ECU SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 274 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-6 Engine Electrical Devices:

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from APP sensor assembly.

3) Remove APP sensor assembly from its bracket.

Installation

Reverse removal procedure for installation noting the

following.

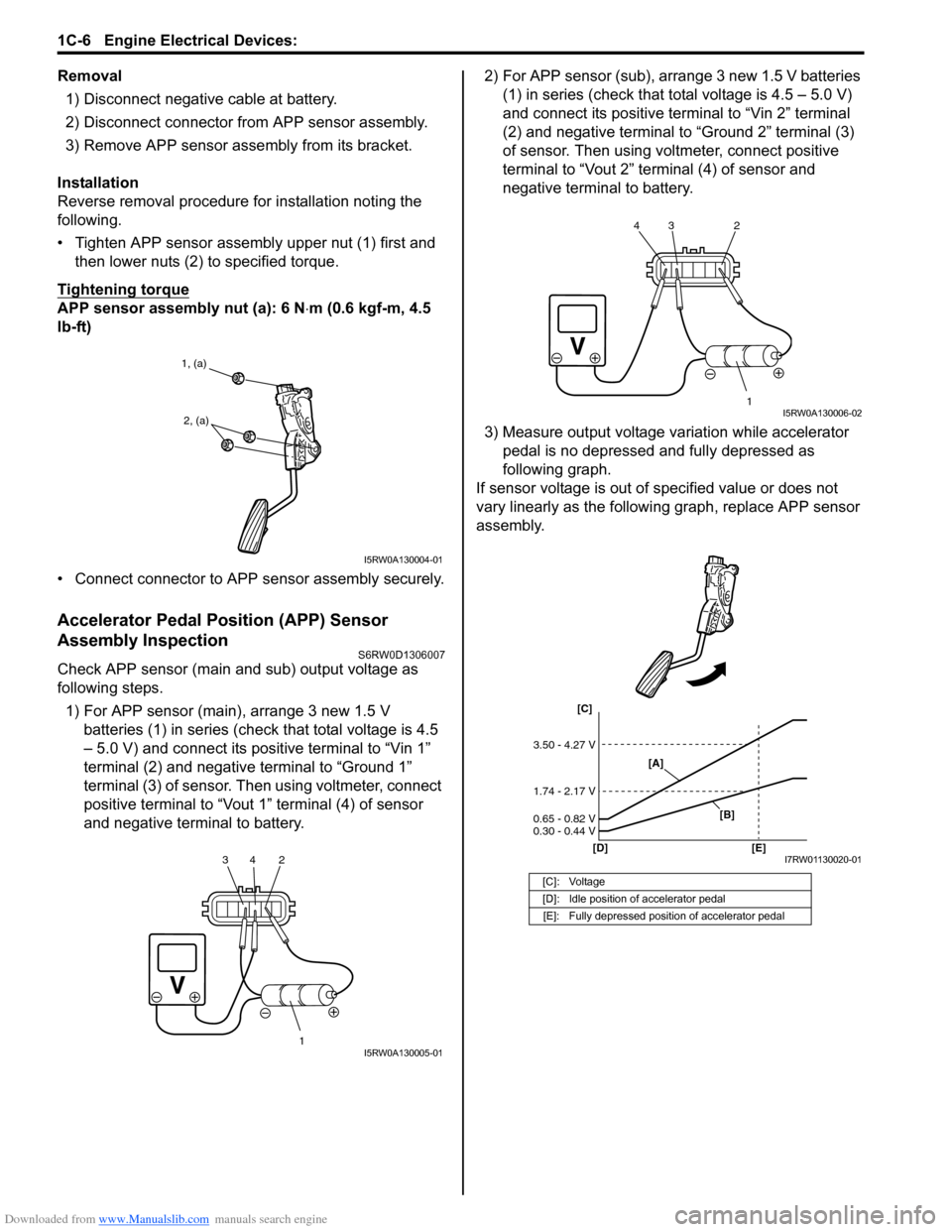

• Tighten APP sensor assembly upper nut (1) first and

then lower nuts (2) to specified torque.

Tightening torque

APP sensor assembly nut (a): 6 N⋅m (0.6 kgf-m, 4.5

lb-ft)

• Connect connector to APP sensor assembly securely.

