oil SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1359 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-7

Low Fuel Warning Light Symptom DiagnosisS6RW0D9304005

NOTE

• Confirm that fuel meter is in good condition before referring to the following possible causes.

• When fuel level sensor circuit is open or short, fuel level meter indicates empty even if fuel tank

does not empty.

• The low fuel warning light comes ON when fuel level is lower than specification below.

Low fuel warning light operation:

Oil Pressure Warning Light Symptom DiagnosisS6RW0D9304006

Low fuel warning light operation: Fuel amount: Resistance of fuel level sensor:

ON (2WD) Approx. 7.5 liter Approx. 261 Ω

ON (4WD) Approx. 6.8 liter Approx. 261 Ω

Condition Possible cause Correction / Reference Item

Low fuel warning light

does not come ON when

fuel level is lower than

specificationCircuit fuse blownReplace fuse and check for short circuit.

Fuel level sensor faultyCheck fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Low fuel warning light

comes ON steadyLow fuelRefill fuel.

Fuel level sensor faultyCheck fuel level sensor referring to “Fuel Level

Sensor Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

ECM faultyReplace after making sure that none of above

parts is faulty.

Condition Possible cause Correction / Reference Item

Oil pressure warning light

does not light up when

ignition switch is turned

to ON position at engine

offCircuit fuse blownReplace fuse and check for short circuit.

Oil pressure switch faultyCheck oil pressure switch referring to “Oil

Pressure Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Oil pressure warning light

stays ONOil pressure switch faultyCheck oil pressure switch referring to “Oil

Pressure Switch Inspection”.

Wiring or grounding faultyRepair circuit.

Combination meter faultyReplace combination meter.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1365 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-13

Auto Volume Control System

Remote Audio Control Switch Symptom Diagnosis (If Equipped)S6RW0D9304018

Navigation Symptom Diagnosis (If Equipped)S6RW0D9304019

CD player is operative,

but all speakers does not

soundWiring or grounding faultyRepair circuit.

Radio assembly faultyReplace radio assembly.

Individual speaker is

noisy or inoperativeWiring or grounding faultyRepair circuit.

Speaker faultyReplace speaker.

Radio assembly faultyReplace radio assembly.

Sound quality or volume

is poorCD-ROM faulty—

Wiring or grounding faultyRepair circuit.

Speaker installed incorrectlyInstall correctly.

Speaker faultyReplace speaker. Condition Possible cause Correction / Reference Item

Condition Possible cause Correction / Reference Item

Sound volume does not

vary according to

changes of vehicle speedAuto volume control system is “OFF”

modeSelect auto volume control.

Vehicle speed signal faultyCheck vehicle speed signal referring to

“Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyCheck input and output signal of BCM referring

to “Inspection of BCM and Its Circuits in

Section 10B”.

Radio assembly faultyReplace radio assembly.

Condition Possible cause Correction / Reference Item

Audio system is

operative, but remote

control switch does not

control audio systemRemote audio control switch faultyCheck remote audio control switch referring to

“Remote Audio Control Switch Inspection (If

Equipped)”.

Contact coil faultyReplace contact coil.

Wiring or grounding faultyRepair circuit.

Radio assembly faultyReplace radio assembly.

Condition Possible cause Correction / Reference Item

No displaying of

navigationCircuit fuse BlownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

Navigation unit faultyReplace unit.

Page 1367 of 1556

Downloaded from www.Manualslib.com manuals search engine Instrumentation / Driver Info. / Horn: 9C-15

