washer TOYOTA CAMRY 1999 Service User Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 204 of 4592

AUTOMATIC TRANSAXLESECOND COAST BRAKE ±

AX±34

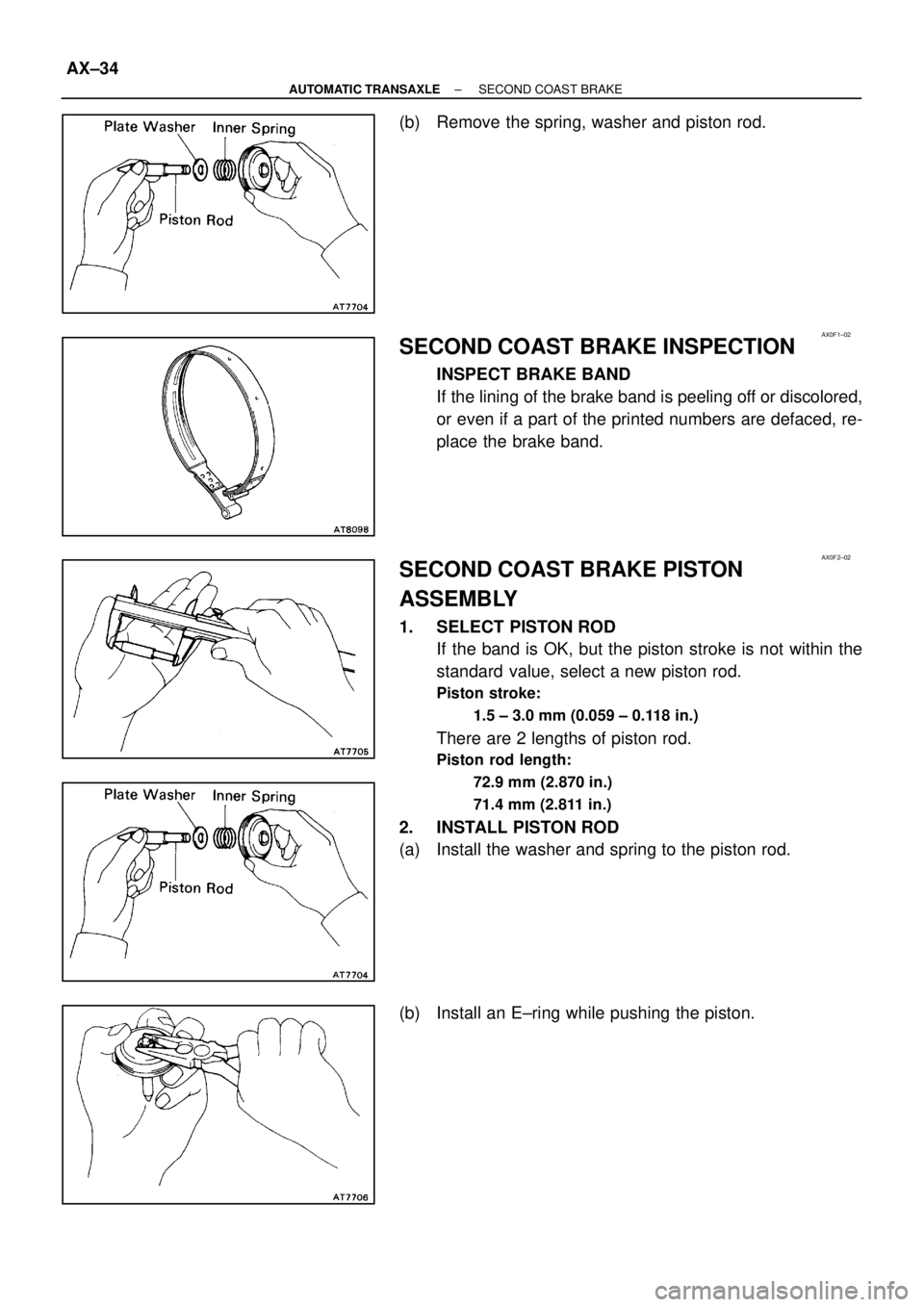

(b) Remove the spring, washer and piston rod.

SECOND COAST BRAKE INSPECTION

INSPECT BRAKE BAND

If the lining of the brake band is peeling off or discolored,

or even if a part of the printed numbers are defaced, re-

place the brake band.

SECOND COAST BRAKE PISTON

ASSEMBLY

1. SELECT PISTON ROD

If the band is OK, but the piston stroke is not within the

standard value, select a new piston rod.

Piston stroke:

1.5 ± 3.0 mm (0.059 ± 0.118 in.)

There are 2 lengths of piston rod.

Piston rod length:

72.9 mm (2.870 in.)

71.4 mm (2.811 in.)

2. INSTALL PISTON ROD

(a) Install the washer and spring to the piston rod.

(b) Install an E±ring while pushing the piston.