Accelerator Pedal Position (APP) Sensor

Assembly Inspection

S6RW0D1306007

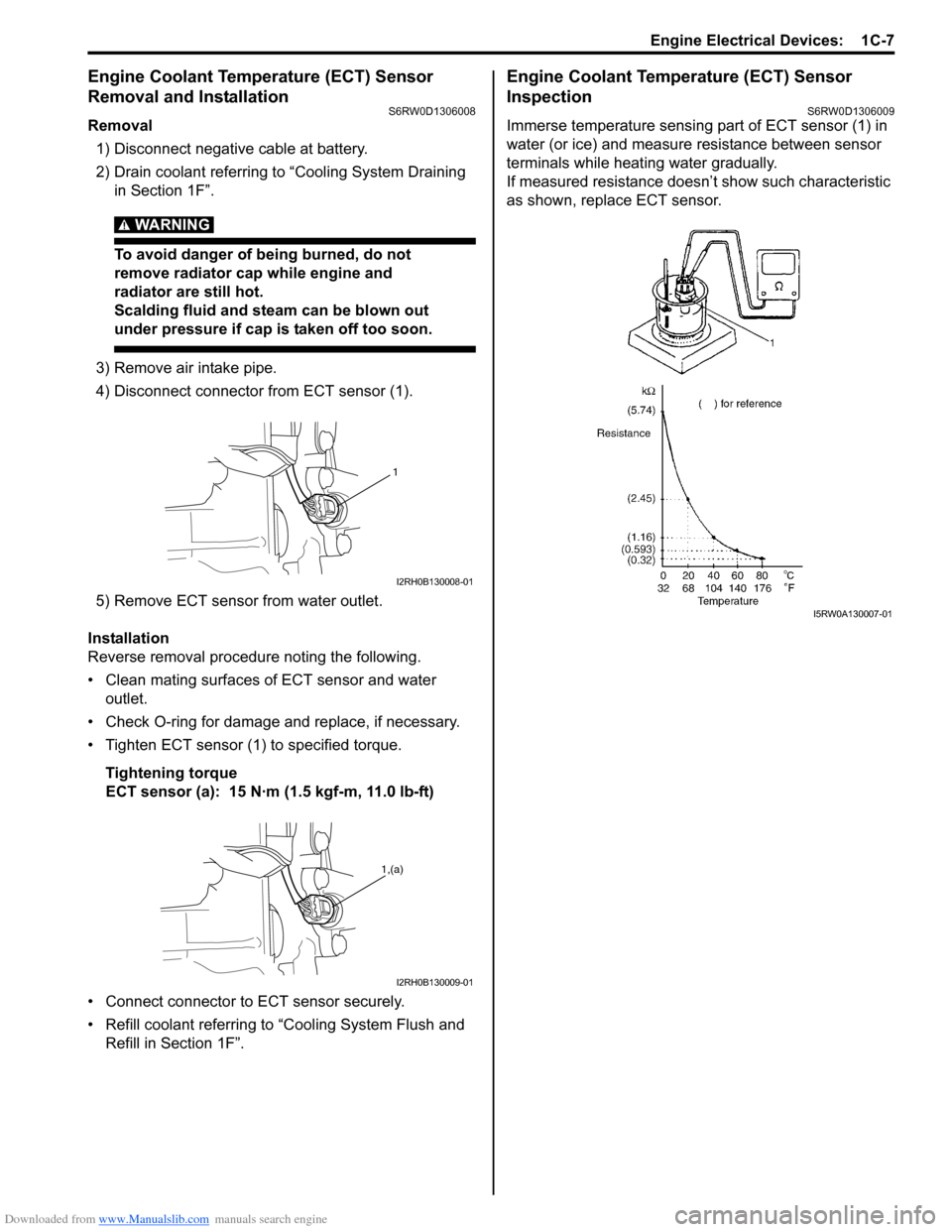

Check APP sensor (main and sub) output voltage as

following steps.

1) For APP sensor (main), arrange 3 new 1.5 V

batteries (1) in series (check that total voltage is 4.5

– 5.0 V) and connect its positive terminal to “Vin 1”

terminal (2) and negative terminal to “Ground 1”

terminal (3) of sensor. Then using voltmeter, connect

positive terminal to “Vout 1” terminal (4) of sensor

and negative terminal to battery.2) For APP sensor (sub), arrange 3 new 1.5 V batteries

(1) in series (check that total voltage is 4.5 – 5.0 V)

and connect its positive terminal to “Vin 2” terminal

(2) and negative terminal to “Ground 2” terminal (3)

of sensor. Then using voltmeter, connect positive

terminal to “Vout 2” terminal (4) of sensor and

negative terminal to battery.

3) Measure output voltage variation while accelerator

pedal is no depressed and fully depressed as

following graph.

If sensor voltage is out of specified value or does not

vary linearly as the following graph, replace APP sensor

assembly.

1, (a)

2, (a)

I5RW0A130004-01

1 2 34I5RW0A130005-01

[C]: Voltage

[D]: Idle position of accelerator pedal

[E]: Fully depressed position of accelerator pedal

1 2 3 4I5RW0A130006-02

[C]

[D] [E]

3.50 - 4.27 V

1.74 - 2.17 V

0.65 - 0.82 V

0.30 - 0.44 V

[A]

[B]

I7RW01130020-01

Page 275 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-7

Engine Coolant Temperature (ECT) Sensor

Removal and Installation

S6RW0D1306008

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining

in Section 1F”.

WARNING!

To avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot.

Scalding fluid and steam can be blown out

under pressure if cap is taken off too soon.

3) Remove air intake pipe.

4) Disconnect connector from ECT sensor (1).

5) Remove ECT sensor from water outlet.

Installation

Reverse removal procedure noting the following.

• Clean mating surfaces of ECT sensor and water

outlet.

• Check O-ring for damage and replace, if necessary.

• Tighten ECT sensor (1) to specified torque.

Tightening torque

ECT sensor (a): 15 N·m (1.5 kgf-m, 11.0 lb-ft)

• Connect connector to ECT sensor securely.

• Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

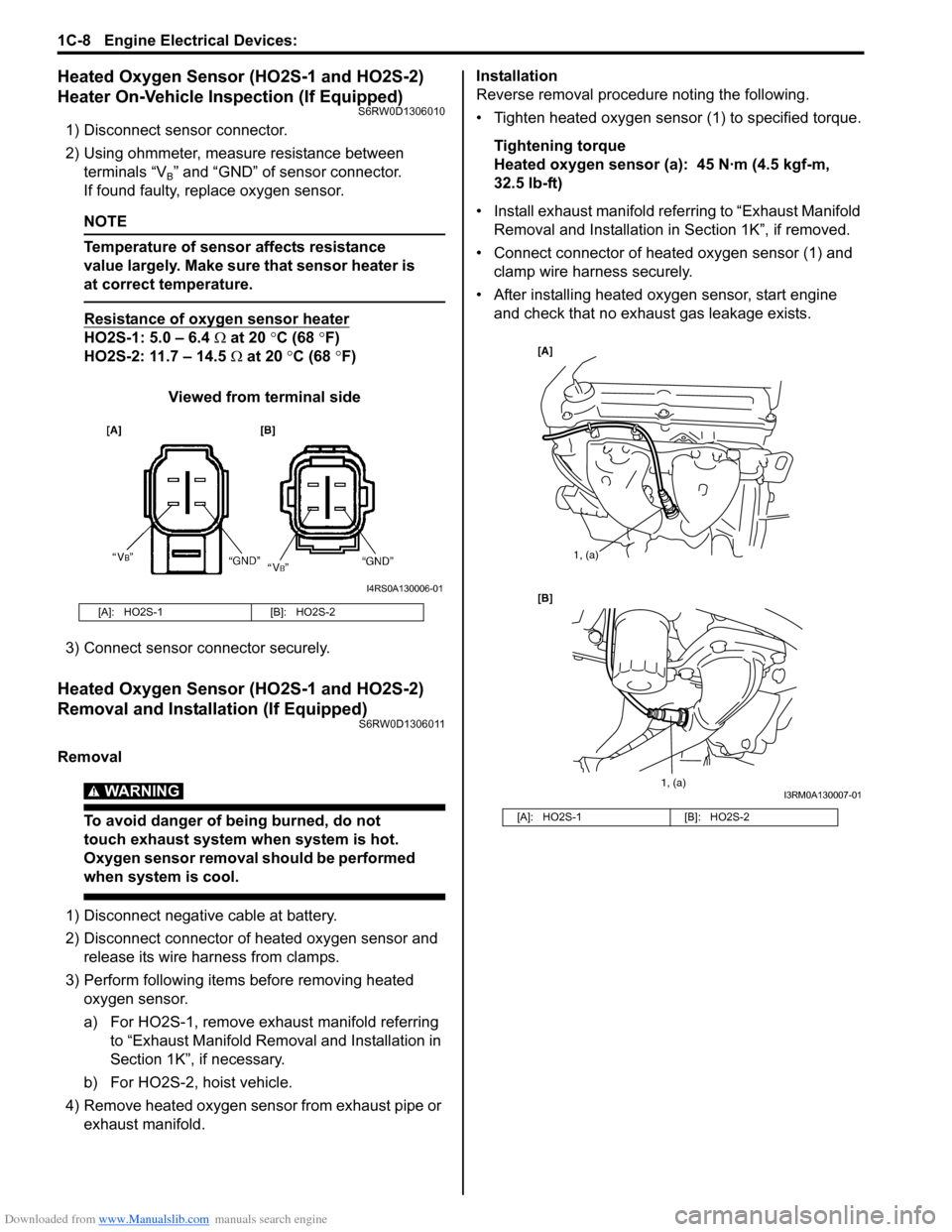

Engine Coolant Temperature (ECT) Sensor

Inspection

S6RW0D1306009

Immerse temperature sensing part of ECT sensor (1) in

water (or ice) and measure resistance between sensor

terminals while heating water gradually.

