display SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 140 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-90 Engine General Information and Diagnosis:

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 1 Volt”

displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is displayed TP sensor value as described voltage in “Scan

To o l D a t a ” ?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3ECM voltage check

1) Disconnect connector from electric throttle body

assembly with ignition switch turned OFF.

2) Check for proper connection to electric throttle body

assembly at “RED”, “GRN” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of

electric throttle body assembly connector and engine

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 5. Go to Step 4.

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C01-

43” terminal.

3) Measure voltage between “C01-43” terminal of ECM

connector and engine ground with ignition switch turned

ON.

Is voltage 0 V?Substitute a known-

good ECM and recheck. “RED” wire is shorted to

power circuit.

“WHT”

“YEL”“RED”

“GRN” “BLU”“BLK”

I5RW0C110016-01

Page 147 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-97

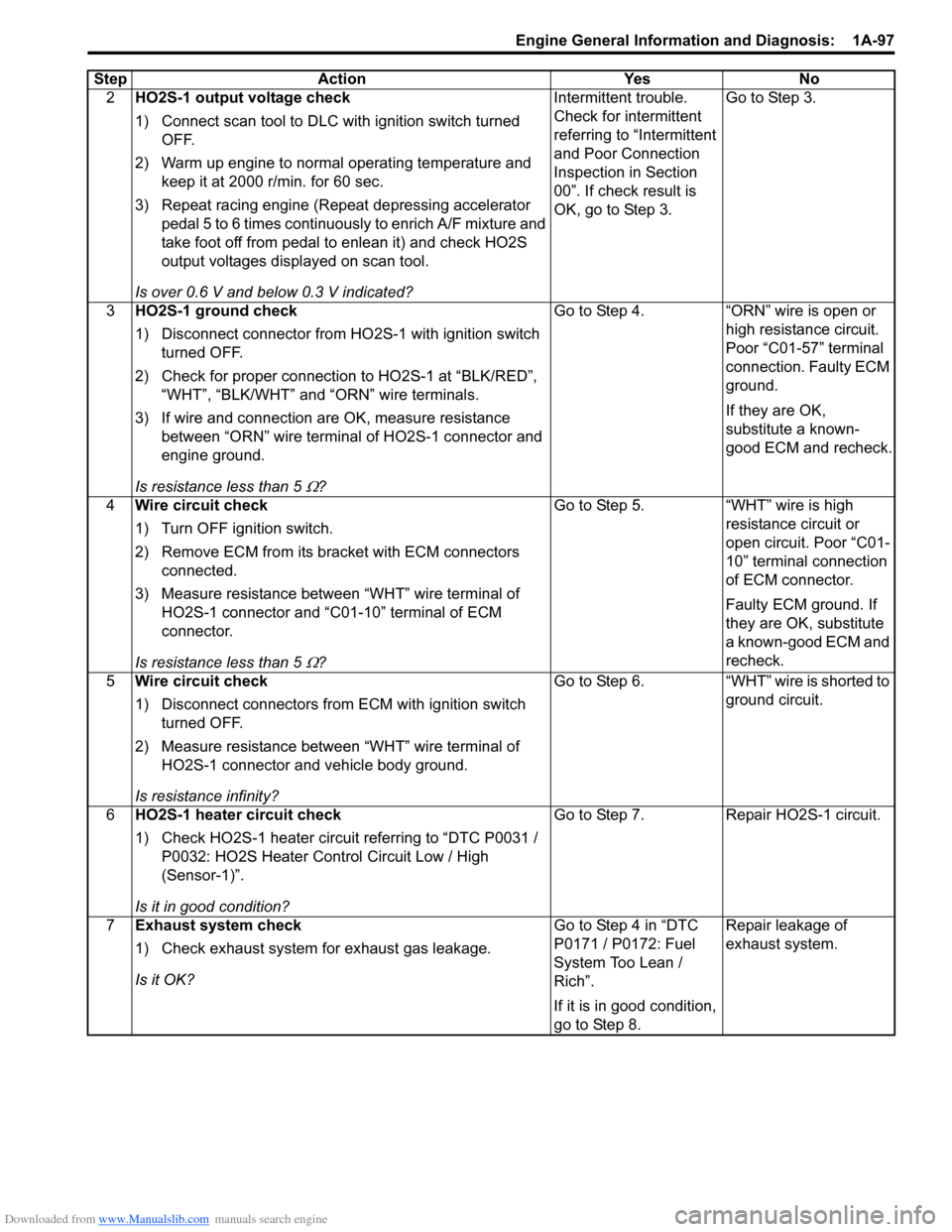

2HO2S-1 output voltage check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Warm up engine to normal operating temperature and

keep it at 2000 r/min. for 60 sec.

3) Repeat racing engine (Repeat depressing accelerator

pedal 5 to 6 times continuously to enrich A/F mixture and

take foot off from pedal to enlean it) and check HO2S

output voltages displayed on scan tool.

Is over 0.6 V and below 0.3 V indicated?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”. If check result is

OK, go to Step 3.Go to Step 3.

3HO2S-1 ground check

1) Disconnect connector from HO2S-1 with ignition switch

turned OFF.

2) Check for proper connection to HO2S-1 at “BLK/RED”,

“WHT”, “BLK/WHT” and “ORN” wire terminals.

3) If wire and connection are OK, measure resistance

between “ORN” wire terminal of HO2S-1 connector and

engine ground.

Is resistance less than 5

Ω?Go to Step 4. “ORN” wire is open or

high resistance circuit.

Poor “C01-57” terminal

connection. Faulty ECM

ground.

If they are OK,

substitute a known-

good ECM and recheck.

4Wire circuit check

1) Turn OFF ignition switch.

2) Remove ECM from its bracket with ECM connectors

connected.

