installation (If

Equipped) ........................................................9C-19

Page 1168 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-1 Wiring Systems:

Body, Cab and Accessories

Wiring Systems

Precautions

Cautions in Body Electrical System ServicingS6RW0D9100001

When servicing the electric systems, observe the cautions described in “Air Bag Warning in Section 00” to protect

electrical parts and to prevent a fire.

General Description

AbbreviationsS6RW0D9101001

Refer to the “Abbreviations in Section 0A” for the general abbreviations.

ESP

® is a registered trademark of Daimler Chrysler AG.

Wire / Connector Color SymbolsS6RW0D9101002

Refer to “Wire Color Symbols in Section 0A”. Abbreviation Full term Abbreviation Full term

2WD 2 wheel drive vehicles J/B Junction block

4WD 4 wheel drive vehicles J/C Joint connector

A/B Air bag KLS Keyless start system

ACC Accessory L Left

CAN Controller area network LED Light emitting diode

COMB Combination LHD Left hand drive vehicle

DSL Diesel engine LO Low

ELCM EVAP leak check module OCV Oil control valve

ESP

®Electronic stability program P/N Power normal

FWD Forward R Right

HI High RHD Right hand drive vehicle

IF EQPD If equipped ST Starter

IG COIL Ignition coil TPMS Tire pressure monitoring system

ILL Illumination VIM Valiable intake manifold

IND Indicator VSV Vacuum switching valve

INT Intermittent 5 dr 5 door

Page 1169 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-2

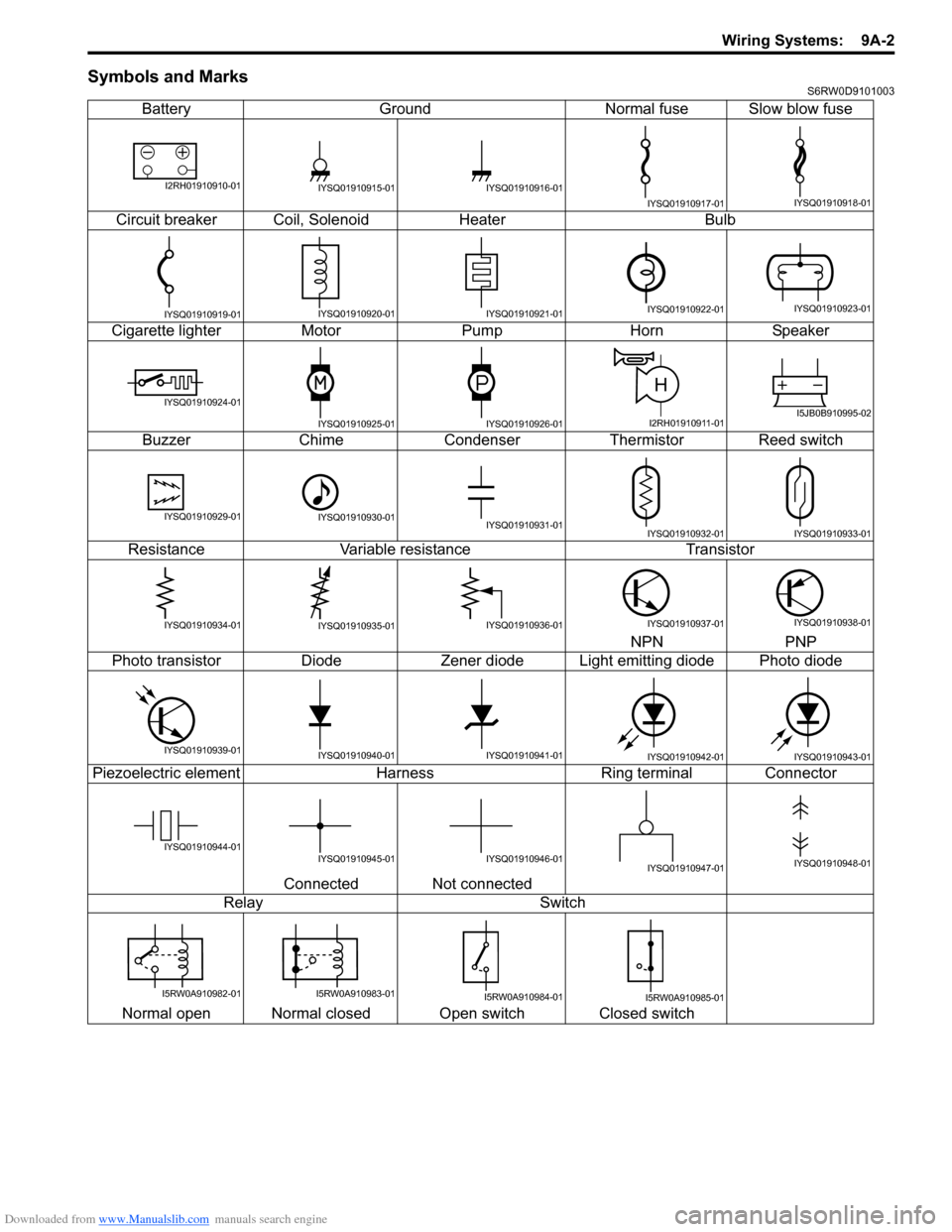

Symbols and MarksS6RW0D9101003

Battery Ground Normal fuse Slow blow fuse

Circuit breaker Coil, Solenoid Heater Bulb

Cigarette lighter Motor Pump Horn Speaker

Buzzer Chime Condenser Thermistor Reed switch

Resistance Variable resistance Transistor

NPN PNP

