lock SUZUKI SX4 2006 1.G Service Manual Online

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 398 of 1556

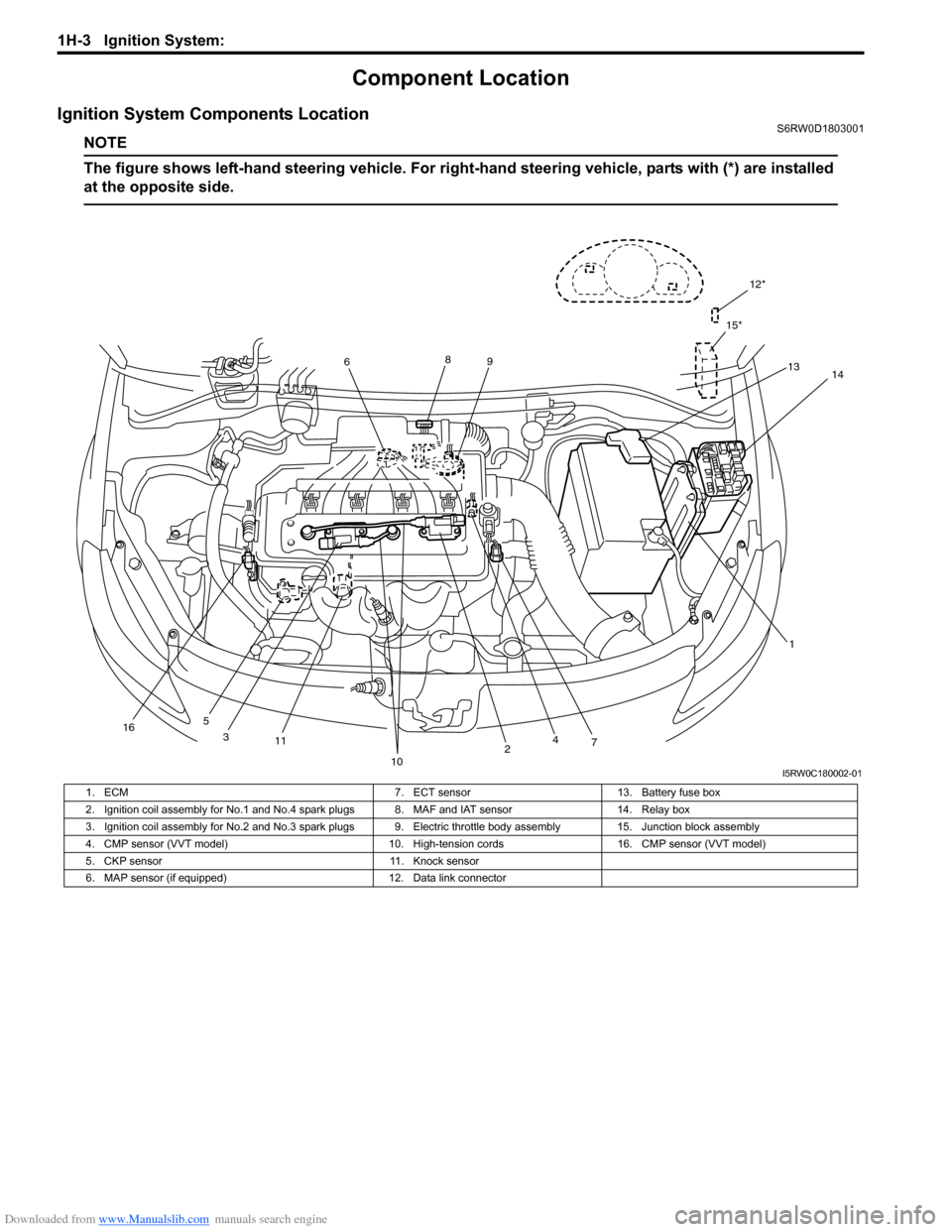

Downloaded from www.Manualslib.com manuals search engine 1H-3 Ignition System:

Component Location

Ignition System Components LocationS6RW0D1803001

NOTE

The figure shows left-hand steering vehicle. For right-hand steering vehicle, parts with (*) are installed

at the opposite side.

12*

15*

13

1 689

11

10

74

5

14

2 3

16

I5RW0C180002-01

1. ECM 7. ECT sensor 13. Battery fuse box

2. Ignition coil assembly for No.1 and No.4 spark plugs 8. MAF and IAT sensor 14. Relay box

3. Ignition coil assembly for No.2 and No.3 spark plugs 9. Electric throttle body assembly 15. Junction block assembly

4. CMP sensor (VVT model) 10. High-tension cords 16. CMP sensor (VVT model)

5. CKP sensor 11. Knock sensor

6. MAP sensor (if equipped) 12. Data link connector

Page 412 of 1556

Downloaded from www.Manualslib.com manuals search engine 1I-7 Starting System:

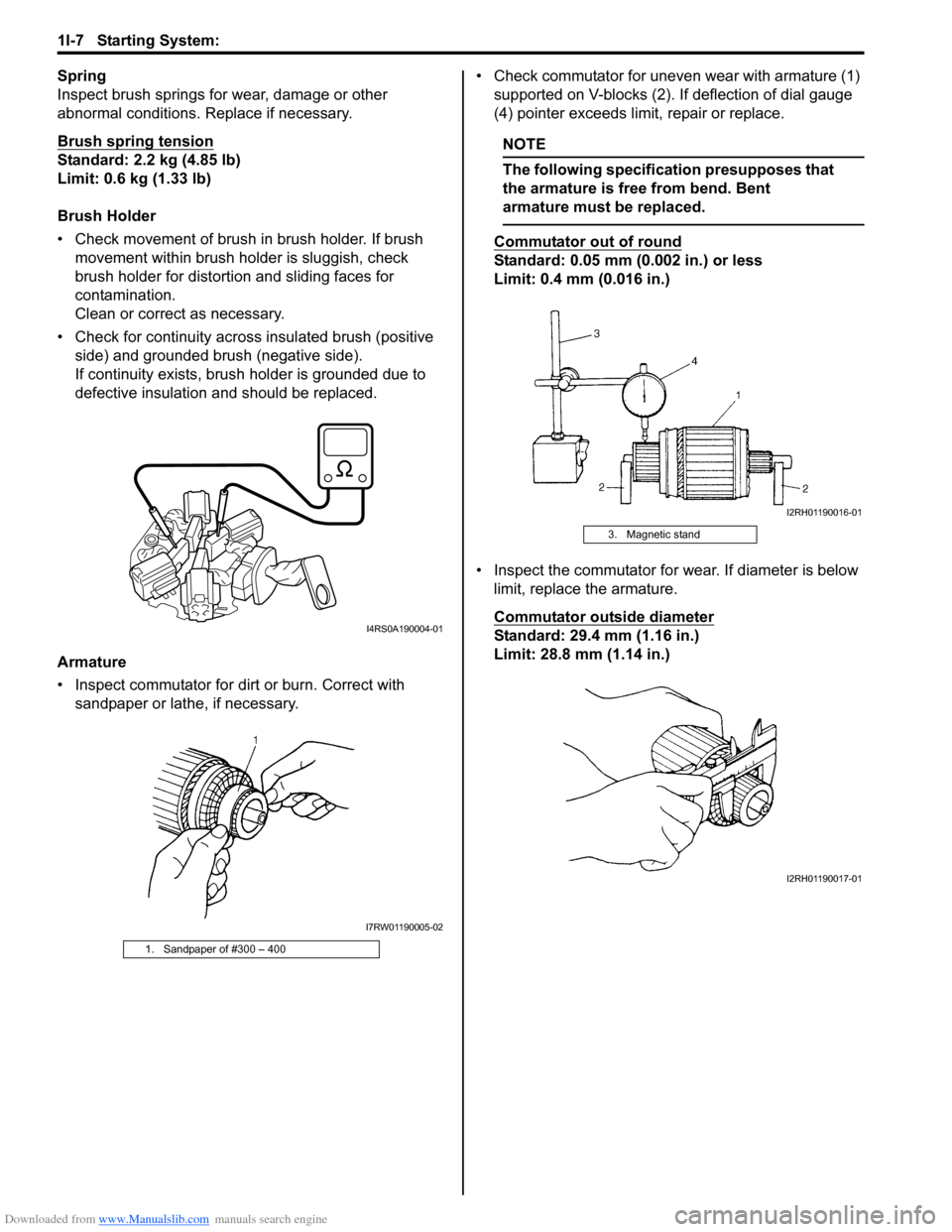

Spring

Inspect brush springs for wear, damage or other

abnormal conditions. Replace if necessary.

Brush spring tension

Standard: 2.2 kg (4.85 lb)

Limit: 0.6 kg (1.33 lb)

Brush Holder

• Check movement of brush in brush holder. If brush

movement within brush holder is sluggish, check

brush holder for distortion and sliding faces for

contamination.

Clean or correct as necessary.

• Check for continuity across insulated brush (positive

side) and grounded brush (negative side).

If continuity exists, brush holder is grounded due to

defective insulation and should be replaced.

Armature

• Inspect commutator for dirt or burn. Correct with

sandpaper or lathe, if necessary.• Check commutator for uneven wear with armature (1)

supported on V-blocks (2). If deflection of dial gauge

(4) pointer exceeds limit, repair or replace.

NOTE

The following specification presupposes that

the armature is free from bend. Bent

armature must be replaced.

Commutator out of round

Standard: 0.05 mm (0.002 in.) or less

Limit: 0.4 mm (0.016 in.)

• Inspect the commutator for wear. If diameter is below

limit, replace the armature.

Commutator outside diameter

Standard: 29.4 mm (1.16 in.)

Limit: 28.8 mm (1.14 in.)

1. Sandpaper of #300 – 400

I4RS0A190004-01

I7RW01190005-02

3. Magnetic stand

I2RH01190016-01

I2RH01190017-01

Page 413 of 1556

Downloaded from www.Manualslib.com manuals search engine Starting System: 1I-8

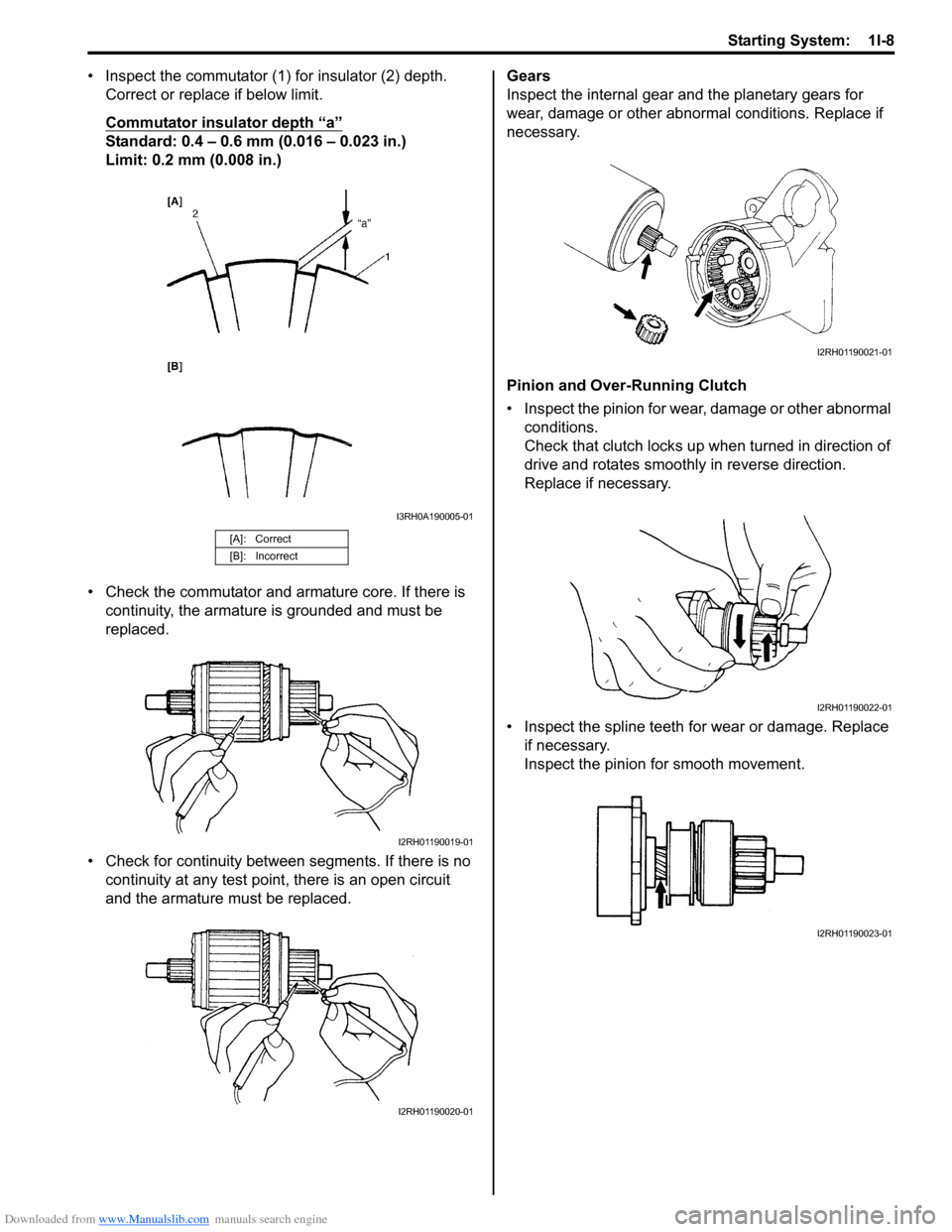

• Inspect the commutator (1) for insulator (2) depth.