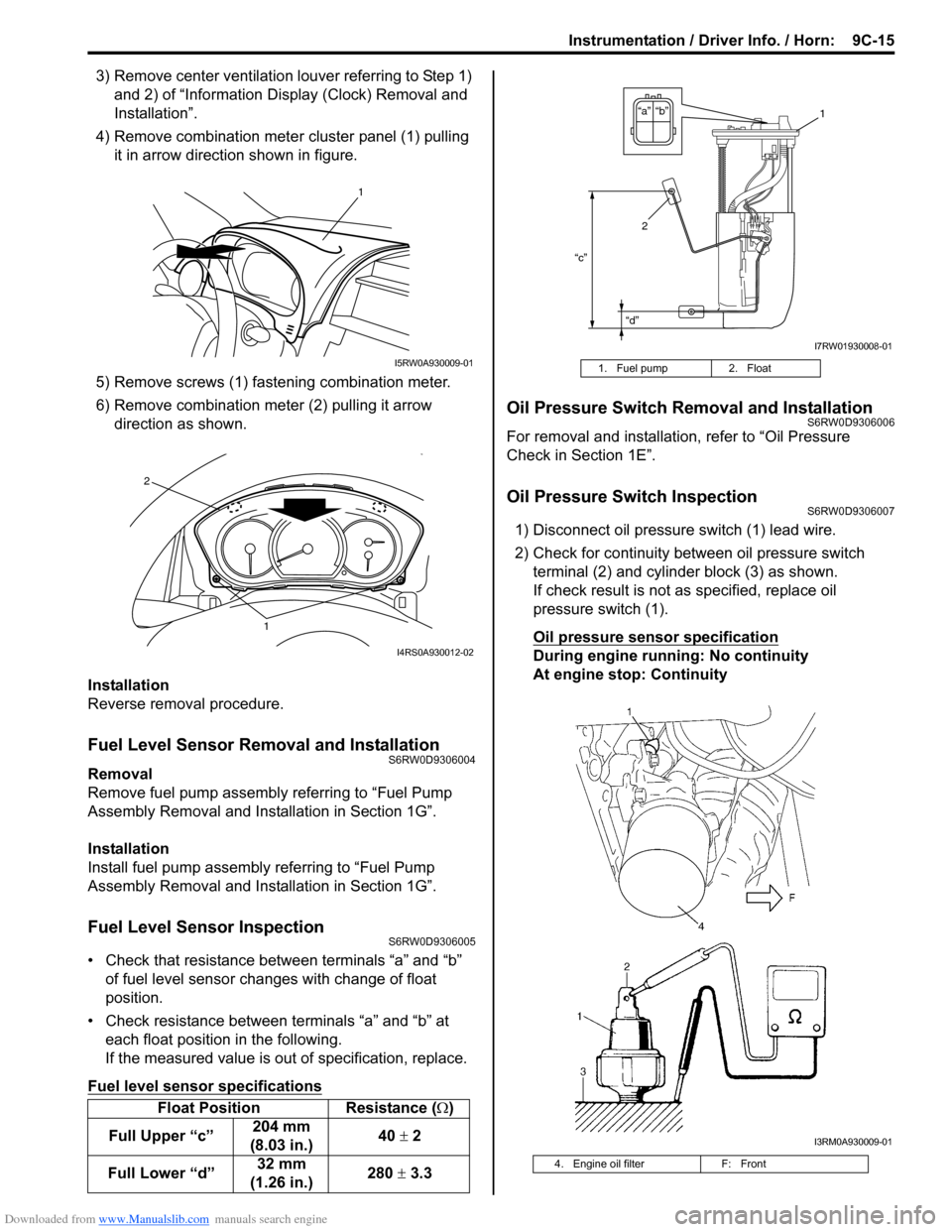

3) Remove center ventilation louver referring to Step 1)

and 2) of “Information Display (Clock) Removal and

Installation”.

4) Remove combination meter cluster panel (1) pulling

it in arrow direction shown in figure.

5) Remove screws (1) fastening combination meter.

6) Remove combination meter (2) pulling it arrow

direction as shown.

Installation

Reverse removal procedure.

Fuel Level Sensor Removal and InstallationS6RW0D9306004

Removal

Remove fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Installation

Install fuel pump assembly referring to “Fuel Pump

Assembly Removal and Installation in Section 1G”.

Fuel Level Sensor InspectionS6RW0D9306005

• Check that resistance between terminals “a” and “b”

of fuel level sensor changes with change of float

position.

• Check resistance between terminals “a” and “b” at

each float position in the following.

If the measured value is out of specification, replace.

Fuel level sensor specifications

Oil Pressure Switch Removal and InstallationS6RW0D9306006

For removal and installation, refer to “Oil Pressure

Check in Section 1E”.

Oil Pressure Switch InspectionS6RW0D9306007

1) Disconnect oil pressure switch (1) lead wire.

2) Check for continuity between oil pressure switch

terminal (2) and cylinder block (3) as shown.

If check result is not as specified, replace oil

pressure switch (1).

Oil pressure sensor specification

During engine running: No continuity

At engine stop: Continuity

Float Position Resistance (Ω)

Full Upper “c”204 mm

(8.03 in.)40 ± 2

Full Lower “d”32 mm

(1.26 in.)280 ± 3.3

1

I5RW0A930009-01

1

2

I4RS0A930012-02

1. Fuel pump 2. Float

4. Engine oil filter F: Front

“c”

“d”

“b” “a”1

2

I7RW01930008-01

I3RM0A930009-01

Page 1374 of 1556

Downloaded from www.Manualslib.com manuals search engine 9C-22 Instrumentation / Driver Info. / Horn:

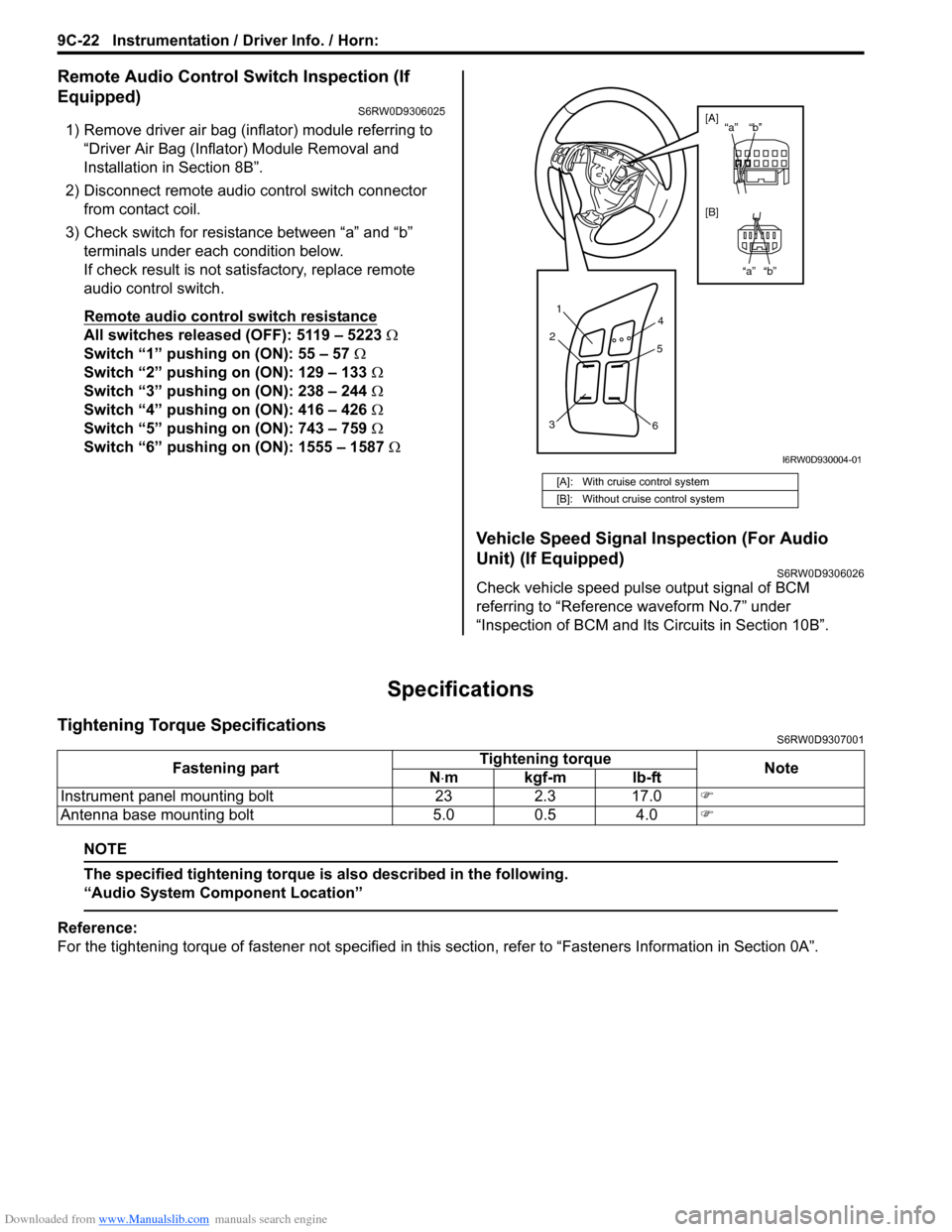

Remote Audio Control Switch Inspection (If

Equipped)

S6RW0D9306025

1) Remove driver air bag (inflator) module referring to

“Driver Air Bag (Inflator) Module Removal and

Installation in Section 8B”.

2) Disconnect remote audio control switch connector

from contact coil.

3) Check switch for resistance between “a” and “b”

terminals under each condition below.

If check result is not satisfactory, replace remote

audio control switch.

Remote audio control switch resistance

All switches released (OFF): 5119 – 5223 Ω

Switch “1” pushing on (ON): 55 – 57 Ω

Switch “2” pushing on (ON): 129 – 133 Ω

Switch “3” pushing on (ON): 238 – 244 Ω

Switch “4” pushing on (ON): 416 – 426 Ω

Switch “5” pushing on (ON): 743 – 759 Ω

Switch “6” pushing on (ON): 1555 – 1587 Ω

Vehicle Speed Signal Inspection (For Audio

Unit) (If Equipped)

S6RW0D9306026

Check vehicle speed pulse output signal of BCM

referring to “Reference waveform No.7” under

“Inspection of BCM and Its Circuits in Section 10B”.

Specifications

Tightening Torque SpecificationsS6RW0D9307001

NOTE

The specified tightening torque is also described in the following.

“Audio System Component Location”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

[A]: With cruise control system

[B]: Without cruise control system

1

2

34

5

6

“b” “a”

“b” “a” [A]

[B]

I6RW0D930004-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Instrument panel mounting bolt 23 2.3 17.0�)

Antenna base mounting bolt 5.0 0.5 4.0�)

Page 1392 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-7 Glass / Windows / Mirrors:

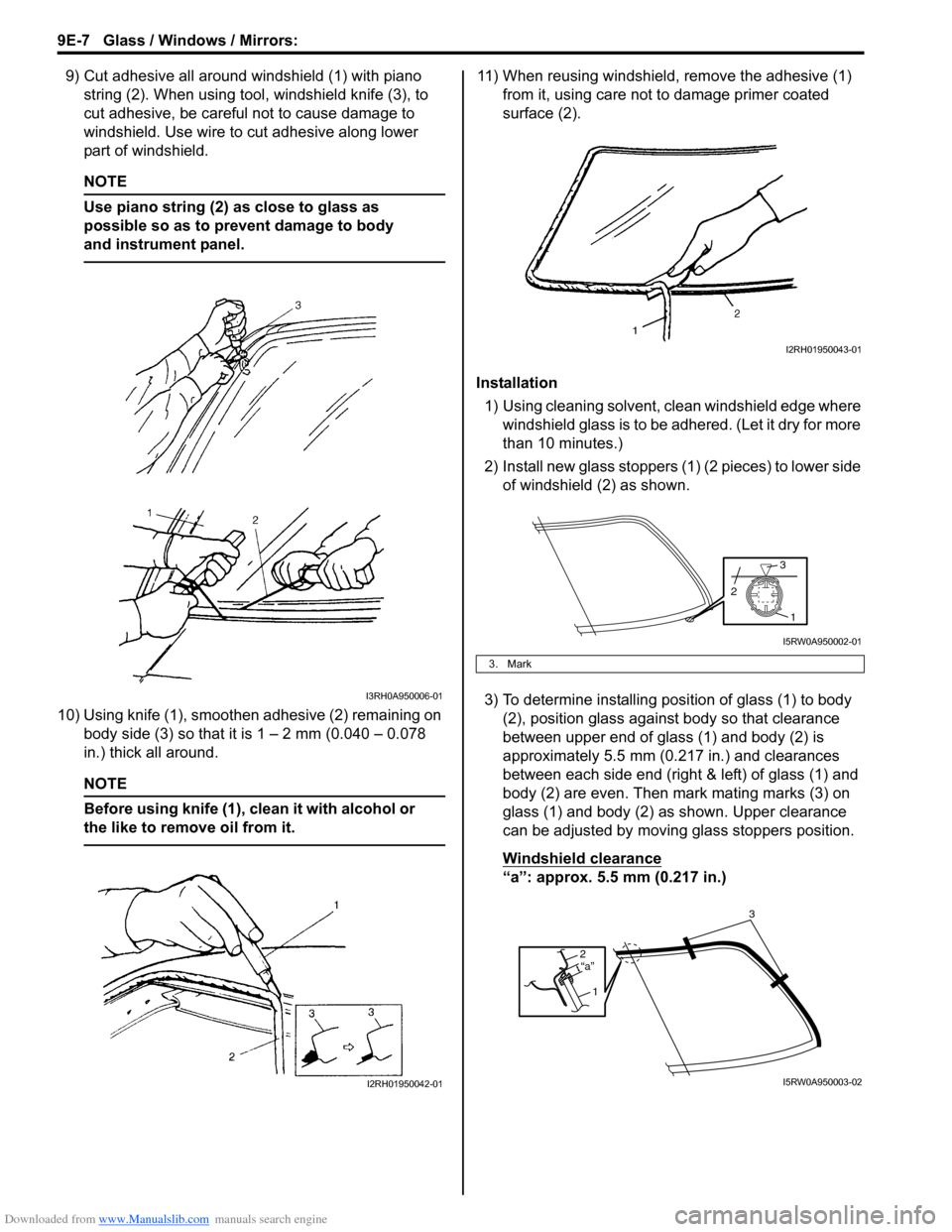

9) Cut adhesive all around windshield (1) with piano

string (2). When using tool, windshield knife (3), to

cut adhesive, be careful not to cause damage to

windshield. Use wire to cut adhesive along lower

part of windshield.

NOTE

Use piano string (2) as close to glass as

possible so as to prevent damage to body

and instrument panel.

10) Using knife (1), smoothen adhesive (2) remaining on

body side (3) so that it is 1 – 2 mm (0.040 – 0.078

in.) thick all around.

NOTE

Before using knife (1), clean it with alcohol or

the like to remove oil from it.

11) When reusing windshield, remove the adhesive (1)

from it, using care not to damage primer coated

surface (2).

Installation

1) Using cleaning solvent, clean windshield edge where

windshield glass is to be adhered. (Let it dry for more

than 10 minutes.)

2) Install new glass stoppers (1) (2 pieces) to lower side

of windshield (2) as shown.

3) To determine installing position of glass (1) to body

(2), position glass against body so that clearance

between upper end of glass (1) and body (2) is

approximately 5.5 mm (0.217 in.) and clearances

between each side end (right & left) of glass (1) and

body (2) are even. Then mark mating marks (3) on

glass (1) and body (2) as shown. Upper clearance

can be adjusted by moving glass stoppers position.

Windshield clearance

“a”: approx. 5.5 mm (0.217 in.)

I3RH0A950006-01

I2RH01950042-01

3. Mark

I2RH01950043-01

1

3

2

I5RW0A950002-01

2

1“a”

3

I5RW0A950003-02

Page 1404 of 1556

Downloaded from www.Manualslib.com manuals search engine 9E-19 Glass / Windows / Mirrors:

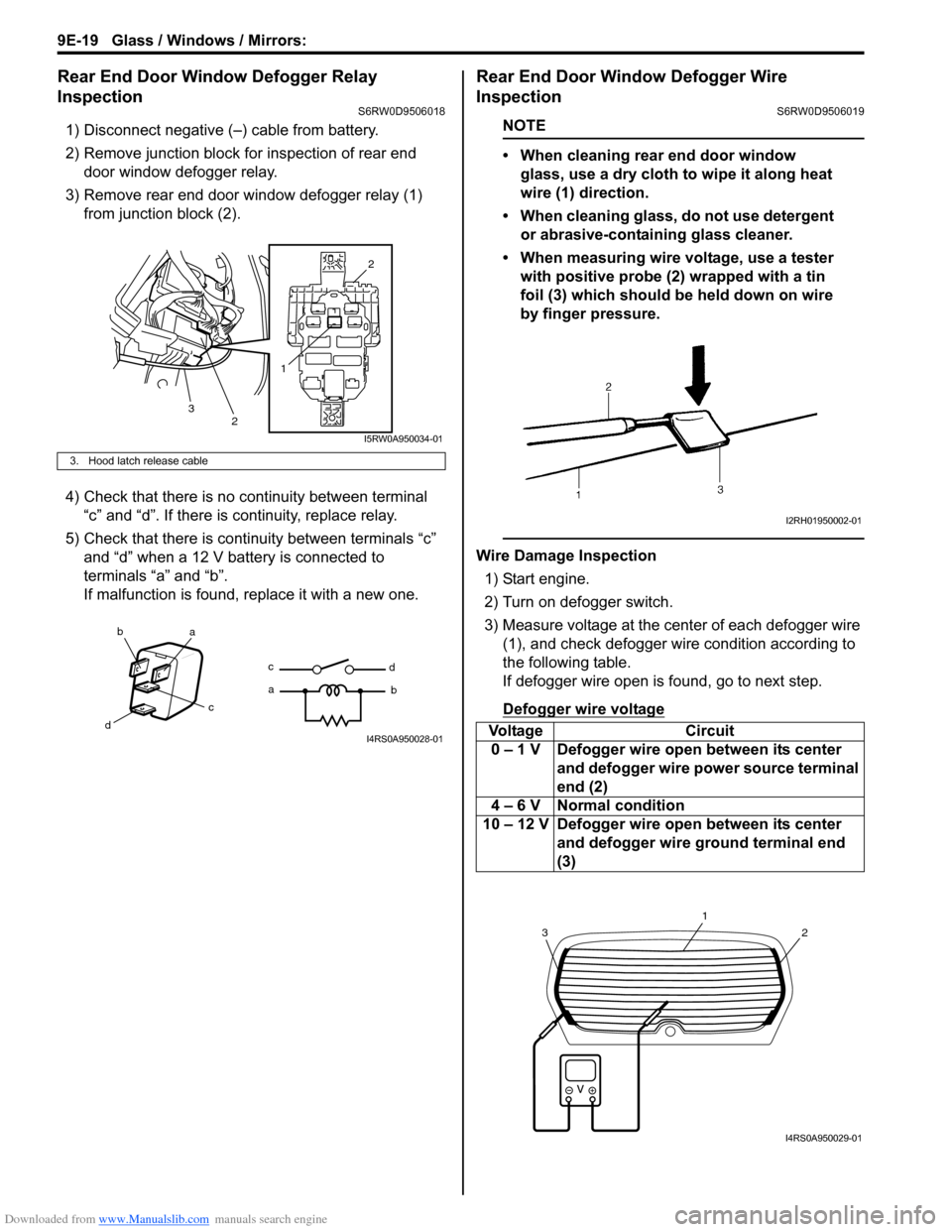

Rear End Door Window Defogger Relay

Inspection

S6RW0D9506018

1) Disconnect negative (–) cable from battery.

2) Remove junction block for inspection of rear end

door window defogger relay.

3) Remove rear end door window defogger relay (1)

from junction block (2).

4) Check that there is no continuity between terminal

“c” and “d”. If there is continuity, replace relay.

5) Check that there is continuity between terminals “c”

and “d” when a 12 V battery is connected to

terminals “a” and “b”.

If malfunction is found, replace it with a new one.

Rear End Door Window Defogger Wire

Inspection

S6RW0D9506019

NOTE

• When cleaning rear end door window

glass, use a dry cloth to wipe it along heat

wire (1) direction.

• When cleaning glass, do not use detergent

or abrasive-containing glass cleaner.

• When measuring wire voltage, use a tester

with positive probe (2) wrapped with a tin

foil (3) which should be held down on wire

by finger pressure.

Wire Damage Inspection

1) Start engine.

2) Turn on defogger switch.

3) Measure voltage at the center of each defogger wire

(1), and check defogger wire condition according to

the following table.

If defogger wire open is found, go to next step.

Defogger wire voltage

3. Hood latch release cable

12

2

3

I5RW0A950034-01

ba

c

dc

ad

bI4RS0A950028-01Voltage Circuit

0 – 1 V Defogger wire open between its center

and defogger wire power source terminal

end (2)

4 – 6 V Normal condition

10 – 12 V Defogger wire open between its center

and defogger wire ground terminal end

(3)

I2RH01950002-01

2

1

3

I4RS0A950029-01

Page 1405 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-20

4) Touch voltmeter negative (–) lead to defogger wire

ground terminal end (1).

5) Touch voltmeter positive (+) lead with a foil strip to

defogger wire power source terminal end (2), then

move it along wire to defogger wire ground terminal

end (1).

The place where voltmeter fluctuates from 10 – 12 V

to 0 – 1 V is where there is open.

If found defective, repair defogger wire referring to

“Rear End Door Window Defogger Wire Repair”.

Rear End Door Window Defogger Wire RepairS6RW0D9506020

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower

sides of heat wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a

fine-tip brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours

before operating the defogger again.

Power Window Main Switch InspectionS6RW0D9506021

Switch for Driver Side Window

Without Pinching Prevention Function Model

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Connect 12 V battery positive (+) terminal to terminal

“IG” of power window main switch and its negative (–

) terminal to terminal “E” of power window main

switch.

4) Check for continuity between terminals as shown

below.

If check result is not as specified, replace power

window main switch.

