combination TOYOTA CAMRY 1994 XV10 / 4.G Wiring Diagrams User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1994, Model line: CAMRY, Model: TOYOTA CAMRY 1994 XV10 / 4.GPages: 307, PDF Size: 5.48 MB

Page 74 of 307

74

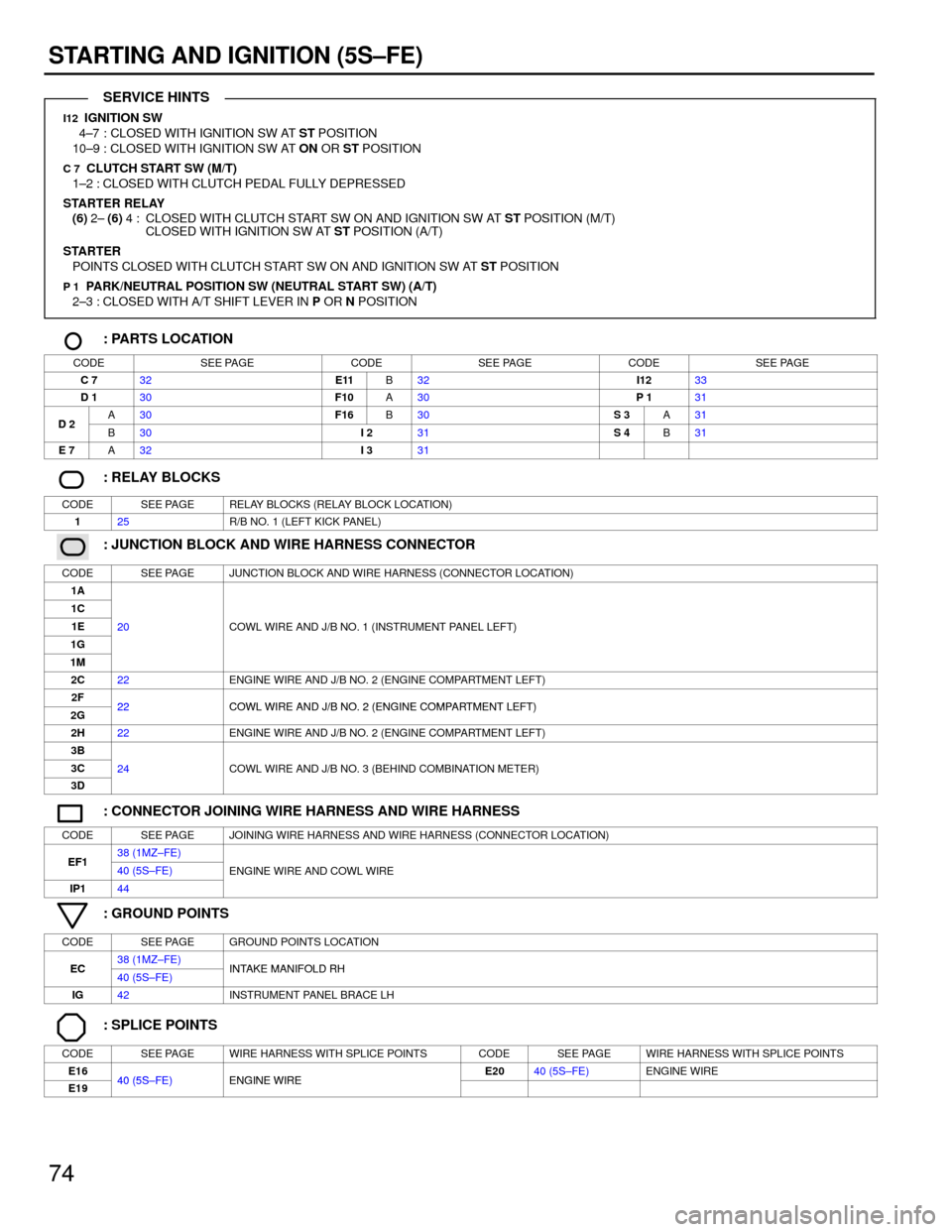

STARTING AND IGNITION (5S±FE)

I12 IGNITION SW

4±7 : CLOSED WITH IGNITION SW AT ST POSITION

10±9 : CLOSED WITH IGNITION SW AT ON OR ST POSITION

C 7 CLUTCH START SW (M/T)

1±2 : CLOSED WITH CLUTCH PEDAL FULLY DEPRESSED

STARTER RELAY

(6) 2± (6) 4 : CLOSED WITH CLUTCH START SW ON AND IGNITION SW AT ST POSITION (M/T)

CLOSED WITH IGNITION SW AT ST POSITION (A/T)

STARTER

POINTS CLOSED WITH CLUTCH START SW ON AND IGNITION SW AT ST POSITION

P 1 PARK/NEUTRAL POSITION SW (NEUTRAL START SW) (A/T)

2±3 : CLOSED WITH A/T SHIFT LEVER IN P OR N POSITION

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C 732E11B32I1233

D 130F10A30P 131

D2A30F16B30S 3A31D 2B30I 231S 4B31

E 7A32I 331

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

125R/B NO. 1 (LEFT KICK PANEL)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1A

1C

1E20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1G

20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1M

2C22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2F22COWL WIRE AND J/B NO 2 (ENGINE COMPARTMENT LEFT)2G22COWL WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2H22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

3B

3C24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

3D

24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EF138 (1MZ±FE)EF140 (5S±FE)ENGINE WIRE AND COWL WIRE

IP144

ENGINE WIRE AND COWL WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EC38 (1MZ±FE)INTAKE MANIFOLD RHEC40 (5S±FE)INTAKE MANIFOLD RH

IG42INSTRUMENT PANEL BRACE LH

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E1640 (5S FE)ENGINE WIREE2040 (5S±FE)ENGINE WIRE