If measured resistance doesn’t show such characteristic

as shown, replace ECT sensor.

1

I2RH0B130008-01

1,(a)

I2RH0B130009-01

I5RW0A130007-01

Page 276 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-8 Engine Electrical Devices:

Heated Oxygen Sensor (HO2S-1 and HO2S-2)

Heater On-Vehicle Inspection (If Equipped)

S6RW0D1306010

1) Disconnect sensor connector.

2) Using ohmmeter, measure resistance between

terminals “V

B” and “GND” of sensor connector.

If found faulty, replace oxygen sensor.

NOTE

Temperature of sensor affects resistance

value largely. Make sure that sensor heater is

at correct temperature.

Resistance of oxygen sensor heater

HO2S-1: 5.0 – 6.4 Ω at 20 °C (68 °F)

HO2S-2: 11.7 – 14.5 Ω at 20 °C (68 °F)

Viewed from terminal side

3) Connect sensor connector securely.

Heated Oxygen Sensor (HO2S-1 and HO2S-2)

Removal and Installation (If Equipped)

S6RW0D1306011

Removal

WARNING!

To avoid danger of being burned, do not

touch exhaust system when system is hot.

Oxygen sensor removal should be performed

when system is cool.

1) Disconnect negative cable at battery.

2) Disconnect connector of heated oxygen sensor and

release its wire harness from clamps.

3) Perform following items before removing heated

oxygen sensor.

a) For HO2S-1, remove exhaust manifold referring

to “Exhaust Manifold Removal and Installation in

Section 1K”, if necessary.

b) For HO2S-2, hoist vehicle.

4) Remove heated oxygen sensor from exhaust pipe or

exhaust manifold.Installation

Reverse removal procedure noting the following.

• Tighten heated oxygen sensor (1) to specified torque.

Tightening torque

Heated oxygen sensor (a): 45 N·m (4.5 kgf-m,

32.5 lb-ft)

• Install exhaust manifold referring to “Exhaust Manifold

Removal and Installation in Section 1K”, if removed.

• Connect connector of heated oxygen sensor (1) and

clamp wire harness securely.

• After installing heated oxygen sensor, start engine

and check that no exhaust gas leakage exists.

[A]: HO2S-1 [B]: HO2S-2

I4RS0A130006-01

[A]: HO2S-1 [B]: HO2S-2

[A]

[B]

1, (a)

1, (a)

I3RM0A130007-01

Page 277 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-9

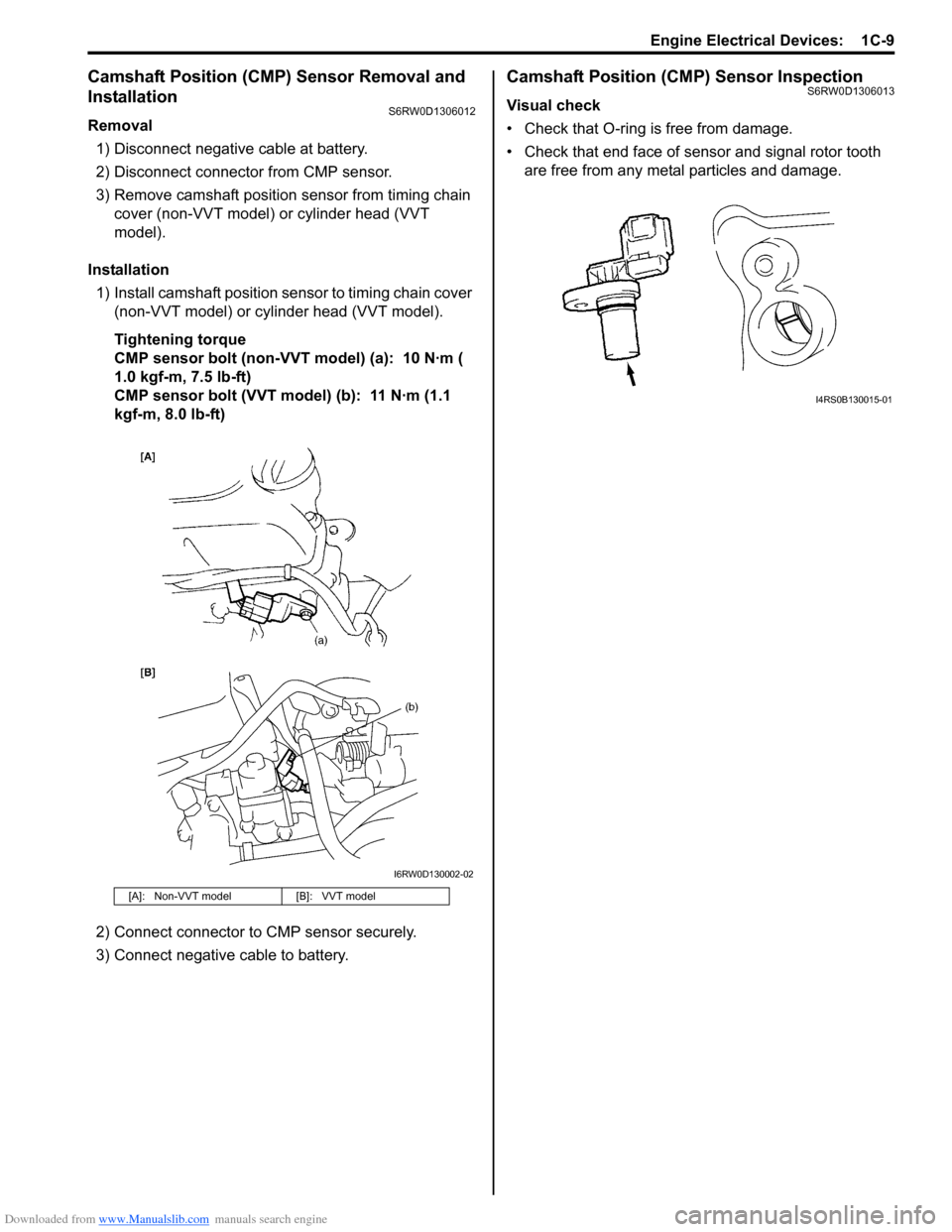

Camshaft Position (CMP) Sensor Removal and

Installation

S6RW0D1306012

Removal

1) Disconnect negative cable at battery.

