lights SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 689 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-41

Transmission Warning Light Circuit Check – Light Remains “ON” at Ignition Switch ON (Non-Euro-

OBD Model)

S6RW0D5104054

Troubleshooting

Transmission Warning Light Circuit Check – Light Does Not Come “ON” at Ignition Switch ON (Non-

Euro-OBD Model)

S6RW0D5104055

TroubleshootingNon operate TCC (lock-

up) systemFaulty torque converterReplace.

Excessive “N”

→ “D” time

lagFaulty oil pumpInspect. If NG, replace.

Faulty forward clutchInspect. If NG, replace.

Faulty one-way No.2 clutchInspect. If NG, replace.

Leakage from “D” range fluid pressure

circuitOverhaul or replace valve body assembly.

Excessive “N”

→ “R” time

lagFaulty oil pumpInspect. If NG, replace.

Faulty reverse clutchInspect. If NG, replace.

Faulty 1st and reverse brakeInspect. If NG, replace.

Leakage from “R” range fluid pressure

circuitOverhaul or replace valve body assembly.

Poor engine brake in

downshift to “2” rangeFaulty O/D and 2nd coast brakeInspect. If NG, replace.

Poor engine brake in

downshift to “L” rangeFaulty 1st and reverse brakeInspect. If NG, replace. Condition Possible cause Correction / Reference Item

Step Action Yes No

1Diagnostic Trouble Code (DTC) Check

1) Check DTC referring to “DTC Check”.

Is there any DTC(s)?Perform DTC Flow to

repair and retry.Substitute a known-

good TCM and recheck.

If OK, substitute a

known-good

combination meter and

recheck.

Step Action Yes No

1Combination Meter Power Supply Check

1) Turn ignition switch ON.

Does other indicator / warning lights in combination meter

comes ON?Go to Step 2. Repair combination

meter power supply

circuit referring to

“Combination Meter

Circuit Diagram in

Section 9C”.

2 1) TCM power and ground circuit check referring to “TCM

Power and Ground Circuit Check”.

Is it in good condition?Go to Step 3. Repair or replace.

3DTC check

1) Check DTC referring to “DTC Check”.

Is there DTC U0073 or U0100?Go to applicable DTC

diag. flow.Go to Step 4.

4Combination Meter Function Check

1) Turn ignition switch ON.

Does A/T selector position indicator show correct select

lever position?Replace combination

meter.Substitute a known-

good TCM and recheck.

Page 738 of 1556

Downloaded from www.Manualslib.com manuals search engine 5A-90 Automatic Transmission/Transaxle:

3) Check that engine starts in “N” and “P” ranges but it

doesn’t start in “D”, “2”, “L” or “R” range. Also, check

that back-up lamp lights in “R” range.

If faulty condition cannot be corrected by adjustment,

disconnect transmission range sensor connector

and check that continuity exists as shown by moving

manual select lever.

Output Shaft Speed Sensor (VSS) Removal and

Installation

S6RW0D5106010

Removal

1) Disconnect negative cable at battery.

2) Disconnect output shaft speed sensor connector (2).

3) Remove output shaft speed sensor (VSS) (1) by

removing its bolt.

Installation

1) Apply A/T fluid to output shaft speed sensor O-ring.

2) Install output shaft speed sensor (VSS) (1) to A/T

case and tighten bolt to specified torque.

Tightening torque

Output shaft speed sensor (VSS) bolt (a): 13

N·m (1.3 kgf-m, 9.5 lb-ft)3) Connect output shaft speed sensor connector (2) to

output shaft speed sensor (VSS) (1).

4) Connect negative cable to battery.

Output Shaft Speed Sensor (VSS) InspectionS6RW0D5106011

1) Connect positive cable of 12 volt battery to “A”

terminal of sensor and ground cable to “C” terminal.

Then using voltmeter, check voltage between “B”

terminal and “C” terminal with output shaft speed

sensor (VSS) driven gear rotated.

If measured voltage (pulse signal) is not as

specified, replace sensor.

Output shaft speed sensor (VSS) output voltage

Pulse signal of alternating 0 – 1 V and 10 – 14 V

2) Check output shaft speed sensor (VSS) driven gear

(1) for wear.

Replace if necessary.

1 2

3

4

5

9

87

6

1

P

R

N

D

2

LTerminal No.

Sensor Position

23456789

I3RH0A510038-01

12I5RW0C510032-01

(a)

12

I5RW0C510033-01

I2RH0B510045-01

I2RH0B510046-01

Page 883 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-3

EPS Diagnosis General DescriptionS6RW0D6301002

The P/S system in this vehicle is controlled by the P/S control module. The P/S control module has an on-board

diagnostic system which detects a malfunction in this system. When diagnosing troubles, be sure to have full

understanding of the outline of “On-Board Diagnostic System Description” and each item in “Precautions in

Diagnosing Troubles”, and then execute diagnosis according to “EPS System Check”.

On-Board Diagnostic System DescriptionS6RW0D6301003

The P/S control module performs the on-board diagnosis (self-diagnosis) on the system and operates the “EPS”

warning light (1) as follows.

• The “EPS” warning light lights when the ignition switch is turned to ON position (but the engine at stop) regardless

of the condition of the P/S control system. This is only to check if the “EPS” warning light is operated properly.