E1940 (5S±FE)ENGINE WIRE

SERVICE HINTS

Page 78 of 307

78

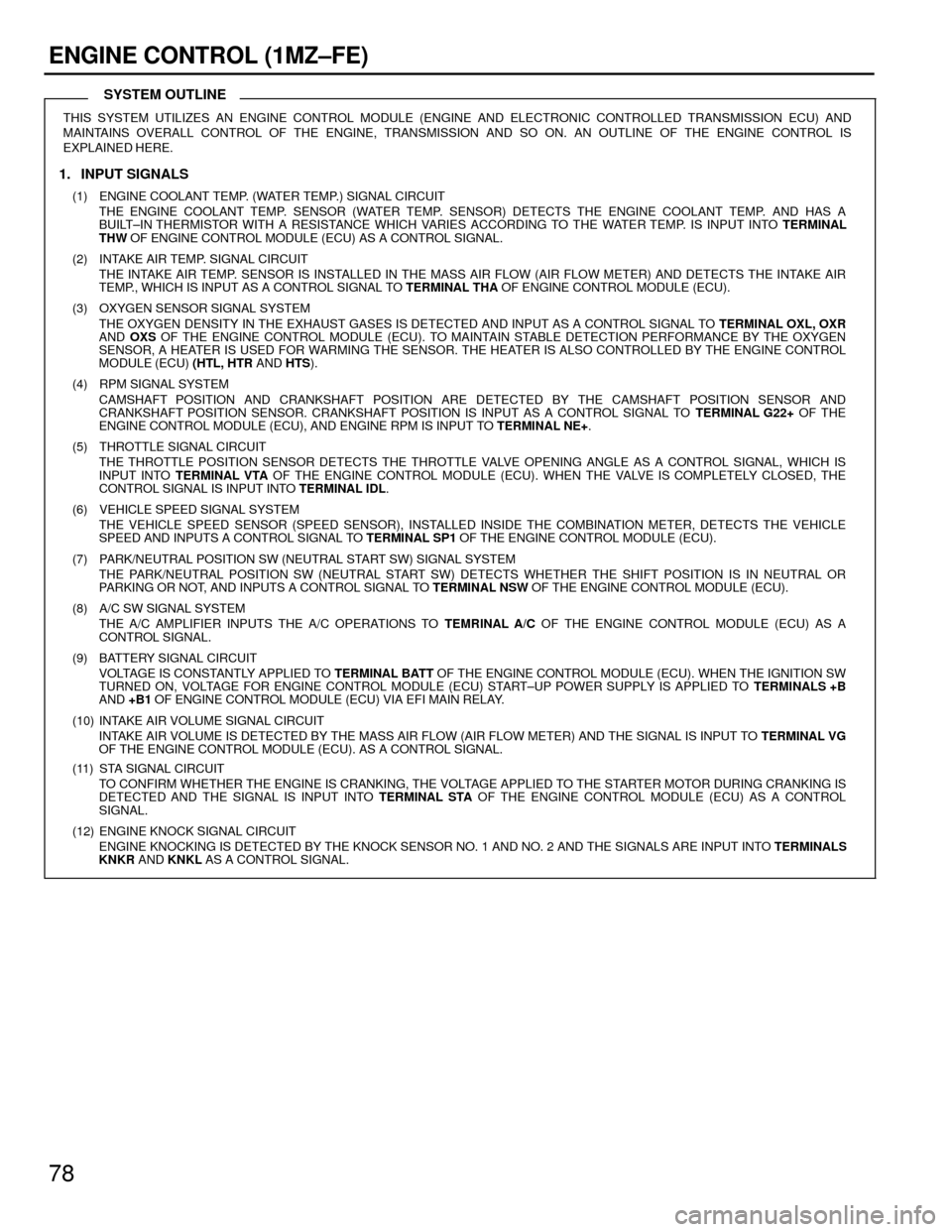

ENGINE CONTROL (1MZ±FE)

THIS SYSTEM UTILIZES AN ENGINE CONTROL MODULE (ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU) AND

MAINTAINS OVERALL CONTROL OF THE ENGINE, TRANSMISSION AND SO ON. AN OUTLINE OF THE ENGINE CONTROL IS

EXPLAINED HERE.

1. INPUT SIGNALS

(1) ENGINE COOLANT TEMP. (WATER TEMP.) SIGNAL CIRCUIT

THE ENGINE COOLANT TEMP. SENSOR (WATER TEMP. SENSOR) DETECTS THE ENGINE COOLANT TEMP. AND HAS A

BUILT±IN THERMISTOR WITH A RESISTANCE WHICH VARIES ACCORDING TO THE WATER TEMP. IS INPUT INTO TERMINAL

THW OF ENGINE CONTROL MODULE (ECU) AS A CONTROL SIGNAL.

(2) INTAKE AIR TEMP. SIGNAL CIRCUIT

THE INTAKE AIR TEMP. SENSOR IS INSTALLED IN THE MASS AIR FLOW (AIR FLOW METER) AND DETECTS THE INTAKE AIR

TEMP., WHICH IS INPUT AS A CONTROL SIGNAL TO TERMINAL THA OF ENGINE CONTROL MODULE (ECU).

(3) OXYGEN SENSOR SIGNAL SYSTEM

THE OXYGEN DENSITY IN THE EXHAUST GASES IS DETECTED AND INPUT AS A CONTROL SIGNAL TO TERMINAL OXL, OXR

AND OXS OF THE ENGINE CONTROL MODULE (ECU). TO MAINTAIN STABLE DETECTION PERFORMANCE BY THE OXYGEN

SENSOR, A HEATER IS USED FOR WARMING THE SENSOR. THE HEATER IS ALSO CONTROLLED BY THE ENGINE CONTROL

MODULE (ECU) (HTL, HTR AND HTS).

(4) RPM SIGNAL SYSTEM

CAMSHAFT POSITION AND CRANKSHAFT POSITION ARE DETECTED BY THE CAMSHAFT POSITION SENSOR AND

CRANKSHAFT POSITION SENSOR. CRANKSHAFT POSITION IS INPUT AS A CONTROL SIGNAL TO TERMINAL G22+ OF THE

ENGINE CONTROL MODULE (ECU), AND ENGINE RPM IS INPUT TO TERMINAL NE+.

(5) THROTTLE SIGNAL CIRCUIT

THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE AS A CONTROL SIGNAL, WHICH IS

INPUT INTO TERMINAL VTA OF THE ENGINE CONTROL MODULE (ECU). WHEN THE VALVE IS COMPLETELY CLOSED, THE

CONTROL SIGNAL IS INPUT INTO TERMINAL IDL.

(6) VEHICLE SPEED SIGNAL SYSTEM

THE VEHICLE SPEED SENSOR (SPEED SENSOR), INSTALLED INSIDE THE COMBINATION METER, DETECTS THE VEHICLE

SPEED AND INPUTS A CONTROL SIGNAL TO TERMINAL SP1 OF THE ENGINE CONTROL MODULE (ECU).

(7) PARK/NEUTRAL POSITION SW (NEUTRAL START SW) SIGNAL SYSTEM

THE PARK/NEUTRAL POSITION SW (NEUTRAL START SW) DETECTS WHETHER THE SHIFT POSITION IS IN NEUTRAL OR

PARKING OR NOT, AND INPUTS A CONTROL SIGNAL TO TERMINAL NSW OF THE ENGINE CONTROL MODULE (ECU).

(8) A/C SW SIGNAL SYSTEM

THE A/C AMPLIFIER INPUTS THE A/C OPERATIONS TO TEMRINAL A/C OF THE ENGINE CONTROL MODULE (ECU) AS A

CONTROL SIGNAL.

(9) BATTERY SIGNAL CIRCUIT

VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE ENGINE CONTROL MODULE (ECU). WHEN THE IGNITION SW

TURNED ON, VOLTAGE FOR ENGINE CONTROL MODULE (ECU) START±UP POWER SUPPLY IS APPLIED TO TERMINALS +B

AND +B1 OF ENGINE CONTROL MODULE (ECU) VIA EFI MAIN RELAY.

(10) INTAKE AIR VOLUME SIGNAL CIRCUIT

INTAKE AIR VOLUME IS DETECTED BY THE MASS AIR FLOW (AIR FLOW METER) AND THE SIGNAL IS INPUT TO TERMINAL VG

OF THE ENGINE CONTROL MODULE (ECU). AS A CONTROL SIGNAL.

(11) STA SIGNAL CIRCUIT

TO CONFIRM WHETHER THE ENGINE IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING CRANKING IS

DETECTED AND THE SIGNAL IS INPUT INTO TERMINAL STA OF THE ENGINE CONTROL MODULE (ECU) AS A CONTROL

SIGNAL.

(12) ENGINE KNOCK SIGNAL CIRCUIT

ENGINE KNOCKING IS DETECTED BY THE KNOCK SENSOR NO. 1 AND NO. 2 AND THE SIGNALS ARE INPUT INTO TERMINALS

KNKR AND KNKL AS A CONTROL SIGNAL.