2) Disconnect connector from CMP sensor.

3) Remove camshaft position sensor from timing chain

cover (non-VVT model) or cylinder head (VVT

model).

Installation

1) Install camshaft position sensor to timing chain cover

(non-VVT model) or cylinder head (VVT model).

Tightening torque

CMP sensor bolt (non-VVT model) (a): 10 N·m (

1.0 kgf-m, 7.5 lb-ft)

CMP sensor bolt (VVT model) (b): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

2) Connect connector to CMP sensor securely.

3) Connect negative cable to battery.

Camshaft Position (CMP) Sensor InspectionS6RW0D1306013

Visual check

• Check that O-ring is free from damage.

• Check that end face of sensor and signal rotor tooth

are free from any metal particles and damage.

[A]: Non-VVT model [B]: VVT model

I6RW0D130002-02

I4RS0B130015-01

Page 278 of 1556

Downloaded from www.Manualslib.com manuals search engine 1C-10 Engine Electrical Devices:

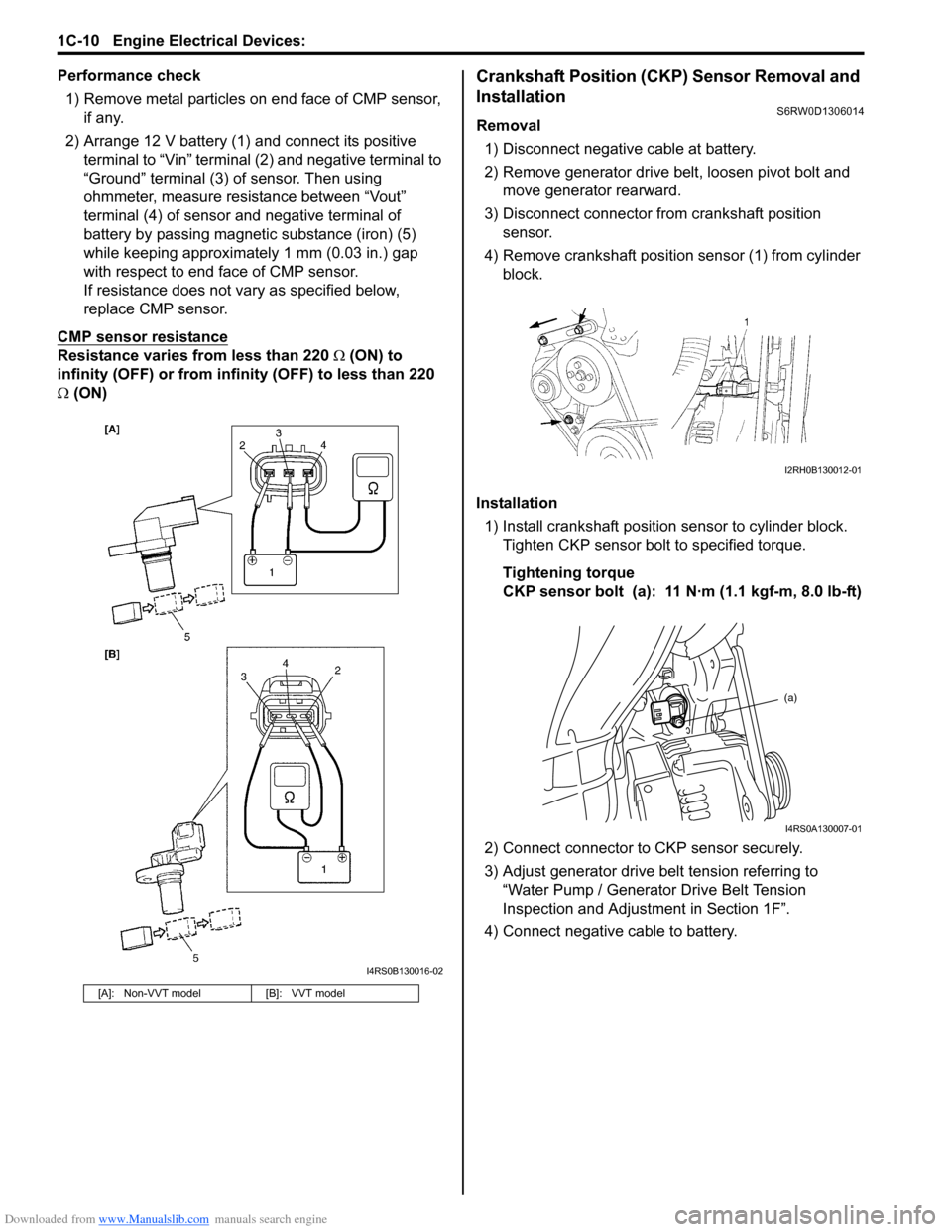

Performance check

1) Remove metal particles on end face of CMP sensor,

if any.

2) Arrange 12 V battery (1) and connect its positive

terminal to “Vin” terminal (2) and negative terminal to

“Ground” terminal (3) of sensor. Then using

ohmmeter, measure resistance between “Vout”

terminal (4) of sensor and negative terminal of

battery by passing magnetic substance (iron) (5)

while keeping approximately 1 mm (0.03 in.) gap

with respect to end face of CMP sensor.

If resistance does not vary as specified below,

replace CMP sensor.

CMP sensor resistance

Resistance varies from less than 220 Ω (ON) to

infinity (OFF) or from infinity (OFF) to less than 220

Ω (ON)

Crankshaft Position (CKP) Sensor Removal and

Installation

S6RW0D1306014

Removal

1) Disconnect negative cable at battery.

2) Remove generator drive belt, loosen pivot bolt and

move generator rearward.

3) Disconnect connector from crankshaft position

sensor.

4) Remove crankshaft position sensor (1) from cylinder

block.

Installation

1) Install crankshaft position sensor to cylinder block.

Tighten CKP sensor bolt to specified torque.

Tightening torque

CKP sensor bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

2) Connect connector to CKP sensor securely.

3) Adjust generator drive belt tension referring to

“Water Pump / Generator Drive Belt Tension

Inspection and Adjustment in Section 1F”.

4) Connect negative cable to battery.

[A]: Non-VVT model [B]: VVT model

I4RS0B130016-02

I2RH0B130012-01

(a)

I4RS0A130007-01

Page 281 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Electrical Devices: 1C-13

Mass Air Flow (MAF) and Intake Air

Temperature (IAT) Sensor Removal and

Installation

S6RW0D1306019

CAUTION!

• Do not disassemble MAF and IAT sensor.

• Do not expose MAF and IAT sensor to any

shock.

• Do not clean MAF and IAT sensor.

• If MAF and IAT sensor has been dropped, it

should be replaced.

• Do not blow compressed air by using air

gun or the like.