• If the areas monitored by the P/S control module is free from any trouble after the engine start (while engine is

running), the “EPS” warning light turns OFF.

• When the P/S control module detects a trouble which has occurred in the monitored areas the “EPS” warning light

comes ON while the engine is running to warn the driver of such occurrence of the trouble and at the same time it

stores the exact trouble area in memory inside of the P/S control module.

Driving Cycle

A “Driving Cycle” consists of engine startup and engine shutoff.

3 Driving Cycles Detection Logic

The malfunction detected in the first and second driving cycle is stored in P/S control module memory (in the form of

pending DTC) but the “EPS” warning light does not light at these time. It lights up at the third detection of same

malfunction also in the next driving cycle.

1

I7RW01632002-01

Page 888 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

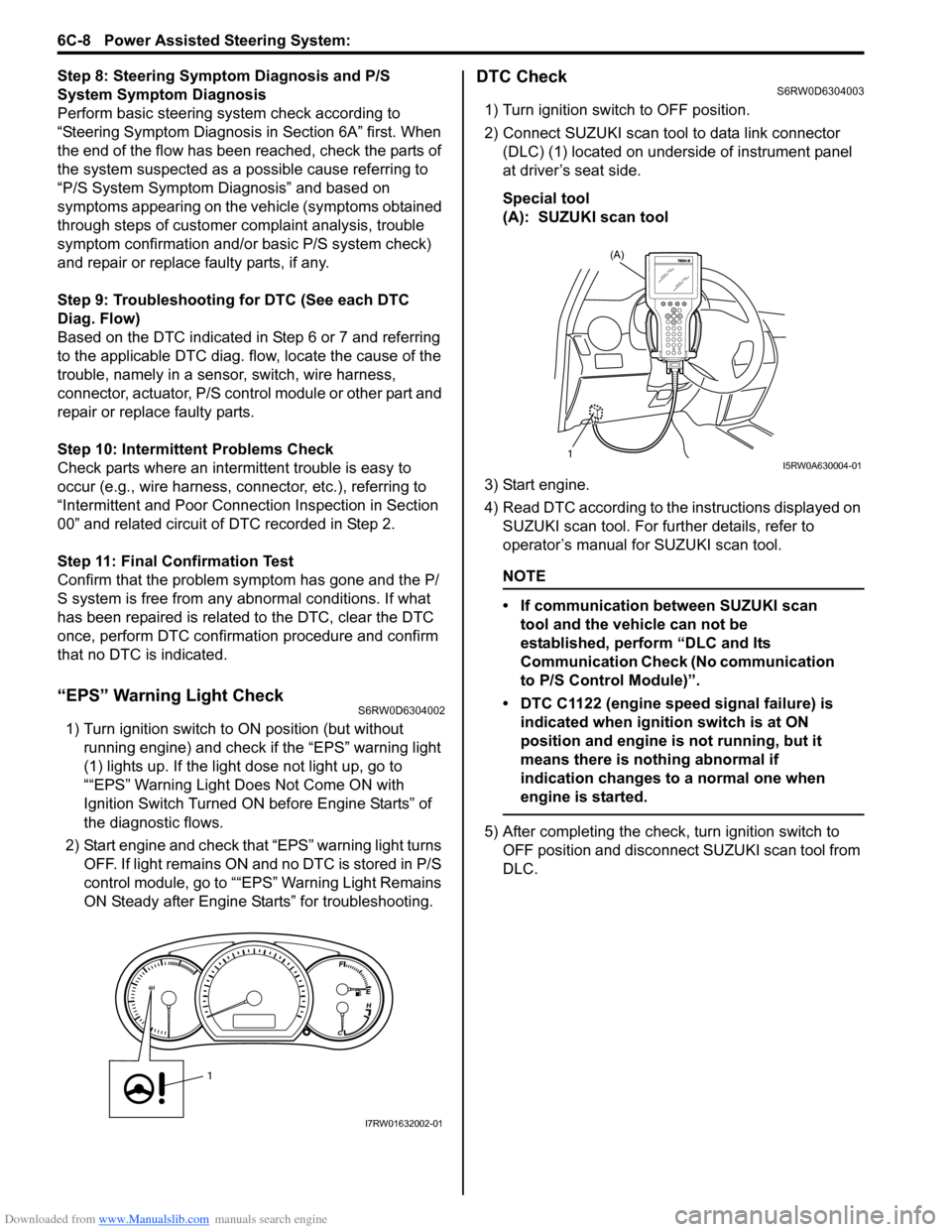

“EPS” Warning Light CheckS6RW0D6304002

1) Turn ignition switch to ON position (but without

running engine) and check if the “EPS” warning light

(1) lights up. If the light dose not light up, go to

““EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine Starts” of

the diagnostic flows.

2) Start engine and check that “EPS” warning light turns

OFF. If light remains ON and no DTC is stored in P/S

control module, go to ““EPS” Warning Light Remains

ON Steady after Engine Starts” for troubleshooting.

DTC CheckS6RW0D6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan

tool and the vehicle can not be

established, perform “DLC and Its

Communication Check (No communication

to P/S Control Module)”.

