washer TOYOTA CAMRY 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 489 of 4592

AUTOMATIC TRANSAXLEOIL PUMP ±

AX±40

2. INSTALL DRIVEN GEAR AND DRIVE GEAR

Make sure the top of the gears are facing upward.

3. INSTALL STATOR SHAFT TO PUMP BODY

(a) Align the stator shaft with each bolt hole.

(b) Torque the 11 bolts.

Torque: 10 N´m (100 kgf´cm, 7 ft´lbf)

4. INSTALL THRUST WASHER

(a) Coat the thrust washer with petroleum jelly.

(b) Align the tab of the washer with the hollow of the pump

body.

5. INSTALL OIL SEAL RINGS

Install the 2 oil seal rings to the stator shaft back side.

NOTICE: Do not spread the ring ends more than necessary.

HINT: After installing the oil seal rings, check that they

move smoothly.

6. CHECK PUMP DRIVE GEAR ROTATION

Turn the drive gear with 2 screwdrivers and make sure it

rotates smoothly.

NOTICE: Be careful not to damage the oil seal lip.

Page 504 of 4592

AUTOMATIC TRANSAXLEREAR PLANETARY GEAR ±

AX±55

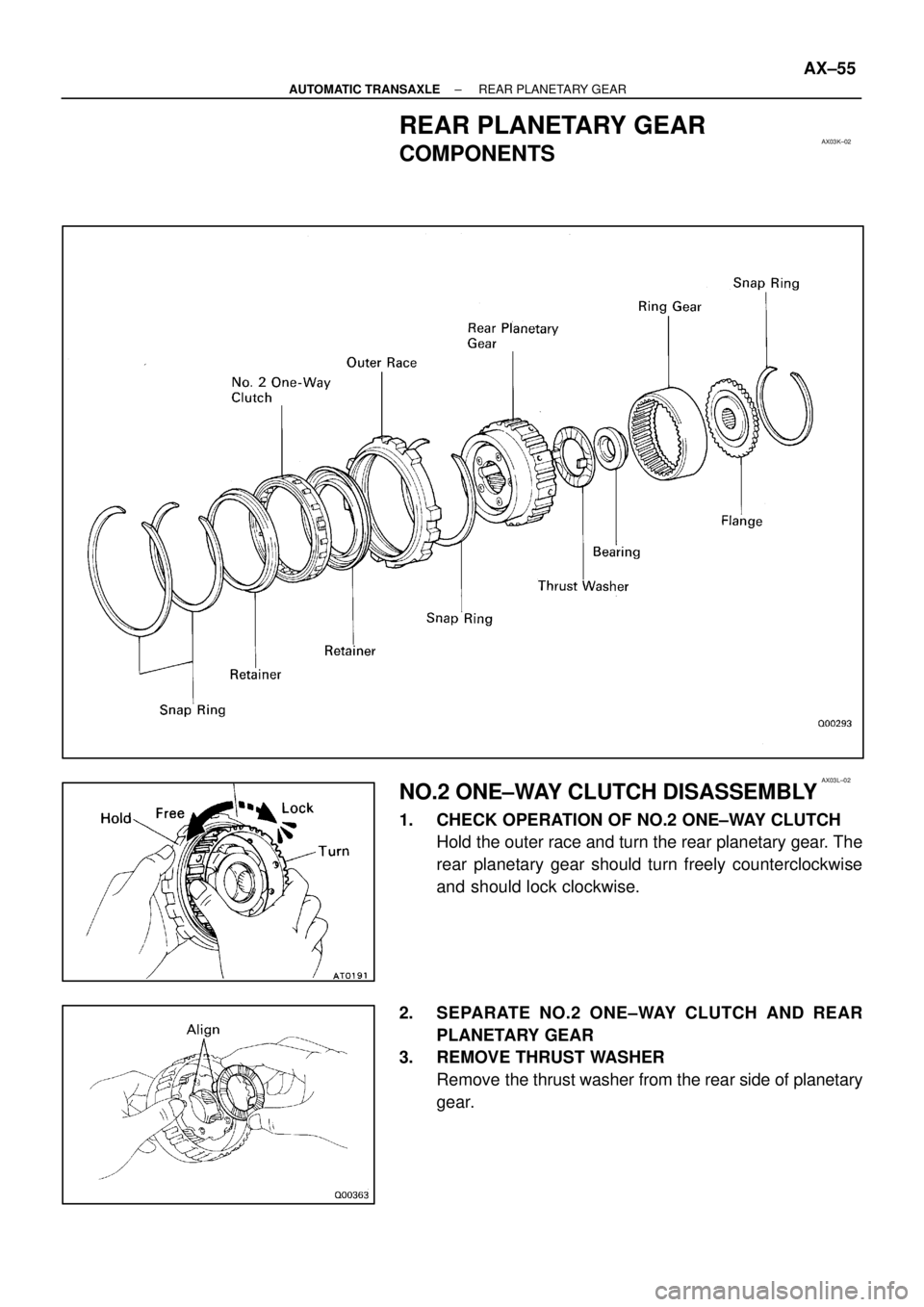

REAR PLANETARY GEAR

COMPONENTS

NO.2 ONE±WAY CLUTCH DISASSEMBLY

1. CHECK OPERATION OF NO.2 ONE±WAY CLUTCH

Hold the outer race and turn the rear planetary gear. The

rear planetary gear should turn freely counterclockwise

and should lock clockwise.

