DTC SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1011 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-71

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

Serial communication signal is higher than or lower than specified value for

specified time continuously.• Back-up power supply circuit

• Serial communication circuit

•BCM

• Information display

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2Back-up power supply circuit fuse check

1) Check back-up power supply circuit fuse for blowing.

Is fuse(s) blown?Replace blown fuse and

check for short in back-

up power supply circuit.Go to Step 3.

3Wire harness check

1) Turn ignition switch to OFF position.

2) Disconnect connectors from BCM, information display

and HVAC control module.

3) Check for proper connection to serial communication

circuit terminal of BCM, information display and HVAC

control module connectors.

4) If OK, check that serial communication circuit is as

follows.

• Wiring harness resistance of serial communication

circuit is less than 3 Ω

• Insulation resistance between serial communication

circuit terminal and vehicle body ground is Infinity

• Circuit voltage of serial communication circuit is 0 - 1

V with ignition switch turned ON

Are they in good condition?Go to Step 4. Serial communication

circuit is open, short or

high resistance.

4Serial communication signal check

1) Connect connectors to BCM and HVAC control module

with ignition switch turned OFF.

2) Turn ignition switch to ON position.

3) Check that serial communication signal is outputted from

BCM referring to “Voltage Check” under “Inspection of

BCM and Its Circuits in Section 10B”.

Is serial communication signal outputted?Replace information

display.Go to Step 5.

5Communication data check

1) Connect connector to information display with ignition

switch turned OFF.

2) Check that serial communication signal is outputted from

BCM referring to “Voltage Check” under “Inspection of

BCM and Its Circuits in Section 10B”.

Is serial communication signal outputted?Substitute a known-

good HVAC control

module and recheck.Substitute a known-

good BCM and recheck.

Page 1012 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-72 Air Conditioning System: Automatic Type

DTC B1552: HVAC Control Module Check Sum ErrorS6RW0D7224021

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1553: CAN Communication Circuit MalfunctionS6RW0D7224022

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

Data received by HVAC control module from BCM is erroneous continuously. • BCM

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2Serial communication signal data check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Start engine and select “DATA LIST” mode on scan tool.

3) Check “Refrigerant Pressure”, “Vehicle Speed”, “Coolant

Temp” and “Outside Air Temp” displayed on scan tool.

Are values of A/C refrigerant pressure sensor and outside air

temperature within specified ranges indicated in “Scan Tool

Data”?Intermittent trouble.

Check for intermittent

referring to “Intermittent

and Poor Connection

Inspection in Section

00”Substitute a known-

good HVAC control

module and recheck.

If DTC is still detected

substitute a known-

good BCM and recheck.

DTC detecting condition Trouble area

HVAC control module receives error code from BCM continuously. • CAN communication circuit

•BCM

•ECM

• Combination meter

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check DTC in BCM.

Is DTC U0073 (No.0073), U0100 (No.0100) and/or U0155

(No.0155) detected?Go to applicable DTC

diag. flow.Substitute a known-

good HVAC control

module and recheck.

