torque SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 360 of 1556

Downloaded from www.Manualslib.com manuals search engine 1E-4 Engine Lubrication System:

Oil Pan and Oil Pump Strainer Removal and

Installation

S6RW0D1506002

Removal

1) Remove oil level gauge.

2) Drain engine oil by removing drain plug.

3) For 4WD model, dismount transfer referring to

“Transfer Dismounting and Remounting in Section

3C”.

4) Remove clutch housing lower plate (1).

5) Remove oil pan and then oil pump strainer (1) from

cylinder block.

Installation

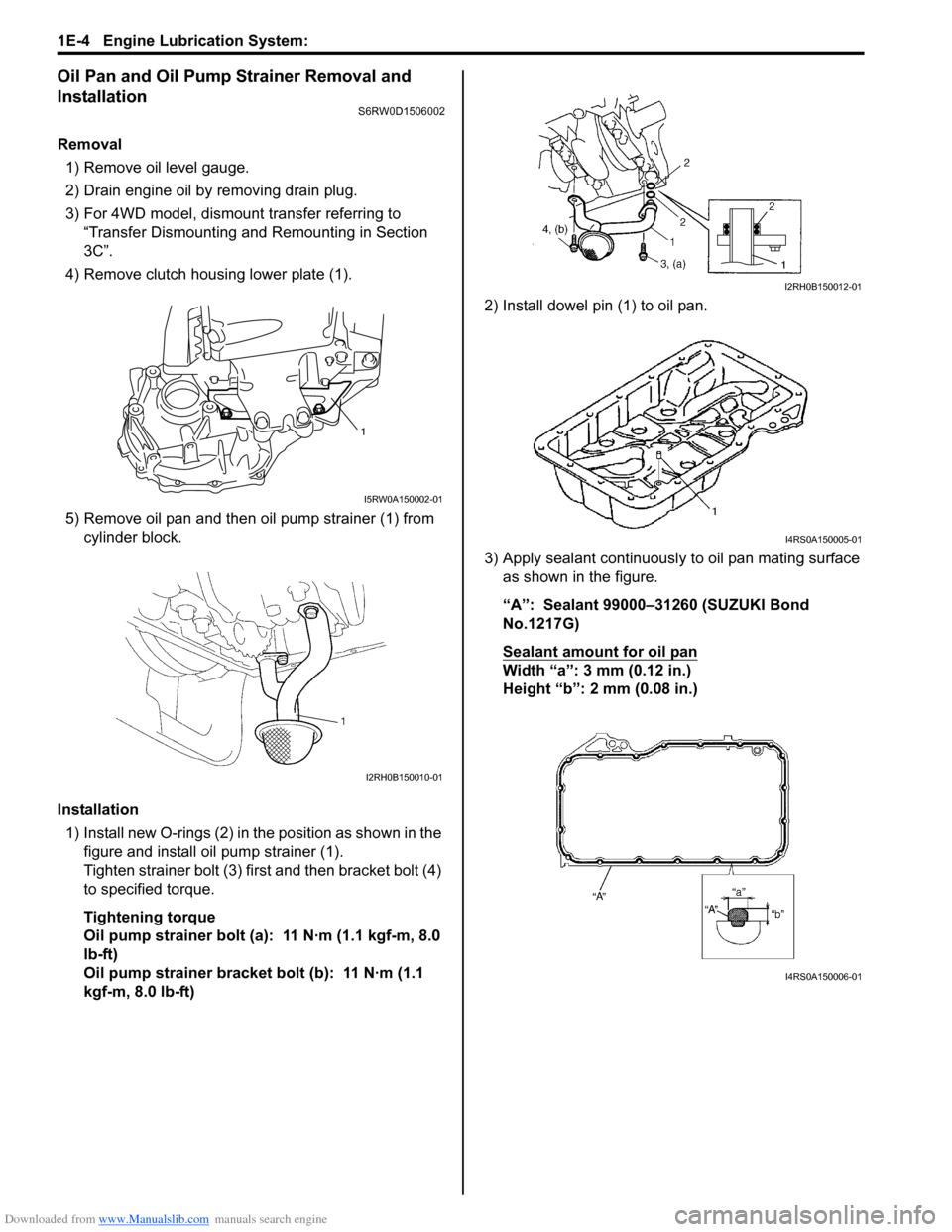

1) Install new O-rings (2) in the position as shown in the

figure and install oil pump strainer (1).

Tighten strainer bolt (3) first and then bracket bolt (4)

to specified torque.

Tightening torque

Oil pump strainer bolt (a): 11 N·m (1.1 kgf-m, 8.0

lb-ft)

Oil pump strainer bracket bolt (b): 11 N·m (1.1

kgf-m, 8.0 lb-ft)2) Install dowel pin (1) to oil pan.

