PPL SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1140 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-101 Air Bag System:

2) Install new sleeve (1) and sleeve lock nut (2) to side-

air bag (inflator) module, then tighten nut to specified

torque.

Tightening torque

Sleeve lock nut (a): 2.5 N·m (0.25 kgf-m, 2.0 lb-

ft)

3) Connect side-air bag (inflator) module connector (1)

securely as shown in the figure.

a) Connect connector.

b) Lock connector with lock button (2).

4) Insert claw (1) of side-air bag (inflator) module on

installation hole (2).

5) Install side-air bag (inflator) module by pushing it into

fastener (3) securely.

6) Roll down backside seat back surface and fix seat

back surface fastener securely.Side-Air Bag (Inflator) InspectionS6RW0D8206021

WARNING!

• Never attempt to disassemble or repair the

side-air bag (inflator) module. If any

abnormality is found, be sure to replace it

with new one as an assembly.

• Be sure to read “Precautions on Service

and Diagnosis of Air Bag System” before

starting to work and observe every

precaution during work. Neglecting them

may result in personal injury or

undeployment of the air bag when

necessary.

CAUTION!

If air bag (inflator) module was dropped from

a height of 90 cm (3 ft) or more, it should be

replaced.

Check air bag (inflator) module appearance visually for

the following symptoms and if any one of them is found,

replace with a new one.

• Air bag has deployed.

• There is a crack in trim cover (pad surface).

• Wire harness or connector is damaged.

• Air bag (inflator) module is damaged or a strong

impact was applied to it.

• Bend or deformity of air bag (inflator) module bracket.

12, (a)

I4RS0A820073-02

1

2

a) b)

I4RS0A820070-01

1

2

3

I4RS0A820074-02

I4RS0A820075-02

Page 1152 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-113 Air Bag System:

12) Notify all people in immediate area that you intend to

deploy / activate air bag (inflator) module or seat belt

pretensioner.

NOTE

• When air bag (inflator) module deploys and

seat belt pretensioner activates, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or

activate seat belt pretensioner and suitable

ear protection should be worn.

• When driver air bag (inflator) module

deploys, driver air bag (inflator) module

may jump about 30 cm (1 ft) vertically. This

is normal reaction to force of rapid gas

expansion inside of drive air bag (inflator)

module.

• After air bag (inflator) module has been

deployed, surface of air bag (inflator) may

contain powdery residue. This powder

consists primarily of cornstarch (used to

lubricate bag (inflator) as it inflates) and by

products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator)

module and activated seat belt

pretensioner near any flammable objects.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and activated seat

belt pretensioner.

• Wait for about 30 minutes before touching

any metal surface of air bag (inflater)

module or seat belt pretensioner module.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

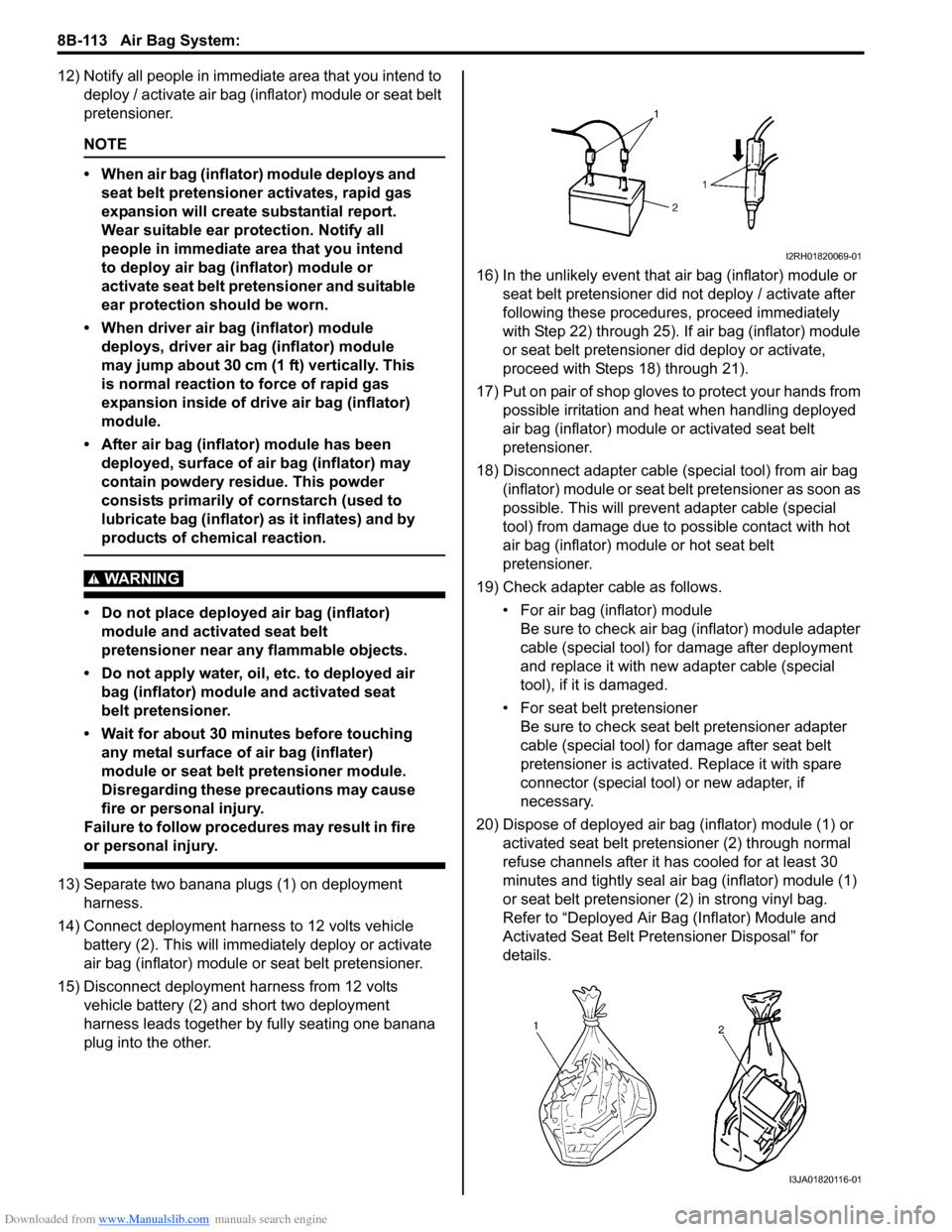

13) Separate two banana plugs (1) on deployment

harness.

