Valve SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 172 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-122 Engine General Information and Diagnosis:

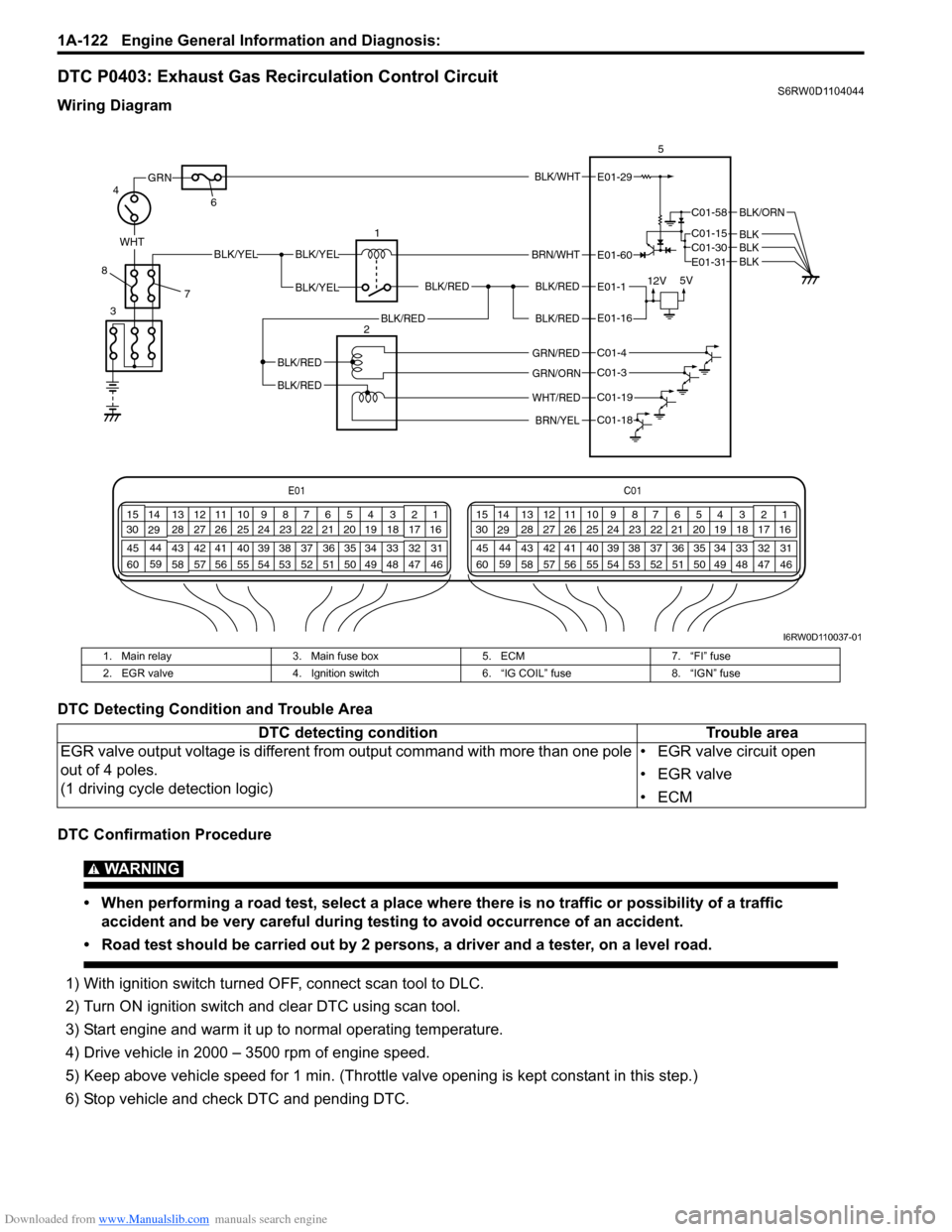

DTC P0403: Exhaust Gas Recirculation Control CircuitS6RW0D1104044

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) With ignition switch turned OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle in 2000 – 3500 rpm of engine speed.

5) Keep above vehicle speed for 1 min. (Throttle valve opening is kept constant in this step.)

6) Stop vehicle and check DTC and pending DTC.

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK/WHT

BLK/RED

BLK/RED

WHTBLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V5V

4

1 65E01-29

E01-1

E01-60

C01-58

C01-15 C01-30

BLK/ORN

BLKBLK

E01-16 2BLK/RED

C01-4

C01-3

C01-19

C01-18

BLK/RED

BLK/RED

BLK/RED

GRN/RED

GRN/ORN

WHT/RED

BRN/YEL

37 8

E01-31 BLK

I6RW0D110037-01

1. Main relay 3. Main fuse box 5. ECM 7. “FI” fuse

2. EGR valve 4. Ignition switch6. “IG COIL” fuse 8. “IGN” fuse

DTC detecting condition Trouble area

EGR valve output voltage is different from output command with more than one pole

out of 4 poles.

