Exhaus SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 318 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-36 Engine Mechanical:

Camshaft, Tappet and Shim InspectionS6RW0D1406024

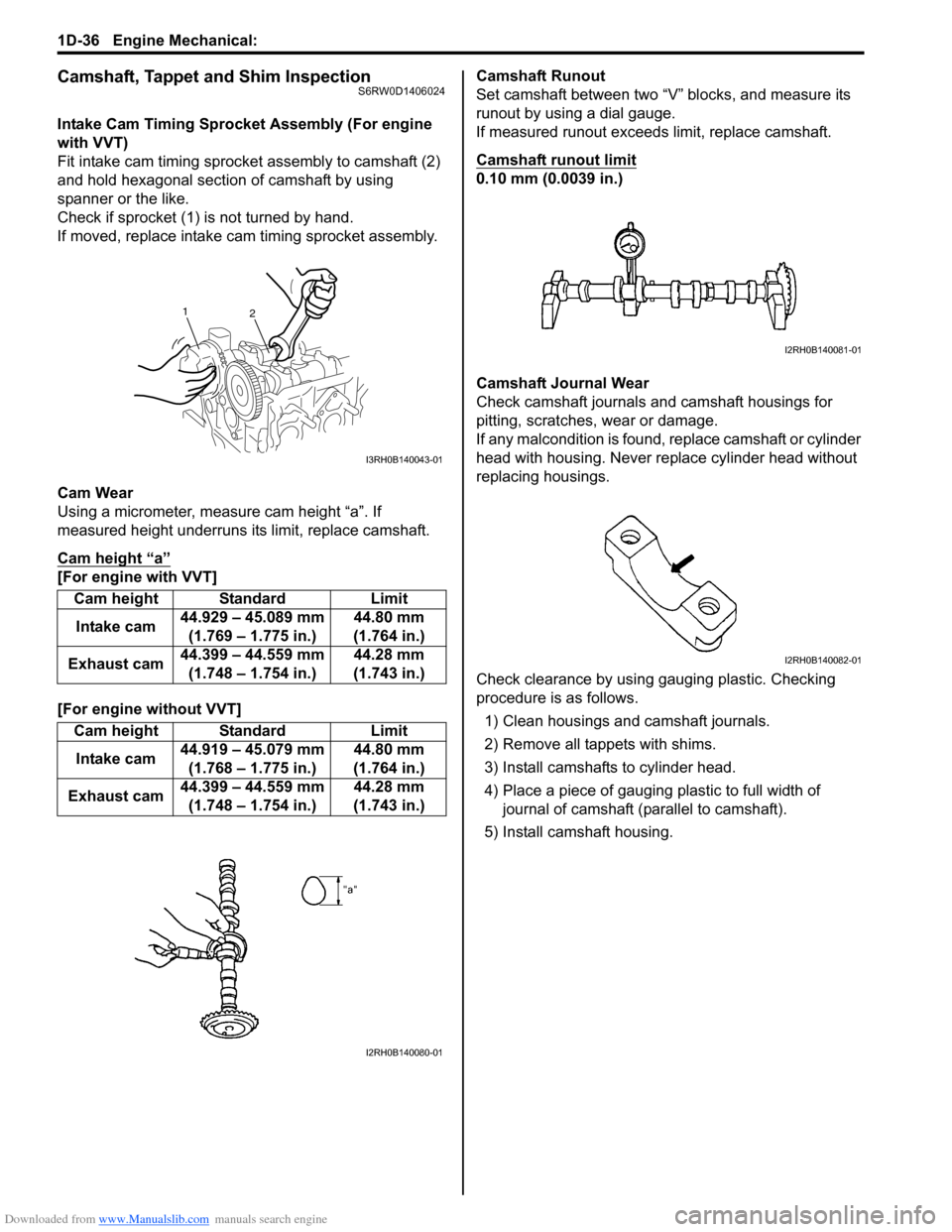

Intake Cam Timing Sprocket Assembly (For engine

with VVT)

Fit intake cam timing sprocket assembly to camshaft (2)

and hold hexagonal section of camshaft by using

spanner or the like.

Check if sprocket (1) is not turned by hand.

If moved, replace intake cam timing sprocket assembly.

Cam Wear

Using a micrometer, measure cam height “a”. If

measured height underruns its limit, replace camshaft.

Cam height “a”

[For engine with VVT]

[For engine without VVT]Camshaft Runout

Set camshaft between two “V” blocks, and measure its

runout by using a dial gauge.

If measured runout exceeds limit, replace camshaft.

Camshaft runout limit

0.10 mm (0.0039 in.)

Camshaft Journal Wear

Check camshaft journals and camshaft housings for

pitting, scratches, wear or damage.

If any malcondition is found, replace camshaft or cylinder

head with housing. Never replace cylinder head without

replacing housings.

Check clearance by using gauging plastic. Checking

procedure is as follows.

1) Clean housings and camshaft journals.

2) Remove all tappets with shims.

3) Install camshafts to cylinder head.

4) Place a piece of gauging plastic to full width of

journal of camshaft (parallel to camshaft).

5) Install camshaft housing. Cam height Standard Limit

Intake cam44.929 – 45.089 mm

(1.769 – 1.775 in.)44.80 mm

(1.764 in.)

Exhaust cam44.399 – 44.559 mm

(1.748 – 1.754 in.)44.28 mm

(1.743 in.)

Cam height Standard Limit

Intake cam44.919 – 45.079 mm

(1.768 – 1.775 in.)44.80 mm

(1.764 in.)

Exhaust cam44.399 – 44.559 mm

(1.748 – 1.754 in.)44.28 mm

(1.743 in.)