2. SEPARATE NO.2 ONE±WAY CLUTCH AND REAR

PLANETARY GEAR

3. REMOVE THRUST WASHER

Remove the thrust washer from the rear side of planetary

gear.

AX03K±02

AX03L±02

Page 506 of 4592

AUTOMATIC TRANSAXLEREAR PLANETARY GEAR ±

AX±57

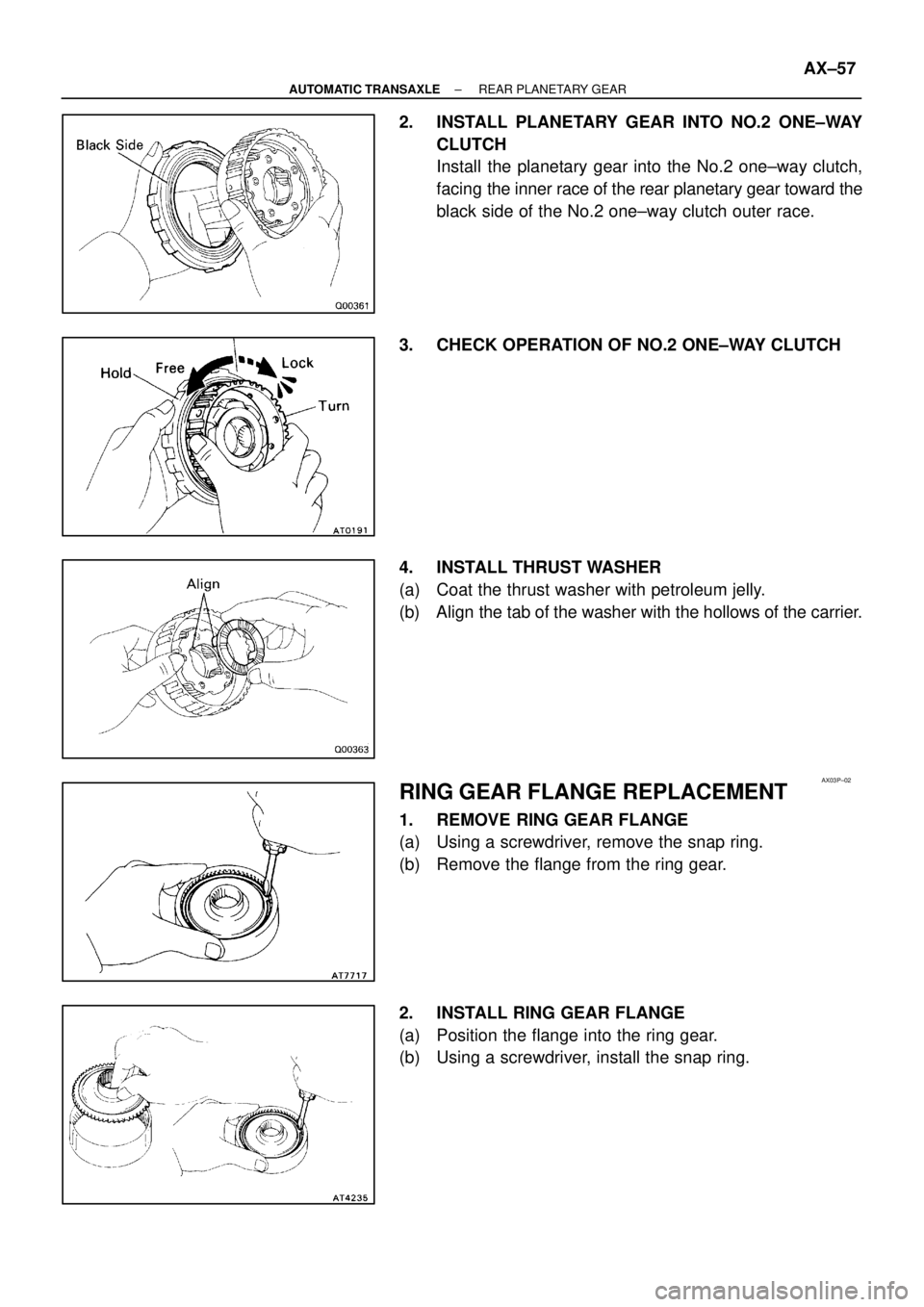

2. INSTALL PLANETARY GEAR INTO NO.2 ONE±WAY

CLUTCH

Install the planetary gear into the No.2 one±way clutch,

facing the inner race of the rear planetary gear toward the

black side of the No.2 one±way clutch outer race.

3. CHECK OPERATION OF NO.2 ONE±WAY CLUTCH

4. INSTALL THRUST WASHER

(a) Coat the thrust washer with petroleum jelly.