(1 driving cycle detection logic)• EGR valve circuit open

• EGR valve

•ECM

Page 173 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-123

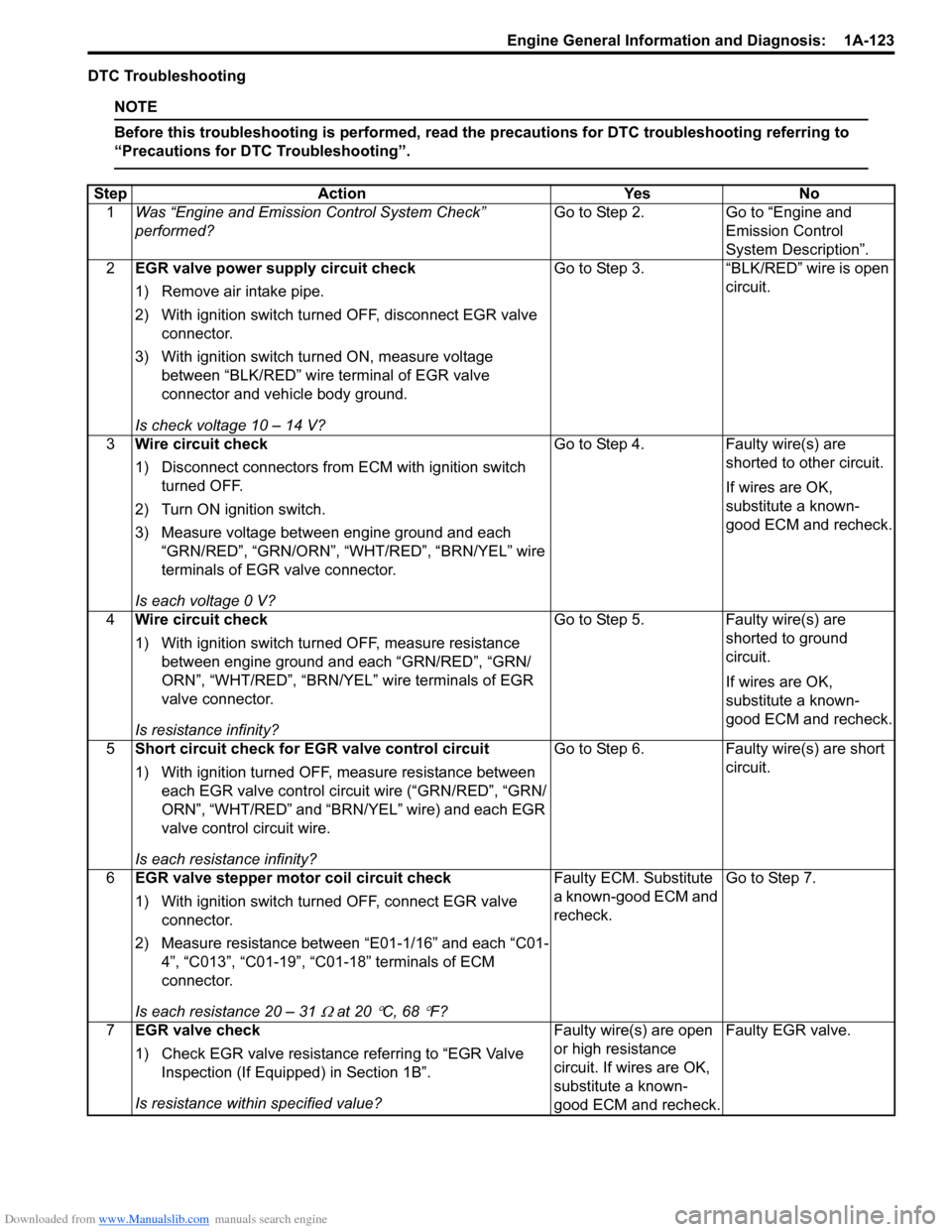

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Description”.

2EGR valve power supply circuit check

1) Remove air intake pipe.

2) With ignition switch turned OFF, disconnect EGR valve

connector.

3) With ignition switch turned ON, measure voltage

between “BLK/RED” wire terminal of EGR valve

connector and vehicle body ground.

Is check voltage 10 – 14 V?Go to Step 3. “BLK/RED” wire is open

circuit.

3Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Turn ON ignition switch.

3) Measure voltage between engine ground and each

“GRN/RED”, “GRN/ORN”, “WHT/RED”, “BRN/YEL” wire

terminals of EGR valve connector.

Is each voltage 0 V?Go to Step 4. Faulty wire(s) are

shorted to other circuit.

If wires are OK,

substitute a known-

good ECM and recheck.

4Wire circuit check

1) With ignition switch turned OFF, measure resistance

between engine ground and each “GRN/RED”, “GRN/

ORN”, “WHT/RED”, “BRN/YEL” wire terminals of EGR

valve connector.

Is resistance infinity?Go to Step 5. Faulty wire(s) are

shorted to ground

circuit.

If wires are OK,

substitute a known-

good ECM and recheck.

5Short circuit check for EGR valve control circuit

1) With ignition turned OFF, measure resistance between

each EGR valve control circuit wire (“GRN/RED”, “GRN/

ORN”, “WHT/RED” and “BRN/YEL” wire) and each EGR

valve control circuit wire.

Is each resistance infinity?Go to Step 6. Faulty wire(s) are short

circuit.

6EGR valve stepper motor coil circuit check

1) With ignition switch turned OFF, connect EGR valve

connector.

2) Measure resistance between “E01-1/16” and each “C01-

4”, “C013”, “C01-19”, “C01-18” terminals of ECM

connector.