14) Connect deployment harness to 12 volts vehicle

battery (2). This will immediately deploy or activate

air bag (inflator) module or seat belt pretensioner.

15) Disconnect deployment harness from 12 volts

vehicle battery (2) and short two deployment

harness leads together by fully seating one banana

plug into the other.16) In the unlikely event that air bag (inflator) module or

seat belt pretensioner did not deploy / activate after

following these procedures, proceed immediately

with Step 22) through 25). If air bag (inflator) module

or seat belt pretensioner did deploy or activate,

proceed with Steps 18) through 21).

17) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module or activated seat belt

pretensioner.

18) Disconnect adapter cable (special tool) from air bag

(inflator) module or seat belt pretensioner as soon as

possible. This will prevent adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

19) Check adapter cable as follows.

• For air bag (inflator) module

Be sure to check air bag (inflator) module adapter

cable (special tool) for damage after deployment

and replace it with new adapter cable (special

tool), if it is damaged.

• For seat belt pretensioner

Be sure to check seat belt pretensioner adapter

cable (special tool) for damage after seat belt

pretensioner is activated. Replace it with spare

connector (special tool) or new adapter, if

necessary.

20) Dispose of deployed air bag (inflator) module (1) or

activated seat belt pretensioner (2) through normal

refuse channels after it has cooled for at least 30

minutes and tightly seal air bag (inflator) module (1)

or seat belt pretensioner (2) in strong vinyl bag.

Refer to “Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal” for

details.

I2RH01820069-01

I3JA01820116-01

Page 1155 of 1556

Downloaded from www.Manualslib.com manuals search engine Air Bag System: 8B-116

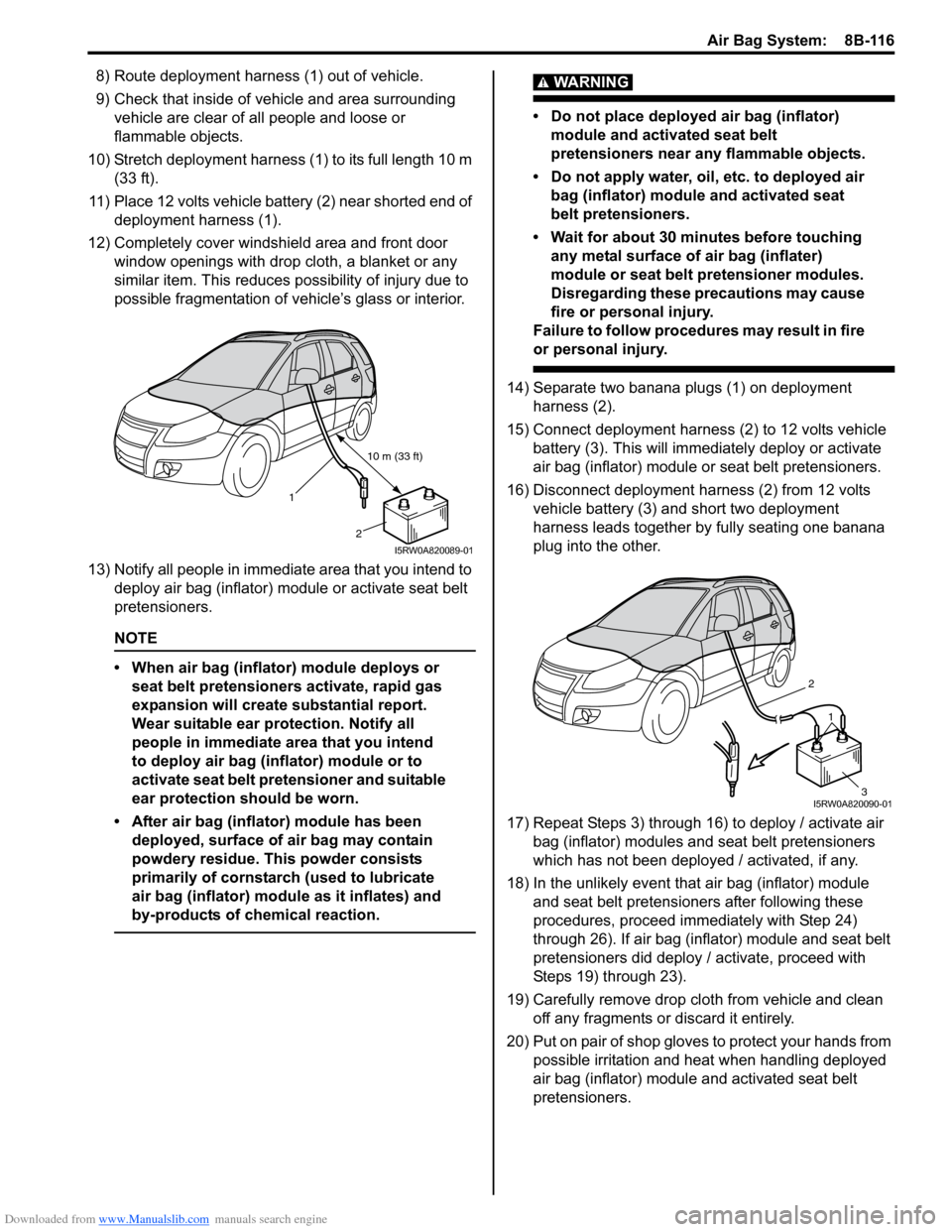

8) Route deployment harness (1) out of vehicle.

9) Check that inside of vehicle and area surrounding

vehicle are clear of all people and loose or

flammable objects.

10) Stretch deployment harness (1) to its full length 10 m

(33 ft).