Page 1013 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-73

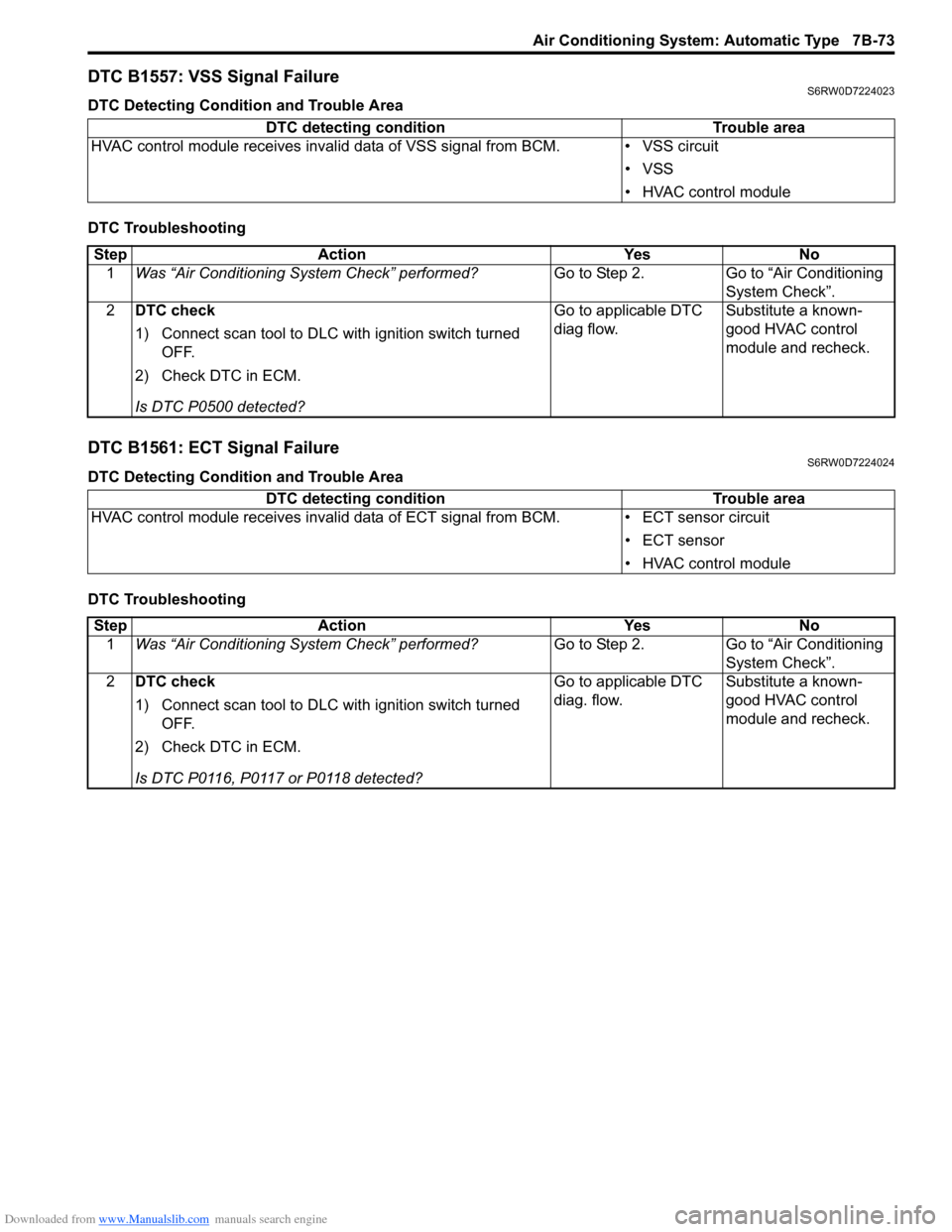

DTC B1557: VSS Signal FailureS6RW0D7224023

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1561: ECT Signal FailureS6RW0D7224024

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives invalid data of VSS signal from BCM. • VSS circuit

• VSS

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check DTC in ECM.

Is DTC P0500 detected?Go to applicable DTC

diag flow.Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition Trouble area

HVAC control module receives invalid data of ECT signal from BCM. • ECT sensor circuit

• ECT sensor

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check DTC in ECM.

Is DTC P0116, P0117 or P0118 detected?Go to applicable DTC

diag. flow.Substitute a known-

good HVAC control

module and recheck.

Page 1014 of 1556

Downloaded from www.Manualslib.com manuals search engine 7B-74 Air Conditioning System: Automatic Type

DTC B1562: Outside Air Temperature Signal FailureS6RW0D7224025

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1563: A/C Refrigerant Pressure Signal FailureS6RW0D7224026

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives invalid data of outside air temperature signal

from BCM.• Outside air temperature sensor

circuit

• Outside air temperature sensor

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check DTC in BCM.

Is DTC B1141 or B1142 detected?Go to applicable DTC

diag. flow.Substitute a known-

good HVAC control

module and recheck.

DTC detecting condition Trouble area

HVAC control module receives invalid data of A/C refrigerant pressure signal

from BCM.• A/C refrigerant pressure sensor

circuit

• A/C refrigerant pressure sensor

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Check DTC in ECM.

Is DTC P0532 or P0533 detected?Go to applicable DTC

diag. flow.Substitute a known-

good HVAC control

module and recheck.

Page 1015 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Conditioning System: Automatic Type 7B-75

DTC B1570: Engine Type Signal FailureS6RW0D7224027

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

DTC B1571: Combination Meter Spec Signal FailureS6RW0D7224028

DTC Detecting Condition and Trouble Area

DTC TroubleshootingDTC detecting condition Trouble area

HVAC control module receives invalid data of engine type signal from BCM. • CAN communication circuit

• HVAC control module

•ECM

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2Scan tool data check

1) Connect scan tool with ignition switch turned OFF

position.

2) Ignition switch turned ON and select “DATA LIST” mode.

3) Check “ENGINE TYPE” displayed on scan tool.

Is value of engine type signal within specified ranges

indicated in “Scan Tool Data”?Substitute a known

good HVAC control

module and recheck.Go to step 3.

3Scan tool data check

1) Check “ENGINE TYPE” displayed on scan tool.

Is “CAN Err” displayed on scan tool data?Check CAN

communication circuit

referring to “DTC Check

in Section 1A”.Substitute a known

good ECM and recheck.

DTC detecting condition Trouble area

HVAC control module receives invalid data of Combination meter spec signal

from BCM.• CAN communication circuit

• Combination meter

• HVAC control module

Step Action Yes No

1Was “Air Conditioning System Check” performed?Go to Step 2. Go to “Air Conditioning

System Check”.

2Scan tool data check

1) Connect scan tool with ignition switch turned OFF

position.

2) Ignition switch turned ON and select “DATA LIST” mode.

3) Check “METER SPEC” displayed on scan tool.

Is value of combination meter spec signal within specified

ranges indicated in “Scan Tool Data”?Substitute a known

good HVAC control

module and recheck.Go to step 3.

3Scan tool data check

1) Check “METER SPEC” displayed on scan tool.

Is “CAN Err” displayed on scan tool data?Check CAN

communication circuit

referring to “DTC Check

in Section 1A”.Substitute a known

good combination meter

and recheck.