SYSTEM OUTLINE

Page 83 of 307

83

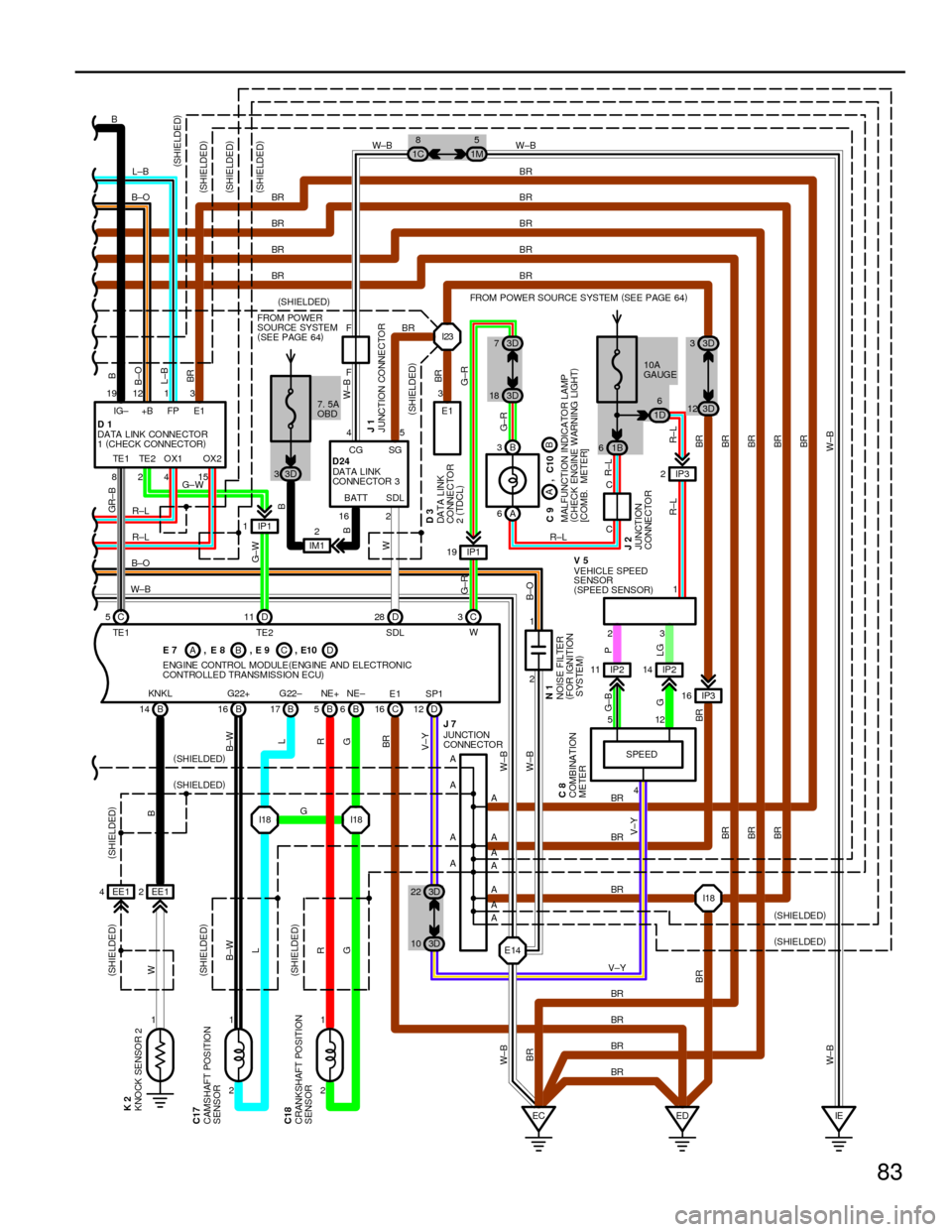

AB

A

EC 1 C 5

TE 1D 11

TE2

B 14KNKL

B 16G22+

B 5NE +

EE1 4EE12

1 1

BR

B

B±O

L±B

BR GR±B

WB

B±W

R R B±W

3 1 12 19

8FP +B IG±

SG

TE 2 TE 1 DATA LINK CONNECTOR

1(

CHECK CONNECTOR) D1

V5

CRANKSHAFT POSITION

SENSOR C18KNOCK SENSOR 2 K2

CAMSHAFT POSITION

SENSOR C17

C 3

G±R

6B 3

G±R

A

W

(

SHIELDED) (

SHIELDED)

D 12FROM POWER SOURCE SYSTEM(

SEE PAGE 64)

C CIP3 2

IP2 11 IP2141

23

4 512 SP1G±B

GLGP

R±LR±L

R±L

VEHICLE SPEED

SENSOR

(

SPEED SENSOR)

B

MALFUNCTION INDICATOR LAMP

(

CHECK ENGINE WARNING LIGHT)

[COMB. METER] C9 , C10

SPEED

JUNCTION

CONNECTOR J2 COMBINATION

METER C8

D

E NG INE CO NTROL MODULE(

ENGINE AND ELECTRONIC

CONTROLLED TRANSMISSION ECU) E7 , E8 ,E9 ,E10C

E142 1

NOISE FILTER

(

FOR IGNITION

SYSTEM) W±B

W±B B±O

W±B

N1

V±Y

ED B±OR±L

R±L B

I23

D 28

SDL DA TA LINK

CO NNE CTOR 3 D24 FROM POWER

SO TEM

(

S)

.5A

OBD

DA TA LINK

CO NNE CTO R

2(

TDCL) D3

IP3 16 IP1 1

22I18 I18B 6NE±

C E1

I18 IM12

J1

J UNCTION CO NNE CTO R

IE JUNCTION

CONNECTOR J7

L

G

BR

V±Y L

G

V±Y

BR BR W±B

W±B

BR

BR

BR BR BR BR

G (

SHIELDED)

(

SHIELDED)

(

SHIELDED)

(

SHIELDED)

A

A

A

AA

A

A

A

A

A

A

BR

BR

BR

BR

BR

W±B BR

BR

BRBR

(

SHIELDED)

(

SHIELDED) BR BR

BR

BR BR W±B

F F

24 15

2 45

G± WBR W±B

L±B

B±O

BR

BR

BR

BR BB G±W

W3

E1

OX1

SDL

16W±BE1

CG

OX2

BATT(

SHIELDED)

(

SHIELDED) BR

(

SHIELDED)

(

SHIELDED)

(

SHIELDED)

(

SHIELDED)

16 B 17G22±IP1 19

G±R

10A

GAUGE

1B 616

R± L

D

3D 3

3D 12

3D 183D 7

3D 3

3D 22

3D 10

1M5

1C8

URCE SYS

EE PAGE 64

7

Page 85 of 307

85

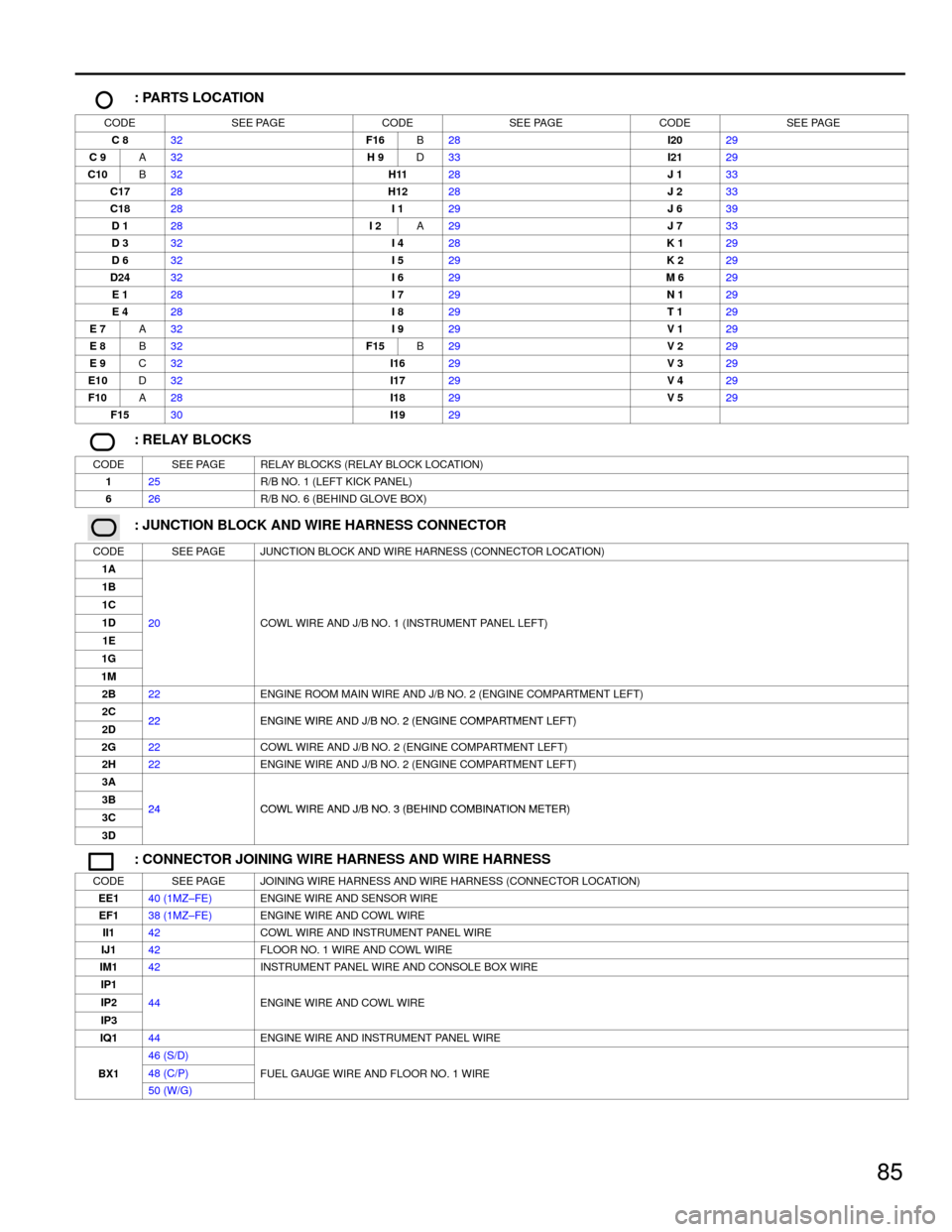

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

C 832F16B28I2029

C 9A32H 9D33I2129

C10B32H1128J 133

C1728H1228J 233

C1828I 129J 639

D 128I 2A29J 733

D 332I 428K 129

D 632I 529K 229

D2432I 629M 629

E 128I 729N 129

E 428I 829T 129

E 7A32I 929V 129

E 8B32F15B29V 229

E 9C32I1629V 329

E10D32I1729V 429

F10A28I1829V 529

F1530I1929

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

125R/B NO. 1 (LEFT KICK PANEL)