11) Place 12 volts vehicle battery (2) near shorted end of

deployment harness (1).

12) Completely cover windshield area and front door

window openings with drop cloth, a blanket or any

similar item. This reduces possibility of injury due to

possible fragmentation of vehicle’s glass or interior.

13) Notify all people in immediate area that you intend to

deploy air bag (inflator) module or activate seat belt

pretensioners.

NOTE

• When air bag (inflator) module deploys or

seat belt pretensioners activate, rapid gas

expansion will create substantial report.

Wear suitable ear protection. Notify all

people in immediate area that you intend

to deploy air bag (inflator) module or to

activate seat belt pretensioner and suitable

ear protection should be worn.

• After air bag (inflator) module has been

deployed, surface of air bag may contain

powdery residue. This powder consists

primarily of cornstarch (used to lubricate

air bag (inflator) module as it inflates) and

by-products of chemical reaction.

WARNING!

• Do not place deployed air bag (inflator)

module and activated seat belt

pretensioners near any flammable objects.

• Do not apply water, oil, etc. to deployed air

bag (inflator) module and activated seat

belt pretensioners.

• Wait for about 30 minutes before touching

any metal surface of air bag (inflater)

module or seat belt pretensioner modules.

Disregarding these precautions may cause

fire or personal injury.

Failure to follow procedures may result in fire

or personal injury.

14) Separate two banana plugs (1) on deployment

harness (2).

15) Connect deployment harness (2) to 12 volts vehicle

battery (3). This will immediately deploy or activate

air bag (inflator) module or seat belt pretensioners.

16) Disconnect deployment harness (2) from 12 volts

vehicle battery (3) and short two deployment

harness leads together by fully seating one banana

plug into the other.

17) Repeat Steps 3) through 16) to deploy / activate air

bag (inflator) modules and seat belt pretensioners

which has not been deployed / activated, if any.

18) In the unlikely event that air bag (inflator) module

and seat belt pretensioners after following these

procedures, proceed immediately with Step 24)

through 26). If air bag (inflator) module and seat belt

pretensioners did deploy / activate, proceed with

Steps 19) through 23).

19) Carefully remove drop cloth from vehicle and clean

off any fragments or discard it entirely.

20) Put on pair of shop gloves to protect your hands from

possible irritation and heat when handling deployed

air bag (inflator) module and activated seat belt

pretensioners.

10 m (33 ft)

1

2

I5RW0A820089-01

1

3 2

I5RW0A820090-01

Page 1156 of 1556

Downloaded from www.Manualslib.com manuals search engine 8B-117 Air Bag System:

21) Disconnect adapter cable (special tool) from air bag

(inflator) module or seat belt pretensioner as soon as

possible. This will prevent adapter cable (special

tool) from damage due to possible contact with hot

air bag (inflator) module or hot seat belt

pretensioner.

22) Check adapter cable connector as follows.

Adapter cable connector (special tool) is designed to

be reused. However it should be inspected for

damage after deployment and replaced if necessary.

23) With air bag (inflator) modules deployed and seat

belt pretensioners activated, vehicle may be

scrapped in the same manner as non-air bag system

/ seat belt pretensioner equipped vehicle.

NOTE

Remaining steps are to be followed in the

unlikely event that air bag (inflator) module

did not deploy or seat belt pretensioner did

not activate.

24) Remove undeployed air bag (inflator) module(s) and/

or inactivated seat belt pretensioner(s) from vehicle.

For driver air bag (inflator) module, refer to “Driver

Air Bag (Inflator) Module Removal and Installation”.

For passenger air bag (inflator) module, refer to

“Passenger Air Bag (Inflator) Module Removal and

Installation”. For side air bag (inflator) module, refer

to “Side-Air Bag (Inflator) Module Removal and

Installation”. For side curtain-air bag (inflator)

module, refer to “Side Curtain-Air Bag (Inflator)

Module Removal and Installation”. For seat belt

pretensioner, refer to “Front Seat Belt Removal and

Installation in Section 8A”.

25) Temporarily store undeployed air bag (inflator)

module referring to “Precautions on Service and

Diagnosis of Air Bag System” for details.

26) Contact your local distributor for further assistance.

Deployed Air Bag (Inflator) Module and

Activated Seat Belt Pretensioner Disposal

S6RW0D8206019

WARNING!

Failure to follow proper air bag (inflator)

module and seat belt pretensioner disposal

procedures can result in air bag deployment

and pretensioner activation which may cause

personal injury. The undeployed air bag

(inflator) module and the inactivated seat belt

pretensioner must not be disposed of

through normal refuse channels.

The undeployed air bag (inflator) module and

the inactivated seat belt pretensioner

contains substances that can cause severe

illness or personal injury if the sealed

container is damaged during disposal.

