oil SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1274 of 1556

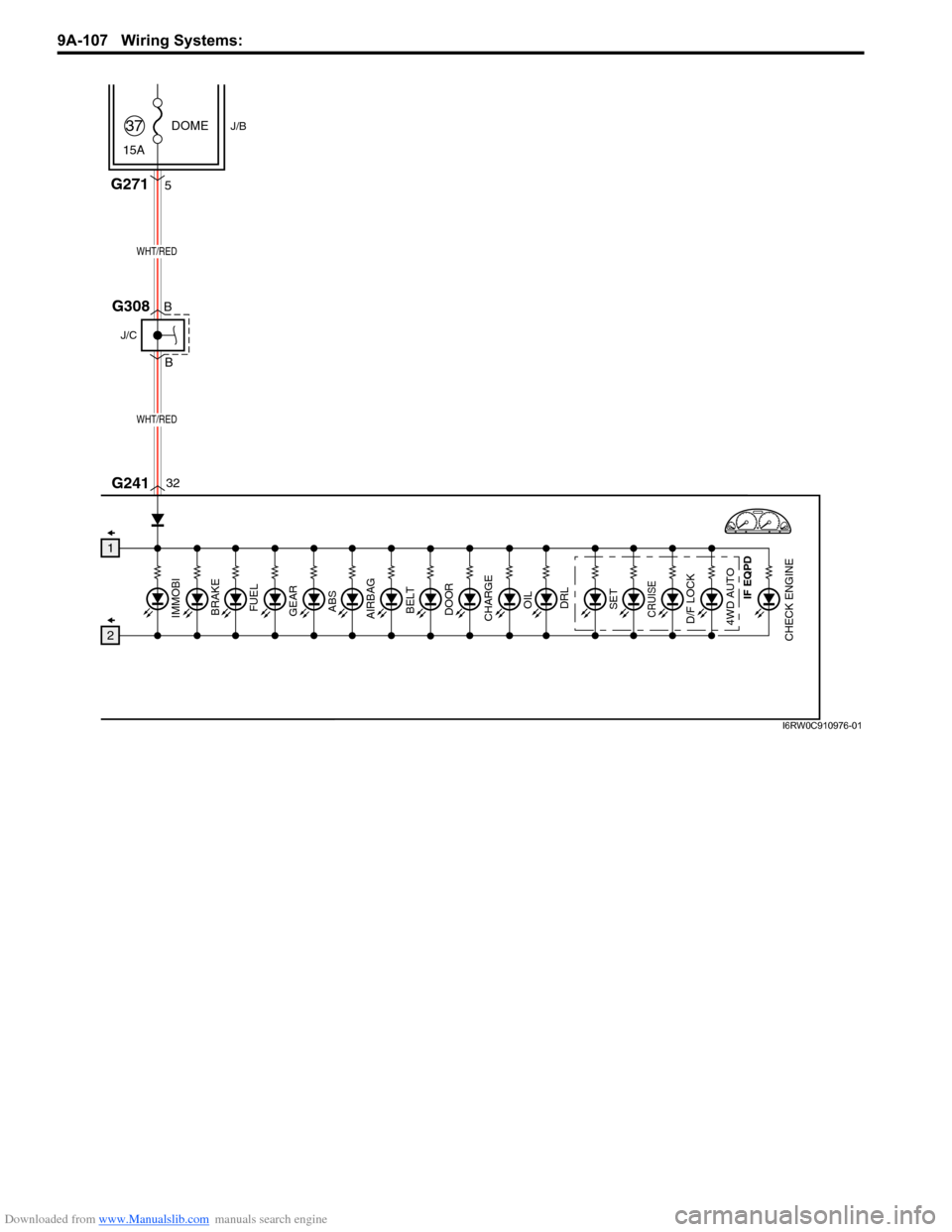

Downloaded from www.Manualslib.com manuals search engine 9A-107 Wiring Systems:

GEAR

ABS

BELT

DOOR

CHARGE

CHECK ENGINEAIRBAG

OILDRLD/F LOCK4WD AUTO

SETCRUISEIMMOBI

BRAKE

FUEL

DOME

15A37

32 5

WHT/RED

WHT/RED

J/B

G271

G241

1

2

J/C

G308B

B

IF EQPD

I6RW0C910976-01

Page 1298 of 1556

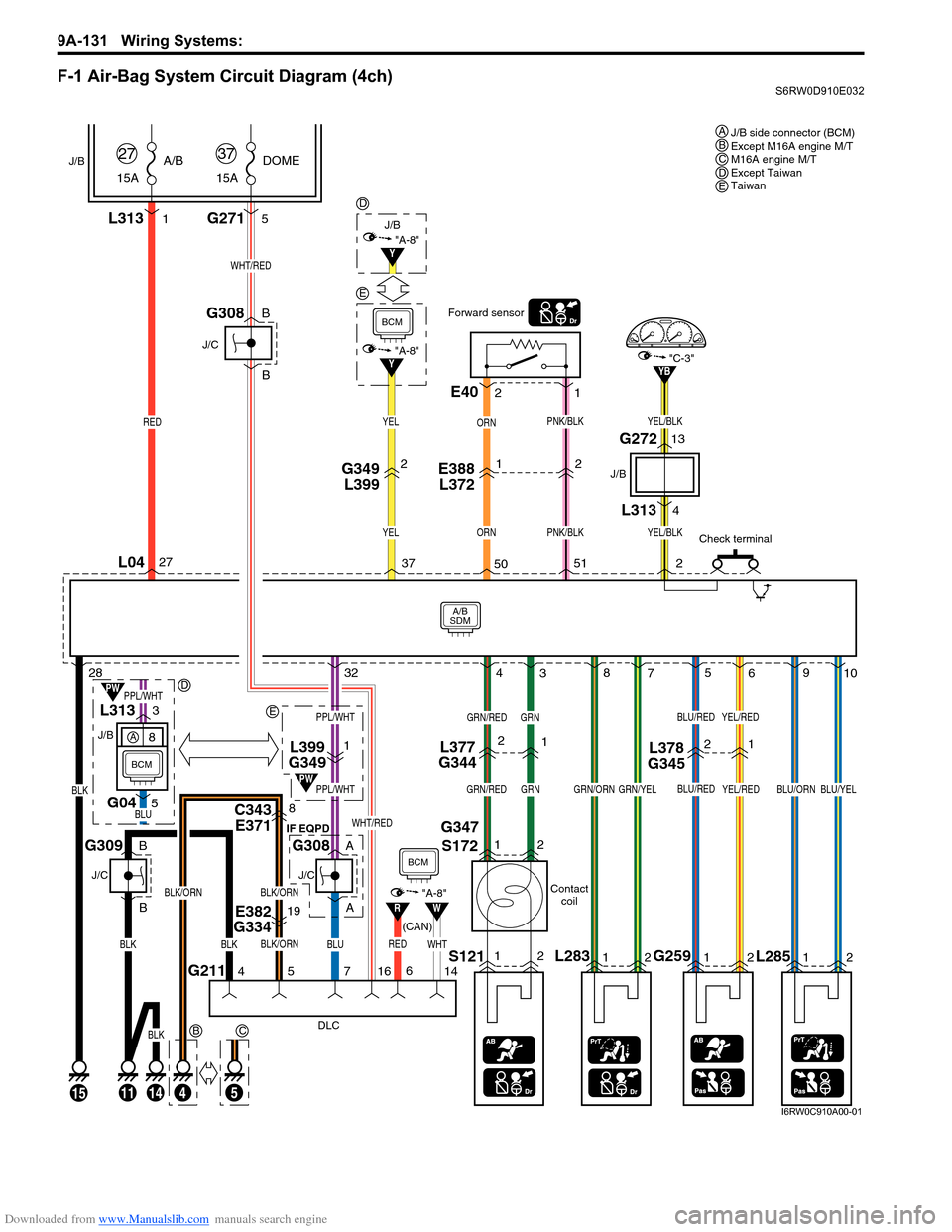

Downloaded from www.Manualslib.com manuals search engine 9A-131 Wiring Systems:

F-1 Air-Bag System Circuit Diagram (4ch)S6RW0D910E032

2

ORN

Y

A/B

SDM

L04

J/B

15AA/B

27

RED

L313

BCM

15

BLK

1

15ADOME

37

WHT/RED

G2715

E388

L3721G349

L3992

PNK/BLK

E40

Forward sensor

1 2

Contact

coil

G347

S172

L377

G3442L399

G34911

L28312S121

YEL/RED

GRN

12

21

YEL/RED

L285 G25912

4

38

75

69

10 2832 27

37

5051

2

"A-8"

L378

G345

ORN

PNK/BLKYEL

YEL

GRN/RED

GRN/REDGRNGRN/ORNGRN/YEL

BLU/RED

BLU/REDBLU/ORNBLU/YEL

L3134

G27213

J/B J/B

"C-3"YB

YEL/BLK

YEL/BLK

J/B side connector (BCM)

Except M16A engine M/T

M16A engine M/T

Except Taiwan

Taiwan A

B

E

D

2 12 1

BCDE

Check terminal

J/C

G308B

B

5

4

C

51114

E382

G33419

C343

E3718

BLK/ORN

BLK/ORNBLK/ORN

7

BLU

PPL/WHT

PPL/WHT

BLU

PPL/WHT

J/C IF EQPD

G308A

A

L313

G043

5

J/CJ/B

G309B

B

DLC

16

WHT

WHT/RED

RED

RW

PW

PW

"A-8"

14 6

BCM

BCM

(CAN)

G2114

BLKBLK

BLK

E

Y"A-8"

D

8A

I6RW0C910A00-01

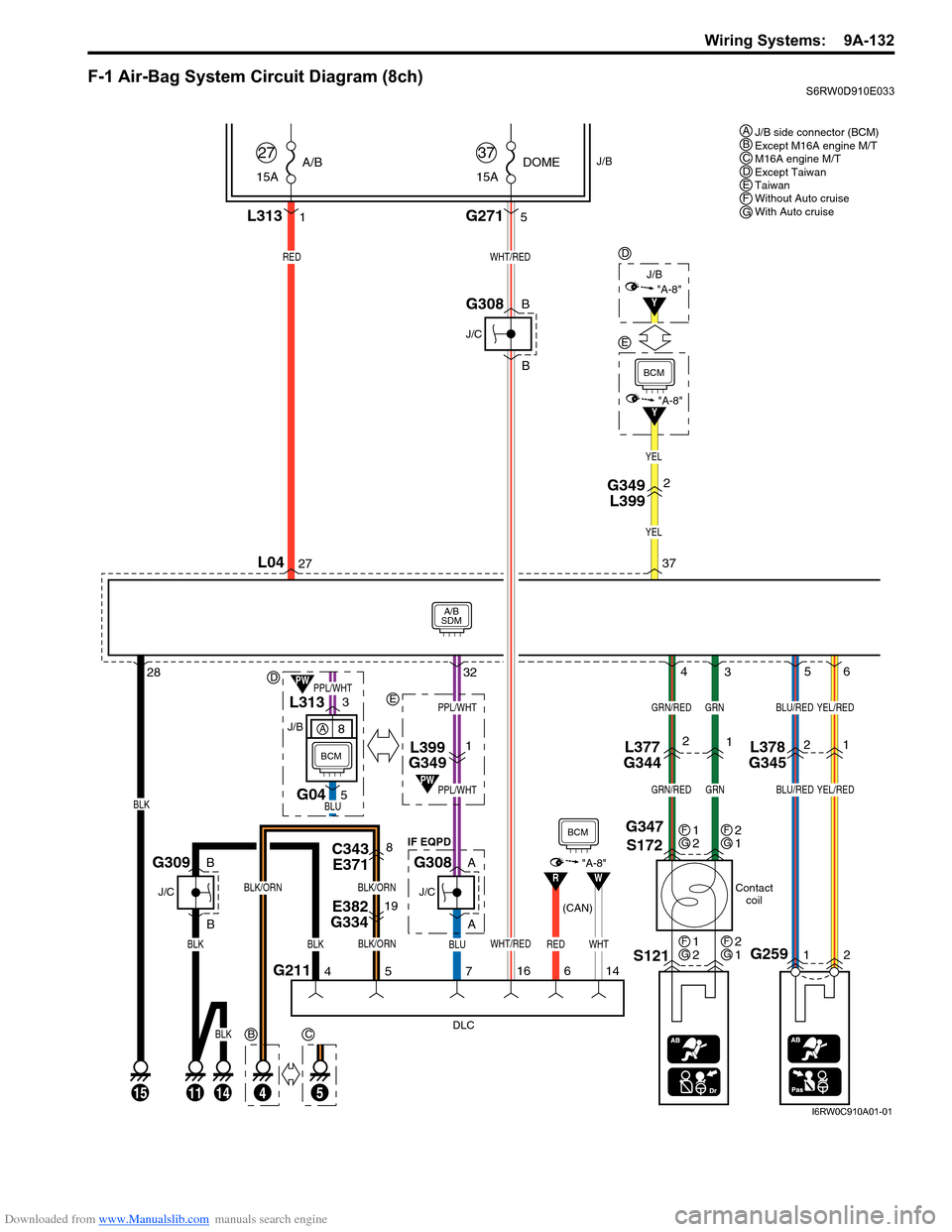

Page 1299 of 1556

Downloaded from www.Manualslib.com manuals search engine Wiring Systems: 9A-132

F-1 Air-Bag System Circuit Diagram (8ch)S6RW0D910E033

Y

A/B

SDM

L04

J/B

15AA/B

27

REDWHT/RED

L313

BCM

15

BLK

1

15ADOME

37

G2715

2

2832 2737

"A-8"

