coolant level SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 289 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-7

7) Install air cleaner assembly with air suction hose

referring to “Air Cleaner Assembly Removal and

Installation”.

8) Run engine at specified idle speed and read vacuum

gauge. Vacuum should be within specification.

Vacuum specification (at sea level)

59 – 73 kPa (45 – 55 cmHg, 17.7 – 21.6 in.Hg) at

specified idle speed

9) After checking, disconnect special tool (Vacuum

gauge) from PCV valve.

10) Detach blind cap from PCV valve.

11) Install air cleaner assembly with air suction hose

referring to “Air Cleaner Assembly Removal and

Installation”.

Valve Lash (Clearance) InspectionS6RW0D1404003

1) Remove negative cable at battery.

2) Remove cylinder head cover referring to “Cylinder

Head Cover Removal and Installation”.

3) Remove right side engine under cover, if necessary.

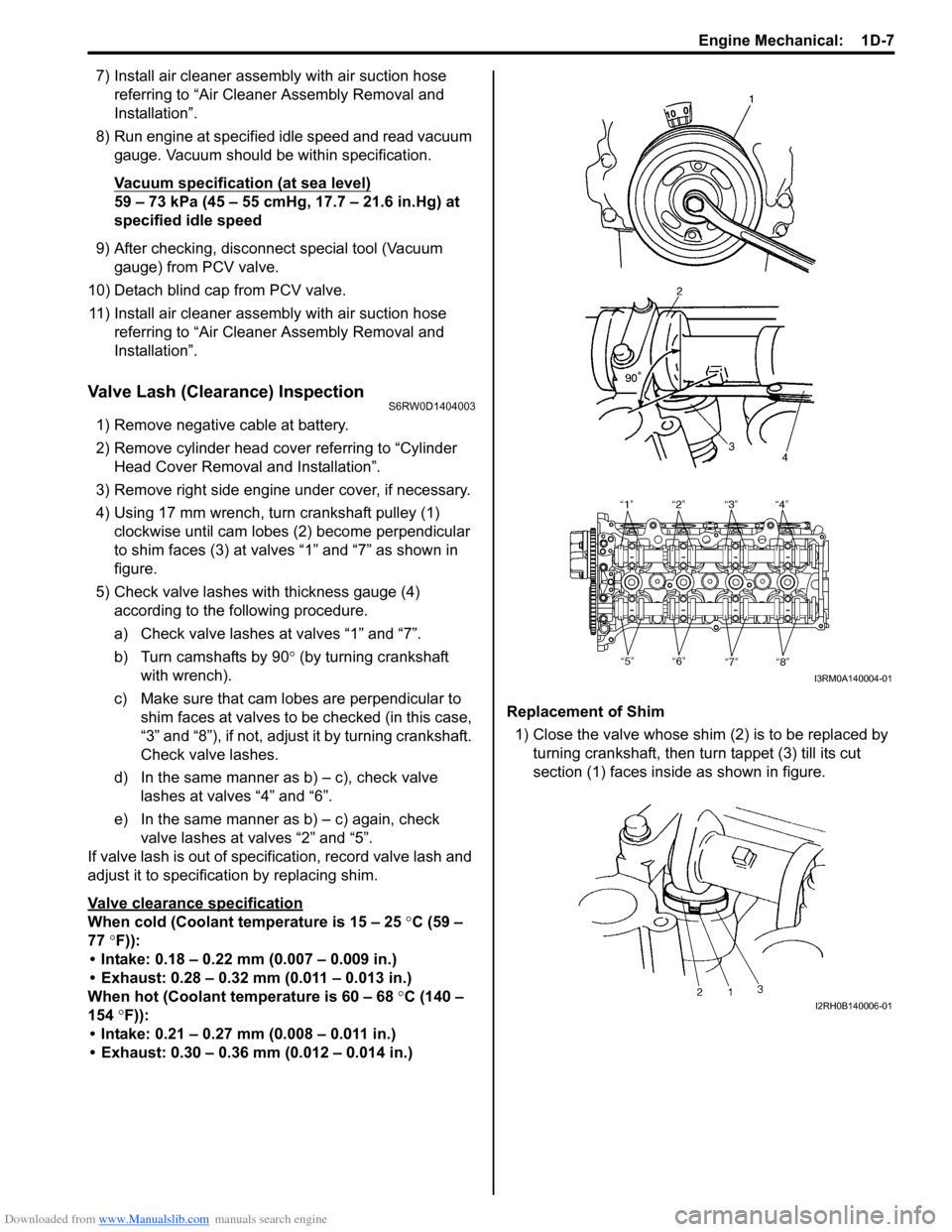

4) Using 17 mm wrench, turn crankshaft pulley (1)

clockwise until cam lobes (2) become perpendicular

to shim faces (3) at valves “1” and “7” as shown in

figure.

5) Check valve lashes with thickness gauge (4)

according to the following procedure.

a) Check valve lashes at valves “1” and “7”.

b) Turn camshafts by 90° (by turning crankshaft

with wrench).

c) Make sure that cam lobes are perpendicular to

shim faces at valves to be checked (in this case,

“3” and “8”), if not, adjust it by turning crankshaft.

Check valve lashes.

d) In the same manner as b) – c), check valve

lashes at valves “4” and “6”.

e) In the same manner as b) – c) again, check

valve lashes at valves “2” and “5”.

If valve lash is out of specification, record valve lash and

adjust it to specification by replacing shim.

Valve clearance specification

When cold (Coolant temperature is 15 – 25 °C (59 –

77 °F)):

• Intake: 0.18 – 0.22 mm (0.007 – 0.009 in.)

• Exhaust: 0.28 – 0.32 mm (0.011 – 0.013 in.)

When hot (Coolant temperature is 60 – 68 °C (140 –

154 °F)):

• Intake: 0.21 – 0.27 mm (0.008 – 0.011 in.)

• Exhaust: 0.30 – 0.36 mm (0.012 – 0.014 in.)Replacement of Shim

1) Close the valve whose shim (2) is to be replaced by

turning crankshaft, then turn tappet (3) till its cut

section (1) faces inside as shown in figure.

I3RM0A140004-01

I2RH0B140006-01

Page 366 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-1 Engine Cooling System:

Engine

Engine Cooling System

General Description

Cooling System DescriptionS6RW0D1601001

The cooling system consists of the radiator cap, radiator,

coolant reservoir, hoses, water pump, cooling fan and

thermostat. The radiator is of tube-and-fin type.

Coolant DescriptionS6RW0D1601002

WARNING!

• Do not remove radiator cap to check

engine coolant level; check coolant

visually at the see-through coolant

reservoir. Coolant should be added only to

reservoir as necessary.

• As long as there is pressure in the cooling

system, the temperature can be

considerably higher than the boiling

temperature of the solution in the radiator

without causing the solution to boil.

Removal of the radiator cap while engine is

hot and pressure is high will cause the

solution to boil instantaneously and

possibly with explosive force, spewing the

solution over engine, fenders and person

removing cap. If the solution contains

flammable anti-freeze such as alcohol (not

recommended for use at any time), there is

also the possibility of causing a serious

fire.

• Check to make sure that engine coolant

temperature is cold before removing any

part of cooling system.

• Also be sure to disconnect negative cable

from battery terminal before removing any

part.

The coolant recovery system is standard. The coolant in

the radiator expands with heat, and the coolant is

overflowed to the reservoir.