• DTC C1122 (engine speed signal failure) is

indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

1

I7RW01632002-01

(A)

1I5RW0A630004-01

Page 990 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-50 Air Conditioning System: Automatic Type

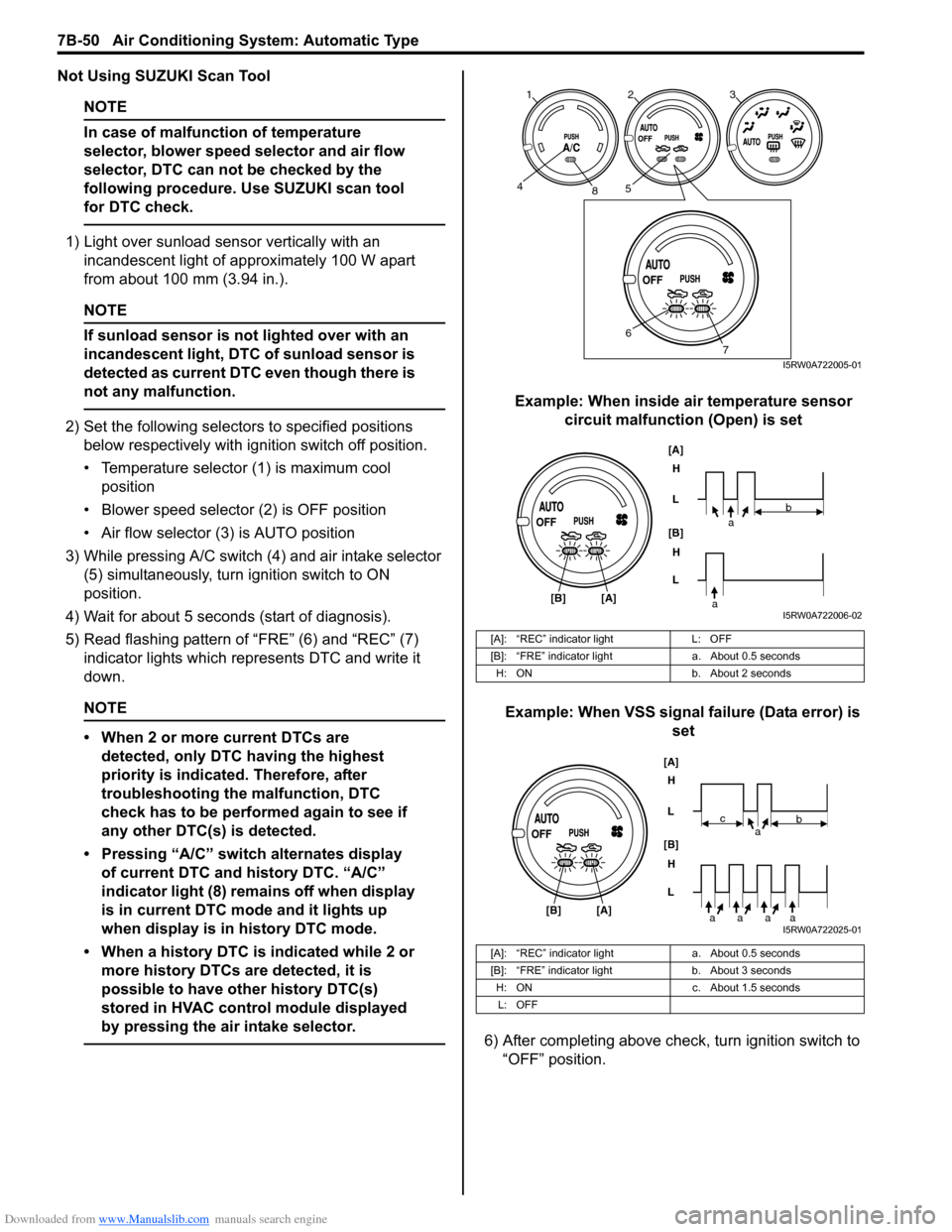

Not Using SUZUKI Scan Tool

NOTE

In case of malfunction of temperature

selector, blower speed selector and air flow

selector, DTC can not be checked by the

following procedure. Use SUZUKI scan tool

for DTC check.

1) Light over sunload sensor vertically with an

incandescent light of approximately 100 W apart

from about 100 mm (3.94 in.).

NOTE

If sunload sensor is not lighted over with an

incandescent light, DTC of sunload sensor is

detected as current DTC even though there is

not any malfunction.

2) Set the following selectors to specified positions

below respectively with ignition switch off position.

• Temperature selector (1) is maximum cool

position

• Blower speed selector (2) is OFF position

• Air flow selector (3) is AUTO position

3) While pressing A/C switch (4) and air intake selector

(5) simultaneously, turn ignition switch to ON

position.

4) Wait for about 5 seconds (start of diagnosis).

5) Read flashing pattern of “FRE” (6) and “REC” (7)

indicator lights which represents DTC and write it

down.

NOTE

• When 2 or more current DTCs are

detected, only DTC having the highest

priority is indicated. Therefore, after

troubleshooting the malfunction, DTC

check has to be performed again to see if

any other DTC(s) is detected.

• Pressing “A/C” switch alternates display

of current DTC and history DTC. “A/C”

indicator light (8) remains off when display

is in current DTC mode and it lights up

when display is in history DTC mode.