YEL

YEL

G349

L399

J/C

G308B

B

L399

G3491

5

41114

E382

G33419

C343

E3718

BLK/ORNWHT/RED

BLK/ORNBLK/ORN

7

BLU

PPL/WHT

PPL/WHT

J/C IF EQPD

G308A

A

J/C

G309B

B

DLC

16

WHTRED

RW

PW

"A-8"

14 6

BCM

(CAN)

G2114

BLKBLK

BLK

J/B

E

Y"A-8"

D

B

5

C

D

E

J/B side connector (BCM)

Except M16A engine M/T

M16A engine M/T

Except Taiwan

Taiwan

Without Auto cruise

With Auto cruise ABCDEFG

Contact

coil

G347

S172

L377

G34421

S121

GRN

4

3

GRN/RED

GRN/REDGRN

1

2FG2

1FG

1

2FG2

1FG

BLU

PPL/WHTL313

G043

5

J/B

PW

BCM

8A

G25912

21

5

6

L378

G345

BLU/RED

BLU/RED

YEL/RED

YEL/RED

I6RW0C910A01-01

Page 1306 of 1556

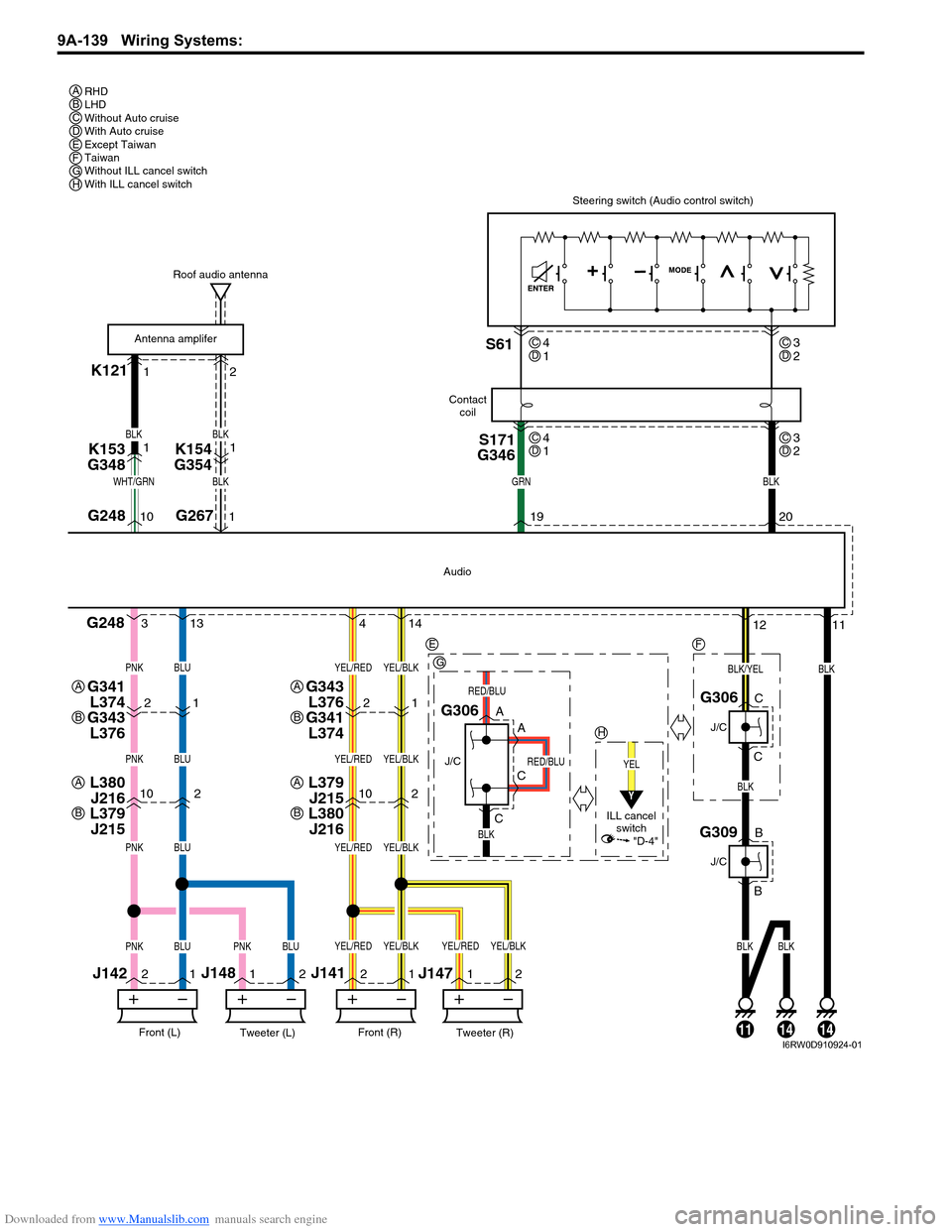

Downloaded from www.Manualslib.com manuals search engine 9A-139 Wiring Systems:

K12112

102102

2

11

22

11

211

G248

G248

BLK

Tweeter (L)Front (L)

J142J148

Tweeter (R)Front (R)

J141

J147

BLK

YEL

BLK

Audio

G306

J/C

ILL cancel

switch

A

A

C

C

G306

J/C

C

C

Steering switch (Audio control switch)

19G26710 120

BLKGRNWHT/GRN

BLK

BLUPNK

BLUPNK

BLUPNK

BLUBLKBLKBLUPNKPNK

YEL/BLKYEL/RED

YEL/BLKYEL/RED

YEL/BLKYEL/RED

YEL/BLKYEL/BLKYEL/REDYEL/RED

S171

G346S61

Roof audio antenna

Contact

coil

Antenna amplifer

4 313 14

K153

G3481

BLK

BLK

K154

G3541

21

G343

L376

G341

L3742112

BLK/YEL

RED/BLU

RED/BLU

G309

J/C

B

B

141114

RHD

LHD

Without Auto cruise

With Auto cruise

Except Taiwan

Taiwan

Without ILL cancel switch

With ILL cancel switch A

E

G

H

A

B

G341

L374

G343

L376A

B

L379

J215

L380

J216A

B

L380

J216

L379

J215A

B

F

BCDEFGH

4

1CD3

2CD

4

1CD3

2CD

Y

"D-4"

I6RW0D910924-01

Page 1320 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-1 Lighting Systems:

Body, Cab and Accessories

Lighting Systems

Precautions

Precautions for Discharge Headlight Service (If Equipped)S6RW0D9200001

WARNING!

• Do not touch igniter or ballast when lighting switch is at “HEAD” position to avoid possible electric

shock.