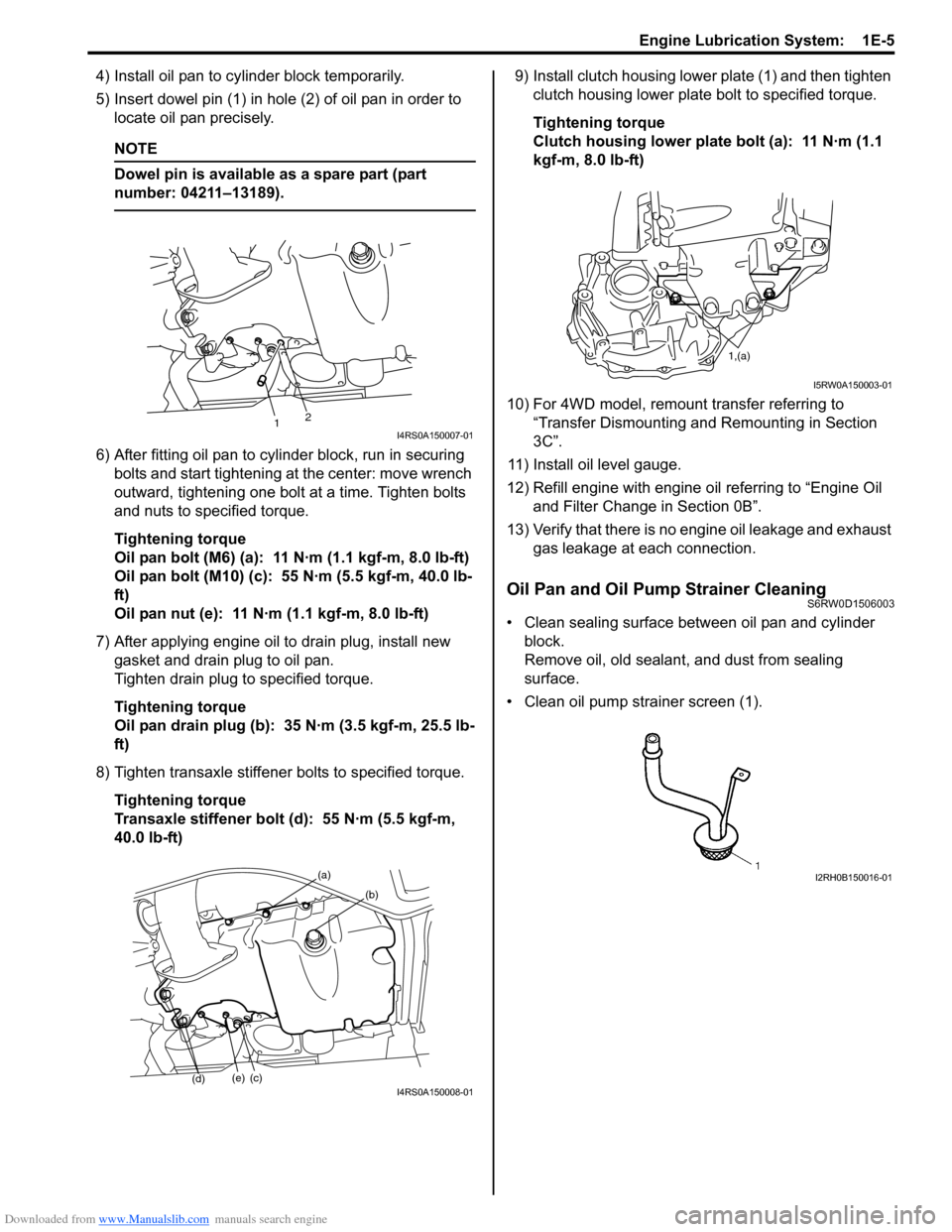

3) Apply sealant continuously to oil pan mating surface

as shown in the figure.

“A”: Sealant 99000–31260 (SUZUKI Bond

No.1217G)

Sealant amount for oil pan

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

1

I5RW0A150002-01

I2RH0B150010-01

I2RH0B150012-01

I4RS0A150005-01

I4RS0A150006-01

Page 361 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-5

4) Install oil pan to cylinder block temporarily.

5) Insert dowel pin (1) in hole (2) of oil pan in order to

locate oil pan precisely.

NOTE

Dowel pin is available as a spare part (part

number: 04211–13189).

6) After fitting oil pan to cylinder block, run in securing

bolts and start tightening at the center: move wrench

outward, tightening one bolt at a time. Tighten bolts

and nuts to specified torque.

Tightening torque

Oil pan bolt (M6) (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

Oil pan bolt (M10) (c): 55 N·m (5.5 kgf-m, 40.0 lb-

ft)

Oil pan nut (e): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

7) After applying engine oil to drain plug, install new

gasket and drain plug to oil pan.

Tighten drain plug to specified torque.

Tightening torque

Oil pan drain plug (b): 35 N·m (3.5 kgf-m, 25.5 lb-

ft)

8) Tighten transaxle stiffener bolts to specified torque.

Tightening torque

Transaxle stiffener bolt (d): 55 N·m (5.5 kgf-m,

40.0 lb-ft)9) Install clutch housing lower plate (1) and then tighten

clutch housing lower plate bolt to specified torque.

Tightening torque

Clutch housing lower plate bolt (a): 11 N·m (1.1

kgf-m, 8.0 lb-ft)

10) For 4WD model, remount transfer referring to

“Transfer Dismounting and Remounting in Section

3C”.

11) Install oil level gauge.

12) Refill engine with engine oil referring to “Engine Oil

and Filter Change in Section 0B”.

13) Verify that there is no engine oil leakage and exhaust

gas leakage at each connection.

Oil Pan and Oil Pump Strainer CleaningS6RW0D1506003

• Clean sealing surface between oil pan and cylinder

block.

Remove oil, old sealant, and dust from sealing

surface.

• Clean oil pump strainer screen (1).

21I4RS0A150007-01

(a)

(b)

(c)(e)

(d)I4RS0A150008-01

1,(a)

