fuse box SUZUKI SX4 2006 1.G Service Repair Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 745 of 1556

Downloaded from www.Manualslib.com manuals search engine Automatic Transmission/Transaxle: 5A-97

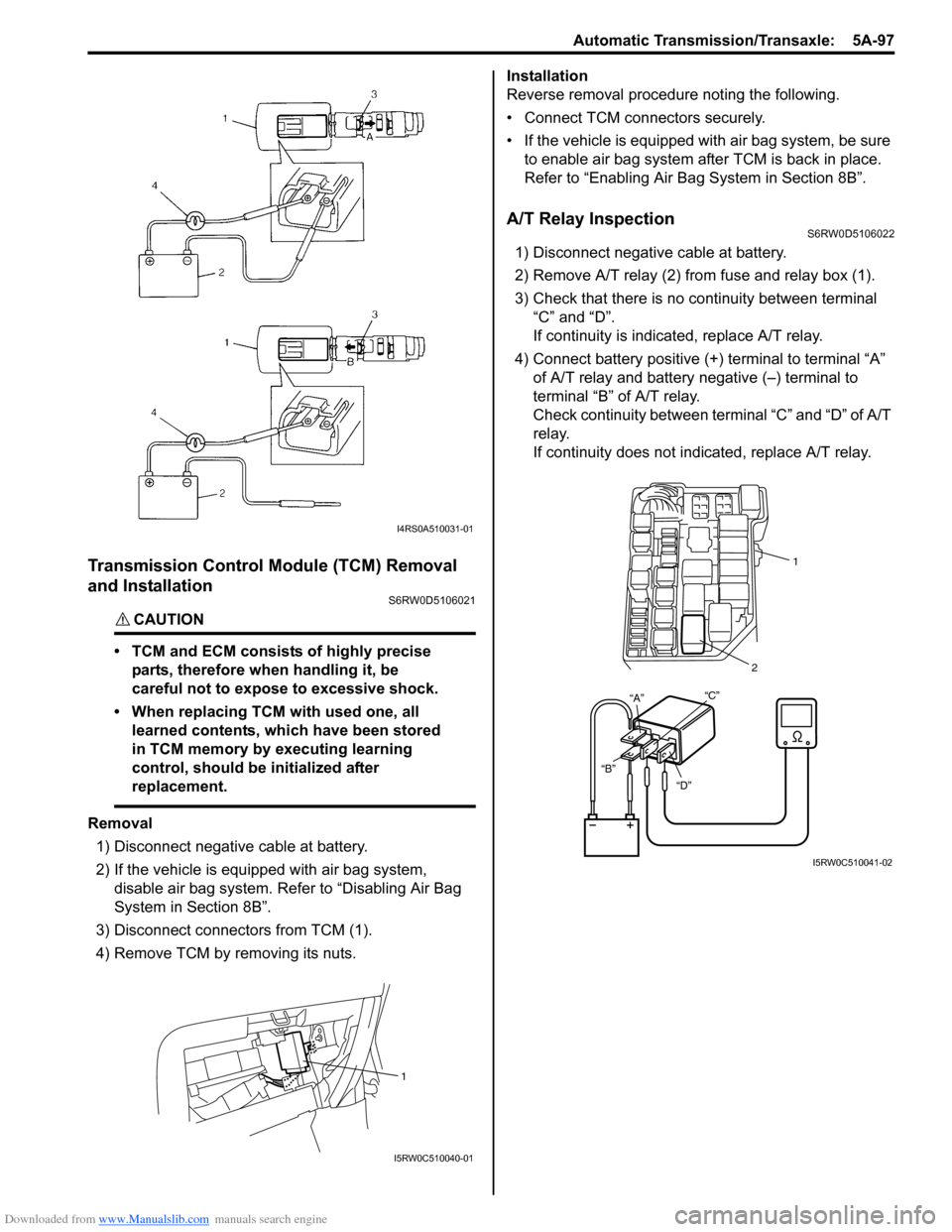

Transmission Control Module (TCM) Removal

and Installation

S6RW0D5106021

CAUTION!

• TCM and ECM consists of highly precise

parts, therefore when handling it, be

careful not to expose to excessive shock.

• When replacing TCM with used one, all

learned contents, which have been stored

in TCM memory by executing learning

control, should be initialized after

replacement.

Removal

1) Disconnect negative cable at battery.

2) If the vehicle is equipped with air bag system,

disable air bag system. Refer to “Disabling Air Bag

System in Section 8B”.

3) Disconnect connectors from TCM (1).

4) Remove TCM by removing its nuts.Installation

Reverse removal procedure noting the following.

• Connect TCM connectors securely.

• If the vehicle is equipped with air bag system, be sure

to enable air bag system after TCM is back in place.

Refer to “Enabling Air Bag System in Section 8B”.

A/T Relay InspectionS6RW0D5106022

1) Disconnect negative cable at battery.

2) Remove A/T relay (2) from fuse and relay box (1).

3) Check that there is no continuity between terminal

“C” and “D”.

If continuity is indicated, replace A/T relay.

4) Connect battery positive (+) terminal to terminal “A”

of A/T relay and battery negative (–) terminal to

terminal “B” of A/T relay.

Check continuity between terminal “C” and “D” of A/T

relay.

If continuity does not indicated, replace A/T relay.

I4RS0A510031-01

1

I5RW0C510040-01

“D” “B”“C”21

“A”

I5RW0C510041-02

Page 884 of 1556

![SUZUKI SX4 2006 1.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11 SUZUKI SX4 2006 1.G Service Repair Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11](/img/20/7612/w960_7612-883.png)

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11

10 12 13

141516

17 18 19201

2

[B]

1

2

[C] [D]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[F][E]

12

BRN RED/

BLU GRY LT GRN/

BLK

BLK

RED

WHT GRN

BLK

E11-1

E11-5

E11-14

E11-12

[J]:E01-44E01-4

[J]:E01-27E01-26

E12-1

E12-2

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

G241-25G241-31

RED/BLK

11

12

1314 3 18

20

21

7 19

4 12

22

12V

E13-2BLK

9V

REDE11-20

12V

12V

E61-2

E61-1

610

55

5V

8

E11-115V

PPL

E11-4

9

23

+BB

BLU/

WHTE04-9

1524YELE11-18E31-5

E31-2

E31-39V

3V

E31-4

E31-1IG11617

C07-25

[H]

[G]

G04-15

[I]:G04-22

25L313-3

[I]

I6RW0D630001-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 15. BCM

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 16. Output shaft speed sensor