AX0F1±02

AX0F2±02

Page 206 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±36

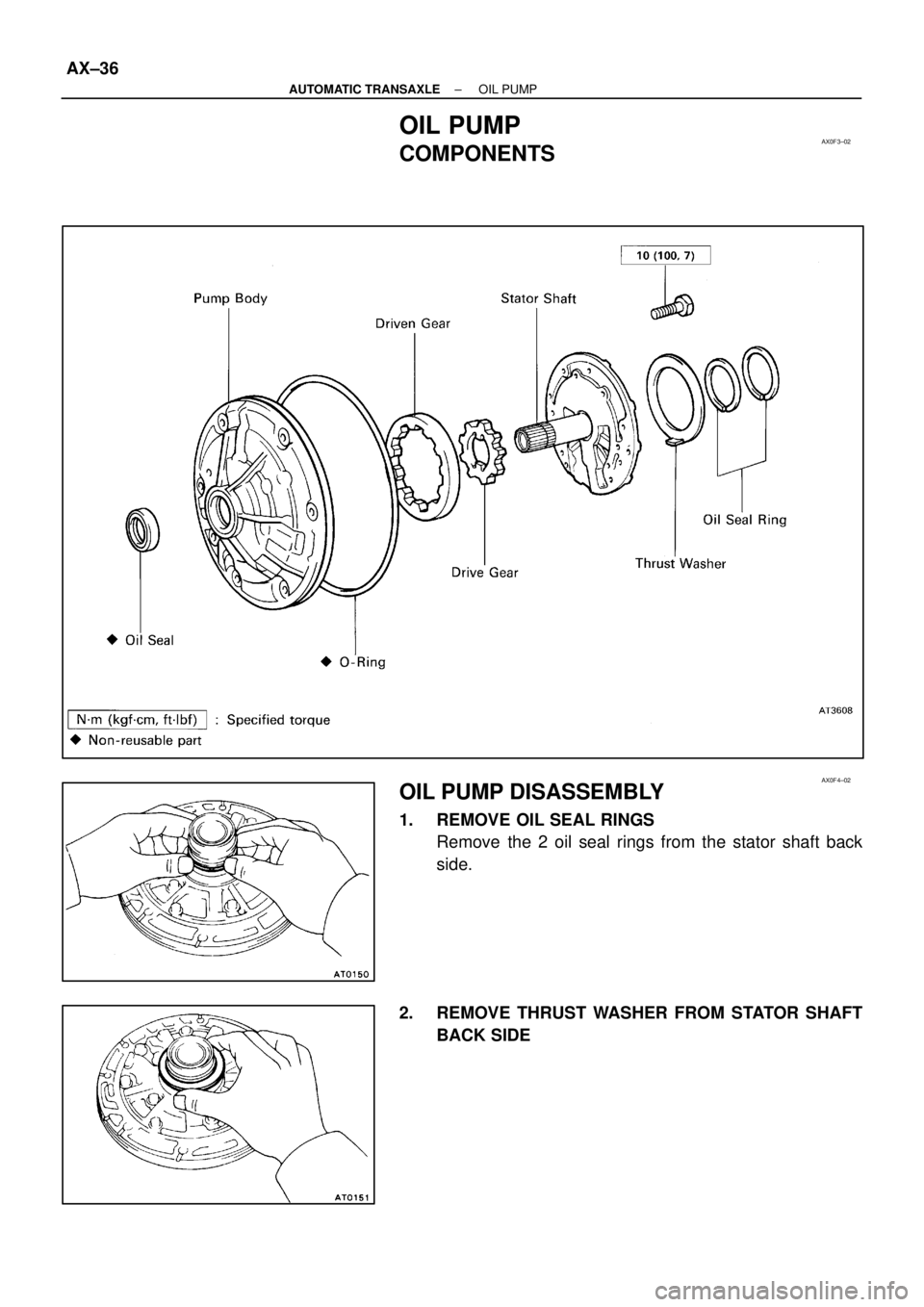

OIL PUMP

COMPONENTS

OIL PUMP DISASSEMBLY

1. REMOVE OIL SEAL RINGS

Remove the 2 oil seal rings from the stator shaft back

side.