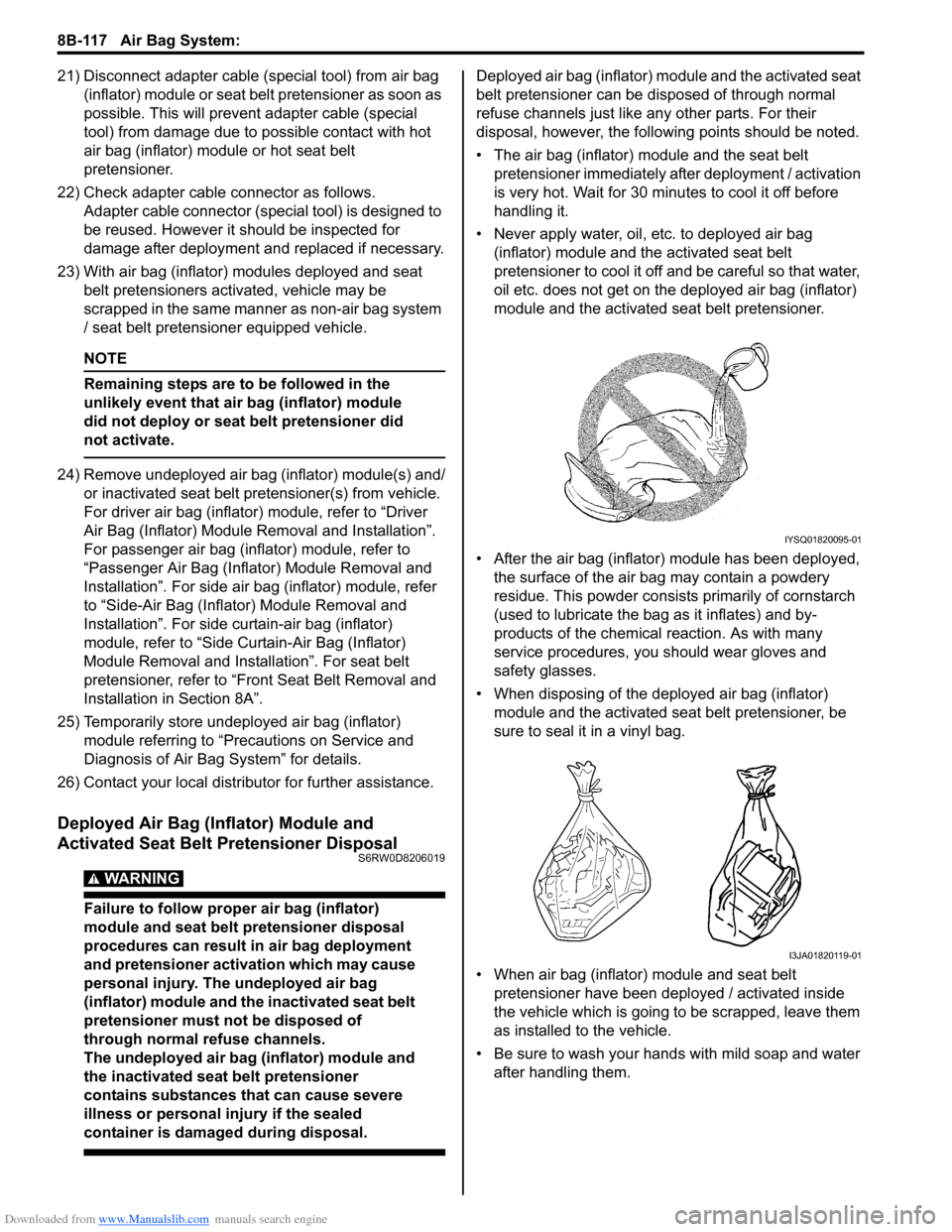

Deployed air bag (inflator) module and the activated seat

belt pretensioner can be disposed of through normal

refuse channels just like any other parts. For their

disposal, however, the following points should be noted.

• The air bag (inflator) module and the seat belt

pretensioner immediately after deployment / activation

is very hot. Wait for 30 minutes to cool it off before

handling it.

• Never apply water, oil, etc. to deployed air bag

(inflator) module and the activated seat belt

pretensioner to cool it off and be careful so that water,

oil etc. does not get on the deployed air bag (inflator)

module and the activated seat belt pretensioner.

• After the air bag (inflator) module has been deployed,

the surface of the air bag may contain a powdery

residue. This powder consists primarily of cornstarch

(used to lubricate the bag as it inflates) and by-

products of the chemical reaction. As with many

service procedures, you should wear gloves and

safety glasses.

• When disposing of the deployed air bag (inflator)

module and the activated seat belt pretensioner, be

sure to seal it in a vinyl bag.

• When air bag (inflator) module and seat belt

pretensioner have been deployed / activated inside

the vehicle which is going to be scrapped, leave them

as installed to the vehicle.

• Be sure to wash your hands with mild soap and water

after handling them.

IYSQ01820095-01

I3JA01820119-01

Page 1161 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9- i

9

Section 9

CONTENTS

Body, Cab and Accessories

Precautions ................................................. 9-1

Precautions............................................................. 9-1

Precautions on Body, Cab and Accessories ......... 9-1

Precautions for Body Service ................................ 9-1

Fastener Caution for Body Service ....................... 9-1

Wiring Systems........................................ 9A-1

Precautions........................................................... 9A-1

Cautions in Body Electrical System Servicing..... 9A-1

General Description ............................................. 9A-1

Abbreviations ...................................................... 9A-1

Wire / Connector Color Symbols ......................... 9A-1

Symbols and Marks ............................................ 9A-2

How to Read Connector Layout Diagram ........... 9A-4

How to Read Connector Codes and Terminal

Nos.................................................................... 9A-5

How to Read Ground Point ................................. 9A-8

How to Read Power Supply Diagram.................. 9A-9

How to Read System Circuit Diagram................. 9A-9

Connector Layout Diagram ............................... 9A-11

Connector Layout Diagram ............................... 9A-11

Engine Compartment ........................................ 9A-11

Instrument Panel ............................................... 9A-19

Door, Roof......................................................... 9A-25

Floor .................................................................. 9A-28

Rear .................................................................. 9A-32

Ground Point ...................................................... 9A-33

Ground (earth) Point ......................................... 9A-33

Power Supply Diagram ...................................... 9A-34

Power Supply Diagram ..................................... 9A-34

Fuses and the Protected Parts ......................... 9A-36

Fuses in Main Fuse Box ................................... 9A-36

Individual Circuit Fuse Box No. 1 ...................... 9A-37

Individual Circuit Fuse Box No. 2 (In J/B

(Except Taiwan)) ............................................. 9A-38

Individual Circuit Fuse Box No. 2 (In J/B

(Taiwan)) ......................................................... 9A-40

Junction Block (J/B) Connector / Fuse Layout .. 9A-42

Junction Block Inner Circuit (Overview

(Except Taiwan)) ............................................. 9A-43

Junction Block Inner Circuit (Detail (Except

Taiwan)) .......................................................... 9A-45

Junction Block Inner Circuit (Overview

(Taiwan)) ......................................................... 9A-50Junction Block Inner Circuit (Detail (Taiwan)) ... 9A-52