I5RW0A150003-01

I2RH0B150016-01

Page 363 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-7

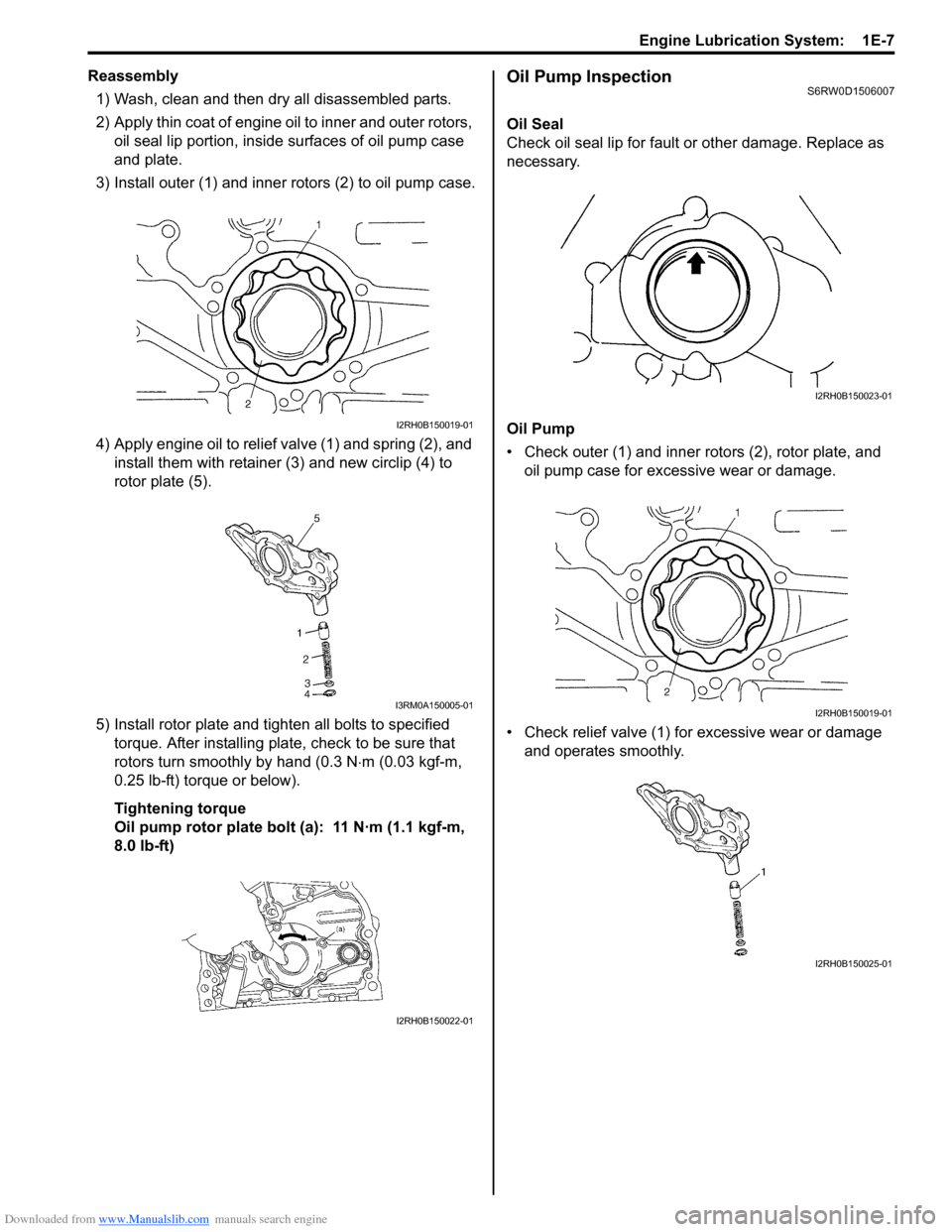

Reassembly

1) Wash, clean and then dry all disassembled parts.

2) Apply thin coat of engine oil to inner and outer rotors,

oil seal lip portion, inside surfaces of oil pump case

and plate.

3) Install outer (1) and inner rotors (2) to oil pump case.

4) Apply engine oil to relief valve (1) and spring (2), and

install them with retainer (3) and new circlip (4) to

rotor plate (5).

5) Install rotor plate and tighten all bolts to specified

torque. After installing plate, check to be sure that

rotors turn smoothly by hand (0.3 N⋅m (0.03 kgf-m,

0.25 lb-ft) torque or below).

Tightening torque

Oil pump rotor plate bolt (a): 11 N·m (1.1 kgf-m,

8.0 lb-ft)Oil Pump InspectionS6RW0D1506007

Oil Seal

Check oil seal lip for fault or other damage. Replace as

necessary.

Oil Pump

• Check outer (1) and inner rotors (2), rotor plate, and

oil pump case for excessive wear or damage.

• Check relief valve (1) for excessive wear or damage

and operates smoothly.

I2RH0B150019-01

I3RM0A150005-01

I2RH0B150022-01

I2RH0B150023-01

I2RH0B150019-01

I2RH0B150025-01

Page 365 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Lubrication System: 1E-9

Specifications

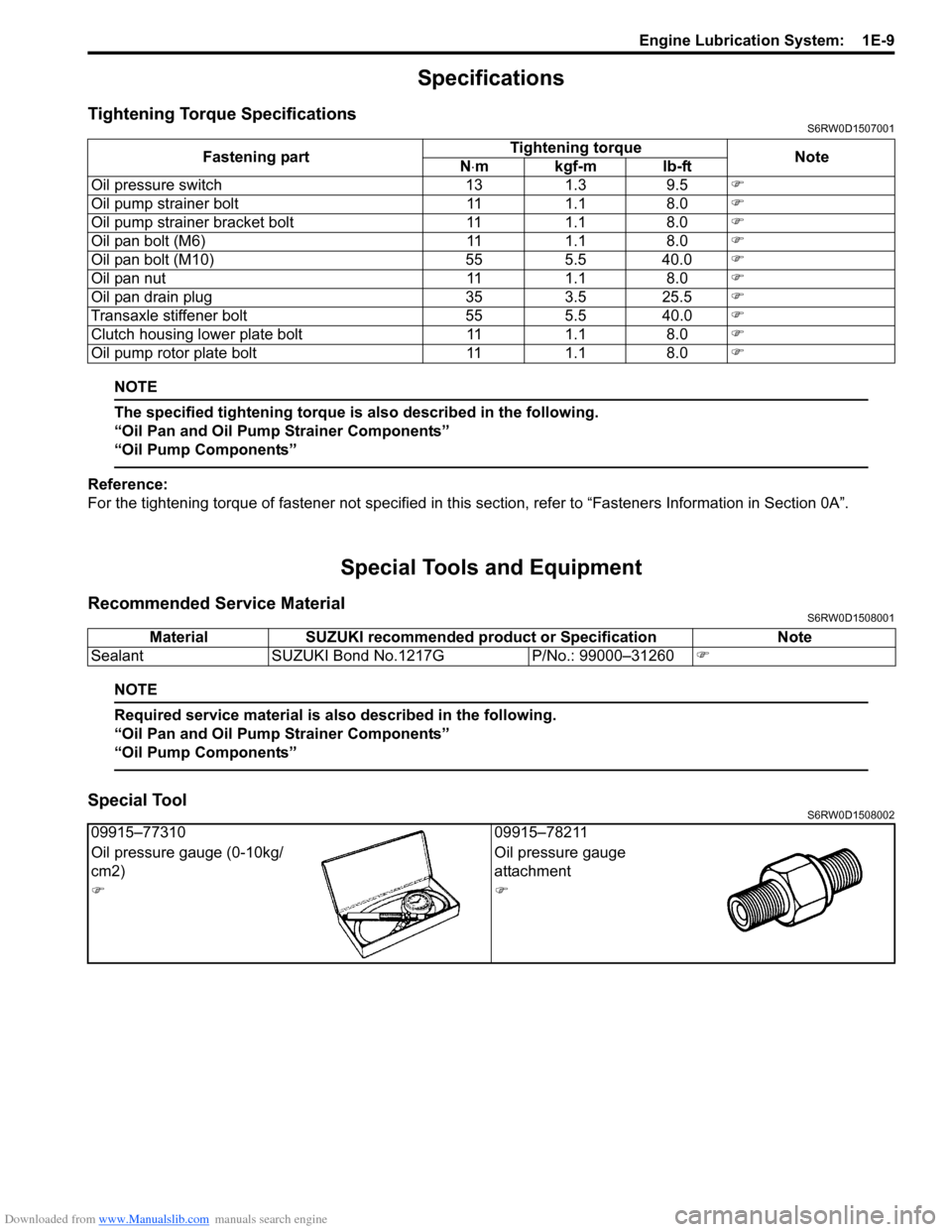

Tightening Torque SpecificationsS6RW0D1507001

NOTE

The specified tightening torque is also described in the following.

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS6RW0D1508001

NOTE

Required service material is also described in the following.