Photo transistor Diode Zener diode Light emitting diode Photo diode

Piezoelectric element Harness Ring terminal Connector

Connected Not connected

Relay Switch

Normal open Normal closed Open switch Closed switch

I2RH01910910-01IYSQ01910915-01IYSQ01910916-01

IYSQ01910917-01IYSQ01910918-01

IYSQ01910919-01IYSQ01910920-01IYSQ01910921-01IYSQ01910922-01IYSQ01910923-01

IYSQ01910924-01

IYSQ01910925-01IYSQ01910926-01

H

I2RH01910911-01I5JB0B910995-02

IYSQ01910929-01IYSQ01910930-01IYSQ01910931-01IYSQ01910932-01IYSQ01910933-01

IYSQ01910934-01IYSQ01910935-01IYSQ01910936-01IYSQ01910937-01IYSQ01910938-01

IYSQ01910939-01IYSQ01910940-01IYSQ01910941-01IYSQ01910942-01IYSQ01910943-01

IYSQ01910944-01IYSQ01910945-01IYSQ01910946-01IYSQ01910947-01IYSQ01910948-01

I5RW0A910982-01I5RW0A910983-01I5RW0A910984-01I5RW0A910985-01

Page 1171 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-4

How to Read Connector Layout DiagramS6RW0D9101004

[A-1]: Harness symbol and corresponding harness name

A: Battery harness SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-4

How to Read Connector Layout DiagramS6RW0D9101004

[A-1]: Harness symbol and corresponding harness name

A: Battery harness](/img/20/7612/w960_7612-1170.png)

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-4

How to Read Connector Layout DiagramS6RW0D9101004

[A-1]: Harness symbol and corresponding harness name

A: Battery harness

B: A/C harness

C: Engine harness

D: Injector harness

E: Main harness, Oil pressure switch wire, Console wire

G: Instrument panel harness

J: Side door wire (Power window)

K: Interior light harness, Rear speaker wire, Roof wire

L: Floor harness, G sensor wire (Fuel pump harness)

M: Rear bumper harness

O: Rear end door harness

Q: Air bag/Pretensioner harness

R: (Fuel pump wire)

[A-2]: Connector Number

[B]: Ground point No.

