warning light SUZUKI SX4 2006 1.G Service Owner's Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 618 of 1556

![SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 4E-13 ABS:

ABS Warning Light Does Not Come ON at Ignition Switch ONS6RW0D4504008

Wiring Diagram

E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

SUZUKI SX4 2006 1.G Service Owners Manual Downloaded from www.Manualslib.com manuals search engine 4E-13 ABS:

ABS Warning Light Does Not Come ON at Ignition Switch ONS6RW0D4504008

Wiring Diagram

E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19](/img/20/7612/w960_7612-617.png)

Downloaded from www.Manualslib.com manuals search engine 4E-13 ABS:

ABS Warning Light Does Not Come ON at Ignition Switch ONS6RW0D4504008

Wiring Diagram

E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26 G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32

WHTGRN

3

E08-2

E08-13REDWHT 5

4 13

9

E08-23BLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

14

G241-31

RED/BLK

8

REDWHTREDWHT

9

12V

12V

11

12E04-5

G04-4G04-2E04-1E04-2

L01-6

RED/BLK

RED/BLU

10

[E]

1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17

18 19 20 21 22G041 2 3 4 5 6 7

8 9 10 11 12 13 14E048 9

10 11 12

13 14

15

16

17 18L011

2 3 4 5 6

7 [A]

I6RW0D450007-01

Page 619 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-14

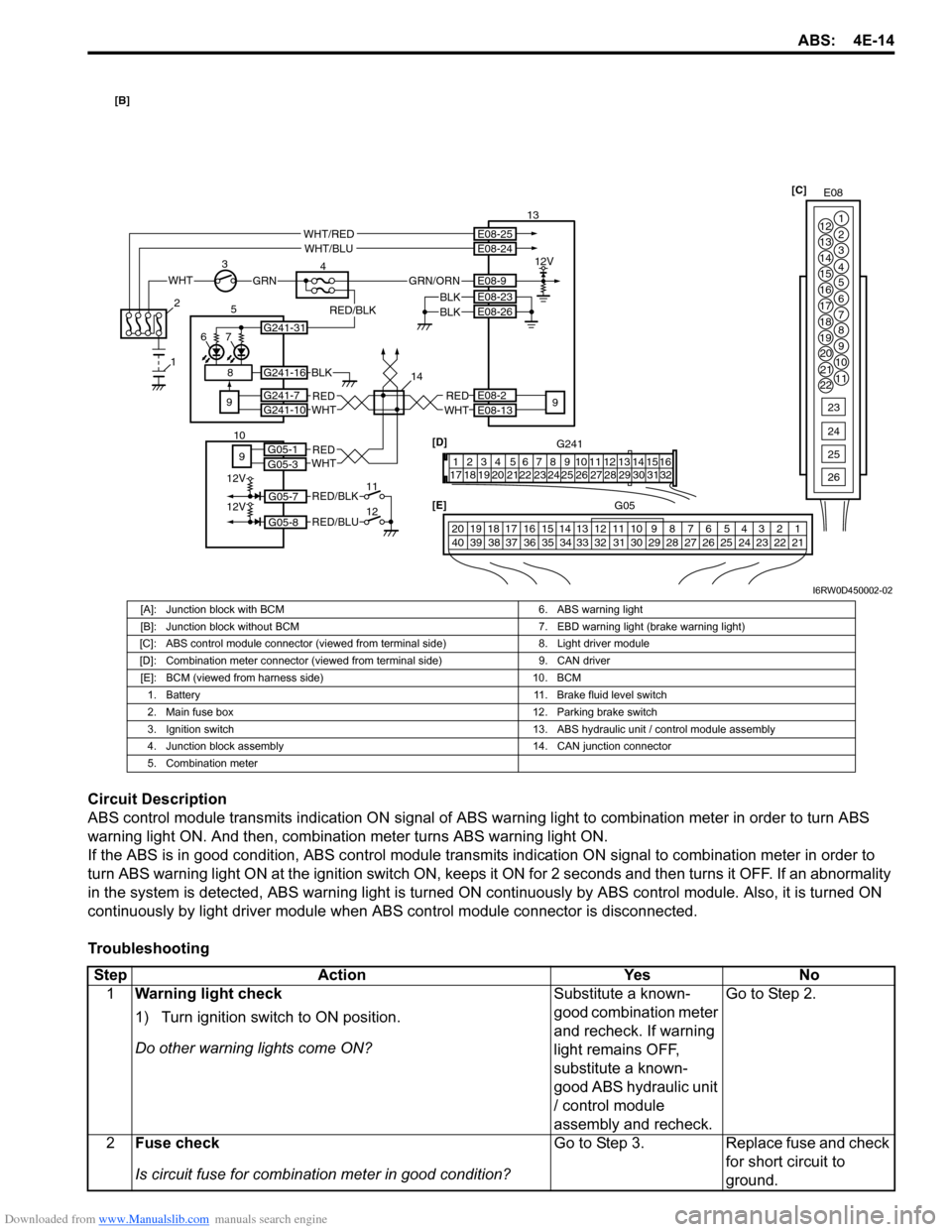

Circuit Description

ABS control module transmits indication ON signal of ABS warning light to combination meter in order to turn ABS

warning light ON. And then, combination meter turns ABS warning light ON.

