Power steering control module SUZUKI SX4 2006 1.G Service Workshop Manual

[x] Cancel search | Manufacturer: SUZUKI, Model Year: 2006, Model line: SX4, Model: SUZUKI SX4 2006 1.GPages: 1556, PDF Size: 37.31 MB

Page 24 of 1556

Downloaded from www.Manualslib.com manuals search engine 0A-1 General Information:

General Information

General Information

General Description

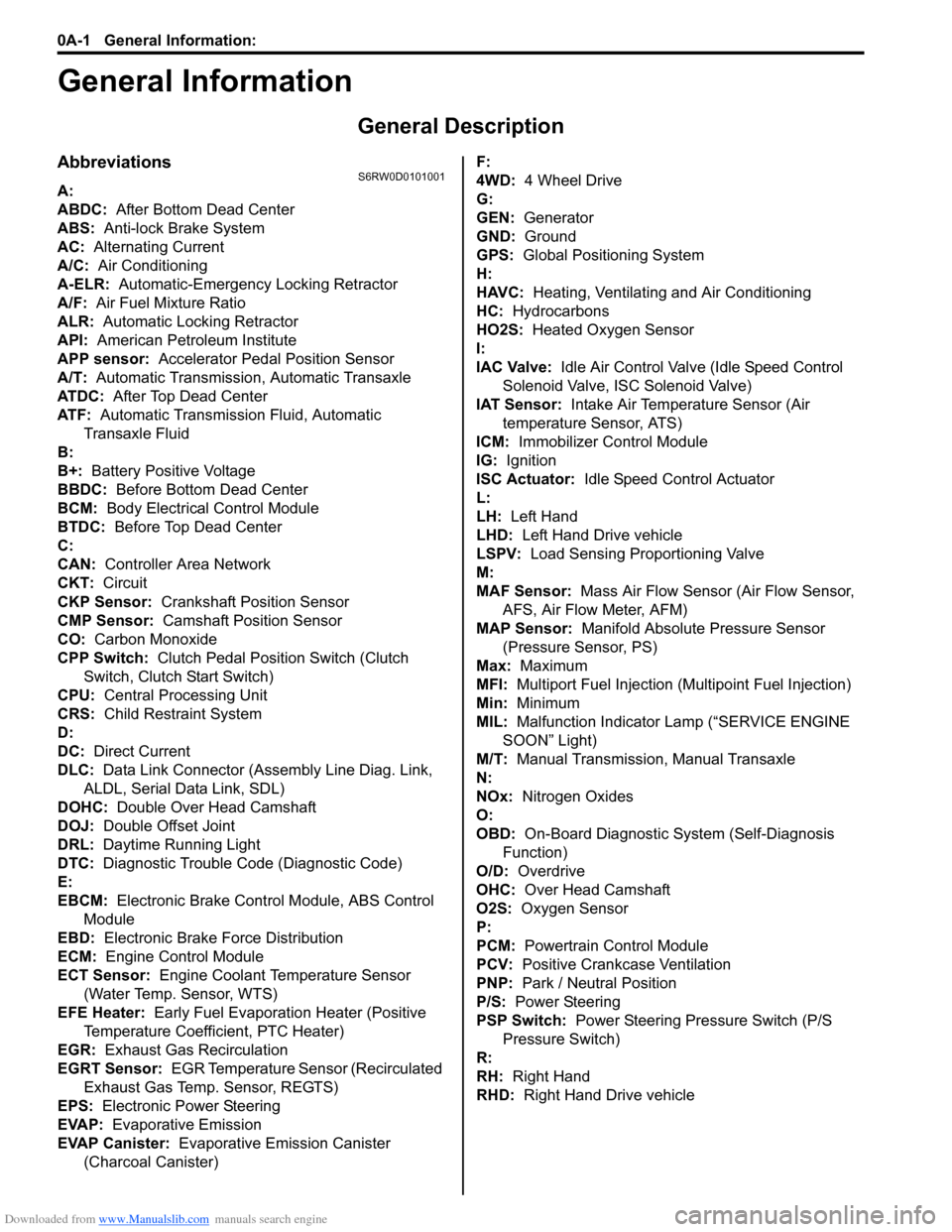

AbbreviationsS6RW0D0101001

A:

ABDC: After Bottom Dead Center

ABS: Anti-lock Brake System

AC: Alternating Current

A/C: Air Conditioning

A-ELR: Automatic-Emergency Locking Retractor

A/F: Air Fuel Mixture Ratio

ALR: Automatic Locking Retractor

API: American Petroleum Institute

APP sensor: Accelerator Pedal Position Sensor

A/T: Automatic Transmission, Automatic Transaxle

AT D C : After Top Dead Center

ATF: Automatic Transmission Fluid, Automatic

Transaxle Fluid

B:

B+: Battery Positive Voltage

BBDC: Before Bottom Dead Center

BCM: Body Electrical Control Module

BTDC: Before Top Dead Center

C:

CAN: Controller Area Network

CKT: Circuit

CKP Sensor: Crankshaft Position Sensor

CMP Sensor: Camshaft Position Sensor

CO: Carbon Monoxide

CPP Switch: Clutch Pedal Position Switch (Clutch

Switch, Clutch Start Switch)

CPU: Central Processing Unit

CRS: Child Restraint System

D:

DC: Direct Current

DLC: Data Link Connector (Assembly Line Diag. Link,

ALDL, Serial Data Link, SDL)

DOHC: Double Over Head Camshaft

DOJ: Double Offset Joint

DRL: Daytime Running Light

DTC: Diagnostic Trouble Code (Diagnostic Code)

E:

EBCM: Electronic Brake Control Module, ABS Control

Module

EBD: Electronic Brake Force Distribution

ECM: Engine Control Module

ECT Sensor: Engine Coolant Temperature Sensor

(Water Temp. Sensor, WTS)

EFE Heater: Early Fuel Evaporation Heater (Positive

Temperature Coefficient, PTC Heater)

EGR: Exhaust Gas Recirculation

EGRT Sensor: EGR Temperature Sensor (Recirculated

Exhaust Gas Temp. Sensor, REGTS)

EPS: Electronic Power Steering

EVAP: Evaporative Emission

EVAP Canister: Evaporative Emission Canister

(Charcoal Canister)F:

4WD: 4 Wheel Drive

G:

GEN: Generator

GND: Ground

GPS: Global Positioning System

H:

HAVC: Heating, Ventilating and Air Conditioning

HC: Hydrocarbons

HO2S: Heated Oxygen Sensor

I:

IAC Valve: Idle Air Control Valve (Idle Speed Control

Solenoid Valve, ISC Solenoid Valve)

IAT Sensor: Intake Air Temperature Sensor (Air

temperature Sensor, ATS)

ICM: Immobilizer Control Module

IG: Ignition

ISC Actuator: Idle Speed Control Actuator

L:

LH: Left Hand

LHD: Left Hand Drive vehicle

LSPV: Load Sensing Proportioning Valve

M:

MAF Sensor: Mass Air Flow Sensor (Air Flow Sensor,

AFS, Air Flow Meter, AFM)

MAP Sensor: Manifold Absolute Pressure Sensor

(Pressure Sensor, PS)

Max: Maximum

MFI: Multiport Fuel Injection (Multipoint Fuel Injection)

Min: Minimum

MIL: Malfunction Indicator Lamp (“SERVICE ENGINE

SOON” Light)

M/T: Manual Transmission, Manual Transaxle

N:

NOx: Nitrogen Oxides

O:

OBD: On-Board Diagnostic System (Self-Diagnosis

Function)

O/D: Overdrive

OHC: Over Head Camshaft

O2S: Oxygen Sensor

P:

PCM: Powertrain Control Module

PCV: Positive Crankcase Ventilation

PNP: Park / Neutral Position

P/S: Power Steering

PSP Switch: Power Steering Pressure Switch (P/S

Pressure Switch)

R:

RH: Right Hand

RHD: Right Hand Drive vehicle

Page 25 of 1556

Downloaded from www.Manualslib.com manuals search engine General Information: 0A-2

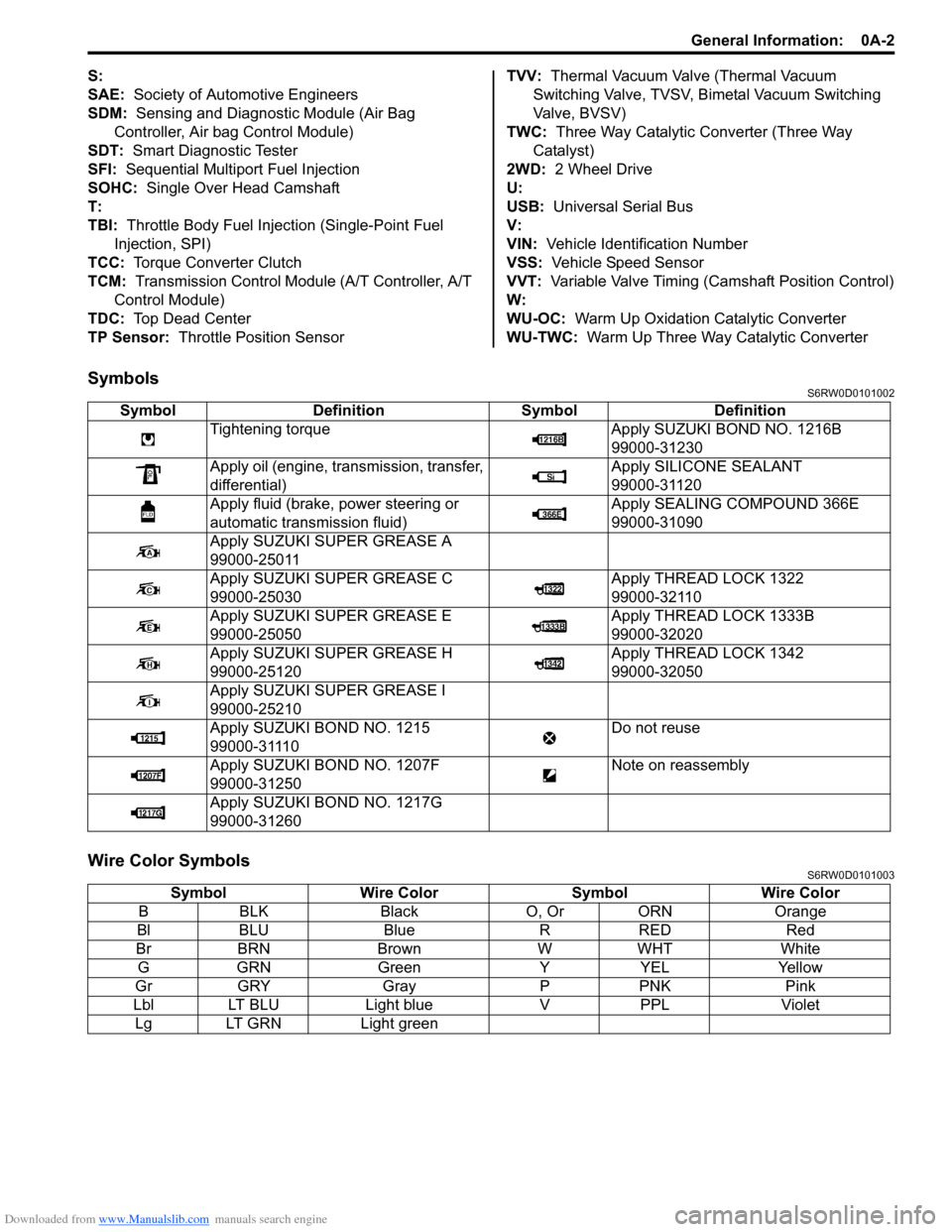

S:

SAE: Society of Automotive Engineers

SDM: Sensing and Diagnostic Module (Air Bag

Controller, Air bag Control Module)

SDT: Smart Diagnostic Tester

SFI: Sequential Multiport Fuel Injection

SOHC: Single Over Head Camshaft

T:

TBI: Throttle Body Fuel Injection (Single-Point Fuel

Injection, SPI)

TCC: Torque Converter Clutch

TCM: Transmission Control Module (A/T Controller, A/T

Control Module)

TDC: Top Dead Center

TP Sensor: Throttle Position SensorTVV: Thermal Vacuum Valve (Thermal Vacuum

Switching Valve, TVSV, Bimetal Vacuum Switching

Valve, BVSV)

TWC: Three Way Catalytic Converter (Three Way

Catalyst)

2WD: 2 Wheel Drive

U:

USB: Universal Serial Bus

V:

VIN: Vehicle Identification Number

VSS: Vehicle Speed Sensor

VVT: Variable Valve Timing (Camshaft Position Control)

W:

WU-OC: Warm Up Oxidation Catalytic Converter

WU-TWC: Warm Up Three Way Catalytic Converter

SymbolsS6RW0D0101002

Wire Color SymbolsS6RW0D0101003

Symbol Definition Symbol Definition

Tightening torque Apply SUZUKI BOND NO. 1216B

99000-31230

Apply oil (engine, transmission, transfer,

differential)Apply SILICONE SEALANT

99000-31120

Apply fluid (brake, power steering or

automatic transmission fluid)Apply SEALING COMPOUND 366E

99000-31090

Apply SUZUKI SUPER GREASE A

99000-25011

Apply SUZUKI SUPER GREASE C

99000-25030Apply THREAD LOCK 1322

99000-32110

Apply SUZUKI SUPER GREASE E

99000-25050Apply THREAD LOCK 1333B

99000-32020

Apply SUZUKI SUPER GREASE H

99000-25120Apply THREAD LOCK 1342

99000-32050

Apply SUZUKI SUPER GREASE I

99000-25210

Apply SUZUKI BOND NO. 1215

99000-31110Do not reuse

Apply SUZUKI BOND NO. 1207F

99000-31250Note on reassembly

Apply SUZUKI BOND NO. 1217G

99000-31260

Symbol Wire Color Symbol Wire Color

B BLK Black O, Or ORN Orange

Bl BLU Blue R RED Red

Br BRN Brown W WHT White

G GRN Green Y YEL Yellow

Gr GRY Gray P PNK Pink

Lbl LT BLU Light blue V PPL Violet

Lg LT GRN Light green

Page 617 of 1556

Downloaded from www.Manualslib.com manuals search engine ABS: 4E-12

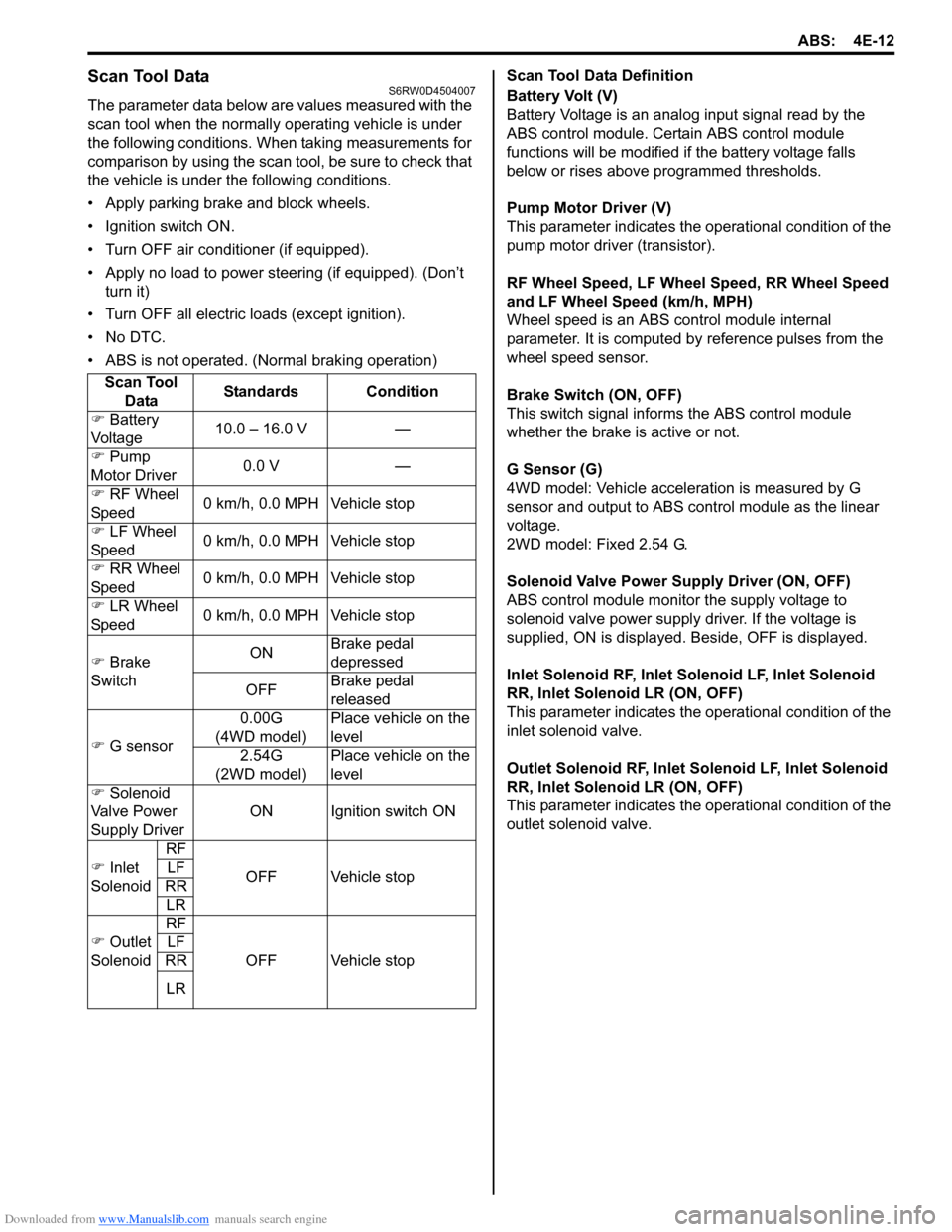

Scan Tool DataS6RW0D4504007

The parameter data below are values measured with the

scan tool when the normally operating vehicle is under

the following conditions. When taking measurements for

comparison by using the scan tool, be sure to check that

the vehicle is under the following conditions.

• Apply parking brake and block wheels.

• Ignition switch ON.

• Turn OFF air conditioner (if equipped).

• Apply no load to power steering (if equipped). (Don’t

turn it)

• Turn OFF all electric loads (except ignition).

• No DTC.

• ABS is not operated. (Normal braking operation)Scan Tool Data Definition

Battery Volt (V)

Battery Voltage is an analog input signal read by the

ABS control module. Certain ABS control module

functions will be modified if the battery voltage falls

below or rises above programmed thresholds.

Pump Motor Driver (V)

This parameter indicates the operational condition of the

pump motor driver (transistor).

RF Wheel Speed, LF Wheel Speed, RR Wheel Speed

and LF Wheel Speed (km/h, MPH)

Wheel speed is an ABS control module internal

parameter. It is computed by reference pulses from the

wheel speed sensor.