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 5. Front (left/right) wheel speed sensor 17. TCM

[D]: Combination meter connector “G241” (viewed from harness side) 6. ABS control module 18. Individual circuit fuse box No.1

[E]: Torque sensor connector “E31” (viewed from harness side) 7. Combination meter 19. “IGN” fuse

[F]: Motor connector “E61” (viewed from harness side) 8. “EPS” warning light 20. “P/S” fuse

[G]: M/T model 9. Data link connector (DLC) 21. “IG1 SIG” fuse

[H]: A/T model 10. ECM 22. “MTR” fuse

[I]: Junction block without BCM model (Taiwan model) 11. P/S control module 23. To ABS control module

[J]: M15A engine with 4A/T equipped with slip control model (Hong Kong

model)12. P/S motor 24. To HVAC control module

1. Main fuse box 13. Shield 25. To SDM

2. Ignition switch 14. Torque sensor (built into steering gear case)

Page 894 of 1556

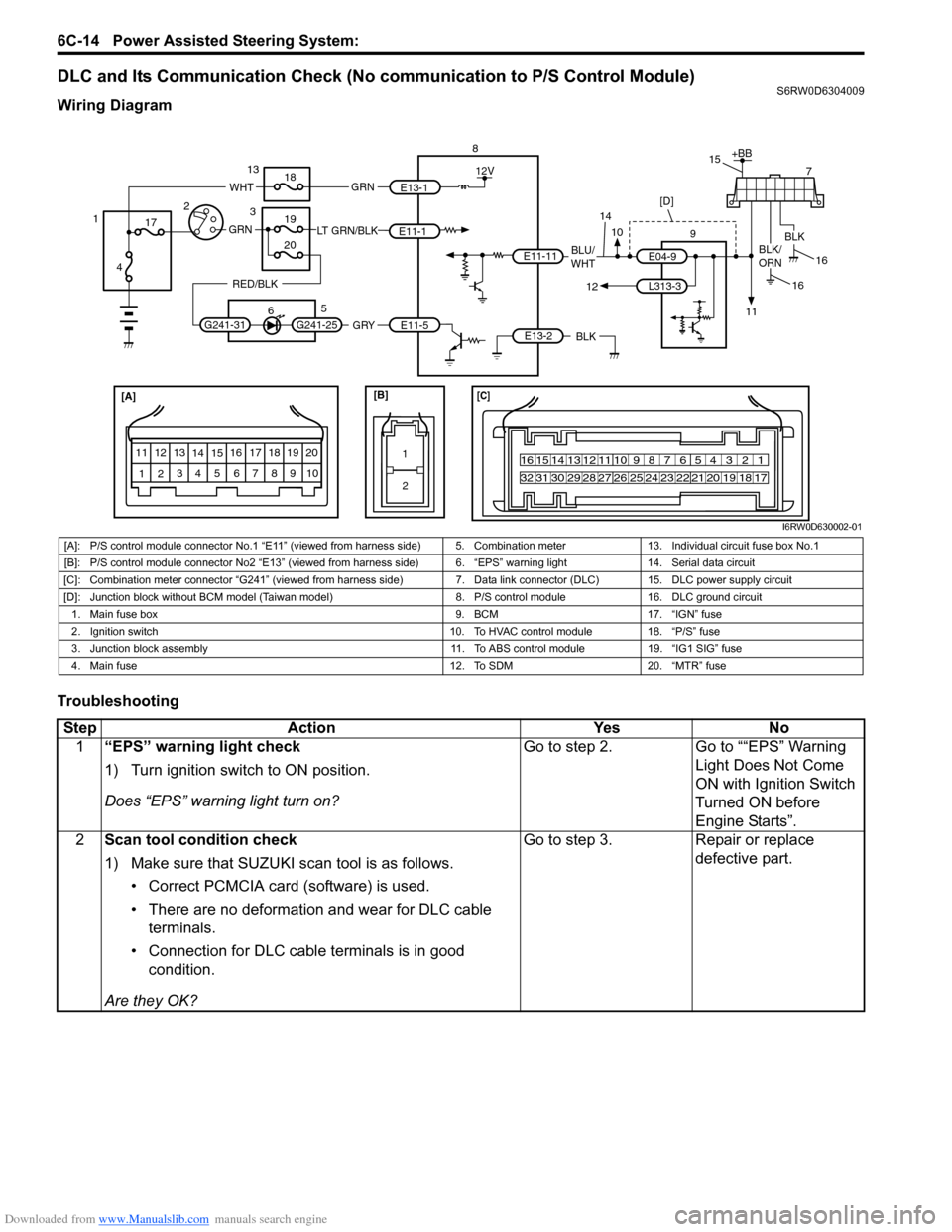

Downloaded from www.Manualslib.com manuals search engine 6C-14 Power Assisted Steering System:

DLC and Its Communication Check (No communication to P/S Control Module)S6RW0D6304009

Wiring Diagram

Troubleshooting

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

LT GRN/BLKE11-1

E11-11

E13-1 GRN

GRN

WHT

8

13

318

19

20

5

6 17

4

12

712V

E13-2BLK

9

G241-31

+BB

BLU/

WHTE04-9

10

11

RED/BLK

G241-25E11-5GRY

L313-312

BLKBLK/

ORN

16

16

15

14[D]

I6RW0D630002-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 5. Combination meter 13. Individual circuit fuse box No.1

[B]: P/S control module connector No2 “E13” (viewed from harness side) 6. “EPS” warning light 14. Serial data circuit

[C]: Combination meter connector “G241” (viewed from harness side) 7. Data link connector (DLC) 15. DLC power supply circuit

[D]: Junction block without BCM model (Taiwan model) 8. P/S control module 16. DLC ground circuit

1. Main fuse box 9. BCM 17. “IGN” fuse

2. Ignition switch 10. To HVAC control module 18. “P/S” fuse

3. Junction block assembly 11. To ABS control module 19. “IG1 SIG” fuse

4. Main fuse 12. To SDM 20. “MTR” fuse

Step Action Yes No

1“EPS” warning light check

1) Turn ignition switch to ON position.

Does “EPS” warning light turn on?Go to step 2. Go to ““EPS” Warning

Light Does Not Come

ON with Ignition Switch

Turned ON before

Engine Starts”.

2Scan tool condition check

1) Make sure that SUZUKI scan tool is as follows.

• Correct PCMCIA card (software) is used.

• There are no deformation and wear for DLC cable

terminals.

• Connection for DLC cable terminals is in good

condition.