(b) Align the tab of the washer with the hollows of the carrier.

RING GEAR FLANGE REPLACEMENT

1. REMOVE RING GEAR FLANGE

(a) Using a screwdriver, remove the snap ring.

(b) Remove the flange from the ring gear.

2. INSTALL RING GEAR FLANGE

(a) Position the flange into the ring gear.

(b) Using a screwdriver, install the snap ring.

AX03P±02

Page 516 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±67

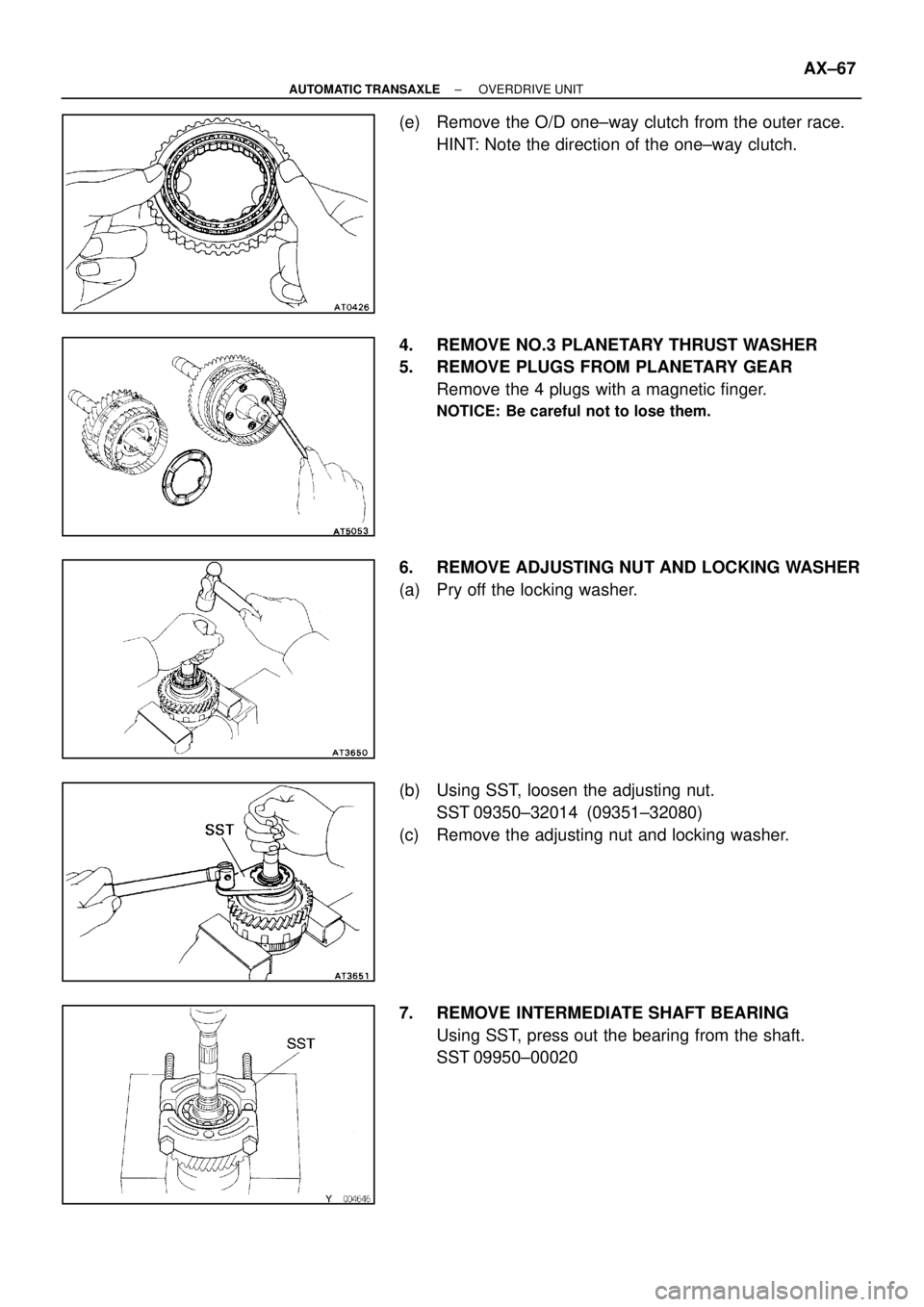

(e) Remove the O/D one±way clutch from the outer race.

HINT: Note the direction of the one±way clutch.

4. REMOVE NO.3 PLANETARY THRUST WASHER

5. REMOVE PLUGS FROM PLANETARY GEAR

Remove the 4 plugs with a magnetic finger.

NOTICE: Be careful not to lose them.

6. REMOVE ADJUSTING NUT AND LOCKING WASHER

(a) Pry off the locking washer.

(b) Using SST, loosen the adjusting nut.

SST 09350±32014 (09351±32080)

(c) Remove the adjusting nut and locking washer.

7. REMOVE INTERMEDIATE SHAFT BEARING

Using SST, press out the bearing from the shaft.