“Oil Pan and Oil Pump Strainer Components”

“Oil Pump Components”

Special ToolS6RW0D1508002

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Oil pressure switch 13 1.3 9.5�)

Oil pump strainer bolt 11 1.1 8.0�)

Oil pump strainer bracket bolt 11 1.1 8.0�)

Oil pan bolt (M6) 11 1.1 8.0�)

Oil pan bolt (M10) 55 5.5 40.0�)

Oil pan nut 11 1.1 8.0�)

Oil pan drain plug 35 3.5 25.5�)

Transaxle stiffener bolt 55 5.5 40.0�)

Clutch housing lower plate bolt 11 1.1 8.0�)

Oil pump rotor plate bolt 11 1.1 8.0�)

Material SUZUKI recommended product or Specification Note

Sealant SUZUKI Bond No.1217G P/No.: 99000–31260�)

09915–77310 09915–78211

Oil pressure gauge (0-10kg/

cm2)Oil pressure gauge

attachment

�)�)

Page 374 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-9 Engine Cooling System:

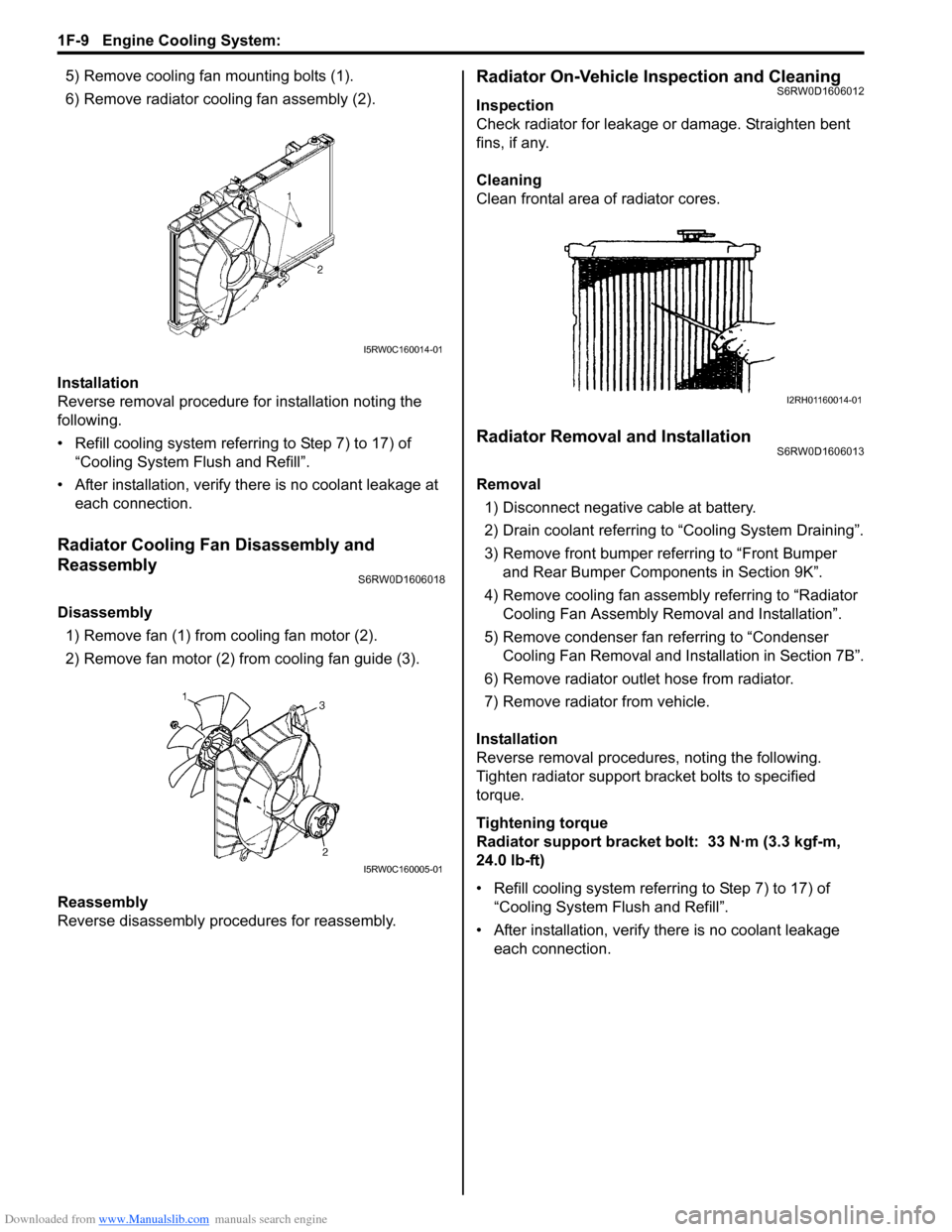

5) Remove cooling fan mounting bolts (1).

6) Remove radiator cooling fan assembly (2).

Installation

Reverse removal procedure for installation noting the

following.

• Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

• After installation, verify there is no coolant leakage at

each connection.

Radiator Cooling Fan Disassembly and

Reassembly

S6RW0D1606018

Disassembly

1) Remove fan (1) from cooling fan motor (2).

2) Remove fan motor (2) from cooling fan guide (3).

Reassembly

Reverse disassembly procedures for reassembly.