Correct or replace if below limit.

Commutator insulator depth “a”

Standard: 0.4 – 0.6 mm (0.016 – 0.023 in.)

Limit: 0.2 mm (0.008 in.)

• Check the commutator and armature core. If there is

continuity, the armature is grounded and must be

replaced.

• Check for continuity between segments. If there is no

continuity at any test point, there is an open circuit

and the armature must be replaced.Gears

Inspect the internal gear and the planetary gears for

wear, damage or other abnormal conditions. Replace if

necessary.

Pinion and Over-Running Clutch

• Inspect the pinion for wear, damage or other abnormal

conditions.

Check that clutch locks up when turned in direction of

drive and rotates smoothly in reverse direction.

Replace if necessary.

• Inspect the spline teeth for wear or damage. Replace

if necessary.

Inspect the pinion for smooth movement.

[A]: Correct

[B]: Incorrect

I3RH0A190005-01

I2RH01190019-01

I2RH01190020-01

I2RH01190021-01

I2RH01190022-01

I2RH01190023-01

Page 414 of 1556

Downloaded from www.Manualslib.com manuals search engine 1I-9 Starting System:

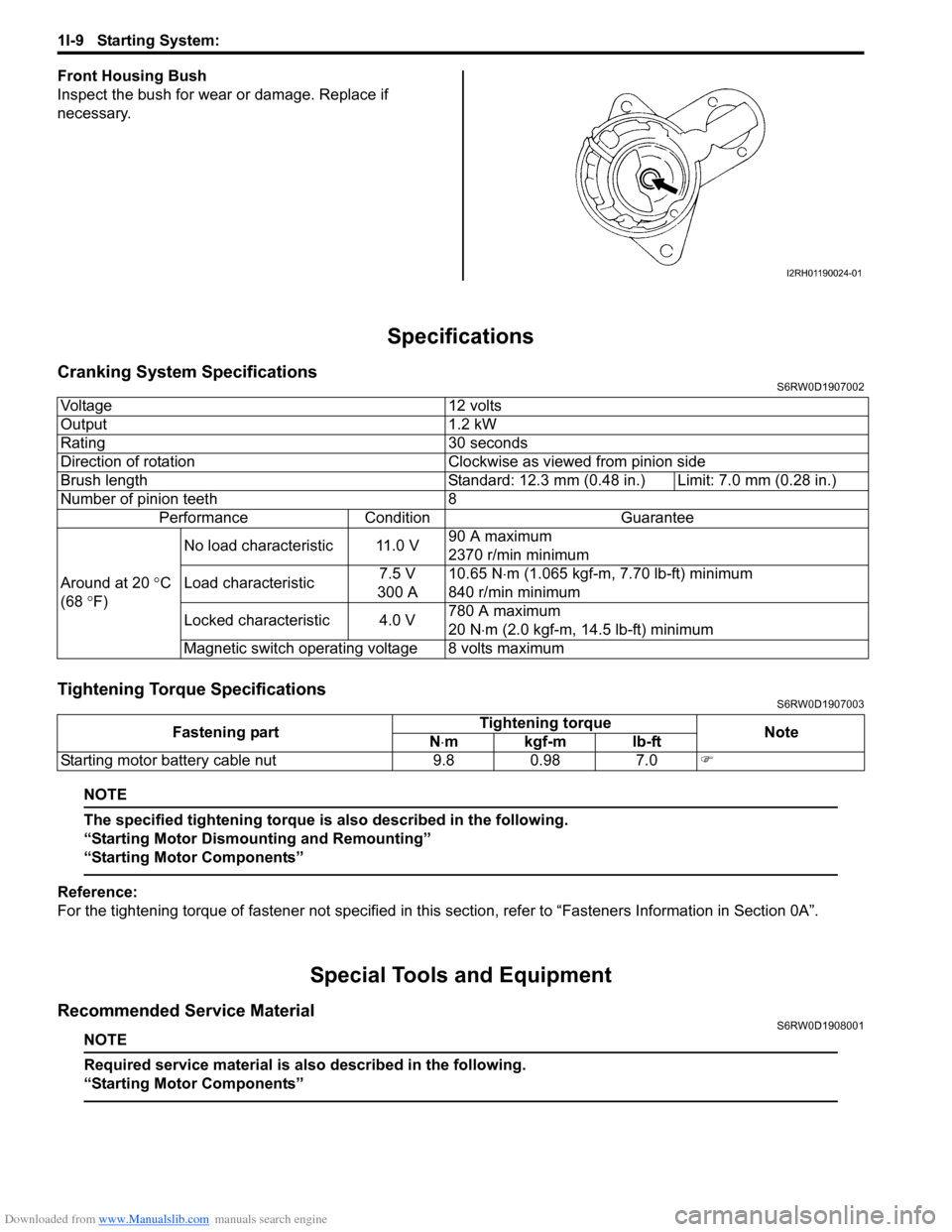

Front Housing Bush

Inspect the bush for wear or damage. Replace if

necessary.

Specifications

Cranking System SpecificationsS6RW0D1907002

Tightening Torque SpecificationsS6RW0D1907003

NOTE

The specified tightening torque is also described in the following.

“Starting Motor Dismounting and Remounting”

“Starting Motor Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”.

Special Tools and Equipment

Recommended Service MaterialS6RW0D1908001

NOTE

Required service material is also described in the following.

“Starting Motor Components”

I2RH01190024-01

Voltage 12 volts

Output 1.2 kW

Rating 30 seconds

Direction of rotation Clockwise as viewed from pinion side

Brush length Standard: 12.3 mm (0.48 in.) Limit: 7.0 mm (0.28 in.)