Page 1029 of 1556

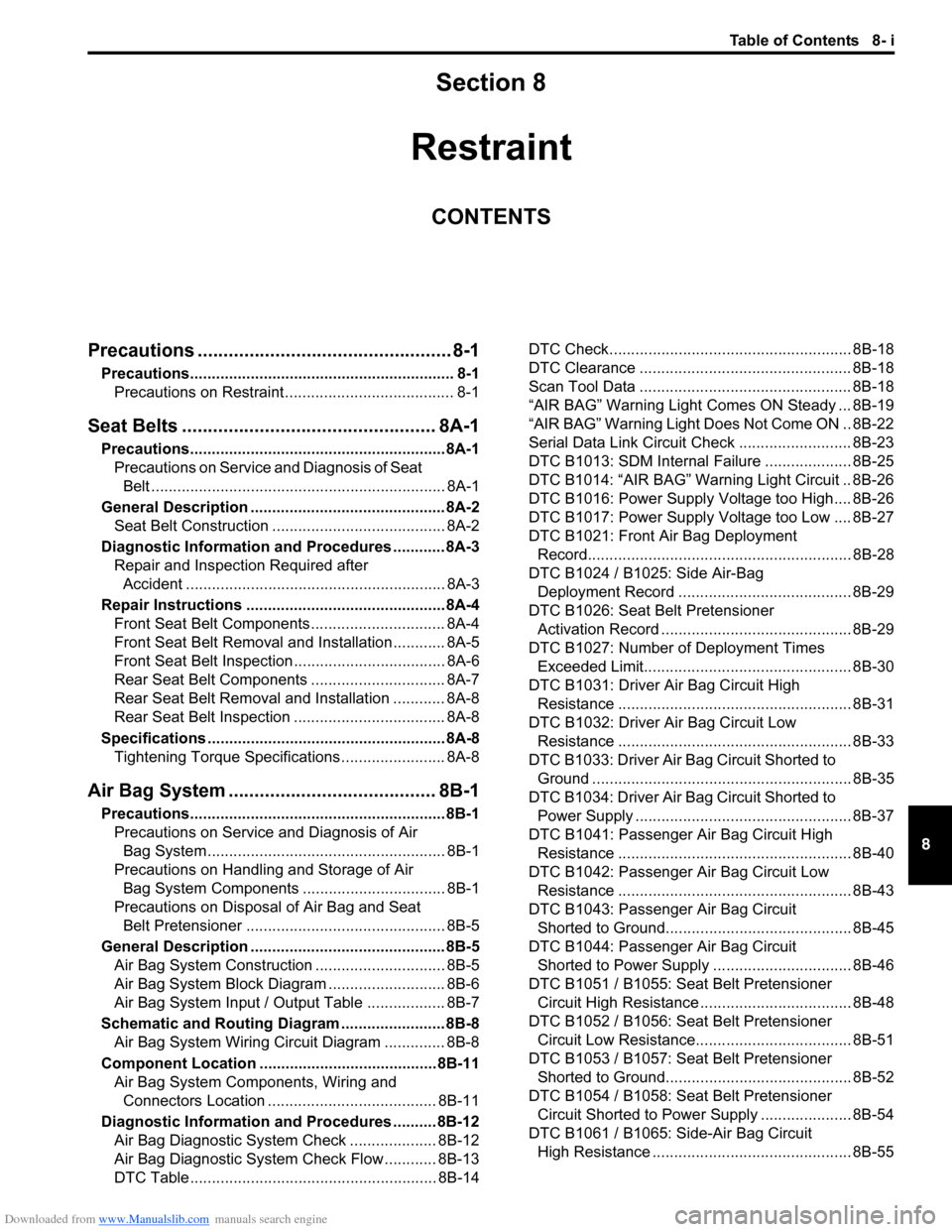

Downloaded from www.Manualslib.com manuals search engine Table of Contents 8- i

8

Section 8

CONTENTS

Restraint

Precautions ................................................. 8-1

Precautions............................................................. 8-1

Precautions on Restraint ....................................... 8-1

Seat Belts ................................................. 8A-1

Precautions........................................................... 8A-1

Precautions on Service and Diagnosis of Seat

Belt .................................................................... 8A-1

General Description ............................................. 8A-2

Seat Belt Construction ........................................ 8A-2

Diagnostic Information and Procedures ............ 8A-3

Repair and Inspection Required after

Accident ............................................................ 8A-3

Repair Instructions .............................................. 8A-4

Front Seat Belt Components ............................... 8A-4

Front Seat Belt Removal and Installation ............ 8A-5

Front Seat Belt Inspection................................... 8A-6

Rear Seat Belt Components ............................... 8A-7

Rear Seat Belt Removal and Installation ............ 8A-8

Rear Seat Belt Inspection ................................... 8A-8

Specifications....................................................... 8A-8

Tightening Torque Specifications ........................ 8A-8

Air Bag System ........................................ 8B-1

Precautions........................................................... 8B-1

Precautions on Service and Diagnosis of Air

Bag System....................................................... 8B-1

Precautions on Handling and Storage of Air

Bag System Components ................................. 8B-1

Precautions on Disposal of Air Bag and Seat

Belt Pretensioner .............................................. 8B-5

General Description ............................................. 8B-5

Air Bag System Construction .............................. 8B-5

Air Bag System Block Diagram ........................... 8B-6

Air Bag System Input / Output Table .................. 8B-7

Schematic and Routing Diagram ........................ 8B-8

Air Bag System Wiring Circuit Diagram .............. 8B-8

Component Location ......................................... 8B-11

Air Bag System Components, Wiring and

Connectors Location ....................................... 8B-11

Diagnostic Information and Procedures .......... 8B-12

Air Bag Diagnostic System Check .................... 8B-12

Air Bag Diagnostic System Check Flow ............ 8B-13

DTC Table ......................................................... 8B-14DTC Check........................................................ 8B-18