12

11

[B][B]

Connector code

[A-1] [A-2]L 36

L13L15

R01 L14L12L11L10 L09 L36

R02 L24 L25 L33

L28 L20 L26 (TO O01)

{

L05

L16

L32 L19 L01 (TO G01)

L02 (TO E04)

L03 (TO E05) L42

R05 R04

L07 (TO K02)

I2RH01910901-01

Page 1174 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-7 Wiring Systems:

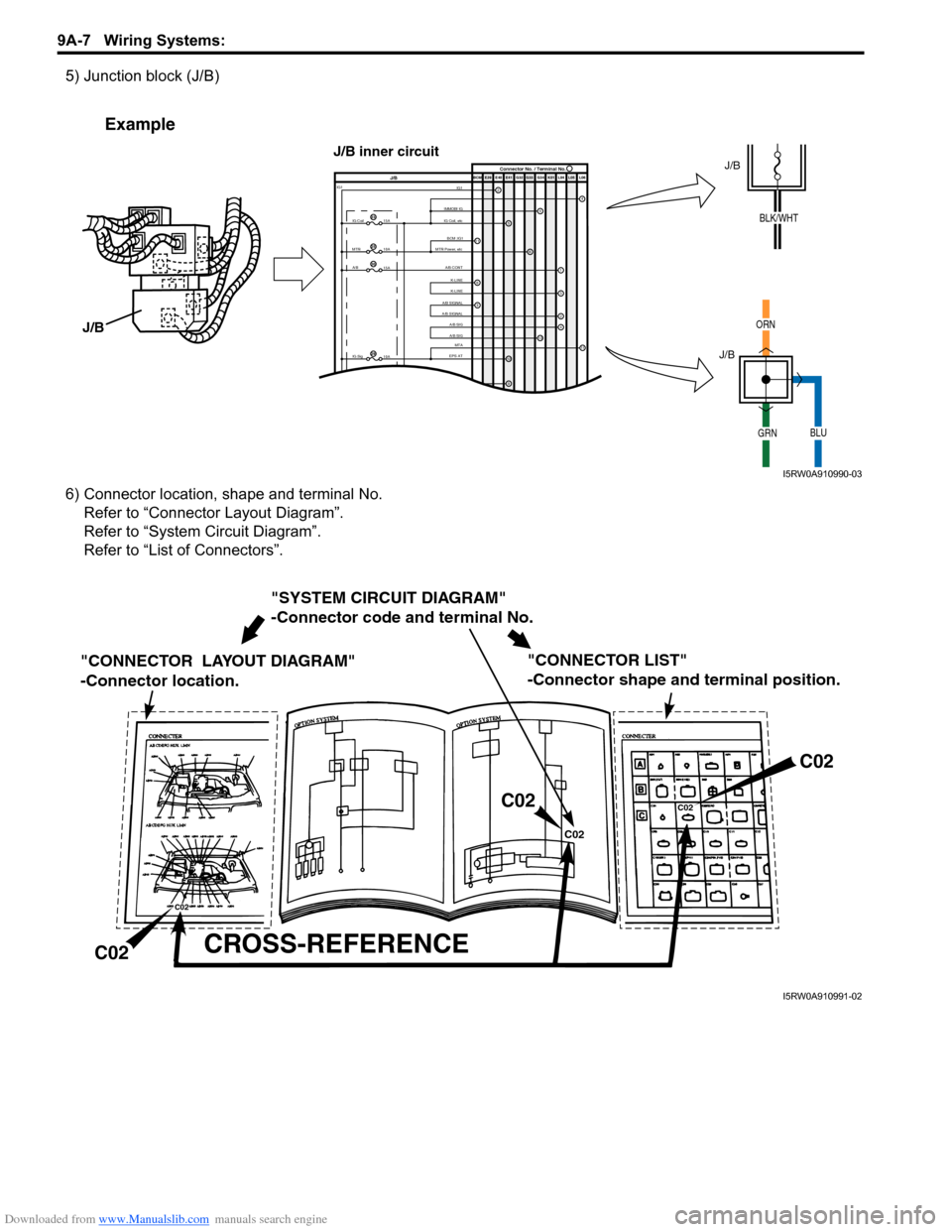

5) Junction block (J/B)

6) Connector location, shape and terminal No.

Refer to “Connector Layout Diagram”.

Refer to “System Circuit Diagram”.

Refer to “List of Connectors”.

IMMOBI IGIG1IG Coil, etcE39 E41E40 BCM G34G33 G32 K01 L04 L05 L06

IG Coil IG1

15A

MTR

10A

A/B

15A

2

65

13

J/BConnector No. / Terminal No.