Number of pinion teeth 8

Performance Condition Guarantee

Around at 20 °C

(68 °F)No load characteristic 11.0 V90 A maximum

2370 r/min minimum

Load characteristic7.5 V

300 A10.65 N⋅m (1.065 kgf-m, 7.70 lb-ft) minimum

840 r/min minimum

Locked characteristic 4.0 V780 A maximum

20 N⋅m (2.0 kgf-m, 14.5 lb-ft) minimum

Magnetic switch operating voltage 8 volts maximum

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Starting motor battery cable nut 9.8 0.98 7.0�)

Page 422 of 1556

Downloaded from www.Manualslib.com manuals search engine 1J-8 Charging System:

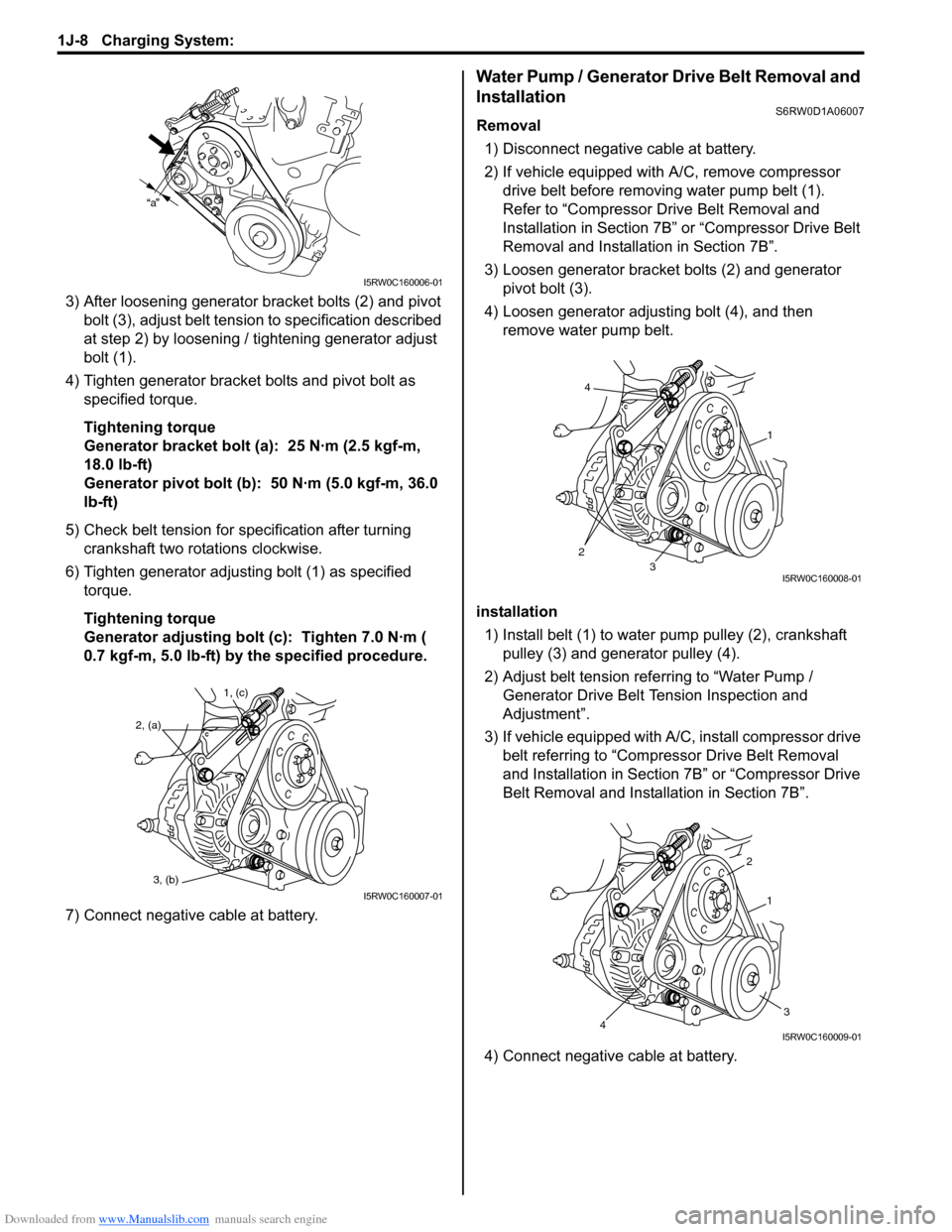

3) After loosening generator bracket bolts (2) and pivot

bolt (3), adjust belt tension to specification described

at step 2) by loosening / tightening generator adjust

bolt (1).

4) Tighten generator bracket bolts and pivot bolt as

specified torque.

Tightening torque

Generator bracket bolt (a): 25 N·m (2.5 kgf-m,

18.0 lb-ft)

Generator pivot bolt (b): 50 N·m (5.0 kgf-m, 36.0

lb-ft)

5) Check belt tension for specification after turning

crankshaft two rotations clockwise.

6) Tighten generator adjusting bolt (1) as specified

torque.

Tightening torque

Generator adjusting bolt (c): Tighten 7.0 N·m (

0.7 kgf-m, 5.0 lb-ft) by the specified procedure.

7) Connect negative cable at battery.