System Circuit Diagram.....................................9A-57

System Circuit Diagram .................................... 9A-57

A-1 Cranking System Circuit Diagram .............. 9A-58

A-2 Charging System Circuit Diagram .............. 9A-59

A-3 Ignition System Circuit Diagram (M15A

engine, M16A engine) ..................................... 9A-60

A-3 Ignition System Circuit Diagram (J20A

engine) ............................................................ 9A-61

A-4 Cooling System Circuit Diagram (M15A

engine, M16A engine) ..................................... 9A-62

A-4 Cooling System Circuit Diagram (J20A

engine) ............................................................ 9A-63

A-5 Engine and A/C Control System Circuit

Diagram (M15A engine) .................................. 9A-64

A-5 Engine and A/C Control System Circuit

Diagram (M16A engine) .................................. 9A-68

A-5 Engine and A/C Control System Circuit

Diagram (J20A engine) ................................... 9A-72

A-6 A/T Control System Circuit Diagram........... 9A-76

A-7 Immobilizer System Circuit Diagram .......... 9A-78

A-8 Body Control System Circuit Diagram

(Except Taiwan) .............................................. 9A-79

A-8 Body Control System Circuit Diagram

(Taiwan) .......................................................... 9A-83

A-10 4WD Control System (Except Taiwan) ..... 9A-87

B-1 Windshield Wiper and Washer Circuit

Diagram........................................................... 9A-88

B-2 Rear Wiper and Washer Circuit Diagram

(Except Taiwan) .............................................. 9A-89

B-2 Rear Wiper and Washer Circuit Diagram

(Taiwan) .......................................................... 9A-90

B-3 Rear Defogger Circuit Diagram (Except

Taiwan) ........................................................... 9A-91

B-3 Rear Defogger Circuit Diagram (Taiwan) ... 9A-92

B-4 Power Window Circuit Diagram .................. 9A-93

B-5 Power Door Lock Circuit Diagram (Except

Taiwan) ........................................................... 9A-95

B-5 Power Door Lock Circuit Diagram

(Taiwan) .......................................................... 9A-97

B-6 Power Mirror Circuit Diagram (Except

Taiwan) ........................................................... 9A-99

B-6 Power Mirror Circuit Diagram (Taiwan) .... 9A-100

B-7 Horn Circuit Diagram ................................ 9A-101

B-8 Seat Heater Circuit Diagram..................... 9A-102

Page 1165 of 1556

Downloaded from www.Manualslib.com manuals search engine Table of Contents 9-v

Power Door Lock System Symptom

Diagnosis (If Equipped)..................................... 9F-3

Power Door Lock System Operation

Inspection (If Equipped) .................................... 9F-3

Keyless Entry System Symptom Diagnosis (If

Equipped).......................................................... 9F-4

Keyless Entry System Operation Inspection

(If Equipped) ..................................................... 9F-5

Door Lock Function of Keyless Start System

Symptom Diagnosis (If Equipped) .................... 9F-5

Rear End Door Opener System Symptom

Diagnosis (If Equipped)..................................... 9F-5

Rear End Door Opener System Operation

Inspection (If Equipped) .................................... 9F-5

Repair Instructions .............................................. 9F-6

Front Door Lock Assembly Components ............ 9F-6

Front Door Lock Assembly Removal and

Installation ......................................................... 9F-6

Front Door Lock Assembly Inspection ................ 9F-8

Power Door Lock Switch Inspection (If

Equipped).......................................................... 9F-8

Door Key Cylinder Switch Inspection (If

Equipped).......................................................... 9F-8

Power Door Lock Actuator Inspection (If

Equipped).......................................................... 9F-9

Rear Door Lock Assembly Components ........... 9F-10

Rear Door Lock Assembly Removal and

Installation ....................................................... 9F-10

Rear Door Lock Assembly Inspection ............... 9F-10

Rear End Door Lock Assembly Components.... 9F-11

Rear End Door Lock Assembly Removal and

Installation ....................................................... 9F-12

Rear End Door Lock Assembly Inspection........ 9F-12

Rear End Door Opener Switch Inspection (If

Equipped)........................................................ 9F-12

Replacement of Transmitter Battery (Other

than Keyless Start Model) ............................... 9F-13

Programming Transmitter Code for Keyless

Entry System (Other than Keyless Start

Model) ............................................................. 9F-13

Keyless Entry Answer Back Function

Change-over Procedure (If Equipped) ............ 9F-14

Keyless Entry Receiver Removal and

Installation (If Equipped)................................. 9F-14

Keyless Entry Receiver and Its Circuit

Inspection (If Equipped) .................................. 9F-15

Specifications..................................................... 9F-16

Tightening Torque Specifications ...................... 9F-16

Special Tools and Equipment ........................... 9F-16

Recommended Service Material ....................... 9F-16

Seats ......................................................... 9G-1

Diagnostic Information and Procedures ............9G-1

Front Seat Heater Symptom Diagnosis (If

Equipped)..........................................................9G-1

Repair Instructions ..............................................9G-2

Front Seat Components ......................................9G-2

Front Seat Removal and Installation ...................9G-3Front Seat Heater Switch (Driver and