626R/B NO. 6 (BEHIND GLOVE BOX)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1A

1B

1C

1D20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1E

20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1G

1M

2B22ENGINE ROOM MAIN WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2C22ENGINE WIRE AND J/B NO 2 (ENGINE COMPARTMENT LEFT)2D22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2G22COWL WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2H22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

3A

3B24COWL WIRE AND J/B NO 3 (BEHIND COMBINATION METER)3C24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

3D

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

EE140 (1MZ±FE)ENGINE WIRE AND SENSOR WIRE

EF138 (1MZ±FE)ENGINE WIRE AND COWL WIRE

II142COWL WIRE AND INSTRUMENT PANEL WIRE

IJ142FLOOR NO. 1 WIRE AND COWL WIRE

IM142INSTRUMENT PANEL WIRE AND CONSOLE BOX WIRE

IP1

IP244ENGINE WIRE AND COWL WIRE

IP3

44ENGINE WIRE AND COWL WIRE

IQ144ENGINE WIRE AND INSTRUMENT PANEL WIRE

46 (S/D)

BX148 (C/P)FUEL GAUGE WIRE AND FLOOR NO. 1 WIREBX1

50 (W/G)

FUEL GAUGE WIRE AND FLOOR NO. 1 WIRE

Page 88 of 307

88

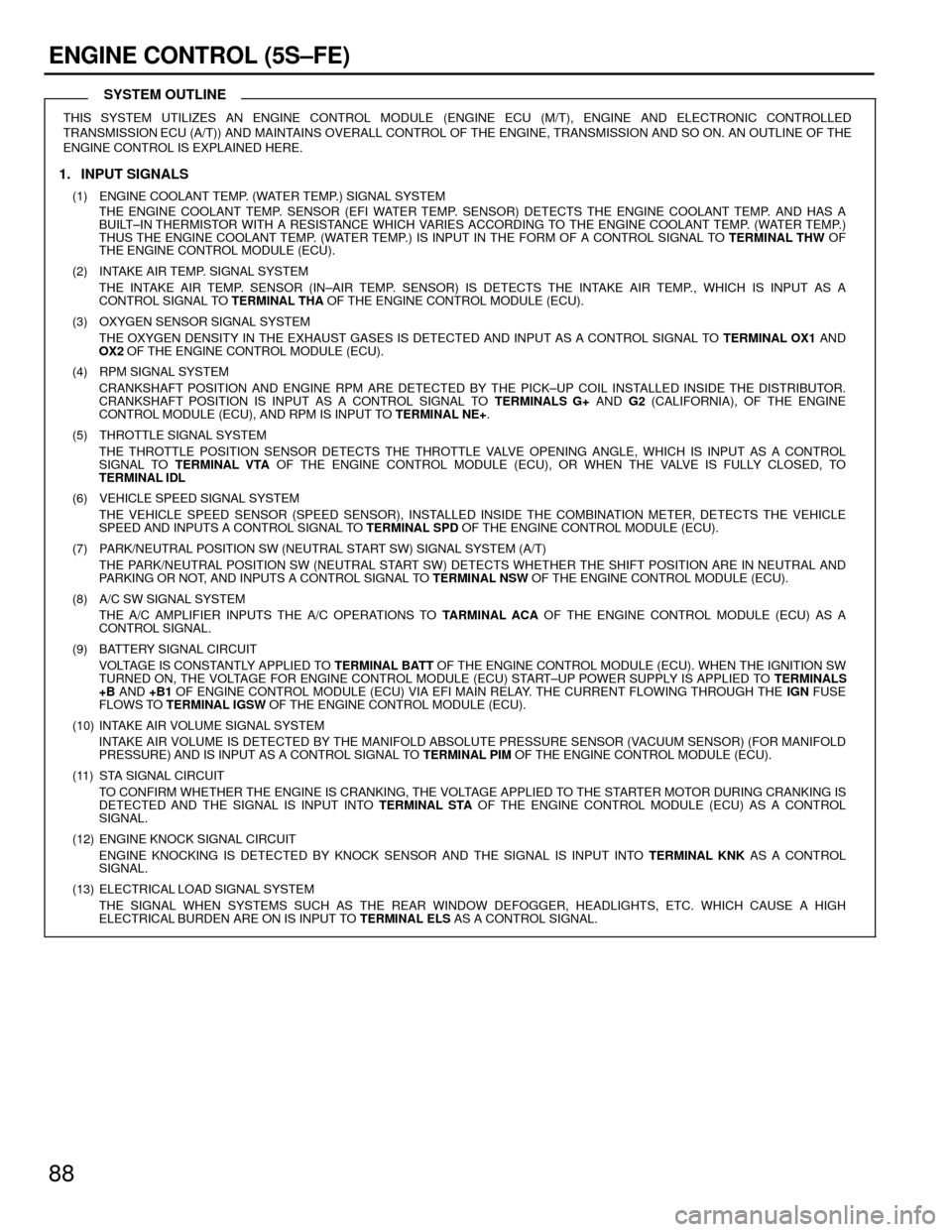

ENGINE CONTROL (5S±FE)

THIS SYSTEM UTILIZES AN ENGINE CONTROL MODULE (ENGINE ECU (M/T), ENGINE AND ELECTRONIC CONTROLLED

TRANSMISSION ECU (A/T)) AND MAINTAINS OVERALL CONTROL OF THE ENGINE, TRANSMISSION AND SO ON. AN OUTLINE OF THE

ENGINE CONTROL IS EXPLAINED HERE.

1. INPUT SIGNALS

(1) ENGINE COOLANT TEMP. (WATER TEMP.) SIGNAL SYSTEM

THE ENGINE COOLANT TEMP. SENSOR (EFI WATER TEMP. SENSOR) DETECTS THE ENGINE COOLANT TEMP. AND HAS A

BUILT±IN THERMISTOR WITH A RESISTANCE WHICH VARIES ACCORDING TO THE ENGINE COOLANT TEMP. (WATER TEMP.)

THUS THE ENGINE COOLANT TEMP. (WATER TEMP.) IS INPUT IN THE FORM OF A CONTROL SIGNAL TO TERMINAL THW OF

THE ENGINE CONTROL MODULE (ECU).

(2) INTAKE AIR TEMP. SIGNAL SYSTEM

THE INTAKE AIR TEMP. SENSOR (IN±AIR TEMP. SENSOR) IS DETECTS THE INTAKE AIR TEMP., WHICH IS INPUT AS A

CONTROL SIGNAL TO TERMINAL THA OF THE ENGINE CONTROL MODULE (ECU).

(3) OXYGEN SENSOR SIGNAL SYSTEM

THE OXYGEN DENSITY IN THE EXHAUST GASES IS DETECTED AND INPUT AS A CONTROL SIGNAL TO TERMINAL OX1 AND

OX2 OF THE ENGINE CONTROL MODULE (ECU).

(4) RPM SIGNAL SYSTEM

CRANKSHAFT POSITION AND ENGINE RPM ARE DETECTED BY THE PICK±UP COIL INSTALLED INSIDE THE DISTRIBUTOR.

CRANKSHAFT POSITION IS INPUT AS A CONTROL SIGNAL TO TERMINALS G+ AND G2 (CALIFORNIA), OF THE ENGINE

CONTROL MODULE (ECU), AND RPM IS INPUT TO TERMINAL NE+.