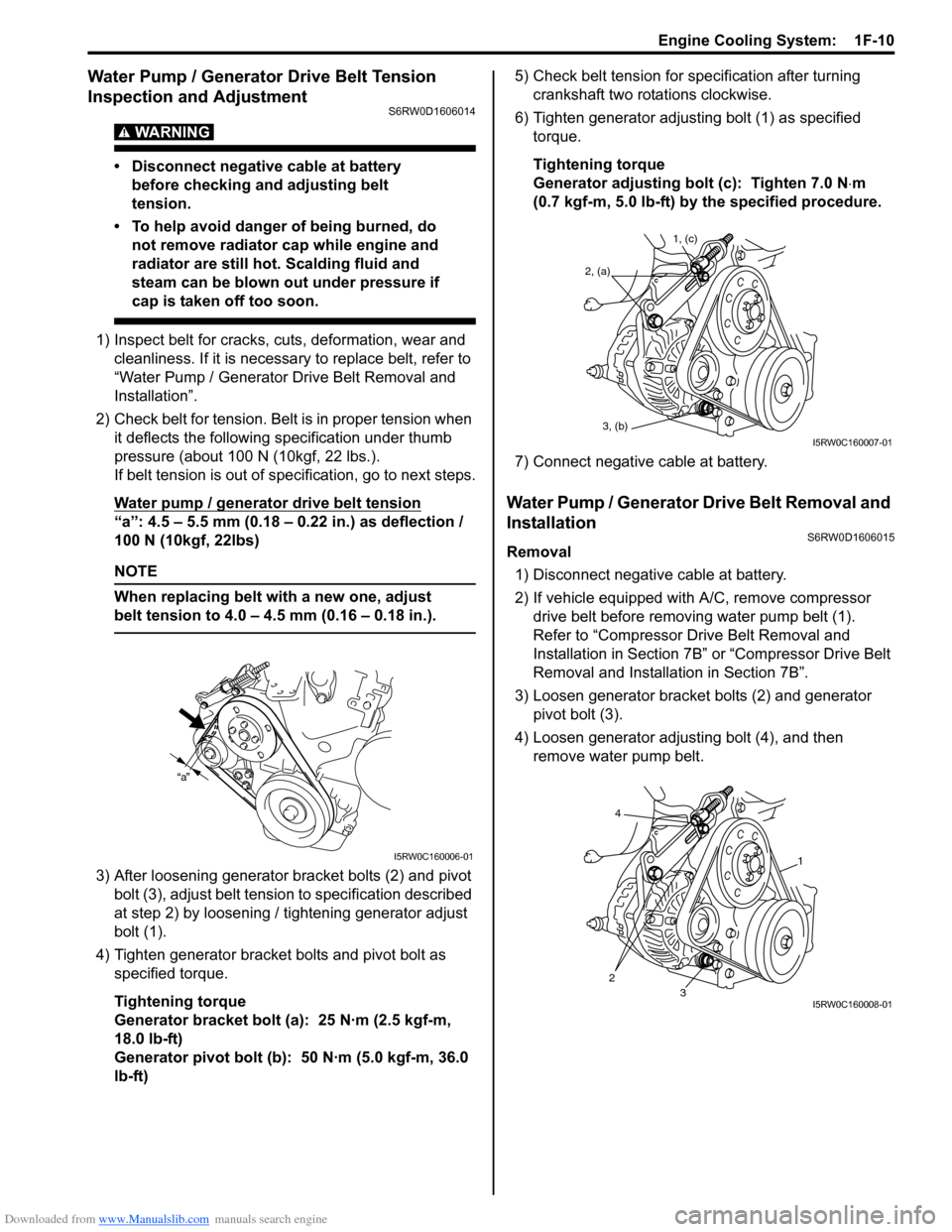

Radiator On-Vehicle Inspection and CleaningS6RW0D1606012

Inspection

Check radiator for leakage or damage. Straighten bent

fins, if any.

Cleaning

Clean frontal area of radiator cores.

Radiator Removal and InstallationS6RW0D1606013

Removal

1) Disconnect negative cable at battery.

2) Drain coolant referring to “Cooling System Draining”.

3) Remove front bumper referring to “Front Bumper

and Rear Bumper Components in Section 9K”.

4) Remove cooling fan assembly referring to “Radiator

Cooling Fan Assembly Removal and Installation”.

5) Remove condenser fan referring to “Condenser

Cooling Fan Removal and Installation in Section 7B”.

6) Remove radiator outlet hose from radiator.

7) Remove radiator from vehicle.

Installation

Reverse removal procedures, noting the following.

Tighten radiator support bracket bolts to specified

torque.

Tightening torque

Radiator support bracket bolt: 33 N·m (3.3 kgf-m,

24.0 lb-ft)

• Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

• After installation, verify there is no coolant leakage

each connection.

I5RW0C160014-01

I5RW0C160005-01

I2RH01160014-01

Page 375 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-10

Water Pump / Generator Drive Belt Tension

Inspection and Adjustment

S6RW0D1606014

WARNING!

• Disconnect negative cable at battery

before checking and adjusting belt

tension.

• To help avoid danger of being burned, do

not remove radiator cap while engine and

radiator are still hot. Scalding fluid and

steam can be blown out under pressure if

cap is taken off too soon.

1) Inspect belt for cracks, cuts, deformation, wear and

cleanliness. If it is necessary to replace belt, refer to

“Water Pump / Generator Drive Belt Removal and

Installation”.

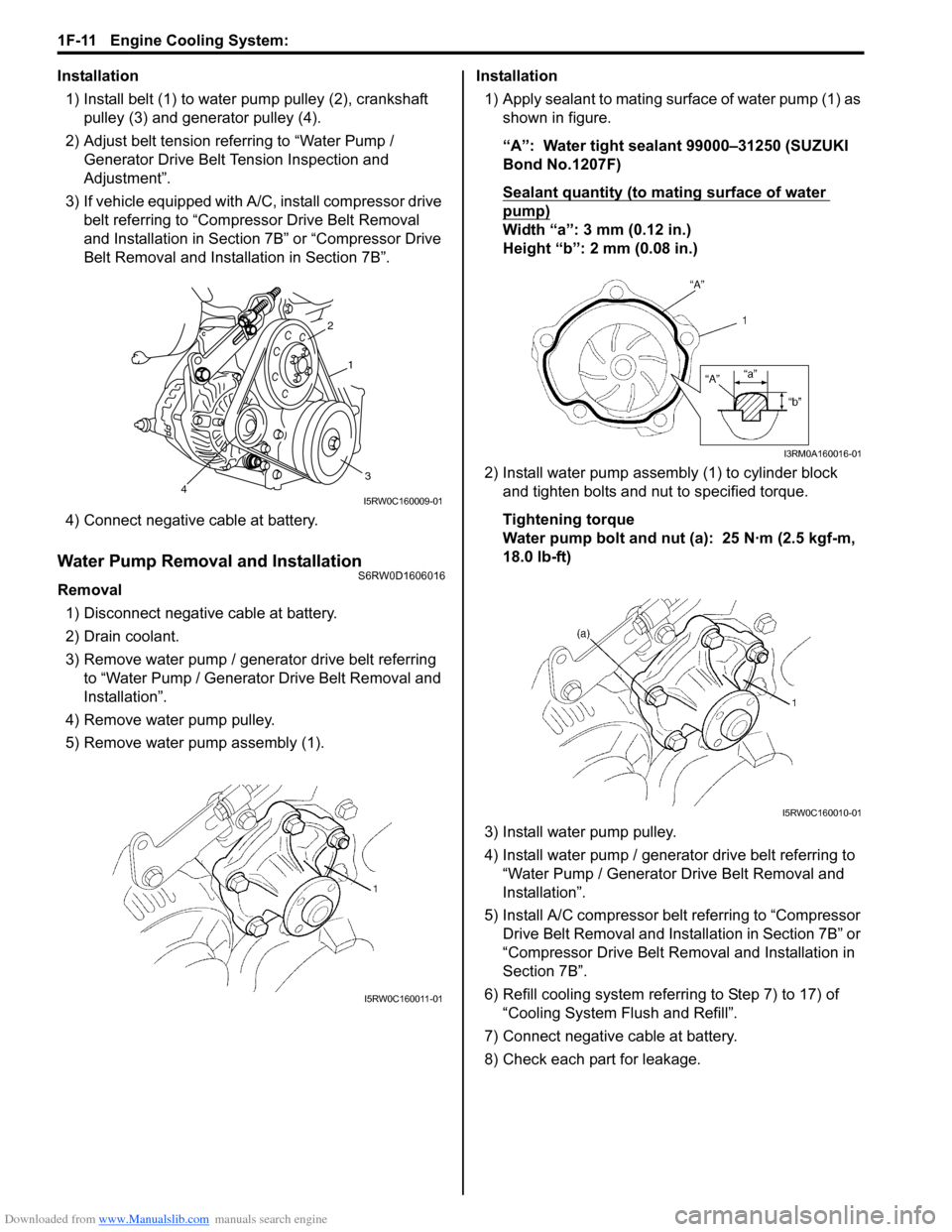

2) Check belt for tension. Belt is in proper tension when

it deflects the following specification under thumb

pressure (about 100 N (10kgf, 22 lbs.).