3) Measure resistance between “WHT” wire terminal of

HO2S-1 connector and “C01-10” terminal of ECM

connector.

Is resistance less than 5

Ω?Go to Step 5. “WHT” wire is high

resistance circuit or

open circuit. Poor “C01-

10” terminal connection

of ECM connector.

Faulty ECM ground. If

they are OK, substitute

a known-good ECM and

recheck.

5Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “WHT” wire terminal of

HO2S-1 connector and vehicle body ground.

Is resistance infinity?Go to Step 6. “WHT” wire is shorted to

ground circuit.

6HO2S-1 heater circuit check

1) Check HO2S-1 heater circuit referring to “DTC P0031 /

P0032: HO2S Heater Control Circuit Low / High

(Sensor-1)”.

Is it in good condition?Go to Step 7. Repair HO2S-1 circuit.

7Exhaust system check

1) Check exhaust system for exhaust gas leakage.

Is it OK?Go to Step 4 in “DTC

P0171 / P0172: Fuel

System Too Lean /

Rich”.

If it is in good condition,

go to Step 8.Repair leakage of

exhaust system. Step Action Yes No

Page 156 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-106 Engine General Information and Diagnosis:

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 2 Volt”

displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is each TP sensor voltage within specified value in the table

“Scan Tool Data”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3ECM voltage check

1) Disconnect connector from electric throttle body

assembly with ignition switch turned OFF.

2) Check for proper connection to electric throttle body

assembly at “RED”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of

electric throttle body assembly connector and engine

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 6. Go to Step 4.

4ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its bracket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “C01-

43” terminal.

4) If OK, measure voltage between “C01-43” terminal of

ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V?“RED” wire is open or

high resistance circuit.Go to Step 5.

“WHT”

“YEL”“RED”

“GRN” “BLU”“BLK”

I5RW0C110016-01

Page 158 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-108 Engine General Information and Diagnosis:

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Throttle position sensor and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “TP Sensor 2 Volt”

displayed on scan tool when accelerator pedal is idle

position and fully depressed.