Passenger Side) Inspection (If Equipped)........ 9G-3

Front Seat Heater Wire Inspection (If

Equipped) ......................................................... 9G-3

Rear Seat Components...................................... 9G-4

Rear Seat Removal and Installation................... 9G-4

Specifications ...................................................... 9G-5

Tightening Torque Specifications ....................... 9G-5

Special Tools and Equipment ............................ 9G-5

Recommended Service Material ........................ 9G-5

Interior Trim ............................................. 9H-1

Repair Instructions ..............................................9H-1

Floor Carpet Removal and Installation ................9H-1

Head Lining Removal and Installation.................9H-2

Console Box Components ..................................9H-3

Specifications .......................................................9H-4

Tightening Torque Specifications ........................9H-4

Hood / Fenders / Doors ............................ 9J-1

Repair Instructions .............................................. 9J-1

Hood Removal and Installation ........................... 9J-1

Hood Inspection and Adjustment ........................ 9J-1

Front Fender Components .................................. 9J-2

Front Fender Removal and Installation ............... 9J-2

Front Door Assembly Components ..................... 9J-3

Front Door Assembly Removal and

Installation ......................................................... 9J-3

Rear Door Assembly Components...................... 9J-5

Rear Door Assembly Removal and

Installation ......................................................... 9J-5

Rear End Door Assembly Components .............. 9J-6

Rear End Door Assembly Removal and

Installation ......................................................... 9J-6

Specifications ....................................................... 9J-8

Tightening Torque Specifications ........................ 9J-8

Special Tools and Equipment ............................. 9J-8

Recommended Service Material ......................... 9J-8

Body Structure......................................... 9K-1

Repair Instructions ..............................................9K-1

Front Bumper and Rear Bumper Components .... 9K-1

Cowl Top and Front Lower Crossmember

Components ...................................................... 9K-2

Specifications .......................................................9K-3

Body Dimensions ................................................ 9K-3

Panel Clearance................................................ 9K-10

Tightening Torque Specifications ...................... 9K-10

Paint / Coatings ........................................9L-1

General Description ............................................. 9L-1

Anti-Corrosion Treatment Construction............... 9L-1

Plastic Parts Finishing ......................................... 9L-2

Component Location ........................................... 9L-3

Sealant Application Areas ................................... 9L-3

Under Coating Application Areas ...................... 9L-10

Anti-Corrosion Compound Application Area ..... 9L-12

Exterior Trim ............................................ 9M-1

Page 1167 of 1556

Downloaded from www.Manualslib.com manuals search engine Precautions: 9-1

Body, Cab and Accessories

Precautions

Precautions

Precautions on Body, Cab and AccessoriesS6RW0D9000001

Air Bag Warning

Refer to “Air Bag Warning in Section 00”.

Fastener Caution

Refer to “Fastener Caution in Section 00”.

Precautions for Body Service

Refer to “Precautions for Body Service”.

Fastener Caution for Body Service:

Refer to “Fastener Caution for Body Service”.

Cautions in Body Electrical System Servicing

Refer to “Cautions in Body Electrical System Servicing in Section 9A”.

Precautions for Discharge Headlight Service (If Equipped)

Refer to “Precautions for Discharge Headlight Service (If Equipped) in Section 9B”.

Precautions for Power Window Service (Pinching Prevention Function Model)

Refer to “Precautions for Power Window Service (Pinching Prevention Function Model) in Section 9E”.

Precautions for Body ServiceS6RW0D9000002

WARNING!

For vehicles equipped with a Supplemental Restraint (Air Bag) System:

When servicing vehicle body, if shock may be applied to air bag system component parts, remove

those parts beforehand.

Fastener Caution for Body ServiceS6RW0D9000003

CAUTION!

• Fasteners are important attaching parts in that they could affect the performance of vital

components and systems, and/or could result in major repair expense. They must be replaced with

one of the same part number of with an equivalent part if replacement become necessary.

• Do not use a replacement part of lesser quality or substitute a design. Torque values must be used

as specified during reassembly to assure proper retention of these parts.

Page 1172 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-5 Wiring Systems:

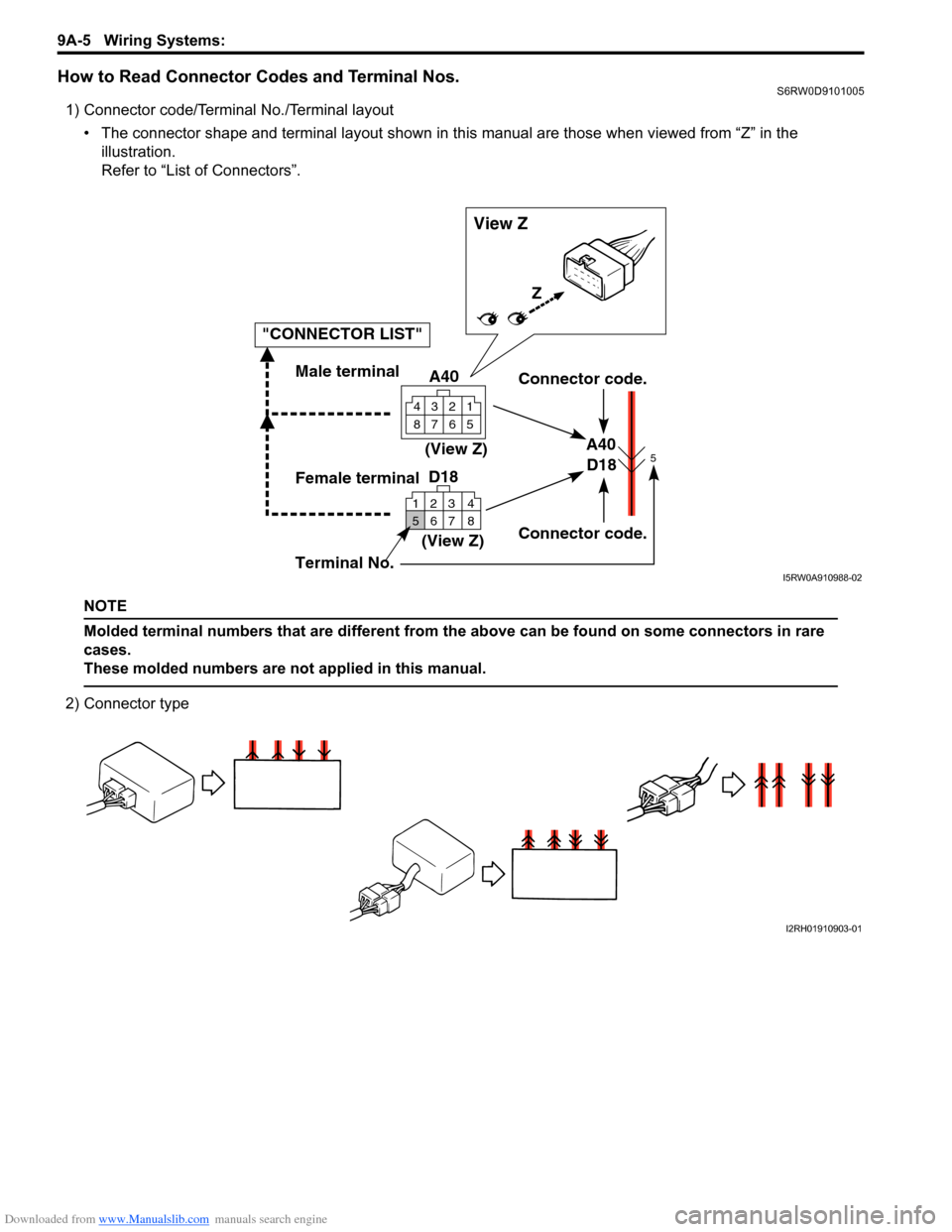

How to Read Connector Codes and Terminal Nos.S6RW0D9101005

1) Connector code/Terminal No./Terminal layout

• The connector shape and terminal layout shown in this manual are those when viewed from “Z” in the

illustration.

Refer to “List of Connectors”.

NOTE

Molded terminal numbers that are different from the above can be found on some connectors in rare

cases.

These molded numbers are not applied in this manual.

2) Connector type

A40

(View Z)

(View Z)

1

123 4

567 82 3 4

5 6 7 8

D185

D18A40

Connector code.

Connector code.

Terminal No.

"CONNECTOR LIST"

Male terminal

Female terminalZ

View Z

I5RW0A910988-02

I2RH01910903-01

Page 1176 of 1556

Downloaded from www.Manualslib.com manuals search engine 9A-9 Wiring Systems:

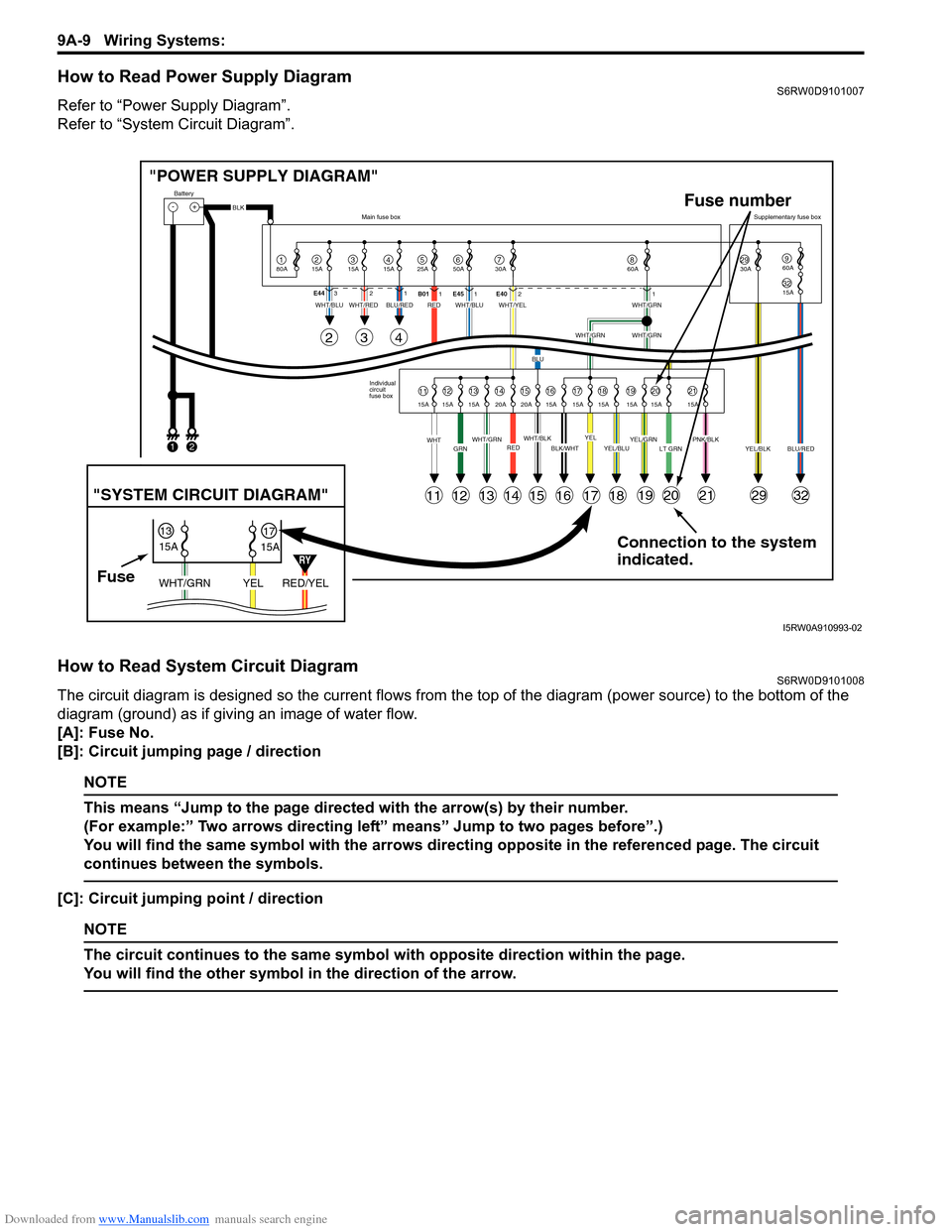

How to Read Power Supply DiagramS6RW0D9101007

Refer to “Power Supply Diagram”.

Refer to “System Circuit Diagram”.

How to Read System Circuit DiagramS6RW0D9101008

The circuit diagram is designed so the current flows from the top of the diagram (power source) to the bottom of the

diagram (ground) as if giving an image of water flow.

[A]: Fuse No.

[B]: Circuit jumping page / direction

NOTE

This means “Jump to the page directed with the arrow(s) by their number.

(For example:” Two arrows directing left” means” Jump to two pages before”.)

You will find the same symbol with the arrows directing opposite in the referenced page. The circuit

continues between the symbols.