SST 09950±00020

Page 520 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±71

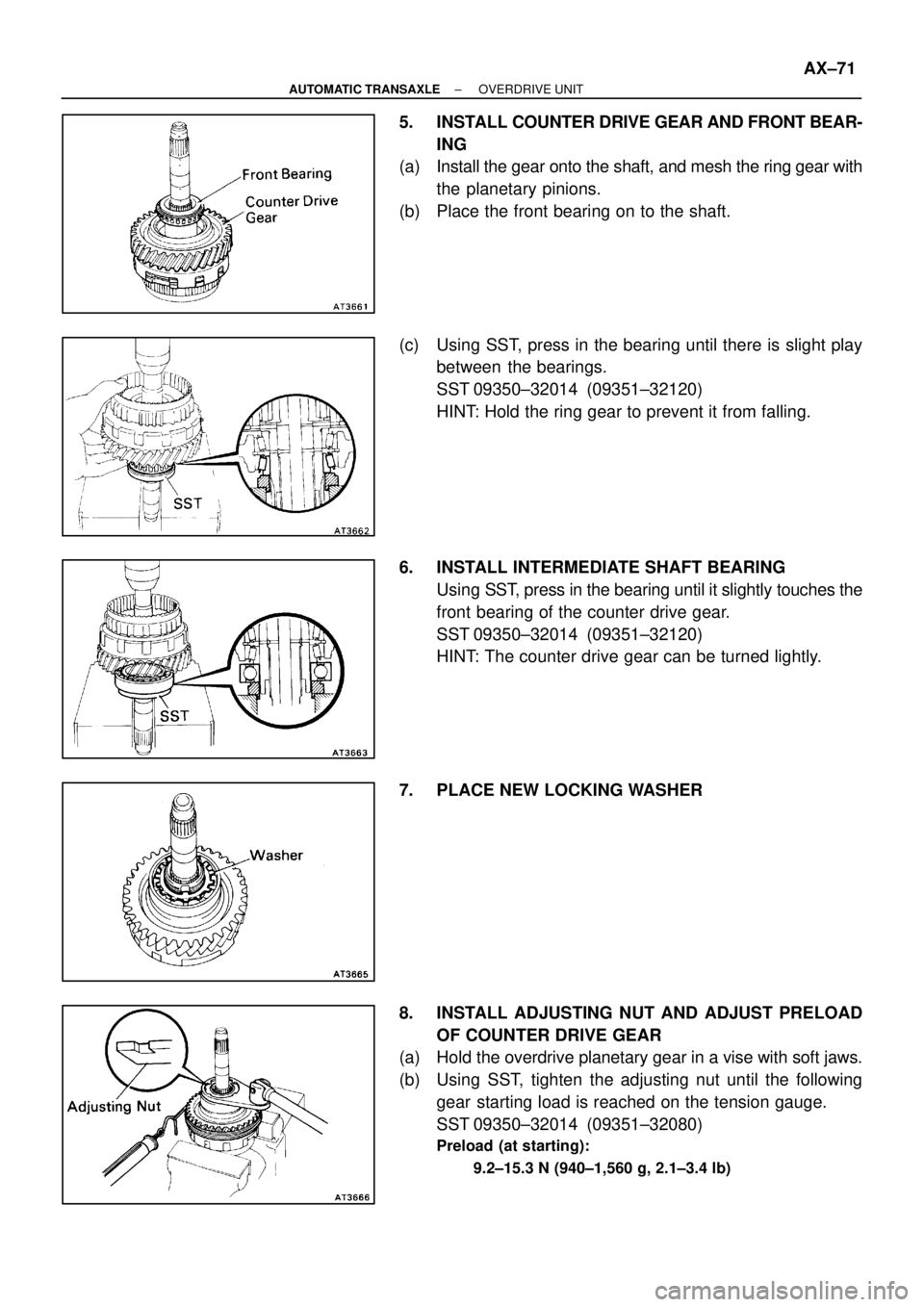

5. INSTALL COUNTER DRIVE GEAR AND FRONT BEAR-

ING

(a) Install the gear onto the shaft, and mesh the ring gear with

the planetary pinions.

(b) Place the front bearing on to the shaft.

(c) Using SST, press in the bearing until there is slight play

between the bearings.

SST 09350±32014 (09351±32120)

HINT: Hold the ring gear to prevent it from falling.

6. INSTALL INTERMEDIATE SHAFT BEARING

Using SST, press in the bearing until it slightly touches the

front bearing of the counter drive gear.

SST 09350±32014 (09351±32120)

HINT: The counter drive gear can be turned lightly.

7. PLACE NEW LOCKING WASHER

8. INSTALL ADJUSTING NUT AND ADJUST PRELOAD

OF COUNTER DRIVE GEAR

(a) Hold the overdrive planetary gear in a vise with soft jaws.

(b) Using SST, tighten the adjusting nut until the following

gear starting load is reached on the tension gauge.