Is each TP sensor voltage within specified value in the table

“Scan Tool Data”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3ECM voltage check

1) Disconnect connector from electric throttle body

assembly with ignition switch turned OFF.

2) Check for proper connection to electric throttle body

assembly at “RED”, “WHT” and “BLK” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of

electric throttle body assembly connector and engine

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 5. Go to Step 4.

4Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “C01-

43” terminal.

3) Measure voltage between “C01-43” terminal of ECM

connector and engine ground with ignition switch turned

ON.

Is voltage 0 V?Substitute a known-

good ECM and recheck.“RED” wire is shorted to

power circuit.

“WHT”

“YEL”“RED”

“GRN” “BLU”“BLK”

I5RW0C110016-01

Page 185 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-135

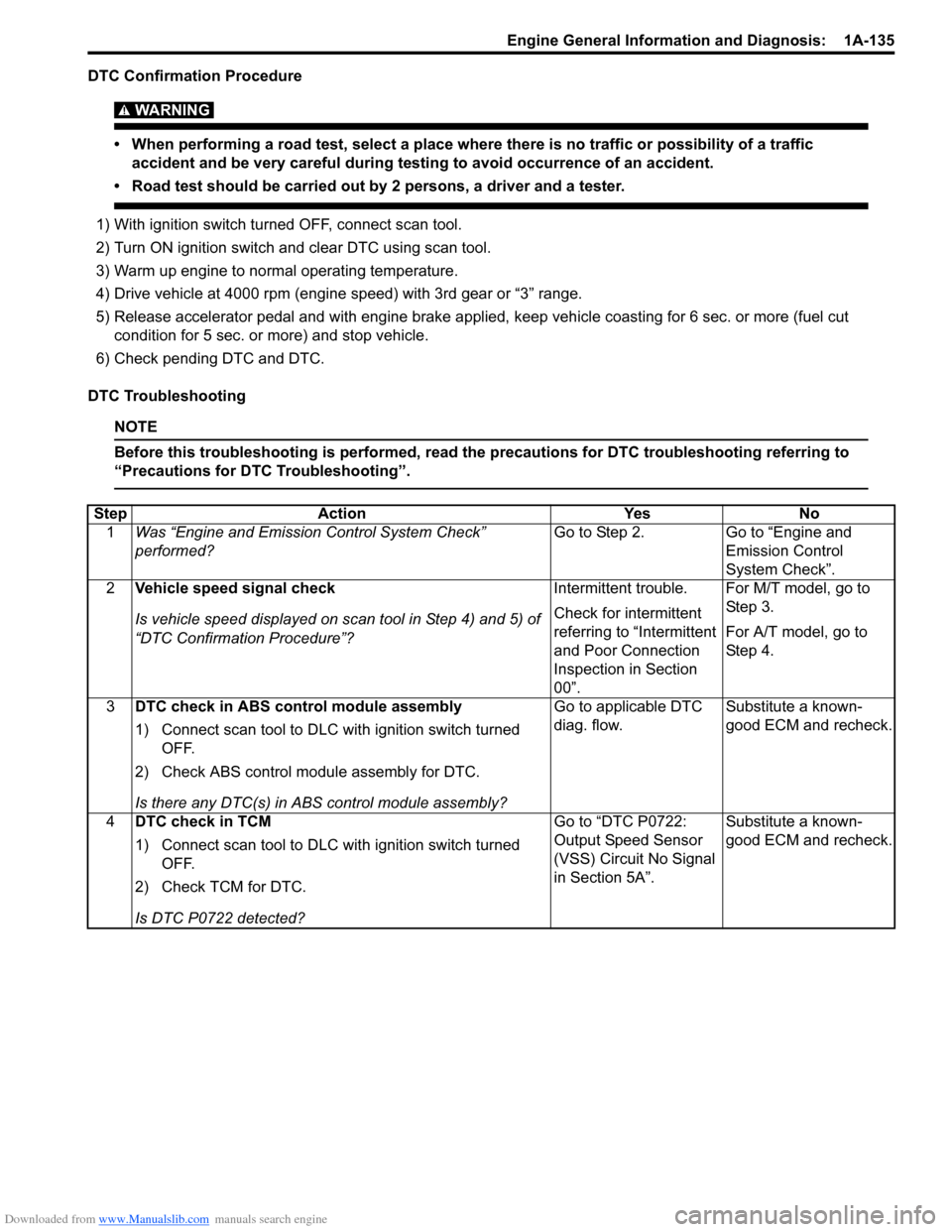

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester.

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Warm up engine to normal operating temperature.

4) Drive vehicle at 4000 rpm (engine speed) with 3rd gear or “3” range.

5) Release accelerator pedal and with engine brake applied, keep vehicle coasting for 6 sec. or more (fuel cut

condition for 5 sec. or more) and stop vehicle.

6) Check pending DTC and DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Vehicle speed signal check

Is vehicle speed displayed on scan tool in Step 4) and 5) of

“DTC Confirmation Procedure”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.For M/T model, go to

Ste p 3.

For A/T model, go to

Ste p 4.

3DTC check in ABS control module assembly

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check ABS control module assembly for DTC.

Is there any DTC(s) in ABS control module assembly?Go to applicable DTC

diag. flow.Substitute a known-

good ECM and recheck.

4DTC check in TCM

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check TCM for DTC.

Is DTC P0722 detected?Go to “DTC P0722:

Output Speed Sensor

(VSS) Circuit No Signal

in Section 5A”.Substitute a known-

good ECM and recheck.