Brake Switch (ON, OFF)

This switch signal informs the ABS control module

whether the brake is active or not.

G Sensor (G)

4WD model: Vehicle acceleration is measured by G

sensor and output to ABS control module as the linear

voltage.

2WD model: Fixed 2.54 G.

Solenoid Valve Power Supply Driver (ON, OFF)

ABS control module monitor the supply voltage to

solenoid valve power supply driver. If the voltage is

supplied, ON is displayed. Beside, OFF is displayed.

Inlet Solenoid RF, Inlet Solenoid LF, Inlet Solenoid

RR, Inlet Solenoid LR (ON, OFF)

This parameter indicates the operational condition of the

inlet solenoid valve.

Outlet Solenoid RF, Inlet Solenoid LF, Inlet Solenoid

RR, Inlet Solenoid LR (ON, OFF)

This parameter indicates the operational condition of the

outlet solenoid valve. Scan Tool

DataStandards Condition

�) Battery

Voltage10.0 – 16.0 V —

�) Pump

Motor Driver0.0 V —

�) RF Wheel

Speed0 km/h, 0.0 MPH Vehicle stop

�) LF Wheel

Speed0 km/h, 0.0 MPH Vehicle stop

�) RR Wheel

Speed0 km/h, 0.0 MPH Vehicle stop

�) LR Wheel

Speed0 km/h, 0.0 MPH Vehicle stop

�) Brake

SwitchONBrake pedal

depressed

OFFBrake pedal

released

�) G sensor0.00G

(4WD model)Place vehicle on the

level

2.54G

(2WD model)Place vehicle on the

level

�) Solenoid

Valve Power

Supply DriverON Ignition switch ON

�) Inlet

SolenoidRF

OFF Vehicle stop LF

RR

LR

�) Outlet

SolenoidRF

OFF Vehicle stop LF

RR

LR

Page 865 of 1556

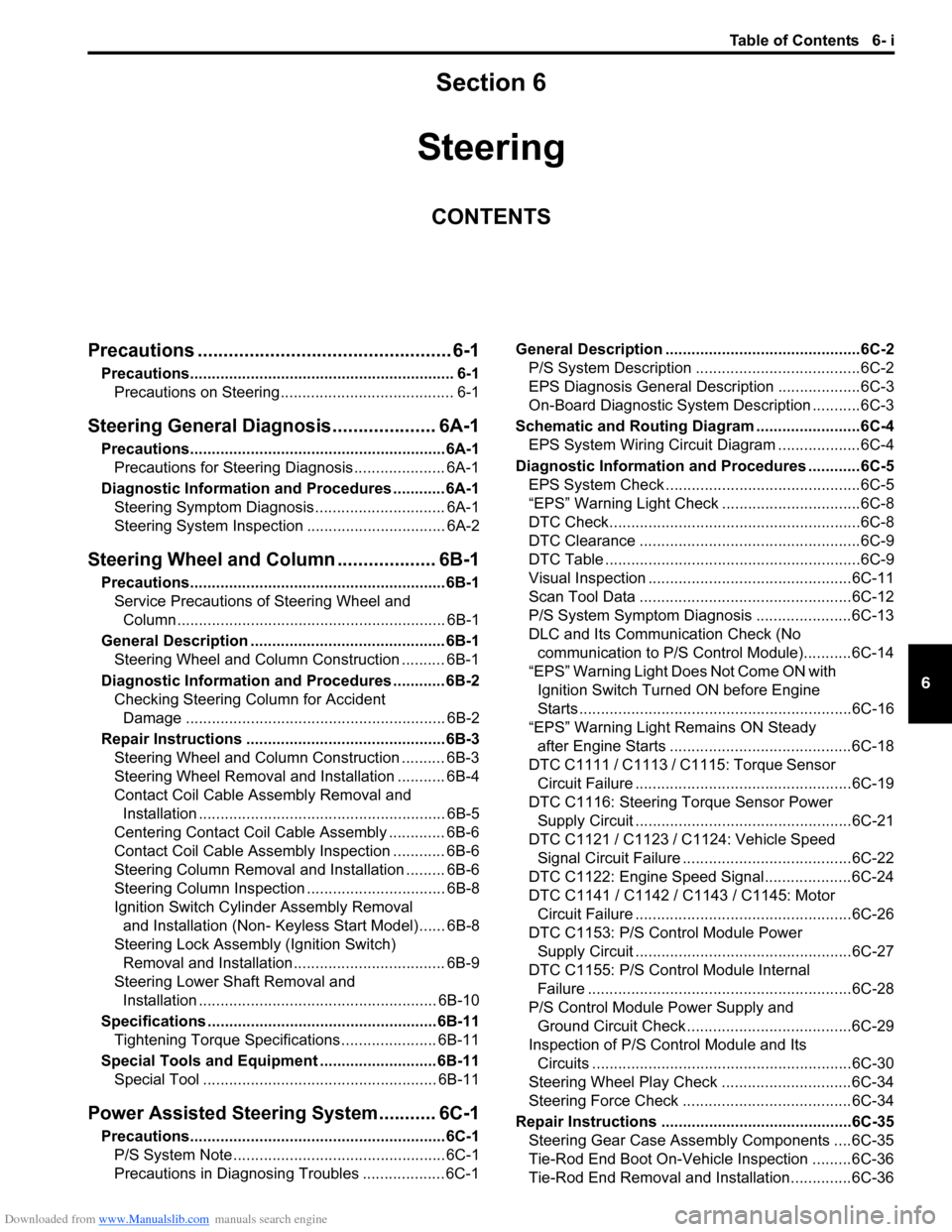

Downloaded from www.Manualslib.com manuals search engine Table of Contents 6- i

6

Section 6

CONTENTS

Steering

Precautions ................................................. 6-1

Precautions............................................................. 6-1

Precautions on Steering........................................ 6-1

Steering General Diagnosis.................... 6A-1

Precautions........................................................... 6A-1

Precautions for Steering Diagnosis ..................... 6A-1

Diagnostic Information and Procedures ............ 6A-1

Steering Symptom Diagnosis .............................. 6A-1

Steering System Inspection ................................ 6A-2

Steering Wheel and Column................... 6B-1

Precautions........................................................... 6B-1

Service Precautions of Steering Wheel and

Column.............................................................. 6B-1

General Description ............................................. 6B-1

Steering Wheel and Column Construction .......... 6B-1

Diagnostic Information and Procedures ............ 6B-2

Checking Steering Column for Accident

Damage ............................................................ 6B-2

Repair Instructions .............................................. 6B-3

Steering Wheel and Column Construction .......... 6B-3

Steering Wheel Removal and Installation ........... 6B-4

Contact Coil Cable Assembly Removal and

Installation ......................................................... 6B-5

Centering Contact Coil Cable Assembly ............. 6B-6

Contact Coil Cable Assembly Inspection ............ 6B-6

Steering Column Removal and Installation ......... 6B-6

Steering Column Inspection ................................ 6B-8

Ignition Switch Cylinder Assembly Removal

and Installation (Non- Keyless Start Model)...... 6B-8

Steering Lock Assembly (Ignition Switch)