If the ABS is in good condition, ABS control module transmits indication ON signal to combination meter in order to

turn ABS warning light ON at the ignition switch ON, keeps it ON for 2 seconds and then turns it OFF. If an abnormality

in the system is detected, ABS warning light is turned ON continuously by ABS control module. Also, it is turned ON

continuously by light driver module when ABS control module connector is disconnected.

Troubleshooting

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32E08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

WHTGRN

3

E08-2

E08-13REDWHT 5

4 13

9

E08-23

E08-26BLKBLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

14

G241-31

RED/BLK

8

REDWHT9

12V

12V

11

12G05-7

G05-1G05-3

G05-8

RED/BLK

RED/BLU

10

[B]

I6RW0D450002-02

[A]: Junction block with BCM 6. ABS warning light

[B]: Junction block without BCM 7. EBD warning light (brake warning light)

[C]: ABS control module connector (viewed from terminal side) 8. Light driver module

[D]: Combination meter connector (viewed from terminal side) 9. CAN driver

[E]: BCM (viewed from harness side) 10. BCM

1. Battery 11. Brake fluid level switch

2. Main fuse box 12. Parking brake switch

3. Ignition switch 13. ABS hydraulic unit / control module assembly

4. Junction block assembly 14. CAN junction connector

5. Combination meter

Step Action Yes No

1Warning light check

1) Turn ignition switch to ON position.

Do other warning lights come ON?Substitute a known-

good combination meter

and recheck. If warning

light remains OFF,

substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Go to Step 2.

2Fuse check

Is circuit fuse for combination meter in good condition?Go to Step 3. Replace fuse and check

for short circuit to

ground.

Page 620 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-15 ABS:

ABS Warning Light Comes ON SteadyS6RW0D4504009

Wiring Diagram

Refer to “Warning Diagram” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

Refer to “Circuit Description” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Troubleshooting 3Combination meter power source circuit check

1) Remove combination meter with ignition switch turned

OFF.

2) Check for proper connection to “RED/BLK” and “BLK”

wire of combination meter connector.

3) If OK then turn ON ignition switch and measure voltage

at “RED/BLK” wire of combination meter connector and

vehicle body ground.

Is it 10 - 14 V?Go to Step 4. Repair power source

circuit for combination

meter.

4Combination meter ground circuit check

1) Measure resistance between “BLK” wire of combination

meter connector and vehicle body ground.

Is resistance less than 2

Ω?Substitute a known-

good combination meter

and recheck.“BLK” circuit open or

high resistance. Step Action Yes No

Step Action Yes No

1DTC check

1) Perform diagnostic trouble code check.

Is there any DTC(s)?Go to Step 7 of “ABS

Check”.Go to Step 2.

2ABS hydraulic unit / control module assembly power

and ground circuit check

1) Check that ABS hydraulic unit / control module assembly

power supply circuit and ground circuit is in good

condition referring to “ABS Hydraulic Unit / Control

Module Assembly Power and Ground Circuit Check”.

Are check results OK?Go to Step 3. Repair ABS hydraulic

unit / control module

assembly power or

ground circuit.

3CAN communication line circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check for proper connection to CAN communication line

wire.

4) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good combination meter

and recheck. If warning

light remains ON,

substitute a known-

good ABS hydraulic unit

/ control module

assembly and recheck.Repair circuit and

recheck.