2 1

I3RH0B140043-01

I2RH0B140080-01

I2RH0B140081-01

I2RH0B140082-01

Page 319 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-37

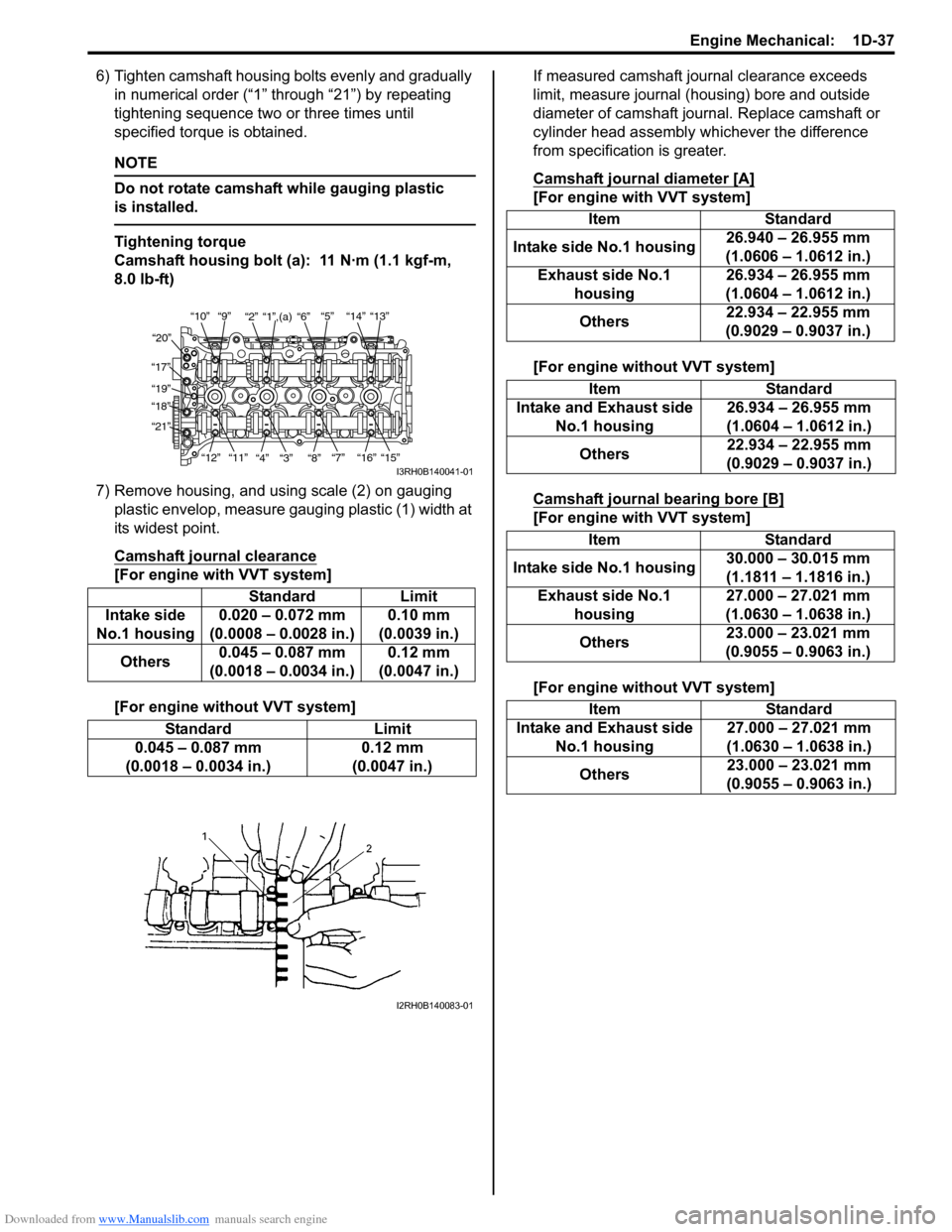

6) Tighten camshaft housing bolts evenly and gradually

in numerical order (“1” through “21”) by repeating

tightening sequence two or three times until

specified torque is obtained.

NOTE

Do not rotate camshaft while gauging plastic

is installed.

Tightening torque

Camshaft housing bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)

7) Remove housing, and using scale (2) on gauging

plastic envelop, measure gauging plastic (1) width at

its widest point.

Camshaft journal clearance

[For engine with VVT system]

[For engine without VVT system]If measured camshaft journal clearance exceeds

limit, measure journal (housing) bore and outside

diameter of camshaft journal. Replace camshaft or

cylinder head assembly whichever the difference

from specification is greater.

Camshaft journal diameter [A]

[For engine with VVT system]

[For engine without VVT system]

Camshaft journal bearing bore [B]

[For engine with VVT system]

[For engine without VVT system] Standard Limit

Intake side

No.1 housing0.020 – 0.072 mm

(0.0008 – 0.0028 in.)0.10 mm

(0.0039 in.)

Others0.045 – 0.087 mm

(0.0018 – 0.0034 in.)0.12 mm

(0.0047 in.)

Standard Limit

0.045 – 0.087 mm

(0.0018 – 0.0034 in.)0.12 mm

(0.0047 in.)

“10”“9”

“2” “1”,(a) “6”“5” “14” “13”

“20”

“17”

“19”

“18”

“21”

“12”

“11”

“4” “3” “8”“7” “16” “15”

I3RH0B140041-01

I2RH0B140083-01

Item Standard

Intake side No.1 housing26.940 – 26.955 mm

(1.0606 – 1.0612 in.)

Exhaust side No.1

housing26.934 – 26.955 mm

(1.0604 – 1.0612 in.)

Others22.934 – 22.955 mm

(0.9029 – 0.9037 in.)

Item Standard

Intake and Exhaust side

No.1 housing26.934 – 26.955 mm

(1.0604 – 1.0612 in.)

Others22.934 – 22.955 mm

(0.9029 – 0.9037 in.)

Item Standard

Intake side No.1 housing30.000 – 30.015 mm

(1.1811 – 1.1816 in.)

Exhaust side No.1

housing27.000 – 27.021 mm

(1.0630 – 1.0638 in.)

Others23.000 – 23.021 mm

(0.9055 – 0.9063 in.)

Item Standard

Intake and Exhaust side

No.1 housing27.000 – 27.021 mm

(1.0630 – 1.0638 in.)

Others23.000 – 23.021 mm

(0.9055 – 0.9063 in.)