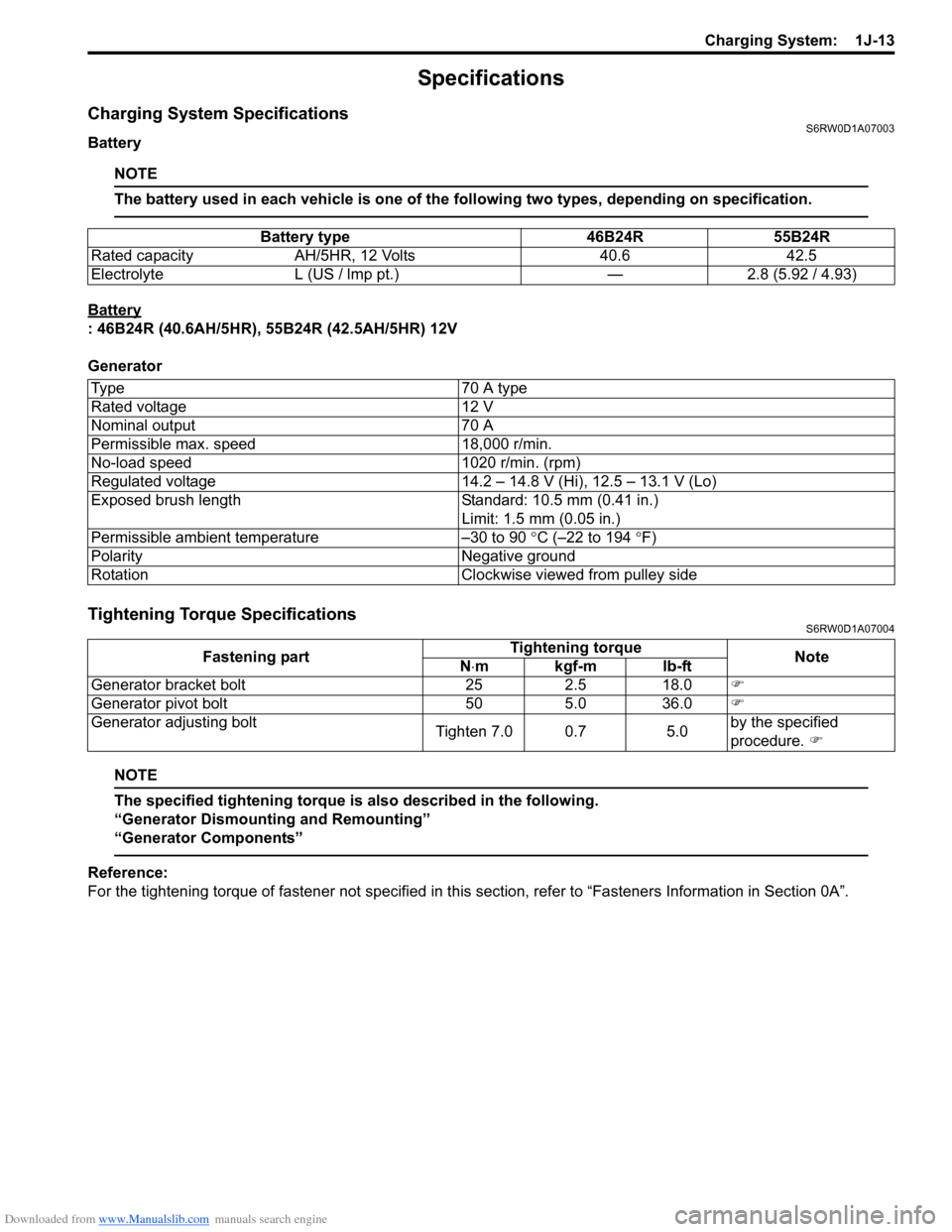

Water Pump / Generator Drive Belt Removal and

Installation

S6RW0D1A06007

Removal

1) Disconnect negative cable at battery.

2) If vehicle equipped with A/C, remove compressor

drive belt before removing water pump belt (1).

Refer to “Compressor Drive Belt Removal and

Installation in Section 7B” or “Compressor Drive Belt

Removal and Installation in Section 7B”.

3) Loosen generator bracket bolts (2) and generator

pivot bolt (3).

4) Loosen generator adjusting bolt (4), and then

remove water pump belt.

installation

1) Install belt (1) to water pump pulley (2), crankshaft

pulley (3) and generator pulley (4).

2) Adjust belt tension referring to “Water Pump /

Generator Drive Belt Tension Inspection and

Adjustment”.

3) If vehicle equipped with A/C, install compressor drive

belt referring to “Compressor Drive Belt Removal

and Installation in Section 7B” or “Compressor Drive

Belt Removal and Installation in Section 7B”.

4) Connect negative cable at battery.

a

I5RW0C160006-01

1, (c)

2, (a)

3, (b)

I5RW0C160007-01

4

23

1

I5RW0C160008-01

2

1

34I5RW0C160009-01

Page 427 of 1556

Downloaded from www.Manualslib.com manuals search engine Charging System: 1J-13

Specifications

Charging System SpecificationsS6RW0D1A07003

Battery

NOTE

The battery used in each vehicle is one of the following two types, depending on specification.

Battery

: 46B24R (40.6AH/5HR), 55B24R (42.5AH/5HR) 12V

Generator

Tightening Torque SpecificationsS6RW0D1A07004

NOTE

The specified tightening torque is also described in the following.

“Generator Dismounting and Remounting”

“Generator Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. Battery type 46B24R 55B24R

Rated capacity AH/5HR, 12 Volts 40.6 42.5

Electrolyte L (US / lmp pt.) — 2.8 (5.92 / 4.93)

Type 70 A type

Rated voltage 12 V

Nominal output 70 A

Permissible max. speed 18,000 r/min.

No-load speed 1020 r/min. (rpm)

Regulated voltage 14.2 – 14.8 V (Hi), 12.5 – 13.1 V (Lo)

Exposed brush length Standard: 10.5 mm (0.41 in.)

Limit: 1.5 mm (0.05 in.)

Permissible ambient temperature –30 to 90 °C (–22 to 194 °F)

Polarity Negative ground

Rotation Clockwise viewed from pulley side

Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Generator bracket bolt 25 2.5 18.0�)

Generator pivot bolt 50 5.0 36.0�)

Generator adjusting bolt

Tighten 7.0 0.7 5.0by the specified

procedure. �)

Page 440 of 1556

Downloaded from www.Manualslib.com manuals search engine 2B-3 Front Suspension:

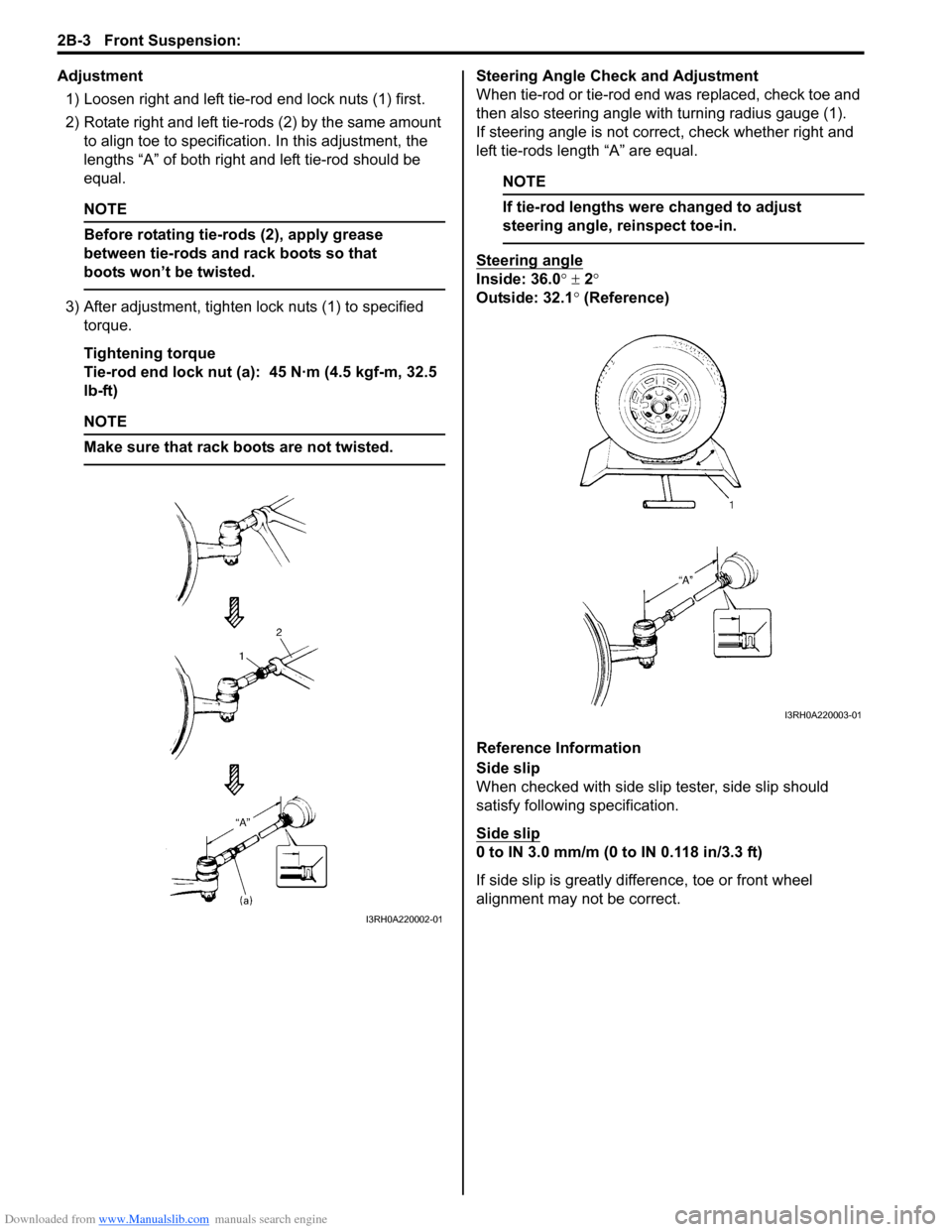

Adjustment

1) Loosen right and left tie-rod end lock nuts (1) first.