Page 621 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-16

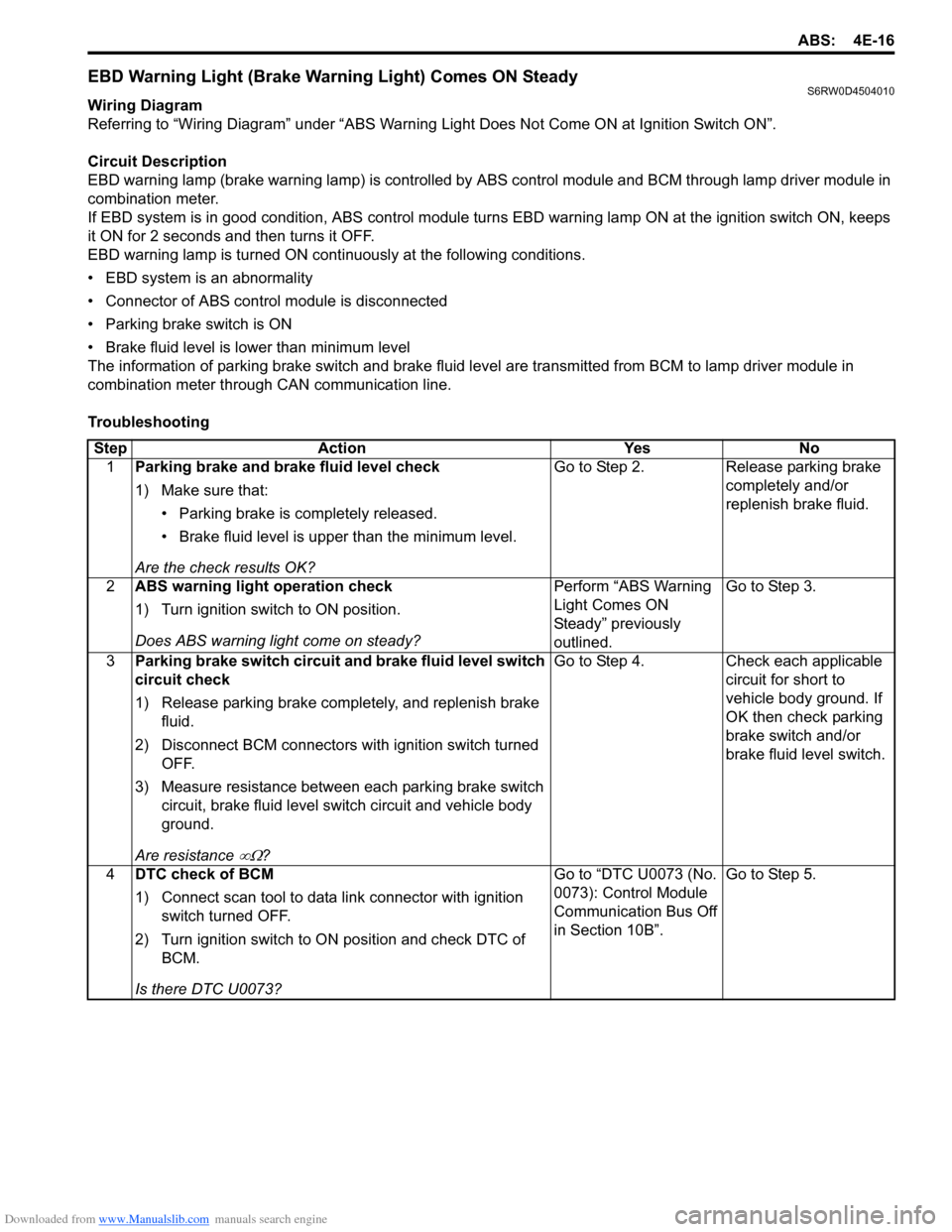

EBD Warning Light (Brake Warning Light) Comes ON SteadyS6RW0D4504010

Wiring Diagram

Referring to “Wiring Diagram” under “ABS Warning Light Does Not Come ON at Ignition Switch ON”.

Circuit Description

EBD warning lamp (brake warning lamp) is controlled by ABS control module and BCM through lamp driver module in

combination meter.

If EBD system is in good condition, ABS control module turns EBD warning lamp ON at the ignition switch ON, keeps

it ON for 2 seconds and then turns it OFF.

EBD warning lamp is turned ON continuously at the following conditions.

• EBD system is an abnormality

• Connector of ABS control module is disconnected

• Parking brake switch is ON

• Brake fluid level is lower than minimum level

The information of parking brake switch and brake fluid level are transmitted from BCM to lamp driver module in

combination meter through CAN communication line.

Troubleshooting

Step Action Yes No

1Parking brake and brake fluid level check

1) Make sure that:

• Parking brake is completely released.

• Brake fluid level is upper than the minimum level.

Are the check results OK?Go to Step 2. Release parking brake

completely and/or

replenish brake fluid.

2ABS warning light operation check

1) Turn ignition switch to ON position.

Does ABS warning light come on steady?Perform “ABS Warning

Light Comes ON

Steady” previously

outlined.Go to Step 3.

3Parking brake switch circuit and brake fluid level switch

circuit check

1) Release parking brake completely, and replenish brake

fluid.

2) Disconnect BCM connectors with ignition switch turned

OFF.

3) Measure resistance between each parking brake switch

circuit, brake fluid level switch circuit and vehicle body

ground.

Are resistance

∞Ω?Go to Step 4. Check each applicable

circuit for short to

vehicle body ground. If

OK then check parking

brake switch and/or

brake fluid level switch.