21

I4RS0A950030-01

I2RH01950005-01

I7RW01950004-01

Page 1442 of 1556

Downloaded from www.Manualslib.com manuals search engine 9J-6 Hood / Fenders / Doors:

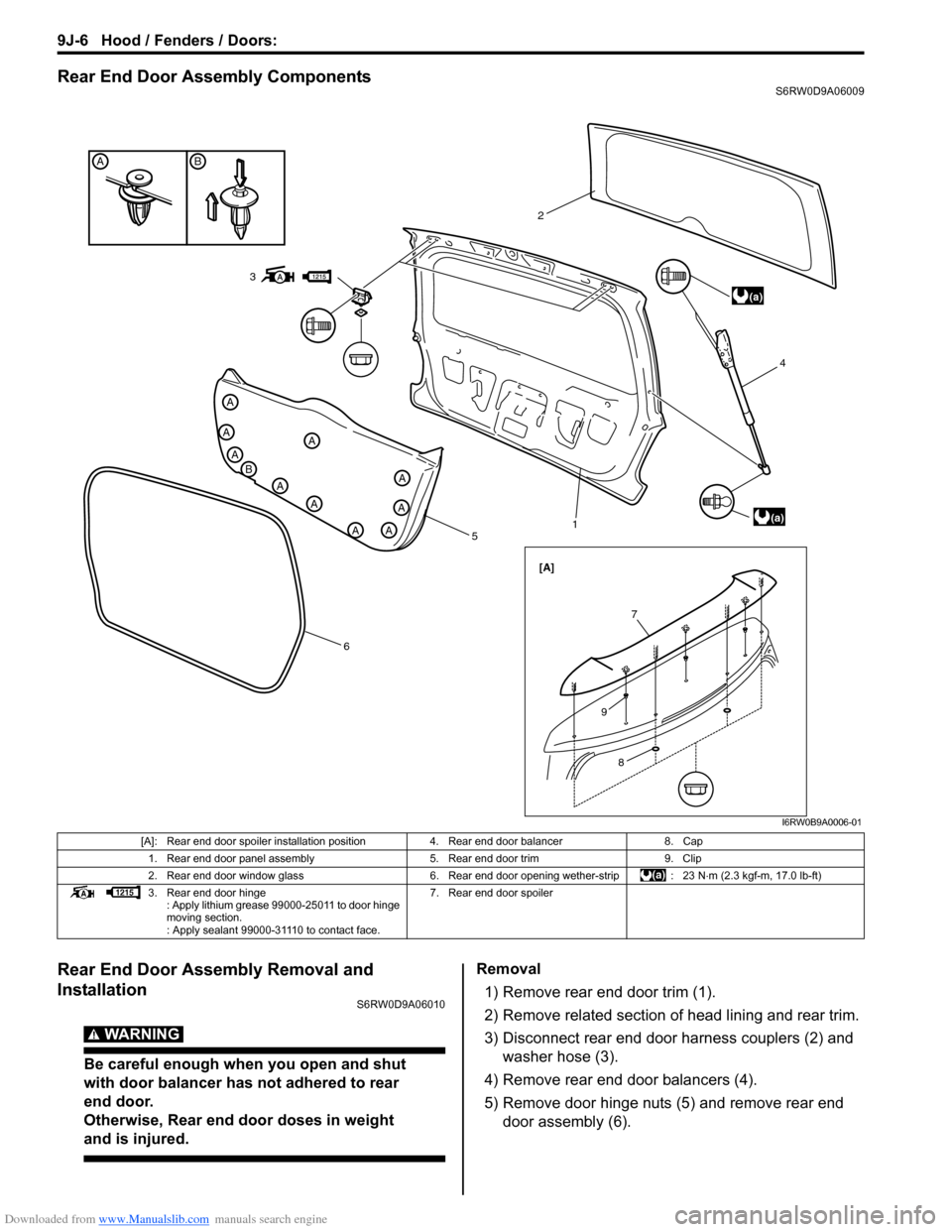

Rear End Door Assembly ComponentsS6RW0D9A06009

Rear End Door Assembly Removal and

Installation

S6RW0D9A06010

WARNING!

Be careful enough when you open and shut

with door balancer has not adhered to rear

end door.

Otherwise, Rear end door doses in weight

and is injured.

Removal

1) Remove rear end door trim (1).

2) Remove related section of head lining and rear trim.

3) Disconnect rear end door harness couplers (2) and

washer hose (3).

4) Remove rear end door balancers (4).

5) Remove door hinge nuts (5) and remove rear end

door assembly (6).

BA

A

B

A

A

A

A

A

AA

A

A

5

614 2

(a)

(a)

[A]

3

7

8

9

I6RW0B9A0006-01

[A]: Rear end door spoiler installation position 4. Rear end door balancer 8. Cap

1. Rear end door panel assembly 5. Rear end door trim 9. Clip

2. Rear end door window glass 6. Rear end door opening wether-strip : 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Rear end door hinge

: Apply lithium grease 99000-25011 to door hinge

moving section.

: Apply sealant 99000-31110 to contact face.7. Rear end door spoiler

Page 1443 of 1556

Downloaded from www.Manualslib.com manuals search engine Hood / Fenders / Doors: 9J-7