Page 200 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-150 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Electric throttle body assembly system check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check each voltage of “TP

Sensor 1 Volt” and “TP Sensor 2 Volt” displayed on scan

tool when accelerator pedal is idle position and fully

depressed.

Is displayed each TP sensor value as described voltage in

“Scan Tool Data”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Go to Step 3.

3Throttle actuator circuit check

1) Disconnect connector from electric throttle body

assembly with ignition switch turned OFF.

2) Check for proper connection to electric throttle body

assembly at “BLU” and “YEL” wire terminals.

3) Disconnect connectors from ECM.

4) Check for proper connection to ECM at “C01-45” and

“C01-44” terminals.

5) Measure resistance at following connector terminals.

• Between “BLU” wire terminal of electric throttle body

assembly connector and “C01-45” terminal of ECM

connector

• Between “YEL” wire terminal of electric throttle body

assembly connector and “C01-44” terminal of ECM

connector

Is each resistance below 5

Ω?Go to Step 4. “BLU” wire and/or “YEL”

wire is open or high

resistance.

4Electric throttle body assembly check

1) Check electric throttle body assembly referring to

“Electric Throttle Body Assembly and Its Circuit Check”

under “Electric Throttle Body Assembly On-Vehicle

Inspection in Section 1C”.

Is check result satisfactory?Substitute a known-

good ECM and recheck.Replace electric throttle

body assembly.

“WHT”

“YEL”“RED”

“GRN” “BLU”“BLK”

I5RW0C110016-01

Page 202 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-152 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2APP sensor assembly mounting check

1) Check that APP sensor assembly has been mounted to

vehicle body properly (no pinched floor carpet, etc.).

Is it OK?Go to Step 3. Reinstall APP sensor

assembly properly

referring to “Accelerator

Pedal Position (APP)

Sensor Assembly

Removal and

Installation in Section

1C”.

3APP sensor (main) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 1 Volt”

displayed on scan tool.

Is displayed voltage below 0.167 V?Go to Step 4. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4ECM voltage check

1) Disconnect connector from APP sensor assembly with

ignition switch turned OFF.