When the system cools down, the coolant is drawn back

into the radiator.

The cooling system has been filled with a quality coolant

that is a 50/50 mixture of water and ethylene glycol

antifreeze.

This 50/50 mixture coolant solution provides freezing

protection to –36 °C (–33 °F).

• Maintain cooling system freeze protection at –36 °C (–

33 °F) to ensure protection against corrosion and loss

of coolant from boiling. This should be done even if

freezing temperatures are not expected.

• Add ethylene glycol base coolant when coolant has to

be added because of coolant loss or to provide added

protection against freezing at temperature lower than

–36 °C (–33 °F).

NOTE

• Alcohol or methanol base coolant or plain

water alone should not be used in cooling

system at any time as damage to cooling

system could occur.

• Coolant must be mixed with demineralized

water or distilled water.

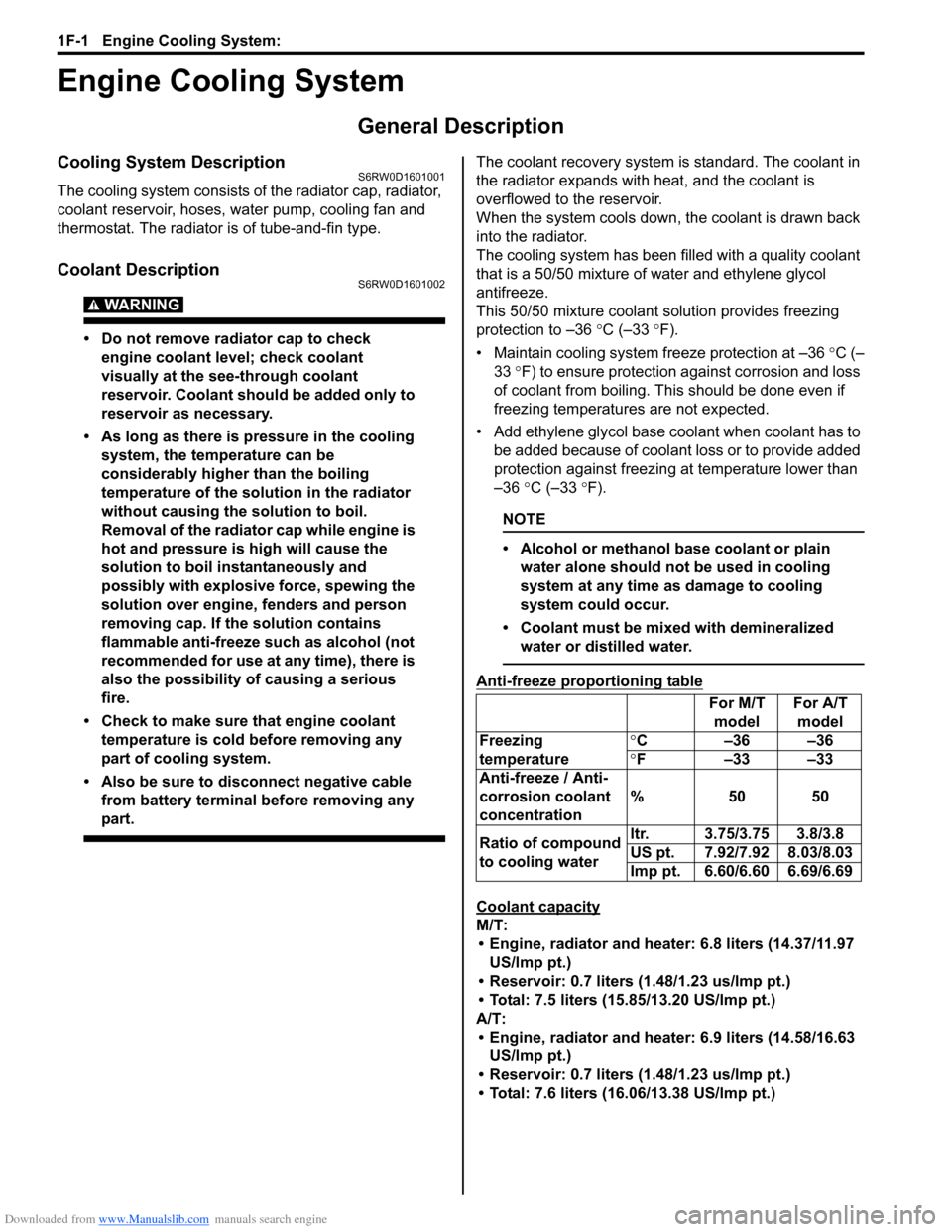

Anti-freeze proportioning table

Coolant capacity

M/T:

• Engine, radiator and heater: 6.8 liters (14.37/11.97

US/lmp pt.)

• Reservoir: 0.7 liters (1.48/1.23 us/lmp pt.)

• Total: 7.5 liters (15.85/13.20 US/lmp pt.)

A/T:

• Engine, radiator and heater: 6.9 liters (14.58/16.63

US/lmp pt.)

• Reservoir: 0.7 liters (1.48/1.23 us/lmp pt.)

• Total: 7.6 liters (16.06/13.38 US/lmp pt.)For M/T

modelFor A/T

model

Freezing

temperature°C–36–36

°F–33–33

Anti-freeze / Anti-

corrosion coolant

concentration%5050

Ratio of compound

to cooling waterltr. 3.75/3.75 3.8/3.8

US pt. 7.92/7.92 8.03/8.03

Imp pt. 6.60/6.60 6.69/6.69

Page 368 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-3 Engine Cooling System:

Diagnostic Information and Procedures

Engine Cooling Symptom DiagnosisS6RW0D1604001

Condition Possible cause Correction / Reference Item

Engine overheats

(Radiator fan operates)Loose or broken water pump beltAdjust or replace.

Not enough coolantCheck coolant level and add as necessary.

Faulty thermostatReplace.

Faulty water pumpReplace.

Dirty or bent radiator finsClean or remedy.

Coolant leakage on cooling systemRepair.

Clogged radiatorCheck and replace radiator as necessary.

Faulty radiator capReplace.

Dragging brakesAdjust brake.

Slipping clutchReplace.

Poor charge batteryCheck and replace as necessary.

Poor generation generatorCheck and repair.

ECT sensor faultyCheck and replace as necessary.

Radiator fan motor faultyCheck and replace as necessary.

ECM faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

Equipped with too much electric load

part(s)Dismount.

Engine overheats

(Radiator fan does not

operate)Fuse blownCheck fuse of relay/fuse box and check for

short circuit to ground.

Radiator cooling fan relay faultyCheck and replace as necessary.

ECT sensor faultyCheck and replace as necessary.

Radiator cooling fan motor faultyCheck and replace as necessary.

Wiring or grounding faultyRepair as necessary.

ECM faultyCheck and replace as necessary.

Page 370 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-5 Engine Cooling System:

Coolant Level CheckS6RW0D1606002

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if radiator

cap is taken off too soon.

