engine coolant TATA SAFARI 2015 User Guide

[x] Cancel search | Manufacturer: TATA, Model Year: 2015, Model line: SAFARI, Model: TATA SAFARI 2015Pages: 161, PDF Size: 2.55 MB

Page 106 of 161

106

Engine Cooling System Engine Cooling SystemEngine Cooling System Engine Cooling System

Engine Cooling System

If engine overheating occurs, there could be a fault in the

cooling system which may be on account of :

1. Less coolant in the cooling system or dirt/scale having

accumulated inside cooling water passages especially

in the radiator core.

2 . Choking of radiator passages due to foreign material or

damages.

3. Defective thermostat.

4. Defective coolant temperature sensor.

5 . Non operation of electrically operated fans (Controlled

by ECU).

6. Coolant leakage.

7. Radiator cap not sealing properly.

8 . A.C. condenser fan not working

9. Excessive refrigerant charging in the A.C. system.

10. No communication between auxiliary tank and radiator.

P PP P

P

r rr r

r

e ee e

e

v vv v

v

en enen en

en

tion of R tion of Rtion of R tion of R

tion of R

ust F ust Fust F ust F

ust F

or oror or

or

ma mama ma

ma

tion tiontion tion

tion

To prevent rust formation in the radiator use premixed

recommended anti-freeze coolant. This is sufficient to

operate the vehicle upto -40

oC.

C CC C

C

OOLING SY OOLING SYOOLING SY OOLING SY

OOLING SY

STEM STEMSTEM STEM

STEMM A I N T E N A N C E

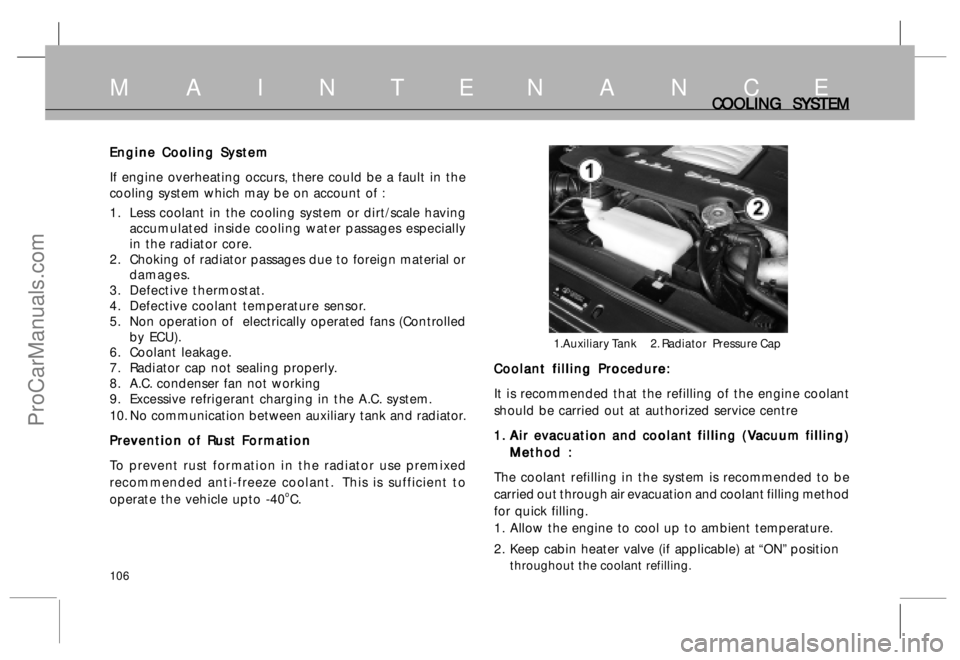

1.Auxiliary Tank 2. Radiator Pressure Cap

Coolant filling Procedure: Coolant filling Procedure:Coolant filling Procedure: Coolant filling Procedure:

Coolant filling Procedure:

It is recommended that the refilling of the engine coolant

should be carried out at authorized service centre

1. 1.1. 1.

1.