If belt tension is out of specification, go to next steps.

Water pump / generator drive belt tension

“a”: 4.5 – 5.5 mm (0.18 – 0.22 in.) as deflection /

100 N (10kgf, 22lbs)

NOTE

When replacing belt with a new one, adjust

belt tension to 4.0 – 4.5 mm (0.16 – 0.18 in.).

3) After loosening generator bracket bolts (2) and pivot

bolt (3), adjust belt tension to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as

specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)5) Check belt tension for specification after turning

crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified

torque.

Tightening torque

Generator adjusting bolt (c): Tighten 7.0 N⋅m

(0.7 kgf-m, 5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.

Water Pump / Generator Drive Belt Removal and

Installation

S6RW0D1606015

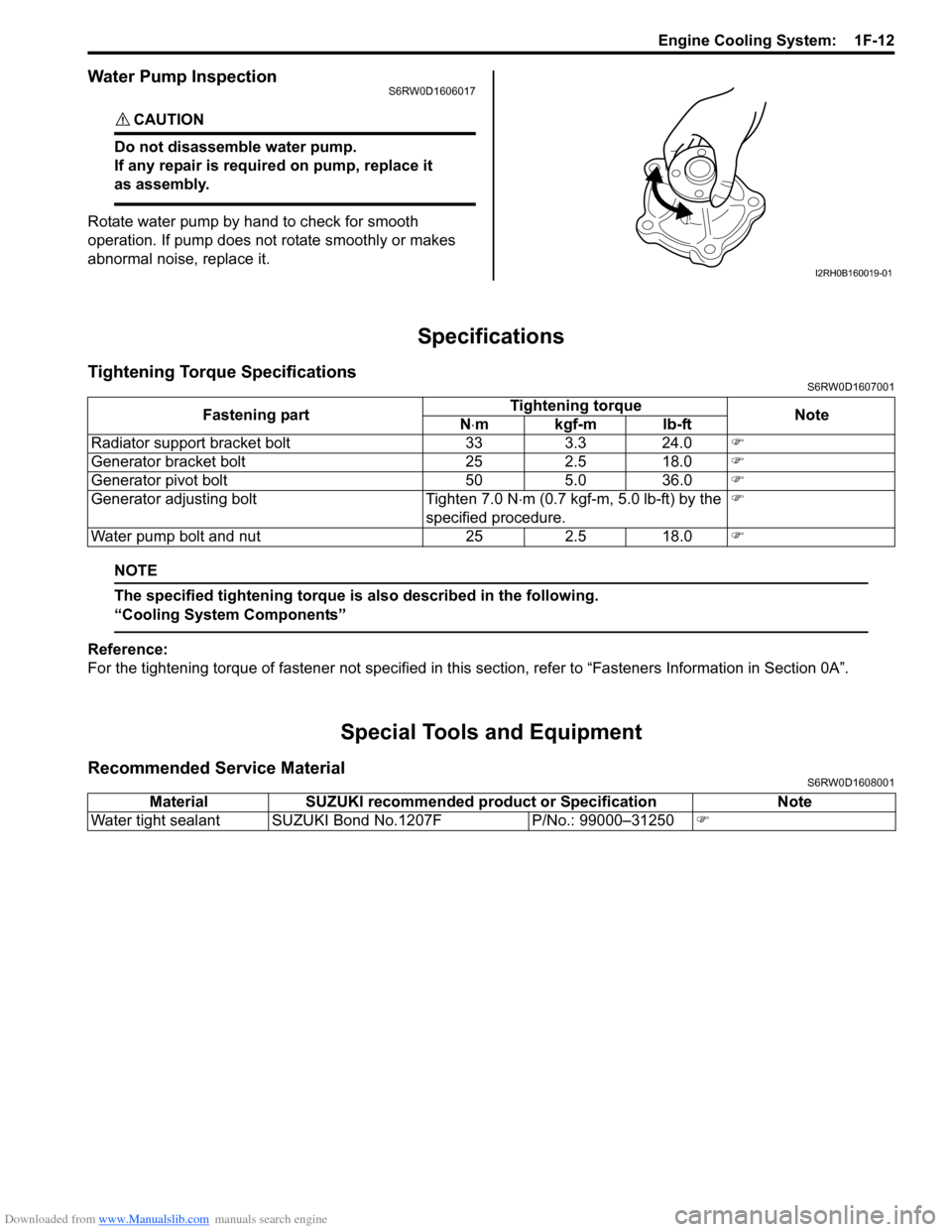

Removal

1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor

drive belt before removing water pump belt (1).

Refer to “Compressor Drive Belt Removal and

Installation in Section 7B” or “Compressor Drive Belt

Removal and Installation in Section 7B”.

3) Loosen generator bracket bolts (2) and generator

pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then

remove water pump belt.

a

I5RW0C160006-01

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I5RW0C160008-01

Page 376 of 1556

Downloaded from www.Manualslib.com manuals search engine 1F-11 Engine Cooling System:

Installation

1) Install belt (1) to water pump pulley (2), crankshaft

pulley (3) and generator pulley (4).

2) Adjust belt tension referring to “Water Pump /

Generator Drive Belt Tension Inspection and

Adjustment”.

3) If vehicle equipped with A/C, install compressor drive

belt referring to “Compressor Drive Belt Removal

and Installation in Section 7B” or “Compressor Drive

Belt Removal and Installation in Section 7B”.

4) Connect negative cable at battery.

Water Pump Removal and InstallationS6RW0D1606016

Removal

1) Disconnect negative cable at battery.

2) Drain coolant.

3) Remove water pump / generator drive belt referring

to “Water Pump / Generator Drive Belt Removal and

Installation”.

4) Remove water pump pulley.

5) Remove water pump assembly (1).Installation

1) Apply sealant to mating surface of water pump (1) as

shown in figure.