2. REMOVE THRUST WASHER FROM STATOR SHAFT

BACK SIDE

AX0F3±02

AX0F4±02

Page 209 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±39

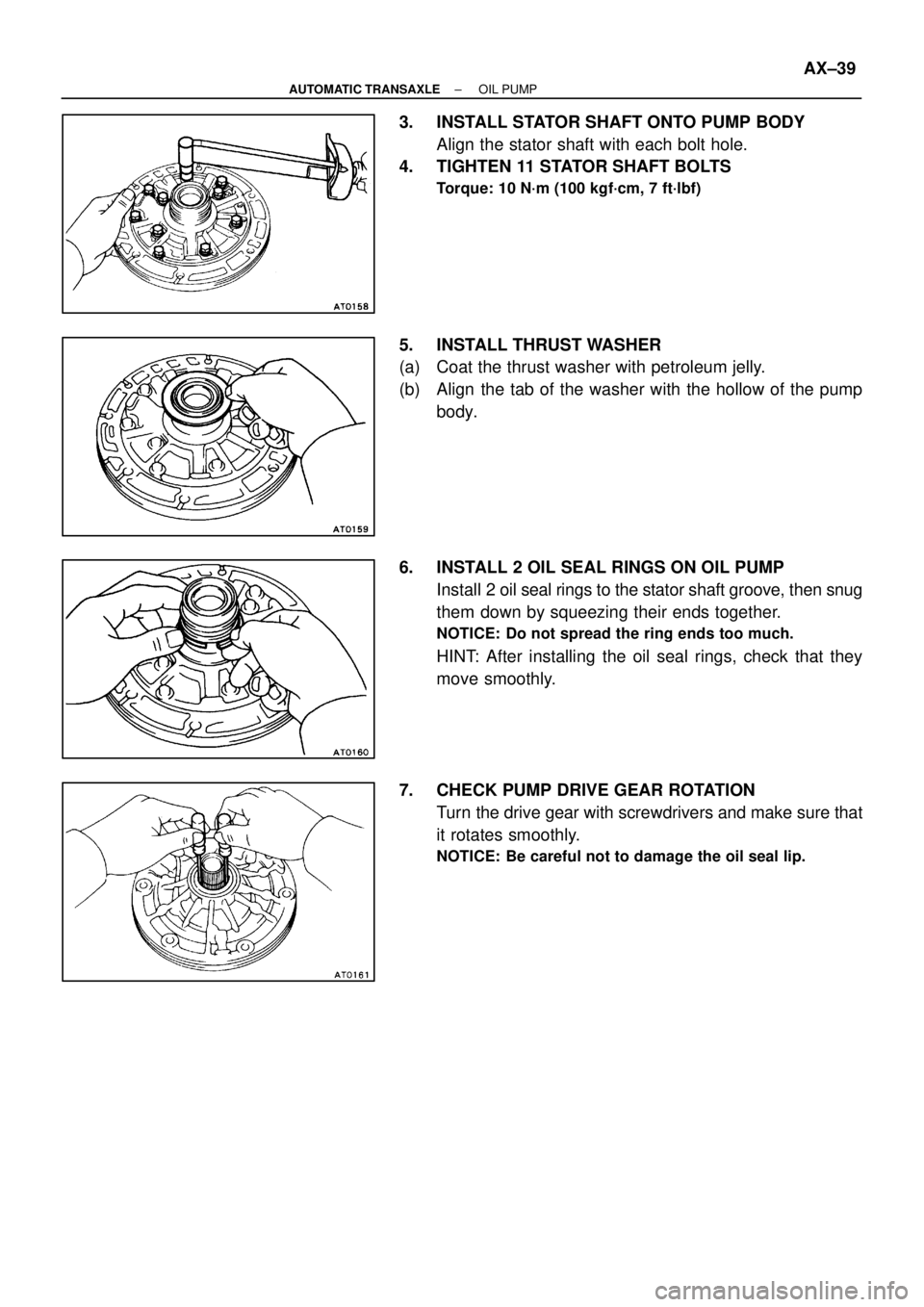

3. INSTALL STATOR SHAFT ONTO PUMP BODY

Align the stator shaft with each bolt hole.

4. TIGHTEN 11 STATOR SHAFT BOLTS

Torque: 10 N´m (100 kgf´cm, 7 ft´lbf)

5. INSTALL THRUST WASHER

(a) Coat the thrust washer with petroleum jelly.

(b) Align the tab of the washer with the hollow of the pump

body.

6. INSTALL 2 OIL SEAL RINGS ON OIL PUMP

Install 2 oil seal rings to the stator shaft groove, then snug

them down by squeezing their ends together.

NOTICE: Do not spread the ring ends too much.

HINT: After installing the oil seal rings, check that they

move smoothly.

7. CHECK PUMP DRIVE GEAR ROTATION

Turn the drive gear with screwdrivers and make sure that

it rotates smoothly.

NOTICE: Be careful not to damage the oil seal lip.

Page 220 of 4592

AUTOMATIC TRANSAXLEFRONT PLANETARY GEAR ±

AX±50

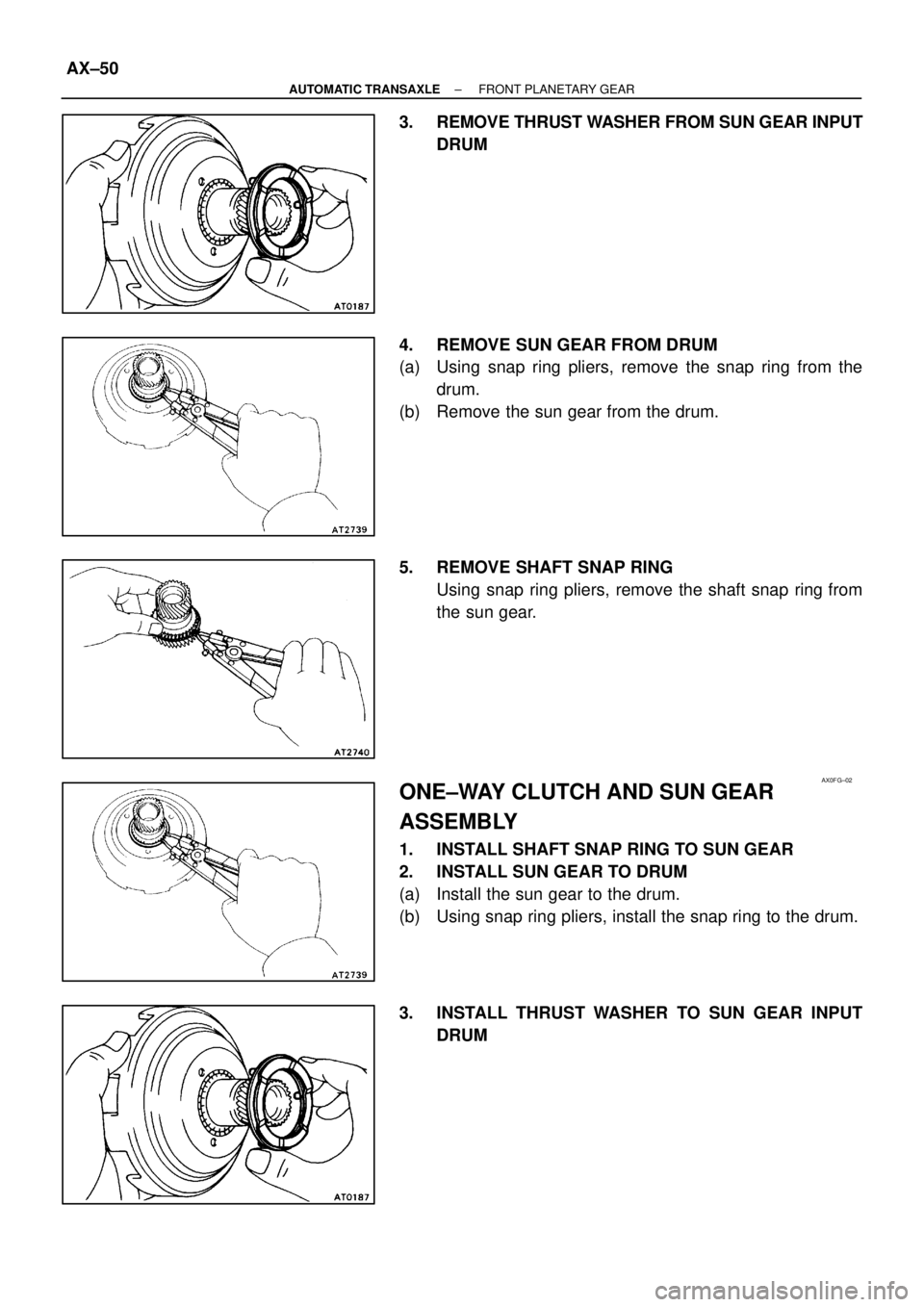

3. REMOVE THRUST WASHER FROM SUN GEAR INPUT

DRUM

4. REMOVE SUN GEAR FROM DRUM

(a) Using snap ring pliers, remove the snap ring from the

drum.