(5) THROTTLE SIGNAL SYSTEM

THE THROTTLE POSITION SENSOR DETECTS THE THROTTLE VALVE OPENING ANGLE, WHICH IS INPUT AS A CONTROL

SIGNAL TO TERMINAL VTA OF THE ENGINE CONTROL MODULE (ECU), OR WHEN THE VALVE IS FULLY CLOSED, TO

TERMINAL IDL

(6) VEHICLE SPEED SIGNAL SYSTEM

THE VEHICLE SPEED SENSOR (SPEED SENSOR), INSTALLED INSIDE THE COMBINATION METER, DETECTS THE VEHICLE

SPEED AND INPUTS A CONTROL SIGNAL TO TERMINAL SPD OF THE ENGINE CONTROL MODULE (ECU).

(7) PARK/NEUTRAL POSITION SW (NEUTRAL START SW) SIGNAL SYSTEM (A/T)

THE PARK/NEUTRAL POSITION SW (NEUTRAL START SW) DETECTS WHETHER THE SHIFT POSITION ARE IN NEUTRAL AND

PARKING OR NOT, AND INPUTS A CONTROL SIGNAL TO TERMINAL NSW OF THE ENGINE CONTROL MODULE (ECU).

(8) A/C SW SIGNAL SYSTEM

THE A/C AMPLIFIER INPUTS THE A/C OPERATIONS TO TARMINAL ACA OF THE ENGINE CONTROL MODULE (ECU) AS A

CONTROL SIGNAL.

(9) BATTERY SIGNAL CIRCUIT

VOLTAGE IS CONSTANTLY APPLIED TO TERMINAL BATT OF THE ENGINE CONTROL MODULE (ECU). WHEN THE IGNITION SW

TURNED ON, THE VOLTAGE FOR ENGINE CONTROL MODULE (ECU) START±UP POWER SUPPLY IS APPLIED TO TERMINALS

+B AND +B1 OF ENGINE CONTROL MODULE (ECU) VIA EFI MAIN RELAY. THE CURRENT FLOWING THROUGH THE IGN FUSE

FLOWS TO TERMINAL IGSW OF THE ENGINE CONTROL MODULE (ECU).

(10) INTAKE AIR VOLUME SIGNAL SYSTEM

INTAKE AIR VOLUME IS DETECTED BY THE MANIFOLD ABSOLUTE PRESSURE SENSOR (VACUUM SENSOR) (FOR MANIFOLD

PRESSURE) AND IS INPUT AS A CONTROL SIGNAL TO TERMINAL PIM OF THE ENGINE CONTROL MODULE (ECU).

(11) STA SIGNAL CIRCUIT

TO CONFIRM WHETHER THE ENGINE IS CRANKING, THE VOLTAGE APPLIED TO THE STARTER MOTOR DURING CRANKING IS

DETECTED AND THE SIGNAL IS INPUT INTO TERMINAL STA OF THE ENGINE CONTROL MODULE (ECU) AS A CONTROL

SIGNAL.

(12) ENGINE KNOCK SIGNAL CIRCUIT

ENGINE KNOCKING IS DETECTED BY KNOCK SENSOR AND THE SIGNAL IS INPUT INTO TERMINAL KNK AS A CONTROL

SIGNAL.

(13) ELECTRICAL LOAD SIGNAL SYSTEM

THE SIGNAL WHEN SYSTEMS SUCH AS THE REAR WINDOW DEFOGGER, HEADLIGHTS, ETC. WHICH CAUSE A HIGH

ELECTRICAL BURDEN ARE ON IS INPUT TO TERMINAL ELS AS A CONTROL SIGNAL.

SYSTEM OUTLINE

Page 92 of 307

92

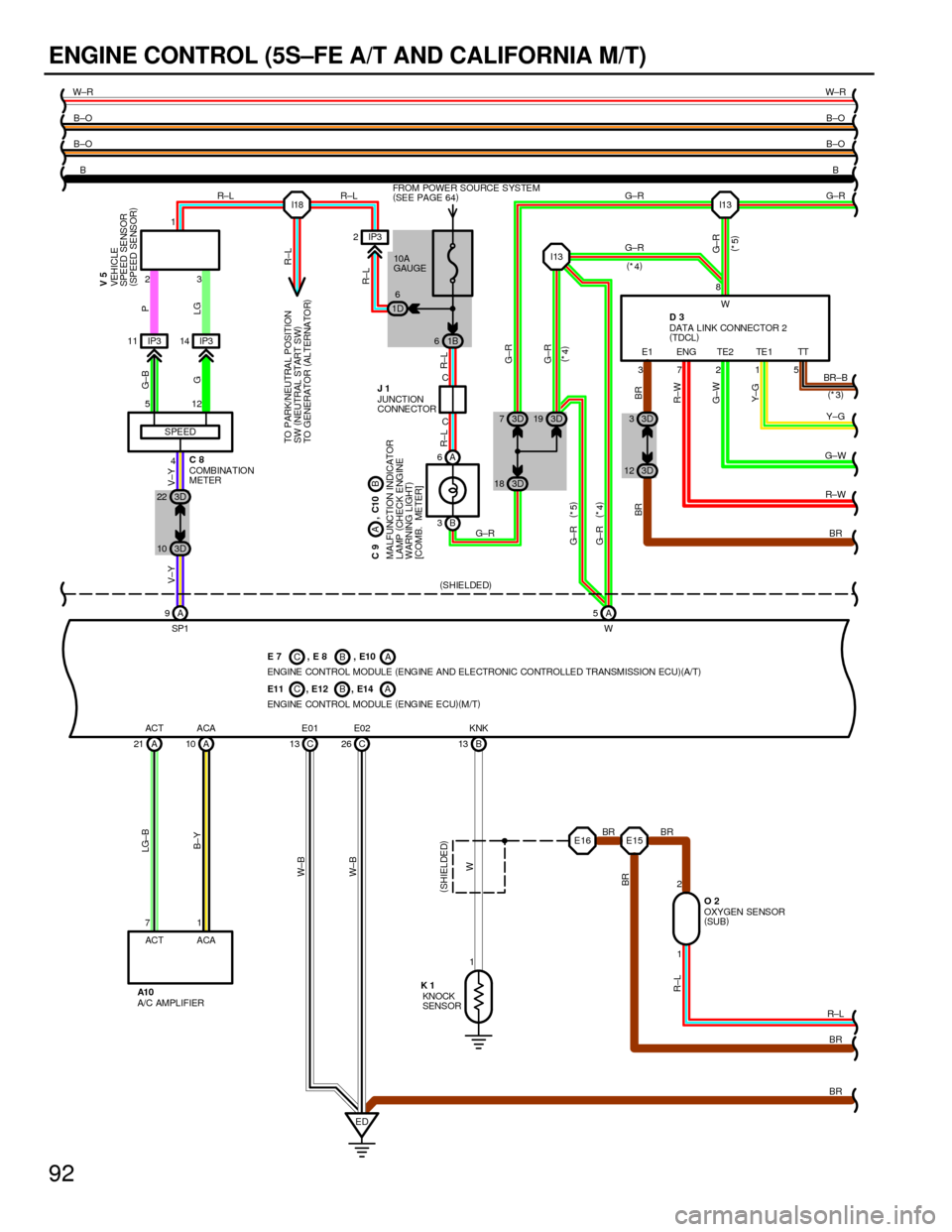

ENGINE CONTROL (5S±FE A/T AND CALIFORNIA M/T)

CB

A

321

C

1 78

C

A 6

B 3

A 21 A10 C13 C26 B13A 5

EDI13G±R R±L R±L

G±R

G±R

Y±G G±WBR LG±B

B±Y

W W±B W±B

W±R

B±O

B±O

B

G±R B±O B±O W±R

R±W G±WY±G G±R

E1 TE2 TE1

WW

DATA LINK CONNECTOR 2

(

TDCL) FROM CE SYSTEM

(

SEE P

JUNCTION

CONNECTOR

MALFUNCTION INDICATOR

LAMP(

CHECK E NG INE

WARNING LIGHT)

[COMB. METER]

ACT ACA E01 E02 KNKENGINE CONTROL MODULE(

ENGINE AND ELECTRONIC CONTROLLED TRANSMISSION ECU)(

A/T)