Page 321 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-39

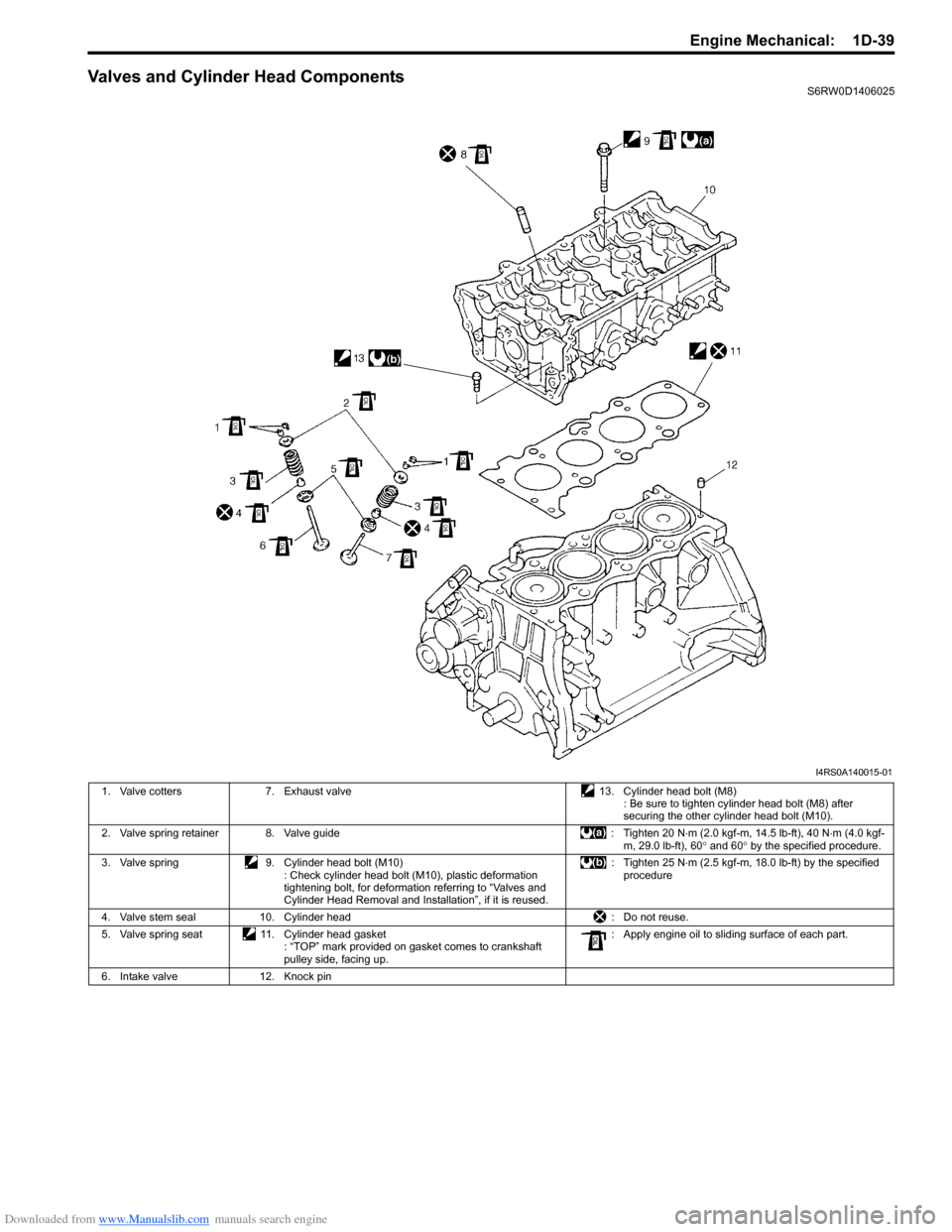

Valves and Cylinder Head ComponentsS6RW0D1406025

I4RS0A140015-01

1. Valve cotters 7. Exhaust valve 13. Cylinder head bolt (M8)

: Be sure to tighten cylinder head bolt (M8) after

securing the other cylinder head bolt (M10).

2. Valve spring retainer 8. Valve guide : Tighten 20 N⋅m (2.0 kgf-m, 14.5 lb-ft), 40 N⋅m (4.0 kgf-

m, 29.0 lb-ft), 60° and 60° by the specified procedure.

3. Valve spring 9. Cylinder head bolt (M10)

: Check cylinder head bolt (M10), plastic deformation

tightening bolt, for deformation referring to “Valves and

Cylinder Head Removal and Installation”, if it is reused.: Tighten 25 N⋅m (2.5 kgf-m, 18.0 lb-ft) by the specified

procedure

4. Valve stem seal 10. Cylinder head : Do not reuse.

5. Valve spring seat 11. Cylinder head gasket

: “TOP” mark provided on gasket comes to crankshaft

pulley side, facing up.: Apply engine oil to sliding surface of each part.

6. Intake valve 12. Knock pin

Page 322 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-40 Engine Mechanical:

Valves and Cylinder Head Removal and

Installation

S6RW0D1406026

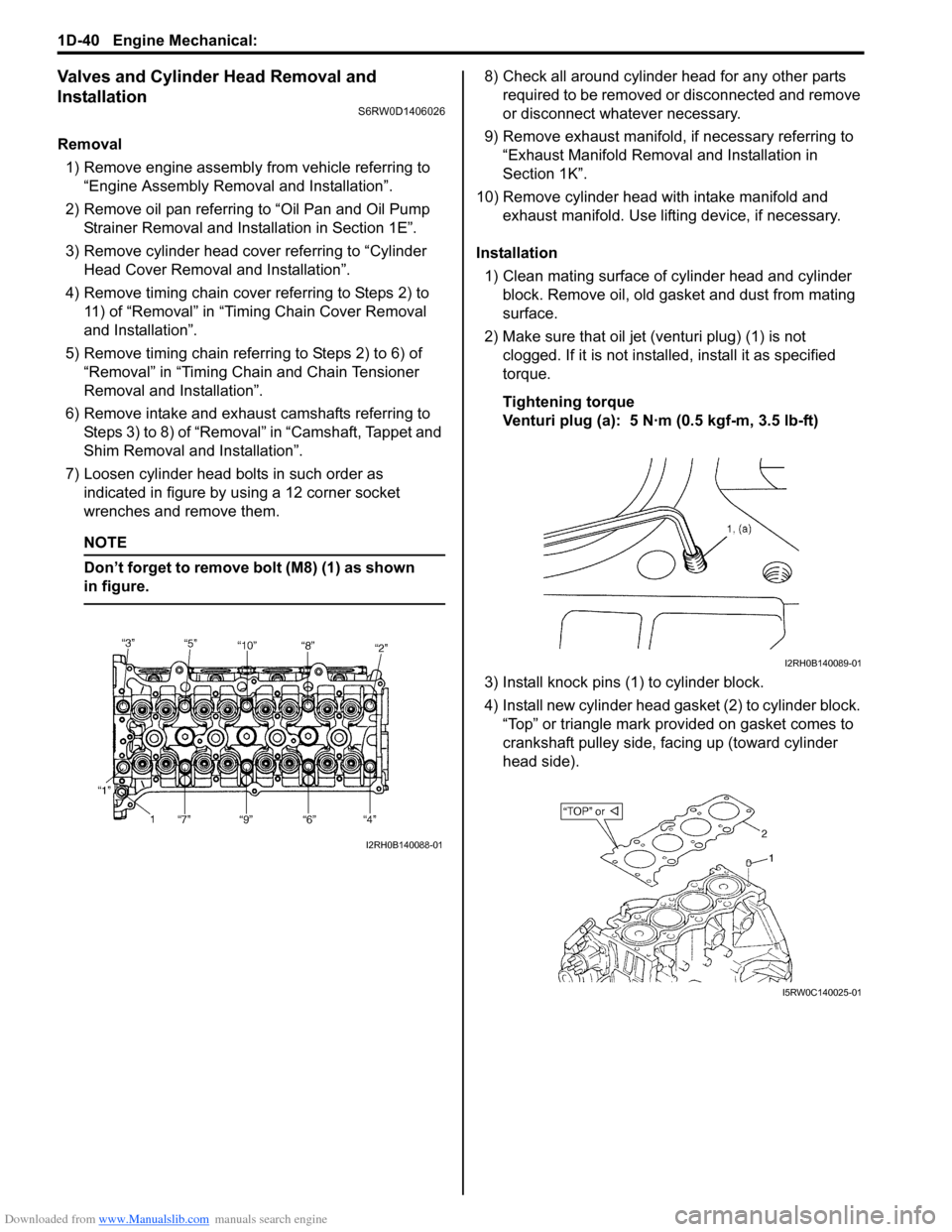

Removal

1) Remove engine assembly from vehicle referring to

“Engine Assembly Removal and Installation”.