(b) Remove the sun gear from the drum.

5. REMOVE SHAFT SNAP RING

Using snap ring pliers, remove the shaft snap ring from

the sun gear.

ONE±WAY CLUTCH AND SUN GEAR

ASSEMBLY

1. INSTALL SHAFT SNAP RING TO SUN GEAR

2. INSTALL SUN GEAR TO DRUM

(a) Install the sun gear to the drum.

(b) Using snap ring pliers, install the snap ring to the drum.

3. INSTALL THRUST WASHER TO SUN GEAR INPUT

DRUM

AX0FG±02

Page 225 of 4592

AUTOMATIC TRANSAXLEREAR PLANETARY GEAR ±

AX±55

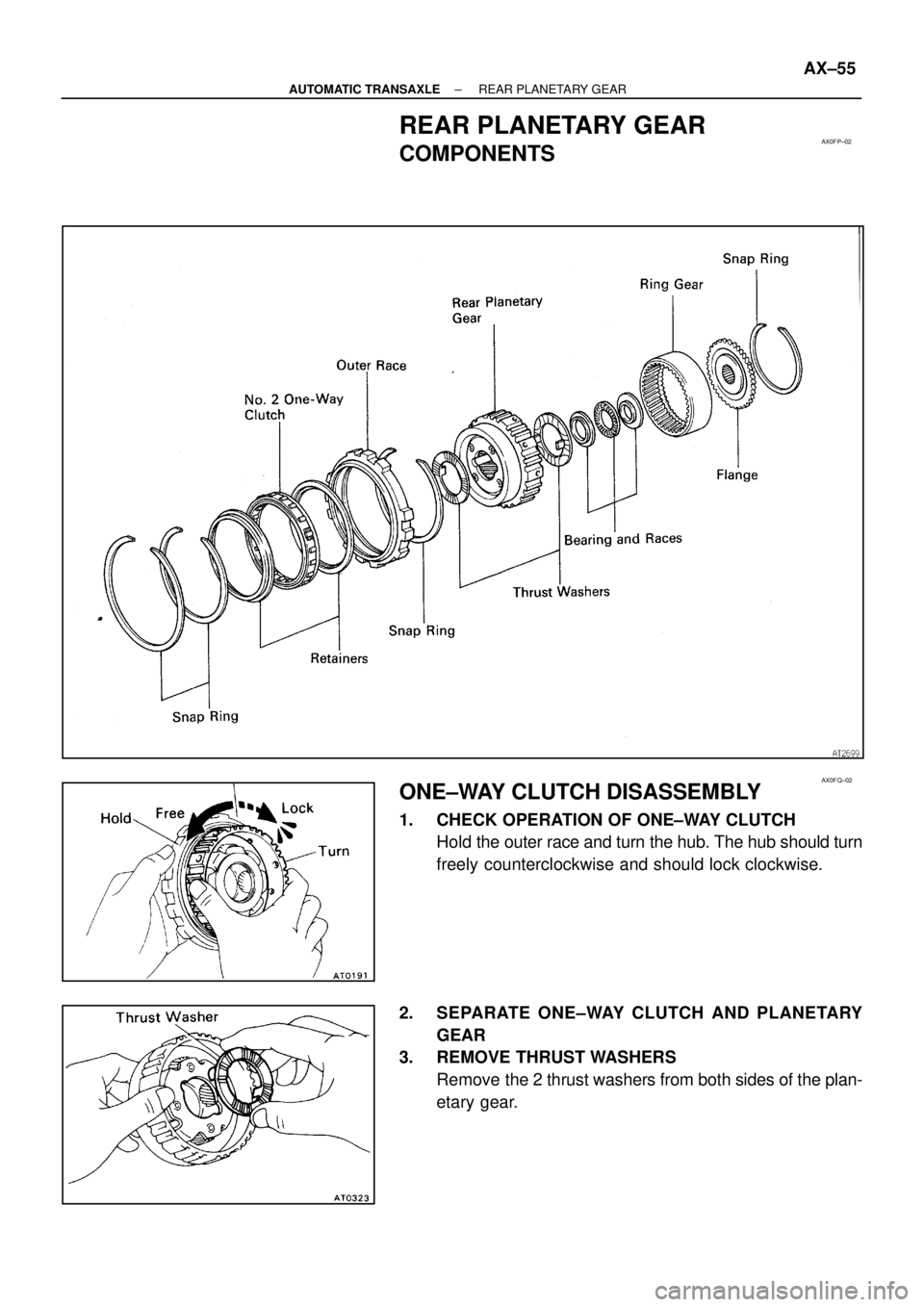

REAR PLANETARY GEAR

COMPONENTS

ONE±WAY CLUTCH DISASSEMBLY

1. CHECK OPERATION OF ONE±WAY CLUTCH

Hold the outer race and turn the hub. The hub should turn

freely counterclockwise and should lock clockwise.

2. SEPARATE ONE±WAY CLUTCH AND PLANETARY

GEAR

3. REMOVE THRUST WASHERS

Remove the 2 thrust washers from both sides of the plan-

etary gear.