Removal and Installation................................... 6B-9

Steering Lower Shaft Removal and

Installation ....................................................... 6B-10

Specifications..................................................... 6B-11

Tightening Torque Specifications ...................... 6B-11

Special Tools and Equipment ........................... 6B-11

Special Tool ...................................................... 6B-11

Power Assisted Steering System........... 6C-1

Precautions........................................................... 6C-1

P/S System Note ................................................. 6C-1

Precautions in Diagnosing Troubles ................... 6C-1General Description .............................................6C-2

P/S System Description ......................................6C-2

EPS Diagnosis General Description ...................6C-3

On-Board Diagnostic System Description ...........6C-3

Schematic and Routing Diagram ........................6C-4

EPS System Wiring Circuit Diagram ...................6C-4

Diagnostic Information and Procedures ............6C-5

EPS System Check .............................................6C-5

“EPS” Warning Light Check ................................6C-8

DTC Check..........................................................6C-8

DTC Clearance ...................................................6C-9

DTC Table ...........................................................6C-9

Visual Inspection ...............................................6C-11

Scan Tool Data .................................................6C-12

P/S System Symptom Diagnosis ......................6C-13

DLC and Its Communication Check (No

communication to P/S Control Module)...........6C-14

“EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine

Starts ...............................................................6C-16

“EPS” Warning Light Remains ON Steady

after Engine Starts ..........................................6C-18

DTC C1111 / C1113 / C1115: Torque Sensor

Circuit Failure ..................................................6C-19

DTC C1116: Steering Torque Sensor Power

Supply Circuit ..................................................6C-21

DTC C1121 / C1123 / C1124: Vehicle Speed

Signal Circuit Failure .......................................6C-22

DTC C1122: Engine Speed Signal....................6C-24

DTC C1141 / C1142 / C1143 / C1145: Motor

Circuit Failure ..................................................6C-26

DTC C1153: P/S Control Module Power

Supply Circuit ..................................................6C-27

DTC C1155: P/S Control Module Internal

Failure .............................................................6C-28

P/S Control Module Power Supply and

Ground Circuit Check ......................................6C-29

Inspection of P/S Control Module and Its

Circuits ............................................................6C-30

Steering Wheel Play Check ..............................6C-34

Steering Force Check .......................................6C-34

Repair Instructions ............................................6C-35

Steering Gear Case Assembly Components ....6C-35

Tie-Rod End Boot On-Vehicle Inspection .........6C-36

Tie-Rod End Removal and Installation..............6C-36

Page 881 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-1

Ste eri ng

Power Assisted Steering System

Precautions

P/S System NoteS6RW0D6300001

NOTE

All steering gear fasteners are important attaching parts in that they could affect the performance of

vital parts and systems, and/or could result in major repair expense. They must be replaced with one of

the same part number or with an equivalent part if replacement becomes necessary. Do not use a

replacement part of lesser quality or substitute design. Torque values must be used as specified

during reassembly to assure proper retention of these parts.

Precautions in Diagnosing TroublesS6RW0D6300002

• Take a note of DTC indicated on the SUZUKI scan tool.

• Before inspection, be sure to read “Precautions for Electrical Circuit Service in Section 00” and understand what is

written there.

• DTC C1122 (engine speed signal failure) is indicated when ignition switch is at ON position and engine is not

running, but it means there is nothing abnormal if indication changes to a normal one when engine is started.

• As DTC is stored in memory of the P/S control module, be sure to clear memory after repair by performing the

procedure described in “DTC Clearance”.

Page 882 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-2 Power Assisted Steering System:

General Description

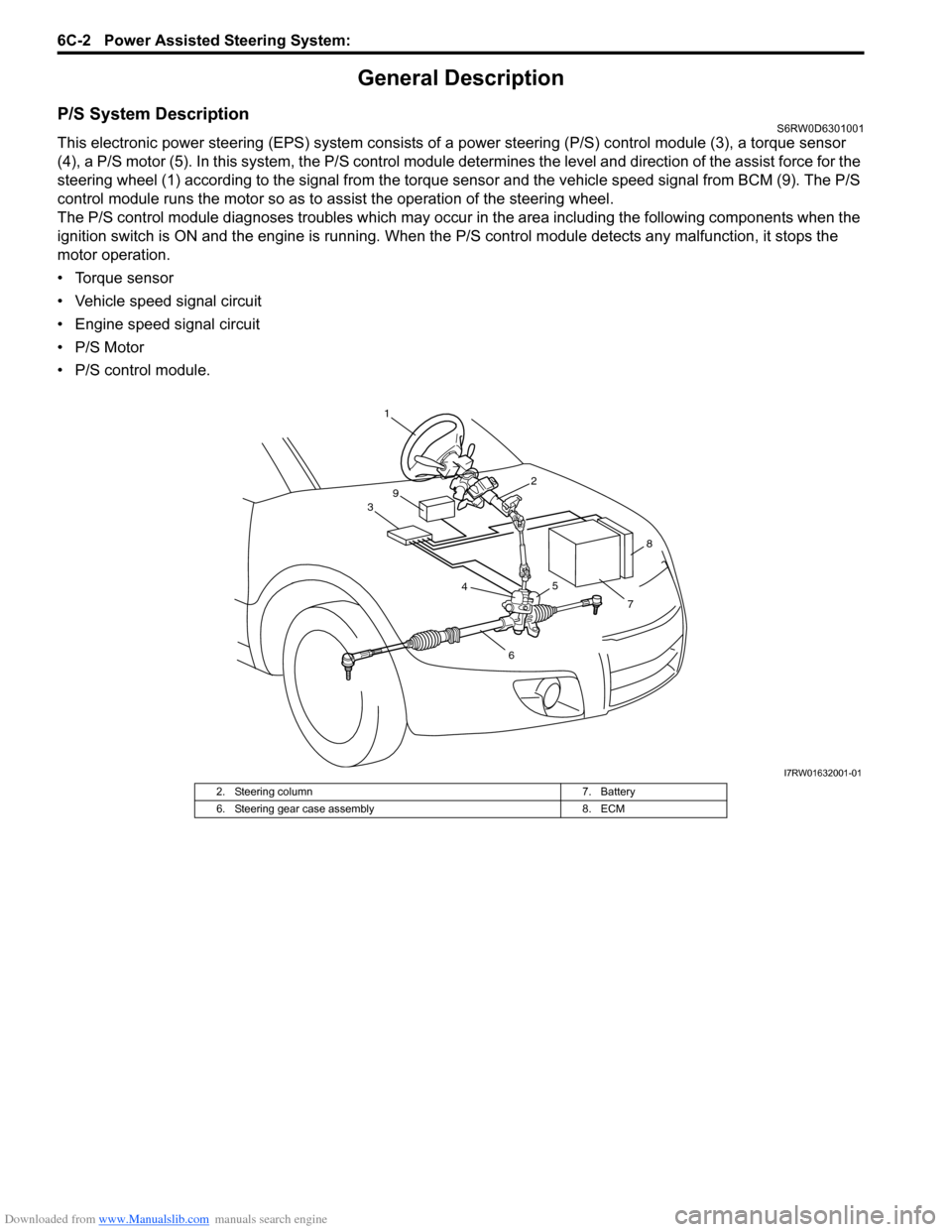

P/S System DescriptionS6RW0D6301001

This electronic power steering (EPS) system consists of a power steering (P/S) control module (3), a torque sensor

(4), a P/S motor (5). In this system, the P/S control module determines the level and direction of the assist force for the

steering wheel (1) according to the signal from the torque sensor and the vehicle speed signal from BCM (9). The P/S

control module runs the motor so as to assist the operation of the steering wheel.

The P/S control module diagnoses troubles which may occur in the area including the following components when the

ignition switch is ON and the engine is running. When the P/S control module detects any malfunction, it stops the

motor operation.

• Torque sensor

• Vehicle speed signal circuit

• Engine speed signal circuit

• P/S Motor

• P/S control module.

1

32

4

6

7

5

8

9

I7RW01632001-01

2. Steering column 7. Battery

6. Steering gear case assembly 8. ECM

Page 883 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-3

EPS Diagnosis General DescriptionS6RW0D6301002

The P/S system in this vehicle is controlled by the P/S control module. The P/S control module has an on-board

diagnostic system which detects a malfunction in this system. When diagnosing troubles, be sure to have full

understanding of the outline of “On-Board Diagnostic System Description” and each item in “Precautions in

Diagnosing Troubles”, and then execute diagnosis according to “EPS System Check”.

On-Board Diagnostic System DescriptionS6RW0D6301003

The P/S control module performs the on-board diagnosis (self-diagnosis) on the system and operates the “EPS”

warning light (1) as follows.

• The “EPS” warning light lights when the ignition switch is turned to ON position (but the engine at stop) regardless

of the condition of the P/S control system. This is only to check if the “EPS” warning light is operated properly.

• If the areas monitored by the P/S control module is free from any trouble after the engine start (while engine is

running), the “EPS” warning light turns OFF.

• When the P/S control module detects a trouble which has occurred in the monitored areas the “EPS” warning light

comes ON while the engine is running to warn the driver of such occurrence of the trouble and at the same time it

stores the exact trouble area in memory inside of the P/S control module.

Driving Cycle

A “Driving Cycle” consists of engine startup and engine shutoff.

3 Driving Cycles Detection Logic

The malfunction detected in the first and second driving cycle is stored in P/S control module memory (in the form of

pending DTC) but the “EPS” warning light does not light at these time. It lights up at the third detection of same

malfunction also in the next driving cycle.

1

I7RW01632002-01

Page 884 of 1556

![SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11 SUZUKI SX4 2006 1.G Service Workshop Manual Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11](/img/20/7612/w960_7612-883.png)

Downloaded from www.Manualslib.com manuals search engine 6C-4 Power Assisted Steering System:

Schematic and Routing Diagram

EPS System Wiring Circuit DiagramS6RW0D6302001

[A]

123

45

3 21

4

567

8

9 11

10 12 13

141516

17 18 19201

2

[B]

1

2

[C] [D]

10 9 8 7654 3 21

16 15 14 13 12 11

26 25 24 2322 21 20 19 18 17

32 31 30 29 28 27

[F][E]

12

BRN RED/

BLU GRY LT GRN/

BLK

BLK

RED

WHT GRN

BLK

E11-1

E11-5

E11-14

E11-12

[J]:E01-44E01-4

[J]:E01-27E01-26

E12-1

E12-2

E11-10E11-8

E11-9

E11-19

E13-1 GRN

GRY

GRN

WHT

G241-25G241-31

RED/BLK

11

12

1314 3 18

20

21

7 19

4 12

22

12V

E13-2BLK

9V

REDE11-20

12V

12V

E61-2

E61-1

610

55

5V

8

E11-115V

PPL

E11-4

9

23

+BB

BLU/

WHTE04-9

1524YELE11-18E31-5

E31-2

E31-39V

3V

E31-4

E31-1IG11617

C07-25

[H]

[G]

G04-15

[I]:G04-22

25L313-3

[I]

I6RW0D630001-01

[A]: P/S control module connector No.1 “E11” (viewed from harness side) 3. Junction block assembly 15. BCM

[B]: P/S control module connector No.2 “E13” (viewed from harness side) 4. Main fuse 16. Output shaft speed sensor

[C]: P/S control module connector No.3 “E12” (viewed from harness side) 5. Front (left/right) wheel speed sensor 17. TCM

[D]: Combination meter connector “G241” (viewed from harness side) 6. ABS control module 18. Individual circuit fuse box No.1

[E]: Torque sensor connector “E31” (viewed from harness side) 7. Combination meter 19. “IGN” fuse

[F]: Motor connector “E61” (viewed from harness side) 8. “EPS” warning light 20. “P/S” fuse

[G]: M/T model 9. Data link connector (DLC) 21. “IG1 SIG” fuse

[H]: A/T model 10. ECM 22. “MTR” fuse

[I]: Junction block without BCM model (Taiwan model) 11. P/S control module 23. To ABS control module