2) Remove oil pan referring to “Oil Pan and Oil Pump

Strainer Removal and Installation in Section 1E”.

3) Remove cylinder head cover referring to “Cylinder

Head Cover Removal and Installation”.

4) Remove timing chain cover referring to Steps 2) to

11) of “Removal” in “Timing Chain Cover Removal

and Installation”.

5) Remove timing chain referring to Steps 2) to 6) of

“Removal” in “Timing Chain and Chain Tensioner

Removal and Installation”.

6) Remove intake and exhaust camshafts referring to

Steps 3) to 8) of “Removal” in “Camshaft, Tappet and

Shim Removal and Installation”.

7) Loosen cylinder head bolts in such order as

indicated in figure by using a 12 corner socket

wrenches and remove them.

NOTE

Don’t forget to remove bolt (M8) (1) as shown

in figure.

8) Check all around cylinder head for any other parts

required to be removed or disconnected and remove

or disconnect whatever necessary.

9) Remove exhaust manifold, if necessary referring to

“Exhaust Manifold Removal and Installation in

Section 1K”.

10) Remove cylinder head with intake manifold and

exhaust manifold. Use lifting device, if necessary.

Installation

1) Clean mating surface of cylinder head and cylinder

block. Remove oil, old gasket and dust from mating

surface.

2) Make sure that oil jet (venturi plug) (1) is not

clogged. If it is not installed, install it as specified

torque.

Tightening torque

Venturi plug (a): 5 N·m (0.5 kgf-m, 3.5 lb-ft)

3) Install knock pins (1) to cylinder block.

4) Install new cylinder head gasket (2) to cylinder block.

“Top” or triangle mark provided on gasket comes to

crankshaft pulley side, facing up (toward cylinder

head side).

I2RH0B140088-01

I2RH0B140089-01

I5RW0C140025-01

Page 324 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-42 Engine Mechanical:

Valves and Cylinder Head Disassembly and

Assembly

S6RW0D1406027

Disassembly

1) For ease in servicing cylinder head, remove intake

manifold, injectors, exhaust manifold from cylinder

head.

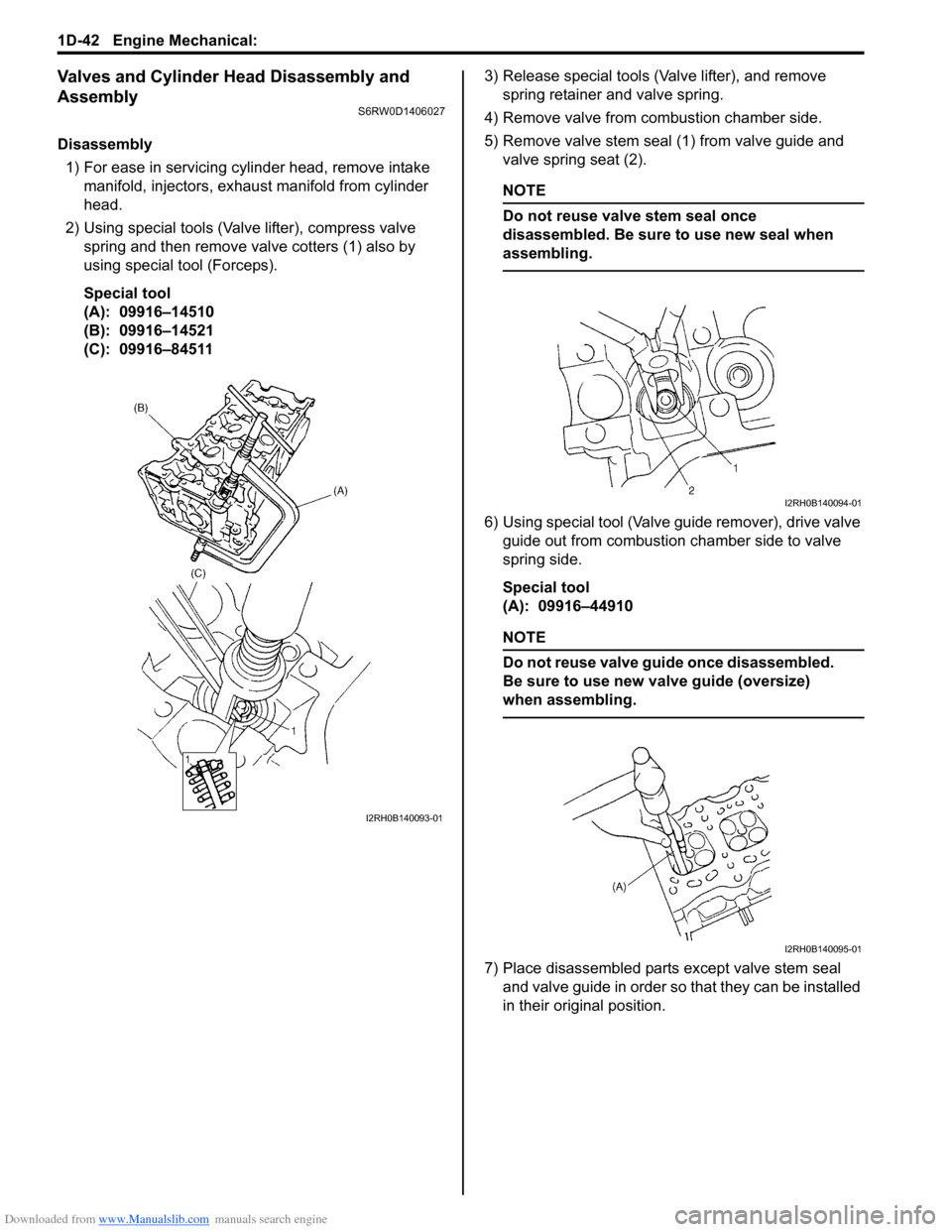

2) Using special tools (Valve lifter), compress valve

spring and then remove valve cotters (1) also by

using special tool (Forceps).

Special tool

(A): 09916–14510

(B): 09916–14521

(C): 09916–845113) Release special tools (Valve lifter), and remove

spring retainer and valve spring.

4) Remove valve from combustion chamber side.

5) Remove valve stem seal (1) from valve guide and

valve spring seat (2).

NOTE

Do not reuse valve stem seal once

disassembled. Be sure to use new seal when

assembling.

6) Using special tool (Valve guide remover), drive valve

guide out from combustion chamber side to valve

spring side.