Are they OK?Go to step 3. Repair or replace

defective part.

Page 896 of 1556

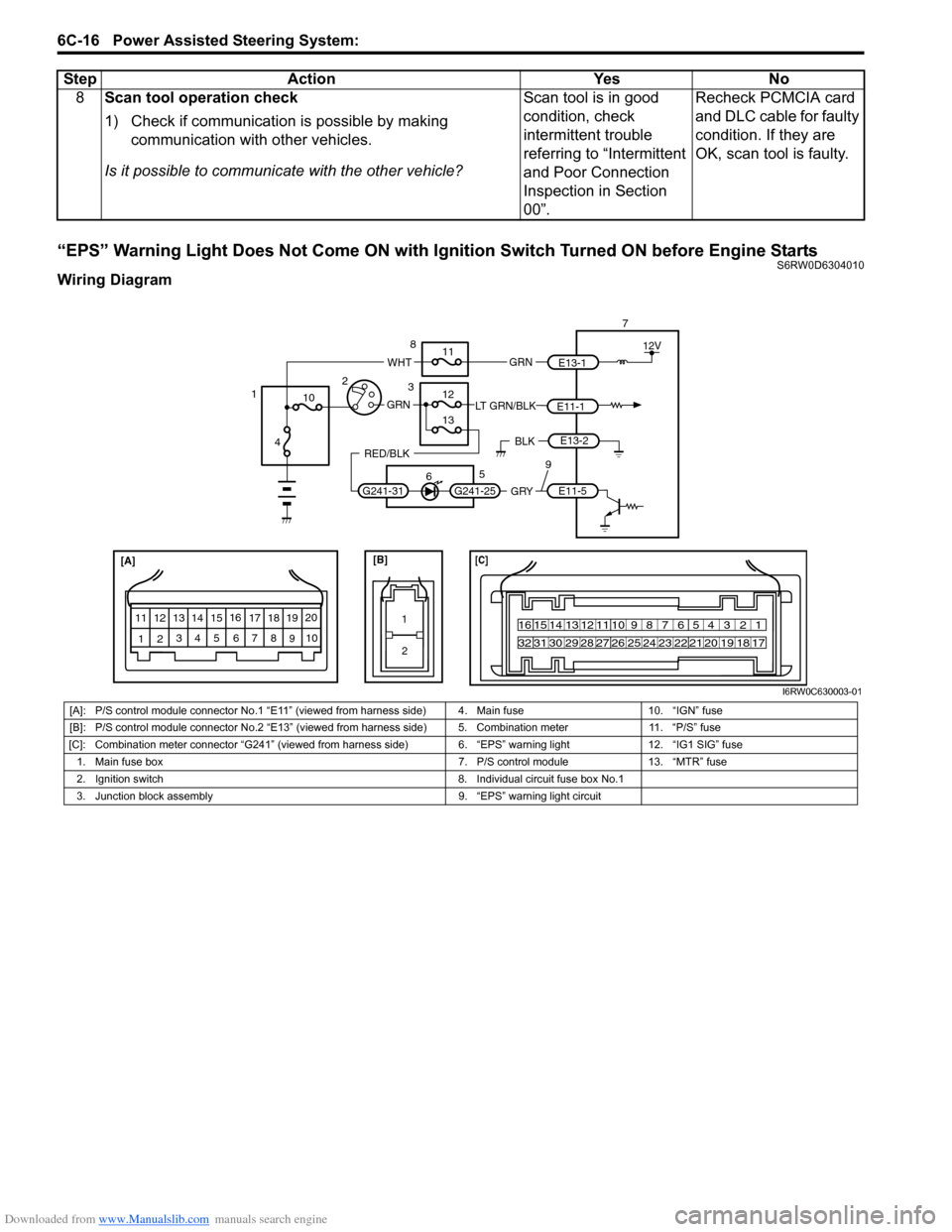

Downloaded from www.Manualslib.com manuals search engine 6C-16 Power Assisted Steering System:

“EPS” Warning Light Does Not Come ON with Ignition Switch Turned ON before Engine StartsS6RW0D6304010

Wiring Diagram8Scan tool operation check

1) Check if communication is possible by making

communication with other vehicles.

Is it possible to communicate with the other vehicle?Scan tool is in good

condition, check

intermittent trouble

referring to “Intermittent

and Poor Connection

Inspection in Section

00”.Recheck PCMCIA card

and DLC cable for faulty

condition. If they are

OK, scan tool is faulty. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[C]

LT GRN/BLKE11-1E13-1 GRNGRN

WHT

7

8

311

12

13

5

6 10

4 12

12V

E13-2BLK

G241-31

RED/BLK

G241-25E11-5GRY

9

I6RW0C630003-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 4. Main fuse 10. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 5. Combination meter 11. “P/S” fuse

[C]: Combination meter connector “G241” (viewed from harness side) 6. “EPS” warning light 12. “IG1 SIG” fuse