A A A A

A

ir e ir eir e ir e

ir e

v vv v

v

acua acuaacua acua

acua

tion and c tion and ction and c tion and c

tion and c

o oo o

o

olan olanolan olan

olan

t filling ( t filling (t filling ( t filling (

t filling (

V VV V

V

acuum filling) acuum filling)acuum filling) acuum filling)

acuum filling)

Method : Method :Method : Method :

Method :

The coolant refilling in the system is recommended to be

carried out through air evacuation and coolant filling method

for quick filling.

1 . Allow the engine to cool up to ambient temperature.

2 . Keep cabin heater valve (if applicable) at “ON” position

throughout the coolant refilling.

ProCarManuals.com

Page 107 of 161

107

C CC C

C

OOLING SY OOLING SYOOLING SY OOLING SY

OOLING SY

STEM STEMSTEM STEM

STEMM A I N T E N A N C E

3. The complete cooling system should be drained (old coolant)

before refilling the system.

a. Remove radiator pressure cap

b. Drain the coolant from engine through the drain hole on

thermostat housing lower part. Drain coolant from radiator

through the radiator drain hole.

c. Refit the drain plugs on thermostat housing lower part and

the radiator.

d. Pour fresh water through the filler neck up to top and again

drain the water through the drain holes. This will ensure

removal of the old coolant from the system

e. After flushing out water, secure the drain plugs on radiator

and thermostat housing lower part properly with new

sealing washer.

f. Drain the auxiliary tank and refit the hoses.

4. Take the recommended coolant and water in 1:1 proportion

5. Carry out air evacuation and coolant filling on machine

( Vacuum filling)

( The machine setting to be done as follows,

Quantity to be filled: 6.1 lit approx, back pressure: 1.7 bar)

6. Fill the coolant in auxiliary tank up to “FIRST FILL / REFILL”

mark.

Manual Coolant refilling : Manual Coolant refilling :Manual Coolant refilling : Manual Coolant refilling :

Manual Coolant refilling :

If the air evacuation and coolant filling (vacuum filling) system is

not available, then alternate procedure is as mentioned below.1. Follow sr. no 1 to 4 indicated in Air evacuation and coolant

filling ( Vacuum filling) procedure.

2. Refill the coolant (coolant and water as per recommendation)

through radiator filler neck.

3. When coolant level comes up to radiator filler neck, wait and

allow air bubbles to escape from the system for 2 to 5 min.

Top up coolant in radiator filler neck when level drops.

4. Fill the coolant in the auxiliary tank up to “FIRST FILL / REFILL”

mark.

5. Start the engine and run at idle for 10 min. with open radiator

filler neck. Allow air to escape from the system.Top up coolant

slowly in the radiator filler neck while idling.

6. Stop the engine and allow air bubbles to escape from the

system. Top up coolant through radiator filler neck. Secure

the radiator pressure cap on radiator filler neck.

7. Start the engine and run in stationary condition at 2200 to

2500 rpm till thermostat opens and continue to run for 5

minutes. ( The radiator fans coming on is the indication of

opening the thermostat)

8. Stop the engine and allow it to cool. Open the radiator

pressure cap & top up coolant in radiator filler neck. Secure

the radiator pressure cap on the radiator filler neck.

9. Refill the coolant in the auxiliary tank till “first fill / Refill” level

mark.

