torque TESLA MODEL Y 2023 Owners Manual

[x] Cancel search | Manufacturer: TESLA, Model Year: 2023, Model line: MODEL Y, Model: TESLA MODEL Y 2023Pages: 298, PDF Size: 10.28 MB

Page 183 of 298

WARNING: When lifting out the lead-acid

battery, stand in front of the vehicle and use

proper lifting technique. The lead-acid battery

weighs approximately 25 lb (12 kg). Failure to

do so may cause serious injury.

11.

Inspect the new lead-acid battery to ensure it has a

red plug in the casing on the positive (+) terminal

side. If the new lead-acid battery does not have a red plug, use a small trim tool to transfer the red plug

from the old battery to the new one.

CAUTION: Dispose of the old lead-acid battery

according to local laws, such as dropping it off

at a battery recycling facility. Keep the lead-

acid battery upright and place it on a towel or

piece of cardboard when transporting it.

Installation:

1. Carefully maneuver the new lead-acid battery into

place, taking care not to touch or damage nearby

components.2.

Install the lead-acid battery hold down and use a 10mm socket to tighten the nut that secures it to the 12V battery. Torque the nut to 6 Nm (4.4 ft-lb).

3.

Reconnect the first responder loop.

4.

Remove the protective caps from the positive (+) and negative (-) posts on the new low voltage lead-acid battery.

5.

Connect the positive (+) terminal by positioning the

clamp over the positive (+) post. Using a 10mm socket, torque the nut to 6 Nm (4.4 ft-lb).

Maintenance Service Intervals

181Maintenance

Page 184 of 298

6.

Install the positive (+) terminal cover.

7.

Connect the negative (-) terminal by positioning the

clamp over the negative (-) post. Using a 10mm socket, torque the nut to 6 Nm (4.4 ft-lb).

8.

Connect the vent tube hose into the negative (-) terminal side of the lead-acid battery.

9.

Open one of the vehicle

Page 185 of 298

d. Route the hose so that it is secured by the tab.e.

Use a 10mm socket to install the bolt that attaches the washer

fluid reservoir neck to the underhood

storage unit. Torque the bolt to 5 Nm (3.7 ft-lb).

11.

Replace the underhood apron by aligning the clips into their openings in the front trunk. Press down to lock them in place. The clips make an audible clicking

sound when secured.

12.

Close the front trunk. If an alert to replace the low-

voltage battery was previously shown on the

touchscreen, ensure the alert no longer appears.