[J]: M15A engine with 4A/T equipped with slip control model (Hong Kong

model)12. P/S motor 24. To HVAC control module

1. Main fuse box 13. Shield 25. To SDM

2. Ignition switch 14. Torque sensor (built into steering gear case)

Page 885 of 1556

Downloaded from www.Manualslib.com manuals search engine Power Assisted Steering System: 6C-5

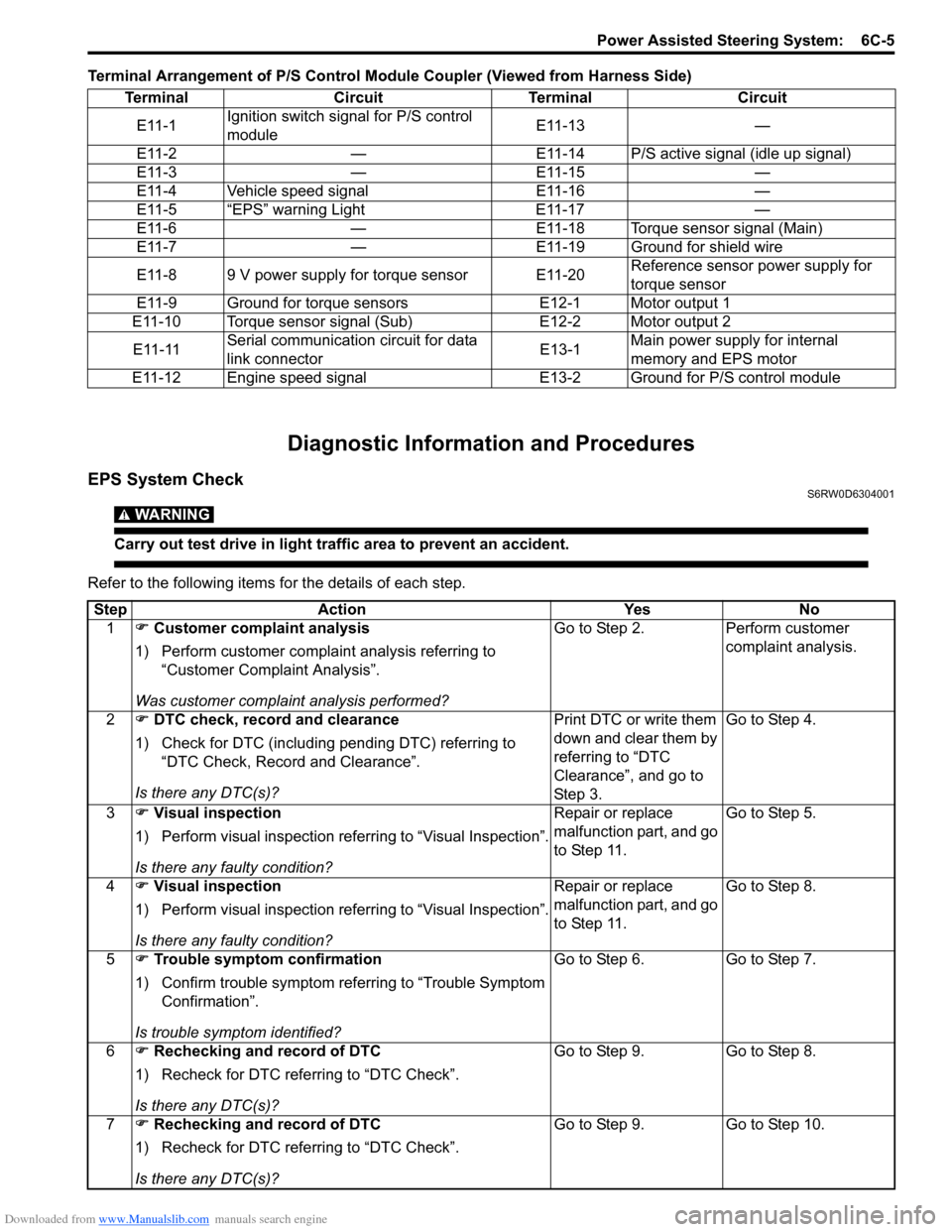

Terminal Arrangement of P/S Control Module Coupler (Viewed from Harness Side)

Diagnostic Information and Procedures

EPS System CheckS6RW0D6304001

WARNING!

Carry out test drive in light traffic area to prevent an accident.

Refer to the following items for the details of each step.Terminal Circuit Terminal Circuit

E11-1Ignition switch signal for P/S control

moduleE11-13 —

E11-2 — E11-14 P/S active signal (idle up signal)

E11-3 — E11-15 —

E11-4 Vehicle speed signal E11-16 —

E11-5 “EPS” warning Light E11-17 —

E11-6 — E11-18 Torque sensor signal (Main)

E11-7 — E11-19 Ground for shield wire

E11-8 9 V power supply for torque sensor E11-20Reference sensor power supply for

torque sensor

E11-9 Ground for torque sensors E12-1 Motor output 1

E11-10 Torque sensor signal (Sub) E12-2 Motor output 2

E11-11Serial communication circuit for data

link connectorE13-1Main power supply for internal

memory and EPS motor

E11-12 Engine speed signal E13-2 Ground for P/S control module

Step Action Yes No

1�) Customer complaint analysis

1) Perform customer complaint analysis referring to

“Customer Complaint Analysis”.

Was customer complaint analysis performed?Go to Step 2. Perform customer

complaint analysis.

2�) DTC check, record and clearance

1) Check for DTC (including pending DTC) referring to

“DTC Check, Record and Clearance”.

Is there any DTC(s)?Print DTC or write them

down and clear them by

referring to “DTC

Clearance”, and go to

St ep 3 .Go to Step 4.

3�) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition?Repair or replace

malfunction part, and go

to Step 11.Go to Step 5.

4�) Visual inspection

1) Perform visual inspection referring to “Visual Inspection”.

Is there any faulty condition?Repair or replace

malfunction part, and go

to Step 11.Go to Step 8.

5�) Trouble symptom confirmation

1) Confirm trouble symptom referring to “Trouble Symptom

Confirmation”.

Is trouble symptom identified?Go to Step 6. Go to Step 7.

6�) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)?Go to Step 9. Go to Step 8.

7�) Rechecking and record of DTC

1) Recheck for DTC referring to “DTC Check”.

Is there any DTC(s)?Go to Step 9. Go to Step 10.