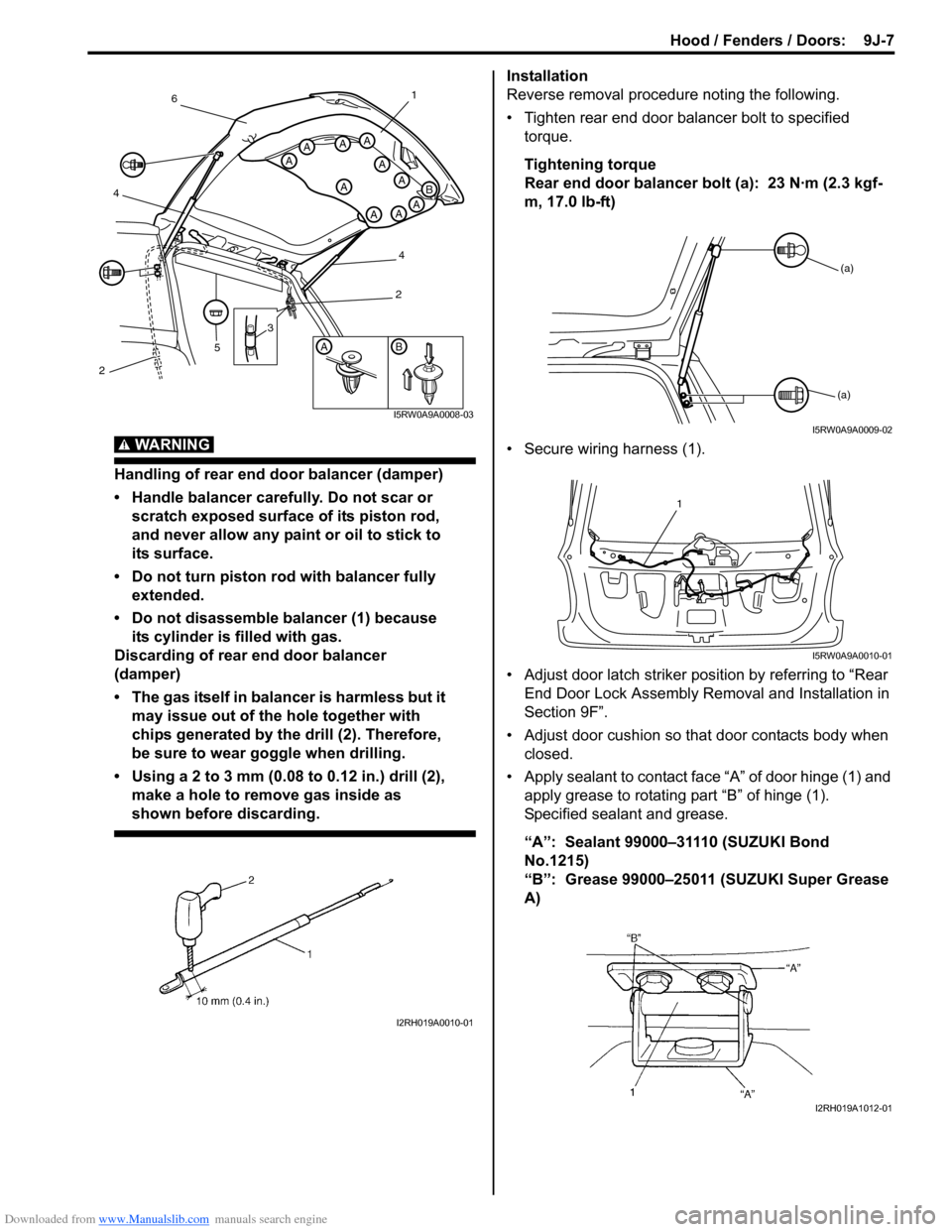

WARNING!

Handling of rear end door balancer (damper)

• Handle balancer carefully. Do not scar or

scratch exposed surface of its piston rod,

and never allow any paint or oil to stick to

its surface.

• Do not turn piston rod with balancer fully

extended.

• Do not disassemble balancer (1) because

its cylinder is filled with gas.

Discarding of rear end door balancer

(damper)

• The gas itself in balancer is harmless but it

may issue out of the hole together with

chips generated by the drill (2). Therefore,

be sure to wear goggle when drilling.

• Using a 2 to 3 mm (0.08 to 0.12 in.) drill (2),

make a hole to remove gas inside as

shown before discarding.

Installation

Reverse removal procedure noting the following.

• Tighten rear end door balancer bolt to specified

torque.

Tightening torque

Rear end door balancer bolt (a): 23 N·m (2.3 kgf-

m, 17.0 lb-ft)

• Secure wiring harness (1).

• Adjust door latch striker position by referring to “Rear

End Door Lock Assembly Removal and Installation in

Section 9F”.

• Adjust door cushion so that door contacts body when

closed.

• Apply sealant to contact face “A” of door hinge (1) and

apply grease to rotating part “B” of hinge (1).

Specified sealant and grease.

“A”: Sealant 99000–31110 (SUZUKI Bond

No.1215)

“B”: Grease 99000–25011 (SUZUKI Super Grease

A)

AB

A

A

A

A

AAA

AAA

B

3

5

461

4

2

2

I5RW0A9A0008-03

I2RH019A0010-01

(a)

(a)