BCM ;IG1

MTR Power, etc

A/B CONTK-LINE

K-LINE

A/B SIGNAL

A/B SIGNAL

A/B SIG

A/B SIG

IG Sig

10AEPS ATMTA

4

6

1

3

24

8

11

9

12

9

11

23

25

30

29

Example

J/B

J/B

ORN

GRNBLU

J/B

J/B inner circuit

BLK/WHT

I5RW0A910990-03

"SYSTEM CIRCUIT DIAGRAM"

-Connector code and terminal No.

"CONNECTOR LAYOUT DIAGRAM"

-Connector location.

CROSS-REFERENCE

"CONNECTOR LIST"

-Connector shape and terminal position.

C02

C02C02

C02

C02

C02

I5RW0A910991-02

Page 1178 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-11 Wiring Systems:

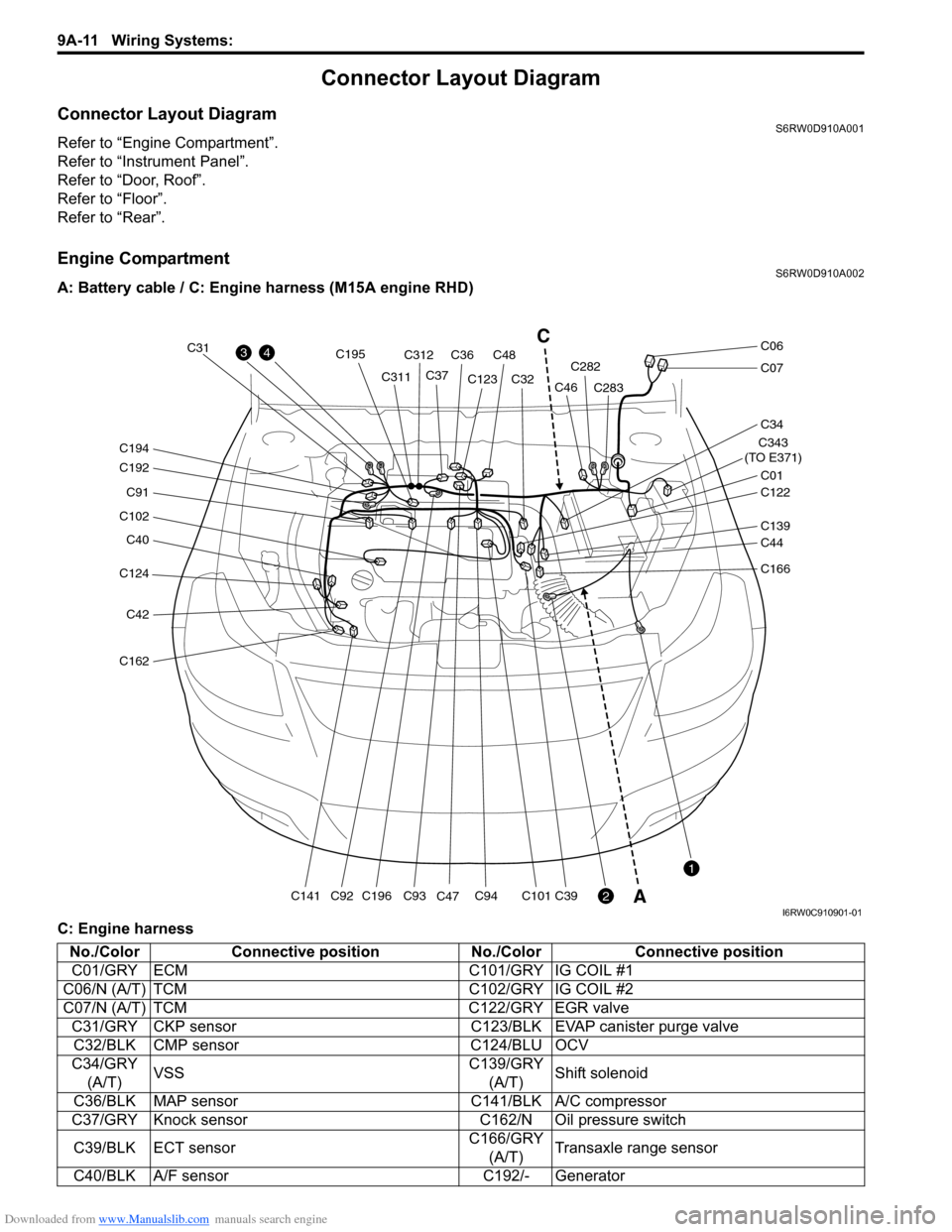

Connector Layout Diagram

Connector Layout DiagramS6RW0D910A001

Refer to “Engine Compartment”.

