Can SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1069 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-30

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

• Clear DTC B1157 (air bag deployed) of BCM referring to “DTC Clearance in Section 10B”, if any.

DTC B1027: Number of Deployment Times Exceeded LimitS6RW0D8204017

DTC Detecting Condition and Trouble Area

NOTE

DTC B1027 can never be cleared once it has been set.

DTC Trouble shootingStep Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Seat belt pretensioner activation check

1) Turn OFF ignition switch.

2) Check that DTC B1026 has been set although

pretensioner has not been activated.

Has pretensioner activated?Inspect and replace

components according

to “Repair and

Inspection Required

after Accident”.Go to Step 3.

3Front impact sign check

1) Inspect front of vehicle and undercarriage for signs of

impact.

Are there any signs of impact?Inspect and replace

components according

to “Repair and

Inspection Required

after Accident”.Replace SDM.

DTC detecting condition Trouble area

Deployment of air bag and/or activation of seat belt

pretensioner have been recorded in SDM 5 times or

more.If this DTC has been recorded even though air bag (front

and side) and pretensioner have not been deployed more

than 4 place.

• SDM (internal fault or reused SDM)

• Each of deployment and activation module

• Those initiator circuit

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2Air bag deployment check

1) Turn OFF ignition switch.

2) Check that DTC B1027 has been set although air bag

(front and side) and pretensioner has not been

deployed.

Have air bag and pretensioner deployed more than 4 place?Inspect and replace

components according

to “Repair and

Inspection Required

after Accident”.Go to Step 3.

3Impact sign check

1) Inspect front, side of vehicle and undercarriage for signs

of impact.

Are there any signs of impact?Inspect and replace

components according

to “Repair and

Inspection Required

after Accident”.Replace SDM.

Page 1105 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-66

DTC B1071: Driver Forward Impact-Sensor Communication Data InconsistentS6RW0D8204034

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1072: Driver Forward Impact-Sensor Communication Data InvalidS6RW0D8204035

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC detecting condition Trouble area

Forward impact-sensor has been communicated with no

response or inconsistent ID code for more than 4 sec.• Forward impact-sensor

• Forward impact-sensor circuit

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTC(s) B1073, B1074?Go to applicable DTC

diag. flow.Replace defective

forward impact-sensor

and recheck.

If this DTC still detected,

replace SDM.

DTC detecting condition Trouble area

Forward impact-sensor has been communicated with

invalid data for more than 4 sec.• Forward impact-sensor

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTC(s) B1071, B1073, B1074?Go to applicable DTC

diag. flow.Replace defective

forward impact-sensor

and recheck.

If this DTC still detected,

replace SDM.

Page 1109 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-70

DTC B1081 / B1091: Side Impact-Sensor No ResponseS6RW0D8204066

DTC B1081: Driver Side Impact-Sensor No Response

DTC B1091: Passenger Side Impact-Sensor No Response

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1082 / B1092: Side Impact-Sensor Communication DATA InvalidS6RW0D8204058

DTC B1082: Driver Side Impact-Sensor Communication DATA Invalid

DTC B1092: Passenger Side Impact-Sensor Communication DATA Invalid

DTC Detecting Condition and Trouble AreaDTC detecting condition Trouble area

DTC B1081:

Driver side impact-sensor has been communicated with

no response for more than 4 sec.

DTC B1091:

Passenger side impact-sensor has been communicated

with no response for more than 4 sec.• Driver / passenger side impact-sensor circuit

• Driver / passenger side impact-sensor

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTCs B1083, B1084 (for DTC B1081) or

B1093, B1094 (for DTC B1091)?Go to applicable DTC

diag. flow.Replace defective side

impact-sensor and

recheck.

If this DTC still detected,

replace SDM.

DTC detecting condition Trouble area

DTC B1082:

Driver side impact-sensor has been communicated with

invalid data for more than 4 sec.

DTC B1092:

Passenger side impact-sensor has been communicated

with invalid data for more than 4 sec.• Driver / passenger side impact-sensor

•SDM

Page 1110 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-71 Air Bag System:

DTC Troubleshooting

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

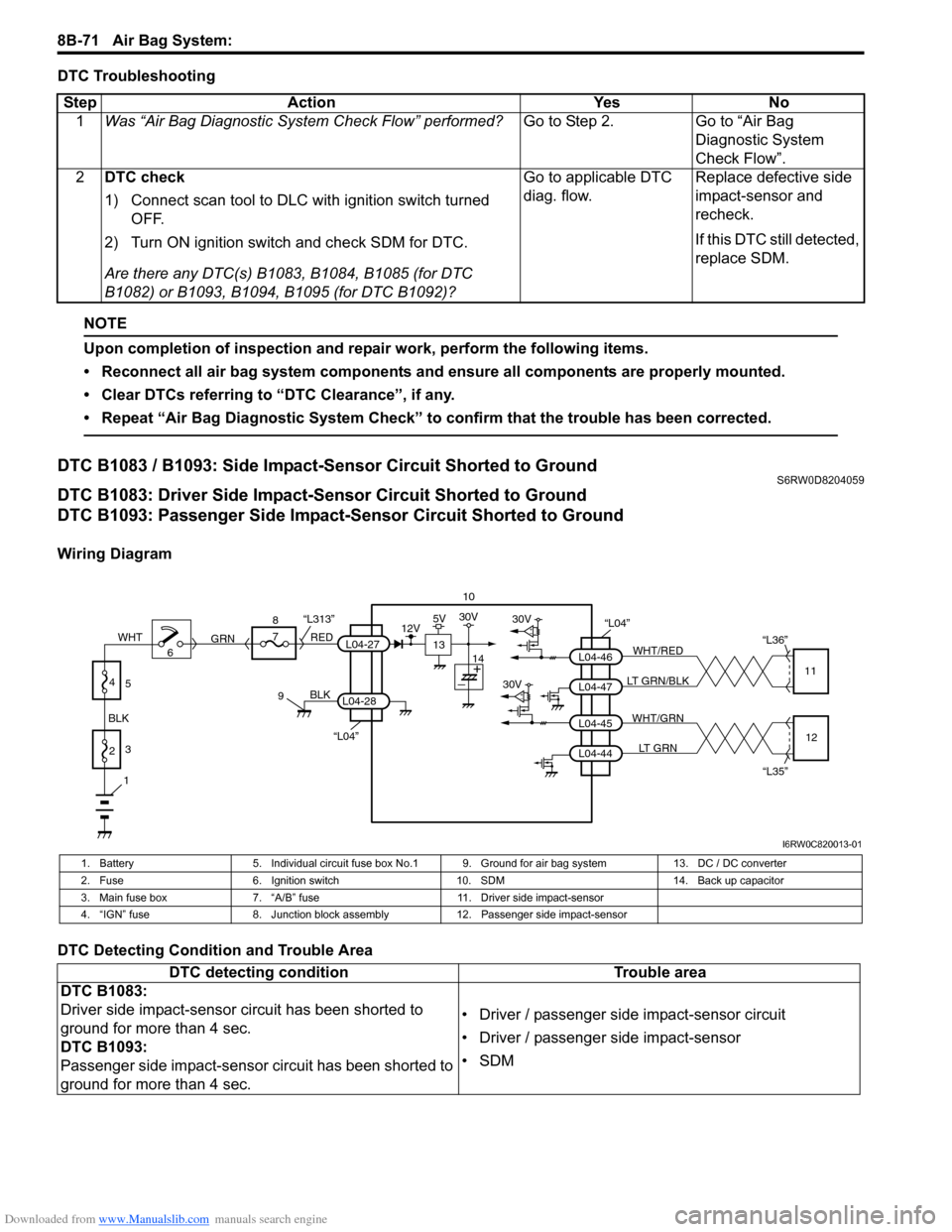

DTC B1083 / B1093: Side Impact-Sensor Circuit Shorted to GroundS6RW0D8204059

DTC B1083: Driver Side Impact-Sensor Circuit Shorted to Ground

DTC B1093: Passenger Side Impact-Sensor Circuit Shorted to Ground

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and check SDM for DTC.

Are there any DTC(s) B1083, B1084, B1085 (for DTC

B1082) or B1093, B1094, B1095 (for DTC B1092)?Go to applicable DTC

diag. flow.Replace defective side

impact-sensor and

recheck.

If this DTC still detected,

replace SDM.

10

“L04”30V

30VL04-47 L04-46WHT/RED

LT GRN/BLK“L36”

11

L04-44 L04-45WHT/GRN

LT GRN

“L35”12

“L04”

BLK

L04-28

6 8

7

RED

GRN“L313”L04-27

9

1

2 BLKWHT3

4

5

13

12V5V30V

14

I6RW0C820013-01

1. Battery 5. Individual circuit fuse box No.1 9. Ground for air bag system 13. DC / DC converter

2. Fuse 6. Ignition switch 10. SDM 14. Back up capacitor

3. Main fuse box 7. “A/B” fuse 11. Driver side impact-sensor

4. “IGN” fuse 8. Junction block assembly 12. Passenger side impact-sensor

DTC detecting condition Trouble area

DTC B1083:

Driver side impact-sensor circuit has been shorted to

ground for more than 4 sec.

DTC B1093:

Passenger side impact-sensor circuit has been shorted to

ground for more than 4 sec.• Driver / passenger side impact-sensor circuit

• Driver / passenger side impact-sensor

•SDM

Page 1113 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-74

NOTE

Upon completion of inspection and repair work, perform the following items.