Is each resistance 20 – 31

Ω at 20 °C, 68 °F?Faulty ECM. Substitute

a known-good ECM and

recheck.Go to Step 7.

7EGR valve check

1) Check EGR valve resistance referring to “EGR Valve

Inspection (If Equipped) in Section 1B”.

Is resistance within specified value?Faulty wire(s) are open

or high resistance

circuit. If wires are OK,

substitute a known-

good ECM and recheck.Faulty EGR valve.

Page 175 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-125

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

NOTE

Check to make sure that following conditions are satisfied when using this “DTC Confirmation

Procedure”.

• Intake air temperature at engine start: –10 (14 °F) to 80 °C (176 °F)

• Intake air temperature: –10 °C (14 °F) to 70 °C (158 °F)

• Engine coolant temp.: 70 °C, 158 °F or more

• Altitude (barometric pressure): 2500 m, 8200 ft or less (560 mmHg, 74.4 kPa or more)

1) Connect scan tool to DLC with ignition switch turned OFF.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Increase vehicle speed to 40 – 50 mph, 60 – 80 km/h.

4) Keep above vehicle speed for 10 min. or more (Throttle valve opening is kept constant in this step).

5) Stop vehicle.

6) For european market model, check whether catalyst monitoring readiness/monitoring test has completed or not by

using scan tool.

If evaporative system readiness/monitoring test has not completed, check vehicle conditions (environmental) and

repeat Steps 3) through 5).

7) Check DTC and pending DTC.

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Exhaust system visual check

1) Check exhaust system for leaks, damage and loose

connection.

Is it in good condition?Go to Step 3. Repair or replace

defective part.

3HO2S-2 output voltage check

1) Check output voltage of HO2S-2 referring to “DTC

P0137 / P0138: O2 Sensor (HO2S) Circuit Low Voltage /

High Voltage (Sensor-2)”.

Is check result satisfactory?Replace exhaust

manifold (built in warm

up three way catalytic

converter) and exhaust

center pipe (built in

three way catalytic

converter).Check “BRN” and / or

“ORN” wires for open

and short, and

connections for poor

connection.

If wires and connections

are OK, replace HO2S-

2.

Page 176 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-126 Engine General Information and Diagnosis:

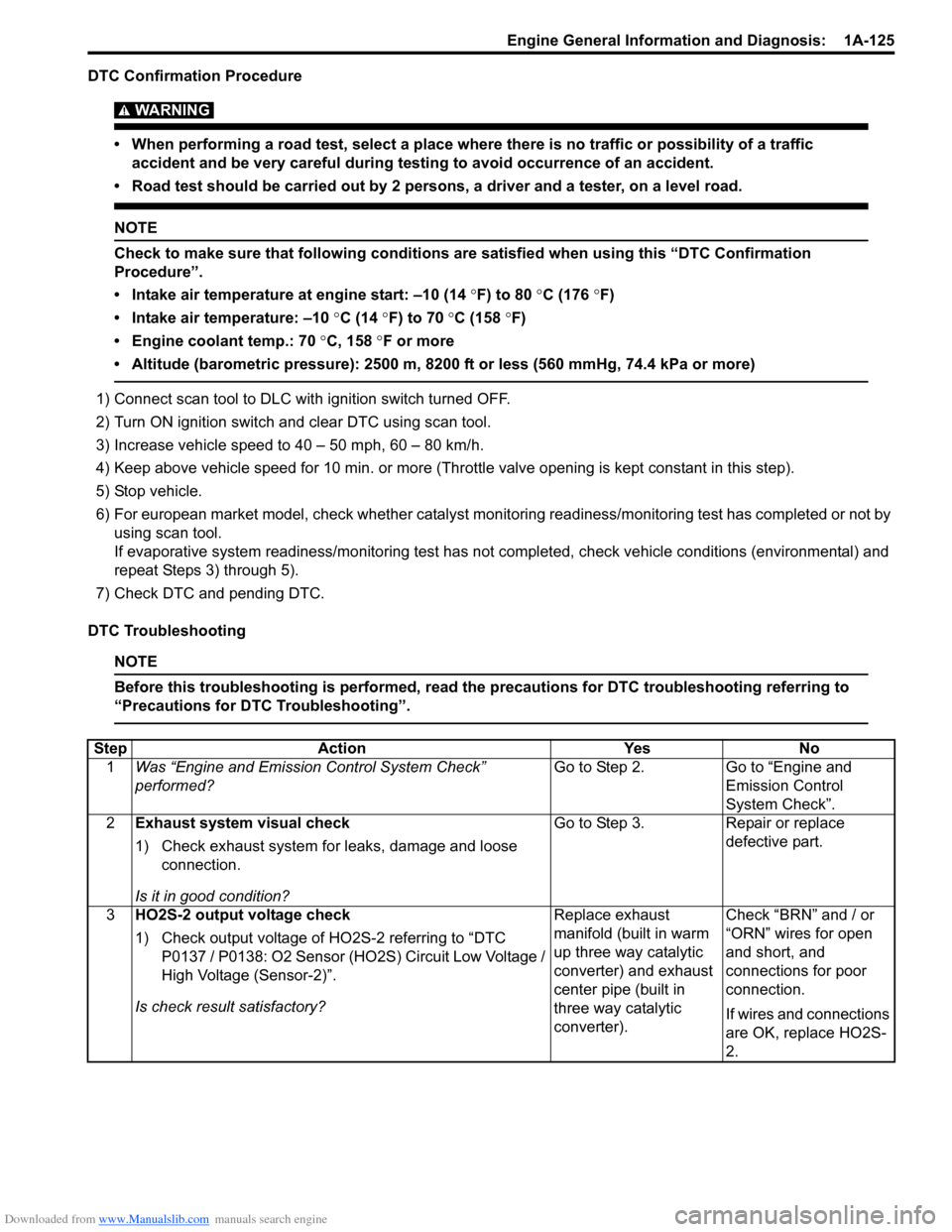

DTC P0443: Evaporative Emission System Purge Control Valve CircuitS6RW0D1104046

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

WARNING!