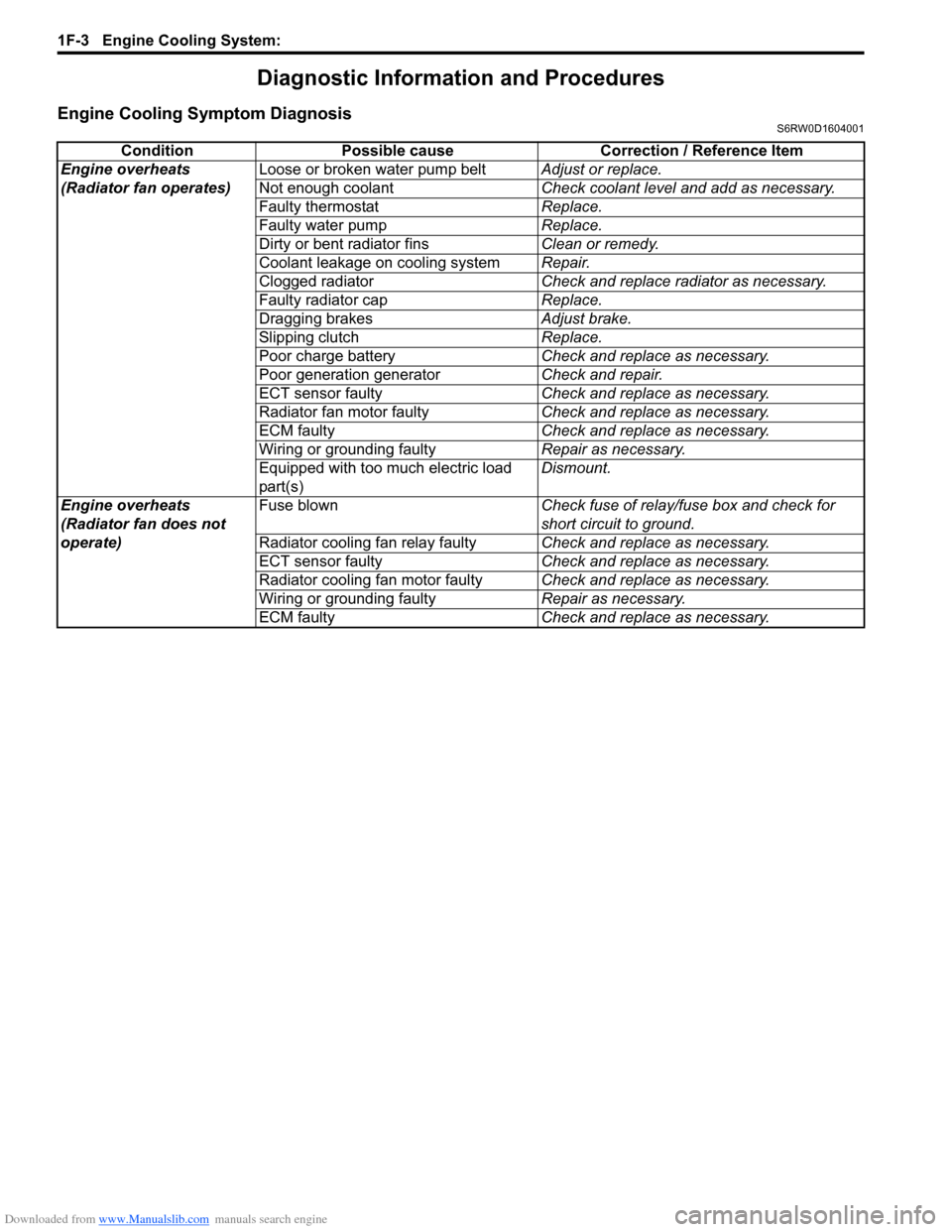

To check level, lift hood and look at “see-through”

coolant reservoir.

It is not necessary to remove radiator cap to check

coolant level.

When engine is cool, check coolant level in reservoir (1).

A normal coolant level should be between FULL mark

(2) and LOW mark (3) on reservoir (1).

If coolant level is below LOW mark (3), remove reservoir

cap (4) and add proper coolant to reservoir to bring

coolant level up to FULL mark (2).

NOTE

If proper quality antifreeze is used, there is

no need to add extra inhibitors or additives

that claim to improve system. They may be

harmful to proper operation of system, and

are unnecessary expense.

Engine Cooling System Inspection and

Cleaning

S6RW0D1606003

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

1) Check cooling system for leakage or damage.

2) Wash radiator cap and filler neck with clean water by

removing radiator cap when engine is cold.

3) Check coolant for proper level and freeze protection.

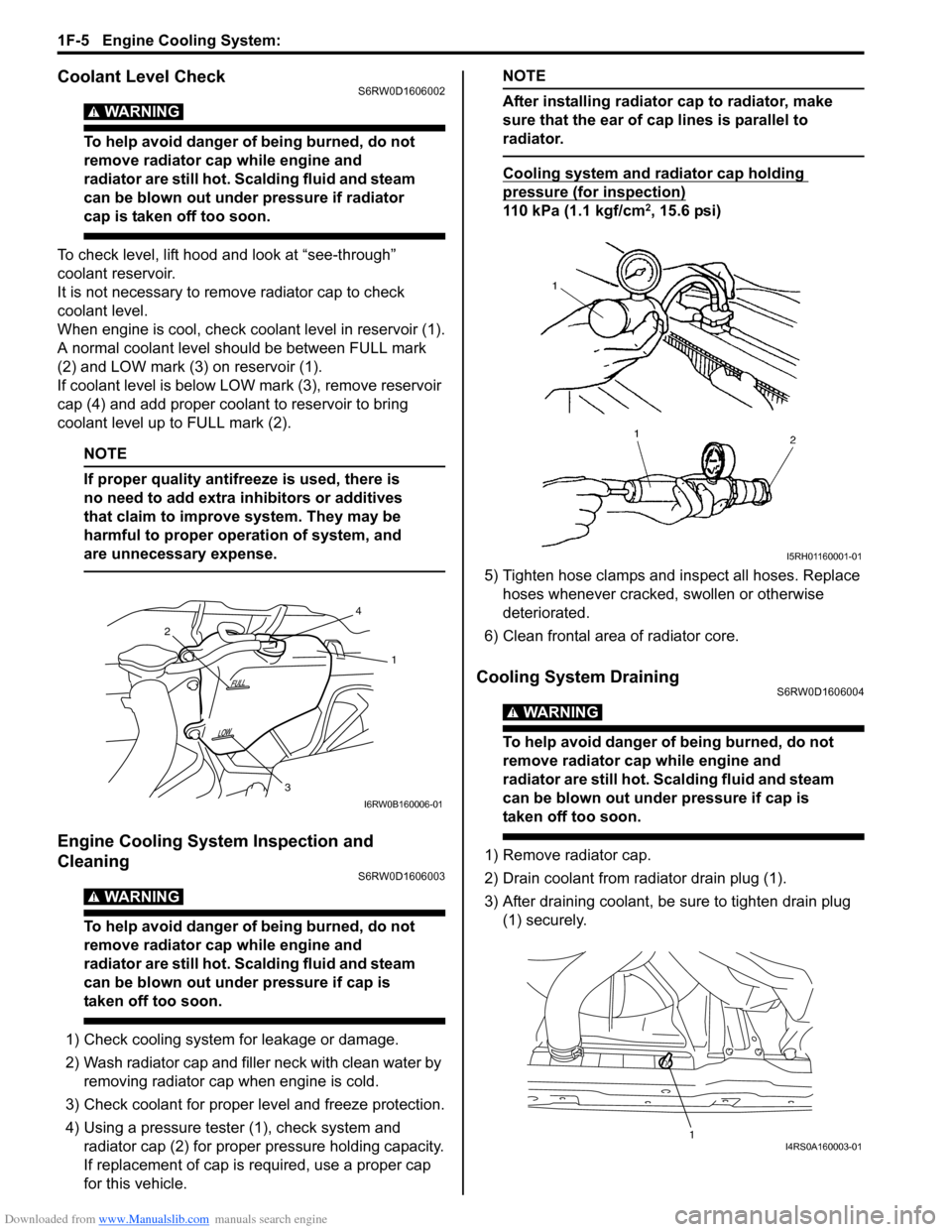

4) Using a pressure tester (1), check system and

radiator cap (2) for proper pressure holding capacity.