• Do not measure voltage or resistance with tester connected to output connector of ballast or igniter

to avoid possible electric shock.

• Do not perform work where exposed to water including rain or with wet hands to avoid possible

electric shock.

• Disassembling igniter or ballast is strictly prohibited as it may cause an electric shock.

• Before inspecting or repairing discharge headlight or its peripheral parts, make sure that lighting

switch is at OFF position and battery is disconnected at negative terminal to avoid possible

electrical shock.

• Do not set lighting switch to “HEAD” position with connector disconnected or any part removed to

avoid possible electric shock.

• Do not touch glass surface of headlight bulb. Oil or grease attached on it may not only make bulb

service life shorter but also cause bulb to burst when lighting switch is turned on.

• Mercury, metal iodide and xenon gas are sealed in discharge headlight bulb. Be sure to dispose of

used discharge headlight bulb properly according to applicable rules or regulations.

Precautions in Diagnosing Troubles (Headlight Auto Leveling System)S6RW0D9200002

• Be sure to read “Air Bag Warning in Section 00” before inspection and observe what is written there.

• Replacement of height sensor and headlight leveling control module. When height sensor and/or headlight leveling

control module is replaced with new one, perform initialization of headlight auto leveling system according to

“Initialization of Headlight Auto Leveling System”.

General Description

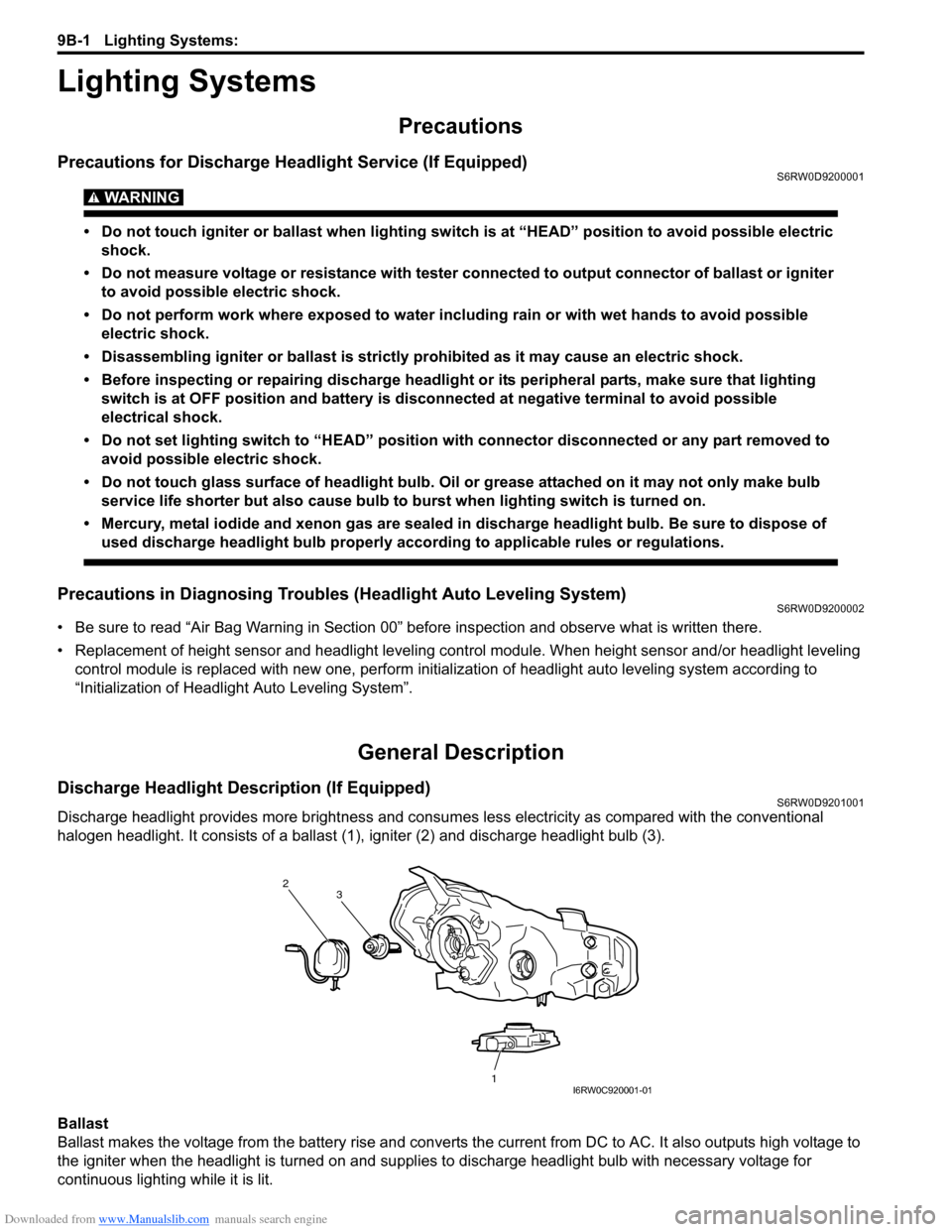

Discharge Headlight Description (If Equipped)S6RW0D9201001

Discharge headlight provides more brightness and consumes less electricity as compared with the conventional

halogen headlight. It consists of a ballast (1), igniter (2) and discharge headlight bulb (3).

Ballast

Ballast makes the voltage from the battery rise and converts the current from DC to AC. It also outputs high voltage to

the igniter when the headlight is turned on and supplies to discharge headlight bulb with necessary voltage for

continuous lighting while it is lit.