DTC Clearance ................................................. 8B-18

Scan Tool Data ................................................. 8B-18

“AIR BAG” Warning Light Comes ON Steady ... 8B-19

“AIR BAG” Warning Light Does Not Come ON .. 8B-22

Serial Data Link Circuit Check .......................... 8B-23

DTC B1013: SDM Internal Failure .................... 8B-25

DTC B1014: “AIR BAG” Warning Light Circuit .. 8B-26

DTC B1016: Power Supply Voltage too High.... 8B-26

DTC B1017: Power Supply Voltage too Low .... 8B-27

DTC B1021: Front Air Bag Deployment

Record............................................................. 8B-28

DTC B1024 / B1025: Side Air-Bag

Deployment Record ........................................ 8B-29

DTC B1026: Seat Belt Pretensioner

Activation Record ............................................ 8B-29

DTC B1027: Number of Deployment Times

Exceeded Limit................................................ 8B-30

DTC B1031: Driver Air Bag Circuit High

Resistance ...................................................... 8B-31

DTC B1032: Driver Air Bag Circuit Low

Resistance ...................................................... 8B-33

DTC B1033: Driver Air Bag Circuit Shorted to

Ground ............................................................ 8B-35

DTC B1034: Driver Air Bag Circuit Shorted to

Power Supply .................................................. 8B-37

DTC B1041: Passenger Air Bag Circuit High

Resistance ...................................................... 8B-40

DTC B1042: Passenger Air Bag Circuit Low

Resistance ...................................................... 8B-43

DTC B1043: Passenger Air Bag Circuit

Shorted to Ground........................................... 8B-45

DTC B1044: Passenger Air Bag Circuit

Shorted to Power Supply ................................ 8B-46

DTC B1051 / B1055: Seat Belt Pretensioner

Circuit High Resistance ................................... 8B-48

DTC B1052 / B1056: Seat Belt Pretensioner

Circuit Low Resistance.................................... 8B-51

DTC B1053 / B1057: Seat Belt Pretensioner

Shorted to Ground........................................... 8B-52

DTC B1054 / B1058: Seat Belt Pretensioner

Circuit Shorted to Power Supply ..................... 8B-54

DTC B1061 / B1065: Side-Air Bag Circuit

High Resistance .............................................. 8B-55

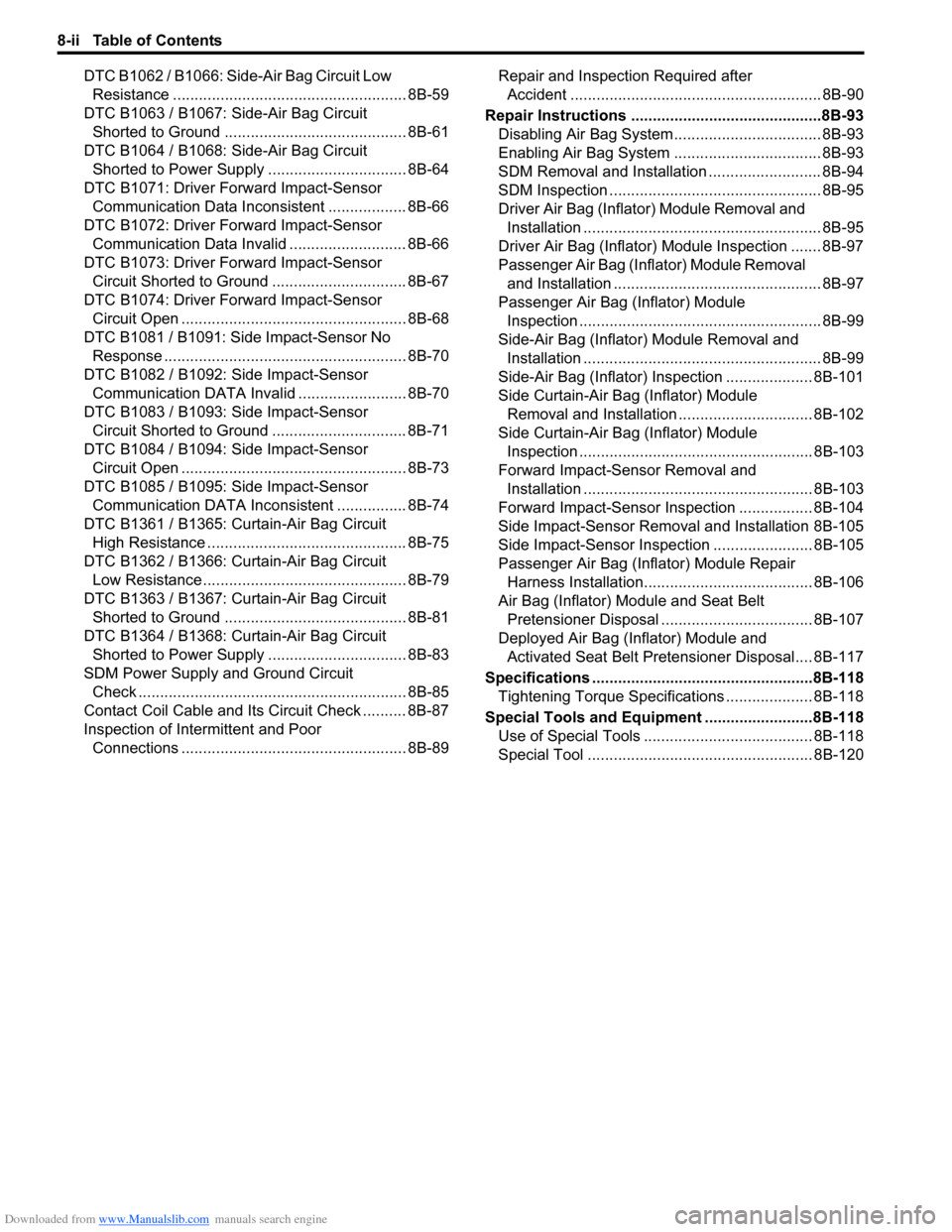

Page 1030 of 1556

Downloaded from www.Manualslib.com manuals search engine 8-ii Table of Contents

DTC B1062 / B1066: Side-Air Bag Circuit Low

Resistance ...................................................... 8B-59

DTC B1063 / B1067: Side-Air Bag Circuit

Shorted to Ground .......................................... 8B-61

DTC B1064 / B1068: Side-Air Bag Circuit

Shorted to Power Supply ................................ 8B-64

DTC B1071: Driver Forward Impact-Sensor

Communication Data Inconsistent .................. 8B-66

DTC B1072: Driver Forward Impact-Sensor

Communication Data Invalid ........................... 8B-66

DTC B1073: Driver Forward Impact-Sensor