If replacement of cap is required, use a proper cap

for this vehicle.

NOTE

After installing radiator cap to radiator, make

sure that the ear of cap lines is parallel to

radiator.

Cooling system and radiator cap holding

pressure (for inspection)

110 kPa (1.1 kgf/cm2, 15.6 psi)

5) Tighten hose clamps and inspect all hoses. Replace

hoses whenever cracked, swollen or otherwise

deteriorated.

6) Clean frontal area of radiator core.

Cooling System DrainingS6RW0D1606004

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

1) Remove radiator cap.

2) Drain coolant from radiator drain plug (1).

3) After draining coolant, be sure to tighten drain plug

(1) securely.

4

1

2

3

I6RW0B160006-01

I5RH01160001-01

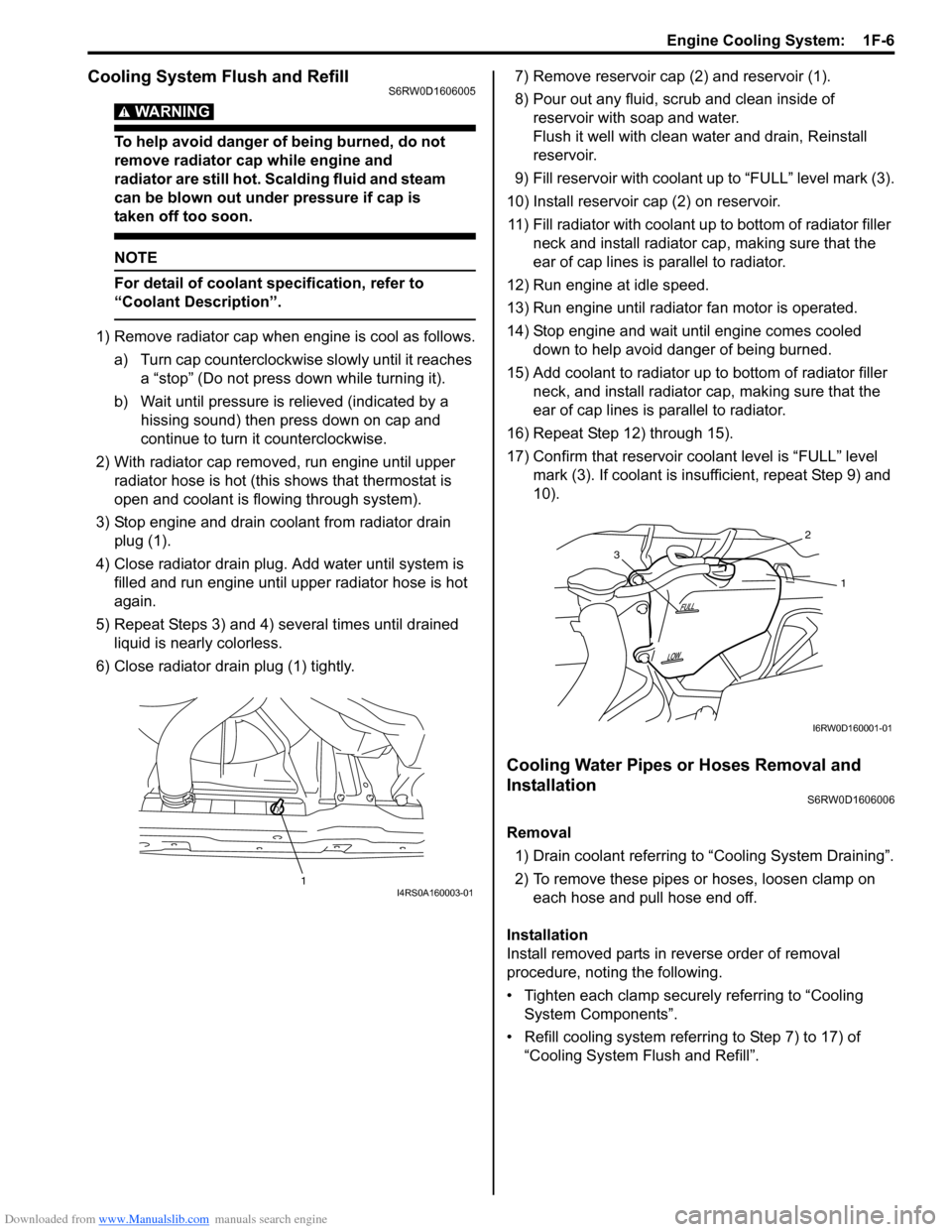

1I4RS0A160003-01

Page 371 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-6

Cooling System Flush and RefillS6RW0D1606005

WARNING!

To help avoid danger of being burned, do not

remove radiator cap while engine and

radiator are still hot. Scalding fluid and steam

can be blown out under pressure if cap is

taken off too soon.

NOTE

For detail of coolant specification, refer to

“Coolant Description”.

1) Remove radiator cap when engine is cool as follows.

a) Turn cap counterclockwise slowly until it reaches

a “stop” (Do not press down while turning it).

b) Wait until pressure is relieved (indicated by a

hissing sound) then press down on cap and

continue to turn it counterclockwise.

2) With radiator cap removed, run engine until upper

radiator hose is hot (this shows that thermostat is

open and coolant is flowing through system).

3) Stop engine and drain coolant from radiator drain

plug (1).

4) Close radiator drain plug. Add water until system is

filled and run engine until upper radiator hose is hot

again.

5) Repeat Steps 3) and 4) several times until drained

liquid is nearly colorless.

6) Close radiator drain plug (1) tightly.7) Remove reservoir cap (2) and reservoir (1).

8) Pour out any fluid, scrub and clean inside of

reservoir with soap and water.

Flush it well with clean water and drain, Reinstall

reservoir.