SST 09350±32014 (09351±32080)

Preload (at starting):

9.2±15.3 N (940±1,560 g, 2.1±3.4 lb)

Page 521 of 4592

AUTOMATIC TRANSAXLEOVERDRIVE UNIT ±

AX±72

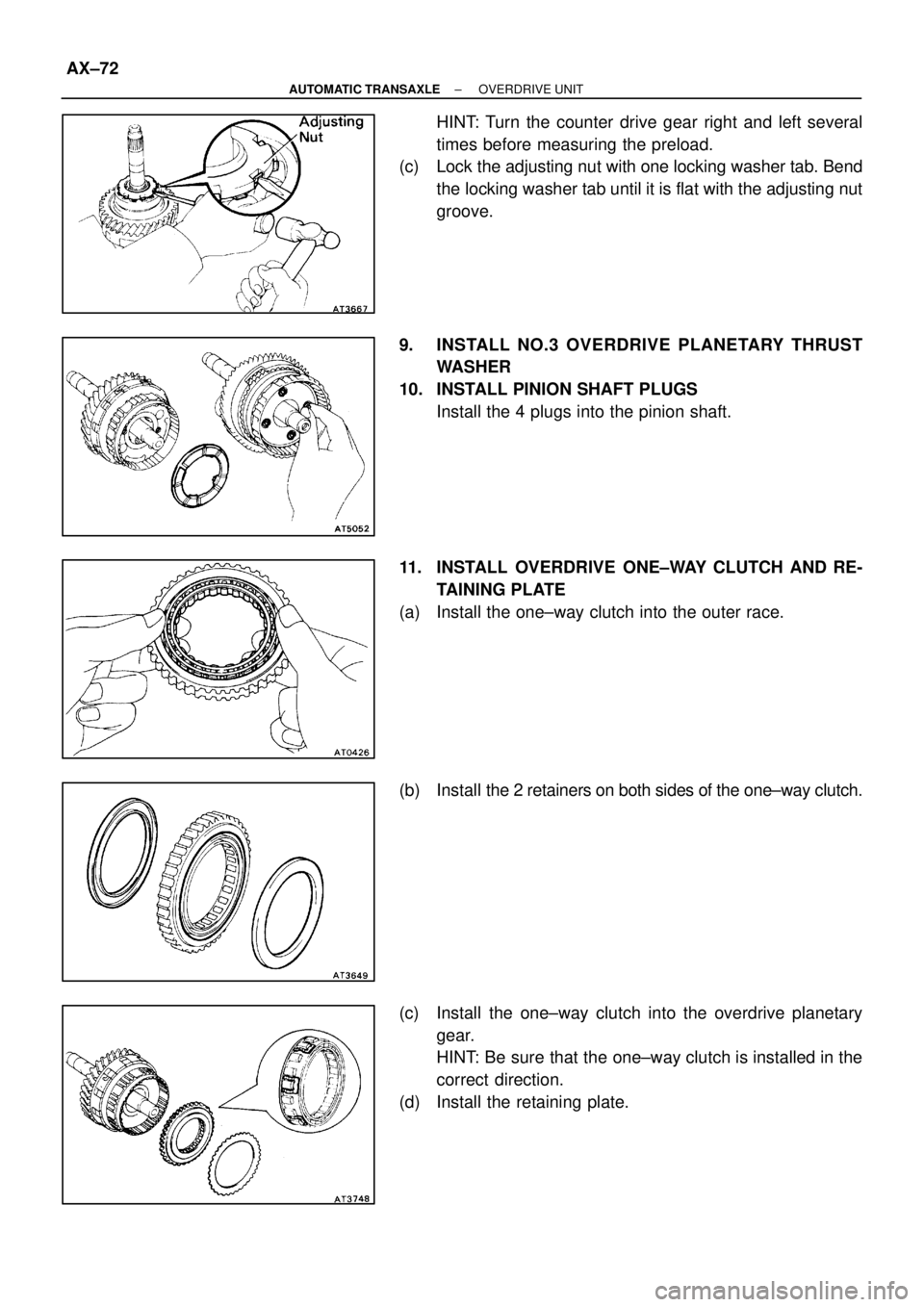

HINT: Turn the counter drive gear right and left several

times before measuring the preload.

(c) Lock the adjusting nut with one locking washer tab. Bend

the locking washer tab until it is flat with the adjusting nut

groove.

9. INSTALL NO.3 OVERDRIVE PLANETARY THRUST

WASHER

10. INSTALL PINION SHAFT PLUGS

Install the 4 plugs into the pinion shaft.

11. INSTALL OVERDRIVE ONE±WAY CLUTCH AND RE-

TAINING PLATE

(a) Install the one±way clutch into the outer race.

(b) Install the 2 retainers on both sides of the one±way clutch.

(c) Install the one±way clutch into the overdrive planetary

gear.

HINT: Be sure that the one±way clutch is installed in the

correct direction.

(d) Install the retaining plate.