• When a history DTC is indicated while 2 or

more history DTCs are detected, it is

possible to have other history DTC(s)

stored in HVAC control module displayed

by pressing the air intake selector.

Example: When inside air temperature sensor

circuit malfunction (Open) is set

Example: When VSS signal failure (Data error) is

set

6) After completing above check, turn ignition switch to

“OFF” position.

[A]: “REC” indicator light L: OFF

[B]: “FRE” indicator light a. About 0.5 seconds

H: ON b. About 2 seconds

[A]: “REC” indicator light a. About 0.5 seconds

[B]: “FRE” indicator light b. About 3 seconds

H: ON c. About 1.5 seconds

L: OFF

123

458

6

7I5RW0A722005-01

[A]

[B]H

L

H

L [B]

[A]

ab

aI5RW0A722006-02

[A]

[B]H

L

H

L [B]

[A]

ab

aaaa

c

I5RW0A722025-01

Page 994 of 1556

![SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 7B-54 Air Conditioning System: Automatic Type

DTC of A/C System detected by ECM

NOTE

When no DTC is detected, “FRE” [A] and “REC” [B] i SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 7B-54 Air Conditioning System: Automatic Type

DTC of A/C System detected by ECM

NOTE

When no DTC is detected, “FRE” [A] and “REC” [B] i](/img/20/7612/w960_7612-993.png)

Downloaded from www.Manualslib.com manuals search engine 7B-54 Air Conditioning System: Automatic Type

DTC of A/C System detected by ECM

NOTE

When no DTC is detected, “FRE” [A] and “REC” [B] indicator lights on HVAC control module flash at

the same time in specific pattern.

Fail-Safe TableS6RW0D7224007

When any of the following malfunctions (DTCs) is detected, fail-safe mode is activated.

However, when HVAC control module detects normal operation of A/C system, fail-safe mode is canceled. DTC No. Detection itemDetecting condition

(DTC will set when detecting)MIL

P0481 Fan 2 Control Circuit

Refer to “Fail-Safe Table in Section 1A”. P0532A/C Refrigerant Pressure

Sensor Circuit Low

P0533A/C Refrigerant Pressure

Sensor Circuit High

H: ON a. About 3 seconds

L: OFF b. About 1 seconds

DTC No. Trouble AreaFail-Safe Operation

When ignition switch is turned ON

after malfunction is already detectedWhen malfunction is detected during

ignition switch is ON

�) B1502Inside air temperature

sensor circuitHVAC control module maintains last

normal value.HVAC control module controls actuators

assuming that inside air temperature is

25 °C (77 °F).

�) B1503A/C evaporator

temperature sensor

circuitHVAC control module assuming that

evaporator temperature is 0 °C (32 °F).• HVAC control module turns off A/C

switch signal.

• HVAC control module controls

actuators assuming that evaporator

temperature is 0 °C (32 °F).

�) B1504 Sunload sensor circuitHVAC control module maintains last

normal value.HVAC control module controls actuators

assuming that amount of sunlight is 0 W/

m

2.

�) B1520Temperature selector

malfunctionHVAC control module maintains last

normal value.HVAC control module controls actuators

assuming that setting of temperature

selector is 25 °C (77 °F) position.

�) B1521Blower speed selector

malfunctionHVAC control module maintains last

normal value.HVAC control module controls actuators

assuming that setting of blower speed

selector is low (1st) position.

�) B1522Air flow selector

malfunctionHVAC control module maintains last

normal value.HVAC control module controls actuators

assuming that setting of air flow selector

is DEF position.

[A]

[A]H

L

H

L [B]

[B]