2) Rotate right and left tie-rods (2) by the same amount

to align toe to specification. In this adjustment, the

lengths “A” of both right and left tie-rod should be

equal.

NOTE

Before rotating tie-rods (2), apply grease

between tie-rods and rack boots so that

boots won’t be twisted.

3) After adjustment, tighten lock nuts (1) to specified

torque.

Tightening torque

Tie-rod end lock nut (a): 45 N·m (4.5 kgf-m, 32.5

lb-ft)

NOTE

Make sure that rack boots are not twisted.

Steering Angle Check and Adjustment

When tie-rod or tie-rod end was replaced, check toe and

then also steering angle with turning radius gauge (1).

If steering angle is not correct, check whether right and

left tie-rods length “A” are equal.

NOTE

If tie-rod lengths were changed to adjust

steering angle, reinspect toe-in.

Steering angle

Inside: 36.0° ± 2°

Outside: 32.1° (Reference)

Reference Information

Side slip

When checked with side slip tester, side slip should

satisfy following specification.

Side slip

0 to IN 3.0 mm/m (0 to IN 0.118 in/3.3 ft)

If side slip is greatly difference, toe or front wheel

alignment may not be correct.

I3RH0A220002-01

I3RH0A220003-01

Page 458 of 1556

Downloaded from www.Manualslib.com manuals search engine 2B-21 Front Suspension:

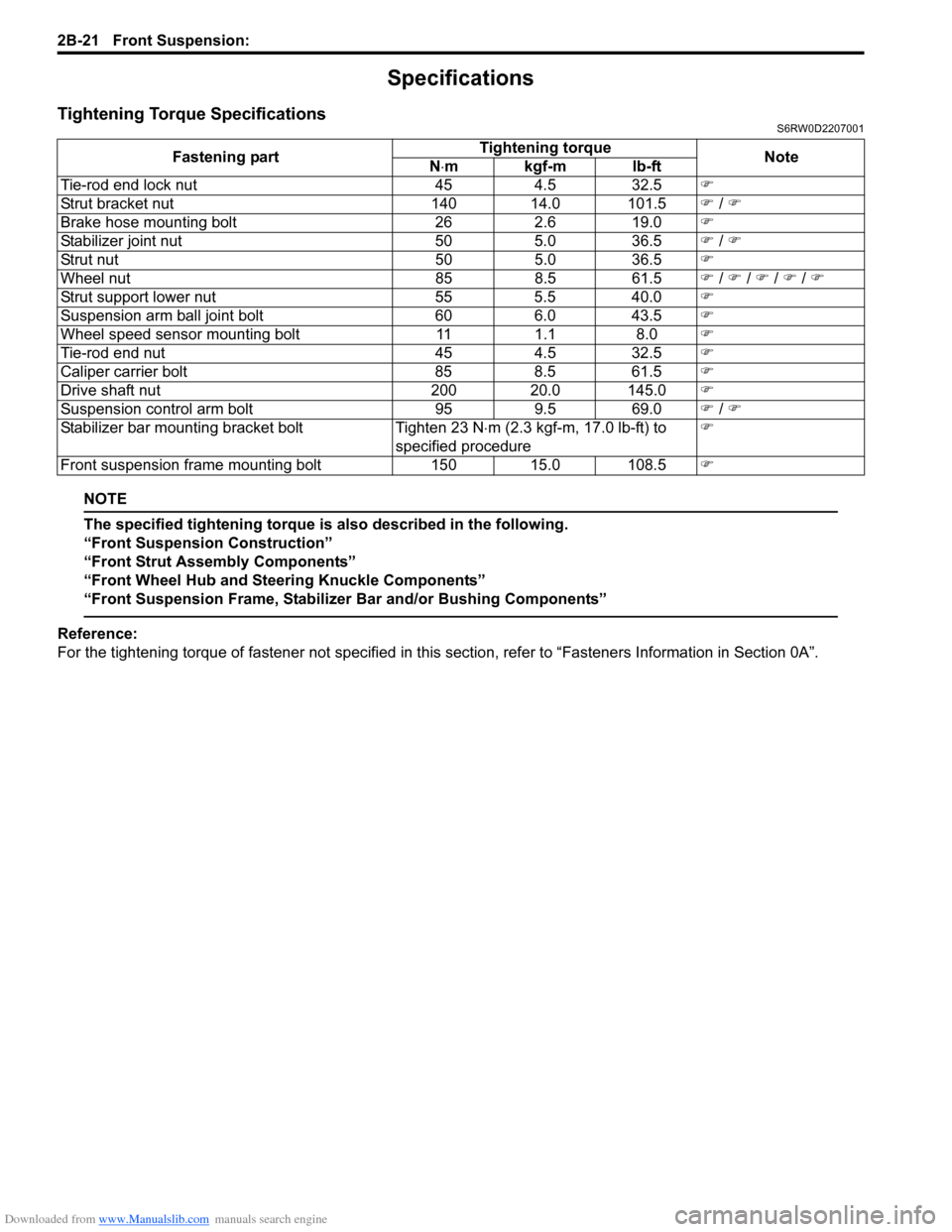

Specifications

Tightening Torque SpecificationsS6RW0D2207001

NOTE

The specified tightening torque is also described in the following.