Circuit Shorted to Ground ............................... 8B-67

DTC B1074: Driver Forward Impact-Sensor

Circuit Open .................................................... 8B-68

DTC B1081 / B1091: Side Impact-Sensor No

Response ........................................................ 8B-70

DTC B1082 / B1092: Side Impact-Sensor

Communication DATA Invalid ......................... 8B-70

DTC B1083 / B1093: Side Impact-Sensor

Circuit Shorted to Ground ............................... 8B-71

DTC B1084 / B1094: Side Impact-Sensor

Circuit Open .................................................... 8B-73

DTC B1085 / B1095: Side Impact-Sensor

Communication DATA Inconsistent ................ 8B-74

DTC B1361 / B1365: Curtain-Air Bag Circuit

High Resistance .............................................. 8B-75

DTC B1362 / B1366: Curtain-Air Bag Circuit

Low Resistance ............................................... 8B-79

DTC B1363 / B1367: Curtain-Air Bag Circuit

Shorted to Ground .......................................... 8B-81

DTC B1364 / B1368: Curtain-Air Bag Circuit

Shorted to Power Supply ................................ 8B-83

SDM Power Supply and Ground Circuit

Check .............................................................. 8B-85

Contact Coil Cable and Its Circuit Check .......... 8B-87

Inspection of Intermittent and Poor

Connections .................................................... 8B-89Repair and Inspection Required after

Accident .......................................................... 8B-90

Repair Instructions ............................................8B-93

Disabling Air Bag System.................................. 8B-93

Enabling Air Bag System .................................. 8B-93

SDM Removal and Installation .......................... 8B-94

SDM Inspection ................................................. 8B-95

Driver Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-95

Driver Air Bag (Inflator) Module Inspection ....... 8B-97

Passenger Air Bag (Inflator) Module Removal

and Installation ................................................ 8B-97

Passenger Air Bag (Inflator) Module

Inspection ........................................................ 8B-99

Side-Air Bag (Inflator) Module Removal and

Installation ....................................................... 8B-99

Side-Air Bag (Inflator) Inspection .................... 8B-101

Side Curtain-Air Bag (Inflator) Module

Removal and Installation ............................... 8B-102

Side Curtain-Air Bag (Inflator) Module

Inspection ...................................................... 8B-103

Forward Impact-Sensor Removal and

Installation ..................................................... 8B-103

Forward Impact-Sensor Inspection ................. 8B-104

Side Impact-Sensor Removal and Installation 8B-105

Side Impact-Sensor Inspection ....................... 8B-105

Passenger Air Bag (Inflator) Module Repair

Harness Installation....................................... 8B-106

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal ................................... 8B-107

