AIR SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 1405 of 1556

Downloaded from www.Manualslib.com manuals search engine Glass / Windows / Mirrors: 9E-20

4) Touch voltmeter negative (–) lead to defogger wire

ground terminal end (1).

5) Touch voltmeter positive (+) lead with a foil strip to

defogger wire power source terminal end (2), then

move it along wire to defogger wire ground terminal

end (1).

The place where voltmeter fluctuates from 10 – 12 V

to 0 – 1 V is where there is open.

If found defective, repair defogger wire referring to

“Rear End Door Window Defogger Wire Repair”.

Rear End Door Window Defogger Wire RepairS6RW0D9506020

1) Use white gasoline for cleaning.

2) Apply masking tape (1) at both upper and lower

sides of heat wire (2) to be repaired.

3) Apply commercially-available repair agent (3) with a

fine-tip brush (4).

4) 2 to 3 minutes later, remove masking tapes (1).

5) Leave repaired heat wire as it is for at least 24 hours

before operating the defogger again.

Power Window Main Switch InspectionS6RW0D9506021

Switch for Driver Side Window

Without Pinching Prevention Function Model

1) Remove driver side door trim referring to step 1) to

3) of “Front Door Glass Removal and Installation”.

2) Remove power window main switch from door trim.

3) Connect 12 V battery positive (+) terminal to terminal

“IG” of power window main switch and its negative (–

) terminal to terminal “E” of power window main

switch.

4) Check for continuity between terminals as shown

below.

If check result is not as specified, replace power

window main switch.

21

I4RS0A950030-01

I2RH01950005-01

I7RW01950004-01

Page 1414 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-3 Security and Locks:

Diagnostic Information and Procedures

Power Door Lock System Symptom Diagnosis (If Equipped)S6RW0D9604001

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Power Door Lock System Operation Inspection (If Equipped)S6RW0D9604002

1) Check the following operation:

a) Turn the driver side key cylinder is turned LOCK once, check all doors lock.

b) Turn the driver side door key cylinder is turned UNLOCK position with door key twice, check all doors unlock.

c) With all doors unlocked, insert key in key cylinder of driver side door and turn it to lock side, turn it again to lock

side within 3 seconds and check that no door can be opened even when door lock knob is moved to unlock

side (dead lock function, if equipped).

If malfunction is found, go to “Power Door Lock System Symptom Diagnosis (If Equipped)”. Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by all of

switchesCircuit fuse blownReplace fuse and check for short circuit.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only power

door lock switchCircuit fuse blownReplace fuse and check for short circuit.

Power door lock switch faultyCheck power door lock switch referring to

“Power Door Lock Switch Inspection (If

Equipped)”.

Wiring harness connected to power door

lock switch faultyRepair.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

All door can not be locked

/ unlocked by only key

cylinder switchCircuit fuse blownReplace fuse and check for short circuit.

Key cylinder switch faultyCheck key cylinder switch referring to “Door

Key Cylinder Switch Inspection (If Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Only one door can not be

locked / unlockedPower door lock actuator faultyCheck actuator referring to “Power Door Lock

Actuator Inspection (If Equipped)”.

Wiring harness connected to applicable

door lock actuator faultyRepair.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1415 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-4