baaba

baaba

I5RW0A722008-01

Page 1025 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-85

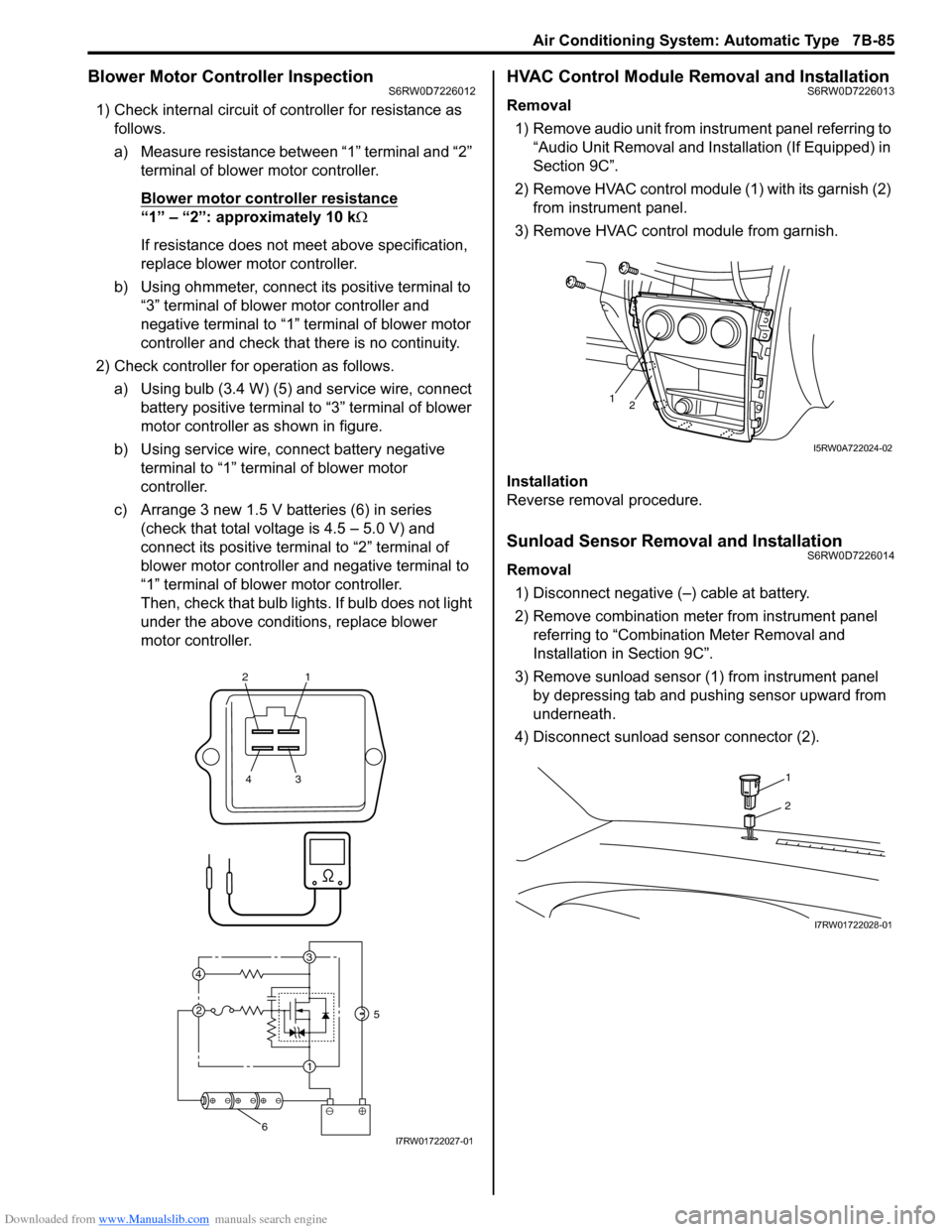

Blower Motor Controller InspectionS6RW0D7226012

1) Check internal circuit of controller for resistance as

follows.

a) Measure resistance between “1” terminal and “2”

terminal of blower motor controller.

Blower motor controller resistance

“1” – “2”: approximately 10 kΩ

If resistance does not meet above specification,

replace blower motor controller.

b) Using ohmmeter, connect its positive terminal to

“3” terminal of blower motor controller and

negative terminal to “1” terminal of blower motor

controller and check that there is no continuity.

2) Check controller for operation as follows.

a) Using bulb (3.4 W) (5) and service wire, connect

battery positive terminal to “3” terminal of blower

motor controller as shown in figure.

b) Using service wire, connect battery negative

terminal to “1” terminal of blower motor

controller.

c) Arrange 3 new 1.5 V batteries (6) in series

(check that total voltage is 4.5 – 5.0 V) and

connect its positive terminal to “2” terminal of

blower motor controller and negative terminal to

“1” terminal of blower motor controller.

Then, check that bulb lights. If bulb does not light

under the above conditions, replace blower

motor controller.

HVAC Control Module Removal and InstallationS6RW0D7226013

Removal

1) Remove audio unit from instrument panel referring to

“Audio Unit Removal and Installation (If Equipped) in

Section 9C”.

2) Remove HVAC control module (1) with its garnish (2)

from instrument panel.

3) Remove HVAC control module from garnish.

Installation

Reverse removal procedure.

Sunload Sensor Removal and InstallationS6RW0D7226014

Removal

1) Disconnect negative (–) cable at battery.

2) Remove combination meter from instrument panel

referring to “Combination Meter Removal and

Installation in Section 9C”.

3) Remove sunload sensor (1) from instrument panel

by depressing tab and pushing sensor upward from

underneath.

4) Disconnect sunload sensor connector (2).

21

43

3

1 2 4

5

6I7RW01722027-01

12

I5RW0A722024-02

1

2

I7RW01722028-01

Page 1321 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-2

Igniter

Igniter generates high voltage needed to turn on the discharge headlight. It is charged with high voltage raised by the

ballast and it applies voltage pulse as high as about 20,000V to the tungsten electrode in the discharge headlight bulb.

After the discharge headlights light up, the ballast supplies voltage to bulbs.