1. Main fuse box 7. P/S control module 13. “MTR” fuse

2. Ignition switch 8. Individual circuit fuse box No.1

3. Junction block assembly 9. “EPS” warning light circuit

Page 899 of 1556

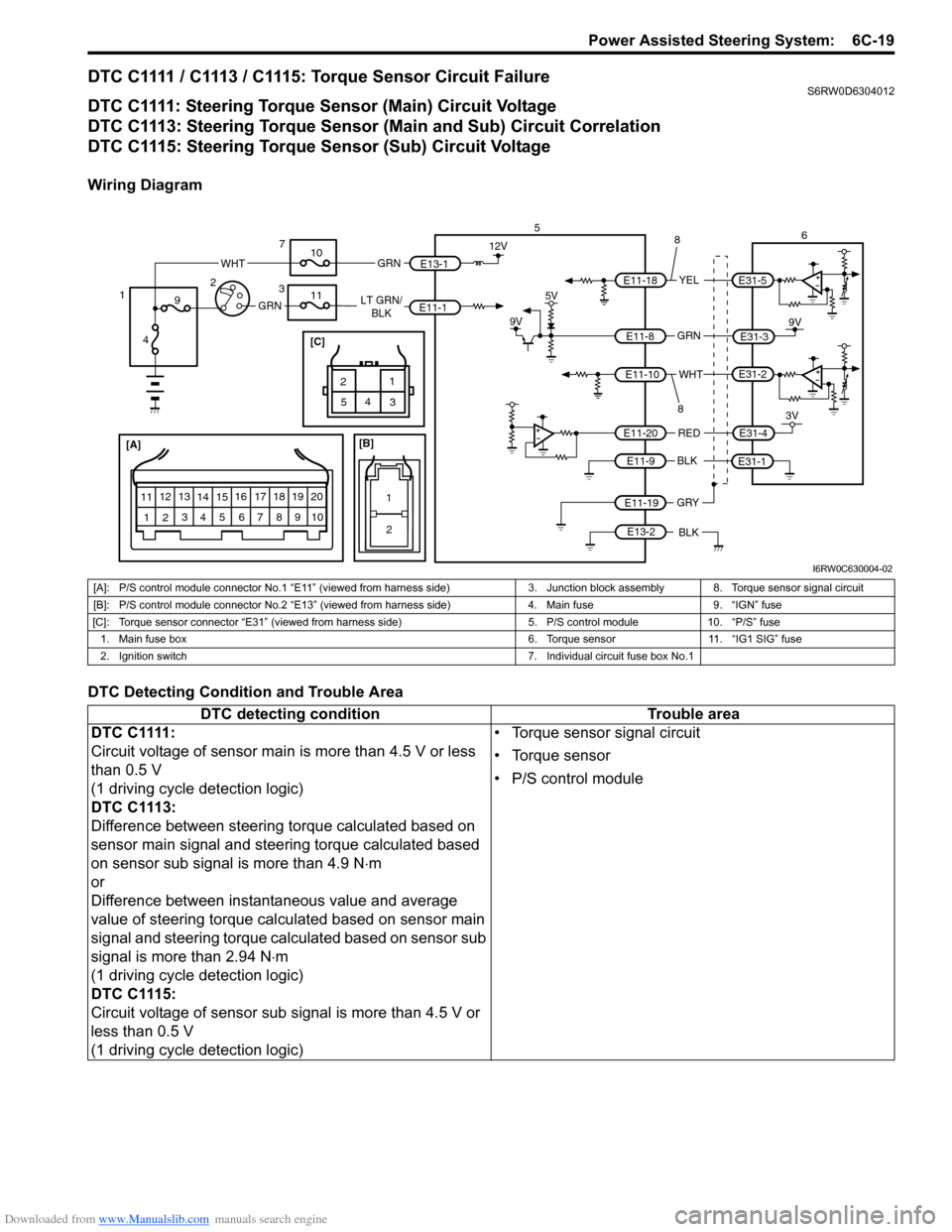

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-19

DTC C1111 / C1113 / C1115: Torque Sensor Circuit FailureS6RW0D6304012

DTC C1111: Steering Torque Sensor (Main) Circuit Voltage

DTC C1113: Steering Torque Sensor (Main and Sub) Circuit Correlation

DTC C1115: Steering Torque Sensor (Sub) Circuit Voltage

Wiring Diagram

DTC Detecting Condition and Trouble Area

[A]

123

453 21

4

5

67

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

[C]

LT GRN/

BLK

WHT GRN

BLK

E11-1

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

5

6

37

10

11

9

4 12

12V

E13-2BLK

9V

REDE11-20

5VYELE11-18E31-5

E31-2

E31-39V

E31-43V

E31-1

8

8

I6RW0C630004-02

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 8. Torque sensor signal circuit

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 9. “IGN” fuse

[C]: Torque sensor connector “E31” (viewed from harness side) 5. P/S control module 10. “P/S” fuse

1. Main fuse box 6. Torque sensor 11. “IG1 SIG” fuse

2. Ignition switch 7. Individual circuit fuse box No.1

DTC detecting condition Trouble area

DTC C1111:

Circuit voltage of sensor main is more than 4.5 V or less

than 0.5 V

(1 driving cycle detection logic)

DTC C1113:

Difference between steering torque calculated based on

sensor main signal and steering torque calculated based

on sensor sub signal is more than 4.9 N⋅m

or

Difference between instantaneous value and average

value of steering torque calculated based on sensor main

signal and steering torque calculated based on sensor sub

signal is more than 2.94 N⋅m

(1 driving cycle detection logic)

DTC C1115:

Circuit voltage of sensor sub signal is more than 4.5 V or

less than 0.5 V

(1 driving cycle detection logic)• Torque sensor signal circuit

• Torque sensor

• P/S control module

Page 901 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-21

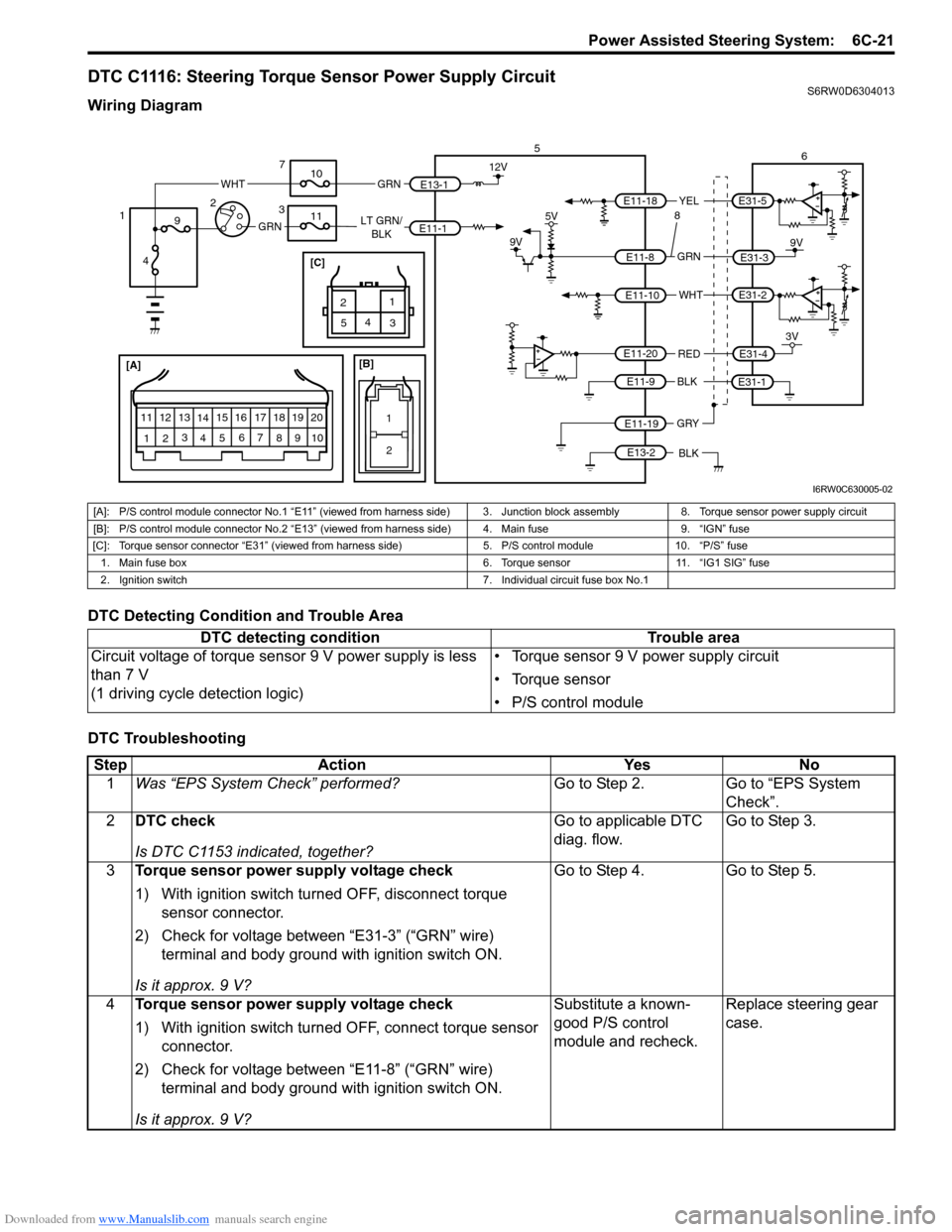

DTC C1116: Steering Torque Sensor Power Supply CircuitS6RW0D6304013

Wiring Diagram

DTC Detecting Condition and Trouble Area

DTC Troubleshooting

[A]

123

453 21

4

5

67

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

[C]

LT GRN/

BLK

WHT GRN

BLK

E11-1

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

5

6

37

10

11

9

4 12

12V

E13-2BLK

9V

REDE11-20

5VYELE11-18E31-5

E31-2

E31-39V

E31-43V

E31-1

8

I6RW0C630005-02

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 8. Torque sensor power supply circuit

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 9. “IGN” fuse

[C]: Torque sensor connector “E31” (viewed from harness side) 5. P/S control module 10. “P/S” fuse

1. Main fuse box 6. Torque sensor 11. “IG1 SIG” fuse

2. Ignition switch 7. Individual circuit fuse box No.1

DTC detecting condition Trouble area

Circuit voltage of torque sensor 9 V power supply is less

than 7 V

(1 driving cycle detection logic)• Torque sensor 9 V power supply circuit

• Torque sensor

• P/S control module

Step Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2DTC check

Is DTC C1153 indicated, together?Go to applicable DTC

diag. flow.Go to Step 3.

3Torque sensor power supply voltage check

1) With ignition switch turned OFF, disconnect torque

sensor connector.

2) Check for voltage between “E31-3” (“GRN” wire)

terminal and body ground with ignition switch ON.

Is it approx. 9 V?Go to Step 4. Go to Step 5.

4Torque sensor power supply voltage check

1) With ignition switch turned OFF, connect torque sensor

connector.

2) Check for voltage between “E11-8” (“GRN” wire)

terminal and body ground with ignition switch ON.

Is it approx. 9 V?Substitute a known-

good P/S control

module and recheck.Replace steering gear

case.

Page 902 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-22 Power Assisted Steering System:

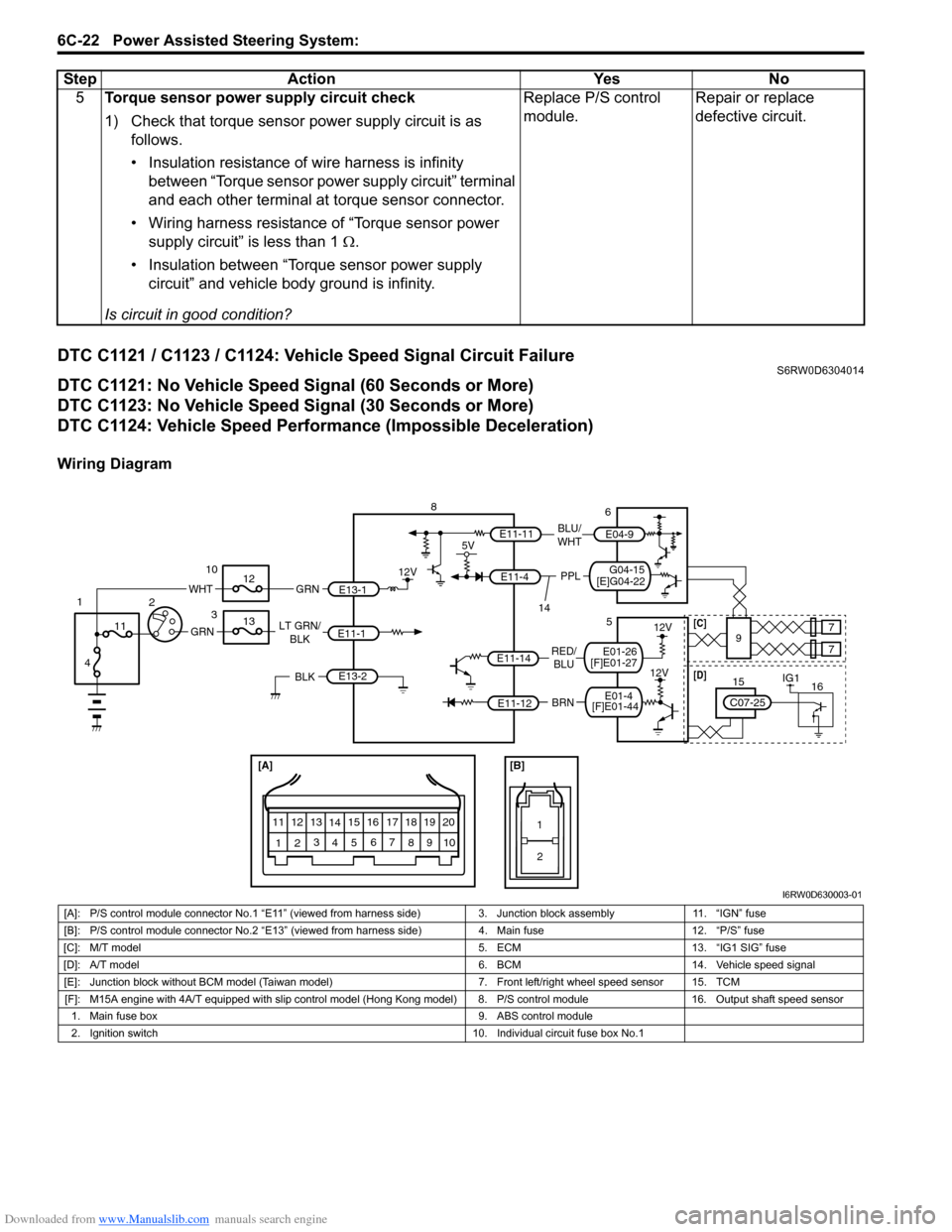

DTC C1121 / C1123 / C1124: Vehicle Speed Signal Circuit FailureS6RW0D6304014

DTC C1121: No Vehicle Speed Signal (60 Seconds or More)

DTC C1123: No Vehicle Speed Signal (30 Seconds or More)

DTC C1124: Vehicle Speed Performance (Impossible Deceleration)

Wiring Diagram5Torque sensor power supply circuit check

1) Check that torque sensor power supply circuit is as

follows.