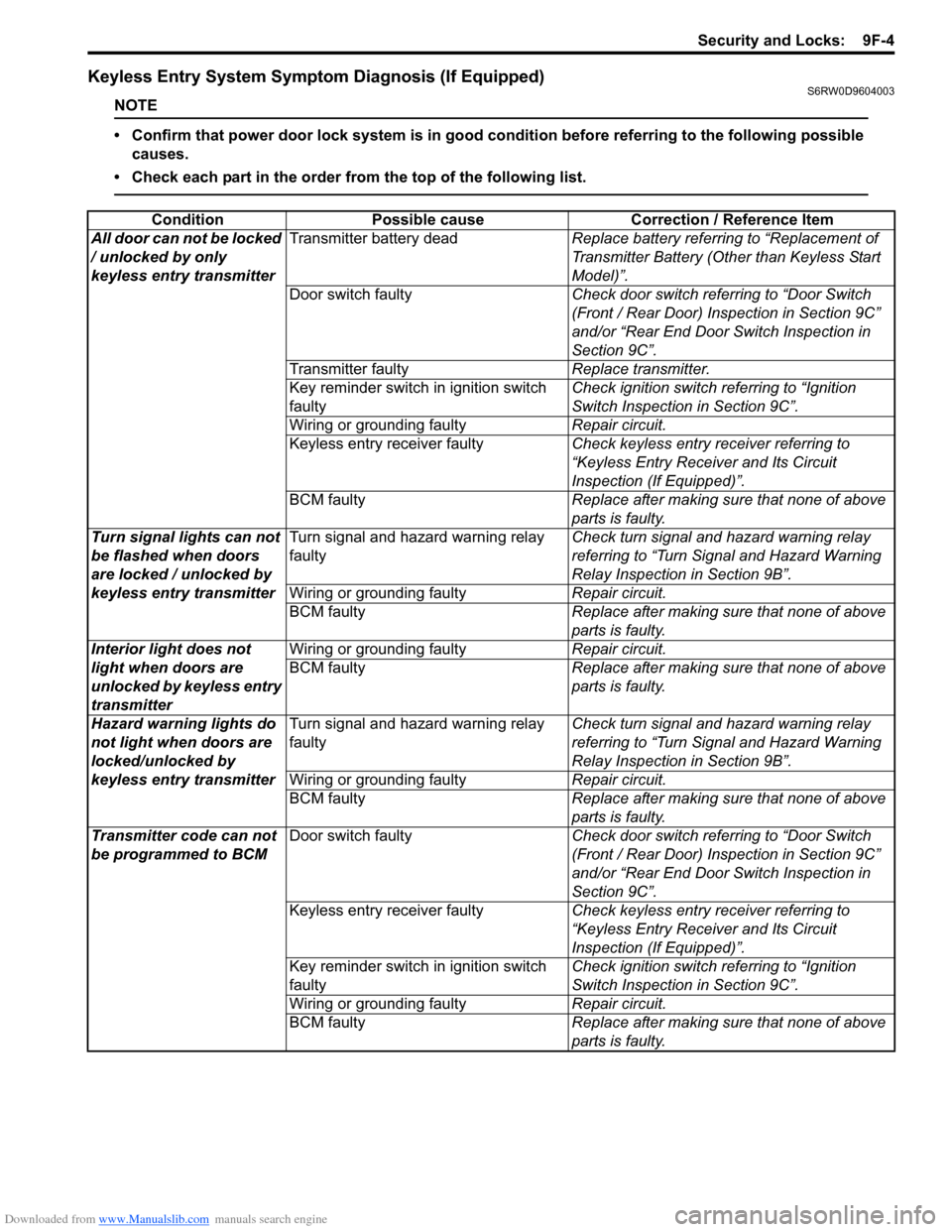

Keyless Entry System Symptom Diagnosis (If Equipped)S6RW0D9604003

NOTE

• Confirm that power door lock system is in good condition before referring to the following possible

causes.

• Check each part in the order from the top of the following list.

Condition Possible cause Correction / Reference Item

All door can not be locked

/ unlocked by only

keyless entry transmitterTransmitter battery deadReplace battery referring to “Replacement of

Transmitter Battery (Other than Keyless Start

Model)”.

Door switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Transmitter faultyReplace transmitter.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

BCM faultyReplace after making sure that none of above

parts is faulty.

Turn signal lights can not

be flashed when doors

are locked / unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Interior light does not

light when doors are

unlocked by keyless entry

transmitterWiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Hazard warning lights do

not light when doors are

locked/unlocked by

keyless entry transmitterTurn signal and hazard warning relay

faultyCheck turn signal and hazard warning relay

referring to “Turn Signal and Hazard Warning

Relay Inspection in Section 9B”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Transmitter code can not

be programmed to BCMDoor switch faultyCheck door switch referring to “Door Switch

(Front / Rear Door) Inspection in Section 9C”

and/or “Rear End Door Switch Inspection in

Section 9C”.

Keyless entry receiver faultyCheck keyless entry receiver referring to

“Keyless Entry Receiver and Its Circuit

Inspection (If Equipped)”.

Key reminder switch in ignition switch

faultyCheck ignition switch referring to “Ignition

Switch Inspection in Section 9C”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1416 of 1556

Downloaded from www.Manualslib.com manuals search engine 9F-5 Security and Locks:

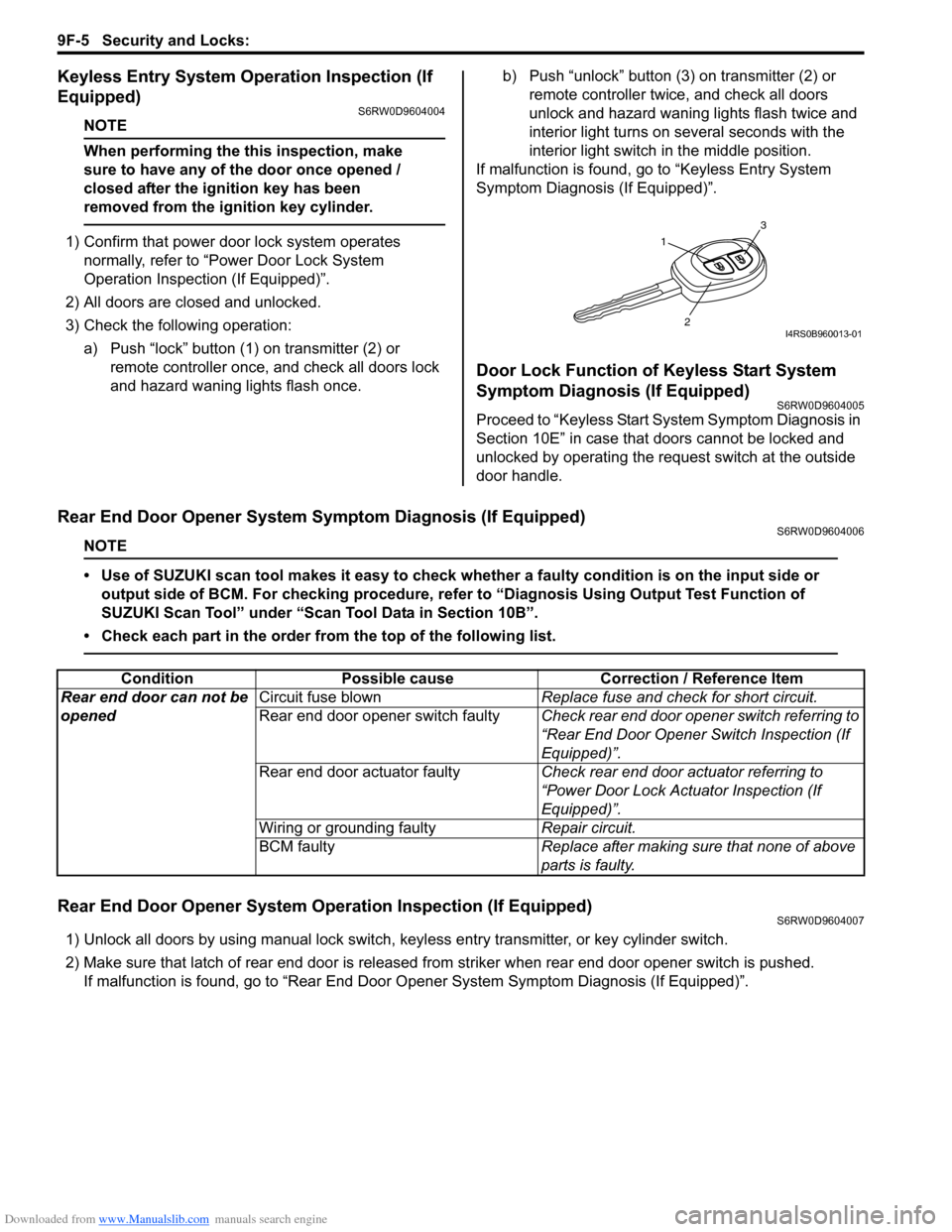

Keyless Entry System Operation Inspection (If

Equipped)

S6RW0D9604004

NOTE

When performing the this inspection, make

sure to have any of the door once opened /

closed after the ignition key has been

removed from the ignition key cylinder.

1) Confirm that power door lock system operates

normally, refer to “Power Door Lock System

Operation Inspection (If Equipped)”.

2) All doors are closed and unlocked.

3) Check the following operation:

a) Push “lock” button (1) on transmitter (2) or

remote controller once, and check all doors lock

and hazard waning lights flash once.b) Push “unlock” button (3) on transmitter (2) or

remote controller twice, and check all doors

unlock and hazard waning lights flash twice and

interior light turns on several seconds with the

interior light switch in the middle position.

If malfunction is found, go to “Keyless Entry System

Symptom Diagnosis (If Equipped)”.

Door Lock Function of Keyless Start System

Symptom Diagnosis (If Equipped)

S6RW0D9604005

Proceed to “Keyless Start System Symptom Diagnosis in

Section 10E” in case that doors cannot be locked and

unlocked by operating the request switch at the outside

door handle.

Rear End Door Opener System Symptom Diagnosis (If Equipped)S6RW0D9604006

NOTE

• Use of SUZUKI scan tool makes it easy to check whether a faulty condition is on the input side or

output side of BCM. For checking procedure, refer to “Diagnosis Using Output Test Function of

SUZUKI Scan Tool” under “Scan Tool Data in Section 10B”.

• Check each part in the order from the top of the following list.

Rear End Door Opener System Operation Inspection (If Equipped)S6RW0D9604007

1) Unlock all doors by using manual lock switch, keyless entry transmitter, or key cylinder switch.

2) Make sure that latch of rear end door is released from striker when rear end door opener switch is pushed.

If malfunction is found, go to “Rear End Door Opener System Symptom Diagnosis (If Equipped)”.

1

3

2I4RS0B960013-01

Condition Possible cause Correction / Reference Item

Rear end door can not be

openedCircuit fuse blownReplace fuse and check for short circuit.

Rear end door opener switch faultyCheck rear end door opener switch referring to

“Rear End Door Opener Switch Inspection (If

Equipped)”.

Rear end door actuator faultyCheck rear end door actuator referring to

“Power Door Lock Actuator Inspection (If

Equipped)”.

Wiring or grounding faultyRepair circuit.

BCM faultyReplace after making sure that none of above

parts is faulty.

Page 1417 of 1556

Downloaded from www.Manualslib.com manuals search engine Security and Locks: 9F-6