[C]: Circuit jumping point / direction

NOTE

The circuit continues to the same symbol with opposite direction within the page.

You will find the other symbol in the direction of the arrow.

Connection to the system

indicated. "POWER SUPPLY DIAGRAM"

-+

1

Battery

80A

215A315A415A525A67850A 30A2930A3215A

960A

60A

BLK

YEL/BLKPNK/BLKLT GRNYEL/GRNYEL/BLUBLK/WHTWHT/BLKWHT/GRNREDGRNWHT

WHT/BLUWHT/REDWHT/BLUWHT/YELWHT/GRN

WHT/GRNWHT/GRN

BLU

BLU/REDRED

YELBLU/RED Individual

circuit

fuse box Main fuse boxSupplementary fuse box

11

11

243

121314151617181920212932

1213141516171819202115A 15A 15A 20A 20A 15A 15A 15A 15A 15A 15A E44321

B011E451E4021

FuseRED/YEL YEL WHT/GRN

15A

15A 1317

"SYSTEM CIRCUIT DIAGRAM"

Fuse number

12

RY

I5RW0A910993-02

Page 1201 of 1556

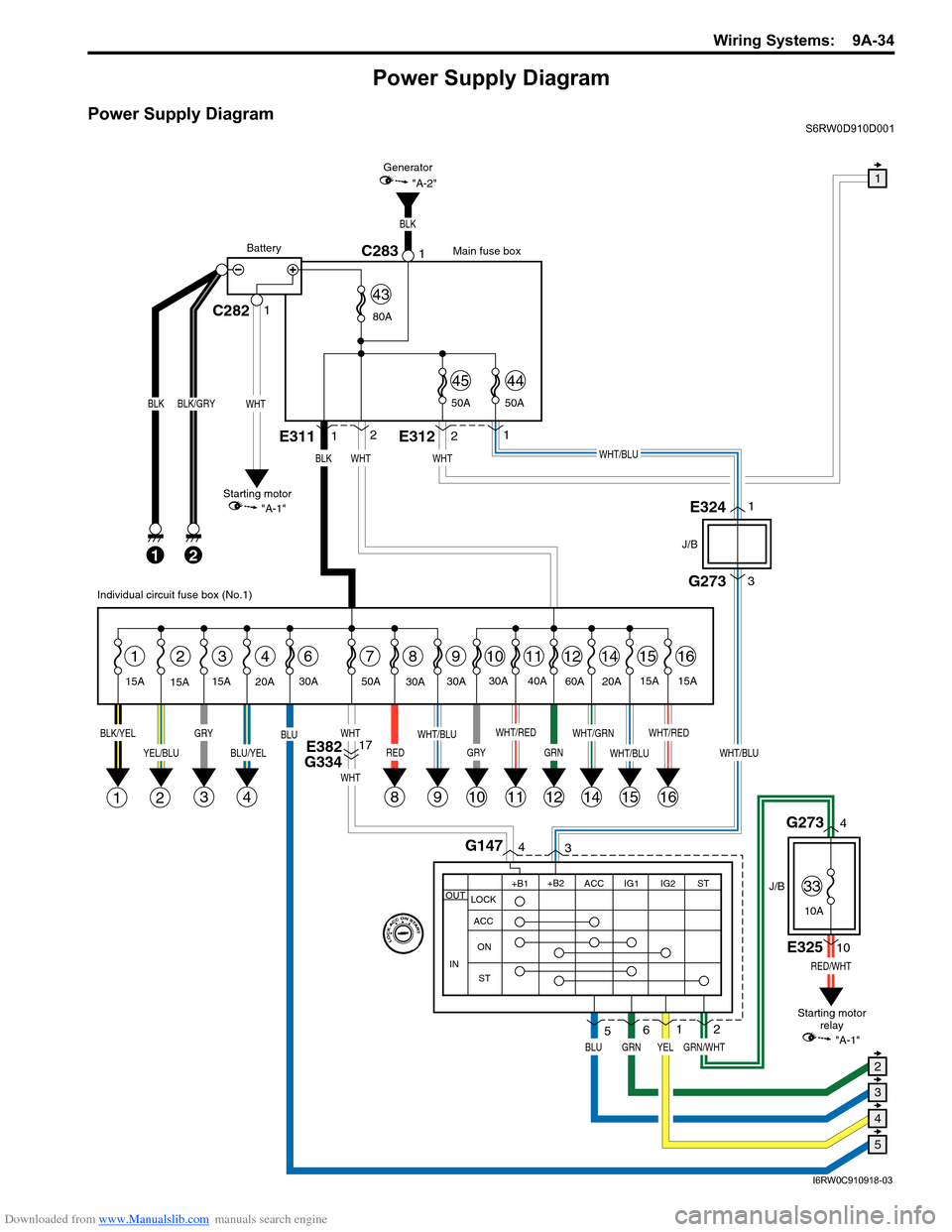

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-34

Power Supply Diagram

Power Supply DiagramS6RW0D910D001

G273

J/B

J/B

3

WHT/BLU

GRN/WHT

RED/WHT

4G1473

1

2

8

BLK

21

BLK/GRY

15A

15A15A

2314678

1E3112

WHT

1112141516

BLK/YELGRY

3

YEL/BLU

21

BLU/YEL

4

BLU

RED

WHT

WHT

WHT/RED

11

WHT/GRN

14

WHT/BLU

1516

WHT/RED

GRN

12

30A

9

WHT/BLU

9

30A

20A30A 50A40A

60A

20A15A

15A

BLK

2E3121

WHT/BLU

C282C28311

WHT

BLK

Main fuse box

Starting motor

"A-1"Generator

"A-2"

Battery

80A

50A 50A

4544

43

E3241

E32510

G2734

WHT

YEL

Individual circuit fuse box (No.1)

+B1

LOCK

ACC

ON

STACC IG1 IG2STOUT

IN

+B2

6

GRNBLU

5

Starting motor

relay

10

GRY

10

30A

E382

G33417

1

5

4

3

2

"A-1"

33

10A

I6RW0C910918-03