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal.... 8B-117

Specifications ...................................................8B-118

Tightening Torque Specifications .................... 8B-118

Special Tools and Equipment .........................8B-118

Use of Special Tools ....................................... 8B-118

Special Tool .................................................... 8B-120

Page 1040 of 1556

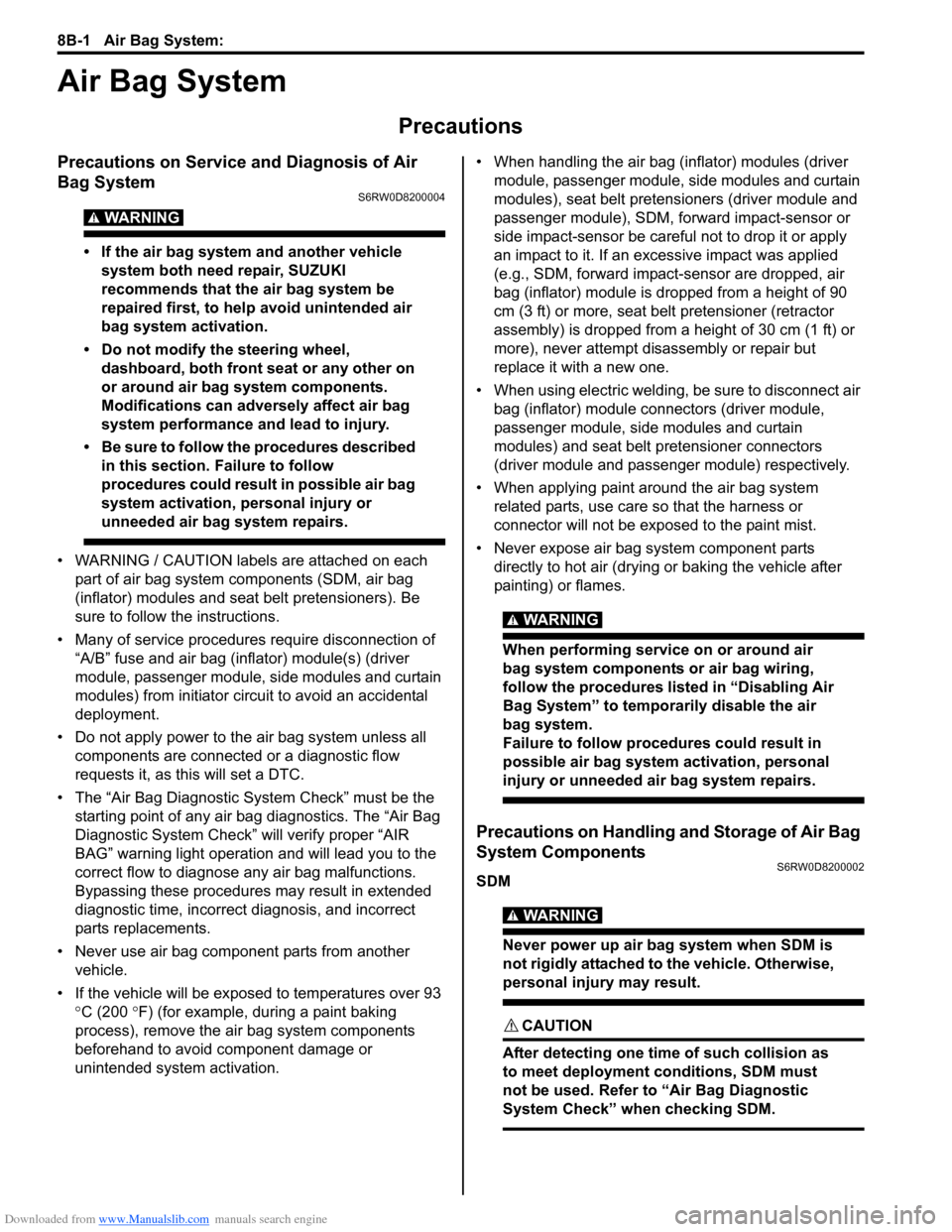

Downloaded from www.Manualslib.com manuals search engine 8B-1 Air Bag System:

Restraint

Air Bag System

Precautions

Precautions on Service and Diagnosis of Air

Bag System

S6RW0D8200004

WARNING!

• If the air bag system and another vehicle

system both need repair, SUZUKI

recommends that the air bag system be

repaired first, to help avoid unintended air

bag system activation.

• Do not modify the steering wheel,

dashboard, both front seat or any other on

or around air bag system components.

Modifications can adversely affect air bag

system performance and lead to injury.

• Be sure to follow the procedures described

in this section. Failure to follow

procedures could result in possible air bag

system activation, personal injury or

unneeded air bag system repairs.

• WARNING / CAUTION labels are attached on each

part of air bag system components (SDM, air bag

(inflator) modules and seat belt pretensioners). Be

sure to follow the instructions.

• Many of service procedures require disconnection of

“A/B” fuse and air bag (inflator) module(s) (driver

module, passenger module, side modules and curtain

modules) from initiator circuit to avoid an accidental

deployment.

• Do not apply power to the air bag system unless all

components are connected or a diagnostic flow

requests it, as this will set a DTC.

• The “Air Bag Diagnostic System Check” must be the

starting point of any air bag diagnostics. The “Air Bag

Diagnostic System Check” will verify proper “AIR

BAG” warning light operation and will lead you to the

correct flow to diagnose any air bag malfunctions.

Bypassing these procedures may result in extended

diagnostic time, incorrect diagnosis, and incorrect

parts replacements.

• Never use air bag component parts from another

vehicle.