AX0FP±02

AX0FQ±02

Page 227 of 4592

AUTOMATIC TRANSAXLEREAR PLANETARY GEAR ±

AX±57

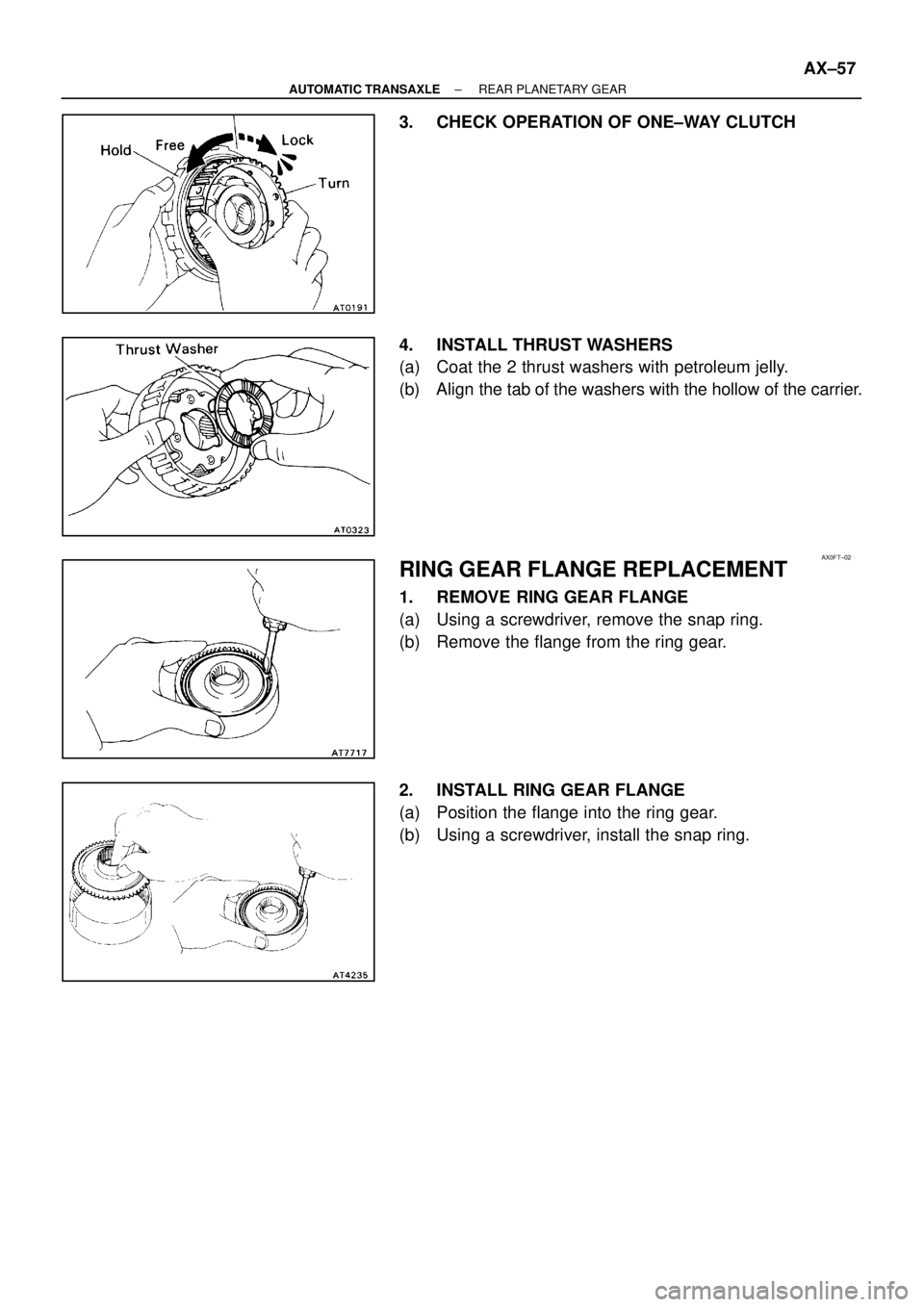

3. CHECK OPERATION OF ONE±WAY CLUTCH

4. INSTALL THRUST WASHERS

(a) Coat the 2 thrust washers with petroleum jelly.

(b) Align the tab of the washers with the hollow of the carrier.

RING GEAR FLANGE REPLACEMENT

1. REMOVE RING GEAR FLANGE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange from the ring gear.

2. INSTALL RING GEAR FLANGE

(a) Position the flange into the ring gear.

(b) Using a screwdriver, install the snap ring.