10. The coolant refilling is complete now.

11. Ensure that there are no leakages in the completesystem.

ProCarManuals.com

Page 136 of 161

136

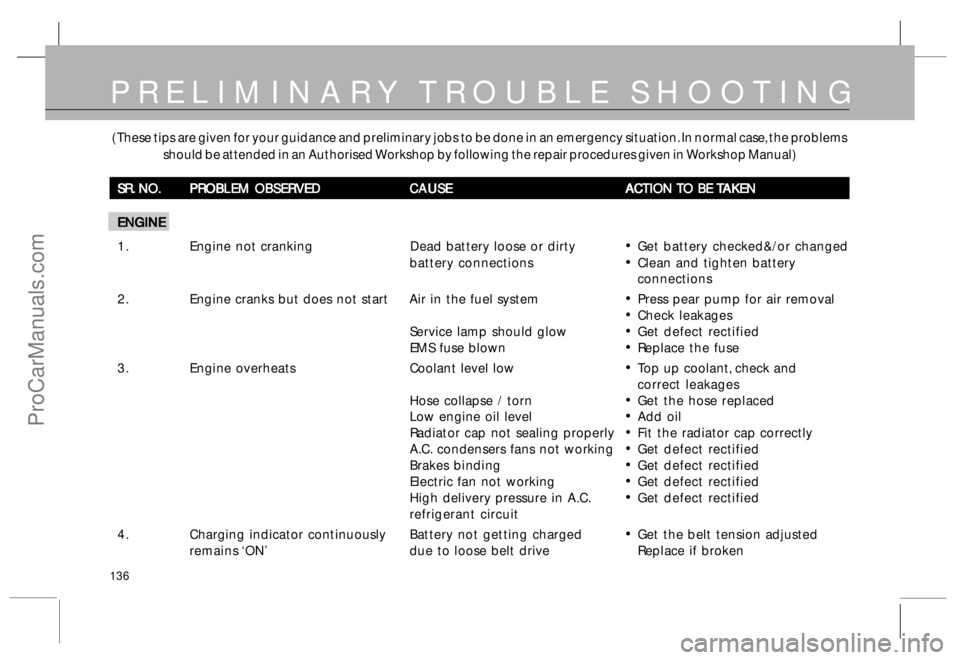

( These tips are given for your guidance and preliminary jobs to be done in an emergency situation. In normal case, the problems

should be attended in an Authorised Workshop by following the repair procedures given in Workshop Manual)

SR. NO. SR. NO.SR. NO. SR. NO.

SR. NO.

PROBLEM OBSERVED PROBLEM OBSERVEDPROBLEM OBSERVED PROBLEM OBSERVED

PROBLEM OBSERVED

CAUSE CAUSECAUSE CAUSE

CAUSE

A AA A

A

CTION CTION CTION CTION

CTION

T TT T

T

O BE O BE O BE O BE

O BE

T TT T

T

AKEN AKENAKEN AKEN

AKEN

ENGINE ENGINEENGINE ENGINE

ENGINE

1 . Engine not cranking Dead battery loose or dirty

•Get battery checked&/or changed

battery connections

•Clean and tighten battery

connections

2 . Engine cranks but does not start Air in the fuel system

•Press pear pump for air removal

•Check leakages

Service lamp should glow

•Get defect rectified

EMS fuse blown

•Replace the fuse

3. Engine overheatsCoolant level low

•Top up coolant, check and

correct leakages

Hose collapse / torn

•Get the hose replaced

Low engine oil level

•Add oil

Radiator cap not sealing properly

•Fit the radiator cap correctly

A.C. condensers fans not working

•Get defect rectified

Brakes binding

•Get defect rectified

Electric fan not working

•Get defect rectified

High delivery pressure in A.C.