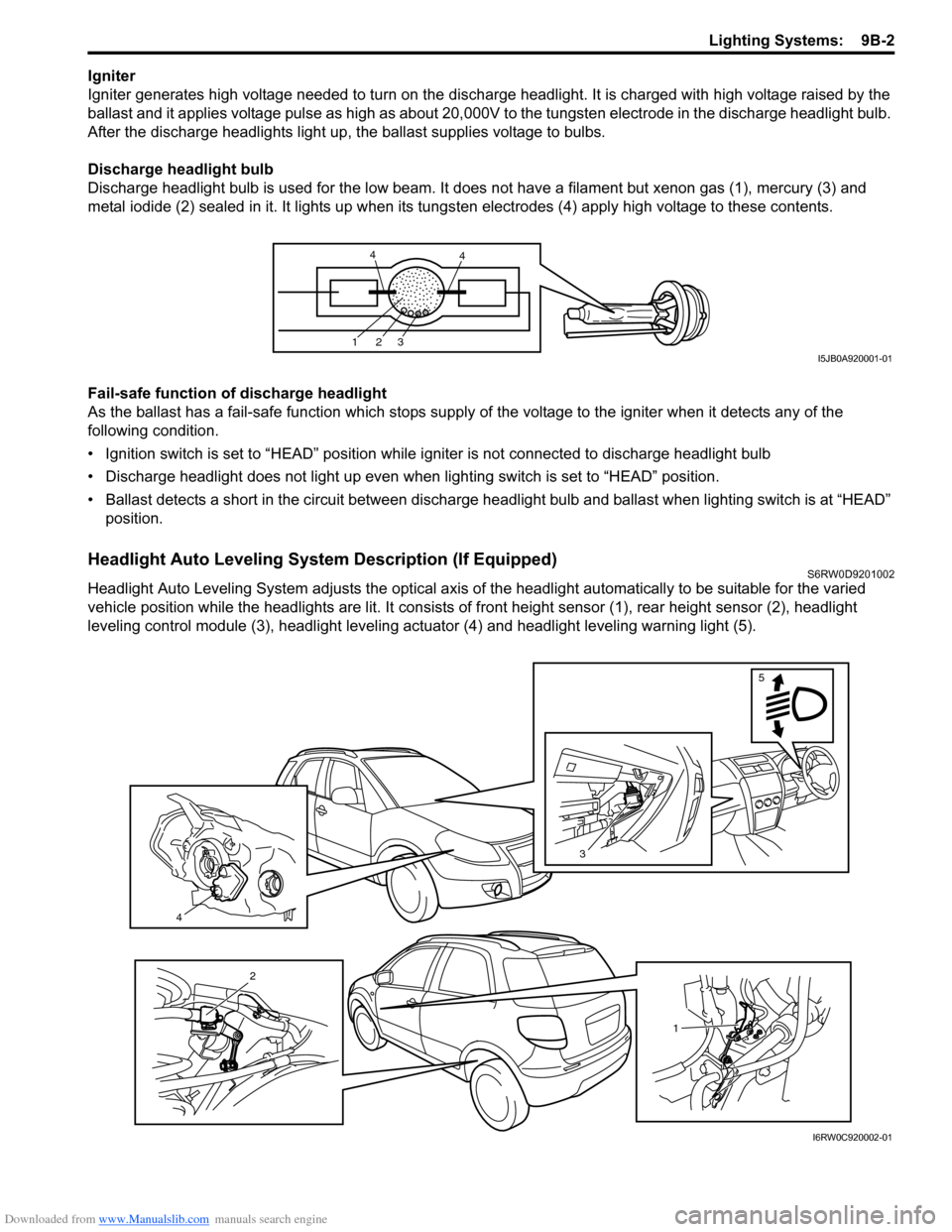

Discharge headlight bulb

Discharge headlight bulb is used for the low beam. It does not have a filament but xenon gas (1), mercury (3) and

metal iodide (2) sealed in it. It lights up when its tungsten electrodes (4) apply high voltage to these contents.

Fail-safe function of discharge headlight

As the ballast has a fail-safe function which stops supply of the voltage to the igniter when it detects any of the

following condition.

• Ignition switch is set to “HEAD” position while igniter is not connected to discharge headlight bulb

• Discharge headlight does not light up even when lighting switch is set to “HEAD” position.

• Ballast detects a short in the circuit between discharge headlight bulb and ballast when lighting switch is at “HEAD”

position.

Headlight Auto Leveling System Description (If Equipped)S6RW0D9201002

Headlight Auto Leveling System adjusts the optical axis of the headlight automatically to be suitable for the varied

vehicle position while the headlights are lit. It consists of front height sensor (1), rear height sensor (2), headlight

leveling control module (3), headlight leveling actuator (4) and headlight leveling warning light (5).