AX0FT±02

Page 237 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±67

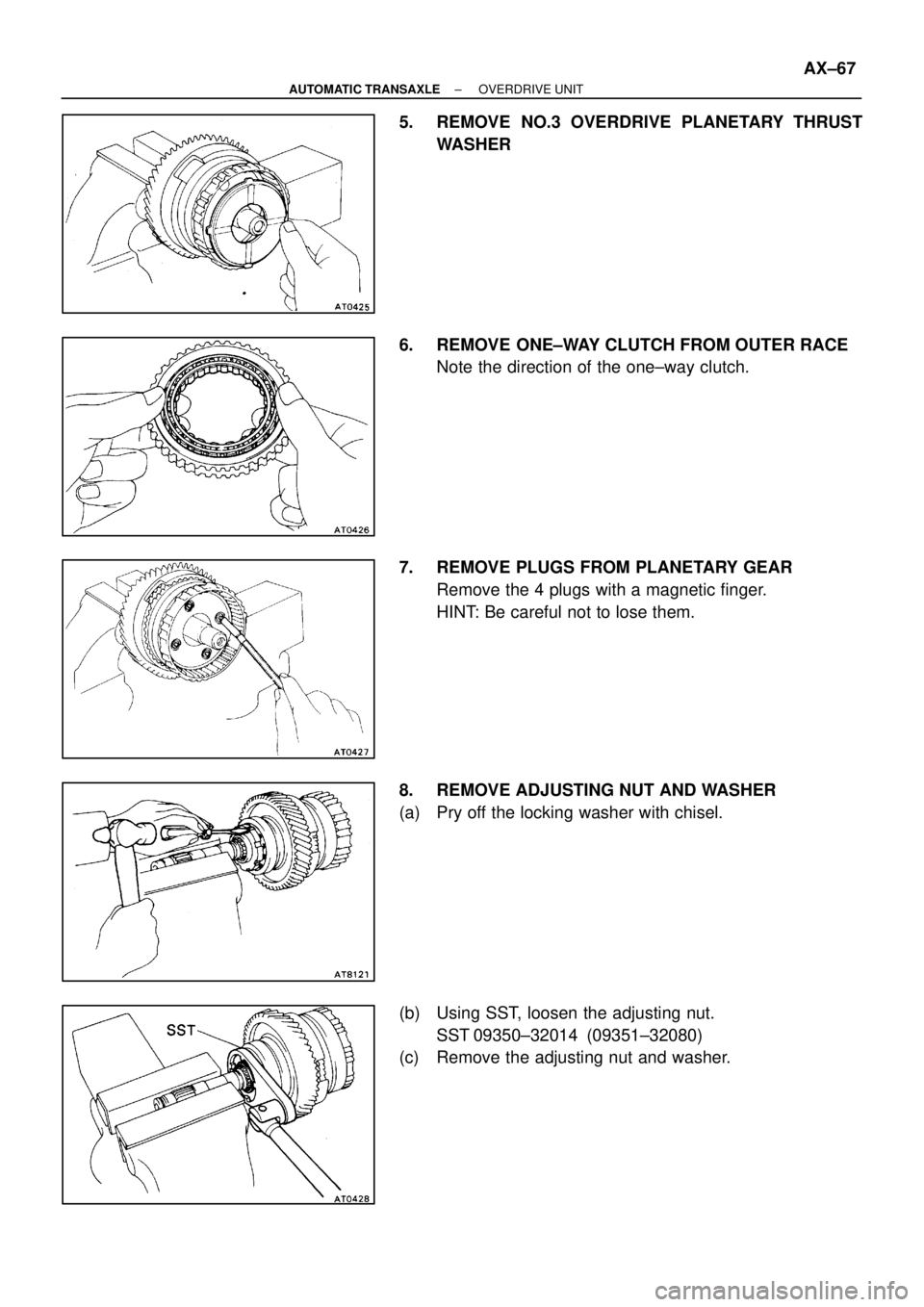

5. REMOVE NO.3 OVERDRIVE PLANETARY THRUST

WASHER

6. REMOVE ONE±WAY CLUTCH FROM OUTER RACE

Note the direction of the one±way clutch.

7. REMOVE PLUGS FROM PLANETARY GEAR

Remove the 4 plugs with a magnetic finger.

HINT: Be careful not to lose them.

8. REMOVE ADJUSTING NUT AND WASHER

(a) Pry off the locking washer with chisel.

(b) Using SST, loosen the adjusting nut.

SST 09350±32014 (09351±32080)

(c) Remove the adjusting nut and washer.