• Reconnect all air bag system components and ensure all components are properly mounted.

• Clear DTCs referring to “DTC Clearance”, if any.

• Repeat “Air Bag Diagnostic System Check” to confirm that the trouble has been corrected.

DTC B1085 / B1095: Side Impact-Sensor Communication DATA InconsistentS6RW0D8204061

DTC B1085: Driver Side Impact-Sensor Communication DATA Inconsistent

DTC B1095: Passenger Side Impact-Sensor Communication DATA Inconsistent

DTC Detecting Condition and Trouble Area

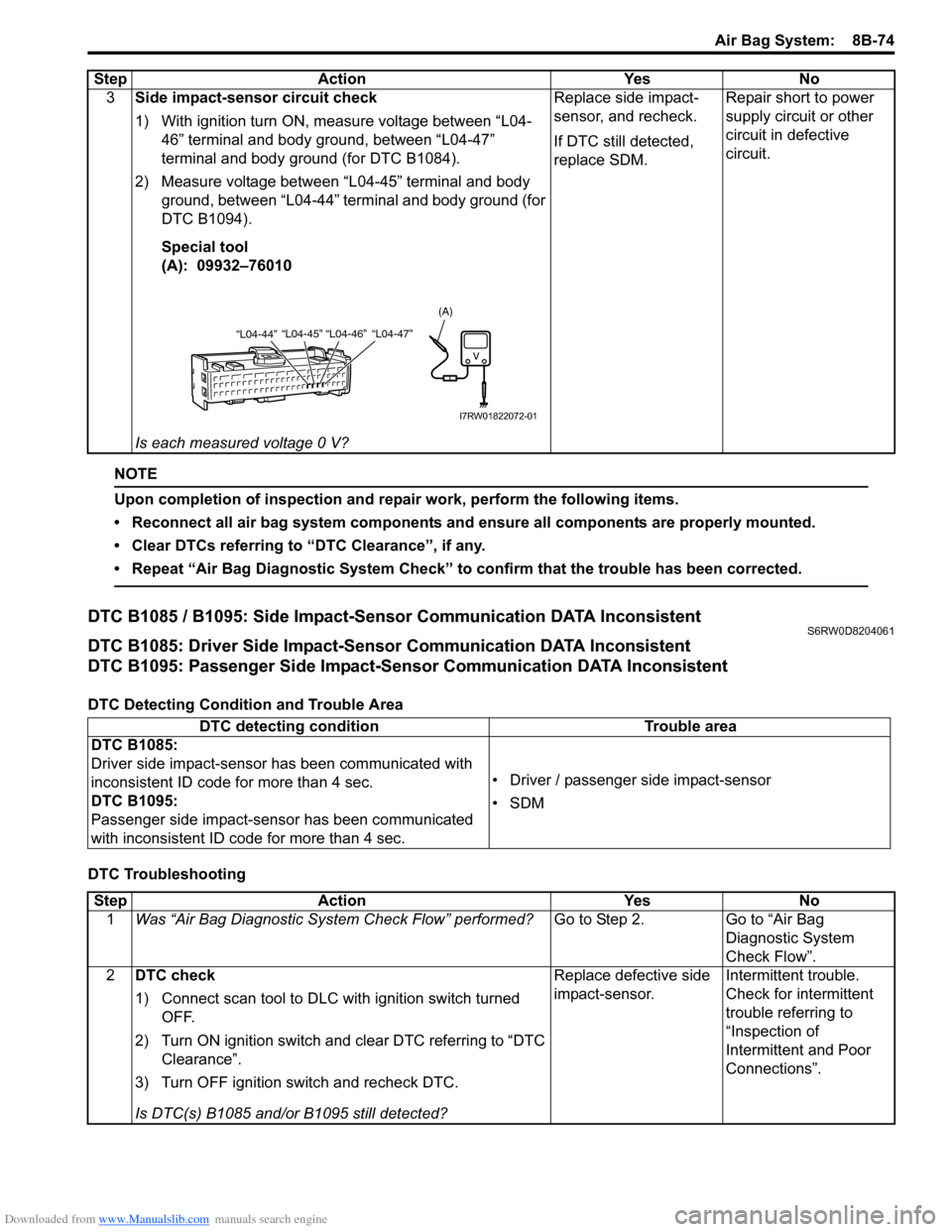

DTC Troubleshooting3Side impact-sensor circuit check

1) With ignition turn ON, measure voltage between “L04-

46” terminal and body ground, between “L04-47”

terminal and body ground (for DTC B1084).

2) Measure voltage between “L04-45” terminal and body

ground, between “L04-44” terminal and body ground (for

DTC B1094).