“A”: Water tight sealant 99000–31250 (SUZUKI

Bond No.1207F)

Sealant quantity (to mating surface of water

pump)

Width “a”: 3 mm (0.12 in.)

Height “b”: 2 mm (0.08 in.)

2) Install water pump assembly (1) to cylinder block

and tighten bolts and nut to specified torque.

Tightening torque

Water pump bolt and nut (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

3) Install water pump pulley.

4) Install water pump / generator drive belt referring to

“Water Pump / Generator Drive Belt Removal and

Installation”.

5) Install A/C compressor belt referring to “Compressor

Drive Belt Removal and Installation in Section 7B” or

“Compressor Drive Belt Removal and Installation in

Section 7B”.

6) Refill cooling system referring to Step 7) to 17) of

“Cooling System Flush and Refill”.

7) Connect negative cable at battery.

8) Check each part for leakage.

2

1

34I5RW0C160009-01

I5RW0C160011-01

I3RM0A160016-01

I5RW0C160010-01

Page 377 of 1556

Downloaded from www.Manualslib.com manuals search engine Engine Cooling System: 1F-12

Water Pump InspectionS6RW0D1606017

CAUTION!

Do not disassemble water pump.

If any repair is required on pump, replace it

as assembly.

Rotate water pump by hand to check for smooth

operation. If pump does not rotate smoothly or makes

abnormal noise, replace it.

Specifications

Tightening Torque SpecificationsS6RW0D1607001

NOTE

The specified tightening torque is also described in the following.

“Cooling System Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS6RW0D1608001

I2RH0B160019-01

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Radiator support bracket bolt 33 3.3 24.0�)

Generator bracket bolt 25 2.5 18.0�)

Generator pivot bolt 50 5.0 36.0�)

Generator adjusting bolt Tighten 7.0 N⋅m (0.7 kgf-m, 5.0 lb-ft) by the

specified procedure.�)

Water pump bolt and nut 25 2.5 18.0�)

Material SUZUKI recommended product or Specification Note

Water tight sealant SUZUKI Bond No.1207F P/No.: 99000–31250�)

Page 387 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-10

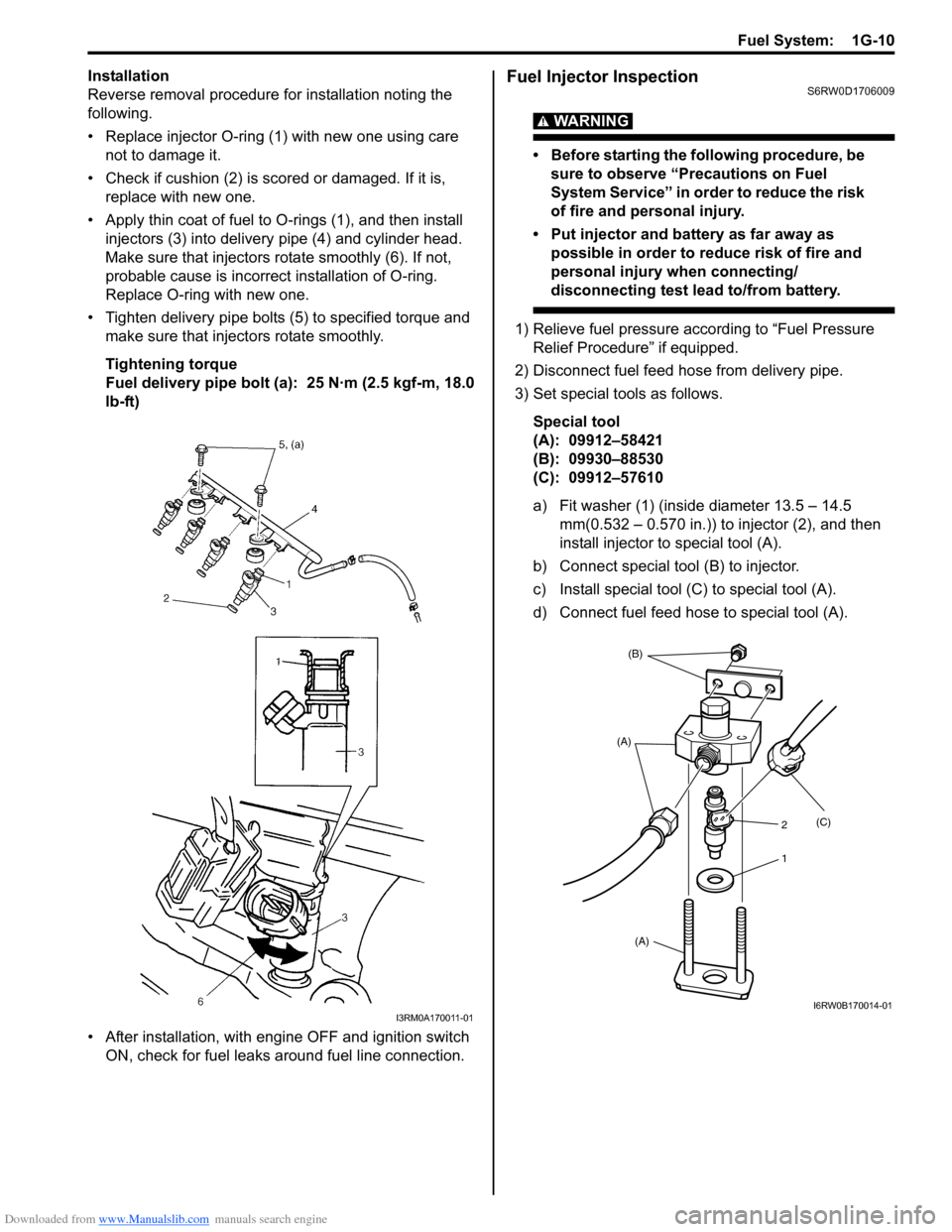

Installation

Reverse removal procedure for installation noting the

following.

• Replace injector O-ring (1) with new one using care

not to damage it.

• Check if cushion (2) is scored or damaged. If it is,

replace with new one.

• Apply thin coat of fuel to O-rings (1), and then install

injectors (3) into delivery pipe (4) and cylinder head.

Make sure that injectors rotate smoothly (6). If not,

probable cause is incorrect installation of O-ring.

Replace O-ring with new one.

• Tighten delivery pipe bolts (5) to specified torque and

make sure that injectors rotate smoothly.

Tightening torque

Fuel delivery pipe bolt (a): 25 N·m (2.5 kgf-m, 18.0

lb-ft)

• After installation, with engine OFF and ignition switch

ON, check for fuel leaks around fuel line connection.Fuel Injector InspectionS6RW0D1706009

WARNING!