Repair Instructions

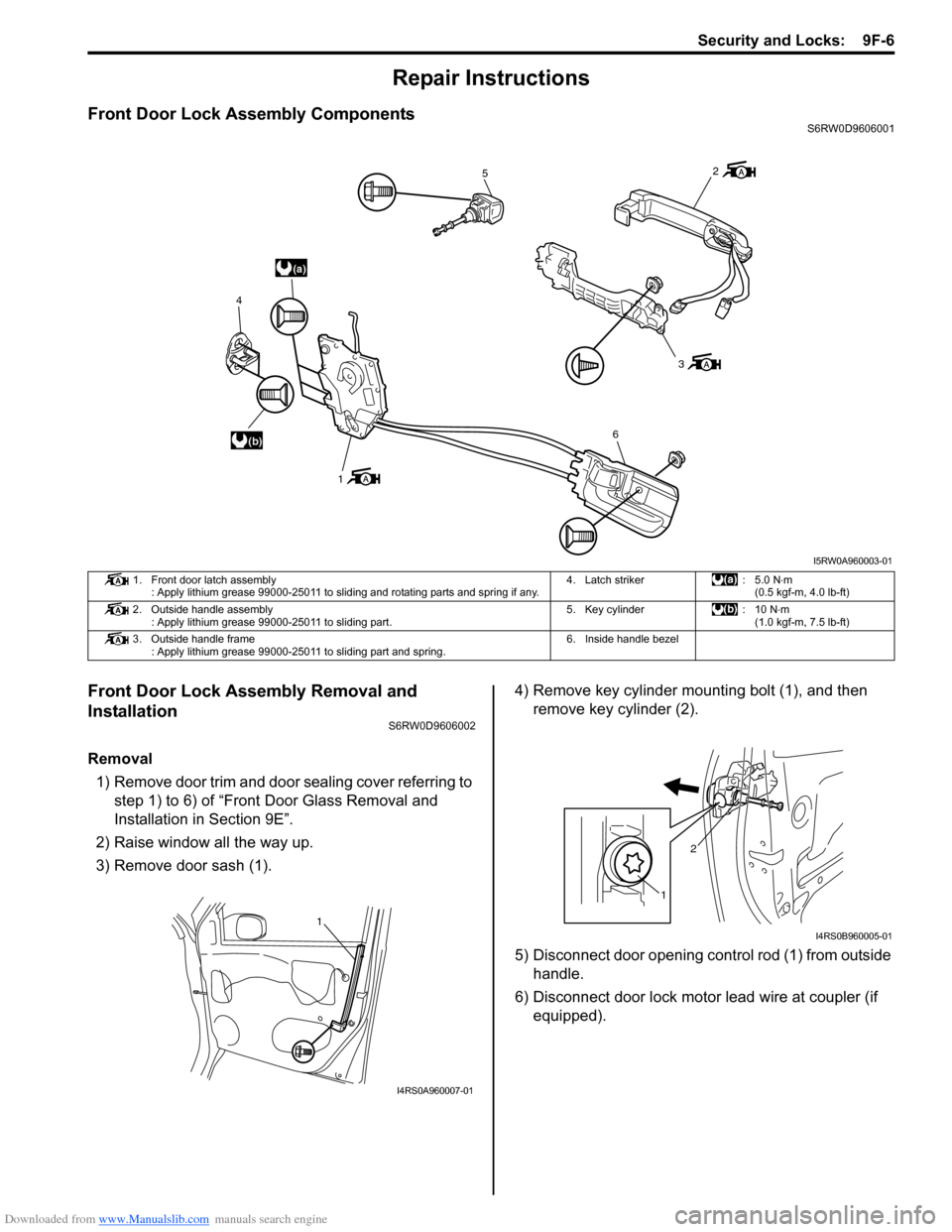

Front Door Lock Assembly ComponentsS6RW0D9606001

Front Door Lock Assembly Removal and

Installation

S6RW0D9606002

Removal

1) Remove door trim and door sealing cover referring to

step 1) to 6) of “Front Door Glass Removal and

Installation in Section 9E”.

2) Raise window all the way up.

3) Remove door sash (1).4) Remove key cylinder mounting bolt (1), and then

remove key cylinder (2).

5) Disconnect door opening control rod (1) from outside

handle.

6) Disconnect door lock motor lead wire at coupler (if

equipped).

(a)

(b)

5

3

6

1 4

2

I5RW0A960003-01

1. Front door latch assembly

: Apply lithium grease 99000-25011 to sliding and rotating parts and spring if any.4. Latch striker : 5.0 N⋅m

(0.5 kgf-m, 4.0 lb-ft)

2. Outside handle assembly

: Apply lithium grease 99000-25011 to sliding part.5. Key cylinder : 10 N⋅m

(1.0 kgf-m, 7.5 lb-ft)

3. Outside handle frame

: Apply lithium grease 99000-25011 to sliding part and spring.6. Inside handle bezel

1

I4RS0A960007-01

12

I4RS0B960005-01

Page 1428 of 1556

Downloaded from www.Manualslib.com manuals search engine 9G-1 Seats:

Body, Cab and Accessories

Seats

Diagnostic Information and Procedures

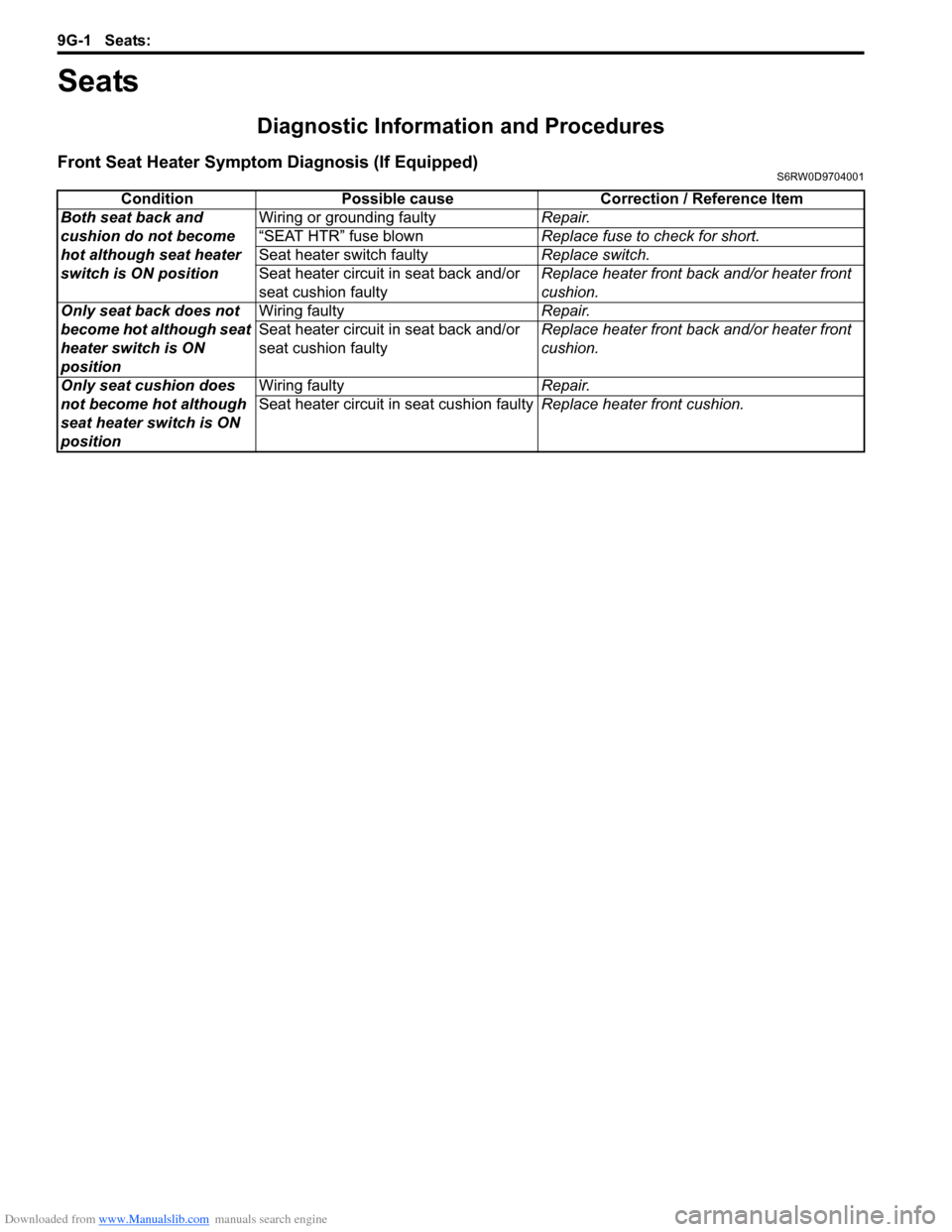

Front Seat Heater Symptom Diagnosis (If Equipped)S6RW0D9704001

Condition Possible cause Correction / Reference Item

Both seat back and

cushion do not become

hot although seat heater

switch is ON positionWiring or grounding faultyRepair.

“SEAT HTR” fuse blownReplace fuse to check for short.

Seat heater switch faultyReplace switch.

Seat heater circuit in seat back and/or

seat cushion faultyReplace heater front back and/or heater front

cushion.

Only seat back does not

become hot although seat

heater switch is ON

positionWiring faultyRepair.

Seat heater circuit in seat back and/or

seat cushion faultyReplace heater front back and/or heater front

cushion.

Only seat cushion does

not become hot although

seat heater switch is ON

positionWiring faultyRepair.

Seat heater circuit in seat cushion faultyReplace heater front cushion.

Page 1429 of 1556

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-2

Repair Instructions

Front Seat ComponentsS6RW0D9706001

3

2

8

7

a

c

4

d

b

1

5

5

4

6

64

a

b

c

d

(b)

(b)

(b)

(b)

(a)

(a)

(a)

(a)

A

A

A

(b)

(c)

BA

A

A

B

A

B

I6RW0C970001-01

1. Seat cushion7. Side air bag module (if equipped)

2. Seat back

: Apply lithium grease 99000-25011 to sliding part of reclining.8. Side air bag harness (if equipped)

3. Headrest: 23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

4. Cover: 35 N⋅m (3.5 kgf-m, 25.5 lb-ft)

5. Seat adjuster

: Apply lithium grease 99000-25011 to seat adjuster inside.: 28 N⋅m (2.8 kgf-m, 20.5 lb-ft) (Seat lifter type)

35 N⋅m (3.5 kgf-m, 25.5 lb-ft) (Non seat lifter type)

6. Knoba, b, c, d: Seat back mounting bolt

Seat mounting bolt

Tightening order: a → b → c → d

Page 1430 of 1556

Downloaded from www.Manualslib.com manuals search engine 9G-3 Seats:

Front Seat Removal and InstallationS6RW0D9706002

Removal

1) Disable air bag system referring to “Disabling Air

Bag System in Section 8B”.