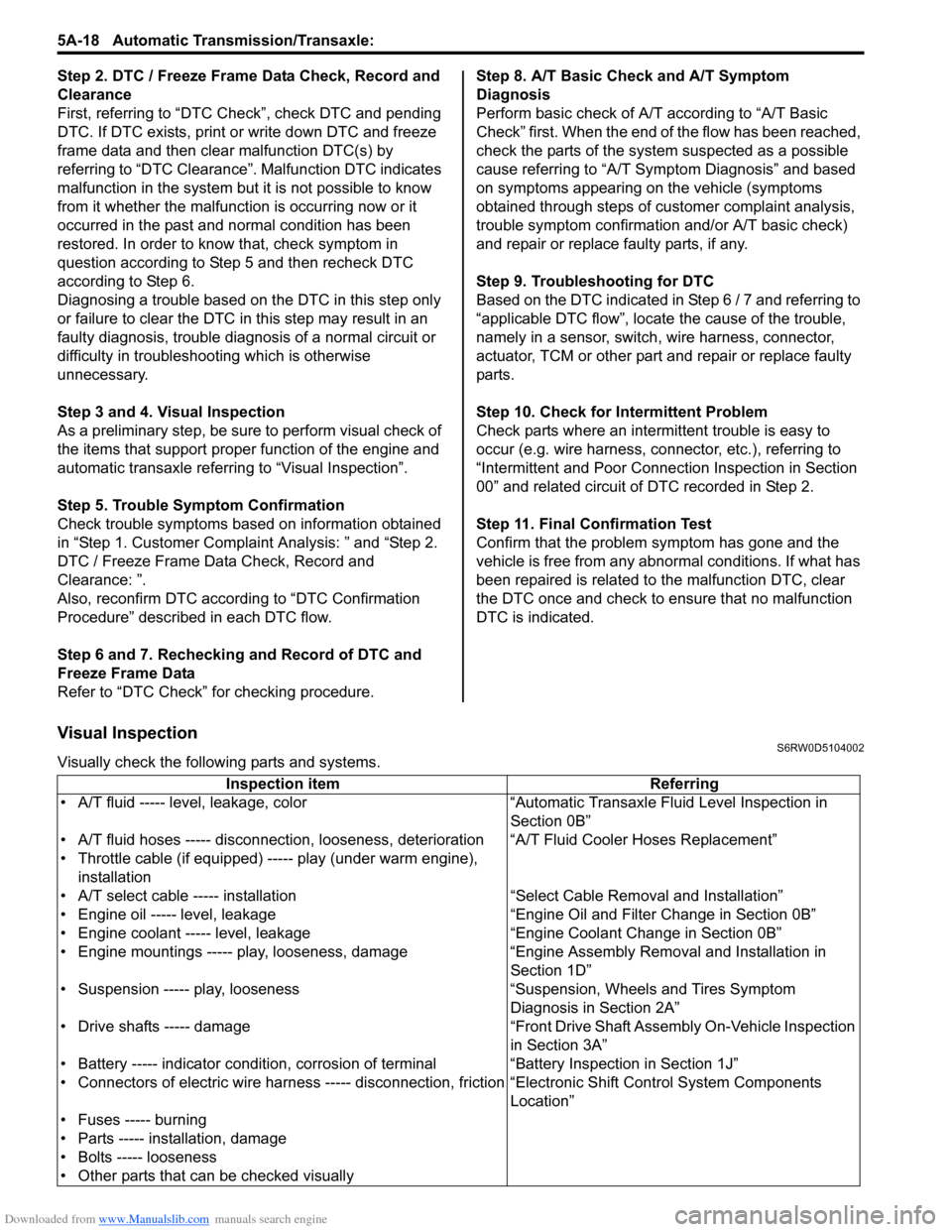

9) Fill reservoir with coolant up to “FULL” level mark (3).

10) Install reservoir cap (2) on reservoir.

11) Fill radiator with coolant up to bottom of radiator filler

neck and install radiator cap, making sure that the

ear of cap lines is parallel to radiator.

12) Run engine at idle speed.

13) Run engine until radiator fan motor is operated.

14) Stop engine and wait until engine comes cooled

down to help avoid danger of being burned.

15) Add coolant to radiator up to bottom of radiator filler

neck, and install radiator cap, making sure that the

ear of cap lines is parallel to radiator.

16) Repeat Step 12) through 15).

17) Confirm that reservoir coolant level is “FULL” level

mark (3). If coolant is insufficient, repeat Step 9) and

10).

Cooling Water Pipes or Hoses Removal and

Installation

S6RW0D1606006

Removal

1) Drain coolant referring to “Cooling System Draining”.

2) To remove these pipes or hoses, loosen clamp on

each hose and pull hose end off.

Installation

Install removed parts in reverse order of removal

procedure, noting the following.

• Tighten each clamp securely referring to “Cooling

System Components”.

• Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

1I4RS0A160003-01

2

1

3

I6RW0D160001-01

Page 666 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-18 Automatic Transmission/Transaxle:

Step 2. DTC / Freeze Frame Data Check, Record and

Clearance

First, referring to “DTC Check”, check DTC and pending

DTC. If DTC exists, print or write down DTC and freeze

frame data and then clear malfunction DTC(s) by

referring to “DTC Clearance”. Malfunction DTC indicates

malfunction in the system but it is not possible to know

from it whether the malfunction is occurring now or it

occurred in the past and normal condition has been

restored. In order to know that, check symptom in

question according to Step 5 and then recheck DTC

according to Step 6.

Diagnosing a trouble based on the DTC in this step only

or failure to clear the DTC in this step may result in an

faulty diagnosis, trouble diagnosis of a normal circuit or

difficulty in troubleshooting which is otherwise

unnecessary.

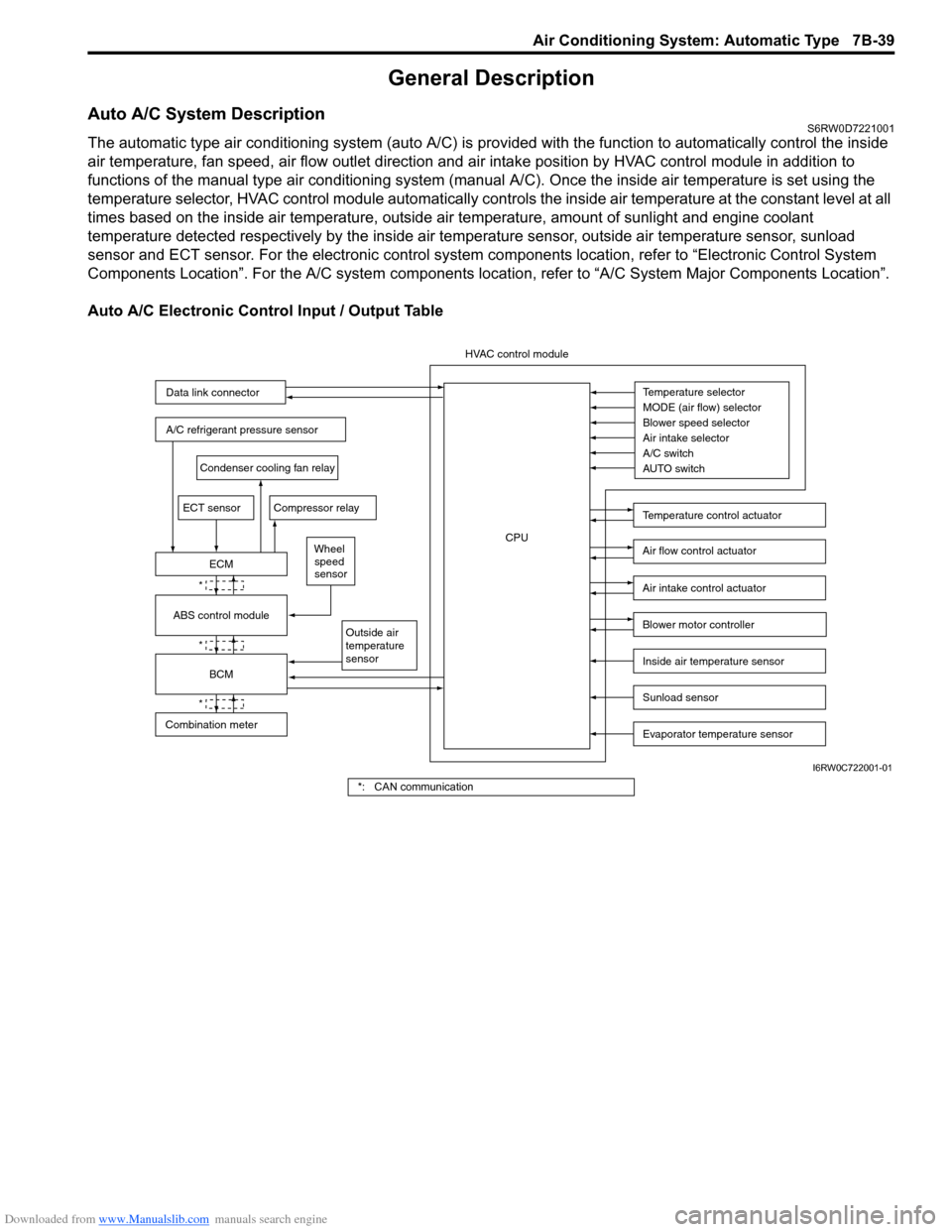

Step 3 and 4. Visual Inspection

As a preliminary step, be sure to perform visual check of

the items that support proper function of the engine and

automatic transaxle referring to “Visual Inspection”.