• Do not put finger or any other object into

MAF and IAT sensor. Malfunction may

occur.

Removal

1) Disconnect negative cable at battery.

2) Disconnect MAF and IAT sensor connector.

3) Remove air cleaner case (1).

4) Remove MAF and IAT sensor (2) from air cleaner

case.

Installation

Reverse removal procedure noting the followings.

• Tighten MAF and IAT sensor screws to specified

torque.

Tightening torque

MAF and IAT sensor screw: 1.5 N·m (0.15 kgf-m,

1.1 lb-ft)

• Connect MAF and IAT sensor connector securely.

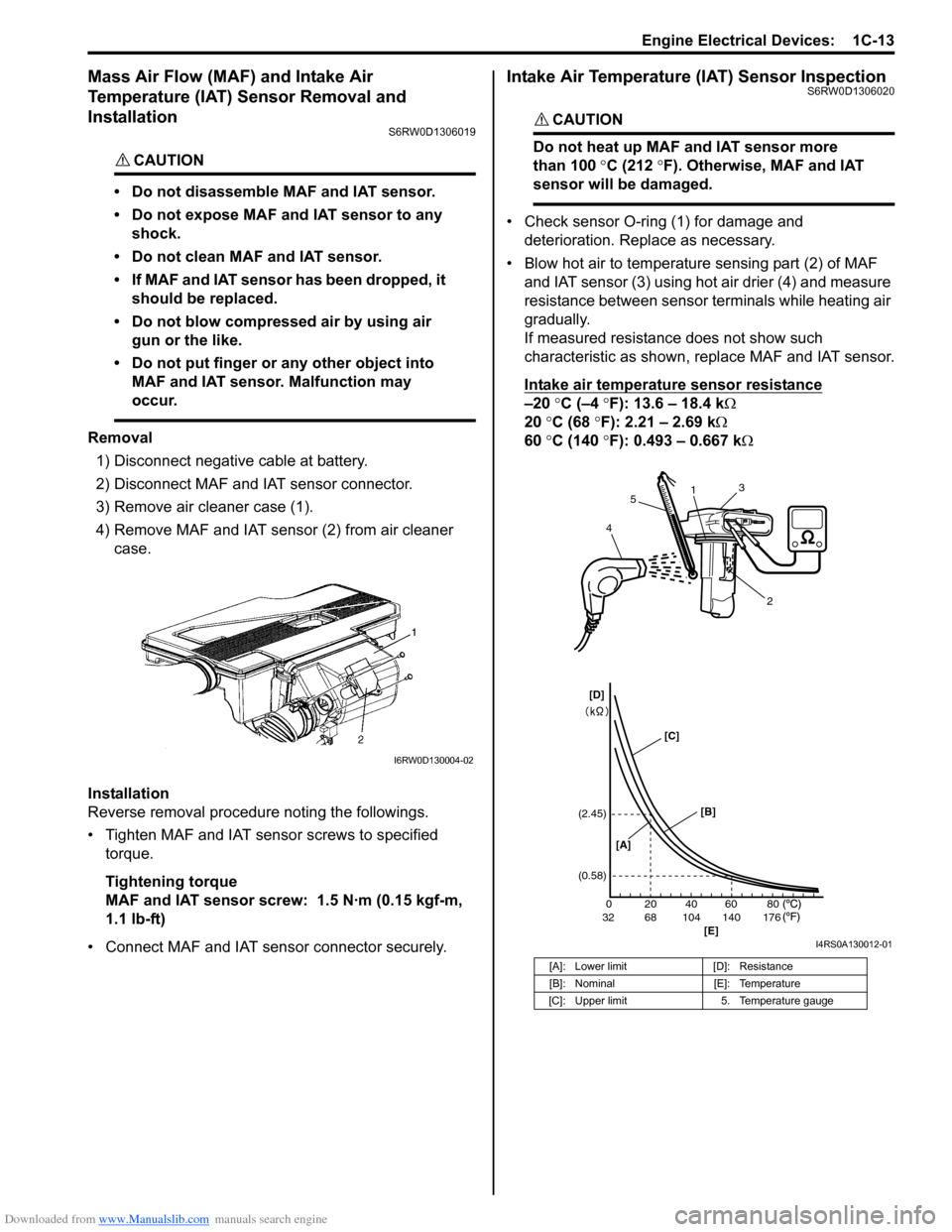

Intake Air Temperature (IAT) Sensor InspectionS6RW0D1306020

CAUTION!

Do not heat up MAF and IAT sensor more

than 100 °C (212 °F). Otherwise, MAF and IAT

sensor will be damaged.

• Check sensor O-ring (1) for damage and

deterioration. Replace as necessary.

• Blow hot air to temperature sensing part (2) of MAF

and IAT sensor (3) using hot air drier (4) and measure

resistance between sensor terminals while heating air

gradually.

If measured resistance does not show such

characteristic as shown, replace MAF and IAT sensor.

Intake air temperature sensor resistance

–20 °C (–4 °F): 13.6 – 18.4 kΩ

20 °C (68 °F): 2.21 – 2.69 kΩ

60 °C (140 °F): 0.493 – 0.667 kΩ

I6RW0D130004-02

[A]: Lower limit [D]: Resistance

[B]: Nominal [E]: Temperature

[C]: Upper limit 5. Temperature gauge

20 0

68 32 104 140 17640 60 80 (2.45)

(0.58)

1

2 3

45

[A][B]

[E] [C] [D]

I4RS0A130012-01

Page 286 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-4 Engine Mechanical:

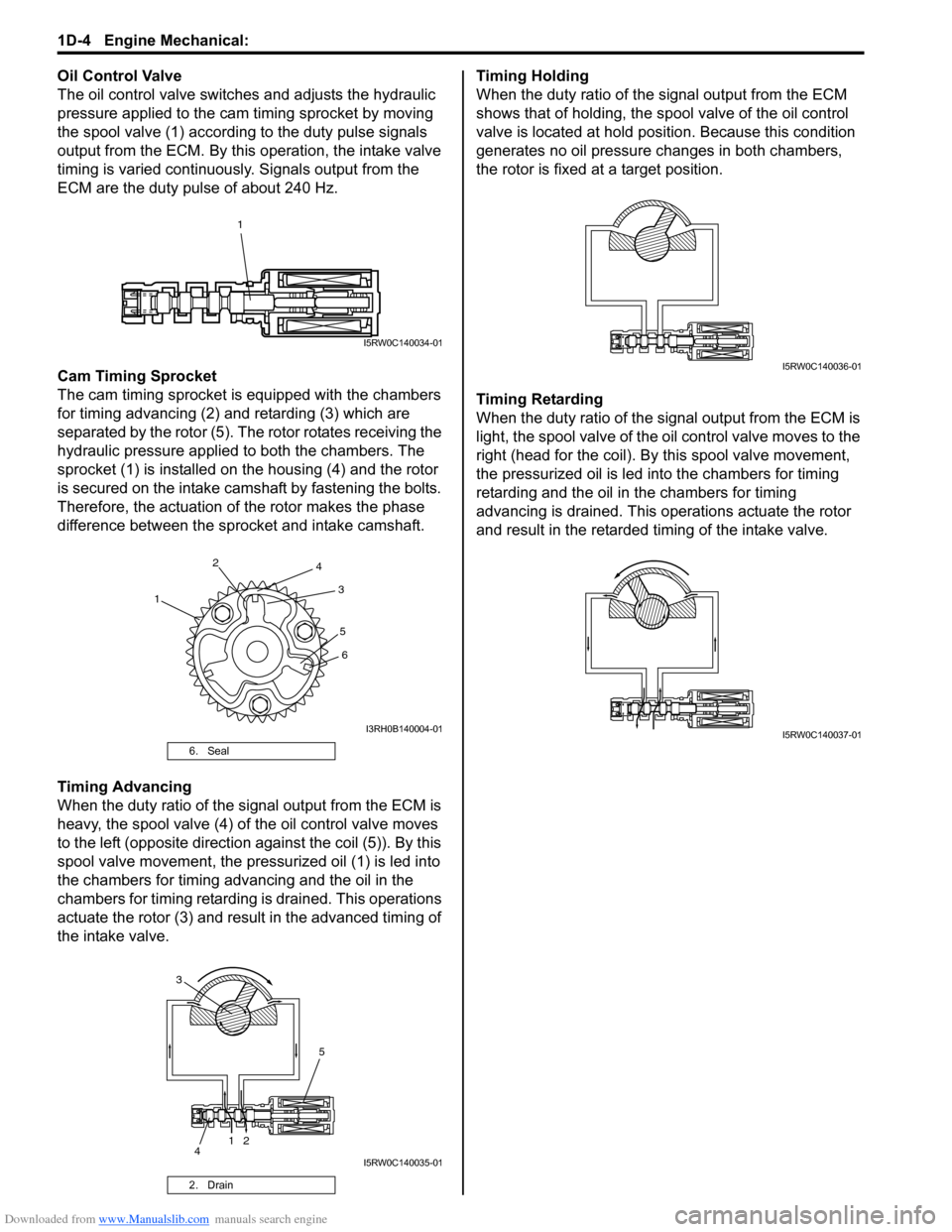

Oil Control Valve

The oil control valve switches and adjusts the hydraulic

pressure applied to the cam timing sprocket by moving

the spool valve (1) according to the duty pulse signals

output from the ECM. By this operation, the intake valve

timing is varied continuously. Signals output from the

ECM are the duty pulse of about 240 Hz.

Cam Timing Sprocket

The cam timing sprocket is equipped with the chambers

for timing advancing (2) and retarding (3) which are

separated by the rotor (5). The rotor rotates receiving the

hydraulic pressure applied to both the chambers. The

sprocket (1) is installed on the housing (4) and the rotor

is secured on the intake camshaft by fastening the bolts.

Therefore, the actuation of the rotor makes the phase

difference between the sprocket and intake camshaft.

Timing Advancing

When the duty ratio of the signal output from the ECM is

heavy, the spool valve (4) of the oil control valve moves

to the left (opposite direction against the coil (5)). By this

spool valve movement, the pressurized oil (1) is led into

the chambers for timing advancing and the oil in the

chambers for timing retarding is drained. This operations

actuate the rotor (3) and result in the advanced timing of

the intake valve.Timing Holding

When the duty ratio of the signal output from the ECM

shows that of holding, the spool valve of the oil control

valve is located at hold position. Because this condition

generates no oil pressure changes in both chambers,

the rotor is fixed at a target position.

Timing Retarding

When the duty ratio of the signal output from the ECM is

light, the spool valve of the oil control valve moves to the

right (head for the coil). By this spool valve movement,

the pressurized oil is led into the chambers for timing

retarding and the oil in the chambers for timing

advancing is drained. This operations actuate the rotor

and result in the retarded timing of the intake valve.

6. Seal

2. Drain

1

I5RW0C140034-01

12

3 4

5

6

I3RH0B140004-01

1

2

5

4

3

I5RW0C140035-01

I5RW0C140036-01

I5RW0C140037-01

Page 294 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-12 Engine Mechanical:

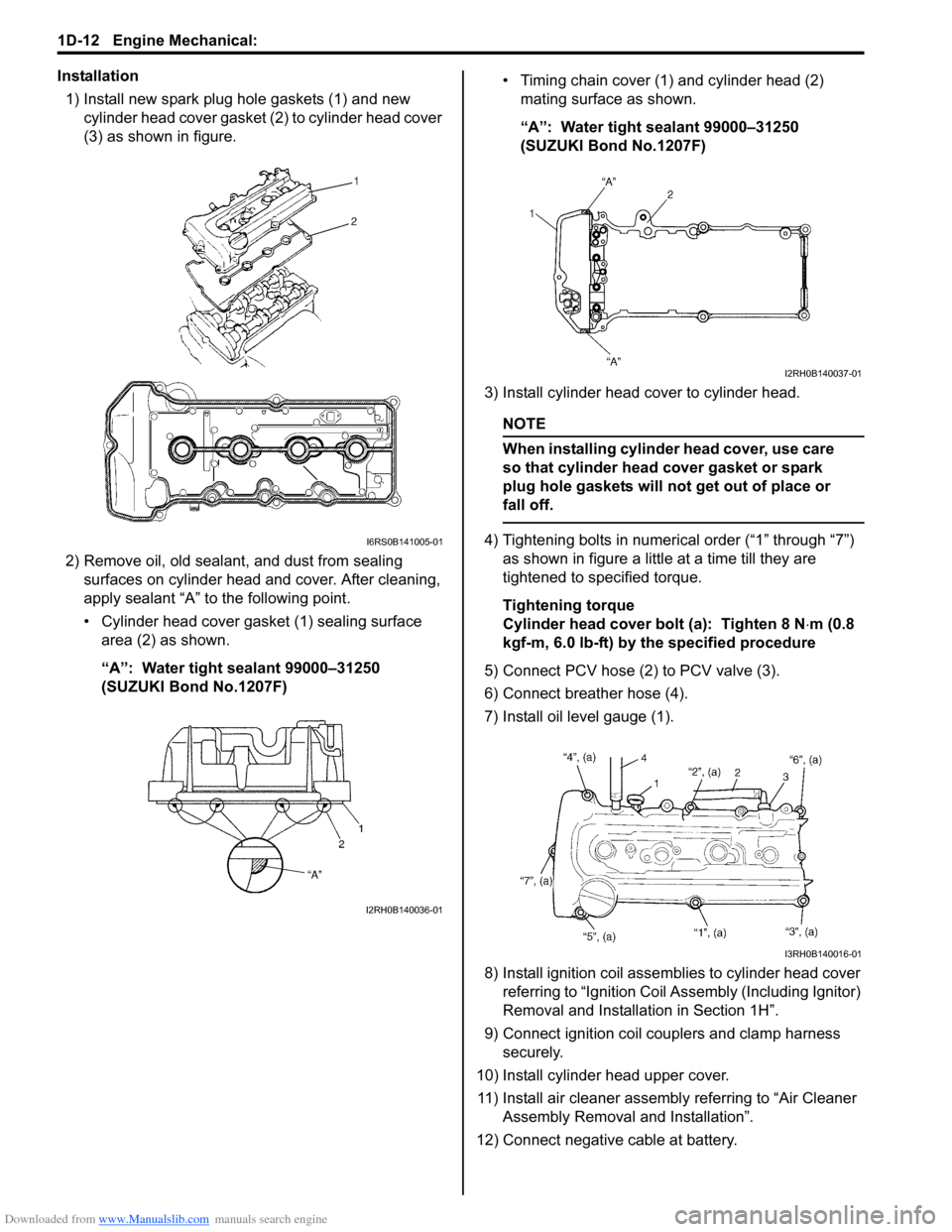

Installation

1) Install new spark plug hole gaskets (1) and new

cylinder head cover gasket (2) to cylinder head cover

(3) as shown in figure.

2) Remove oil, old sealant, and dust from sealing

surfaces on cylinder head and cover. After cleaning,

apply sealant “A” to the following point.

• Cylinder head cover gasket (1) sealing surface

area (2) as shown.

“A”: Water tight sealant 99000–31250

(SUZUKI Bond No.1207F)• Timing chain cover (1) and cylinder head (2)

mating surface as shown.

“A”: Water tight sealant 99000–31250

(SUZUKI Bond No.1207F)

3) Install cylinder head cover to cylinder head.

NOTE

When installing cylinder head cover, use care

so that cylinder head cover gasket or spark

plug hole gaskets will not get out of place or

fall off.

4) Tightening bolts in numerical order (“1” through “7”)

as shown in figure a little at a time till they are

tightened to specified torque.

Tightening torque

Cylinder head cover bolt (a): Tighten 8 N⋅m (0.8

kgf-m, 6.0 lb-ft) by the specified procedure

5) Connect PCV hose (2) to PCV valve (3).

6) Connect breather hose (4).

7) Install oil level gauge (1).

8) Install ignition coil assemblies to cylinder head cover

referring to “Ignition Coil Assembly (Including Ignitor)

Removal and Installation in Section 1H”.

9) Connect ignition coil couplers and clamp harness

securely.

10) Install cylinder head upper cover.

11) Install air cleaner assembly referring to “Air Cleaner

Assembly Removal and Installation”.

12) Connect negative cable at battery.I6RS0B141005-01

I2RH0B140036-01

I2RH0B140037-01

I3RH0B140016-01

Page 296 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-14 Engine Mechanical:

Throttle Body On-Vehicle InspectionS6RW0D1406006

Check electric throttle body assembly referring to

“Throttle Valve Operation Check” and “Electric Throttle

Body Assembly Operation Check” under “Electric

Throttle Body Assembly On-Vehicle Inspection in

Section 1C”.

Electric Throttle Body Assembly Removal and

Installation

S6RW0D1406047

CAUTION!

Never disassemble electric throttle body.

Disassembly will spoil its original

performance. If faulty condition is found,

replace it with new one.

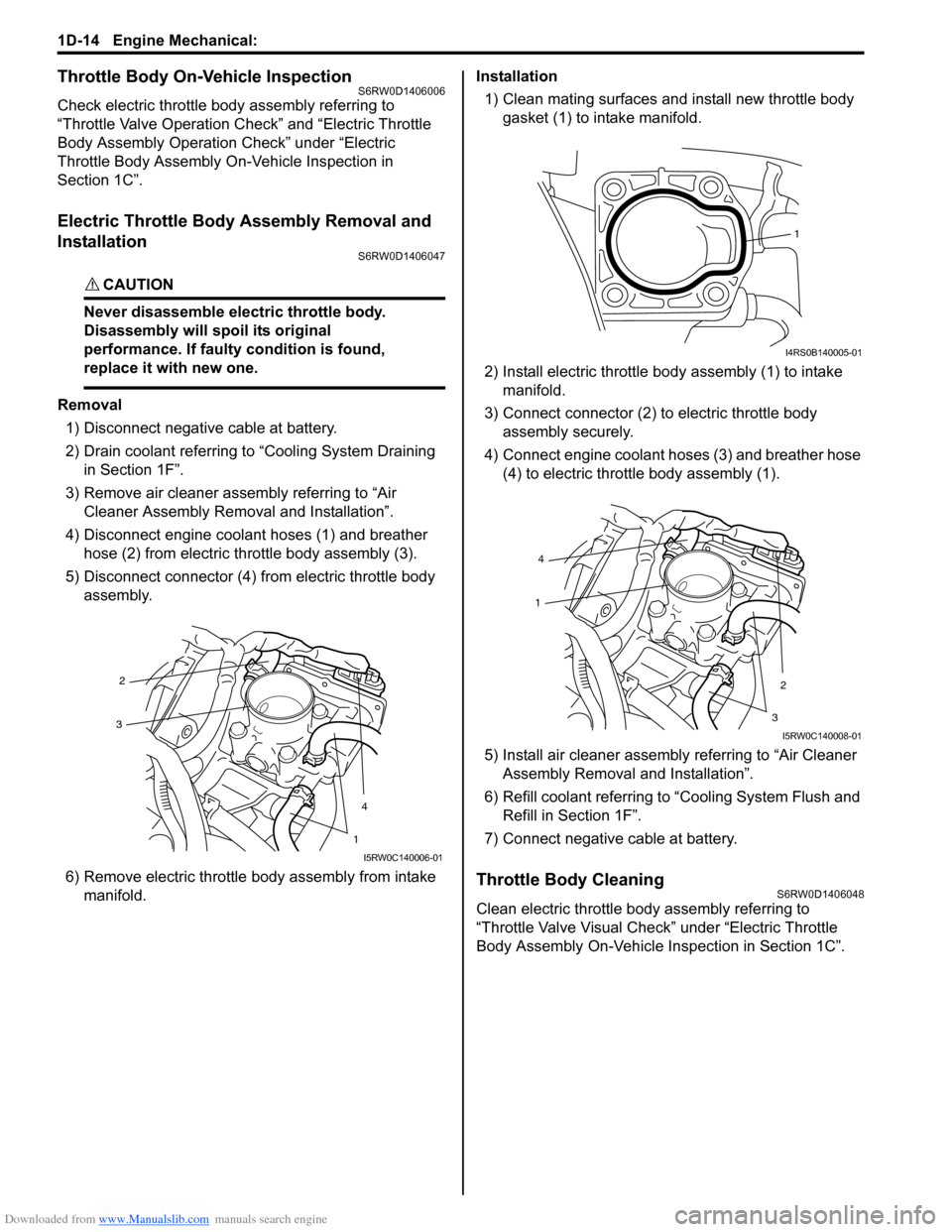

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining

in Section 1F”.