“Front Suspension Construction”

“Front Strut Assembly Components”

“Front Wheel Hub and Steering Knuckle Components”

“Front Suspension Frame, Stabilizer Bar and/or Bushing Components”

Reference:

For the tightening torque of fastener not specified in this section, refer to “Fasteners Information in Section 0A”. Fastening partTightening torque

Note

N⋅mkgf-mlb-ft

Tie-rod end lock nut 45 4.5 32.5�)

Strut bracket nut 140 14.0 101.5�) / �)

Brake hose mounting bolt 26 2.6 19.0�)

Stabilizer joint nut 50 5.0 36.5�) / �)

Strut nut 50 5.0 36.5�)

Wheel nut 85 8.5 61.5�) / �) / �) / �) / �)

Strut support lower nut 55 5.5 40.0�)

Suspension arm ball joint bolt 60 6.0 43.5�)

Wheel speed sensor mounting bolt 11 1.1 8.0�)

Tie-rod end nut 45 4.5 32.5�)

Caliper carrier bolt 85 8.5 61.5�)

Drive shaft nut 200 20.0 145.0�)

Suspension control arm bolt 95 9.5 69.0�) / �)

Stabilizer bar mounting bracket bolt Tighten 23 N⋅m (2.3 kgf-m, 17.0 lb-ft) to

specified procedure�)

Front suspension frame mounting bolt 150 15.0 108.5�)

Page 470 of 1556

Downloaded from www.Manualslib.com manuals search engine 2D-1 Wheels and Tires:

Suspension

Wheels and Tires

General Description

Tires DescriptionS6RW0D2401001

The tire is of tubeless type. The tire is designed to

operate satisfactorily with loads up to the full rated load

capacity when inflated to the recommended inflation

pressures.

Correct tire pressures and driving habits have an

important influence on tire life. Heavy cornering,

excessively rapid acceleration, and unnecessary sharp

braking increase tire wear.

Tire Placard

The “Tire Placard” is located on the left or right door lock

pillar and should be referred to tire information.

The placard lists the maximum load, tire size and cold

tire pressure where applicable.

NOTE

Whether rim size and/or maximum load are

listed or not depends on regulations of each

country.

Inflation of Tires

The pressure recommended for any model is carefully

calculated to give a satisfactory ride, stability, steering,

tread wear, tire life and resistance to bruises.

Tire pressure, with tires cold, (after vehicle has set for 3

hours or more, or driven less than one mile) should be

checked monthly or before any extended trip. Set to the

specifications on the “Tire Placard” located on the left or

right door lock pillar.

It is normal for tire pressure to increase when the tires

become hot during driving.

Do not bleed or reduce tire pressure after driving.

Bleeding reduces the “Cold Inflation Pressure”.

Higher than recommended pressure can cause:

• Hard ride

• Tire bruising or carcass damage

• Rapid tread wear at center of tire

Unequal pressure on same axle can cause:

• Uneven braking

• Steering lead

• Reduced handling

• Swerve on accelerationLower than recommended pressure can cause:

• Tire squeal on turns

• Hard Steering

• Rapid and uneven wear on the edges of the tread

• Tire rim bruises and rupture

• Tire cord breakage

• High tire temperature

• Reduced handling

• High fuel consumption

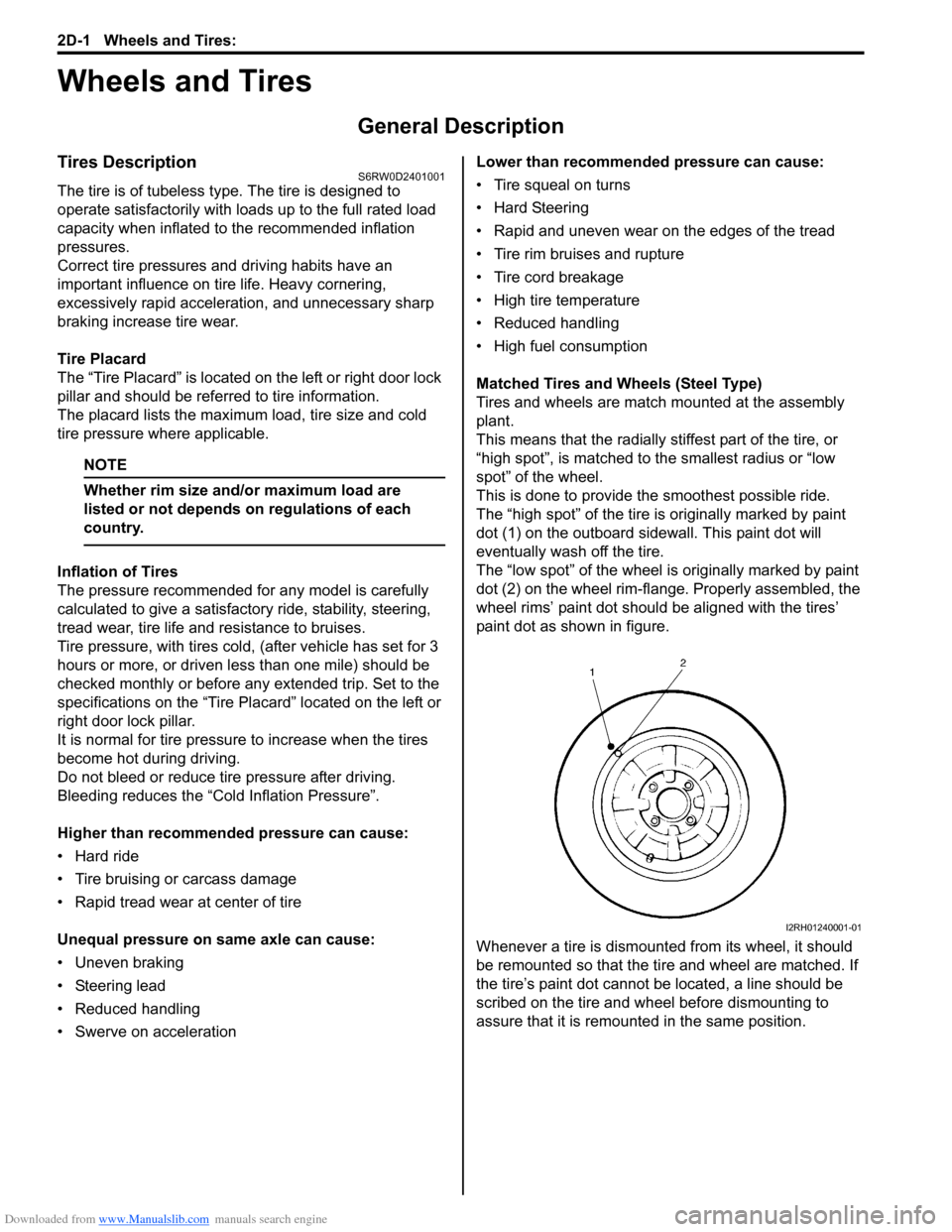

Matched Tires and Wheels (Steel Type)

Tires and wheels are match mounted at the assembly

plant.

This means that the radially stiffest part of the tire, or

“high spot”, is matched to the smallest radius or “low

spot” of the wheel.

This is done to provide the smoothest possible ride.

The “high spot” of the tire is originally marked by paint

dot (1) on the outboard sidewall. This paint dot will

eventually wash off the tire.

The “low spot” of the wheel is originally marked by paint

dot (2) on the wheel rim-flange. Properly assembled, the

wheel rims’ paint dot should be aligned with the tires’

paint dot as shown in figure.