• When performing a road test, select a place where there is no traffic or possibility of a traffic

accident and be very careful during testing to avoid occurrence of an accident.

• Road test should be carried out by 2 persons, a driver and a tester, on a level road.

1) With ignition switch OFF, connect scan tool to DLC.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Start engine and warm up normal operating temperature.

4) Drive vehicle at more than 40 km/h, 25 mph for 5 min. or more.

5) Check DTC and pending DTC.

E01C01

3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238 3 4

18 19 5 6 7 10 11

17 20

47 46 49 50 51 21 22

5216 259

24 14

29

55 57 54 53 59

60 582

26 27 28 15

30

56 4832 31 34 35 36 37 40 42 39 38 44

45 43 41 331 12 13

238

BLK/WHT

BLK/RED

BLK/RED

WHTBLK/YELBLK/YEL

BLK/YEL

GRN

BRN/WHT

12V5V

5

42 36E01-29

E01-1

E01-60

C01-58

C01-15 C01-30

BLK/ORN

BLKBLK

7 8

BLK/REDBLK/REDE01-16

1

C01-29 BLU/BLK

BLKE01-31

I6RW0D110039-01

1. EVAP canister purge valve 3. “IG COIL” fuse 5. Ignition switch 7. “FI” fuse

2. Main relay 4. Main fuse box 6. ECM 8. “IGN” fuse

DTC detecting condition Trouble area

Monitor signal of EVAP canister purge valve is different from command signal.

(Circuit open or short)

(2 driving cycle detection logic)• EVAP canister purge valve

• EVAP canister purge valve circuit

•ECM

Page 177 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-127

DTC Troubleshooting

WARNING!

In order to reduce risk of fire and personal injury, this work must be performed in a well ventilated area

and away from any open flames such as gas water heater.

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2EVAP canister purge power supply circuit check

1) Turn OFF ignition switch and disconnect connector from

EVAP canister purge valve.

2) Measure voltage between engine ground and “BLK/

RED” wire terminal of EVAP canister purge valve

connector with ignition switch turned ON.

Is it voltage 10 – 14 V?Go to Step 3. “BLK/RED” wire is open

circuit.

3Wire circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between “C01-29” terminal of ECM

connector and vehicle body ground.

Is resistance infinity?Go to Step 4. “BLU/BLK” wire is

shorted to ground

circuit.

4Wire circuit check

1) Measure voltage between “C01-29” terminal of ECM

connector and vehicle body ground with ignition switch

turned ON.

Is voltage 0 V?Go to Step 5. “BLU/BLK” wire is

shorted to other circuit.

5Wire circuit check

1) Connect connector to purge control valve with ignition

switch turned OFF.

2) Turn ON ignition switch and measure voltage between

“C01-29” terminal of ECM connector and vehicle body

ground.

Is it voltage 10 – 14 V?Go to Step 6. “BLU/BLK” wire is open

circuit.

6EVAP canister purge control valve check

1) Check EVAP canister purge control valve referring to

“EVAP Canister Purge Valve Inspection in Section 1B”.

Is it in good condition?Go to Step 7. Faulty EVAP canister

purge control valve.

7EVAP canister purge control circuit check

1) With ignition switch turn OFF, measure resistance

between “E01-1/16” terminal and “C01-29” terminal of

ECM connector.

Is resistance below 34

Ω at 20 °C, 68 °F?Faulty ECM. Substitute

a known-good ECM and

recheck.“BLK/RED” and/or

“BLU/BLK” wire are high

resistance circuit.

Page 198 of 1556

Downloaded from www.Manualslib.com manuals search engine 1A-148 Engine General Information and Diagnosis:

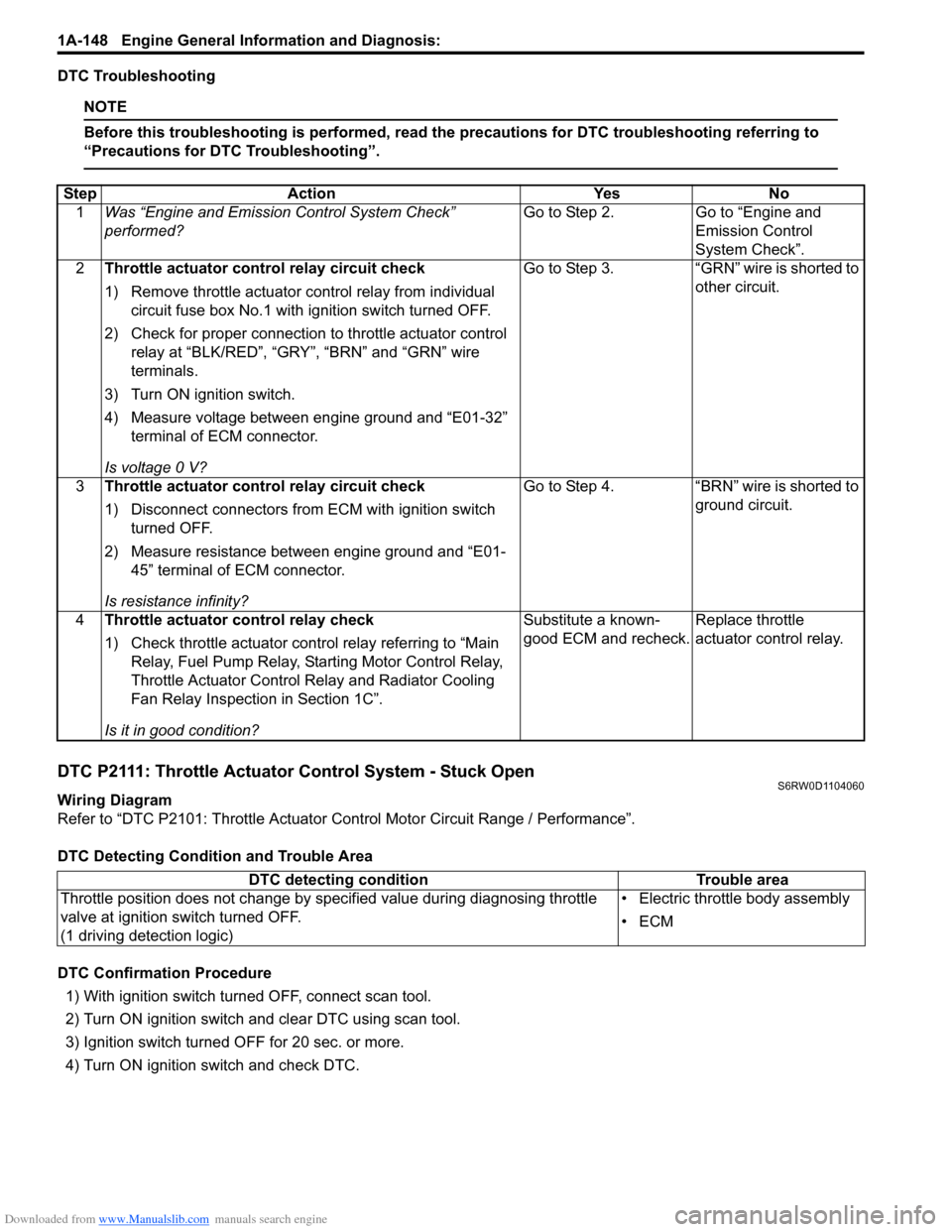

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC P2111: Throttle Actuator Control System - Stuck OpenS6RW0D1104060

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Ignition switch turned OFF for 20 sec. or more.

4) Turn ON ignition switch and check DTC. Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Throttle actuator control relay circuit check

1) Remove throttle actuator control relay from individual

circuit fuse box No.1 with ignition switch turned OFF.

2) Check for proper connection to throttle actuator control

relay at “BLK/RED”, “GRY”, “BRN” and “GRN” wire

terminals.

3) Turn ON ignition switch.

4) Measure voltage between engine ground and “E01-32”

terminal of ECM connector.

Is voltage 0 V?Go to Step 3. “GRN” wire is shorted to

other circuit.

3Throttle actuator control relay circuit check

1) Disconnect connectors from ECM with ignition switch

turned OFF.

2) Measure resistance between engine ground and “E01-

45” terminal of ECM connector.

Is resistance infinity?Go to Step 4. “BRN” wire is shorted to

ground circuit.

4Throttle actuator control relay check

1) Check throttle actuator control relay referring to “Main

Relay, Fuel Pump Relay, Starting Motor Control Relay,

Throttle Actuator Control Relay and Radiator Cooling

Fan Relay Inspection in Section 1C”.

Is it in good condition?Substitute a known-

good ECM and recheck.Replace throttle

actuator control relay.

DTC detecting condition Trouble area

Throttle position does not change by specified value during diagnosing throttle

valve at ignition switch turned OFF.

(1 driving detection logic)• Electric throttle body assembly

•ECM

Page 199 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-149

DTC Troubleshooting

NOTE

Before this troubleshooting is performed, read the precautions for DTC troubleshooting referring to

“Precautions for DTC Troubleshooting”.

DTC P2119: Throttle Actuator Control Throttle Body Range / PerformanceS6RW0D1104061

Wiring Diagram

Refer to “DTC P2101: Throttle Actuator Control Motor Circuit Range / Performance”.

DTC Detecting Condition and Trouble Area

DTC Confirmation Procedure

1) With ignition switch turned OFF, connect scan tool.

2) Turn ON ignition switch and clear DTC using scan tool.

3) Keep the accelerator pedal at idle position for 2 seconds.

4) Keep the accelerator pedal at fully depressed position for 2 seconds.

5) Repeat Step 3) and 4) for 3 times.

6) Check DTC. Step Action Yes No

1Was “Engine and Emission Control System Check”

performed?Go to Step 2. Go to “Engine and

Emission Control

System Check”.