• If the vehicle will be exposed to temperatures over 93

°C (200 °F) (for example, during a paint baking

process), remove the air bag system components

beforehand to avoid component damage or

unintended system activation.• When handling the air bag (inflator) modules (driver

module, passenger module, side modules and curtain

modules), seat belt pretensioners (driver module and

passenger module), SDM, forward impact-sensor or

side impact-sensor be careful not to drop it or apply

an impact to it. If an excessive impact was applied

(e.g., SDM, forward impact-sensor are dropped, air

bag (inflator) module is dropped from a height of 90

cm (3 ft) or more, seat belt pretensioner (retractor

assembly) is dropped from a height of 30 cm (1 ft) or

more), never attempt disassembly or repair but

replace it with a new one.

• When using electric welding, be sure to disconnect air

bag (inflator) module connectors (driver module,

passenger module, side modules and curtain

modules) and seat belt pretensioner connectors

(driver module and passenger module) respectively.

• When applying paint around the air bag system

related parts, use care so that the harness or

connector will not be exposed to the paint mist.

• Never expose air bag system component parts

directly to hot air (drying or baking the vehicle after

painting) or flames.

WARNING!

When performing service on or around air

bag system components or air bag wiring,

follow the procedures listed in “Disabling Air

Bag System” to temporarily disable the air

bag system.

Failure to follow procedures could result in

possible air bag system activation, personal

injury or unneeded air bag system repairs.

Precautions on Handling and Storage of Air Bag

System Components

S6RW0D8200002

SDM

WARNING!

Never power up air bag system when SDM is

not rigidly attached to the vehicle. Otherwise,

personal injury may result.

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, SDM must

not be used. Refer to “Air Bag Diagnostic

System Check” when checking SDM.

Page 1051 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-12

Diagnostic Information and Procedures

Air Bag Diagnostic System CheckS6RW0D8204001

WARNING!

To avoid deployment when troubleshooting

the air bag system, do not use electrical test

equipment such as a battery powered or AC

powered voltmeter, ohmmeter, etc., or any

type of electrical equipment other than that

specified in this manual. Do not use a non-

powered probe type tester.

Instructions in this manual must be followed

carefully, otherwise personal injury may

result.

CAUTION!

• The order in which DTCs are diagnosed is

very important. Failure to diagnose the

DTCs in the order specified may result in

extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.

• When measurement of resistance or

voltage is required in the flow, use a tester

along with a correct terminal adapter from

special tool (Connector test adapter kit).

• When a check for proper connection is

required, refer to “Inspection of

Intermittent and Poor Connections”.

• If an open circuit in the air bag wire

harness damaged, connector or terminal is

found, replace the wire harness,

connectors and terminals as an assembly.

The diagnostic procedures used are designed to find

and repair air bag system malfunctions.

To get the best results, it is important to use the

diagnostic flow and follow the sequence in the following.

1) Perform the “Air Bag Diagnostic System Check

Flow”.

(The “Air Bag Diagnostic System Check Flow” must

be the starting point of any air bag system diagnosis.

The “Air Bag Diagnostic System Check Flow” checks

for proper “AIR BAG” warning light operation through

“AIR BAG” warning light and whether air bag DTCs

exist.)

2) Refer to the proper diagnostic flow as directed by the

“Air Bag Diagnostic System Check Flow”.

(The “Air Bag Diagnostic System Check Flow” will

lead you to the correct flow to diagnose any air bag

system malfunctions. Bypassing these procedures

may result in extended diagnostic time, incorrect

diagnosis and incorrect parts replacement.)

3) Repeat the “Air Bag Diagnostic System Check Flow”

after any repair or diagnostic procedures have been

performed.

(Performing the “Air Bag Diagnostic System Check

Flow” after all repair or diagnostic procedures will

ensure that the repair has been made correctly and

that no other malfunctions exist.)