2

1 3

I6RW0C920001-01

Page 1329 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-10

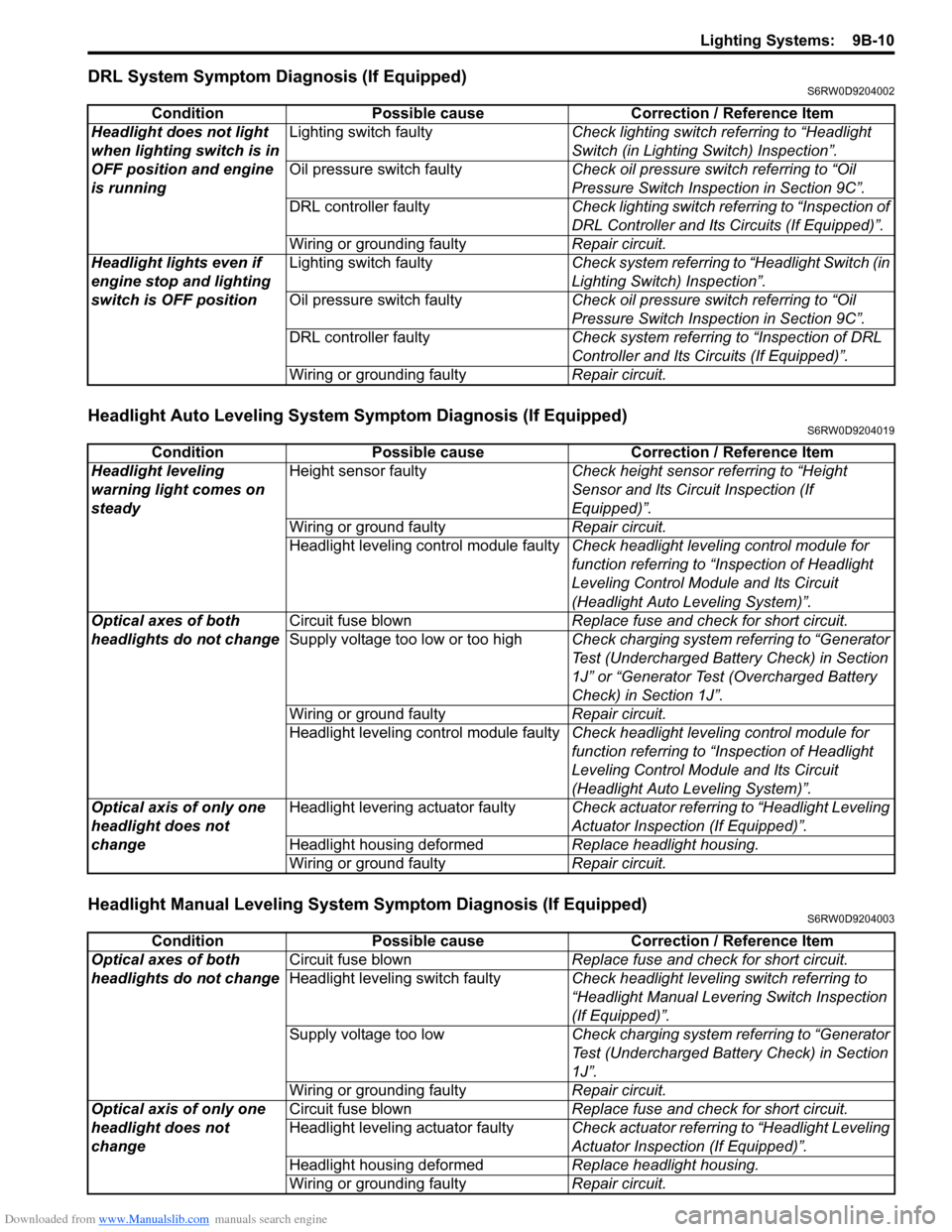

DRL System Symptom Diagnosis (If Equipped)S6RW0D9204002

Headlight Auto Leveling System Symptom Diagnosis (If Equipped)S6RW0D9204019

Headlight Manual Leveling System Symptom Diagnosis (If Equipped)S6RW0D9204003

Condition Possible cause Correction / Reference Item

Headlight does not light

when lighting switch is in

OFF position and engine

is runningLighting switch faultyCheck lighting switch referring to “Headlight

Switch (in Lighting Switch) Inspection”.

Oil pressure switch faultyCheck oil pressure switch referring to “Oil

Pressure Switch Inspection in Section 9C”.

DRL controller faultyCheck lighting switch referring to “Inspection of

DRL Controller and Its Circuits (If Equipped)”.

Wiring or grounding faultyRepair circuit.

Headlight lights even if

engine stop and lighting

switch is OFF positionLighting switch faultyCheck system referring to “Headlight Switch (in

Lighting Switch) Inspection”.

Oil pressure switch faultyCheck oil pressure switch referring to “Oil

Pressure Switch Inspection in Section 9C”.

DRL controller faultyCheck system referring to “Inspection of DRL

Controller and Its Circuits (If Equipped)”.

Wiring or grounding faultyRepair circuit.

Condition Possible cause Correction / Reference Item

Headlight leveling

warning light comes on

steadyHeight sensor faultyCheck height sensor referring to “Height

Sensor and Its Circuit Inspection (If

Equipped)”.

Wiring or ground faultyRepair circuit.

Headlight leveling control module faultyCheck headlight leveling control module for

function referring to “Inspection of Headlight

Leveling Control Module and Its Circuit

(Headlight Auto Leveling System)”.

Optical axes of both

headlights do not changeCircuit fuse blownReplace fuse and check for short circuit.

Supply voltage too low or too highCheck charging system referring to “Generator

Test (Undercharged Battery Check) in Section

1J” or “Generator Test (Overcharged Battery

Check) in Section 1J”.

Wiring or ground faultyRepair circuit.

Headlight leveling control module faultyCheck headlight leveling control module for

function referring to “Inspection of Headlight

Leveling Control Module and Its Circuit

(Headlight Auto Leveling System)”.

Optical axis of only one

headlight does not

changeHeadlight levering actuator faultyCheck actuator referring to “Headlight Leveling

Actuator Inspection (If Equipped)”.

Headlight housing deformedReplace headlight housing.

Wiring or ground faultyRepair circuit.

Condition Possible cause Correction / Reference Item

Optical axes of both

headlights do not changeCircuit fuse blownReplace fuse and check for short circuit.

Headlight leveling switch faultyCheck headlight leveling switch referring to

“Headlight Manual Levering Switch Inspection

(If Equipped)”.

Supply voltage too lowCheck charging system referring to “Generator

Test (Undercharged Battery Check) in Section

1J”.

Wiring or grounding faultyRepair circuit.

Optical axis of only one

headlight does not

changeCircuit fuse blownReplace fuse and check for short circuit.

Headlight leveling actuator faultyCheck actuator referring to “Headlight Leveling

Actuator Inspection (If Equipped)”.

Headlight housing deformedReplace headlight housing.

Wiring or grounding faultyRepair circuit.

Page 1332 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-13 Lighting Systems:

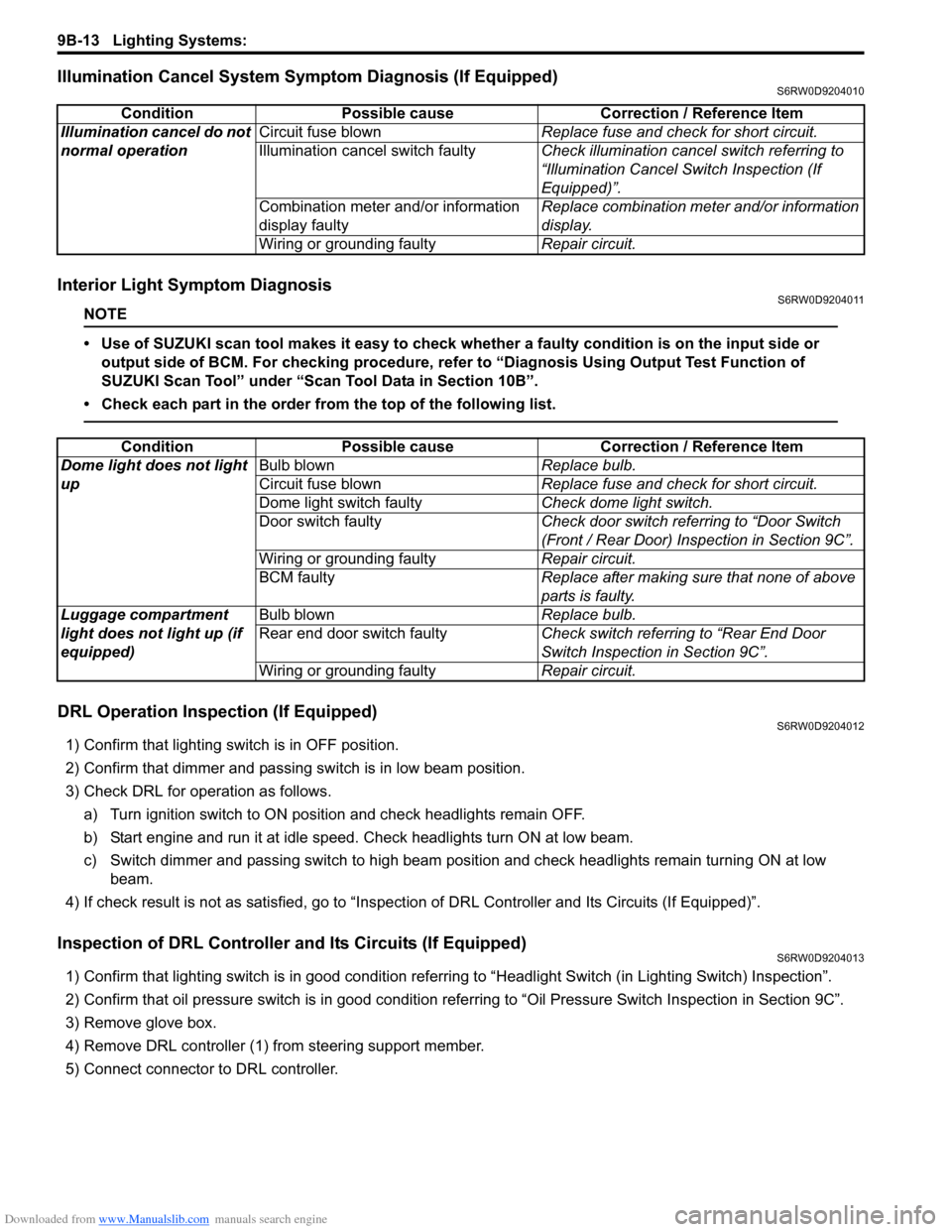

Illumination Cancel System Symptom Diagnosis (If Equipped)S6RW0D9204010

Interior Light Symptom DiagnosisS6RW0D9204011

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

DRL Operation Inspection (If Equipped)S6RW0D9204012

1) Confirm that lighting switch is in OFF position.

2) Confirm that dimmer and passing switch is in low beam position.

3) Check DRL for operation as follows.

a) Turn ignition switch to ON position and check headlights remain OFF.

b) Start engine and run it at idle speed. Check headlights turn ON at low beam.

c) Switch dimmer and passing switch to high beam position and check headlights remain turning ON at low

beam.

4) If check result is not as satisfied, go to “Inspection of DRL Controller and Its Circuits (If Equipped)”.

Inspection of DRL Controller and Its Circuits (If Equipped)S6RW0D9204013

1) Confirm that lighting switch is in good condition referring to “Headlight Switch (in Lighting Switch) Inspection”.

2) Confirm that oil pressure switch is in good condition referring to “Oil Pressure Switch Inspection in Section 9C”.

3) Remove glove box.

4) Remove DRL controller (1) from steering support member.

5) Connect connector to DRL controller.Condition Possible cause Correction / Reference Item

Illumination cancel do not

normal operationCircuit fuse blownReplace fuse and check for short circuit.

Illumination cancel switch faultyCheck illumination cancel switch referring to

“Illumination Cancel Switch Inspection (If

Equipped)”.

Combination meter and/or information

display faultyReplace combination meter and/or information

display.

Wiring or grounding faultyRepair circuit.

Condition Possible cause Correction / Reference Item

Dome light does not light

upBulb blownReplace bulb.

Circuit fuse blownReplace fuse and check for short circuit.

Dome light switch faultyCheck dome light switch.

Door switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Luggage compartment

light does not light up (if

equipped)Bulb blownReplace bulb.