Step 5. Trouble Symptom Confirmation

Check trouble symptoms based on information obtained

in “Step 1. Customer Complaint Analysis: ” and “Step 2.

DTC / Freeze Frame Data Check, Record and

Clearance: ”.

Also, reconfirm DTC according to “DTC Confirmation

Procedure” described in each DTC flow.

Step 6 and 7. Rechecking and Record of DTC and

Freeze Frame Data

Refer to “DTC Check” for checking procedure.Step 8. A/T Basic Check and A/T Symptom

Diagnosis

Perform basic check of A/T according to “A/T Basic

Check” first. When the end of the flow has been reached,

check the parts of the system suspected as a possible

cause referring to “A/T Symptom Diagnosis” and based

on symptoms appearing on the vehicle (symptoms

obtained through steps of customer complaint analysis,

trouble symptom confirmation and/or A/T basic check)

and repair or replace faulty parts, if any.

Step 9. Troubleshooting for DTC

Based on the DTC indicated in Step 6 / 7 and referring to

“applicable DTC flow”, locate the cause of the trouble,

namely in a sensor, switch, wire harness, connector,

actuator, TCM or other part and repair or replace faulty

parts.

Step 10. Check for Intermittent Problem

Check parts where an intermittent trouble is easy to

occur (e.g. wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11. Final Confirmation Test

Confirm that the problem symptom has gone and the

vehicle is free from any abnormal conditions. If what has

been repaired is related to the malfunction DTC, clear

the DTC once and check to ensure that no malfunction

DTC is indicated.

Visual InspectionS6RW0D5104002

Visually check the following parts and systems.

Inspection item Referring

• A/T fluid ----- level, leakage, color “Automatic Transaxle Fluid Level Inspection in

Section 0B”

• A/T fluid hoses ----- disconnection, looseness, deterioration “A/T Fluid Cooler Hoses Replacement”

• Throttle cable (if equipped) ----- play (under warm engine),

installation

• A/T select cable ----- installation “Select Cable Removal and Installation”

• Engine oil ----- level, leakage “Engine Oil and Filter Change in Section 0B”

• Engine coolant ----- level, leakage “Engine Coolant Change in Section 0B”

• Engine mountings ----- play, looseness, damage “Engine Assembly Removal and Installation in

Section 1D”

• Suspension ----- play, looseness “Suspension, Wheels and Tires Symptom

Diagnosis in Section 2A”

• Drive shafts ----- damage “Front Drive Shaft Assembly On-Vehicle Inspection

in Section 3A”

• Battery ----- indicator condition, corrosion of terminal “Battery Inspection in Section 1J”

• Connectors of electric wire harness ----- disconnection, friction “Electronic Shift Control System Components

Location”

• Fuses ----- burning

• Parts ----- installation, damage

• Bolts ----- looseness

• Other parts that can be checked visually

Page 697 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-49

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out with 2 persons, a driver and a tester, on a level road.

1) Connect scan tool to DLC with ignition switch OFF, if available.

2) Clear DTC in TCM memory and start engine.

3) Increase engine coolant temperature to about 50 °C (122 °F) and more.

4) Start vehicle and increase vehicle speed to about 20 km/h (12 mile/h) for 10 minutes or more.

5) Stop vehicle and check DTC.

DTC Troubleshooting

Step Action Yes No

1Was “A/T System Check” performed?Go to Step 2. Go to “A/T System

Check”.

2Check transmission fluid temperature circuit for open

1) Turn ignition switch OFF.

2) Disconnect TCM connectors from TCM.

3) Check for proper connection to transmission fluid

temperature sensor at terminals “C06-11” and “C06-12”.

4) If OK, check continuity between terminals “C06-11” and

“C06-12” of disconnected harness side TCM connector.

Is continuity indicated?Go to Step 3. “LT GRN” or “ORN”

circuit open.

3Check transmission fluid temperature circuit for IG

short

1) Cool down A/T fluid temperature under ambient

temperature.

2) Connect TCM connectors to TCM with ignition switch

OFF.

3) Turn ignition switch ON.

4) Measure voltage between terminal “C06-11” of TCM

connector and ground.

Is it 4.6 V or more?“LT GRN” circuit shorted

to power circuit.

If circuit is OK, go to

St ep 4 .Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.

4Inspect transmission fluid temperature sensor

1) Inspect transmission fluid temperature sensor referring

to “Transmission Fluid Temperature Sensor Inspection”.

Is result satisfactory?Intermittent trouble or

faulty TCM.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

If OK, substitute a

known-good TCM and

recheck.Replace transmission

fluid temperature

sensor.