2) Disconnect seat harness coupler and side air bag

coupler, if equipped.

3) Remove 4 mounting bolts to remove seat assembly.

4) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install front seat.

• Torque to specifications as shown in “Front Seat

Components”.

• Enable air bag system referring to “Enabling Air Bag

System in Section 8B”.

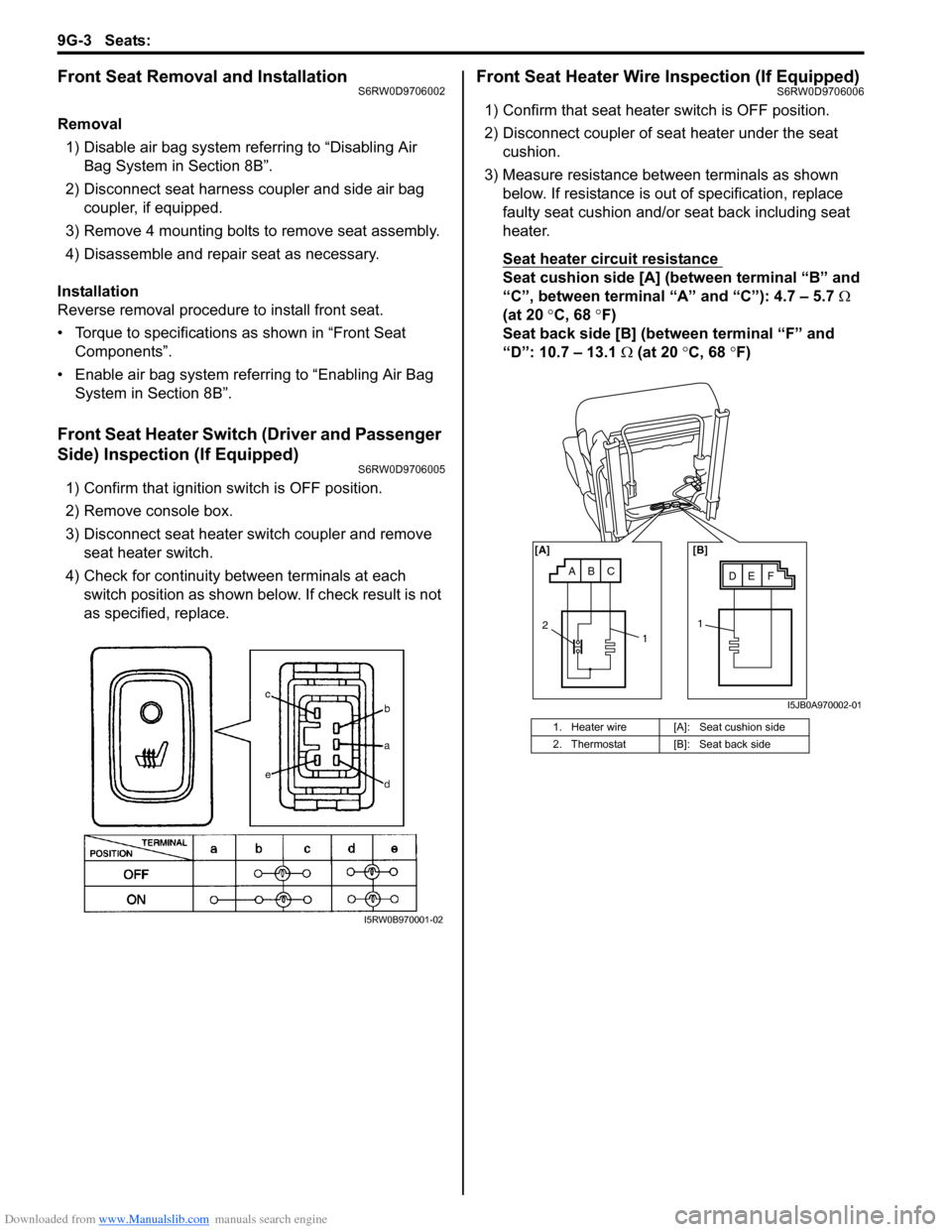

Front Seat Heater Switch (Driver and Passenger

Side) Inspection (If Equipped)

S6RW0D9706005

1) Confirm that ignition switch is OFF position.

2) Remove console box.

3) Disconnect seat heater switch coupler and remove

seat heater switch.

4) Check for continuity between terminals at each

switch position as shown below. If check result is not

as specified, replace.

Front Seat Heater Wire Inspection (If Equipped)S6RW0D9706006

1) Confirm that seat heater switch is OFF position.

2) Disconnect coupler of seat heater under the seat

cushion.

3) Measure resistance between terminals as shown

below. If resistance is out of specification, replace

faulty seat cushion and/or seat back including seat

heater.