123

44

I5JB0A920001-01

4

3

5

1

2

I6RW0C920002-01

Page 1323 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-4

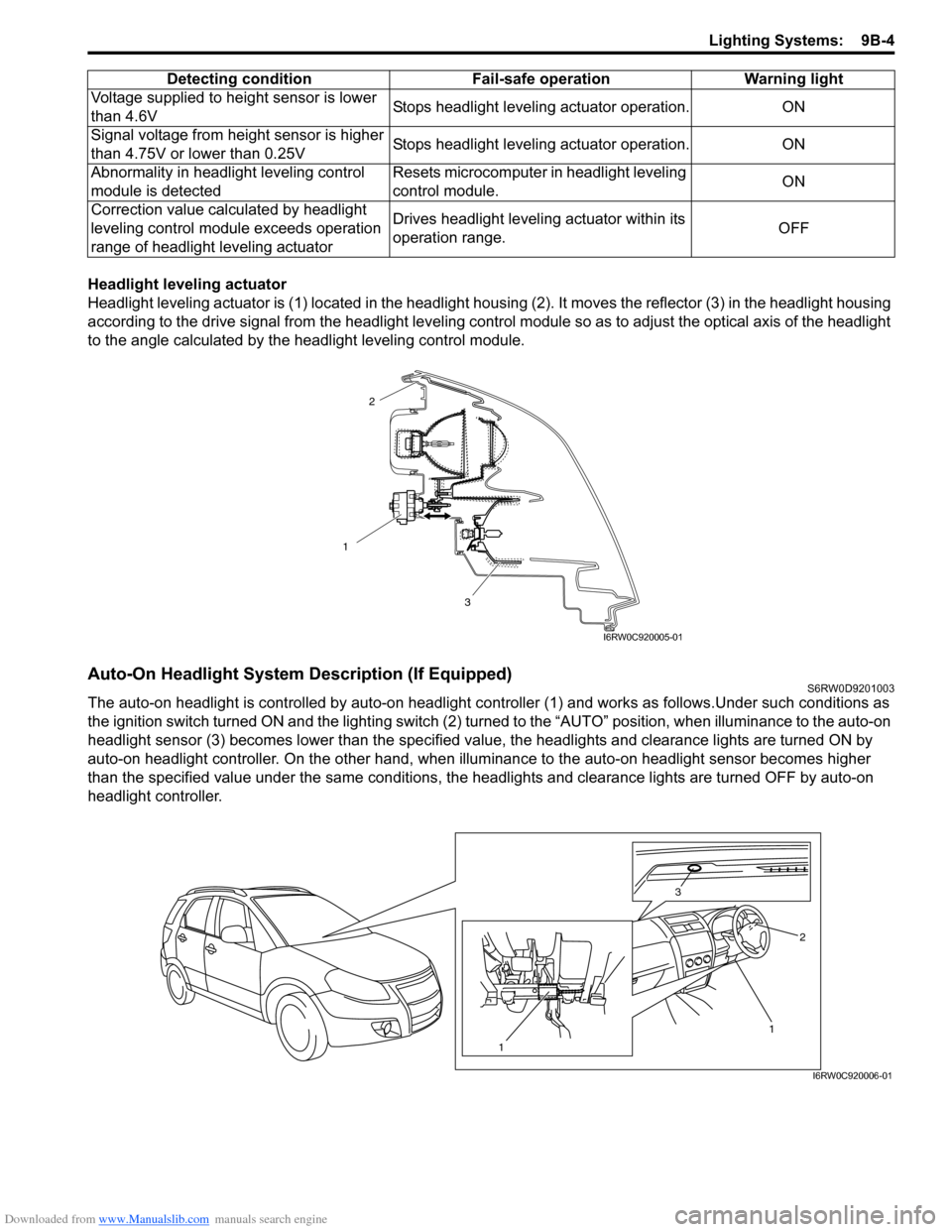

Headlight leveling actuator

Headlight leveling actuator is (1) located in the headlight housing (2). It moves the reflector (3) in the headlight housing

according to the drive signal from the headlight leveling control module so as to adjust the optical axis of the headlight

to the angle calculated by the headlight leveling control module.

Auto-On Headlight System Description (If Equipped)S6RW0D9201003

The auto-on headlight is controlled by auto-on headlight controller (1) and works as follows.Under such conditions as

the ignition switch turned ON and the lighting switch (2) turned to the “AUTO” position, when illuminance to the auto-on

headlight sensor (3) becomes lower than the specified value, the headlights and clearance lights are turned ON by

auto-on headlight controller. On the other hand, when illuminance to the auto-on headlight sensor becomes higher

than the specified value under the same conditions, the headlights and clearance lights are turned OFF by auto-on

headlight controller.Voltage supplied to height sensor is lower

than 4.6VStops headlight leveling actuator operation. ON

Signal voltage from height sensor is higher

than 4.75V or lower than 0.25VStops headlight leveling actuator operation. ON

Abnormality in headlight leveling control

module is detectedResets microcomputer in headlight leveling

control module.ON

Correction value calculated by headlight

leveling control module exceeds operation

range of headlight leveling actuatorDrives headlight leveling actuator within its