• Insulation resistance of wire harness is infinity

between “Torque sensor power supply circuit” terminal

and each other terminal at torque sensor connector.

• Wiring harness resistance of “Torque sensor power

supply circuit” is less than 1 Ω.

• Insulation between “Torque sensor power supply

circuit” and vehicle body ground is infinity.

Is circuit in good condition?Replace P/S control

module.Repair or replace

defective circuit. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

BRN RED/

BLU LT GRN/

BLK

E11-1

E11-14

E11-12

E13-1 GRN

GRN

WHT

8

3 10

12

13

11

4 1

2

12V

E13-2BLK

12V

12V

9 5

77

E11-11

G04-15

[E]G04-22

5V

PPL

E11-4

BLU/

WHTE04-9

6

14

IG11615

C07-25

[D][C]

[F]E01-44E01-4

[F]E01-27E01-26

I6RW0D630003-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 11. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 12. “P/S” fuse

[C]: M/T model 5. ECM 13. “IG1 SIG” fuse

[D]: A/T model 6. BCM 14. Vehicle speed signal

[E]: Junction block without BCM model (Taiwan model) 7. Front left/right wheel speed sensor 15. TCM

[F]: M15A engine with 4A/T equipped with slip control model (Hong Kong model) 8. P/S control module 16. Output shaft speed sensor

1. Main fuse box 9. ABS control module

2. Ignition switch 10. Individual circuit fuse box No.1

Page 904 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-24 Power Assisted Steering System:

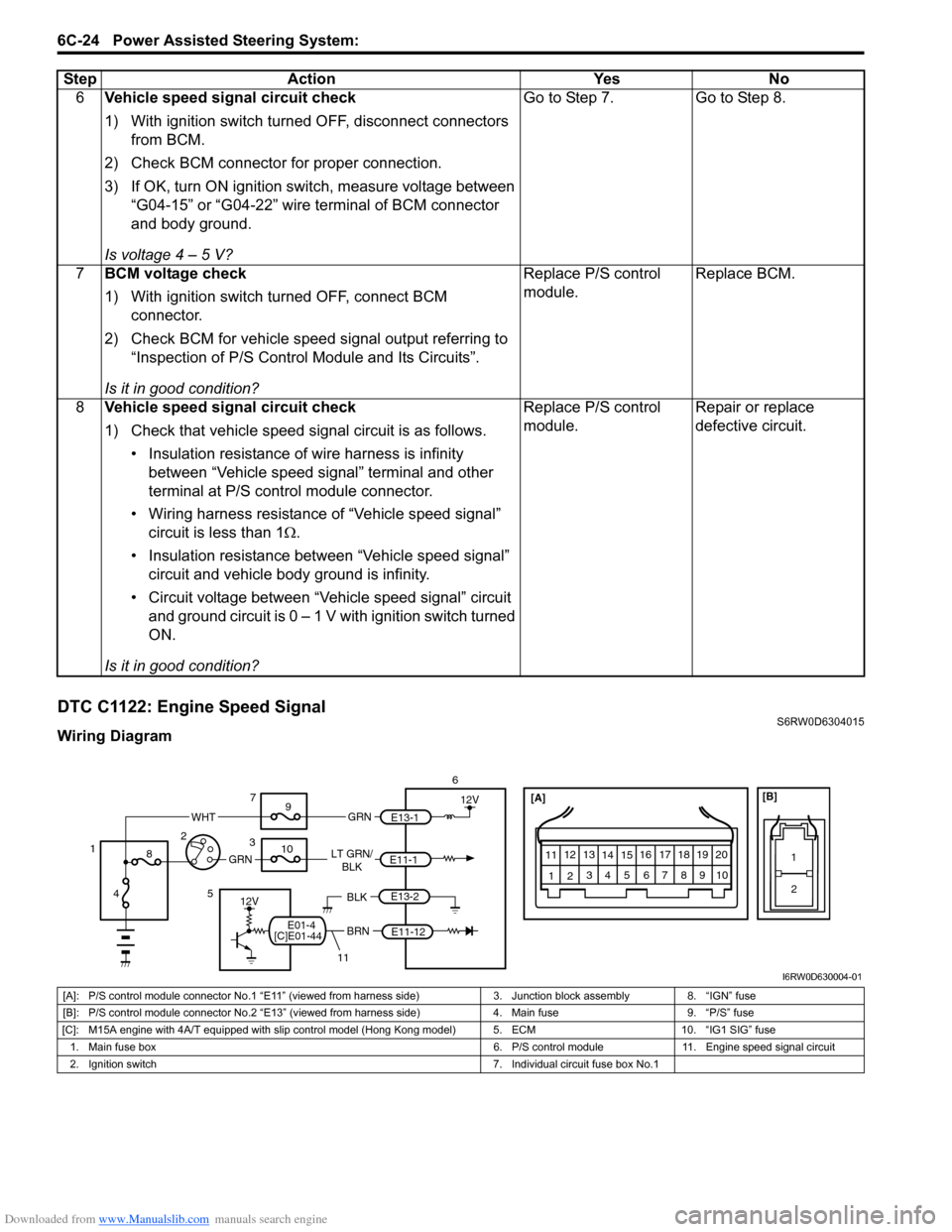

DTC C1122: Engine Speed SignalS6RW0D6304015

Wiring Diagram6Vehicle speed signal circuit check

1) With ignition switch turned OFF, disconnect connectors

from BCM.

2) Check BCM connector for proper connection.

3) If OK, turn ON ignition switch, measure voltage between

“G04-15” or “G04-22” wire terminal of BCM connector

and body ground.