Page 546 of 4592

AUTOMATIC TRANSAXLEDIFFERENTIAL ASSEMBLY ±

AX±97

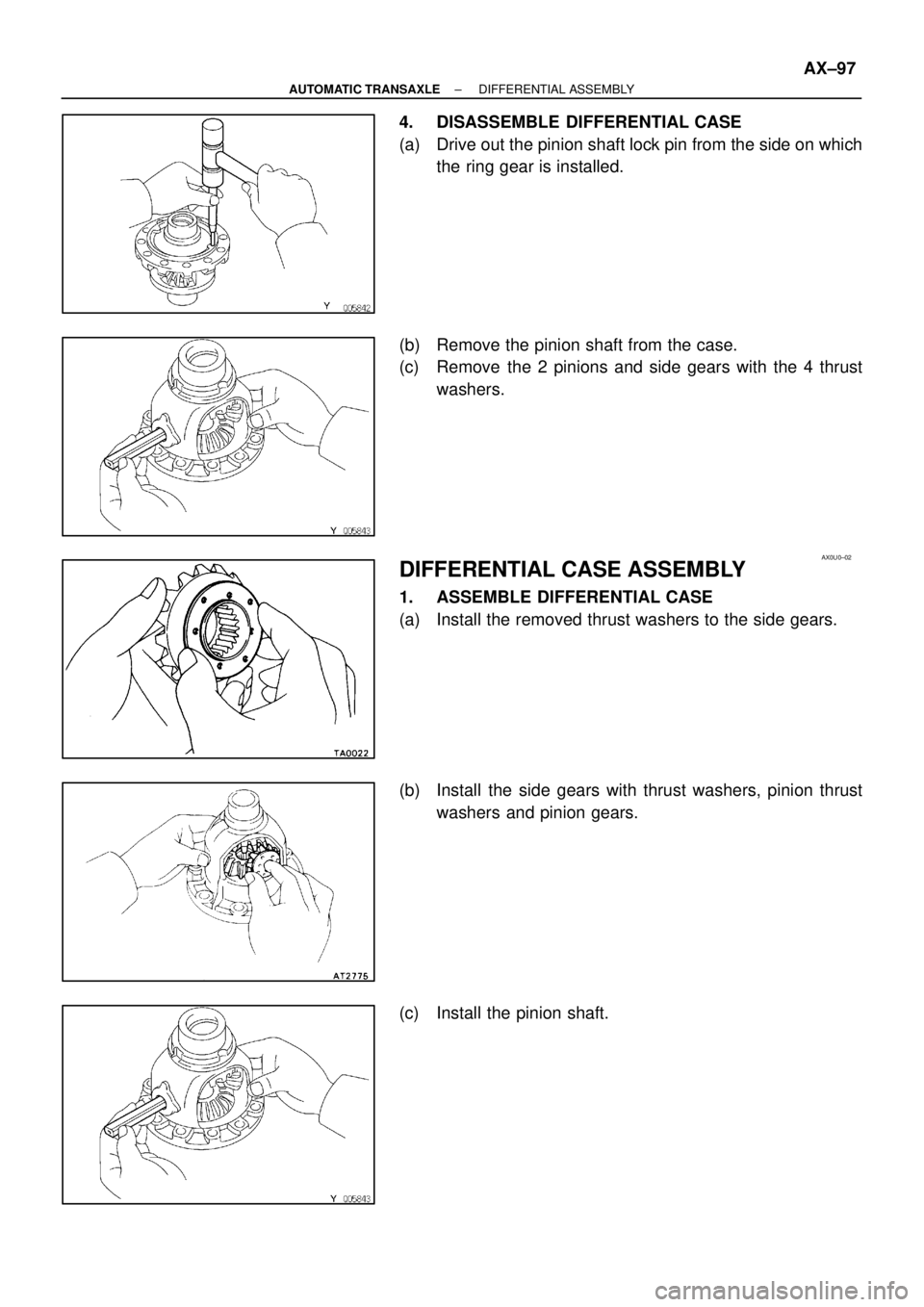

4. DISASSEMBLE DIFFERENTIAL CASE

(a) Drive out the pinion shaft lock pin from the side on which

the ring gear is installed.

(b) Remove the pinion shaft from the case.

(c) Remove the 2 pinions and side gears with the 4 thrust

washers.

DIFFERENTIAL CASE ASSEMBLY

1. ASSEMBLE DIFFERENTIAL CASE

(a) Install the removed thrust washers to the side gears.

(b) Install the side gears with thrust washers, pinion thrust

washers and pinion gears.

(c) Install the pinion shaft.