4DTC check of BCM

1) Connect scan tool to data link connector with ignition

switch turned OFF.

2) Turn ignition switch to ON position and check DTC of

BCM.

Is there DTC U0073?Go to “DTC U0073 (No.

0073): Control Module

Communication Bus Off

in Section 10B”.Go to Step 5.

Page 622 of 1556

Downloaded from www.Manualslib.com manuals search engine 4E-17 ABS:

Serial Data Link Circuit CheckS6RW0D4504011

Wiring Diagram5CAN communication line circuit check

1) Turn ignition switch to OFF position.

2) Disconnect connectors of all control modules

communicating by means of CAN.

3) Check for proper connection to CAN communication line

wire.

4) If OK then check CAN communication line circuit

between control modules for open, short and high

resistance.

Is each CAN communication line circuit in good condition?Substitute a known-

good combination meter

and recheck. If EBD

warning light remains

OFF, substitute a

known-good BCM and/

or ABS hydraulic unit /

control module

assembly and recheck.Repair CAN

communication line

circuit. Step Action Yes No

11+BBBG

G1

12V

14BLU

REDWHTE08 [C]

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26WHTGRN

3

E08-2

E08-13REDWHT 5

4 12

9

E08-23BLK

67

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

2

1

13

G241-31

RED/BLK

8

REDWHTREDWHT

9

10

E08-16 G04-4

G04-2

G04-1

G04-3 E04-1

E04-2

[D]

1 2 3 4 5 6 7 8 9 10 11

12 13 14 15 16 17

18 19 20 21 22G041 2 3 4 5 6 7

8 9 10 11 12 13 14E04

G241 [E]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32 [A]

I6RW0D450008-01

Page 623 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-18

WHTGRN

3

E08-2

E08-13REDWHT 5

4 12

9

E08-23

E08-26BLKBLK

76

BLK

REDWHTG241-7G241-10

G241-16

12V

E08-25E08-24

E08-9

WHT/REDWHT/BLU

GRN/ORN

9

REDWHTG05-1G05-3

REDWHTG05-4G05-2

9

2

1

13

G241-31

RED/BLK

8

11+BBBG

G1

12V

E08-1614BLU 10

[C]E08

1

2

3

4

5

6

7 12

13

14

15

16

17

18

19

20

21

228

9

10

11

23

24

25

26

G05 [E]

1 2 3 4 765 8 9 10 11 14 15 16

36 34 33 32 3135 24 23 2122 28 27 2526 37 39 38 4018 17 13 12 19 20

30 29

G241 [D]

132 4 5 6 7 8 9 10111213141516

17 1918 20 2122 23 24 25 26 27 28 29 30 31 32 [B]

I6RW0D450003-02

[A]: Junction block with BCM 3. Ignition switch 10. BCM

[B]: Junction block without BCM 4. Junction block assembly 11. Data link connector (DLC)

[C]: ABS control module connector (viewed from

terminal side)5. Combination meter 12. ABS hydraulic unit / control module assembly

[D]: BCM connector (viewed from harness side) 6.ABS warning light 13. CAN junction connector

[E]: Combination meter connector (viewed from

terminal side)7. EBD warning light (brake

warning light)14. To TCM (A/T model), BCM, 4WD control module, P/S control

module (electric P/S model), HVAC control module (auto A/C

model) and SDM

1. Battery 8. Light driver module

2. Main fuse box 9. CAN driver

Page 639 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-34

Installation

1) Install hydraulic unit / control module assembly by

reversing removal procedure noting the following.

Install ABS hydraulic unit / control module assembly

bracket bolt as follows.

a) Tighten bracket bolt (1) and (2) by hand.

b) Then tighten bracket bolt to specified torque.

Tightening order (1) → (2)

Tightening torque

Brake pipe flare nut (a): 16 N·m (1.6 kgf-m, 11.5

lb-ft)

ABS hydraulic unit / control module assembly

bolt (b): 9 N·m (0.9 kgf-m, 6.5 lb-ft)

ABS hydraulic unit / control module assembly

bracket bolt (c): 26 N·m (2.6 kgf-m, 19.0 lb-ft)2) Bleed air from brake system referring to “Air

Bleeding of Brake System in Section 4A”.

3) Check each installed part for fluid leakage and

perform “ABS Hydraulic Unit Operation Check”.

NOTE

For new ABS hydraulic unit / control module

assembly, if “ABS Hydraulic Unit Operation

Check” has not been performed, ABS

warning light may flash when ignition switch

is turned ON position.

Accordingly preform “ABS Hydraulic Unit

Operation Check” to stop flashing of ABS

warning light.

Front and Rear Wheel Speed Sensor On-Vehicle

Inspection

S6RW0D4506005

Output Voltage Inspection

1) Disconnect negative (–) cable from battery.