2Throttle valve visual check

1) Check that there isn’t any foreign matter caught between

throttle valve and throttle body housing referring to

“Throttle Valve Visual Check” under “Electric Throttle

Body Assembly On-Vehicle Inspection in Section 1C”.

Is it in good condition?Go to Step 3. Take it out after

removing throttle body

and clean inside of

throttle body thoroughly.

3Throttle valve operation check

1) Check operation of throttle valve referring to “Throttle

Valve Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory?Go to Step 4. Replace electric throttle

body assembly.

4Throttle actuator operation check

1) Check operation of throttle actuator referring to “Throttle

Actuator Operation Check” under “Electric Throttle Body

Assembly On-Vehicle Inspection in Section 1C”.

Is check result satisfactory?Go to Step 5. Replace electric throttle

body assembly.

5Throttle position sensor performance check

1) Check performance of throttle position sensor referring

to “Throttle Position Sensor Performance Check” under

“Electric Throttle Body Assembly On-Vehicle Inspection

in Section 1C”.

Is check result satisfactory?Substitute a known-

good ECM and recheck.Replace electric throttle

body assembly.

DTC detecting condition Trouble area

Difference between the measured (actual) throttle valve opening angle and the

target throttle valve opening angle which is calculated based on accelerator pedal

opening angle and engine condition is more than specification for specified time.

(1 driving detection logic)• Throttle actuator circuit

• Electric throttle body assembly

•ECM

Page 223 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-173

Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

C01-1BLU/

YELFuel injector No.1

output10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ”,

“Reference waveform

No.2: ” and

“Reference waveform

No.28: ”)Engine running at idle

after warmed up engine.Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C01-2BLU/

WHTFuel injector No.2

output10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform

No.3: ”)Engine running at idle

after warmed up engine.Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C01-3GRN/

ORNEGR valve

(stepper motor coil

2) output (if

equipped)10 – 14 V Ignition switch turned ON. —

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.4: ”)Ignition switch is turned to

ST (cranking) position.Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C01-4GRN/

REDEGR valve

(stepper motor coil

1) output (if

equipped)10 – 14 V Ignition switch turned ON. —

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.4: ”)Ignition switch is turned to

ST (cranking) position.Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C01-5GRN/

WHTIgnition coil No.2

and No.3 output0 – 0.6 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

3 – 5 V

(“Reference

waveform No.5: ” and

“Reference waveform

No.6: ”)Engine running at idle

after warmed up engine.Output signal is active

high pulse. Pulse

frequency varies

depending on engine

speed.

C01-6GRN/

YELIgnition coil No.1

and No.4 output0 – 0.6 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

3 – 5 V

(“Reference

waveform No.6: ”,

“Reference waveform

No.7: ” and

“Reference waveform

No.28: ”)Engine running at idle

after warmed up engine.Output signal is active

high pulse. Pulse

frequency varies

depending on engine

speed.