Special tool

(A): 09932–76010

Is each measured voltage 0 V?Replace side impact-

sensor, and recheck.

If DTC still detected,

replace SDM.Repair short to power

supply circuit or other

circuit in defective

circuit. Step Action Yes No

“L04-44”“L04-45” “L04-46” “L04-47”

(A)

I7RW01822072-01

DTC detecting condition Trouble area

DTC B1085:

Driver side impact-sensor has been communicated with

inconsistent ID code for more than 4 sec.

DTC B1095:

Passenger side impact-sensor has been communicated

with inconsistent ID code for more than 4 sec.• Driver / passenger side impact-sensor

•SDM

Step Action Yes No

1Was “Air Bag Diagnostic System Check Flow” performed?Go to Step 2. Go to “Air Bag

Diagnostic System

Check Flow”.

2DTC check

1) Connect scan tool to DLC with ignition switch turned

OFF.

2) Turn ON ignition switch and clear DTC referring to “DTC

Clearance”.

3) Turn OFF ignition switch and recheck DTC.

Is DTC(s) B1085 and/or B1095 still detected?Replace defective side

impact-sensor.Intermittent trouble.

Check for intermittent

trouble referring to

“Inspection of

Intermittent and Poor

Connections”.

Page 1130 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-91 Air Bag System:

CAUTION!

After detecting one time of such collision as

to meet deployment conditions, the SDM

must not be used.

Refer to “Air Bag Diagnostic System Check”

when checking the SDM.

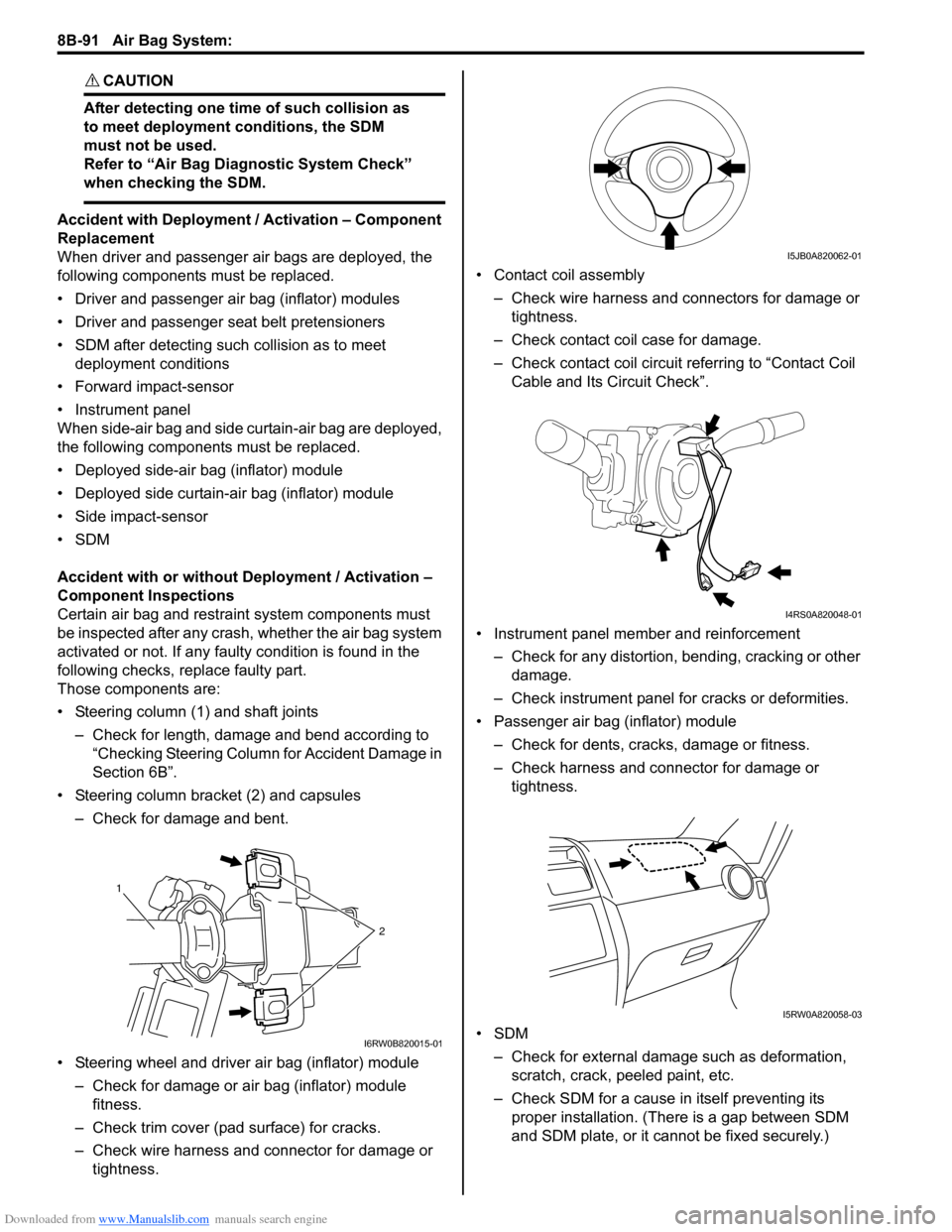

Accident with Deployment / Activation – Component

Replacement

When driver and passenger air bags are deployed, the

following components must be replaced.