Page 979 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-39

General Description

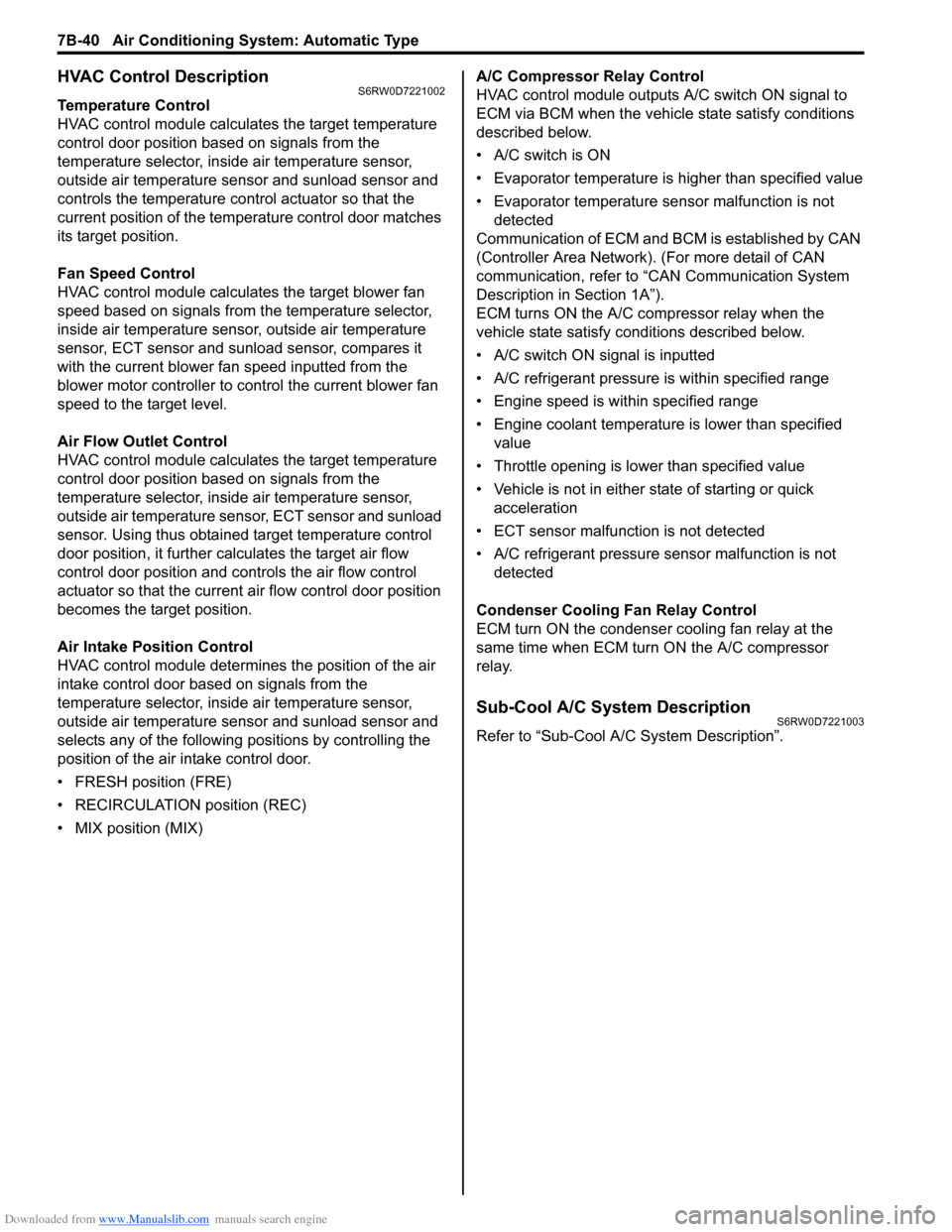

Auto A/C System DescriptionS6RW0D7221001

The automatic type air conditioning system (auto A/C) is provided with the function to automatically control the inside

air temperature, fan speed, air flow outlet direction and air intake position by HVAC control module in addition to

functions of the manual type air conditioning system (manual A/C). Once the inside air temperature is set using the

temperature selector, HVAC control module automatically controls the inside air temperature at the constant level at all

times based on the inside air temperature, outside air temperature, amount of sunlight and engine coolant

temperature detected respectively by the inside air temperature sensor, outside air temperature sensor, sunload

sensor and ECT sensor. For the electronic control system components location, refer to “Electronic Control System

Components Location”. For the A/C system components location, refer to “A/C System Major Components Location”.

Auto A/C Electronic Control Input / Output Table

Temperature selector

MODE (air flow) selector

Blower speed selector

Air intake selector

AUTO switch A/C switch

Outside air

temperature

sensor

A/C refrigerant pressure sensor

Compressor relay

Blower motor controller

Temperature control actuator

Air flow control actuator

Air intake control actuator

BCM

ECM

Data link connector

HVAC control module

CPU

ECT sensor

Sunload sensor

Inside air temperature sensor

Evaporator temperature sensor

Condenser cooling fan relay

Wheel

speed

sensor

*

*

*

Combination meterABS control module

I6RW0C722001-01

*: CAN communication

Page 980 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-40 Air Conditioning System: Automatic Type

HVAC Control DescriptionS6RW0D7221002

Temperature Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

controls the temperature control actuator so that the

current position of the temperature control door matches

its target position.

Fan Speed Control

HVAC control module calculates the target blower fan

speed based on signals from the temperature selector,

inside air temperature sensor, outside air temperature

sensor, ECT sensor and sunload sensor, compares it

with the current blower fan speed inputted from the

blower motor controller to control the current blower fan

speed to the target level.

Air Flow Outlet Control

HVAC control module calculates the target temperature

control door position based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor, ECT sensor and sunload

sensor. Using thus obtained target temperature control

door position, it further calculates the target air flow

control door position and controls the air flow control

actuator so that the current air flow control door position

becomes the target position.

Air Intake Position Control

HVAC control module determines the position of the air

intake control door based on signals from the

temperature selector, inside air temperature sensor,

outside air temperature sensor and sunload sensor and

selects any of the following positions by controlling the

position of the air intake control door.

• FRESH position (FRE)

• RECIRCULATION position (REC)

• MIX position (MIX)A/C Compressor Relay Control

HVAC control module outputs A/C switch ON signal to

ECM via BCM when the vehicle state satisfy conditions

described below.

• A/C switch is ON

• Evaporator temperature is higher than specified value

• Evaporator temperature sensor malfunction is not

detected

Communication of ECM and BCM is established by CAN

(Controller Area Network). (For more detail of CAN

communication, refer to “CAN Communication System

Description in Section 1A”).

ECM turns ON the A/C compressor relay when the

vehicle state satisfy conditions described below.

• A/C switch ON signal is inputted

• A/C refrigerant pressure is within specified range

• Engine speed is within specified range

• Engine coolant temperature is lower than specified

value

• Throttle opening is lower than specified value

• Vehicle is not in either state of starting or quick

acceleration

• ECT sensor malfunction is not detected

• A/C refrigerant pressure sensor malfunction is not

detected

Condenser Cooling Fan Relay Control

ECM turn ON the condenser cooling fan relay at the

same time when ECM turn ON the A/C compressor

relay.

Sub-Cool A/C System DescriptionS6RW0D7221003

Refer to “Sub-Cool A/C System Description”.