Page 240 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±70

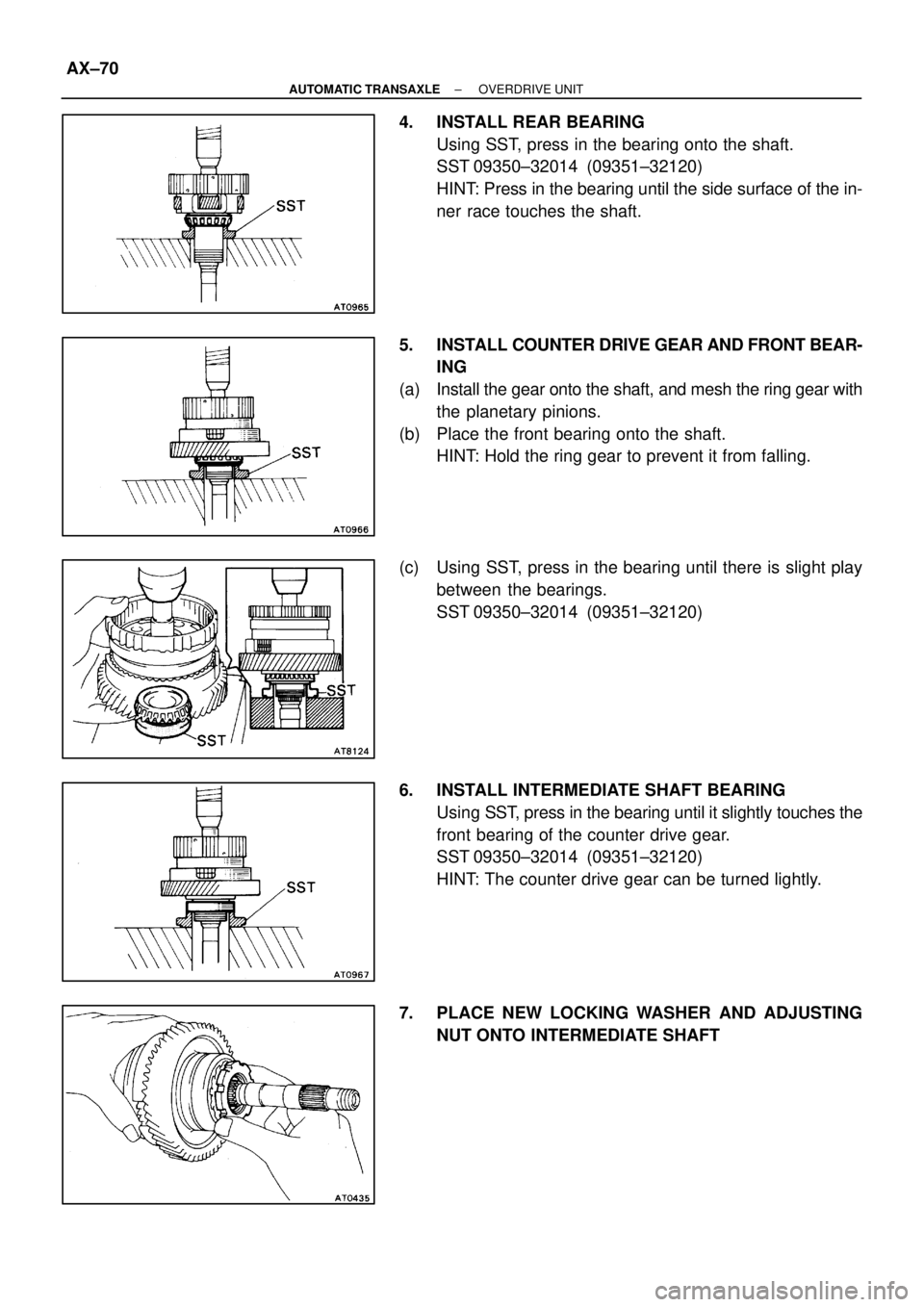

4. INSTALL REAR BEARING

Using SST, press in the bearing onto the shaft.

SST 09350±32014 (09351±32120)

HINT: Press in the bearing until the side surface of the in-

ner race touches the shaft.

5. INSTALL COUNTER DRIVE GEAR AND FRONT BEAR-

ING

(a) Install the gear onto the shaft, and mesh the ring gear with

the planetary pinions.

(b) Place the front bearing onto the shaft.

HINT: Hold the ring gear to prevent it from falling.

(c) Using SST, press in the bearing until there is slight play

between the bearings.

SST 09350±32014 (09351±32120)

6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches the

front bearing of the counter drive gear.

SST 09350±32014 (09351±32120)

HINT: The counter drive gear can be turned lightly.

7. PLACE NEW LOCKING WASHER AND ADJUSTING

NUT ONTO INTERMEDIATE SHAFT

Page 241 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±71

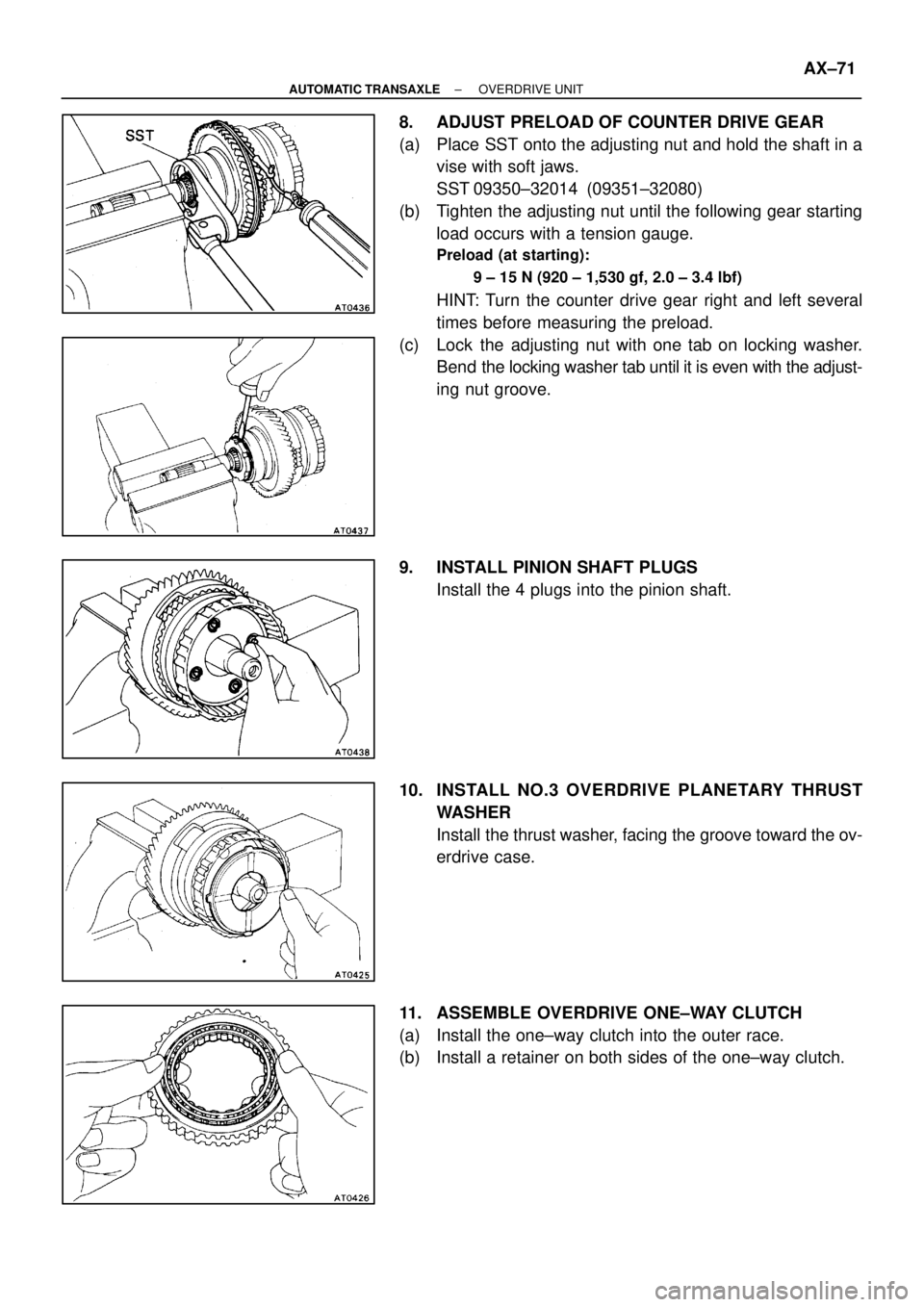

8. ADJUST PRELOAD OF COUNTER DRIVE GEAR

(a) Place SST onto the adjusting nut and hold the shaft in a

vise with soft jaws.