2) Hoist vehicle a little.

3) Disconnect wheel speed sensor connector.

4) Set up measuring device as shown in figure, the

resistance to 115 Ω and the power supply voltage to

12 V.

CAUTION!

Incorrect voltage and/or wrong connection

cause damage to wheel speed sensor.

I6RW0C450011-01

1. Wheel speed sensor connector 4. “BLK” wire terminal

2. Resistance (115Ω) 5. Power supply (12 V)

3. “WHT” wire terminal

V

41

3

2

5

I5JB0A450026-03

Page 645 of 1556

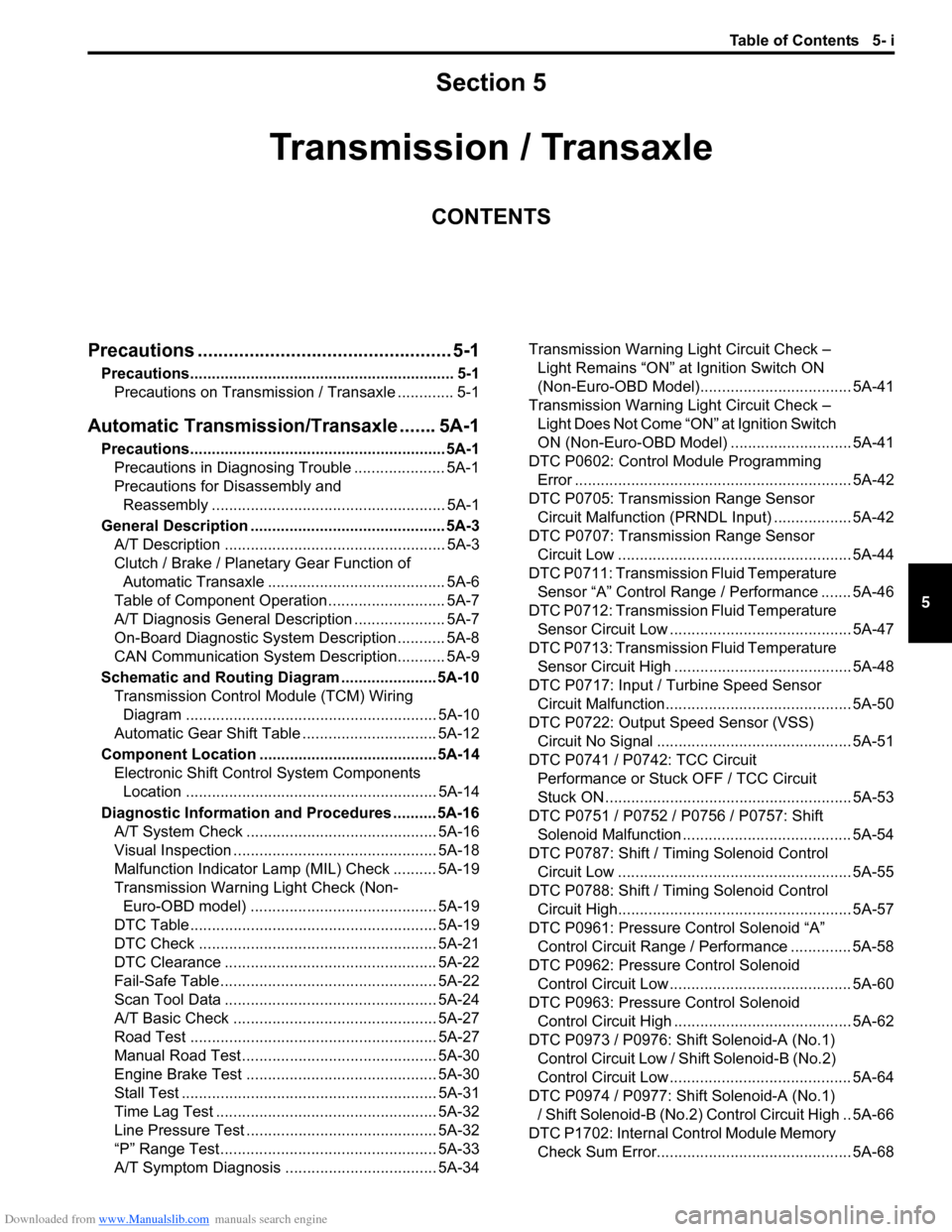

Downloaded from www.Manualslib.com manuals search engine Table of Contents 5- i

5

Section 5

CONTENTS

Transmission / Transaxle

Precautions ................................................. 5-1

Precautions............................................................. 5-1

Precautions on Transmission / Transaxle ............. 5-1

Automatic Transmission/Transaxle ....... 5A-1

Precautions........................................................... 5A-1

Precautions in Diagnosing Trouble ..................... 5A-1

Precautions for Disassembly and

Reassembly ...................................................... 5A-1

General Description ............................................. 5A-3

A/T Description ................................................... 5A-3

Clutch / Brake / Planetary Gear Function of

Automatic Transaxle ......................................... 5A-6

Table of Component Operation ........................... 5A-7

A/T Diagnosis General Description ..................... 5A-7

On-Board Diagnostic System Description ........... 5A-8

CAN Communication System Description........... 5A-9

Schematic and Routing Diagram ...................... 5A-10

Transmission Control Module (TCM) Wiring

Diagram .......................................................... 5A-10

Automatic Gear Shift Table ............................... 5A-12

Component Location ......................................... 5A-14

Electronic Shift Control System Components

Location .......................................................... 5A-14

Diagnostic Information and Procedures .......... 5A-16

A/T System Check ............................................ 5A-16

Visual Inspection ............................................... 5A-18

Malfunction Indicator Lamp (MIL) Check .......... 5A-19

Transmission Warning Light Check (Non-

Euro-OBD model) ........................................... 5A-19

DTC Table ......................................................... 5A-19

DTC Check ....................................................... 5A-21

DTC Clearance ................................................. 5A-22

Fail-Safe Table .................................................. 5A-22

Scan Tool Data ................................................. 5A-24