• Driver and passenger air bag (inflator) modules

• Driver and passenger seat belt pretensioners

• SDM after detecting such collision as to meet

deployment conditions

• Forward impact-sensor

• Instrument panel

When side-air bag and side curtain-air bag are deployed,

the following components must be replaced.

• Deployed side-air bag (inflator) module

• Deployed side curtain-air bag (inflator) module

• Side impact-sensor

•SDM

Accident with or without Deployment / Activation –

Component Inspections

Certain air bag and restraint system components must

be inspected after any crash, whether the air bag system

activated or not. If any faulty condition is found in the

following checks, replace faulty part.

Those components are:

• Steering column (1) and shaft joints

– Check for length, damage and bend according to

“Checking Steering Column for Accident Damage in

Section 6B”.

• Steering column bracket (2) and capsules

– Check for damage and bent.

• Steering wheel and driver air bag (inflator) module

– Check for damage or air bag (inflator) module

fitness.

– Check trim cover (pad surface) for cracks.

– Check wire harness and connector for damage or

tightness.• Contact coil assembly

– Check wire harness and connectors for damage or

tightness.

– Check contact coil case for damage.

– Check contact coil circuit referring to “Contact Coil

Cable and Its Circuit Check”.

• Instrument panel member and reinforcement

– Check for any distortion, bending, cracking or other

damage.

– Check instrument panel for cracks or deformities.

• Passenger air bag (inflator) module

– Check for dents, cracks, damage or fitness.

– Check harness and connector for damage or

tightness.

•SDM

– Check for external damage such as deformation,

scratch, crack, peeled paint, etc.

– Check SDM for a cause in itself preventing its

proper installation. (There is a gap between SDM

and SDM plate, or it cannot be fixed securely.)

1

2

I6RW0B820015-01

I5JB0A820062-01

I4RS0A820048-01

I5RW0A820058-03

Page 1146 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-107 Air Bag System:

7) Install passenger air bag (inflator) module referring

to “Passenger Air Bag (Inflator) Module Removal

and Installation”.

8) Enabling air bag system referring to “Enabling Air

Bag System”.

9) Confirm that there is no DTC detected to SDM with

ignition switch turned ON.

Air Bag (Inflator) Module and Seat Belt

Pretensioner Disposal

S6RW0D8206018

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. Do not dispose of live

(undeployed) air bag (inflator) modules and

seat belt pretensioners. Because undeployed

air bag (inflator) module / inactivated seat

belt pretensioner must not be disposed of

through normal refuse channels. Undeployed

air bag (inflator) module and inactivated seat

belt pretensioner contain substances that

can cause severe illness or personal injury if

sealed container is damaged during disposal.

Air bag (inflator) module / seat belt pretensioner can be

deployed / activated inside or outside of vehicle.

Deployment / Activation method used depends upon

final disposition of vehicle. Review the following

instructions in order to determine which will work best in

a given situation.

Deployment / Activation Outside of Vehicle: When you

intend to return the vehicle to service, deploy the air bag

(inflator) module(s) and/or activate seat belt

pretensioner(s) outside of the vehicle.

Deployment / Activation Inside of Vehicle: When the

vehicle will be destroyed, or salvaged for component

parts, deploy the air bag module(s) and/or activate seat

belt pretensioner(s) installed on vehicle.

WARNING!

The following precautions must be observed

for this work. Failure to observe any of them

may result in personal injury.

• Procedure should be followed strictly as

described here.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System”

beforehand.

• To avoid accidental deployment /

activation, this work should be performed

by no more than one person.

• Since smoke is produced when air bag

(inflator) module is deployed and

pretensioner is activated, select well-

ventilated area.

• Air bag (inflator) module and seat belt

pretensioner will immediately deploy /

activate when 12 volts vehicle battery is

connected to it. Wear safety glasses

throughout this entire deployment /

activation and disposal procedure.

• Wear suitable ear protection when

deploying air bag (inflator) module /

activating seat belt pretensioner. Also,

advise those who are in area close to

deployment / activation site to wear

suitable ear protection.