Special tool

(A): 09916–44910

NOTE

Do not reuse valve guide once disassembled.

Be sure to use new valve guide (oversize)

when assembling.

7) Place disassembled parts except valve stem seal

and valve guide in order so that they can be installed

in their original position.

I2RH0B140093-01

I2RH0B140094-01

I2RH0B140095-01

Page 325 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-43

Assembly

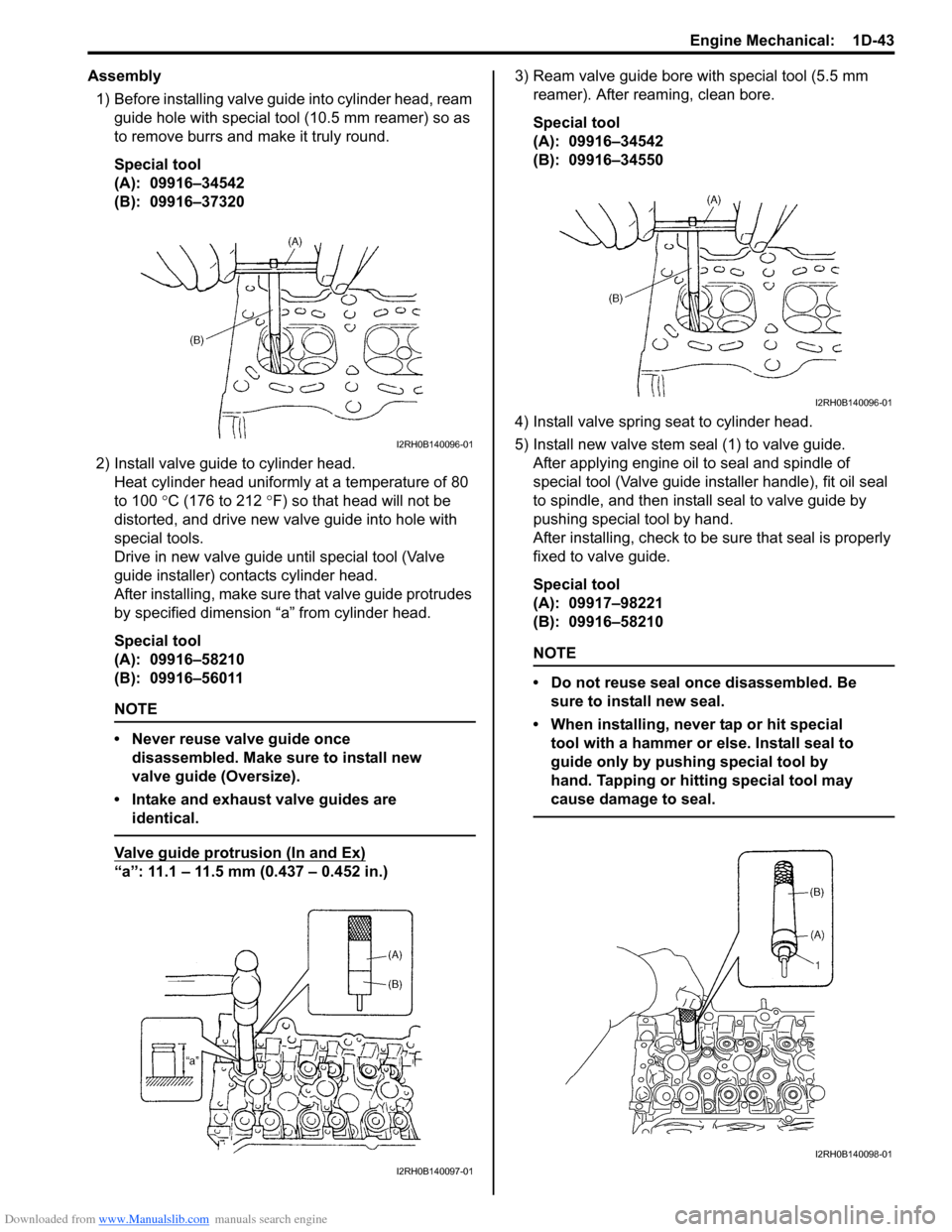

1) Before installing valve guide into cylinder head, ream

guide hole with special tool (10.5 mm reamer) so as

to remove burrs and make it truly round.

Special tool

(A): 09916–34542

(B): 09916–37320

2) Install valve guide to cylinder head.

Heat cylinder head uniformly at a temperature of 80

to 100 °C (176 to 212 °F) so that head will not be

distorted, and drive new valve guide into hole with

special tools.

Drive in new valve guide until special tool (Valve

guide installer) contacts cylinder head.

After installing, make sure that valve guide protrudes

by specified dimension “a” from cylinder head.

Special tool

(A): 09916–58210

(B): 09916–56011

NOTE

• Never reuse valve guide once

disassembled. Make sure to install new

valve guide (Oversize).

• Intake and exhaust valve guides are

identical.

Valve guide protrusion (In and Ex)

“a”: 11.1 – 11.5 mm (0.437 – 0.452 in.)3) Ream valve guide bore with special tool (5.5 mm

reamer). After reaming, clean bore.

Special tool

(A): 09916–34542

(B): 09916–34550

4) Install valve spring seat to cylinder head.

5) Install new valve stem seal (1) to valve guide.

After applying engine oil to seal and spindle of

special tool (Valve guide installer handle), fit oil seal

to spindle, and then install seal to valve guide by

pushing special tool by hand.

After installing, check to be sure that seal is properly

fixed to valve guide.

Special tool

(A): 09917–98221

(B): 09916–58210

NOTE

• Do not reuse seal once disassembled. Be

sure to install new seal.

• When installing, never tap or hit special

tool with a hammer or else. Install seal to

guide only by pushing special tool by

hand. Tapping or hitting special tool may

cause damage to seal.

I2RH0B140096-01

I2RH0B140097-01

I2RH0B140096-01

I2RH0B140098-01

Page 326 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-44 Engine Mechanical:

6) Install valve to valve guide.

Before installing valve to valve guide, apply engine

oil to stem seal, valve guide bore and valve stem.