AX0U0±02

Page 547 of 4592

AUTOMATIC TRANSAXLEDIFFERENTIAL ASSEMBLY ±

AX±98

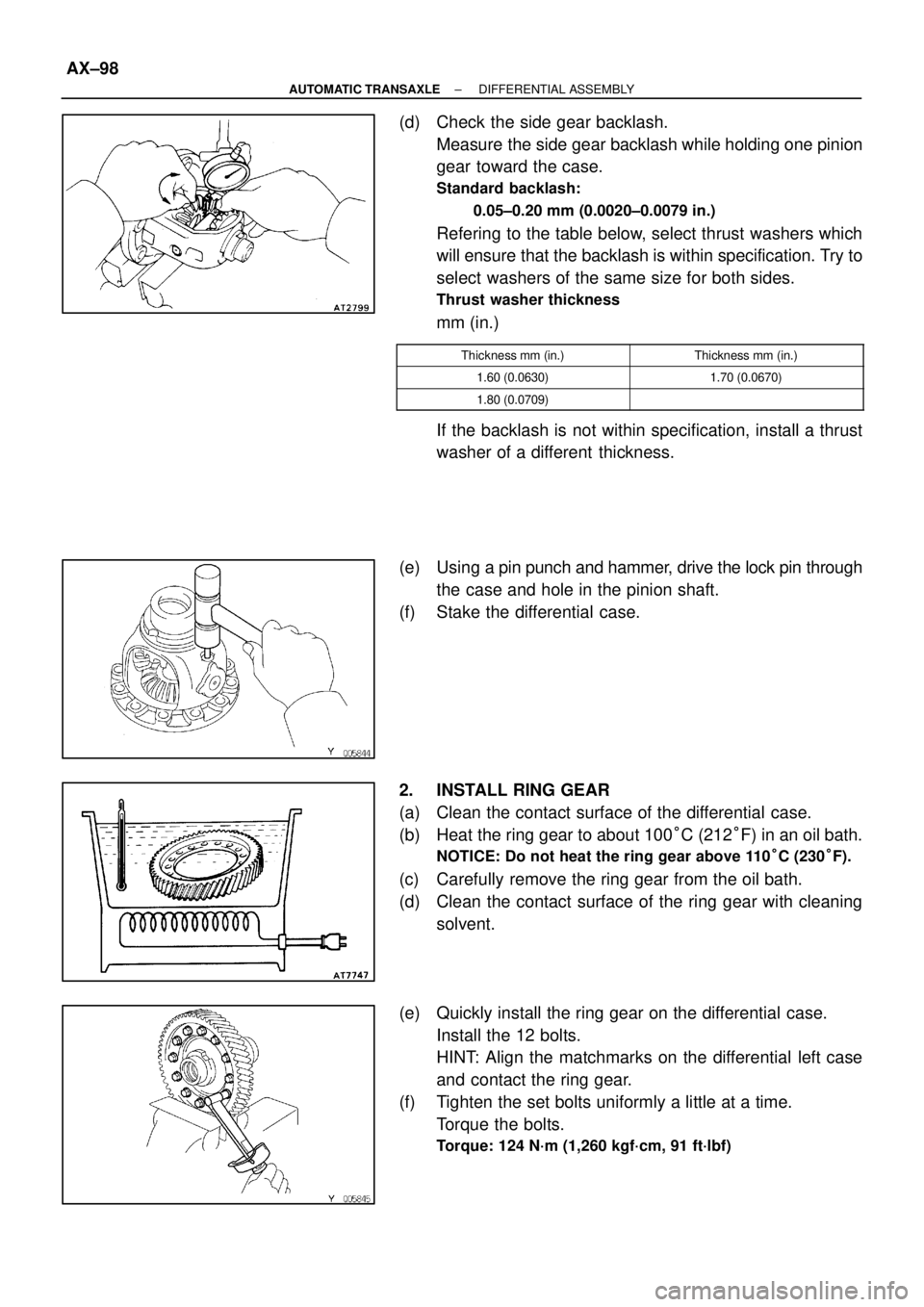

(d) Check the side gear backlash.

Measure the side gear backlash while holding one pinion

gear toward the case.

Standard backlash:

0.05±0.20 mm (0.0020±0.0079 in.)

Refering to the table below, select thrust washers which

will ensure that the backlash is within specification. Try to

select washers of the same size for both sides.

Thrust washer thickness

mm (in.)

Thickness mm (in.)Thickness mm (in.)

1.60 (0.0630)1.70 (0.0670)

1.80 (0.0709)

If the backlash is not within specification, install a thrust

washer of a different thickness.

(e) Using a pin punch and hammer, drive the lock pin through

the case and hole in the pinion shaft.

(f) Stake the differential case.

2. INSTALL RING GEAR

(a) Clean the contact surface of the differential case.

(b) Heat the ring gear to about 100°C (212°F) in an oil bath.

NOTICE: Do not heat the ring gear above 110°C (230°F).

(c) Carefully remove the ring gear from the oil bath.

(d) Clean the contact surface of the ring gear with cleaning

solvent.

(e) Quickly install the ring gear on the differential case.

Install the 12 bolts.

HINT: Align the matchmarks on the differential left case

and contact the ring gear.

(f) Tighten the set bolts uniformly a little at a time.

Torque the bolts.