Whenever a tire is dismounted from its wheel, it should

be remounted so that the tire and wheel are matched. If

the tire’s paint dot cannot be located, a line should be

scribed on the tire and wheel before dismounting to

assure that it is remounted in the same position.

I2RH01240001-01

Page 472 of 1556

Downloaded from www.Manualslib.com manuals search engine 2D-3 Wheels and Tires:

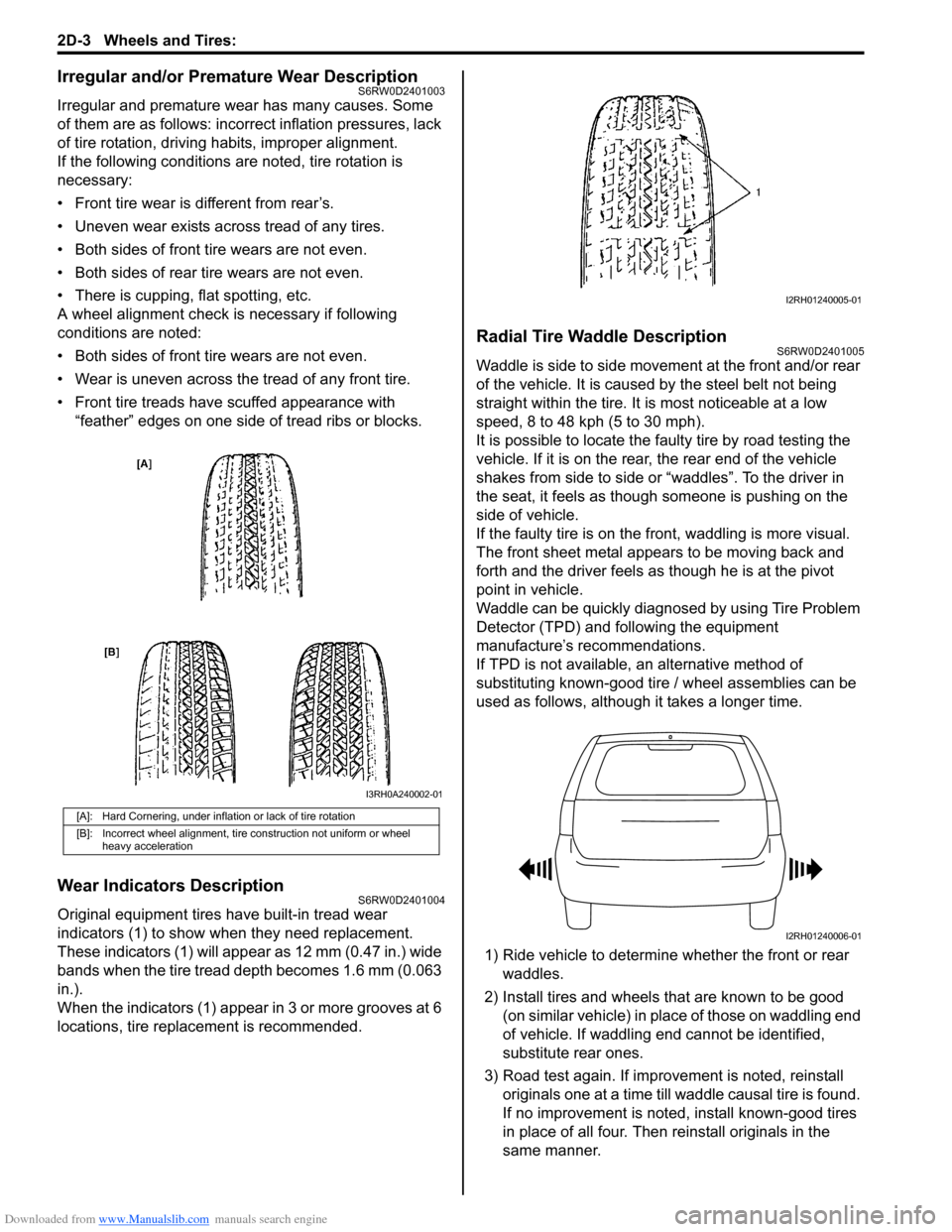

Irregular and/or Premature Wear DescriptionS6RW0D2401003

Irregular and premature wear has many causes. Some

of them are as follows: incorrect inflation pressures, lack

of tire rotation, driving habits, improper alignment.

If the following conditions are noted, tire rotation is

necessary:

• Front tire wear is different from rear’s.

• Uneven wear exists across tread of any tires.

• Both sides of front tire wears are not even.

• Both sides of rear tire wears are not even.

• There is cupping, flat spotting, etc.

A wheel alignment check is necessary if following

conditions are noted:

• Both sides of front tire wears are not even.

• Wear is uneven across the tread of any front tire.

• Front tire treads have scuffed appearance with

“feather” edges on one side of tread ribs or blocks.

Wear Indicators DescriptionS6RW0D2401004

Original equipment tires have built-in tread wear

indicators (1) to show when they need replacement.

These indicators (1) will appear as 12 mm (0.47 in.) wide

bands when the tire tread depth becomes 1.6 mm (0.063

in.).

When the indicators (1) appear in 3 or more grooves at 6

locations, tire replacement is recommended.

Radial Tire Waddle DescriptionS6RW0D2401005

Waddle is side to side movement at the front and/or rear

of the vehicle. It is caused by the steel belt not being

straight within the tire. It is most noticeable at a low

speed, 8 to 48 kph (5 to 30 mph).

It is possible to locate the faulty tire by road testing the

vehicle. If it is on the rear, the rear end of the vehicle

shakes from side to side or “waddles”. To the driver in

the seat, it feels as though someone is pushing on the

side of vehicle.

If the faulty tire is on the front, waddling is more visual.

The front sheet metal appears to be moving back and

forth and the driver feels as though he is at the pivot

point in vehicle.

Waddle can be quickly diagnosed by using Tire Problem

Detector (TPD) and following the equipment

manufacture’s recommendations.

If TPD is not available, an alternative method of

substituting known-good tire / wheel assemblies can be

used as follows, although it takes a longer time.

1) Ride vehicle to determine whether the front or rear

waddles.

2) Install tires and wheels that are known to be good

(on similar vehicle) in place of those on waddling end

of vehicle. If waddling end cannot be identified,

substitute rear ones.

3) Road test again. If improvement is noted, reinstall

originals one at a time till waddle causal tire is found.

If no improvement is noted, install known-good tires

in place of all four. Then reinstall originals in the

same manner.

[A]: Hard Cornering, under inflation or lack of tire rotation

[B]: Incorrect wheel alignment, tire construction not uniform or wheel

heavy acceleration

I3RH0A240002-01

I2RH01240005-01

I2RH01240006-01