ACT ACA

KNOCK

SENSOR A/C AMPLIFIER A1 0K1 E7 ,E8 ,E10

A

C9 , C10

J1D3

B

(

SHIELDED)

(

SHIELDED)

E16

O2

OXYGEN SENSOR

(

SUB)

1E15BR

BR

5TT

BR±B IP3 11 IP314

A 9 23

4 1

512IP3 2

SPEED

LGP G±B

G V±Y V±Y

R±L

R±L

SP1COMBINATION

METER C8

VEHICLE

SPEED SENSOR

(

SPEED SENSOR) V5

B

BR I13

G±R

G±R(

*5)

(

*4)

R±L

BR BR

1 2BR 7

R±W

ENG

BR

R±L

I18

R±L TO PARK/NEUTRAL POSITION

SW(

NEUTRAL START SW)

TO GENERATOR(

ALTERNATOR)

R±L

G±R(

*5)(

*4)

(

*3)

B E11 , E12CA,E14

ENGINE CONTROL MODULE(

ENGINE ECU)(

M/T) G±R

(

*

4)

1B 6 10A

GAUGE

1D6

3D 73D19

3D 18

3D 22

3D 10

3D 3

3D 12

POWER SOUR

AGE 64)

Page 95 of 307

95

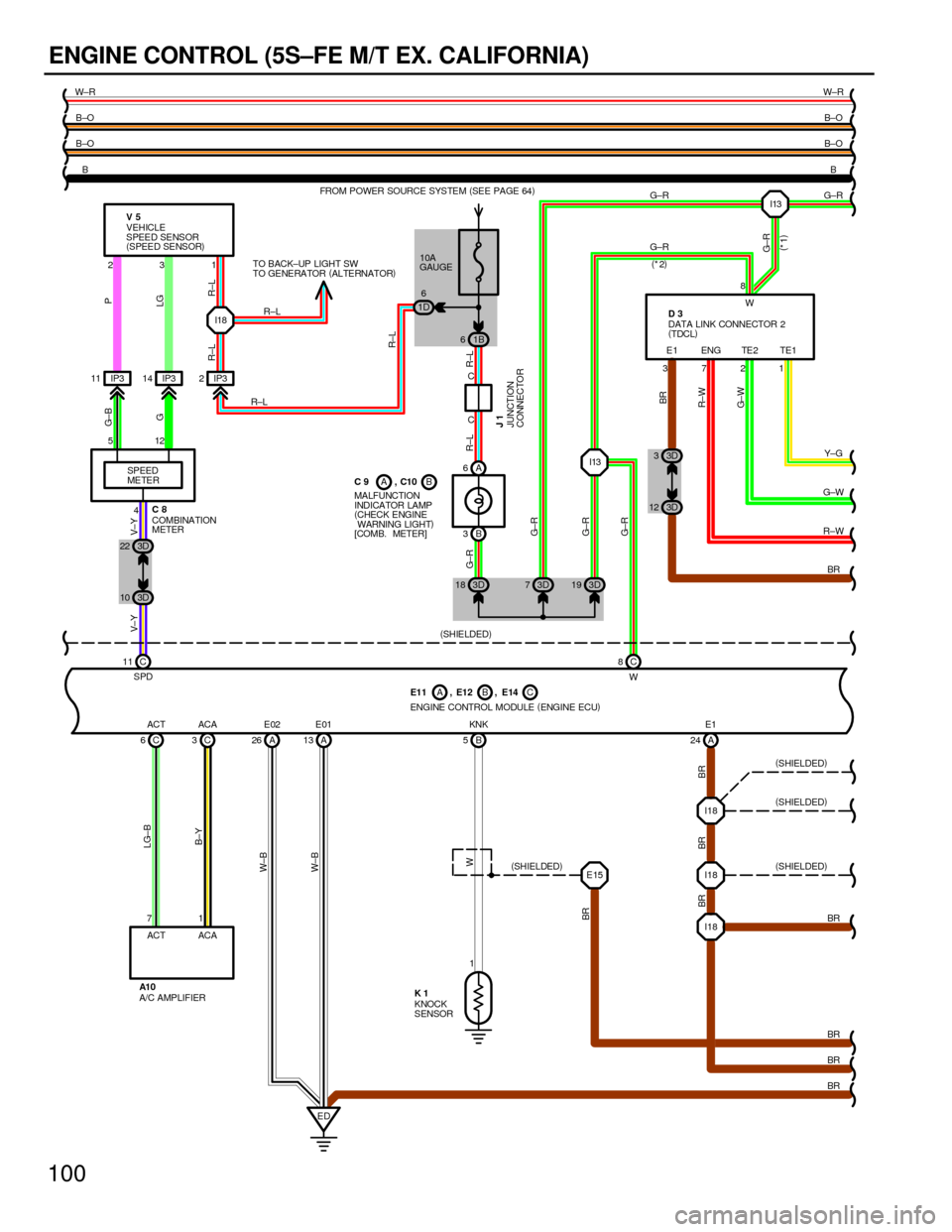

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1A

1B

1C20COWL WIRE AND J/B NO 1 (INSTRUMENT PANEL LEFT)1D20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1G

1M

2D22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

3A

3B24COWL WIRE AND J/B NO 3 (BEHIND COMBINATION METER)3C24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

3D

: CONNECTOR JOINING WIRE HARNESS AND WIRE HARNESS

CODESEE PAGEJOINING WIRE HARNESS AND WIRE HARNESS (CONNECTOR LOCATION)

IJ142FLOOR NO. 1 WIRE AND COWL WIRE

IP144ENGINE WIRE AND COWL WIREIP344ENGINE WIRE AND COWL WIRE

46 (S/D)

BX148 (C/P)FUEL GAUGE WIRE AND FLOOR NO. 1 WIREBX1

50 (W/G)

FUEL GAUGE WIRE AND FLOOR NO. 1 WIRE

: GROUND POINTS

CODESEE PAGEGROUND POINTS LOCATION

EB40 (5S±FE)FRONT LEFT FENDER

EC40 (5S±FE)INTAKE MANIFOLD RH

ED40 (5S±FE)INTAKE MANIFOLD LH

IG42INSTRUMENT PANEL BRACE LH

46 (S/D)

BL48 (C/P)UNDER THE LEFT QUARTER PILLARBL

50 (W/G)