SST 09350±32014 (09351±32080)

(b) Tighten the adjusting nut until the following gear starting

load occurs with a tension gauge.

Preload (at starting):

9 ± 15 N (920 ± 1,530 gf, 2.0 ± 3.4 lbf)

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one tab on locking washer.

Bend the locking washer tab until it is even with the adjust-

ing nut groove.

9. INSTALL PINION SHAFT PLUGS

Install the 4 plugs into the pinion shaft.

10. INSTALL NO.3 OVERDRIVE PLANETARY THRUST

WASHER

Install the thrust washer, facing the groove toward the ov-

erdrive case.

11. ASSEMBLE OVERDRIVE ONE±WAY CLUTCH

(a) Install the one±way clutch into the outer race.

(b) Install a retainer on both sides of the one±way clutch.

Page 261 of 4592

AUTOMATIC TRANSAXLEDIFFERENTIAL ASSEMBLY ±

AX±91

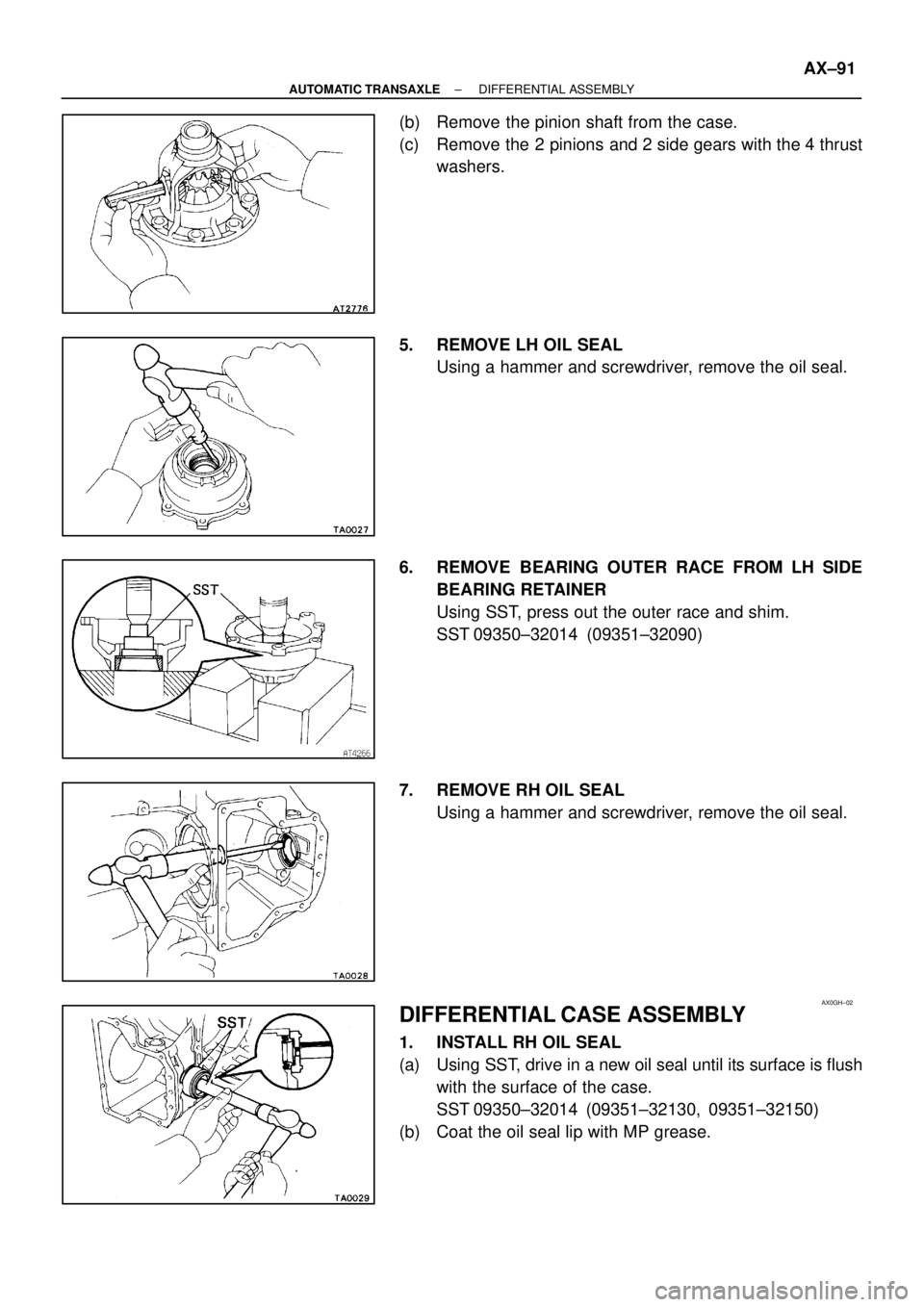

(b) Remove the pinion shaft from the case.

(c) Remove the 2 pinions and 2 side gears with the 4 thrust

washers.

5. REMOVE LH OIL SEAL

Using a hammer and screwdriver, remove the oil seal.

6. REMOVE BEARING OUTER RACE FROM LH SIDE

BEARING RETAINER

Using SST, press out the outer race and shim.

SST 09350±32014 (09351±32090)

7. REMOVE RH OIL SEAL

Using a hammer and screwdriver, remove the oil seal.

DIFFERENTIAL CASE ASSEMBLY

1. INSTALL RH OIL SEAL

(a) Using SST, drive in a new oil seal until its surface is flush

with the surface of the case.

SST 09350±32014 (09351±32130, 09351±32150)

(b) Coat the oil seal lip with MP grease.

AX0GH±02