• Do not deploy / activate two or more air

bag system components (air bag (inflator)

modules and seat belt pretensioners) at

the same time.

• Never connect deployment harness to any

12 volts vehicle battery before connecting

deployment harness to air bag (inflator)

module and seat belt pretensioner.

Deployment harness shall remain shorted

and not be connected to 12 volts vehicle

battery till you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.

Page 1150 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-111 Air Bag System:

• For seat belt pretensioner

a. Cut webbing (1) at tongue plate stopper (3) of

seat belt pretensioner (2) side as shown.

NOTE

Hold seat belt pretensioner (2) vertically in

the same condition as it is installed.

Otherwise, webbing can’t be pulled out.

b. Remove tongue plate (4) and shoulder anchor

(5) from webbing.

c. Tie webbing (1) tightly at 10 cm (3.9 in.) from

cutting edge as shown.

d. Tie seat belt pretensioner (2) with wire

harness (3) to wheel-installed tire (4) as

shown.

Wire harness specifications

Stripped wire harness section 1.25 mm2

(0.0019 in.2) or more (Stripped wire harness

diameter 1.25 mm (0.05 in.) or more)

NOTE

Wind wire harness (3) around at least 3 times.

e. Clear space (5) on ground about 185 cm (6 ft)

in diameter where seat belt pretensioner (2) is

to be activated. Paved, outdoor location where

there is no activity is preferred. If outdoor

location is not available, use space on shop

floor where there is no activity and sufficient

ventilation is provided. Ensure no loose or

flammable object exists within activation area.

f. Place wheel-installed tire (4) with seat belt

pretensioner (2) on ground in Step e.

7) Stretch deployment harness (A) from air bag

(inflator) module or seat belt pretensioner to its full

length 10 m (33 ft).

Special tool

(A): 09932-75031

8) Place 12 volts vehicle battery (1) near the shorted

end of deployment harness (A).

9) Check that area around air bag (inflator) module or

seat belt pretensioner is clear of all people and loose

or flammable objects.

31452I3JA01820037-01

10 cm (3.9 in.)

1

I4RS0A820104-01

1. Webbing

4 3

3

25

I4RS0A820105-01

Page 1154 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-115 Air Bag System:

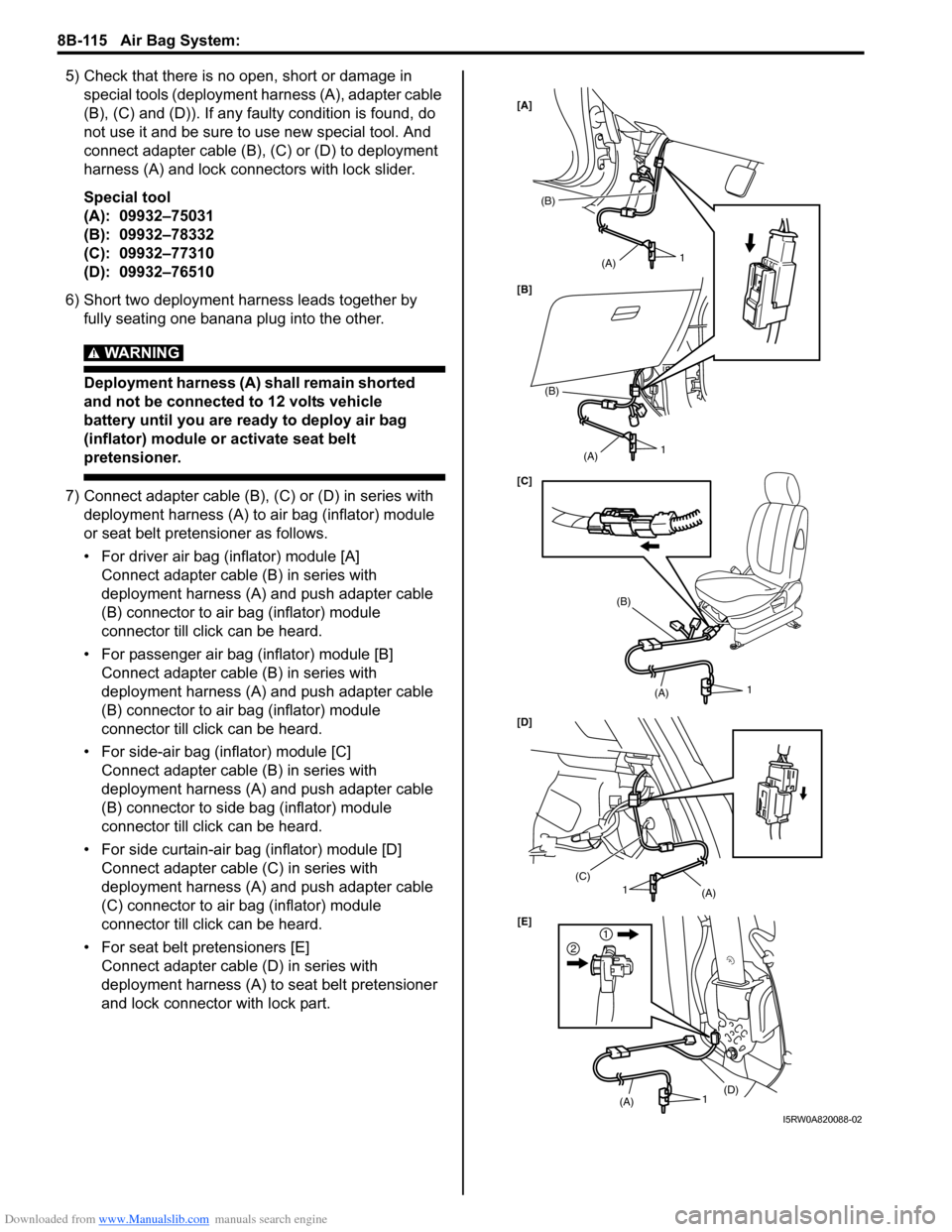

5) Check that there is no open, short or damage in

special tools (deployment harness (A), adapter cable

(B), (C) and (D)). If any faulty condition is found, do

not use it and be sure to use new special tool. And

connect adapter cable (B), (C) or (D) to deployment

harness (A) and lock connectors with lock slider.

Special tool

(A): 09932–75031

(B): 09932–78332

(C): 09932–77310

(D): 09932–76510

6) Short two deployment harness leads together by

fully seating one banana plug into the other.

WARNING!

Deployment harness (A) shall remain shorted

and not be connected to 12 volts vehicle

battery until you are ready to deploy air bag

(inflator) module or activate seat belt

pretensioner.

7) Connect adapter cable (B), (C) or (D) in series with

deployment harness (A) to air bag (inflator) module

or seat belt pretensioner as follows.

• For driver air bag (inflator) module [A]

Connect adapter cable (B) in series with

deployment harness (A) and push adapter cable

(B) connector to air bag (inflator) module

connector till click can be heard.

• For passenger air bag (inflator) module [B]

Connect adapter cable (B) in series with

deployment harness (A) and push adapter cable

(B) connector to air bag (inflator) module

connector till click can be heard.

• For side-air bag (inflator) module [C]

Connect adapter cable (B) in series with

deployment harness (A) and push adapter cable

(B) connector to side bag (inflator) module

connector till click can be heard.

• For side curtain-air bag (inflator) module [D]

Connect adapter cable (C) in series with

deployment harness (A) and push adapter cable

(C) connector to air bag (inflator) module

connector till click can be heard.

• For seat belt pretensioners [E]

Connect adapter cable (D) in series with

deployment harness (A) to seat belt pretensioner

and lock connector with lock part.

[C] [B]

[D]

[E] [A]

12

(D)

(A)1

1

(A)

(B)

1 (C)

(A)

1

(B)

(A)

1

(B)

(A)

I5RW0A820088-02

Page 1156 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-117 Air Bag System:

21) Disconnect adapter cable (special tool) from air bag

(inflator) module or seat belt pretensioner as soon as

possible. This will prevent adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

22) Check adapter cable connector as follows.

Adapter cable connector (special tool) is designed to

be reused. However it should be inspected for

damage after deployment and replaced if necessary.

23) With air bag (inflator) modules deployed and seat

belt pretensioners activated, vehicle may be

scrapped in the same manner as non-air bag system

/ seat belt pretensioner equipped vehicle.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

24) Remove undeployed air bag (inflator) module(s) and/

or inactivated seat belt pretensioner(s) from vehicle.

For driver air bag (inflator) module, refer to “Driver

Air Bag (Inflator) Module Removal and Installation”.

For passenger air bag (inflator) module, refer to

“Passenger Air Bag (Inflator) Module Removal and

Installation”. For side air bag (inflator) module, refer

to “Side-Air Bag (Inflator) Module Removal and

Installation”. For side curtain-air bag (inflator)

module, refer to “Side Curtain-Air Bag (Inflator)

Module Removal and Installation”. For seat belt

pretensioner, refer to “Front Seat Belt Removal and

Installation in Section 8A”.

25) Temporarily store undeployed air bag (inflator)

module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

26) Contact your local distributor for further assistance.

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal

S6RW0D8206019

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. The undeployed air bag

(inflator) module and the inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

the inactivated seat belt pretensioner

contains substances that can cause severe

illness or personal injury if the sealed

container is damaged during disposal.