I5RW0A9A0009-02

1

I5RW0A9A0010-01

I2RH019A1012-01

Page 1474 of 1556

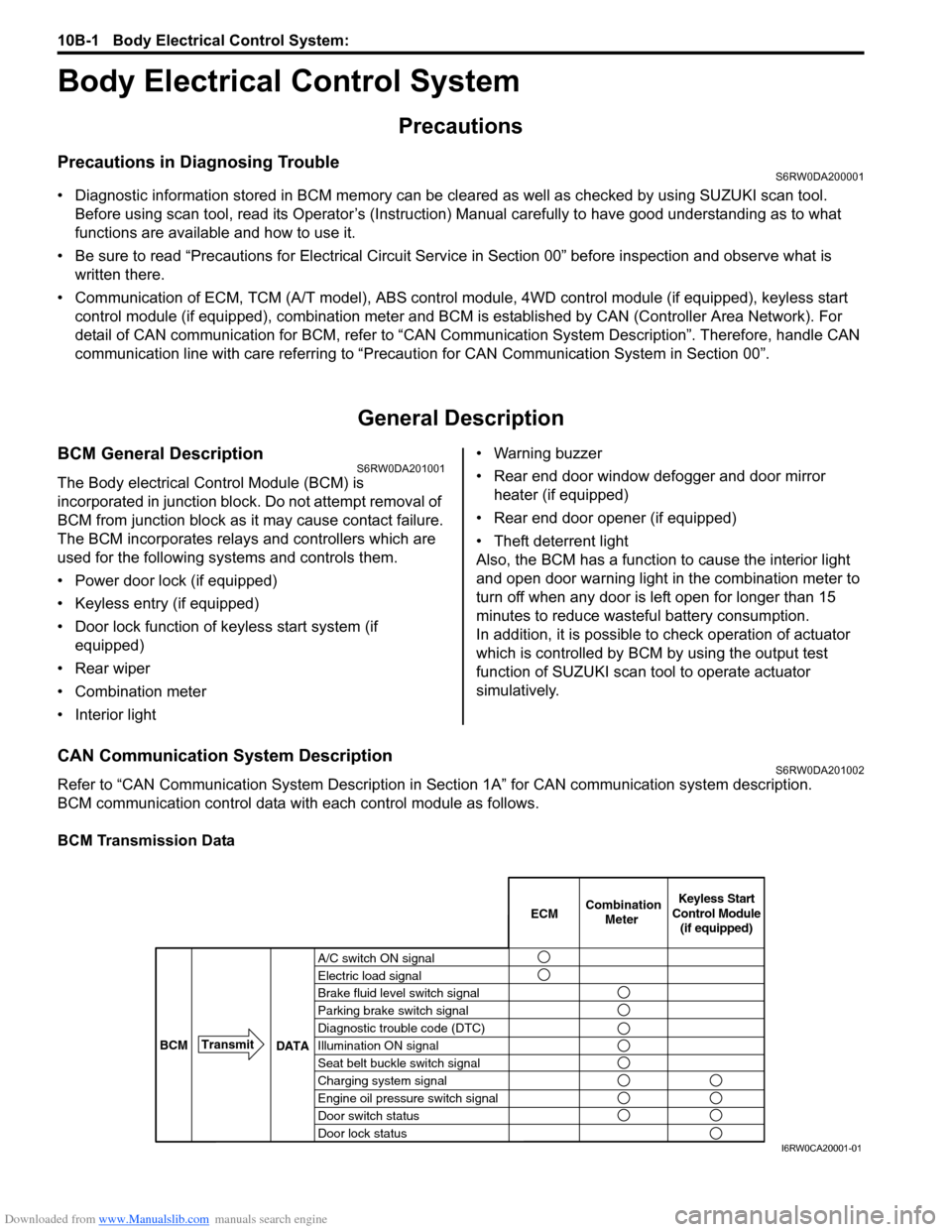

Downloaded from www.Manualslib.com manuals search engine 10B-1 Body Electrical Control System:

Control Systems

Body Electrical Control System

Precautions

Precautions in Diagnosing TroubleS6RW0DA200001

• Diagnostic information stored in BCM memory can be cleared as well as checked by using SUZUKI scan tool.

Before using scan tool, read its Operator’s (Instruction) Manual carefully to have good understanding as to what

functions are available and how to use it.

• Be sure to read “Precautions for Electrical Circuit Service in Section 00” before inspection and observe what is

written there.

• Communication of ECM, TCM (A/T model), ABS control module, 4WD control module (if equipped), keyless start

control module (if equipped), combination meter and BCM is established by CAN (Controller Area Network). For

detail of CAN communication for BCM, refer to “CAN Communication System Description”. Therefore, handle CAN

communication line with care referring to “Precaution for CAN Communication System in Section 00”.

General Description

BCM General DescriptionS6RW0DA201001

The Body electrical Control Module (BCM) is

incorporated in junction block. Do not attempt removal of

BCM from junction block as it may cause contact failure.

The BCM incorporates relays and controllers which are

used for the following systems and controls them.

• Power door lock (if equipped)

• Keyless entry (if equipped)

• Door lock function of keyless start system (if

equipped)

• Rear wiper

• Combination meter

• Interior light• Warning buzzer

• Rear end door window defogger and door mirror

heater (if equipped)

• Rear end door opener (if equipped)

• Theft deterrent light

Also, the BCM has a function to cause the interior light

and open door warning light in the combination meter to

turn off when any door is left open for longer than 15

minutes to reduce wasteful battery consumption.

In addition, it is possible to check operation of actuator

which is controlled by BCM by using the output test

function of SUZUKI scan tool to operate actuator

simulatively.

CAN Communication System DescriptionS6RW0DA201002

Refer to “CAN Communication System Description in Section 1A” for CAN communication system description.

BCM communication control data with each control module as follows.

BCM Transmission Data

A/C switch ON signal

Electric load signal

Brake fluid level switch signal

Parking brake switch signal

Diagnostic trouble code (DTC)

Illumination ON signal

Seat belt buckle switch signal

Charging system signal

Engine oil pressure switch signal

Door switch status

Door lock statusECMKeyless Start

Control Module

(if equipped) Combination

Meter

BCMTransmit

DATA

I6RW0CA20001-01