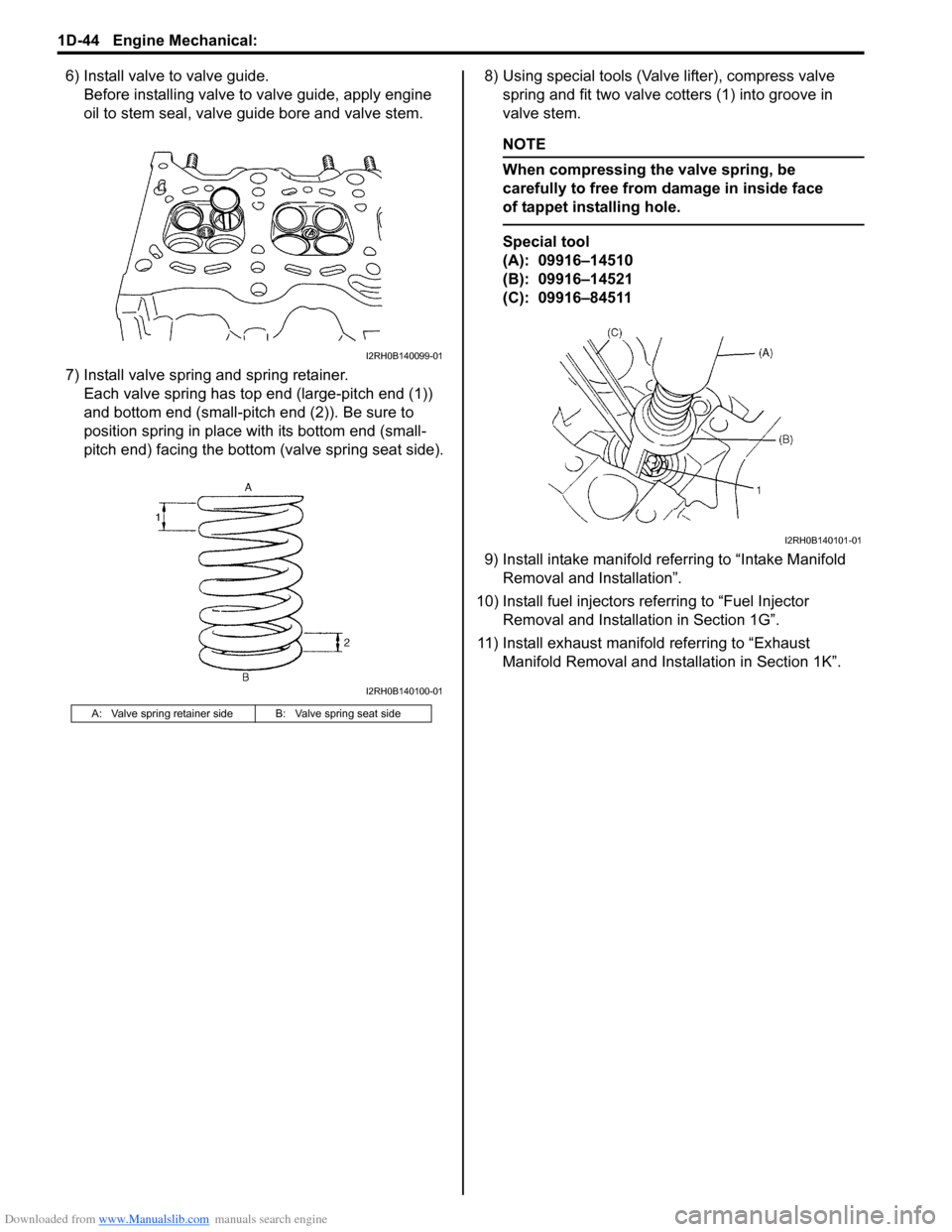

7) Install valve spring and spring retainer.

Each valve spring has top end (large-pitch end (1))

and bottom end (small-pitch end (2)). Be sure to

position spring in place with its bottom end (small-

pitch end) facing the bottom (valve spring seat side).8) Using special tools (Valve lifter), compress valve

spring and fit two valve cotters (1) into groove in

valve stem.

NOTE

When compressing the valve spring, be

carefully to free from damage in inside face

of tappet installing hole.

Special tool

(A): 09916–14510

(B): 09916–14521

(C): 09916–84511

9) Install intake manifold referring to “Intake Manifold

Removal and Installation”.

10) Install fuel injectors referring to “Fuel Injector

Removal and Installation in Section 1G”.

11) Install exhaust manifold referring to “Exhaust

Manifold Removal and Installation in Section 1K”.

A: Valve spring retainer side B: Valve spring seat side

I2RH0B140099-01

I2RH0B140100-01

I2RH0B140101-01

Page 328 of 1556

Downloaded from www.Manualslib.com manuals search engine 1D-46 Engine Mechanical:

Valve head radial runout

Check each valve for radial runout with a dial gauge and

“V” block. To check runout, rotate valve slowly. If runout

exceeds its limit, replace valve.

Valve head radial runout

Limit: 0.08 mm (0.003 in.)

Seating contact width

Create contact pattern on each valve in the usual

manner, i.e., by giving uniform coat of marking

compound to valve seat and by rotatingly tapping seat

with valve head. Valve lapper (tool used in valve lapping)

must be used.

Pattern produced on seating face of valve must be a

continuous ring without any break, and the width of

pattern must be within specified range.