Seat heater circuit resistance

Seat cushion side [A] (between terminal “B” and

“C”, between terminal “A” and “C”): 4.7 – 5.7 Ω

(at 20 °C, 68 °F)

Seat back side [B] (between terminal “F” and

“D”: 10.7 – 13.1 Ω (at 20 °C, 68 °F)

I5RW0B970001-02

1. Heater wire [A]: Seat cushion side

2. Thermostat [B]: Seat back side

ABCDE F [A] [B]

11

2

I5JB0A970002-01

Page 1431 of 1556

Downloaded from www.Manualslib.com manuals search engine Seats: 9G-4

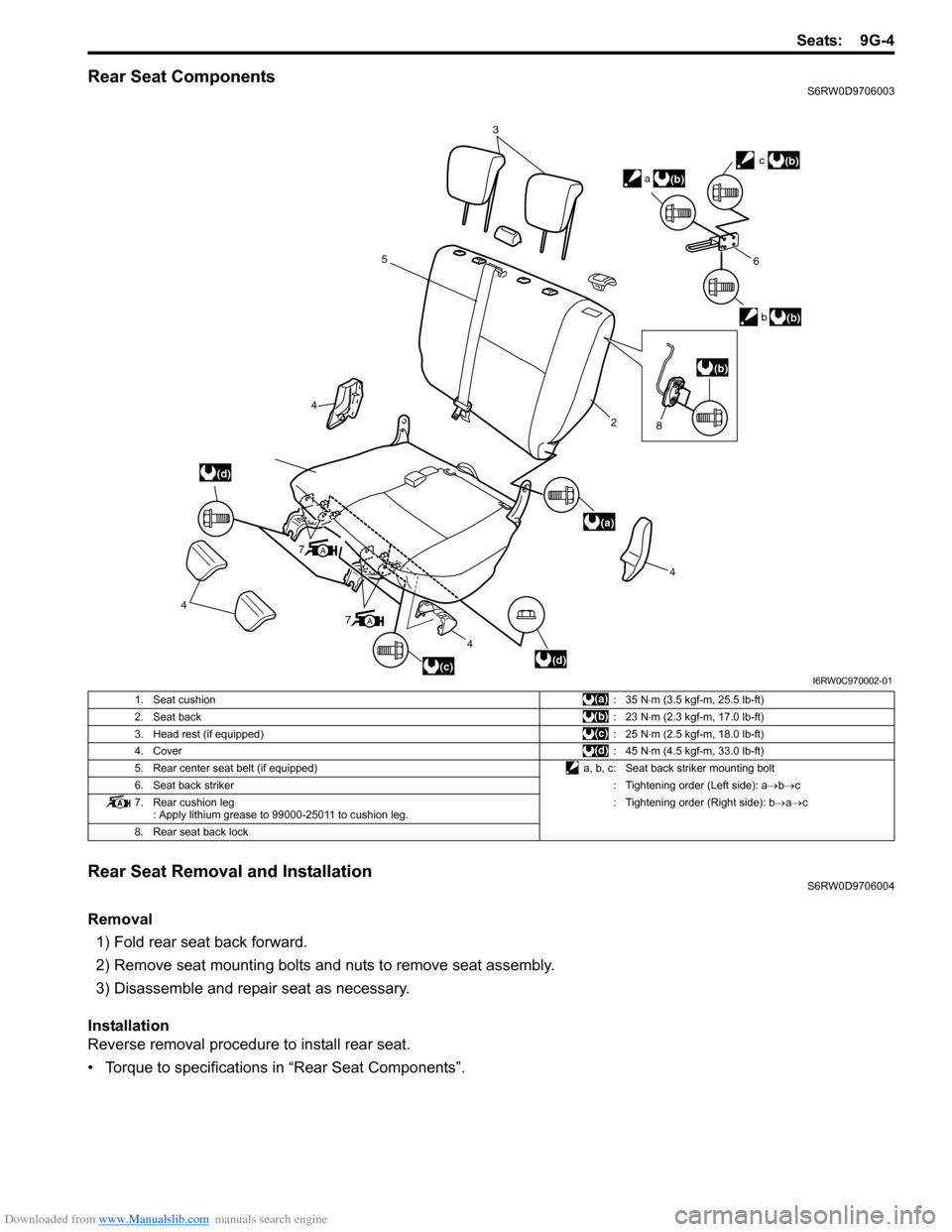

Rear Seat ComponentsS6RW0D9706003

Rear Seat Removal and InstallationS6RW0D9706004

Removal

1) Fold rear seat back forward.

2) Remove seat mounting bolts and nuts to remove seat assembly.

3) Disassemble and repair seat as necessary.

Installation

Reverse removal procedure to install rear seat.

• Torque to specifications in “Rear Seat Components”.

3

5

4

4

4

7

4

2

6

b

c

a

(d)

(a)

(d)

(b)

(b)

(b)

(c)

A

7A

(b)

8

I6RW0C970002-01

1. Seat cushion:35 N⋅m (3.5 kgf-m, 25.5 lb-ft)

2. Seat back:23 N⋅m (2.3 kgf-m, 17.0 lb-ft)

3. Head rest (if equipped):25 N⋅m (2.5 kgf-m, 18.0 lb-ft)

4. Cover:45 N⋅m (4.5 kgf-m, 33.0 lb-ft)

5. Rear center seat belt (if equipped) a, b, c: Seat back striker mounting bolt

6. Seat back striker: Tightening order (Left side): a→b→c

7. Rear cushion leg

: Apply lithium grease to 99000-25011 to cushion leg.: Tightening order (Right side): b→a→c