Refer to “Instrument Panel”.

Refer to “Door, Roof”.

Refer to “Floor”.

Refer to “Rear”.

Engine CompartmentS6RW0D910A002

A: Battery cable / C: Engine harness (M15A engine RHD)

C: Engine harness

C124

C40

C102

C91

C192

C194

C42

C162

C141C196

C195

C93C94C101C39C92

C31

C311C312

C36C48

C37C123

C47C32C282

C283

C343

(TO E371)

C01

C34

C07

C06

C122

C46

C139

C44

C166

43

2

1

C

A

I6RW0C910901-01

No./Color Connective position No./Color Connective position

C01/GRY ECM C101/GRY IG COIL #1

C06/N (A/T) TCM C102/GRY IG COIL #2

C07/N (A/T) TCM C122/GRY EGR valve

C31/GRY CKP sensor C123/BLK EVAP canister purge valve

C32/BLK CMP sensor C124/BLU OCV

C34/GRY

(A/T)VSSC139/GRY

(A/T)Shift solenoid

C36/BLK MAP sensor C141/BLK A/C compressor

C37/GRY Knock sensor C162/N Oil pressure switch

C39/BLK ECT sensorC166/GRY

(A/T)Transaxle range sensor

C40/BLK A/F sensor C192/- Generator

Page 1179 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-12

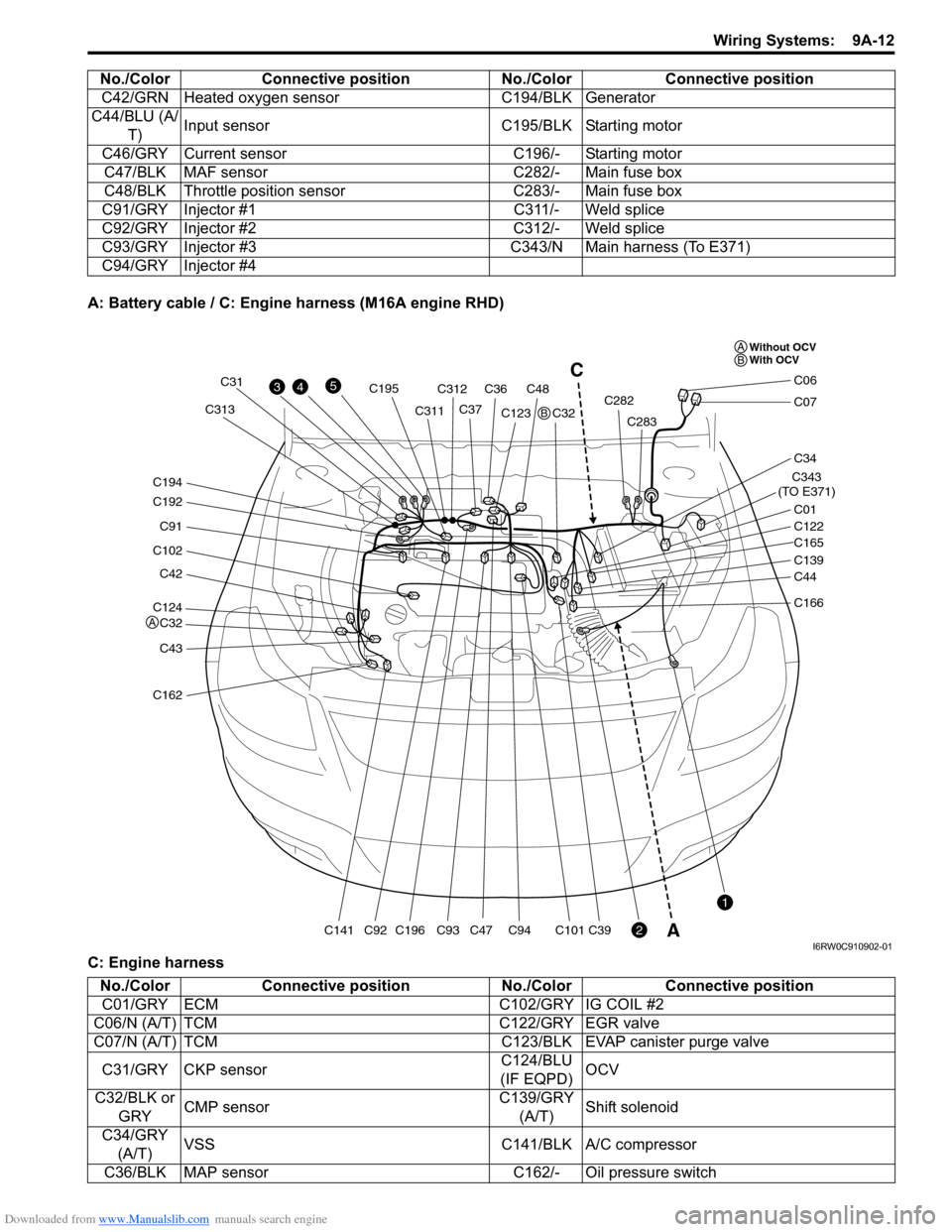

A: Battery cable / C: Engine harness (M16A engine RHD)

C: Engine harnessC42/GRN Heated oxygen sensor C194/BLK Generator