Standard seating width “a” revealed by contact

pattern on valve face

Intake and Exhaust: 1.0 – 1.4 mm (0.0389 – 0.0551

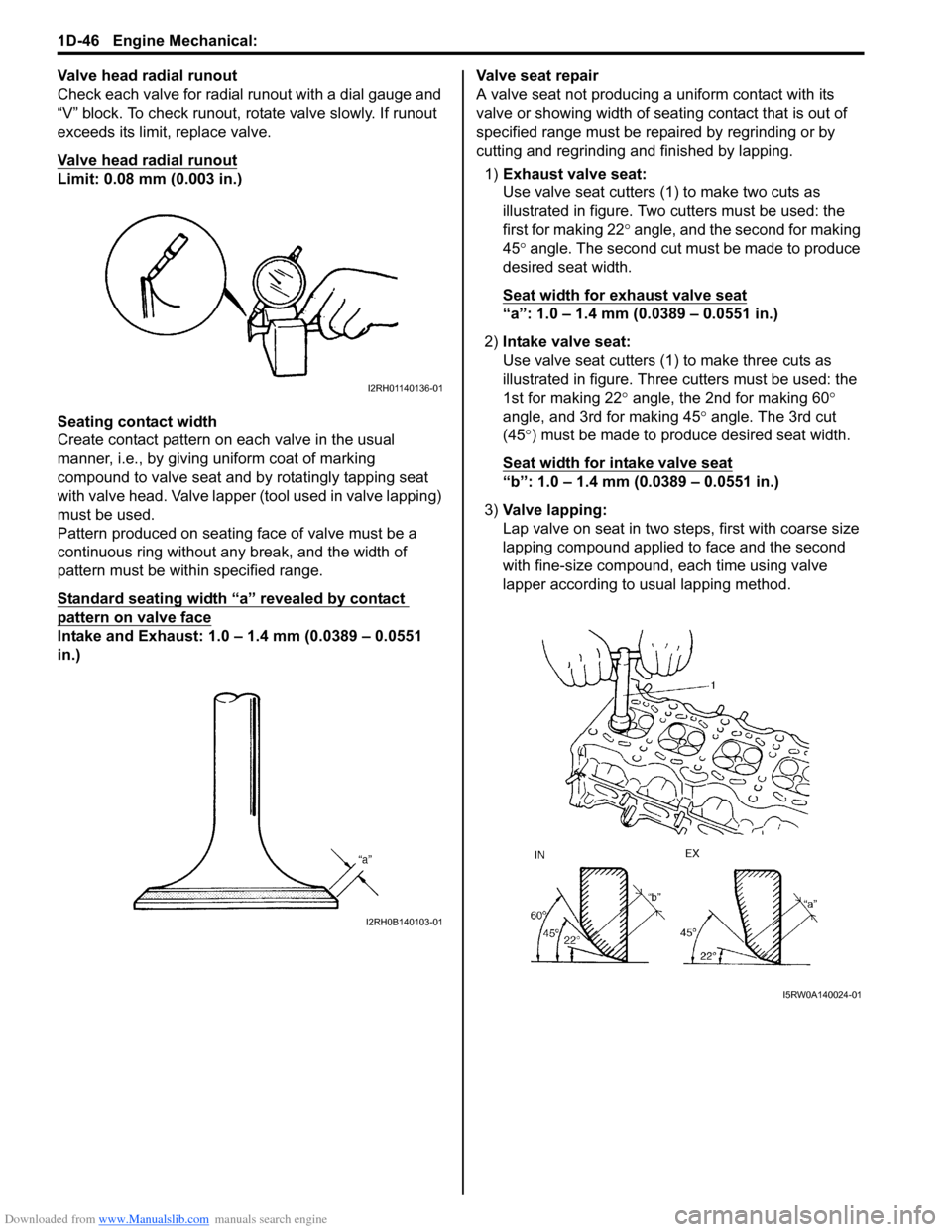

in.)Valve seat repair

A valve seat not producing a uniform contact with its

valve or showing width of seating contact that is out of

specified range must be repaired by regrinding or by

cutting and regrinding and finished by lapping.

1)Exhaust valve seat:

Use valve seat cutters (1) to make two cuts as

illustrated in figure. Two cutters must be used: the

first for making 22° angle, and the second for making

45° angle. The second cut must be made to produce

desired seat width.

Seat width for exhaust valve seat

“a”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

2)Intake valve seat:

Use valve seat cutters (1) to make three cuts as

illustrated in figure. Three cutters must be used: the

1st for making 22° angle, the 2nd for making 60°

angle, and 3rd for making 45° angle. The 3rd cut

(45°) must be made to produce desired seat width.

Seat width for intake valve seat

“b”: 1.0 – 1.4 mm (0.0389 – 0.0551 in.)

3)Valve lapping:

Lap valve on seat in two steps, first with coarse size

lapping compound applied to face and the second

with fine-size compound, each time using valve

lapper according to usual lapping method.

I2RH01140136-01

I2RH0B140103-01

I5RW0A140024-01

Page 329 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Mechanical: 1D-47

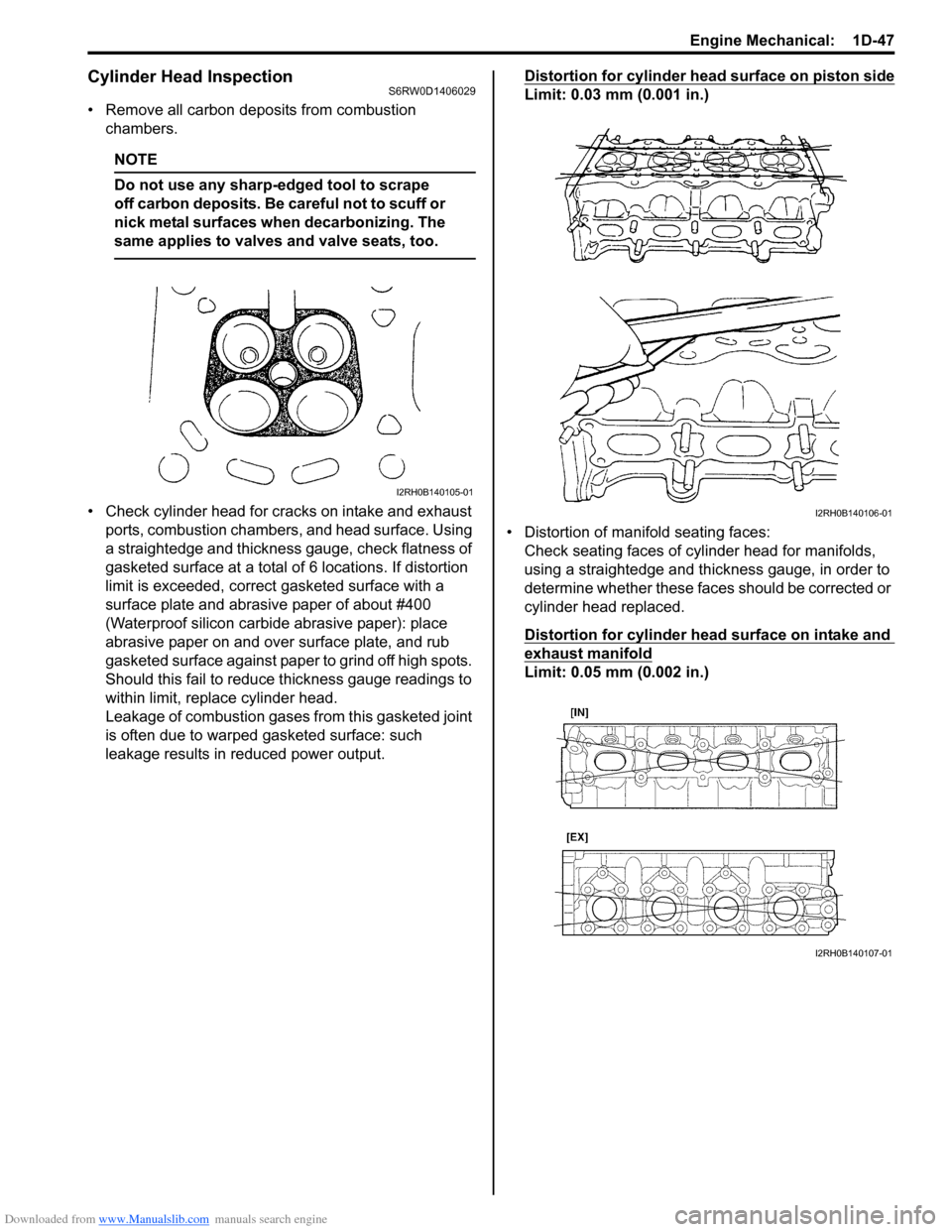

Cylinder Head InspectionS6RW0D1406029

• Remove all carbon deposits from combustion

chambers.

NOTE

Do not use any sharp-edged tool to scrape

off carbon deposits. Be careful not to scuff or

nick metal surfaces when decarbonizing. The

same applies to valves and valve seats, too.