operation range.OFF Detecting condition Fail-safe operation Warning light

1

3

2

I6RW0C920005-01

1 3

2

1

I6RW0C920006-01

Page 1327 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-8

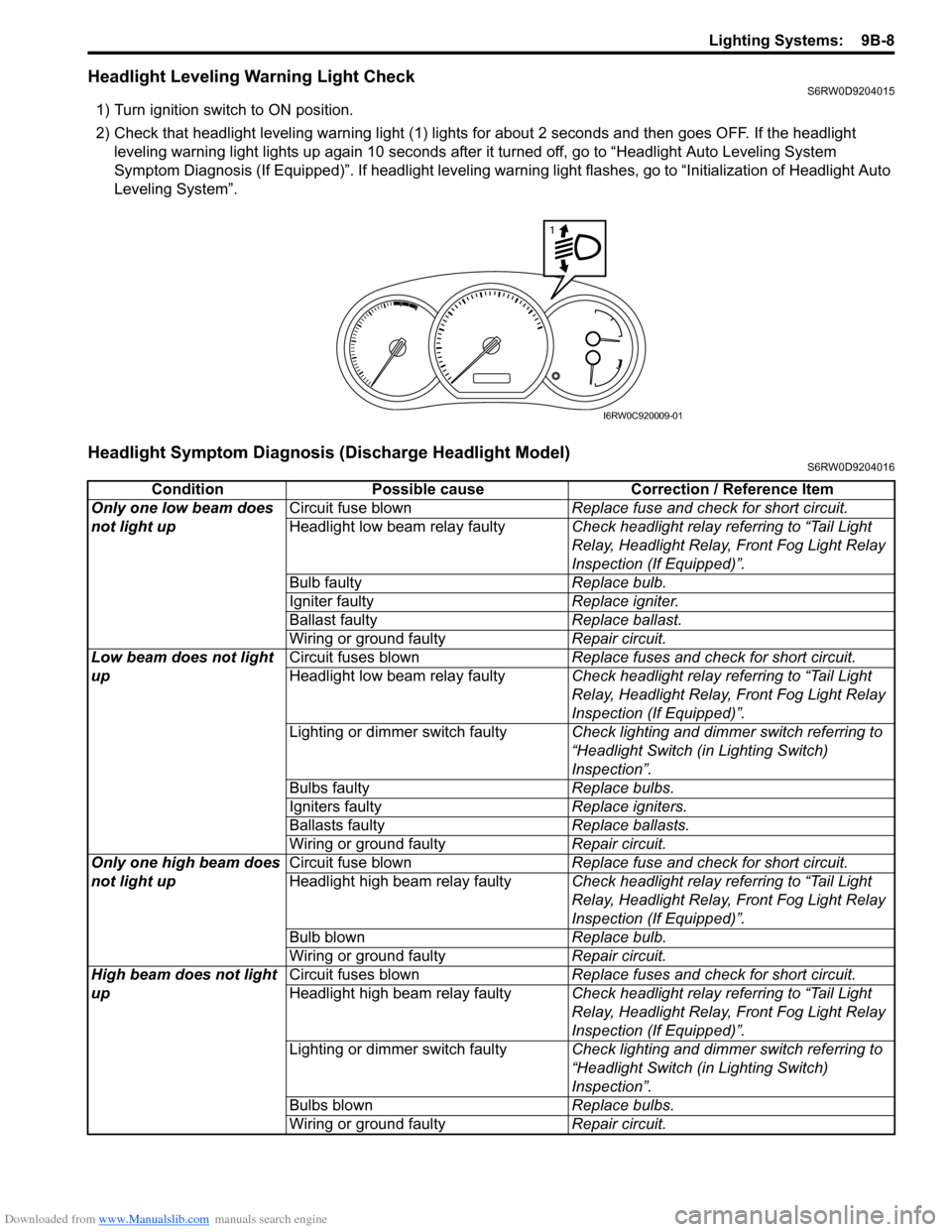

Headlight Leveling Warning Light CheckS6RW0D9204015

1) Turn ignition switch to ON position.

2) Check that headlight leveling warning light (1) lights for about 2 seconds and then goes OFF. If the headlight

leveling warning light lights up again 10 seconds after it turned off, go to “Headlight Auto Leveling System

Symptom Diagnosis (If Equipped)”. If headlight leveling warning light flashes, go to “Initialization of Headlight Auto

Leveling System”.

Headlight Symptom Diagnosis (Discharge Headlight Model)S6RW0D9204016

1

I6RW0C920009-01

Condition Possible cause Correction / Reference Item

Only one low beam does

not light upCircuit fuse blownReplace fuse and check for short circuit.

Headlight low beam relay faultyCheck headlight relay referring to “Tail Light

Relay, Headlight Relay, Front Fog Light Relay

Inspection (If Equipped)”.

Bulb faultyReplace bulb.

Igniter faultyReplace igniter.

Ballast faultyReplace ballast.

Wiring or ground faultyRepair circuit.

Low beam does not light

upCircuit fuses blownReplace fuses and check for short circuit.

Headlight low beam relay faultyCheck headlight relay referring to “Tail Light

Relay, Headlight Relay, Front Fog Light Relay

Inspection (If Equipped)”.

Lighting or dimmer switch faultyCheck lighting and dimmer switch referring to

“Headlight Switch (in Lighting Switch)

Inspection”.

Bulbs faultyReplace bulbs.

Igniters faultyReplace igniters.

Ballasts faultyReplace ballasts.

Wiring or ground faultyRepair circuit.

Only one high beam does

not light upCircuit fuse blownReplace fuse and check for short circuit.

Headlight high beam relay faultyCheck headlight relay referring to “Tail Light

Relay, Headlight Relay, Front Fog Light Relay

Inspection (If Equipped)”.

Bulb blownReplace bulb.

Wiring or ground faultyRepair circuit.

High beam does not light

upCircuit fuses blownReplace fuses and check for short circuit.

Headlight high beam relay faultyCheck headlight relay referring to “Tail Light

Relay, Headlight Relay, Front Fog Light Relay

Inspection (If Equipped)”.

Lighting or dimmer switch faultyCheck lighting and dimmer switch referring to

“Headlight Switch (in Lighting Switch)

Inspection”.

Bulbs blownReplace bulbs.

Wiring or ground faultyRepair circuit.