2) Check for proper connection to APP sensor assembly at

“BRN”, “GRN” and “BLU” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of

APP sensor assembly connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 7. Go to Step 5.

5ECM voltage check

1) Turn OFF ignition switch.

2) Remove ECM from its bracket with ECM connectors

connected.

3) Check for proper connection of ECM connector at “E01-

35” terminal.

4) If OK, measure voltage between “E01-35” terminal of

ECM connector and engine ground with ignition switch

turned ON.

Is voltage 4 – 6 V?“BRN” wire is open or

high resistance circuit.Go to Step 6.

"GRN" "BLU" "BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 204 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-154 Engine General Information and Diagnosis:

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed? Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2APP sensor assembly mounting check

1) Check that APP sensor assembly has been mounted to

vehicle body properly (no pinched floor carpet, etc.).

Is it OK?Go to Step 3. Reinstall APP sensor

assembly properly

referring to “Accelerator

Pedal Position (APP)

Sensor Assembly

Removal and

Installation in Section

1C”.

3APP sensor (main) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 1 Volt”

displayed on scan tool.

Is displayed voltage 4.76 V or more?Go to Step 4. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4ECM voltage check

1) Disconnect connector from APP sensor assembly with

ignition switch turned OFF.

2) Check for proper connection to APP sensor assembly at

“BRN”, “GRN” and “BLU” wire terminals.

3) If OK, measure voltage between “BRN” wire terminal of

APP sensor assembly connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 6. Go to Step 5.

5Wire harness check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Check for proper connection of ECM connector at “E01-

35” terminal.

3) If OK, measure voltage between “E01-35” terminal of

ECM connector and engine ground with ignition switch

turned ON.

Is voltage 0 V?Substitute a known-

good ECM and recheck.“BRN” wire is shorted to

power circuit.

"GRN" "BLU" "BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 206 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-156 Engine General Information and Diagnosis:

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2APP sensor assembly mounting check

1) Check that APP sensor assembly has been mounted to

vehicle body properly (no pinched floor carpet, etc.).

Is it OK?Go to Step 3. Reinstall APP sensor

assembly properly

referring to “Accelerator

Pedal Position (APP)

Sensor Assembly

Removal and

Installation in Section

1C”.

3APP sensor (sub) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 2 Volt”

displayed on scan tool.

Is displayed voltage below 0.179 V?Go to Step 4. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.

4ECM voltage check

1) Disconnect connector from APP sensor assembly with

ignition switch turned OFF.

2) Check for proper connection to APP sensor assembly at

“RED”, “YEL” and “WHT” wire terminals.

3) If OK, measure voltage between “RED” wire terminal of

APP sensor assembly connector and vehicle body

ground with ignition switch turned ON.

Is voltage 4 – 6 V?Go to Step 7. Go to Step 5.

"GRN" "BLU" "BRN"

"YEL"

"WHT"

"RED"

I4RS0B110048-01

Page 208 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-158 Engine General Information and Diagnosis:

DTC P2128: Pedal Position Sensor (Sub) Circuit High InputS6RW0D1104065

Wiring Diagram

Refer to “DTC P2122: Pedal Position Sensor (Main) Circuit Low Input”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC detecting condition Trouble area

Output voltage of APP sensor (sub) is higher than specified value.

(1 driving detection logic)• APP sensor (sub) circuit

• APP sensor assembly

•ECM

• Incorrect mounting of APP sensor assembly

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2APP sensor assembly mounting check

1) Check that APP sensor assembly has been mounted to

vehicle body properly (no pinched floor carpet, etc.).

Is it OK?Go to Step 3. Reinstall APP sensor

assembly properly

referring to “Accelerator

Pedal Position (APP)

Sensor Assembly

Removal and

Installation in Section

1C”.

3APP sensor (sub) and its circuit check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch, check “APP Sensor 2 Volt”

displayed on scan tool.

Is displayed voltage 4.76 V or more?Go to Step 4. Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.