C44/BLU (A/

T)Input sensor C195/BLK Starting motor

C46/GRY Current sensor C196/- Starting motor

C47/BLK MAF sensor C282/- Main fuse box

C48/BLK Throttle position sensor C283/- Main fuse box

C91/GRY Injector #1 C311/- Weld splice

C92/GRY Injector #2 C312/- Weld splice

C93/GRY Injector #3 C343/N Main harness (To E371)

C94/GRY Injector #4 No./Color Connective position No./Color Connective position

C124

C32

C42

C102

C91

C192

C194

C43

C162

C141C196

C195

C93C94C101C39C92

C31

C311C313C312

C36C48

C37C123

C47C32C282

C283

C343

(TO E371)

C01

C34

C07

C06

C122

C165

C139

C44

C166

43

2

1

5C

A

Without OCV

With OCV A

A

B

B

I6RW0C910902-01

No./Color Connective position No./Color Connective position

C01/GRY ECM C102/GRY IG COIL #2

C06/N (A/T) TCM C122/GRY EGR valve

C07/N (A/T) TCM C123/BLK EVAP canister purge valve

C31/GRY CKP sensorC124/BLU

(IF EQPD)OCV

C32/BLK or

GRYCMP sensorC139/GRY

(A/T)Shift solenoid

C34/GRY

(A/T)VSS C141/BLK A/C compressor

C36/BLK MAP sensor C162/- Oil pressure switch

Page 1180 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-13 Wiring Systems:

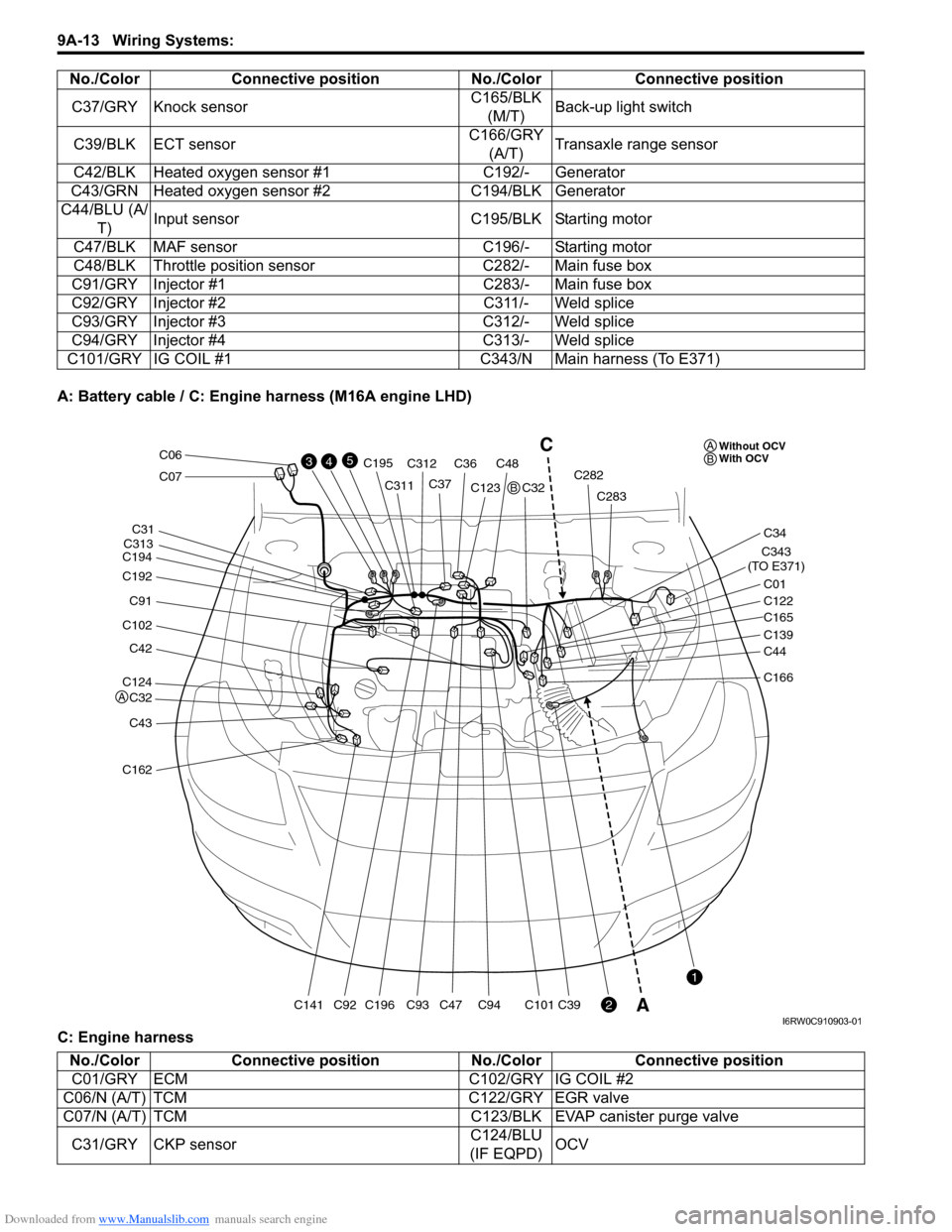

A: Battery cable / C: Engine harness (M16A engine LHD)

C: Engine harnessC37/GRY Knock sensorC165/BLK

(M/T)Back-up light switch

C39/BLK ECT sensorC166/GRY

(A/T)Transaxle range sensor

C42/BLK Heated oxygen sensor #1 C192/- Generator

C43/GRN Heated oxygen sensor #2 C194/BLK Generator

C44/BLU (A/

T)Input sensor C195/BLK Starting motor

C47/BLK MAF sensor C196/- Starting motor

C48/BLK Throttle position sensor C282/- Main fuse box

C91/GRY Injector #1 C283/- Main fuse box

C92/GRY Injector #2 C311/- Weld splice

C93/GRY Injector #3 C312/- Weld splice

C94/GRY Injector #4 C313/- Weld splice

C101/GRY IG COIL #1 C343/N Main harness (To E371)No./Color Connective position No./Color Connective position

C124

C32

C42

C102

C91

C192

C194

C43

C162

C141C196

C195

C93C94C101C39C92

C31

C311

C313C312

C36C48

C37C123

C47C32C282

C283

C343

(TO E371)

C01

C34

C07

C06

C122

C165

C139

C44

C166

43

2

1

5C

AWithout OCV

With OCV A

A

B

B

I6RW0C910903-01

No./Color Connective position No./Color Connective position

C01/GRY ECM C102/GRY IG COIL #2

C06/N (A/T) TCM C122/GRY EGR valve

C07/N (A/T) TCM C123/BLK EVAP canister purge valve

C31/GRY CKP sensorC124/BLU

(IF EQPD)OCV