Is voltage 4 – 5 V?Go to Step 7. Go to Step 8.

7BCM voltage check

1) With ignition switch turned OFF, connect BCM

connector.

2) Check BCM for vehicle speed signal output referring to

“Inspection of P/S Control Module and Its Circuits”.

Is it in good condition?Replace P/S control

module.Replace BCM.

8Vehicle speed signal circuit check

1) Check that vehicle speed signal circuit is as follows.

• Insulation resistance of wire harness is infinity

between “Vehicle speed signal” terminal and other

terminal at P/S control module connector.

• Wiring harness resistance of “Vehicle speed signal”

circuit is less than 1Ω.

• Insulation resistance between “Vehicle speed signal”

circuit and vehicle body ground is infinity.

• Circuit voltage between “Vehicle speed signal” circuit

and ground circuit is 0 – 1 V with ignition switch turned

ON.

Is it in good condition?Replace P/S control

module.Repair or replace

defective circuit. Step Action Yes No

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

BRN LT GRN/

BLK

E11-1

E11-12

E13-1 GRN

GRN

WHT

6

37

9

10

8

4 12

12V

E13-2BLK12V5

11

[C]E01-44E01-4

I6RW0D630004-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 8. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 9. “P/S” fuse

[C]: M15A engine with 4A/T equipped with slip control model (Hong Kong model) 5. ECM 10. “IG1 SIG” fuse

1. Main fuse box 6. P/S control module 11. Engine speed signal circuit

2. Ignition switch 7. Individual circuit fuse box No.1

Page 906 of 1556

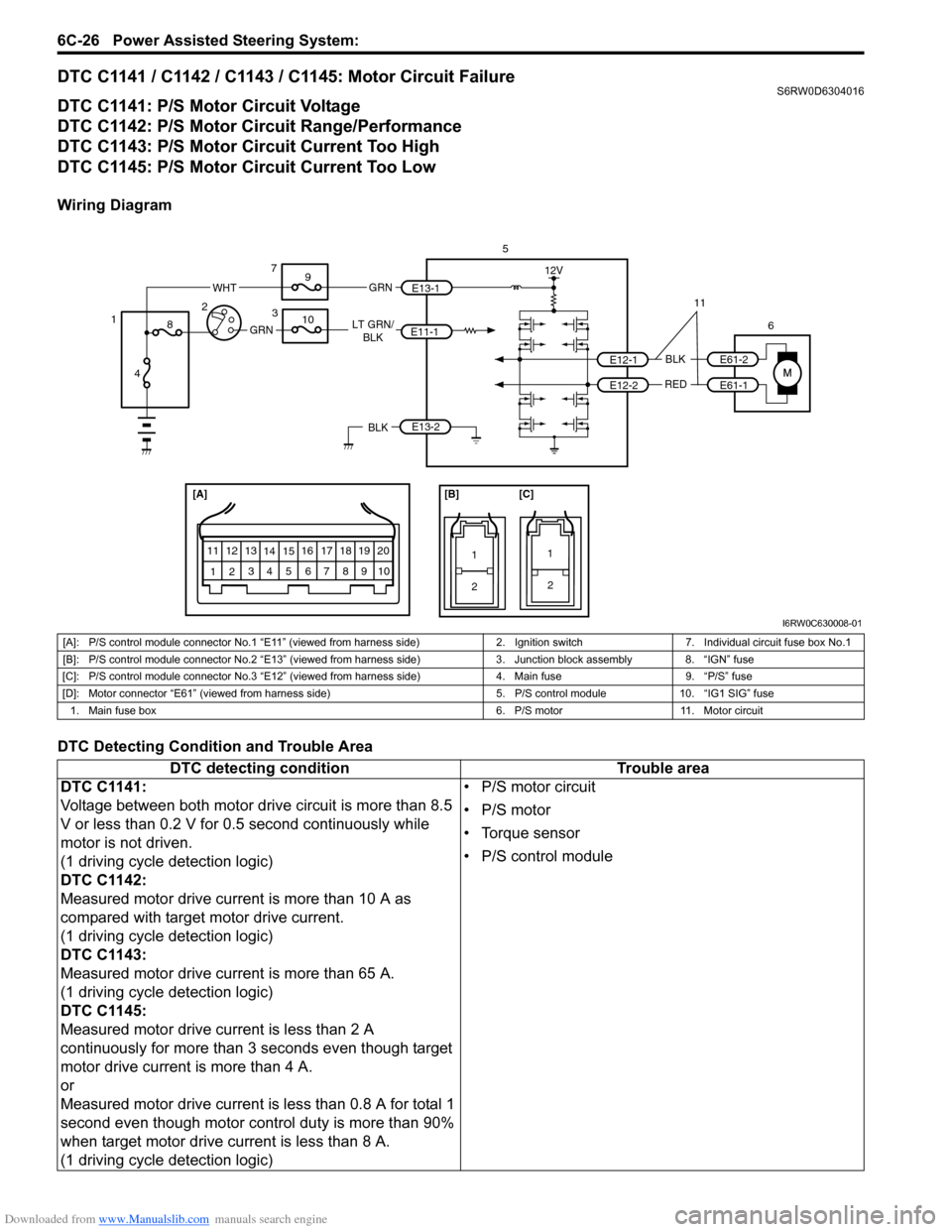

Downloaded from www.Manualslib.com manuals search engine 6C-26 Power Assisted Steering System:

DTC C1141 / C1142 / C1143 / C1145: Motor Circuit FailureS6RW0D6304016

DTC C1141: P/S Motor Circuit Voltage

DTC C1142: P/S Motor Circuit Range/Performance

DTC C1143: P/S Motor Circuit Current Too High

DTC C1145: P/S Motor Circuit Current Too Low

Wiring Diagram

DTC Detecting Condition and Trouble Area

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

1

2

[C]

LT GRN/

BLK

BLK

RED

E11-1

E12-1

E12-2 E13-1 GRNGRN

WHT

5

6 3 7

9

10

8

4 12

12V

E13-2BLK

E61-2

E61-1

11

I6RW0C630008-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 2. Ignition switch 7. Individual circuit fuse box No.1

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 3. Junction block assembly 8. “IGN” fuse

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 4. Main fuse 9. “P/S” fuse

[D]: Motor connector “E61” (viewed from harness side) 5. P/S control module 10. “IG1 SIG” fuse

1. Main fuse box 6. P/S motor 11. Motor circuit

DTC detecting condition Trouble area

DTC C1141:

Voltage between both motor drive circuit is more than 8.5

V or less than 0.2 V for 0.5 second continuously while

motor is not driven.