Page 888 of 1556

Downloaded from www.Manualslib.com manuals search engine 6C-8 Power Assisted Steering System:

Step 8: Steering Symptom Diagnosis and P/S

System Symptom Diagnosis

Perform basic steering system check according to

“Steering Symptom Diagnosis in Section 6A” first. When

the end of the flow has been reached, check the parts of

the system suspected as a possible cause referring to

“P/S System Symptom Diagnosis” and based on

symptoms appearing on the vehicle (symptoms obtained

through steps of customer complaint analysis, trouble

symptom confirmation and/or basic P/S system check)

and repair or replace faulty parts, if any.

Step 9: Troubleshooting for DTC (See each DTC

Diag. Flow)

Based on the DTC indicated in Step 6 or 7 and referring

to the applicable DTC diag. flow, locate the cause of the

trouble, namely in a sensor, switch, wire harness,

connector, actuator, P/S control module or other part and

repair or replace faulty parts.

Step 10: Intermittent Problems Check

Check parts where an intermittent trouble is easy to

occur (e.g., wire harness, connector, etc.), referring to

“Intermittent and Poor Connection Inspection in Section

00” and related circuit of DTC recorded in Step 2.

Step 11: Final Confirmation Test

Confirm that the problem symptom has gone and the P/

S system is free from any abnormal conditions. If what

has been repaired is related to the DTC, clear the DTC

once, perform DTC confirmation procedure and confirm

that no DTC is indicated.

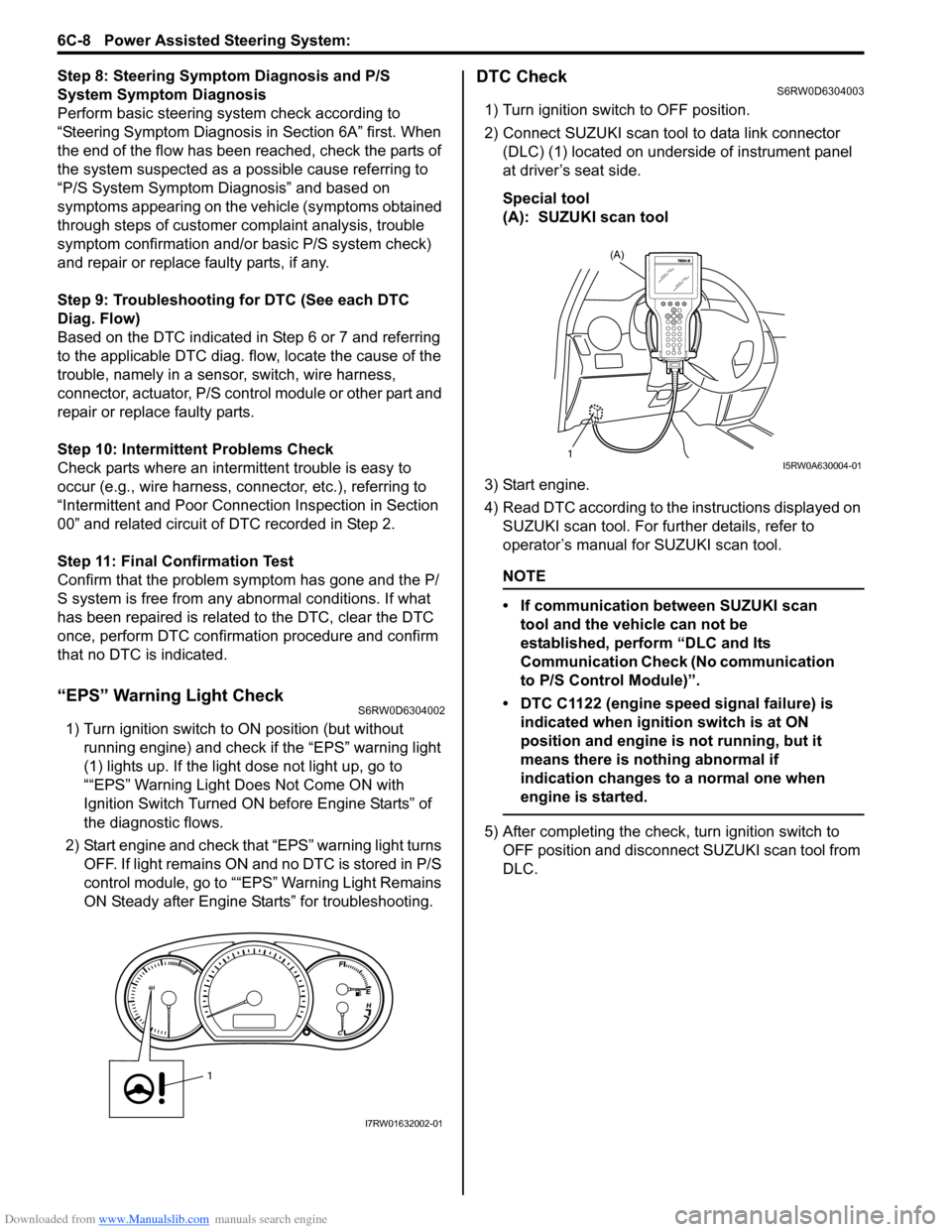

“EPS” Warning Light CheckS6RW0D6304002

1) Turn ignition switch to ON position (but without

running engine) and check if the “EPS” warning light

(1) lights up. If the light dose not light up, go to

““EPS” Warning Light Does Not Come ON with

Ignition Switch Turned ON before Engine Starts” of

the diagnostic flows.

2) Start engine and check that “EPS” warning light turns

OFF. If light remains ON and no DTC is stored in P/S

control module, go to ““EPS” Warning Light Remains

ON Steady after Engine Starts” for troubleshooting.

DTC CheckS6RW0D6304003

1) Turn ignition switch to OFF position.

2) Connect SUZUKI scan tool to data link connector

(DLC) (1) located on underside of instrument panel

at driver’s seat side.

Special tool

(A): SUZUKI scan tool

3) Start engine.

4) Read DTC according to the instructions displayed on

SUZUKI scan tool. For further details, refer to

operator’s manual for SUZUKI scan tool.

NOTE

• If communication between SUZUKI scan

tool and the vehicle can not be

established, perform “DLC and Its

Communication Check (No communication

to P/S Control Module)”.

• DTC C1122 (engine speed signal failure) is

indicated when ignition switch is at ON

position and engine is not running, but it

means there is nothing abnormal if

indication changes to a normal one when

engine is started.

5) After completing the check, turn ignition switch to

OFF position and disconnect SUZUKI scan tool from

DLC.

1

I7RW01632002-01

(A)

1I5RW0A630004-01