•Get defect rectified

refrigerant circuit

4 . Charging indicator continuouslyBattery not getting charged

•Get the belt tension adjusted

remains ‘ON’due to loose belt drive Replace if broken

PRELIMINARY TROUBLE SHOOTING

ProCarManuals.com

Page 146 of 161

146

S E R V I C E S C H E D U L ESERVICE SCHEDULE SERVICE SCHEDULESERVICE SCHEDULE SERVICE SCHEDULE

SERVICE SCHEDULE

SR SRSR SR

SR

x 1000 km x 1000 kmx 1000 km x 1000 km

x 1000 km

NO NONO NO

NO

OPER OPEROPER OPER

OPER

A AA A

A

TIONS TIONSTIONS TIONS

TIONS

FREQUENCY FREQUENCYFREQUENCY FREQUENCY

FREQUENCY

1-1.5 1-1.51-1.5 1-1.5

1-1.5

15 1515 15

15

30 3030 30

30

45 4545 45

45

60 6060 60

60

75 7575 75

75

90 9090 90

90

105 105105 105

105

GENERAL GENERALGENERAL GENERAL

GENERAL

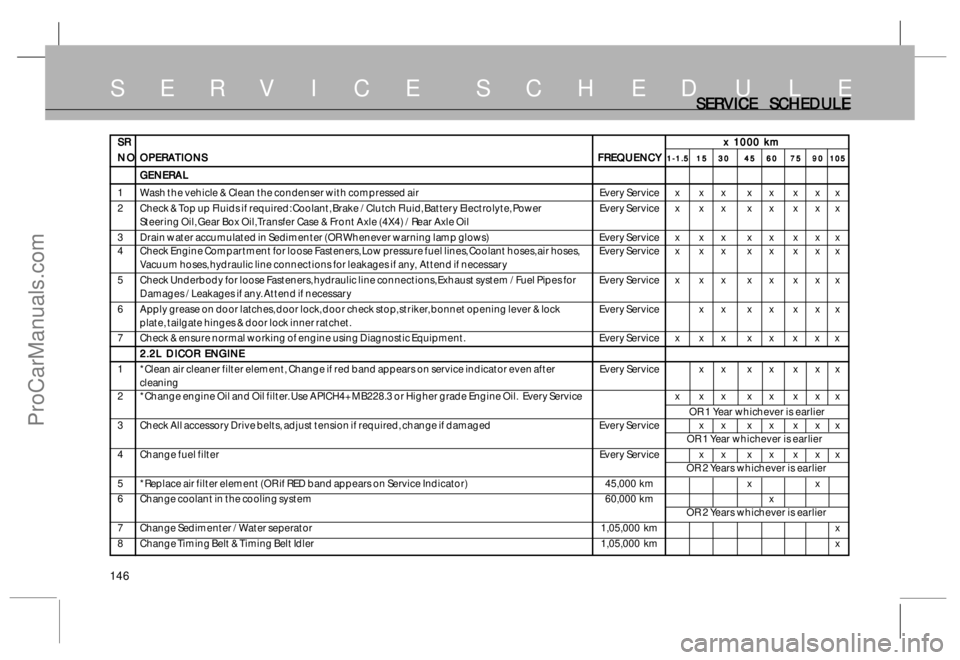

1 Wash the vehicle & Clean the condenser with compressed air Every Service x x x x x x x x

2 Check & Top up Fluids if required: Coolant, Brake / Clutch Fluid, Battery Electrolyte, Power Every Service x x x x x x x x

Steering Oil, Gear Box Oil, Transfer Case & Front Axle (4X4) / Rear Axle Oil

3 Drain water accumulated in Sedimenter (OR Whenever warning lamp glows) Every Service x x x x x x x x

4 Check Engine Compartment for loose Fasteners, Low pressure fuel lines, Coolant hoses, air hoses, Every Service x x x x x x x x

Vacuum hoses, hydraulic line connections for leakages if any, Attend if necessary

5 Check Underbody for loose Fasteners, hydraulic line connections, Exhaust system / Fuel Pipes for Every Service x x x x x x x x

Damages / Leakages if any. Attend if necessary

6 Apply grease on door latches, door lock, door check stop, striker, bonnet opening lever & lock Every Service x x x x x x x

plate, tailgate hinges & door lock inner ratchet.

7 Check & ensure normal working of engine using Diagnostic Equipment. Every Service x x x x x x x x

2.2L DICOR ENGINE 2.2L DICOR ENGINE2.2L DICOR ENGINE 2.2L DICOR ENGINE

2.2L DICOR ENGINE

1 *Clean air cleaner filter element, Change if red band appears on service indicator even after Every Service x x x x x x x

cleaning

2 *Change engine Oil and Oil filter. Use APICH4+MB228.3 or Higher grade Engine Oil.Every Service x x x x x x x x

OR 1 Year whichever is earlier

3 Check All accessory Drive belts, adjust tension if required, change if damaged Every Service x x x x x x x

OR 1 Year whichever is earlier

4 Change fuel filterEvery Service x x x x x x x

OR 2 Years whichever is earlier

5 *Replace air filter element (OR if RED band appears on Service Indicator) 45,000 km x x