(1 driving cycle detection logic)

DTC C1142:

Measured motor drive current is more than 10 A as

compared with target motor drive current.

(1 driving cycle detection logic)

DTC C1143:

Measured motor drive current is more than 65 A.

(1 driving cycle detection logic)

DTC C1145:

Measured motor drive current is less than 2 A

continuously for more than 3 seconds even though target

motor drive current is more than 4 A.

or

Measured motor drive current is less than 0.8 A for total 1

second even though motor control duty is more than 90%

when target motor drive current is less than 8 A.

(1 driving cycle detection logic)• P/S motor circuit

• P/S motor

• Torque sensor

• P/S control module

Page 907 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-27

DTC Troubleshooting

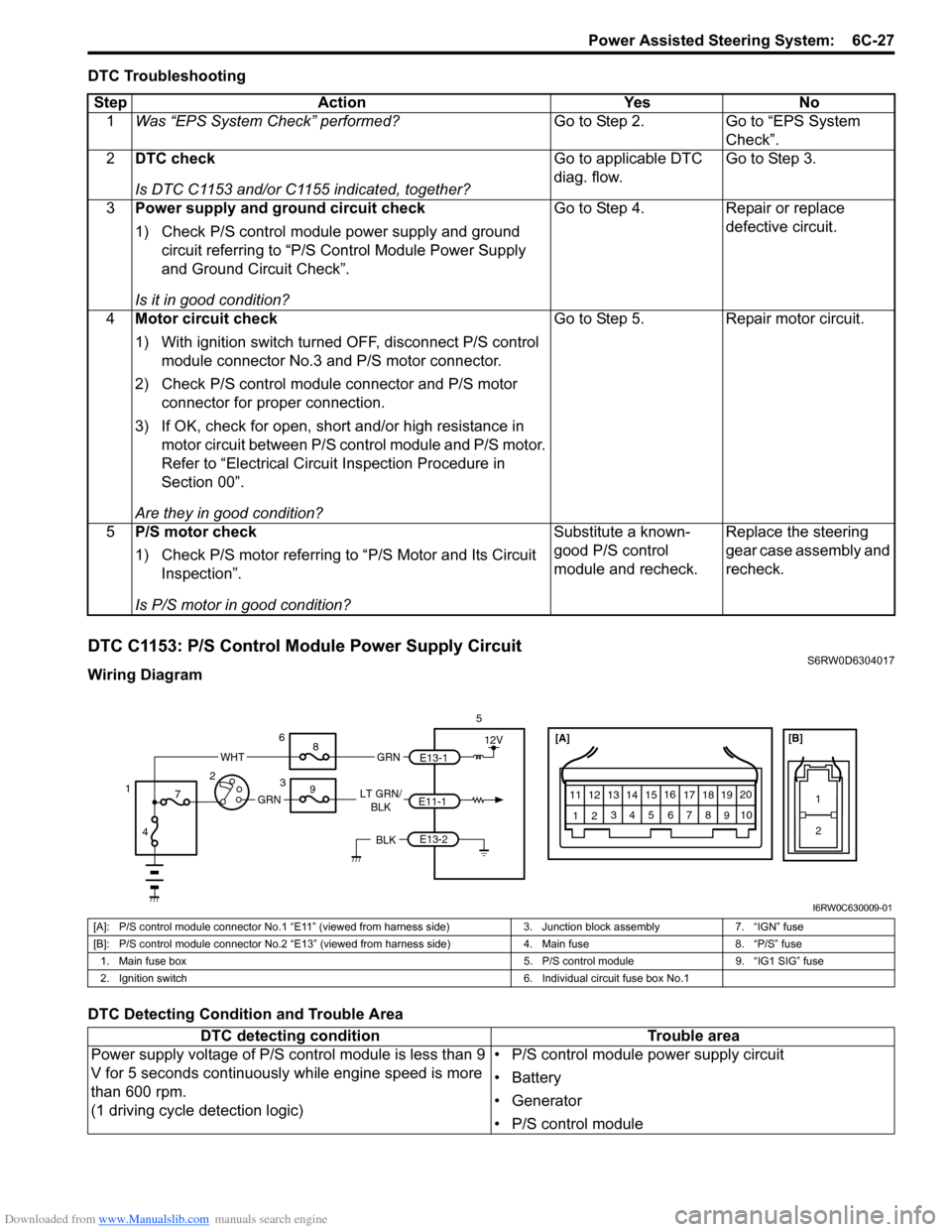

DTC C1153: P/S Control Module Power Supply CircuitS6RW0D6304017

Wiring Diagram

DTC Detecting Condition and Trouble AreaStep Action Yes No

1Was “EPS System Check” performed?Go to Step 2. Go to “EPS System

Check”.

2DTC check

Is DTC C1153 and/or C1155 indicated, together?Go to applicable DTC

diag. flow.Go to Step 3.

3Power supply and ground circuit check

1) Check P/S control module power supply and ground

circuit referring to “P/S Control Module Power Supply

and Ground Circuit Check”.

Is it in good condition?Go to Step 4. Repair or replace

defective circuit.

4Motor circuit check

1) With ignition switch turned OFF, disconnect P/S control

module connector No.3 and P/S motor connector.

2) Check P/S control module connector and P/S motor

connector for proper connection.

3) If OK, check for open, short and/or high resistance in

motor circuit between P/S control module and P/S motor.

Refer to “Electrical Circuit Inspection Procedure in

Section 00”.

Are they in good condition?Go to Step 5. Repair motor circuit.

5P/S motor check

1) Check P/S motor referring to “P/S Motor and Its Circuit

Inspection”.

Is P/S motor in good condition?Substitute a known-

good P/S control

module and recheck.Replace the steering

gear case assembly and

recheck.

[A]

123

4567

8

9 11

10 12 13

141516

17 18 1920

1

2

[B]

LT GRN/

BLKE11-1E13-1 GRNGRN

WHT

5

3 6

8

9

7

4 12

12V

E13-2BLK

I6RW0C630009-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 7. “IGN” fuse

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 8. “P/S” fuse

1. Main fuse box 5. P/S control module 9. “IG1 SIG” fuse

2. Ignition switch 6. Individual circuit fuse box No.1

DTC detecting condition Trouble area

Power supply voltage of P/S control module is less than 9

V for 5 seconds continuously while engine speed is more

than 600 rpm.

(1 driving cycle detection logic)• P/S control module power supply circuit

• Battery

• Generator

• P/S control module