UNDER THE LEFT QUARTER PILLAR

: SPLICE POINTS

CODESEE PAGEWIRE HARNESS WITH SPLICE POINTSCODESEE PAGEWIRE HARNESS WITH SPLICE POINTS

E15I 244COWL WIREE16I1344COWL WIRE

E1740 (5S FE)ENGINE WIREI1844ENGINE WIRE

E1840 (5S±FE)ENGINE WIREI2044COWL WIREE19I2344COWL WIRE

E20

Page 100 of 307

100

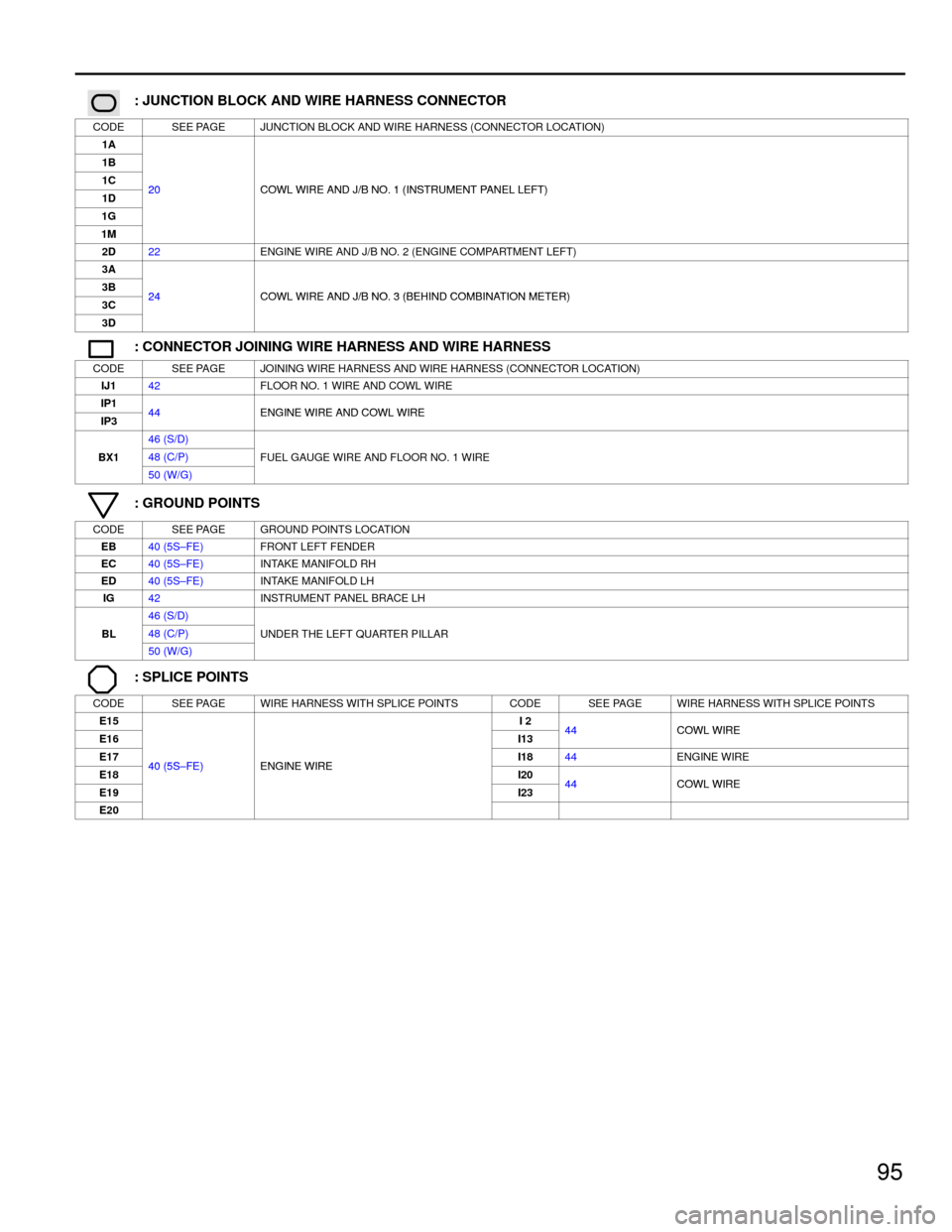

ENGINE CONTROL (5S±FE M/T EX. CALIFORNIA)

AB A

321

C

1 78

C

A 6

B 3

C 6A13 A 26 B5C 8

1

ED

G±R G±R R±L R±L

G±R

G±WBR LG±B

B±Y

W W±B

W±B

W±R

B±O

B±O

G±RB±O B±O W±R

R±W G±WY±G E1 TE2 TE1

WW

DATA LINK CONNECTOR 2

(

TDCL) FROM POWER SOURCE SYST GE 64)

COMBINATION

METER

ACT ACA E01E02 KNKENGINE CONTROL MODULE(

ENGINE ECU)

ACT ACA

KNOCK

SENSOR A/C AMPLIFIER A1 0

K1 E11 , E12 , E14C C8D3

(

SHIELDED)

I18 I18 24

BR BR

(

SHIELDED) (

SHIELDED) (

SHIELDED) E1

AB

IP3 11 IP314

C 11IP3 2

4 231

512

P

LG

R±L

R±L G±B

G V±Y V±Y

MALFUNCTION

INDICATOR LAMP

(

CHECK ENGINE

WARNING LIGHT)

[COMB. METER] C9 ,C10B SPEED

METER V5

VEHICLE

SPEED SENSOR

(

SPEED SENSOR)

JUNCTION

CONNECTOR J1

SPD

BR

G±R

7

R±W

ENG

I18

BR BR E15

BR BRBR (

SHIELDED)G±R

BR I18

R±L

R±L

R±LTO BACK±UP LIGHT SW

TO GE NE RA TOR(

ALTERNATOR) B

I13I13 G±R

(

*2)

G±R

(

*1)

C 3

3D 3

3D 12

3D 22

3D 10

3D 18 3D73D19

1B 6 10A

GAUGE

1D6

EM(

SEE PA

Page 102 of 307

102

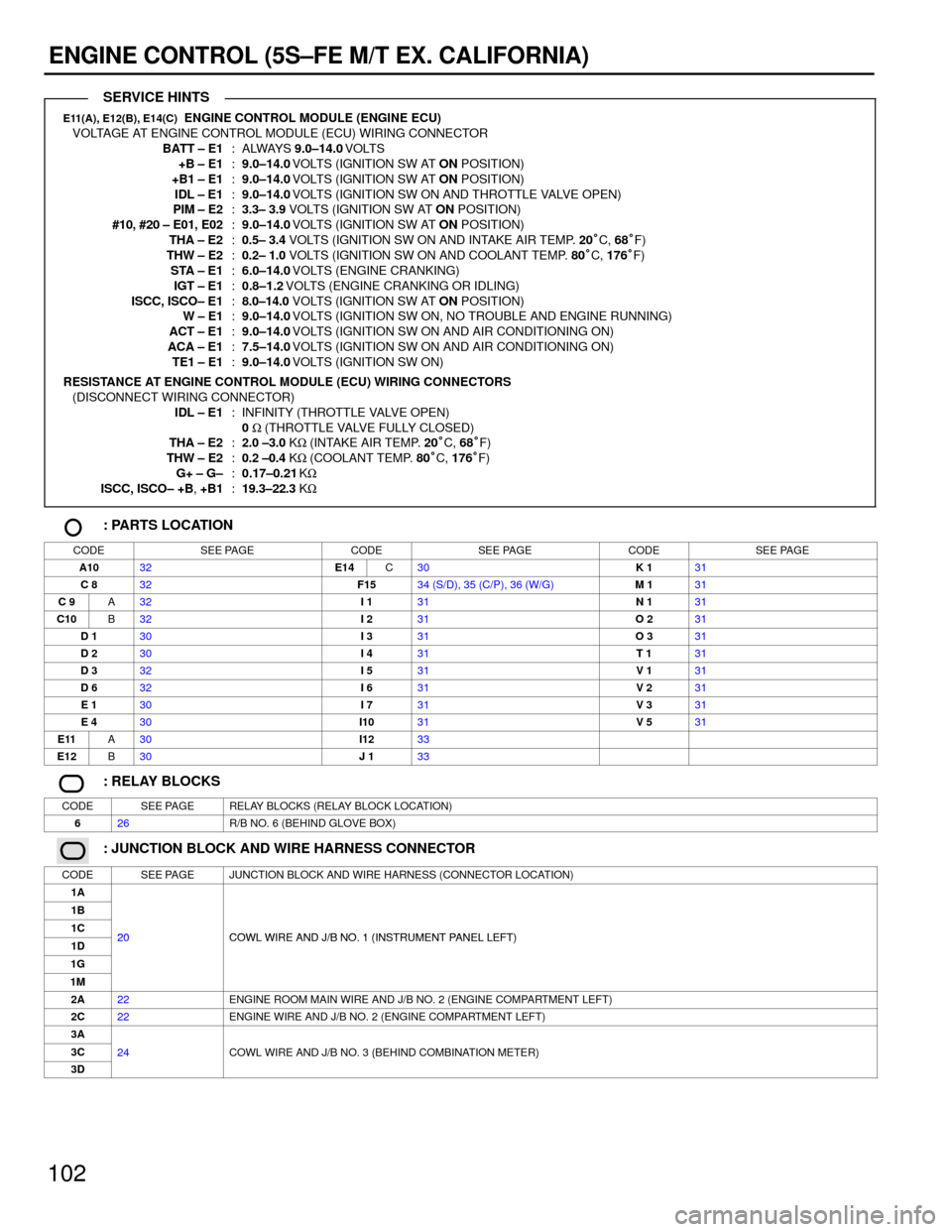

ENGINE CONTROL (5S±FE M/T EX. CALIFORNIA)

E11(A), E12(B), E14(C) ENGINE CONTROL MODULE (ENGINE ECU)

VOLTAGE AT ENGINE CONTROL MODULE (ECU) WIRING CONNECTOR

BATT ± E1: ALWAYS 9.0±14.0 VOLTS

+B ± E1:9.0±14.0 VOLTS (IGNITION SW AT ON POSITION)