6 Change coolant in the cooling system 60,000 km x

OR 2 Years whichever is earlier

7 Change Sedimenter / Water seperator1,05,000 km x

8 Change Timing Belt & Timing Belt Idler1,05,000 km x

ProCarManuals.com

Page 155 of 161

155

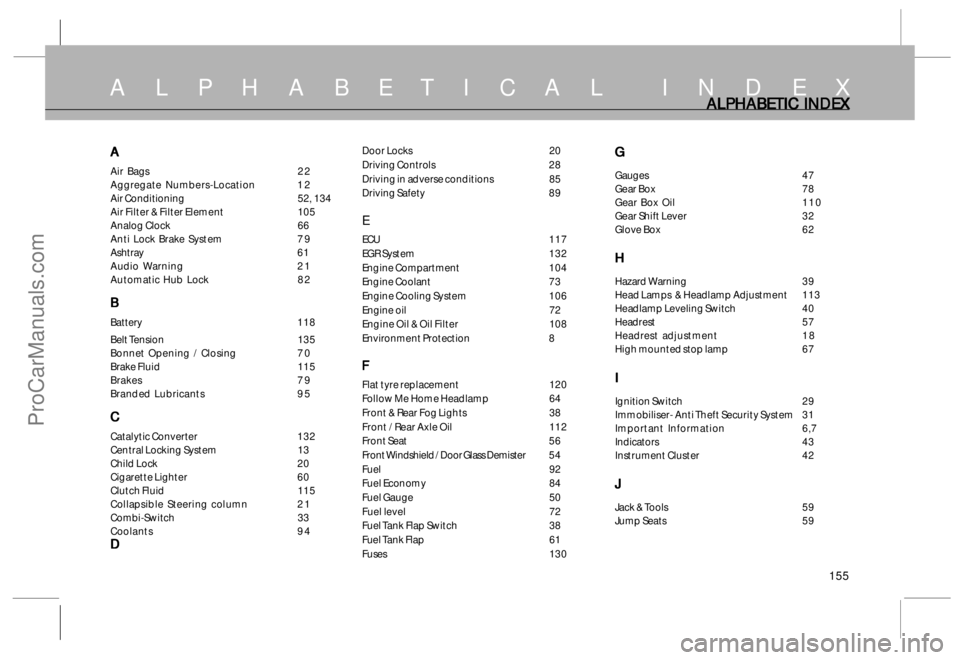

A L P H A B E T I C A L I N D E X ALPHABETIC INDEX ALPHABETIC INDEX ALPHABETIC INDEX ALPHABETIC INDEX

ALPHABETIC INDEX

A AA A

A

Air Bags 2 2

Aggregate Numbers-Location 1 2

Air Conditioning52, 134

Air Filter & Filter Element 105

Analog Clock 66

Anti Lock Brake System 7 9

Ashtray 6 1

Audio Warning 2 1

Automatic Hub Lock 8 2

B BB B

B

Battery 118

Belt Tension 135

Bonnet Opening / Closing 7 0

Brake Fluid 115

Brakes 7 9

Branded Lubricants 9 5

C CC C

C

Catalytic Converter 132

Central Locking System 13

Child Lock 20

Cigarette Lighter 60

Clutch Fluid 115

Collapsible Steering column 2 1

Combi-Switch 33

Coolants 9 4

D DD D

D

Door Locks 20

Driving Controls 28

Driving in adverse conditions 85

Driving Safety 89

E

ECU 1 1 7

EGR System 132

Engine Compartment 104

Engine Coolant 73

Engine Cooling System 106

Engine oil 72

Engine Oil & Oil Filter 108

Environment Protection 8

F FF F

F

Flat tyre replacement 120

Follow Me Home Headlamp 64

Front & Rear Fog Lights 38

Front / Rear Axle Oil 112

Front Seat 56

Front Windshield / Door Glass Demister 5 4

Fuel 92

Fuel Economy 84

Fuel Gauge 50

Fuel level 72

Fuel Tank Flap Switch 38

Fuel Tank Flap 61

Fuses 130

G GG G

G

Gauges 4 7

Gear Box 78

Gear Box Oil 1 1 0

Gear Shift Lever 32

Glove Box 62

H HH H

H

Hazard Warning 39

Head Lamps & Headlamp Adjustment 113

Headlamp Leveling Switch 40

Headrest 57

Headrest adjustment 1 8

High mounted stop lamp 67

I II I

I

Ignition Switch 29

Immobiliser- Anti Theft Security System 31

Important Information 6,7

Indicators 43

Instrument Cluster 42

J JJ J

J

Jack & Tools 59

Jump Seats 59

ProCarManuals.com