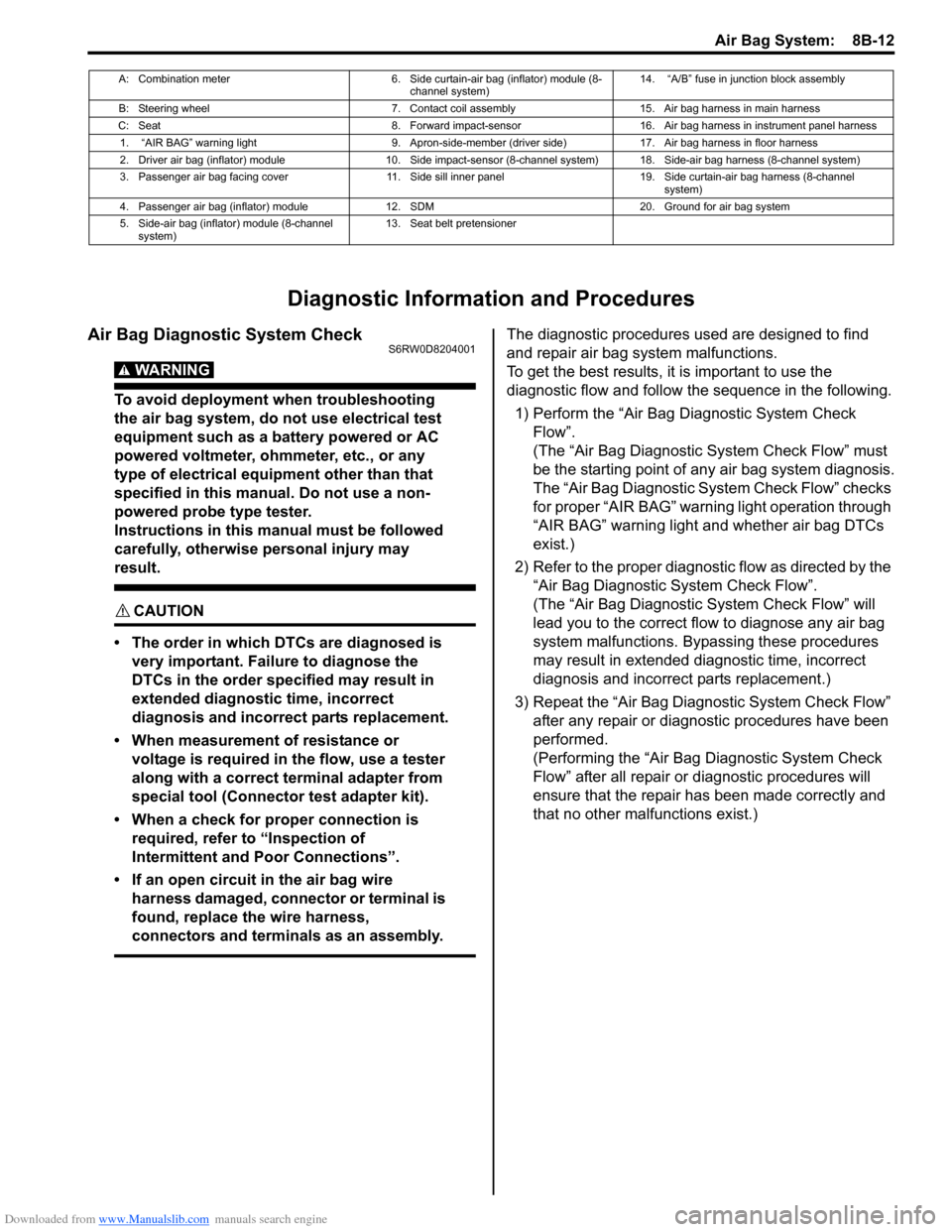

A: Combination meter 6. Side curtain-air bag (inflator) module (8-

channel system)14. “A/B” fuse in junction block assembly

B: Steering wheel 7. Contact coil assembly 15. Air bag harness in main harness

C: Seat 8. Forward impact-sensor 16. Air bag harness in instrument panel harness

1. “AIR BAG” warning light 9. Apron-side-member (driver side) 17. Air bag harness in floor harness

2. Driver air bag (inflator) module 10. Side impact-sensor (8-channel system) 18. Side-air bag harness (8-channel system)

3. Passenger air bag facing cover 11. Side sill inner panel 19. Side curtain-air bag harness (8-channel

system)

4. Passenger air bag (inflator) module 12. SDM 20. Ground for air bag system

5. Side-air bag (inflator) module (8-channel

system)13. Seat belt pretensioner

Page 1052 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-13 Air Bag System:

Air Bag Diagnostic System Check FlowS6RW0D8204002

CAUTION!

• Be sure to perform “Air Bag Diagnostic System Check” before starting diagnosis according to each

flow.

• When measurement of resistance or voltage is required in the flow, use a tester along with a correct

terminal adapter from special tool (Connector test adapter kit).

• When a check for proper connection is required, refer to “Inspection of Intermittent and Poor

Connections”.

• If an open circuit in the air bag wire harness damaged, connector or terminal is found, replace the

wire harness, connectors and terminals as an assembly.

Step Action Yes No

1Battery voltage check.

1) Measure battery voltage.

Is it 10 – 14 V?Go to Step 2. Proceed to “Battery

Inspection in Section

1J”.

2“AIR BAG” warning light check (6 times flushing check).

1) Turn ON ignition switch, and then check that “AIR BAG”

warning light flushes.

Does “AIR BAG” warning light flash 6 times?Go to Step 3. Go to Step 4.

3“AIR BAG” warning light check (turning off check).

1) In the state of Step 2. check that “AIR BAG” warning light

turn OFF after flashing 6 times.

Does “AIR BAG” warning light turn OFF?Go to Step 5. Go to Step 6.

4“AIR BAG” warning light circuit check

Does “AIR BAG” warning light come ON steady?Go to checking flow of

““AIR BAG” Warning

Light Comes ON

Steady”. After carrying

out it flow, proceed to

St ep 6 .Go to checking flow of

““AIR BAG” Warning

Light Does Not Come

ON”. After carrying out it

flow, proceed to Step 6.

5DTC check

1) Check DTC using SUZUKI scan tool referring to “DTC

Check”.

Is “NO CODES” displayed on SUZUKI scan tool?Air bag system is in

good condition.Check intermittent

troubles referring to

“Inspection of

Intermittent and Poor

Connections”.

If intermittent troubles

are OK, check and

repair applicable DTC

flow and then repeat

this flow.

6DTC check

1) Check DTC using SUZUKI scan tool, referring to “DTC

Check”.

Is “NO CODES” displayed on SUZUKI scan tool?Substitute a known-

good SDM and recheck.Check and repair

applicable DTC flow,

and then repeat this

flow.