Rear end door switch faultyCheck switch referring to “Rear End Door

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Page 1333 of 1556

Downloaded from www.Manualslib.com manuals search engine Lighting Systems: 9B-14

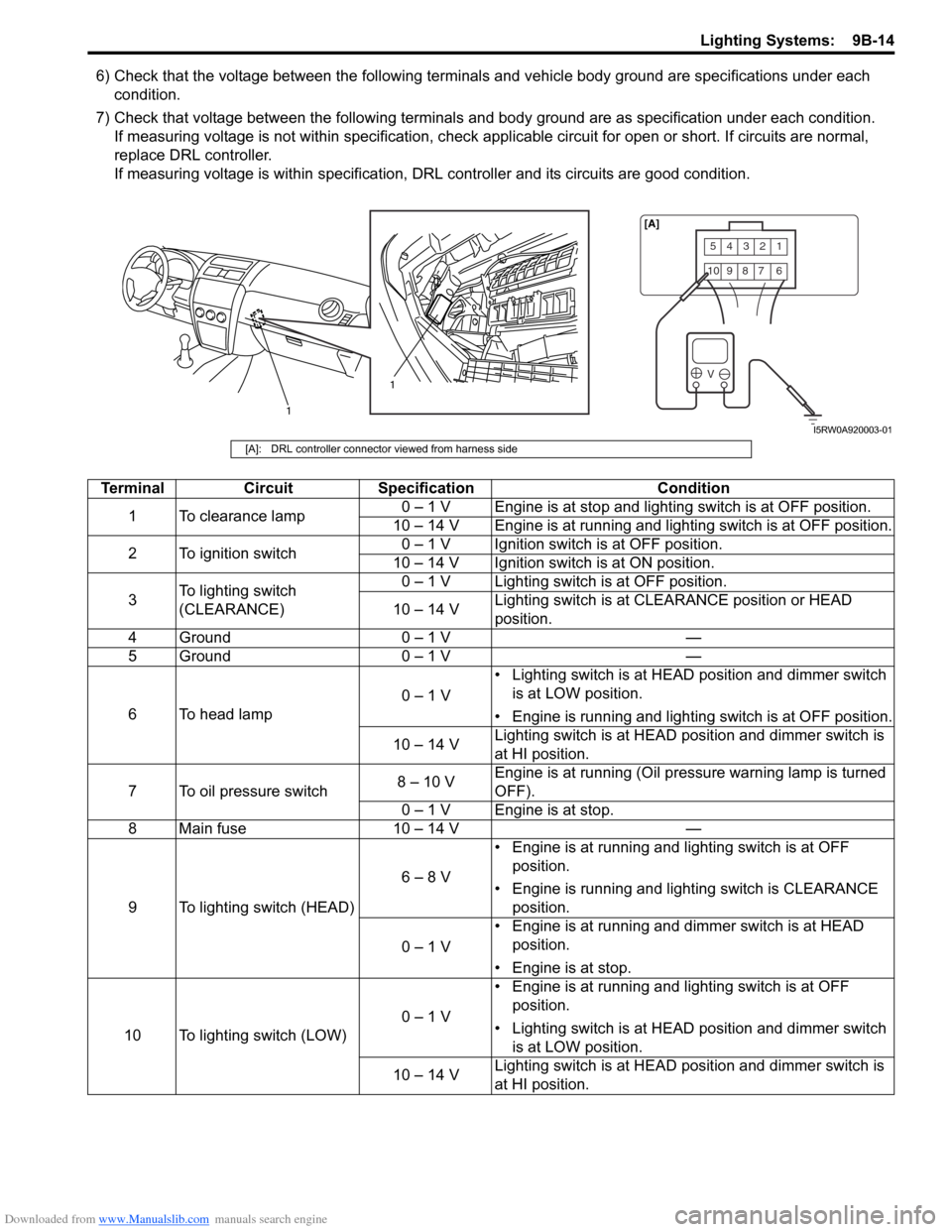

6) Check that the voltage between the following terminals and vehicle body ground are specifications under each

condition.

7) Check that voltage between the following terminals and body ground are as specification under each condition.

If measuring voltage is not within specification, check applicable circuit for open or short. If circuits are normal,

replace DRL controller.

If measuring voltage is within specification, DRL controller and its circuits are good condition.

54321

10987 6

V

1

1[A]

I5RW0A920003-01

[A]: DRL controller connector viewed from harness side

Terminal Circuit Specification Condition

1 To clearance lamp0 – 1 V Engine is at stop and lighting switch is at OFF position.

10 – 14 V Engine is at running and lighting switch is at OFF position.

2 To ignition switch0 – 1 V Ignition switch is at OFF position.

10 – 14 V Ignition switch is at ON position.

3To lighting switch

(CLEARANCE)0 – 1 V Lighting switch is at OFF position.

10 – 14 VLighting switch is at CLEARANCE position or HEAD

position.

4 Ground 0 – 1 V —

5 Ground 0 – 1 V —

6 To head lamp0 – 1 V• Lighting switch is at HEAD position and dimmer switch

is at LOW position.

• Engine is running and lighting switch is at OFF position.

10 – 14 VLighting switch is at HEAD position and dimmer switch is

at HI position.

7 To oil pressure switch8 – 10 VEngine is at running (Oil pressure warning lamp is turned

OFF).

0 – 1 V Engine is at stop.

8 Main fuse 10 – 14 V —

9 To lighting switch (HEAD)6 – 8 V• Engine is at running and lighting switch is at OFF

position.

• Engine is running and lighting switch is CLEARANCE

position.

0 – 1 V• Engine is at running and dimmer switch is at HEAD

position.

• Engine is at stop.

10 To lighting switch (LOW)0 – 1 V• Engine is at running and lighting switch is at OFF

position.

• Lighting switch is at HEAD position and dimmer switch

is at LOW position.

10 – 14 VLighting switch is at HEAD position and dimmer switch is

at HI position.

Page 1348 of 1556

Downloaded from www.Manualslib.com manuals search engine 9B-29 Lighting Systems:

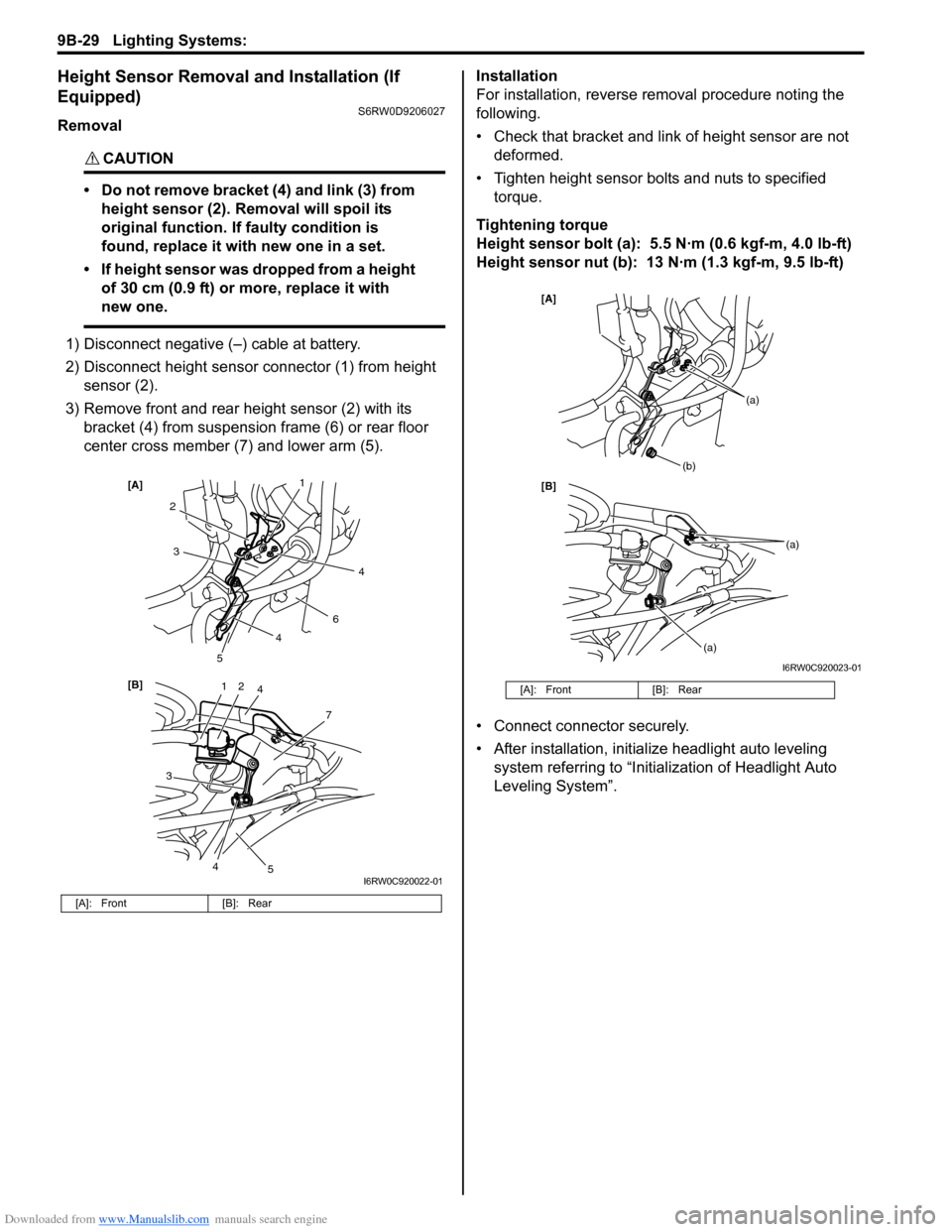

Height Sensor Removal and Installation (If

Equipped)

S6RW0D9206027

Removal

CAUTION!