A/T Basic Check ............................................... 5A-27

Road Test ......................................................... 5A-27

Manual Road Test ............................................. 5A-30

Engine Brake Test ............................................ 5A-30

Stall Test ........................................................... 5A-31

Time Lag Test ................................................... 5A-32

Line Pressure Test ............................................ 5A-32

“P” Range Test.................................................. 5A-33

A/T Symptom Diagnosis ................................... 5A-34Transmission Warning Light Circuit Check –

Light Remains “ON” at Ignition Switch ON

(Non-Euro-OBD Model)................................... 5A-41

Transmission Warning Light Circuit Check –

Light Does Not Come “ON” at Ignition Switch

ON (Non-Euro-OBD Model)............................ 5A-41

DTC P0602: Control Module Programming

Error ................................................................ 5A-42

DTC P0705: Transmission Range Sensor

Circuit Malfunction (PRNDL Input) .................. 5A-42

DTC P0707: Transmission Range Sensor

Circuit Low ...................................................... 5A-44

DTC P0711: Transmission Fluid Temperature

Sensor “A” Control Range / Performance ....... 5A-46

DTC P0712: Transmission Fluid Temperature

Sensor Circuit Low .......................................... 5A-47

DTC P0713: Transmission Fluid Temperature

Sensor Circuit High ......................................... 5A-48

DTC P0717: Input / Turbine Speed Sensor

Circuit Malfunction........................................... 5A-50

DTC P0722: Output Speed Sensor (VSS)

Circuit No Signal ............................................. 5A-51

DTC P0741 / P0742: TCC Circuit

Performance or Stuck OFF / TCC Circuit

Stuck ON ......................................................... 5A-53

DTC P0751 / P0752 / P0756 / P0757: Shift

Solenoid Malfunction ....................................... 5A-54

DTC P0787: Shift / Timing Solenoid Control

Circuit Low ...................................................... 5A-55

DTC P0788: Shift / Timing Solenoid Control

Circuit High...................................................... 5A-57

DTC P0961: Pressure Control Solenoid “A”

Control Circuit Range / Performance .............. 5A-58

DTC P0962: Pressure Control Solenoid

Control Circuit Low .......................................... 5A-60

DTC P0963: Pressure Control Solenoid

Control Circuit High ......................................... 5A-62

DTC P0973 / P0976: Shift Solenoid-A (No.1)

Control Circuit Low / Shift Solenoid-B (No.2)

Control Circuit Low .......................................... 5A-64

DTC P0974 / P0977: Shift Solenoid-A (No.1)