C01-7 — — — — —

C01-8 — — — — —

C01-9 — — — — —

Page 224 of 1556

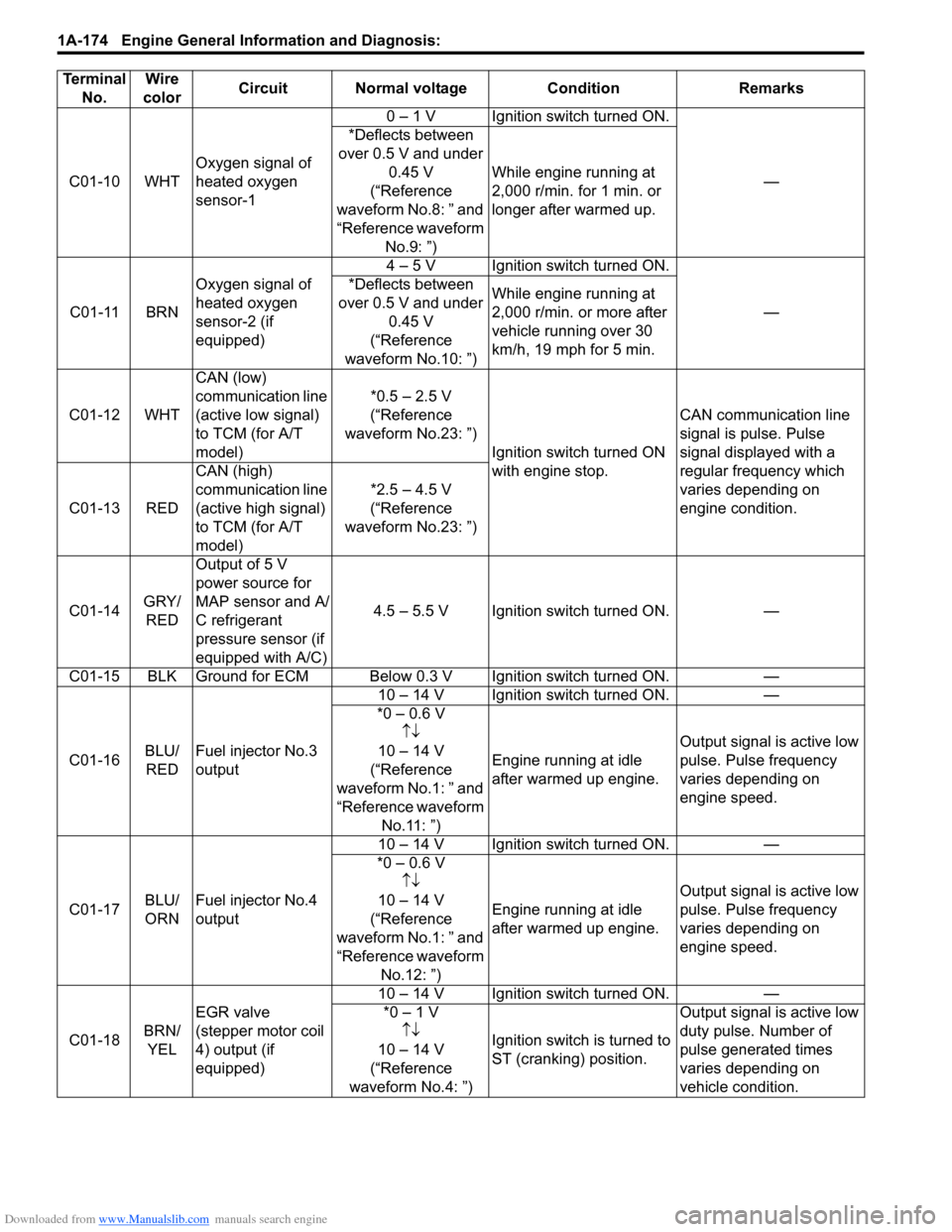

Downloaded from www.Manualslib.com manuals search engine 1A-174 Engine General Information and Diagnosis:

C01-10 WHTOxygen signal of

heated oxygen

sensor-10 – 1 V Ignition switch turned ON.

— *Deflects between

over 0.5 V and under

0.45 V

(“Reference

waveform No.8: ” and

“Reference waveform

No.9: ”)While engine running at

2,000 r/min. for 1 min. or

longer after warmed up.

C01-11 BRNOxygen signal of

heated oxygen

sensor-2 (if

equipped)4 – 5 V Ignition switch turned ON.

— *Deflects between

over 0.5 V and under

0.45 V

(“Reference

waveform No.10: ”)While engine running at

2,000 r/min. or more after

vehicle running over 30

km/h, 19 mph for 5 min.

C01-12 WHTCAN (low)

communication line

(active low signal)

to TCM (for A/T

model)*0.5 – 2.5 V

(“Reference

waveform No.23: ”)

Ignition switch turned ON

with engine stop.CAN communication line

signal is pulse. Pulse

signal displayed with a

regular frequency which

varies depending on

engine condition. C01-13 REDCAN (high)

communication line

(active high signal)

to TCM (for A/T

model)*2.5 – 4.5 V

(“Reference

waveform No.23: ”)

C01-14GRY/

REDOutput of 5 V

power source for

MAP sensor and A/

C refrigerant

pressure sensor (if

equipped with A/C)4.5 – 5.5 V Ignition switch turned ON. —

C01-15 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C01-16BLU/

REDFuel injector No.3

output10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform

No.11: ”)Engine running at idle

after warmed up engine.Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C01-17BLU/

ORNFuel injector No.4

output10 – 14 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.1: ” and

“Reference waveform

No.12: ”)Engine running at idle

after warmed up engine.Output signal is active low

pulse. Pulse frequency

varies depending on

engine speed.

C01-18BRN/

YELEGR valve

(stepper motor coil

4) output (if

equipped)10 – 14 V Ignition switch turned ON. —

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.4: ”)Ignition switch is turned to

ST (cranking) position.Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition. Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks

Page 225 of 1556

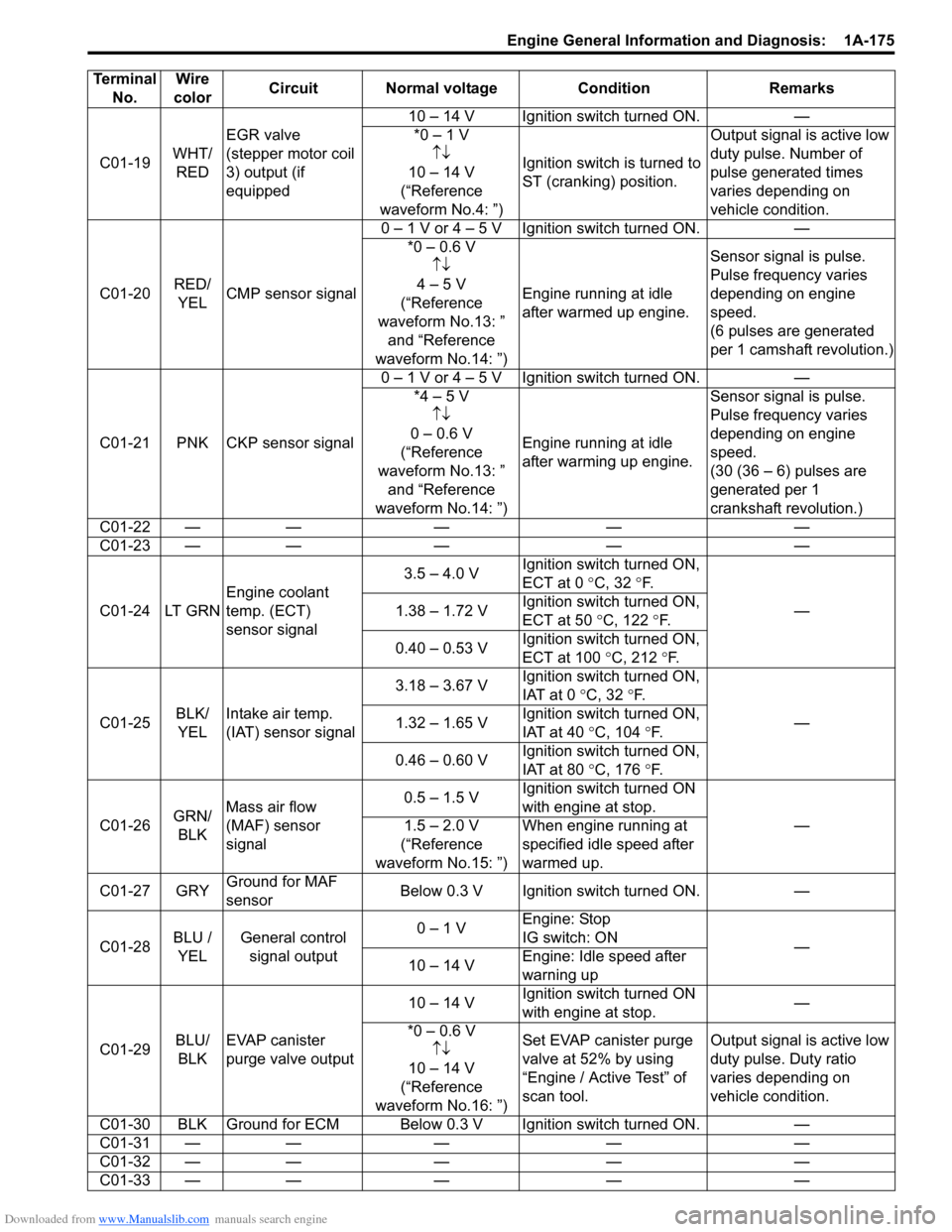

Downloaded from www.Manualslib.com manuals search engine Engine General Information and Diagnosis: 1A-175

C01-19WHT/

REDEGR valve

(stepper motor coil

3) output (if

equipped10 – 14 V Ignition switch turned ON. —

*0 – 1 V

↑↓

10 – 14 V

(“Reference

waveform No.4: ”)Ignition switch is turned to

ST (cranking) position.Output signal is active low

duty pulse. Number of

pulse generated times

varies depending on

vehicle condition.

C01-20RED/

YELCMP sensor signal0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*0 – 0.6 V

↑↓

4 – 5 V

(“Reference

waveform No.13: ”

and “Reference

waveform No.14: ”)Engine running at idle

after warmed up engine.Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(6 pulses are generated

per 1 camshaft revolution.)

C01-21 PNK CKP sensor signal0 – 1 V or 4 – 5 V Ignition switch turned ON. —

*4 – 5 V

↑↓

0 – 0.6 V

(“Reference

waveform No.13: ”

and “Reference

waveform No.14: ”)Engine running at idle

after warming up engine.Sensor signal is pulse.

Pulse frequency varies

depending on engine

speed.

(30 (36 – 6) pulses are

generated per 1

crankshaft revolution.)

C01-22 — — — — —

C01-23 — — — — —

C01-24 LT GRNEngine coolant

temp. (ECT)

sensor signal3.5 – 4.0 VIgnition switch turned ON,

ECT at 0 °C, 32 °F.

— 1.38 – 1.72 VIgnition switch turned ON,

ECT at 50 °C, 122 °F.

0.40 – 0.53 VIgnition switch turned ON,

ECT at 100 °C, 212 °F.

C01-25BLK/

YELIntake air temp.

(IAT) sensor signal3.18 – 3.67 VIgnition switch turned ON,

IAT at 0 °C, 32 °F.

— 1.32 – 1.65 VIgnition switch turned ON,

IAT at 40 °C, 104 °F.

0.46 – 0.60 VIgnition switch turned ON,

IAT at 80 °C, 176 °F.

C01-26GRN/

BLKMass air flow

(MAF) sensor

signal0.5 – 1.5 VIgnition switch turned ON

with engine at stop.

— 1.5 – 2.0 V

(“Reference

waveform No.15: ”)When engine running at

specified idle speed after

warmed up.

C01-27 GRYGround for MAF

sensorBelow 0.3 V Ignition switch turned ON. —

C01-28BLU /

YELGeneral control

signal output0 – 1 VEngine: Stop

IG switch: ON

—

10 – 14 VEngine: Idle speed after

warning up

C01-29BLU/

BLKEVAP canister

purge valve output10 – 14 VIgnition switch turned ON

with engine at stop.—

*0 – 0.6 V

↑↓

10 – 14 V

(“Reference

waveform No.16: ”)Set EVAP canister purge

valve at 52% by using

“Engine / Active Test” of

scan tool.Output signal is active low

duty pulse. Duty ratio

varies depending on

vehicle condition.

C01-30 BLK Ground for ECM Below 0.3 V Ignition switch turned ON. —

C01-31 — — — — —

C01-32 — — — — —

C01-33 — — — — — Terminal

No.Wire

colorCircuit Normal voltage Condition Remarks