Page 1163 of 1556

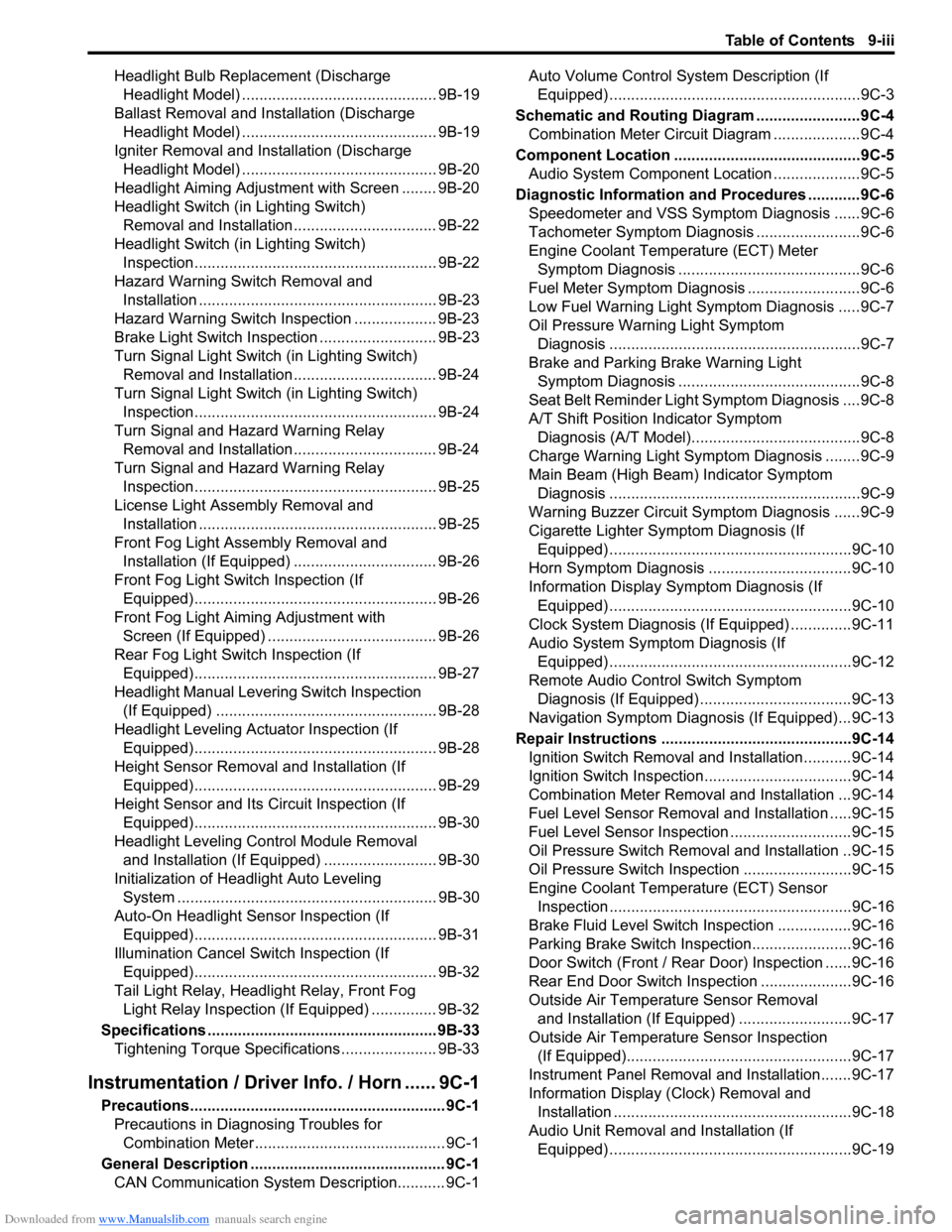

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-iii

Headlight Bulb Replacement (Discharge

Headlight Model) ............................................. 9B-19

Ballast Removal and Installation (Discharge

Headlight Model) ............................................. 9B-19

Igniter Removal and Installation (Discharge

Headlight Model) ............................................. 9B-20

Headlight Aiming Adjustment with Screen ........ 9B-20

Headlight Switch (in Lighting Switch)

Removal and Installation................................. 9B-22

Headlight Switch (in Lighting Switch)

Inspection........................................................ 9B-22

Hazard Warning Switch Removal and

Installation ....................................................... 9B-23

Hazard Warning Switch Inspection ................... 9B-23

Brake Light Switch Inspection ........................... 9B-23

Turn Signal Light Switch (in Lighting Switch)

Removal and Installation................................. 9B-24

Turn Signal Light Switch (in Lighting Switch)

Inspection........................................................ 9B-24

Turn Signal and Hazard Warning Relay

Removal and Installation................................. 9B-24

Turn Signal and Hazard Warning Relay

Inspection........................................................ 9B-25

License Light Assembly Removal and

Installation ....................................................... 9B-25

Front Fog Light Assembly Removal and

Installation (If Equipped) ................................. 9B-26

Front Fog Light Switch Inspection (If

Equipped)........................................................ 9B-26

Front Fog Light Aiming Adjustment with

Screen (If Equipped) ....................................... 9B-26

Rear Fog Light Switch Inspection (If

Equipped)........................................................ 9B-27

Headlight Manual Levering Switch Inspection

(If Equipped) ................................................... 9B-28

Headlight Leveling Actuator Inspection (If

Equipped)........................................................ 9B-28

Height Sensor Removal and Installation (If

Equipped)........................................................ 9B-29

Height Sensor and Its Circuit Inspection (If

Equipped)........................................................ 9B-30

Headlight Leveling Control Module Removal

and Installation (If Equipped) .......................... 9B-30

Initialization of Headlight Auto Leveling

System ............................................................ 9B-30

Auto-On Headlight Sensor Inspection (If

Equipped)........................................................ 9B-31

Illumination Cancel Switch Inspection (If

Equipped)........................................................ 9B-32

Tail Light Relay, Headlight Relay, Front Fog

Light Relay Inspection (If Equipped) ............... 9B-32

Specifications..................................................... 9B-33

Tightening Torque Specifications ...................... 9B-33

Instrumentation / Driver Info. / Horn ...... 9C-1

Precautions........................................................... 9C-1

Precautions in Diagnosing Troubles for

Combination Meter............................................ 9C-1

General Description ............................................. 9C-1

CAN Communication System Description........... 9C-1Auto Volume Control System Description (If

Equipped) ..........................................................9C-3

Schematic and Routing Diagram ........................9C-4

Combination Meter Circuit Diagram ....................9C-4

Component Location ...........................................9C-5

Audio System Component Location ....................9C-5

Diagnostic Information and Procedures ............9C-6

Speedometer and VSS Symptom Diagnosis ......9C-6

Tachometer Symptom Diagnosis ........................9C-6

Engine Coolant Temperature (ECT) Meter

Symptom Diagnosis ..........................................9C-6

Fuel Meter Symptom Diagnosis ..........................9C-6

Low Fuel Warning Light Symptom Diagnosis .....9C-7

Oil Pressure Warning Light Symptom

Diagnosis ..........................................................9C-7

Brake and Parking Brake Warning Light

Symptom Diagnosis ..........................................9C-8

Seat Belt Reminder Light Symptom Diagnosis ....9C-8

A/T Shift Position Indicator Symptom

Diagnosis (A/T Model).......................................9C-8

Charge Warning Light Symptom Diagnosis ........9C-9

Main Beam (High Beam) Indicator Symptom

Diagnosis ..........................................................9C-9

Warning Buzzer Circuit Symptom Diagnosis ......9C-9

Cigarette Lighter Symptom Diagnosis (If

Equipped) ........................................................9C-10

Horn Symptom Diagnosis .................................9C-10

Information Display Symptom Diagnosis (If

Equipped) ........................................................9C-10

Clock System Diagnosis (If Equipped) ..............9C-11

Audio System Symptom Diagnosis (If

Equipped) ........................................................9C-12

Remote Audio Control Switch Symptom

Diagnosis (If Equipped) ...................................9C-13

Navigation Symptom Diagnosis (If Equipped)...9C-13

Repair Instructions ............................................9C-14

Ignition Switch Removal and Installation...........9C-14

Ignition Switch Inspection..................................9C-14

Combination Meter Removal and Installation ...9C-14

Fuel Level Sensor Removal and Installation .....9C-15

Fuel Level Sensor Inspection ............................9C-15

Oil Pressure Switch Removal and Installation ..9C-15

Oil Pressure Switch Inspection .........................9C-15

Engine Coolant Temperature (ECT) Sensor

Inspection ........................................................9C-16

Brake Fluid Level Switch Inspection .................9C-16

Parking Brake Switch Inspection.......................9C-16

Door Switch (Front / Rear Door) Inspection ......9C-16

Rear End Door Switch Inspection .....................9C-16

Outside Air Temperature Sensor Removal

and Installation (If Equipped) ..........................9C-17

Outside Air Temperature Sensor Inspection

(If Equipped)....................................................9C-17

Instrument Panel Removal and Installation.......9C-17

Information Display (Clock) Removal and

Installation .......................................................9C-18

Audio Unit Removal and Installation (If

Equipped) ........................................................9C-19