/ Shift Solenoid-B (No.2) Control Circuit High .. 5A-66

DTC P1702: Internal Control Module Memory

Check Sum Error............................................. 5A-68

Page 656 of 1556

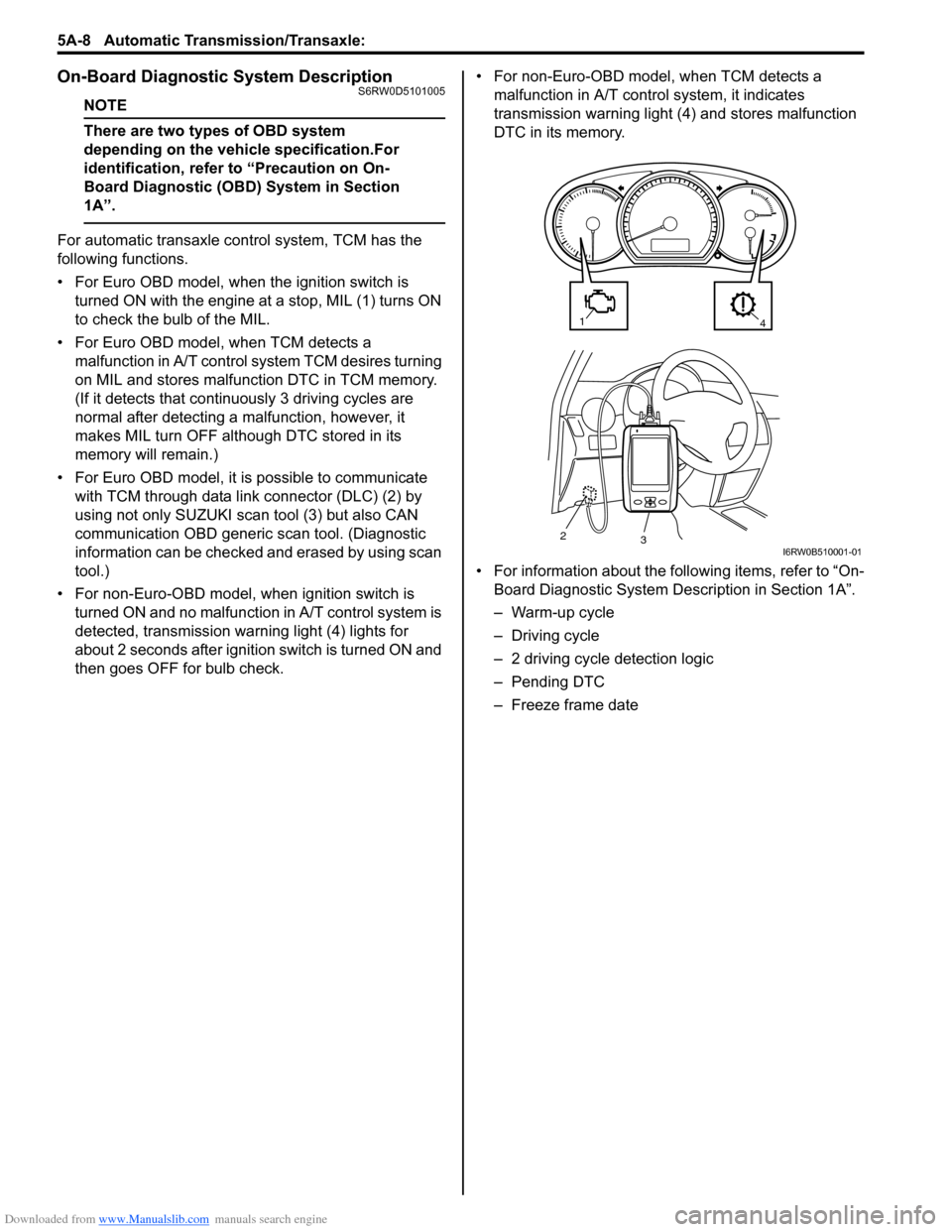

Downloaded from www.Manualslib.com manuals search engine 5A-8 Automatic Transmission/Transaxle:

On-Board Diagnostic System DescriptionS6RW0D5101005

NOTE

There are two types of OBD system

depending on the vehicle specification.For

identification, refer to “Precaution on On-

Board Diagnostic (OBD) System in Section

1A”.

For automatic transaxle control system, TCM has the

following functions.

• For Euro OBD model, when the ignition switch is

turned ON with the engine at a stop, MIL (1) turns ON

to check the bulb of the MIL.

• For Euro OBD model, when TCM detects a

malfunction in A/T control system TCM desires turning

on MIL and stores malfunction DTC in TCM memory.

(If it detects that continuously 3 driving cycles are

normal after detecting a malfunction, however, it

makes MIL turn OFF although DTC stored in its

memory will remain.)

• For Euro OBD model, it is possible to communicate

with TCM through data link connector (DLC) (2) by

using not only SUZUKI scan tool (3) but also CAN

communication OBD generic scan tool. (Diagnostic

information can be checked and erased by using scan

tool.)

• For non-Euro-OBD model, when ignition switch is

turned ON and no malfunction in A/T control system is

detected, transmission warning light (4) lights for

about 2 seconds after ignition switch is turned ON and

then goes OFF for bulb check.• For non-Euro-OBD model, when TCM detects a

malfunction in A/T control system, it indicates

transmission warning light (4) and stores malfunction

DTC in its memory.

• For information about the following items, refer to “On-

Board Diagnostic System Description in Section 1A”.