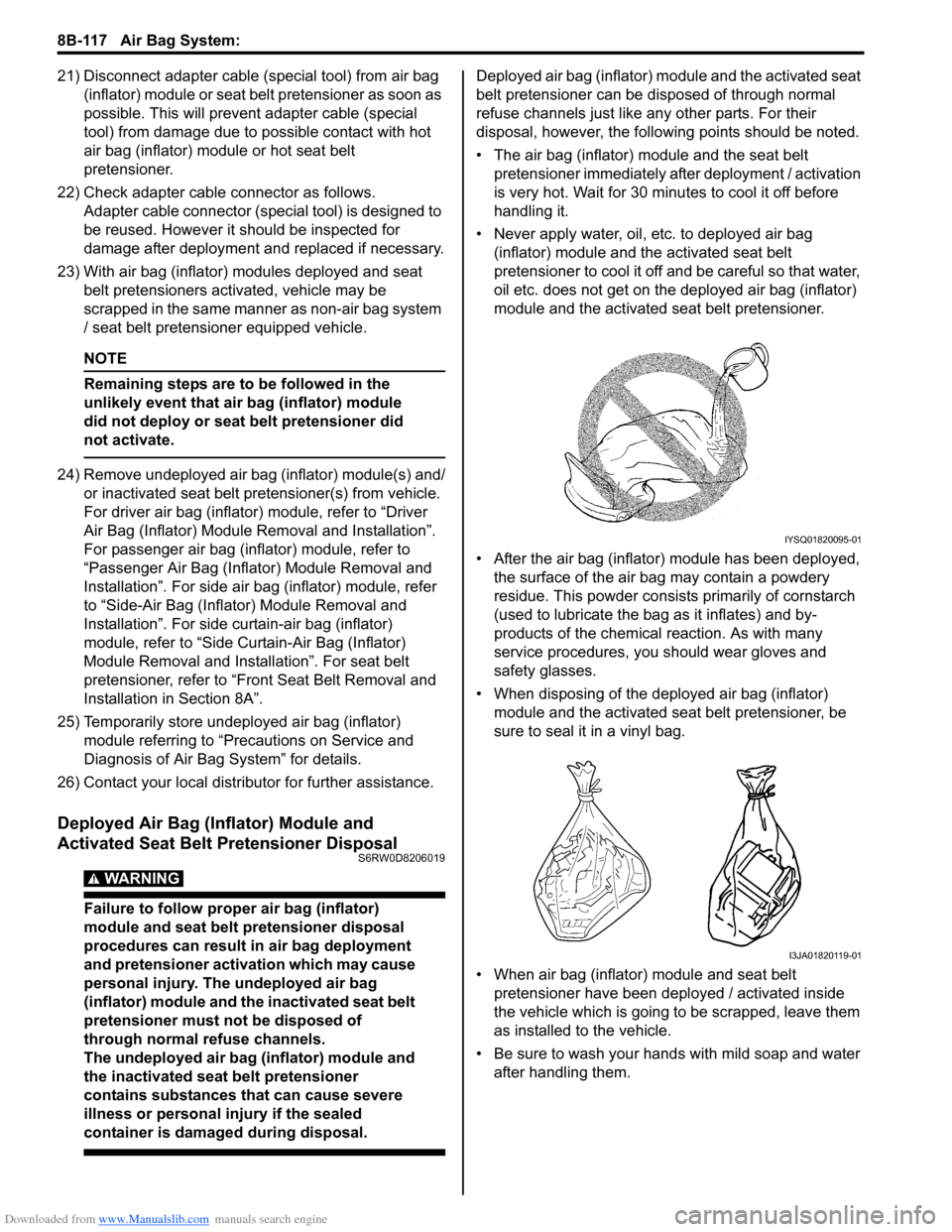

Deployed air bag (inflator) module and the activated seat

belt pretensioner can be disposed of through normal

refuse channels just like any other parts. For their

disposal, however, the following points should be noted.

• The air bag (inflator) module and the seat belt

pretensioner immediately after deployment / activation

is very hot. Wait for 30 minutes to cool it off before

handling it.

• Never apply water, oil, etc. to deployed air bag

(inflator) module and the activated seat belt

pretensioner to cool it off and be careful so that water,

oil etc. does not get on the deployed air bag (inflator)

module and the activated seat belt pretensioner.

• After the air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery

residue. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-

products of the chemical reaction. As with many

service procedures, you should wear gloves and

safety glasses.

• When disposing of the deployed air bag (inflator)

module and the activated seat belt pretensioner, be

sure to seal it in a vinyl bag.

• When air bag (inflator) module and seat belt

pretensioner have been deployed / activated inside

the vehicle which is going to be scrapped, leave them

as installed to the vehicle.

• Be sure to wash your hands with mild soap and water

after handling them.

IYSQ01820095-01

I3JA01820119-01