+B1 ± E1:9.0±14.0 VOLTS (IGNITION SW AT ON POSITION)

IDL ± E1:9.0±14.0 VOLTS (IGNITION SW ON AND THROTTLE VALVE OPEN)

PIM ± E2:3.3± 3.9 VOLTS (IGNITION SW AT ON POSITION)

#10, #20 ± E01, E02:9.0±14.0 VOLTS (IGNITION SW AT ON POSITION)

THA ± E2:0.5± 3.4 VOLTS (IGNITION SW ON AND INTAKE AIR TEMP. 20°C, 68°F)

THW ± E2:0.2± 1.0 VOLTS (IGNITION SW ON AND COOLANT TEMP. 80°C, 176°F)

STA ± E1:6.0±14.0 VOLTS (ENGINE CRANKING)

IGT ± E1:0.8±1.2 VOLTS (ENGINE CRANKING OR IDLING)

ISCC, ISCO± E1:8.0±14.0 VOLTS (IGNITION SW AT ON POSITION)

W ± E1:9.0±14.0 VOLTS (IGNITION SW ON, NO TROUBLE AND ENGINE RUNNING)

ACT ± E1:9.0±14.0 VOLTS (IGNITION SW ON AND AIR CONDITIONING ON)

ACA ± E1:7.5±14.0 VOLTS (IGNITION SW ON AND AIR CONDITIONING ON)

TE1 ± E1:9.0±14.0 VOLTS (IGNITION SW ON)

RESISTANCE AT ENGINE CONTROL MODULE (ECU) WIRING CONNECTORS

(DISCONNECT WIRING CONNECTOR)

IDL ± E1: INFINITY (THROTTLE VALVE OPEN)

0 W (THROTTLE VALVE FULLY CLOSED)

THA ± E2:2.0 ±3.0 KW (INTAKE AIR TEMP. 20°C, 68°F)

THW ± E2:0.2 ±0.4 KW (COOLANT TEMP. 80°C, 176°F)

G+ ± G±:0.17±0.21 KW

ISCC, ISCO± +B, +B1:19.3±22.3 KW

: PARTS LOCATION

CODESEE PAGECODESEE PAGECODESEE PAGE

A1032E14C30K 131

C 832F1534 (S/D), 35 (C/P), 36 (W/G)M 131

C 9A32I 131N 131

C10B32I 231O 231

D 130I 331O 331

D 230I 431T 131

D 332I 531V 131

D 632I 631V 231

E 130I 731V 331

E 430I1031V 531

E11A30I1233

E12B30J 133

: RELAY BLOCKS

CODESEE PAGERELAY BLOCKS (RELAY BLOCK LOCATION)

626R/B NO. 6 (BEHIND GLOVE BOX)

: JUNCTION BLOCK AND WIRE HARNESS CONNECTOR

CODESEE PAGEJUNCTION BLOCK AND WIRE HARNESS (CONNECTOR LOCATION)

1A

1B

1C20COWL WIRE AND J/B NO 1 (INSTRUMENT PANEL LEFT)1D20COWL WIRE AND J/B NO. 1 (INSTRUMENT PANEL LEFT)

1G

1M

2A22ENGINE ROOM MAIN WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

2C22ENGINE WIRE AND J/B NO. 2 (ENGINE COMPARTMENT LEFT)

3A

3C24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

3D

24COWL WIRE AND J/B NO. 3 (BEHIND COMBINATION METER)

SERVICE HINTS

Page 104 of 307

104

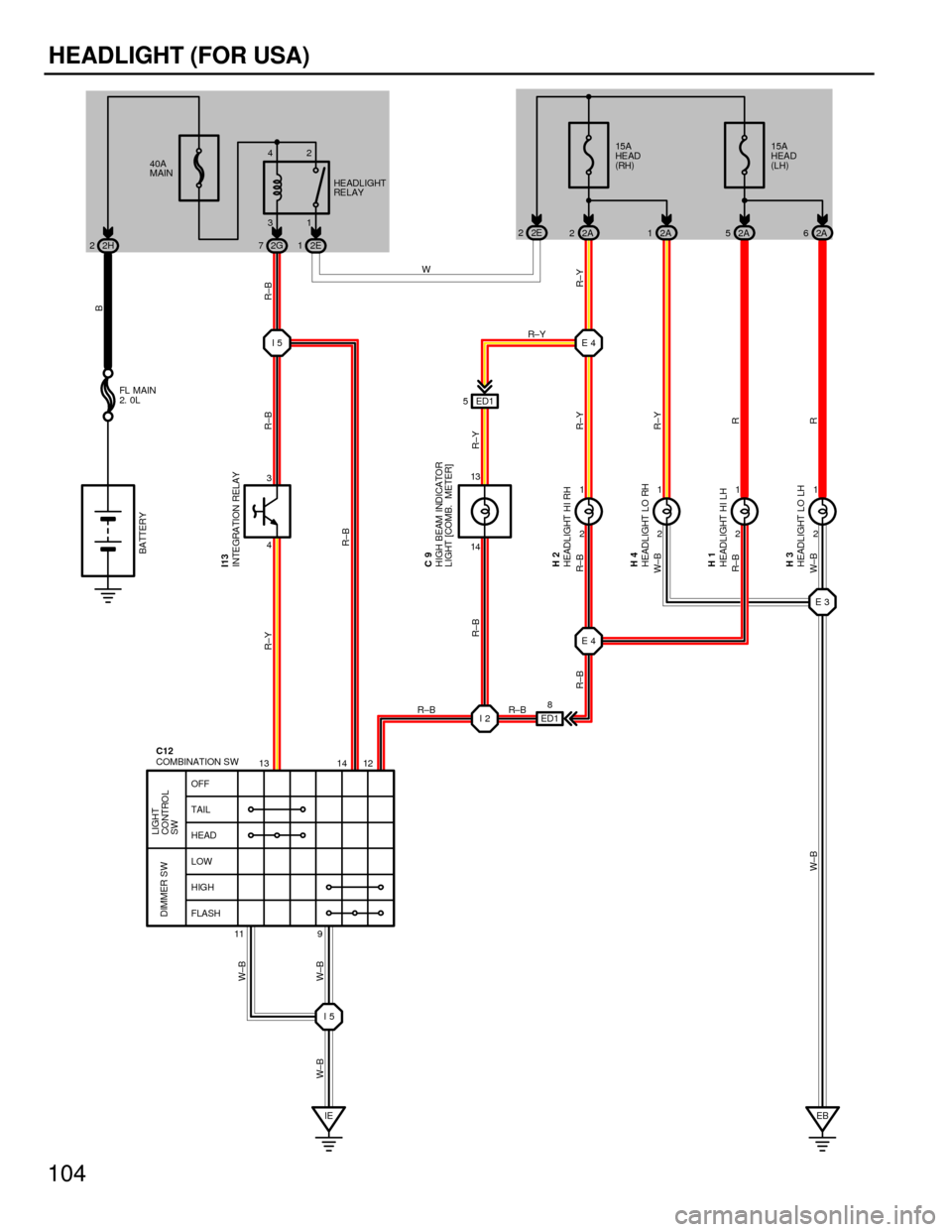

HEADLIGHT (FOR USA)

3

4

13 14 12

11 9 OFF

TAIL

HEAD

LOW

HIGH

FLASH

LIGHT

CO NTRO L

SW DIMMER SW

COMBINATION SW

R±B

I5E4

IE I52 1

2 1

2 1

2 1

14 13

E4E3

EB I2 ED18 W

R±B

R±Y R±Y

R±Y

R

R W±BR±B R±B

W±B R±B

R±B

W±B W±B

W±B W±BR±B

R±B R±YB

R±B ED1 5R±Y

R±Y INTEGRATION RELAYBATTERY

FL M AI N

2. 0L

HIGH BEAM INDICATOR

LIGHT [COMB. METER]

HEADLIGHT HI RH

HEADLIGHT LO RH

HEADLIGHT HI LH

HEADLIGHT LO LH

C12

I13

C9

H2

H4

H1

H3

2G 72E1HE ADLIGHT

RE LAY

31 42

40A

MAIN

2H 2

15A

HE AD

(

RH)15A

HEAD

(

LH)

2A 2A 15 2E 2

2A 22A6