– Warm-up cycle

– Driving cycle

– 2 driving cycle detection logic

– Pending DTC

– Freeze frame date

1

3 2

4

I6RW0B510001-01

Page 657 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-9

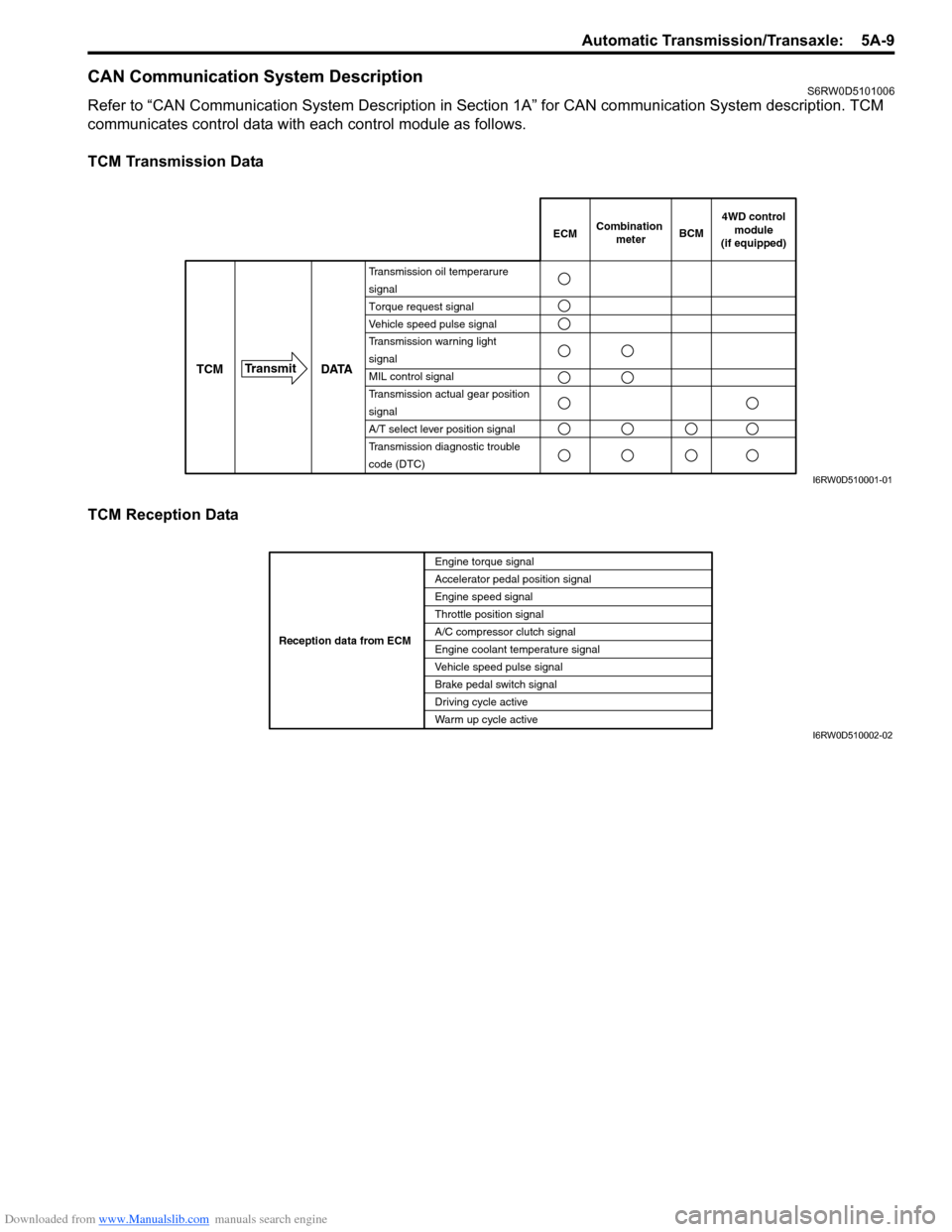

CAN Communication System DescriptionS6RW0D5101006

Refer to “CAN Communication System Description in Section 1A” for CAN communication System description. TCM

communicates control data with each control module as follows.

TCM Transmission Data

TCM Reception Data

DATA TCMTransmit

Transmission oil temperarure

signal

Torque request signal

Vehicle speed pulse signal

Transmission warning light

signal

MIL control signal

Transmission actual gear position

signal

A/T select lever position signal

Transmission diagnostic trouble

code (DTC)

ECMCombination

meterBCM

4WD control

module

(if equipped)

I6RW0D510001-01

Engine torque signal

Accelerator pedal position signal

Engine speed signal

Throttle position signal

A/C compressor clutch signal

Engine coolant temperature signal

Vehicle speed pulse signal

Brake pedal switch signal

Driving cycle active

Warm up cycle active Reception data from ECM

I6RW0D510002-02