• Check cylinder head for cracks on intake and exhaust

ports, combustion chambers, and head surface. Using

a straightedge and thickness gauge, check flatness of

gasketed surface at a total of 6 locations. If distortion

limit is exceeded, correct gasketed surface with a

surface plate and abrasive paper of about #400

(Waterproof silicon carbide abrasive paper): place

abrasive paper on and over surface plate, and rub

gasketed surface against paper to grind off high spots.

Should this fail to reduce thickness gauge readings to

within limit, replace cylinder head.

Leakage of combustion gases from this gasketed joint

is often due to warped gasketed surface: such

leakage results in reduced power output.Distortion for cylinder head surface on piston side

Limit: 0.03 mm (0.001 in.)

• Distortion of manifold seating faces:

Check seating faces of cylinder head for manifolds,

using a straightedge and thickness gauge, in order to

determine whether these faces should be corrected or

cylinder head replaced.

Distortion for cylinder head surface on intake and

exhaust manifold

Limit: 0.05 mm (0.002 in.)

I2RH0B140105-01

I2RH0B140106-01

I2RH0B140107-01

Page 358 of 1556

Downloaded from www.Manualslib.com manuals search engine 1E-2 Engine Lubrication System:

Diagnostic Information and Procedures

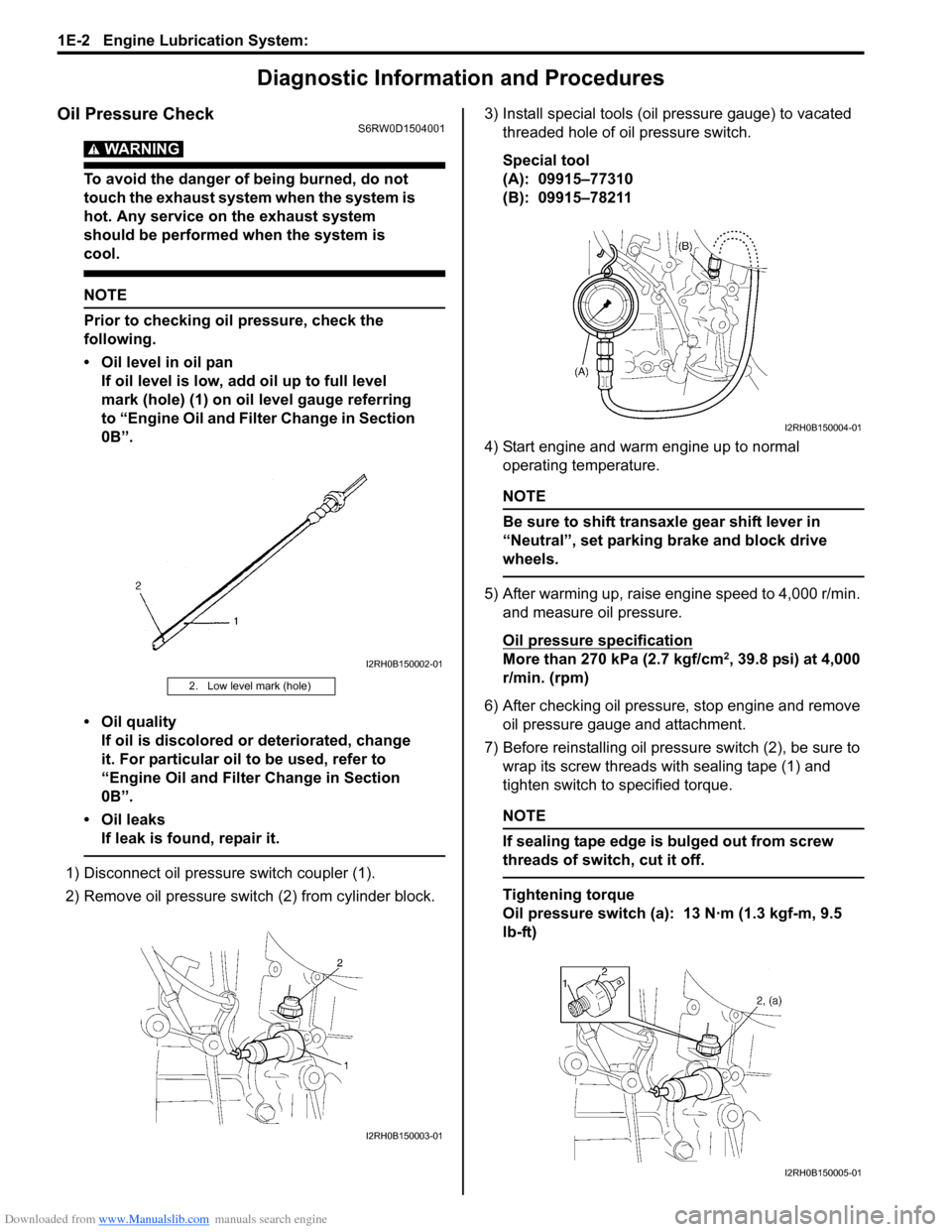

Oil Pressure CheckS6RW0D1504001

WARNING!

To avoid the danger of being burned, do not

touch the exhaust system when the system is

hot. Any service on the exhaust system

should be performed when the system is

cool.

NOTE

Prior to checking oil pressure, check the

following.

• Oil level in oil pan

If oil level is low, add oil up to full level

mark (hole) (1) on oil level gauge referring

to “Engine Oil and Filter Change in Section

0B”.

• Oil quality

If oil is discolored or deteriorated, change

it. For particular oil to be used, refer to

“Engine Oil and Filter Change in Section

0B”.

• Oil leaks

If leak is found, repair it.

1) Disconnect oil pressure switch coupler (1).

2) Remove oil pressure switch (2) from cylinder block.3) Install special tools (oil pressure gauge) to vacated

threaded hole of oil pressure switch.

Special tool

(A): 09915–77310

(B): 09915–78211

4) Start engine and warm engine up to normal

operating temperature.

NOTE

Be sure to shift transaxle gear shift lever in

“Neutral”, set parking brake and block drive

wheels.

5) After warming up, raise engine speed to 4,000 r/min.

and measure oil pressure.

Oil pressure specification

More than 270 kPa (2.7 kgf/cm2, 39.8 psi) at 4,000

r/min. (rpm)

6) After checking oil pressure, stop engine and remove

oil pressure gauge and attachment.

7) Before reinstalling oil pressure switch (2), be sure to

wrap its screw threads with sealing tape (1) and

tighten switch to specified torque.

NOTE

If sealing tape edge is bulged out from screw

threads of switch, cut it off.

Tightening torque

Oil pressure switch (a): 13 N·m (1.3 kgf-m, 9.5

lb-ft)

2. Low level mark (hole)

I2RH0B150002-01

I2RH0B150003-01

I2RH0B150004-01

I2RH0B150005-01