• Do not remove bracket (4) and link (3) from

height sensor (2). Removal will spoil its

original function. If faulty condition is

found, replace it with new one in a set.

• If height sensor was dropped from a height

of 30 cm (0.9 ft) or more, replace it with

new one.

1) Disconnect negative (–) cable at battery.

2) Disconnect height sensor connector (1) from height

sensor (2).

3) Remove front and rear height sensor (2) with its

bracket (4) from suspension frame (6) or rear floor

center cross member (7) and lower arm (5).Installation

For installation, reverse removal procedure noting the

following.

• Check that bracket and link of height sensor are not

deformed.

• Tighten height sensor bolts and nuts to specified

torque.

Tightening torque

Height sensor bolt (a): 5.5 N·m (0.6 kgf-m, 4.0 lb-ft)

Height sensor nut (b): 13 N·m (1.3 kgf-m, 9.5 lb-ft)

• Connect connector securely.

• After installation, initialize headlight auto leveling

system referring to “Initialization of Headlight Auto

Leveling System”.

[A]: Front [B]: Rear

12

7

[B] [A]

4

3

2

6

3

5

5

1

4

4

4

I6RW0C920022-01

[A]: Front [B]: Rear

[B] [A]

(b)

(a)

(a)

(a)

I6RW0C920023-01

Page 1354 of 1556

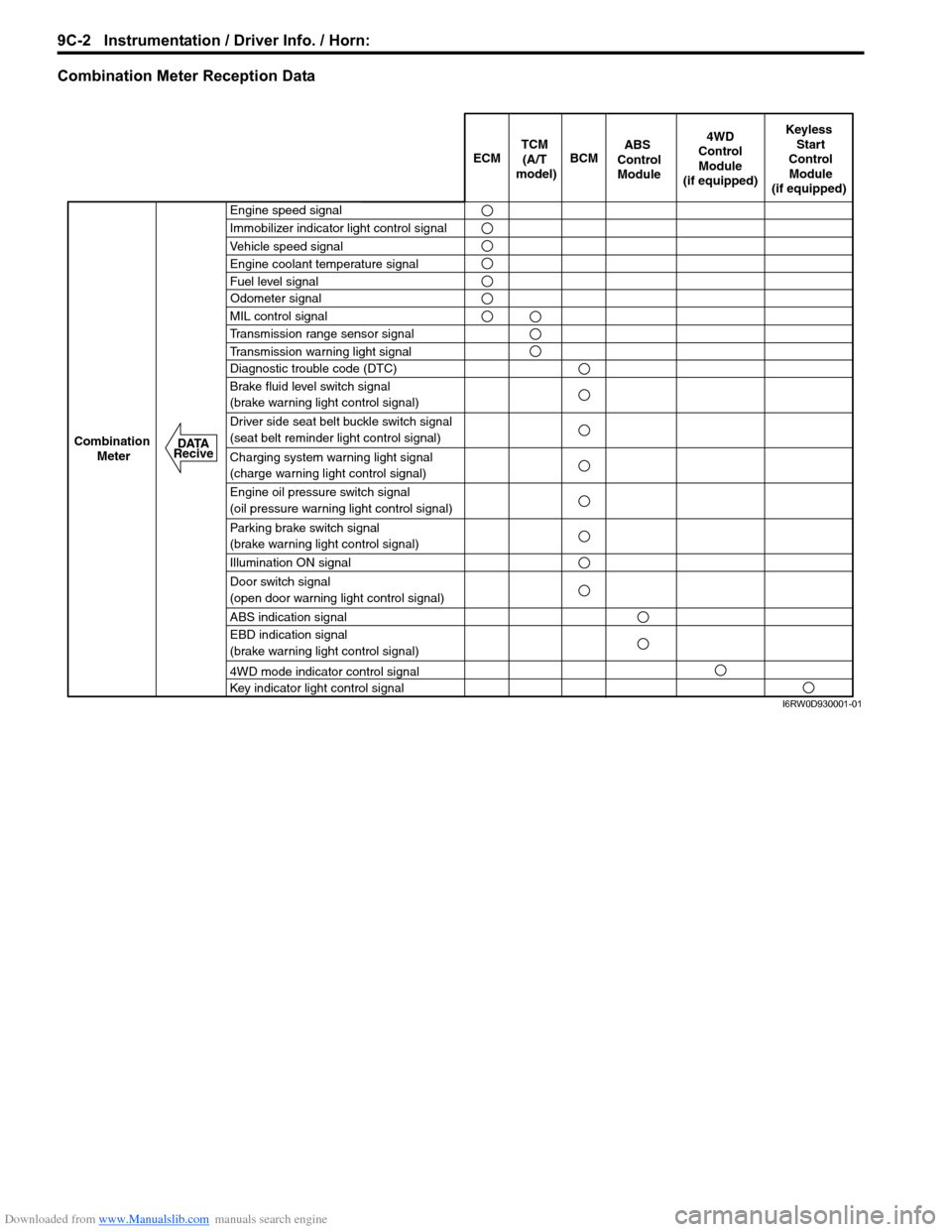

Downloaded from www.Manualslib.com manuals search engine 9C-2 Instrumentation / Driver Info. / Horn:

Combination Meter Reception Data

ECM BCM

Keyless

Start

Control

Module

(if equipped)

Combination

Meter4WD

Control

Module

(if equipped)TCM

(A/T

model)

Engine speed signal

Immobilizer indicator light control signal

Vehicle speed signal

Engine coolant temperature signal

Fuel level signal

MIL control signal

Transmission range sensor signal

Transmission warning light signal

Diagnostic trouble code (DTC)

Brake fluid level switch signal

(brake warning light control signal)

Driver side seat belt buckle switch signal

(seat belt reminder light control signal)

Charging system warning light signal

(charge warning light control signal)

Engine oil pressure switch signal

(oil pressure warning light control signal)

Parking brake switch signal

(brake warning light control signal)

Illumination ON signal

Door switch signal

(open door warning light control signal)

ABS indication signal

EBD indication signal

(brake warning light control signal)

4WD mode indicator control signal

Key indicator light control signal

ABS

Control

Module

Odometer signal

DATA

Recive

I6RW0D930001-01