Maintenance Service Intervals

183Maintenance

Page 188 of 298

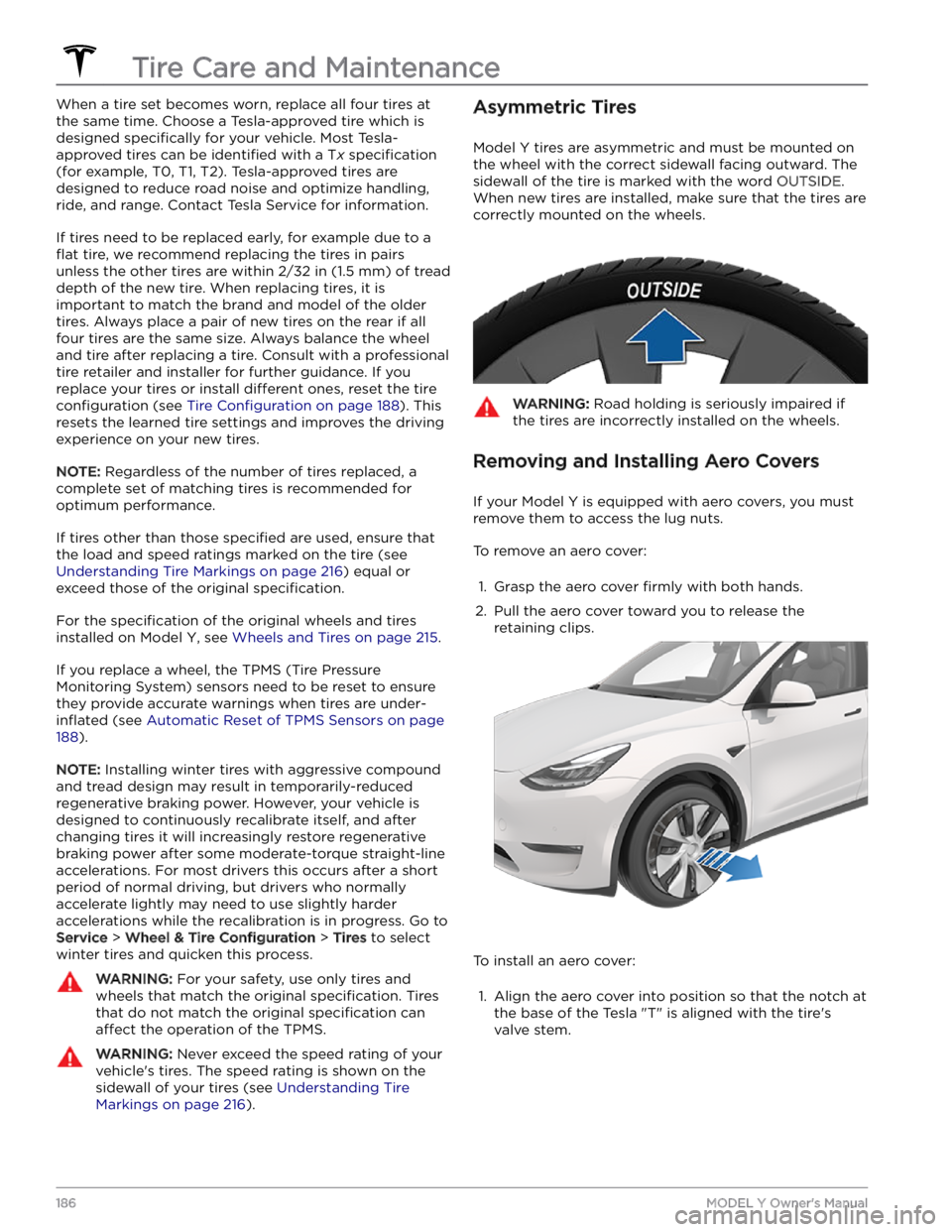

When a tire set becomes worn, replace all four tires at

the same time. Choose a Tesla-approved tire which is

designed

specifically for your vehicle. Most Tesla-

approved tires can be

identified with a Tx specification

(for example, T0, T1, T2). Tesla-approved tires are

designed to reduce road noise and optimize handling, ride, and range. Contact Tesla Service for information.

If tires need to be replaced early, for example due to a

flat tire, we recommend replacing the tires in pairs

unless the other tires are within

2/32 in (1.5 mm) of tread

depth of the new tire. When replacing tires, it is important to match the brand and model of the older

tires. Always place a pair of new tires on the rear if all four tires are the same size. Always balance the wheel and tire after replacing a tire. Consult with a professional tire retailer and installer for further guidance.

If you

replace your tires or install different ones, reset the tire

configuration (see Tire Configuration on page 188). This

resets the learned tire settings and improves the driving

experience on your new tires.

NOTE: Regardless of the number of tires replaced, a

complete set of matching tires is recommended for optimum performance.

If tires other than those specified are used, ensure that

the load and speed ratings marked on the tire

(see

Understanding Tire Markings on page 216) equal or

exceed those of the original

specification.

For the specification of the original wheels and tires

installed on

Model Y, see Wheels and Tires on page 215.

If you replace a wheel, the TPMS (Tire Pressure Monitoring System) sensors need to be reset to ensure they provide accurate warnings when tires are

under-

inflated (see Automatic Reset of TPMS Sensors on page

188).

NOTE: Installing winter tires with aggressive compound

and tread design may result in temporarily-reduced regenerative braking power. However, your vehicle is

designed to continuously recalibrate itself, and after changing tires it will increasingly restore regenerative

braking power after some moderate-torque straight-line accelerations. For most drivers this occurs after a short period of normal driving, but drivers who normally accelerate lightly may need to use slightly harder accelerations while the recalibration is in progress. Go to

Service > Wheel & Tire Configuration > Tires to select

winter tires and quicken this process.

WARNING: For your safety, use only tires and

wheels that match the original specification. Tires

that do not match the original specification can

affect the operation of the TPMS.

WARNING: Never exceed the speed rating of your

vehicle

Page 203 of 298

9.

Loosen the nut on the battery hold down on the top of the lead-acid battery with a 10mm socket. To

release the battery hold down, unhook and slide the

strap back. If needed, tilt the battery hold down

backward so it does not slip into the vehicle.

10.

Using the battery handle, carefully remove the lead- acid battery, taking care not to touch or damage the surrounding components.

WARNING: When lifting out the lead-acid

battery, stand in front of the vehicle and use

proper lifting technique. The lead-acid battery

weighs approximately 25 lb (12 kg). Failure to

do so may cause serious injury.

11.

Inspect the new lead-acid battery to ensure it has a

red plug in the casing on the positive (+) terminal

side. If the new lead-acid battery does not have a red plug, use a small trim tool to transfer the red plug

from the old battery to the new one.

CAUTION: Dispose of the old lead-acid battery

according to local laws, such as dropping it off

at a battery recycling facility. Keep the lead-

acid battery upright and place it on a towel or

piece of cardboard when transporting it.

Installation:

1.

Carefully maneuver the new lead-acid battery into

place, taking care not to touch or damage nearby

components.

2.

Install the lead-acid battery hold down and use a 10mm socket to tighten the nut that secures it to the 12V battery. Torque the nut to 6 Nm (4.4 ft-lb).

Parts and Accessories

201Maintenance

Page 204 of 298

3.

Reconnect the first responder loop.

4.

Remove the protective caps from the positive (+) and negative (-) posts on the new low voltage lead-acid battery.

5.

Connect the positive (+) terminal by positioning the

clamp over the positive (+) post. Using a 10mm socket, torque the nut to 6 Nm (4.4 ft-lb).

6.

Install the positive (+) terminal cover.