• Before starting the following procedure, be

sure to observe “Precautions on Fuel

System Service” in order to reduce the risk

of fire and personal injury.

• Put injector and battery as far away as

possible in order to reduce risk of fire and

personal injury when connecting/

disconnecting test lead to/from battery.

1) Relieve fuel pressure according to “Fuel Pressure

Relief Procedure” if equipped.

2) Disconnect fuel feed hose from delivery pipe.

3) Set special tools as follows.

Special tool

(A): 09912–58421

(B): 09930–88530

(C): 09912–57610

a) Fit washer (1) (inside diameter 13.5 – 14.5

mm(0.532 – 0.570 in.)) to injector (2), and then

install injector to special tool (A).

b) Connect special tool (B) to injector.

c) Install special tool (C) to special tool (A).

d) Connect fuel feed hose to special tool (A).

I3RM0A170011-01

(B)

(A)

(A)(C)

2

1

I6RW0B170014-01

Page 391 of 1556

Downloaded from www.Manualslib.com manuals search engine Fuel System: 1G-14

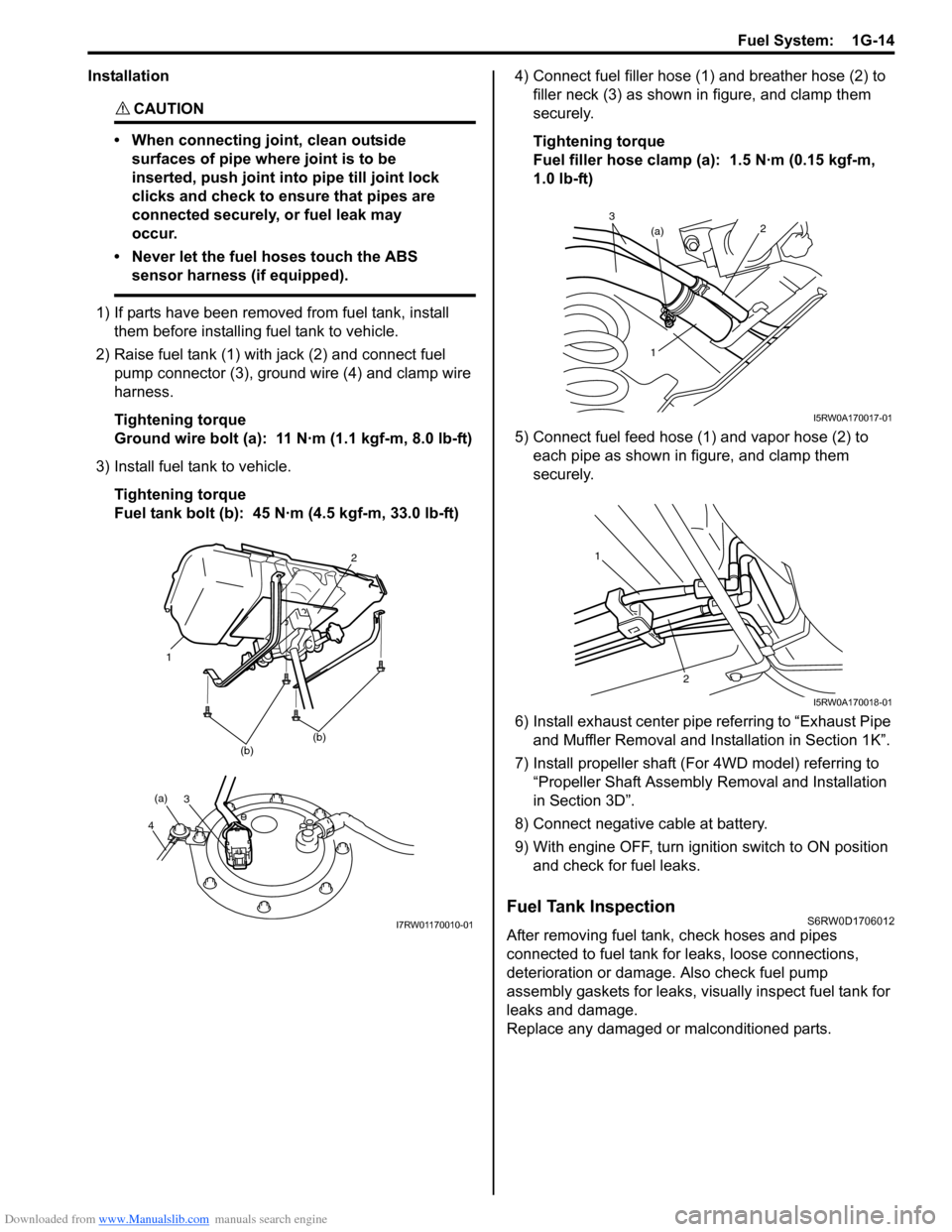

Installation

CAUTION!

• When connecting joint, clean outside

surfaces of pipe where joint is to be

inserted, push joint into pipe till joint lock

clicks and check to ensure that pipes are

connected securely, or fuel leak may

occur.

• Never let the fuel hoses touch the ABS

sensor harness (if equipped).

1) If parts have been removed from fuel tank, install

them before installing fuel tank to vehicle.

2) Raise fuel tank (1) with jack (2) and connect fuel

pump connector (3), ground wire (4) and clamp wire

harness.

Tightening torque

Ground wire bolt (a): 11 N·m (1.1 kgf-m, 8.0 lb-ft)

3) Install fuel tank to vehicle.

Tightening torque

Fuel tank bolt (b): 45 N·m (4.5 kgf-m, 33.0 lb-ft)4) Connect fuel filler hose (1) and breather hose (2) to

filler neck (3) as shown in figure, and clamp them

securely.

Tightening torque

Fuel filler hose clamp (a): 1.5 N·m (0.15 kgf-m,

1.0 lb-ft)

5) Connect fuel feed hose (1) and vapor hose (2) to

each pipe as shown in figure, and clamp them

securely.

6) Install exhaust center pipe referring to “Exhaust Pipe

and Muffler Removal and Installation in Section 1K”.

7) Install propeller shaft (For 4WD model) referring to

“Propeller Shaft Assembly Removal and Installation

in Section 3D”.

8) Connect negative cable at battery.

9) With engine OFF, turn ignition switch to ON position

and check for fuel leaks.

Fuel Tank InspectionS6RW0D1706012

After removing fuel tank, check hoses and pipes

connected to fuel tank for leaks, loose connections,

deterioration or damage. Also check fuel pump

assembly gaskets for leaks, visually inspect fuel tank for

leaks and damage.

Replace any damaged or malconditioned parts.

(b)(b)

1

2

3

4

(a)

I7RW01170010-01

1(a)2

3

I5RW0A170017-01

1

2

I5RW0A170018-01