3) Remove air cleaner assembly referring to “Air

Cleaner Assembly Removal and Installation”.

4) Disconnect engine coolant hoses (1) and breather

hose (2) from electric throttle body assembly (3).

5) Disconnect connector (4) from electric throttle body

assembly.

6) Remove electric throttle body assembly from intake

manifold.Installation

1) Clean mating surfaces and install new throttle body

gasket (1) to intake manifold.

2) Install electric throttle body assembly (1) to intake

manifold.

3) Connect connector (2) to electric throttle body

assembly securely.

4) Connect engine coolant hoses (3) and breather hose

(4) to electric throttle body assembly (1).

5) Install air cleaner assembly referring to “Air Cleaner

Assembly Removal and Installation”.

6) Refill coolant referring to “Cooling System Flush and

Refill in Section 1F”.

7) Connect negative cable at battery.

Throttle Body CleaningS6RW0D1406048

Clean electric throttle body assembly referring to

“Throttle Valve Visual Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

2

4

3

1

I5RW0C140006-01

1

I4RS0B140005-01

4

2

1

3

I5RW0C140008-01

Page 306 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-24 Engine Mechanical:

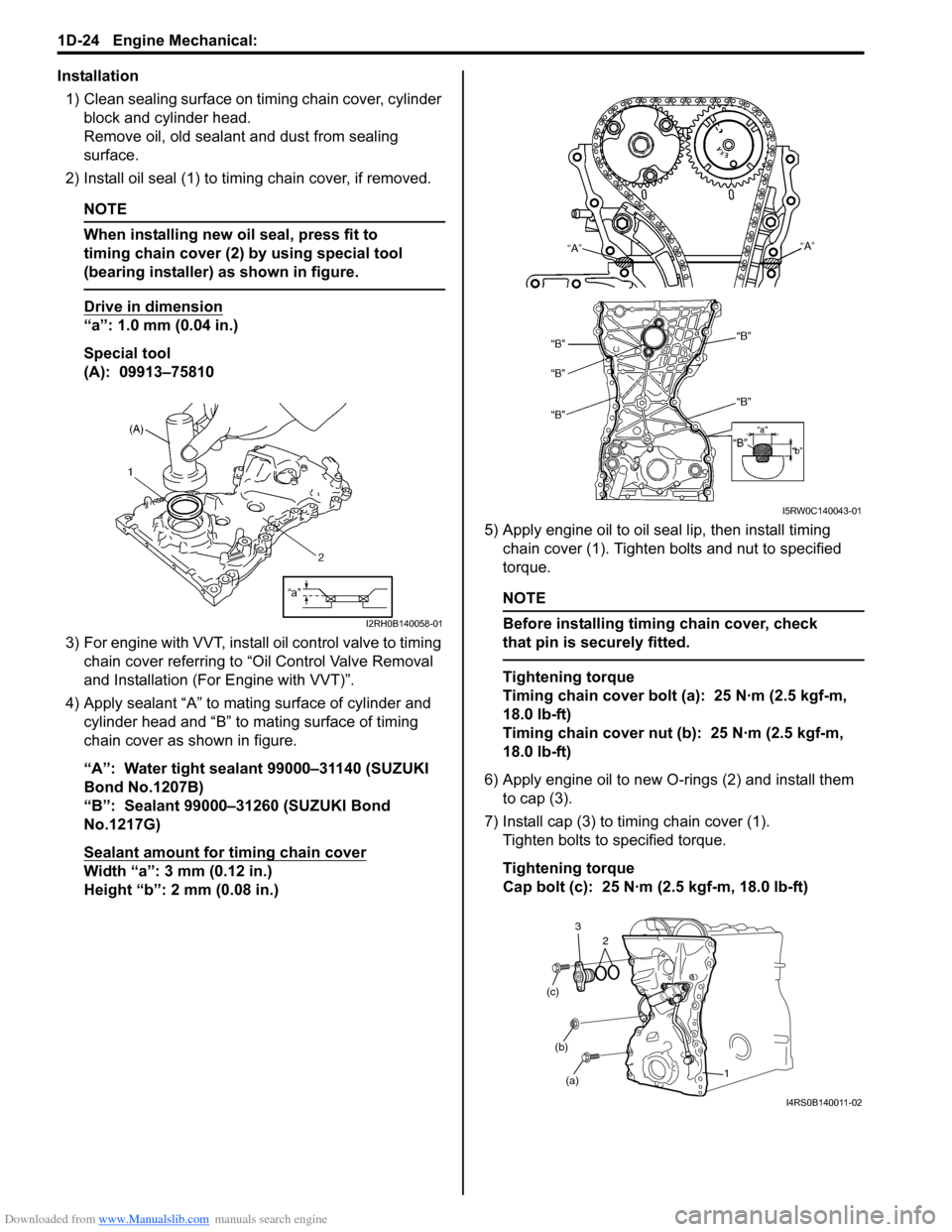

Installation

1) Clean sealing surface on timing chain cover, cylinder

block and cylinder head.

Remove oil, old sealant and dust from sealing

surface.

2) Install oil seal (1) to timing chain cover, if removed.

NOTE

When installing new oil seal, press fit to

timing chain cover (2) by using special tool

(bearing installer) as shown in figure.

Drive in dimension

“a”: 1.0 mm (0.04 in.)

Special tool

(A): 09913–75810

3) For engine with VVT, install oil control valve to timing

chain cover referring to “Oil Control Valve Removal

and Installation (For Engine with VVT)”.

4) Apply sealant “A” to mating surface of cylinder and

cylinder head and “B” to mating surface of timing

chain cover as shown in figure.

“A”: Water tight sealant 99000–31140 (SUZUKI

Bond No.1207B)

“B”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for timing chain cover

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)5) Apply engine oil to oil seal lip, then install timing

chain cover (1). Tighten bolts and nut to specified

torque.

NOTE

Before installing timing chain cover, check

that pin is securely fitted.

Tightening torque

Timing chain cover bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Timing chain cover nut (b): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

6) Apply engine oil to new O-rings (2) and install them

to cap (3).

7) Install cap (3) to timing chain cover (1).

Tighten bolts to specified torque.

Tightening torque

Cap bolt (c): 25 N·m (2.5 kgf-m, 18.0 lb-ft)

I2RH0B140058-01

I5RW0C140043-01

(a) (b) (c)

1 2 3

I4RS0B140011-02