7. Connect the negative (-) terminal by positioning the

clamp over the negative (-) post. Using a 10mm socket, torque the nut to 6 Nm (4.4 ft-lb).8.

Connect the vent tube hose into the negative (-) terminal side of the lead-acid battery.

9.

Open one of the vehicle

Page 205 of 298

b.

With a 10mm socket, tighten the bolts (x2) and

torque them to 5 Nm (3.7 ft-lb).

c.

Ensure the O-ring on the washer tank neck is fully seated, then install the washer tank neck by inserting it into the washer tank.

d.

Route the hose so that it is secured by the tab.

e.

Use a 10mm socket to install the bolt that attaches

the washer

fluid reservoir neck to the underhood

storage unit. Torque the bolt to 5 Nm (3.7 ft-lb).

11.

Replace the underhood apron by aligning the clips into their openings in the front trunk. Press down to lock them in place. The clips make an audible clicking

sound when secured.

Parts and Accessories

203Maintenance

Page 217 of 298

Wheel Specifications (Factory)

Wheel DiameterLocationWidth (in)Offset (mm)19"Front/Rear9.54520"Front/Rear9.54521"Front9.54021"Rear10.548Lug Nut Torque129 lb. ft (175 Nm)Lug Nut Socket Size21 mm

NOTE: For instructions on how to jack/lift Model Y, see Jacking and Lifting on page 197.

Tire Specifications (Factory)

Tire SizeLocationSize19"Front/Rear255/45R19 XL20"Front/Rear255/40R20 XL21"Front255/35R21 XL21"Rear275/35R21 XLTire pressures vary depending on the type of tires fitted. Refer to the tire pressures printed on the Tire and

Loading Information label. This label is located on the center door pillar and is visible when the driver

Page 237 of 298

CC_a003

Unable to charge - Wall Connector GFCI tripped

Disconnect and retry or use different equipment

What this alert means:

Ground fault. Current is leaking through an unsafe path. Possible Line to ground or Neutral to ground fault.

What to do:

Try charging again by disconnecting the Wall Connector from the vehicle and reconnecting. If the issue persists, turn

OFF the circuit breaker servicing the Wall Connector, wait 10 seconds, turn the circuit breaker ON again, then try reconnecting the Wall Connector to the vehicle. If the issue persists, consult your electrician or contact Tesla.

For more information, see the installation guide for your Wall Connector.

CC_a004

Unable to charge - Wall Connector issue

Wall Connector needs service

What this alert means:

Wall Connector hardware issue. Possible issues include:

1.

Contactor not working

2.

Self-test of internal ground fault monitoring circuit failed

3.

Thermal sensor disconnected

4.

Other hardware component issues

What to do:

An internal issue was detected by the Wall Connector.

1.

Try charging again by disconnecting the Wall Connector from the vehicle and reconnecting.

2.

If the issue persists, turn OFF the circuit breaker for the Wall Connector, wait 10 seconds, and turn the circuit

breaker ON again. Then try reconnecting the Wall Connector to the vehicle.

3.

If the issue persists, have an electrician make sure all wires are properly connected and torqued according to the

instructions in the Wall Connector Installation Manual.

4.

Once your electrician has completed all work and restored power to the Wall Connector, try charging again by reconnecting the Wall Connector to the vehicle.

5.

If the issue persists, the Wall Connector requires service.

For more information, see the installation guide for your Wall Connector.

CC_a005

Unable to charge - Wall Connector GFCI tripped

Disconnect and retry or use different equipment

What this alert means:

Ground fault. Current is leaking through an unsafe path. Possible Line to ground or Neutral to ground fault.

What to do:

Troubleshooting Alerts

235Troubleshooting

Page 239 of 298

The wiring between the wall power and the Wall Connector has been incorrectly installed. Consult your electrician.

For more information, see the installation guide for your Wall Connector.

CC_a010

Unable to charge - Wall Connector issue

Wall Connector needs service

What this alert means:

Wall Connector hardware issue. Possible issues include:

1.

Contactor not working

2.

Self-test of internal ground fault monitoring circuit failed

3.

Thermal sensor disconnected

4.

Other hardware component issues

What to do:

An internal issue was detected by the Wall Connector.

1.

Try charging again by disconnecting the Wall Connector from the vehicle and reconnecting.

2.

If the issue persists, turn OFF the circuit breaker for the Wall Connector, wait 10 seconds, and turn the circuit

breaker ON again. Then try reconnecting the Wall Connector to the vehicle.

3.

If the issue persists, have an electrician make sure all wires are properly connected and torqued according to the

instructions in the Wall Connector Installation Manual.

4.

Once your electrician has completed all work and restored power to the Wall Connector, try charging again by reconnecting the Wall Connector to the vehicle.

5.

If the issue persists, the Wall Connector requires service.

For more information, see the installation guide for your Wall Connector.

CC_a011

Unable to charge - Wall Connector too hot

Let Wall Connector cool and try again

What this alert means:

Over temperature protection (latchoff).

What to do:

Make sure the Wall Connector is not covered by anything and that there is no heat source nearby. If the problem

persists in normal ambient temperatures

(under 100