8. Rear seat back lock

Page 1433 of 1556

Downloaded from www.Manualslib.com manuals search engine Interior Trim: 9H-1

Body, Cab and Accessories

Interior Trim

Repair Instructions

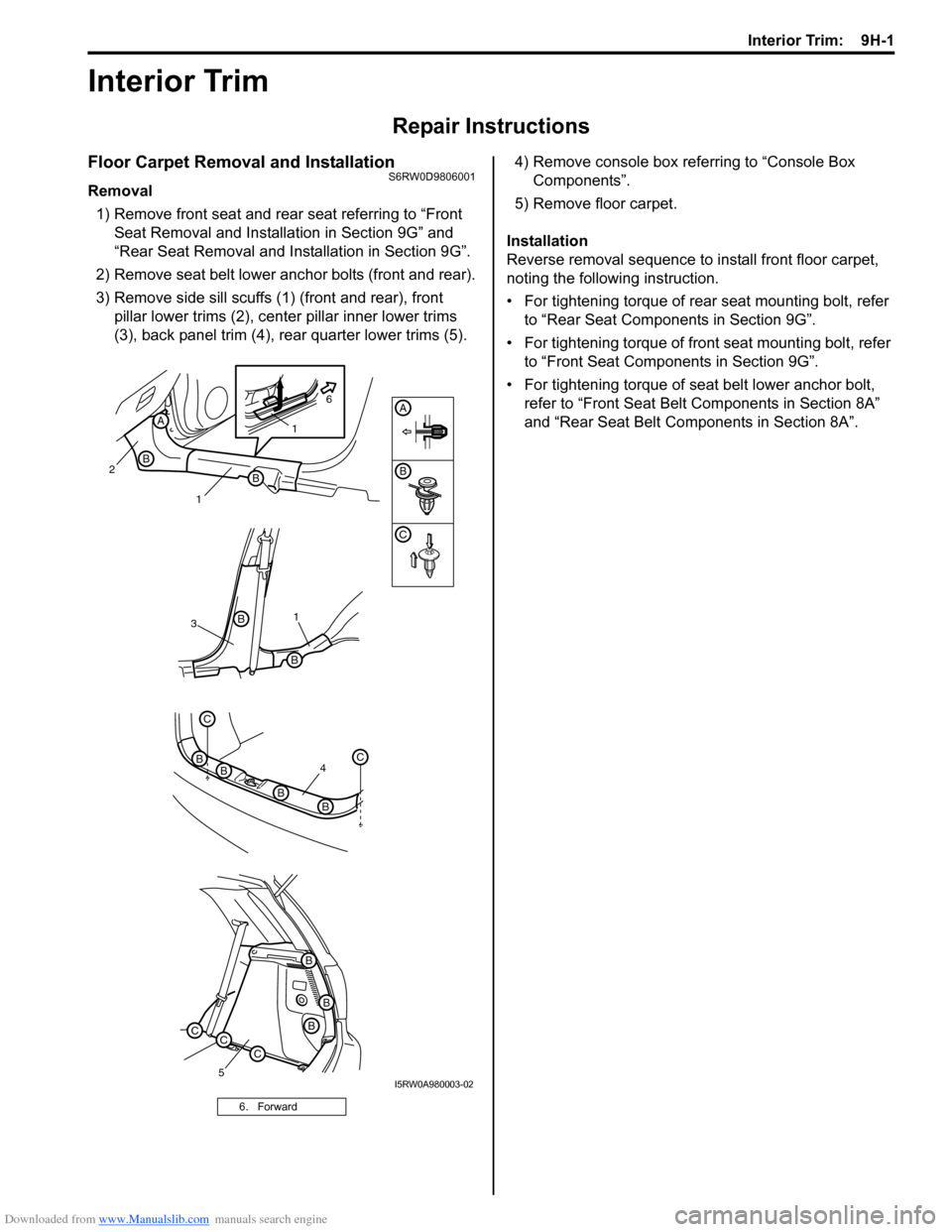

Floor Carpet Removal and InstallationS6RW0D9806001

Removal

1) Remove front seat and rear seat referring to “Front

Seat Removal and Installation in Section 9G” and

“Rear Seat Removal and Installation in Section 9G”.

2) Remove seat belt lower anchor bolts (front and rear).

3) Remove side sill scuffs (1) (front and rear), front

pillar lower trims (2), center pillar inner lower trims

(3), back panel trim (4), rear quarter lower trims (5).4) Remove console box referring to “Console Box

Components”.

5) Remove floor carpet.

Installation

Reverse removal sequence to install front floor carpet,

noting the following instruction.

• For tightening torque of rear seat mounting bolt, refer

to “Rear Seat Components in Section 9G”.

• For tightening torque of front seat mounting bolt, refer

to “Front Seat Components in Section 9G”.

• For tightening torque of seat belt lower anchor bolt,

refer to “Front Seat Belt Components in Section 8A”

and “Rear Seat Belt Components in Section 8A”.

6. Forward

B

C

A

4

C

BC

BB

B

31

B

B

5

B

B

B

CCC

2

1B

B

A1

6

I5RW0A980003-02