Torque: 124 N´m (1,260 kgf´cm, 91 ft´lbf)

Page 561 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±112

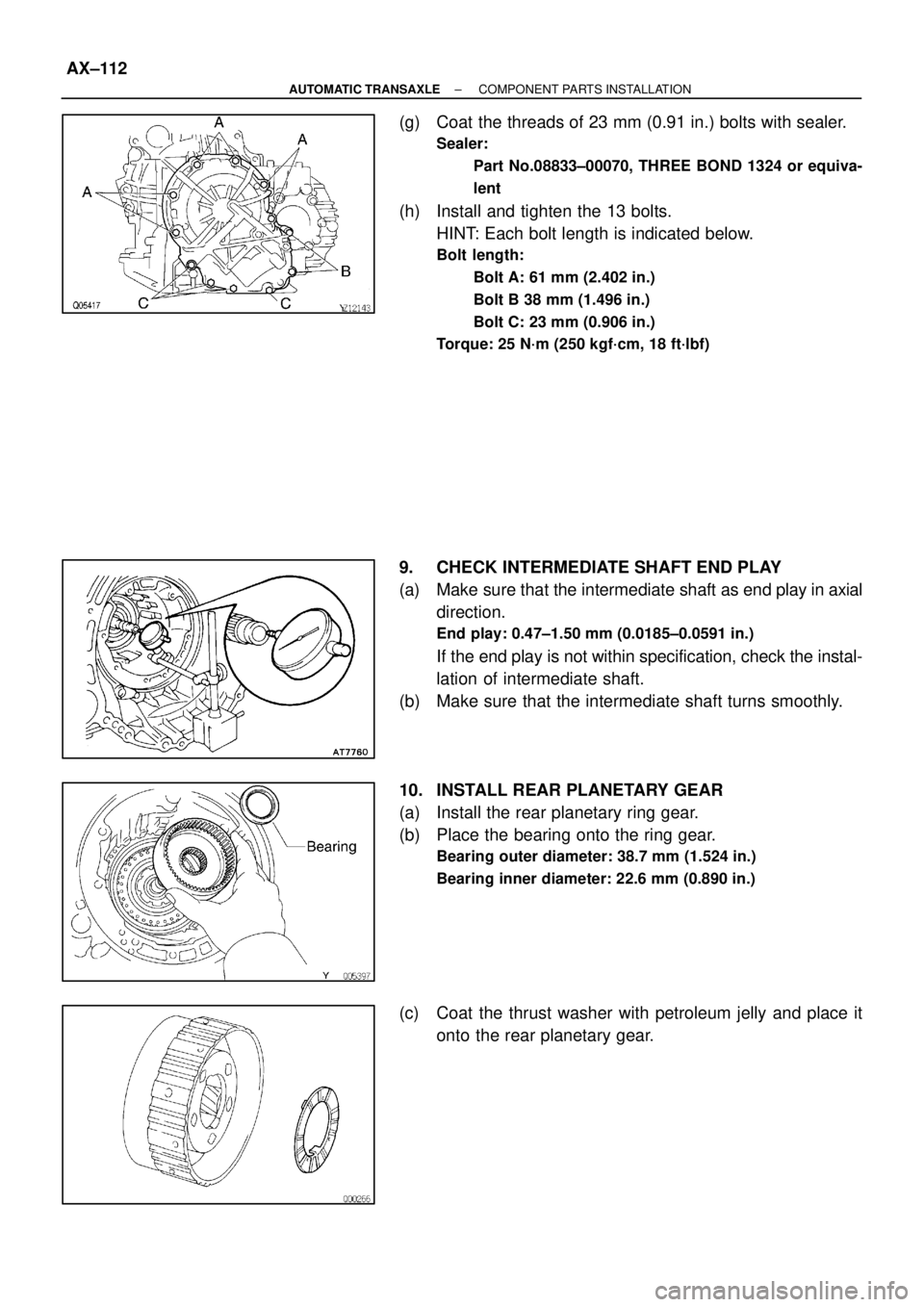

(g) Coat the threads of 23 mm (0.91 in.) bolts with sealer.

Sealer:

Part No.08833±00070, THREE BOND 1324 or equiva-

lent

(h) Install and tighten the 13 bolts.

HINT: Each bolt length is indicated below.

Bolt length:

Bolt A: 61 mm (2.402 in.)

Bolt B 38 mm (1.496 in.)

Bolt C: 23 mm (0.906 in.)

Torque: 25 N´m (250 kgf´cm, 18 ft´lbf)

9. CHECK INTERMEDIATE SHAFT END PLAY

(a) Make sure that the intermediate shaft as end play in axial

direction.

End play: 0.47±1.50 mm (0.0185±0.0591 in.)

If the end play is not within specification, check the instal-

lation of intermediate shaft.

(b) Make sure that the intermediate shaft turns smoothly.

10. INSTALL REAR PLANETARY GEAR

(a) Install the rear planetary ring gear.

(b) Place the bearing onto the ring gear.

Bearing outer diameter: 38.7 mm (1.524 in.)

Bearing inner diameter: 22.6 mm (0.890 in.)

(c) Coat the thrust washer with petroleum jelly and place it

onto the rear planetary gear.

Page 563 of 4592

AUTOMATIC TRANSAXLECOMPONENT PARTS INSTALLATION ±

AX±114

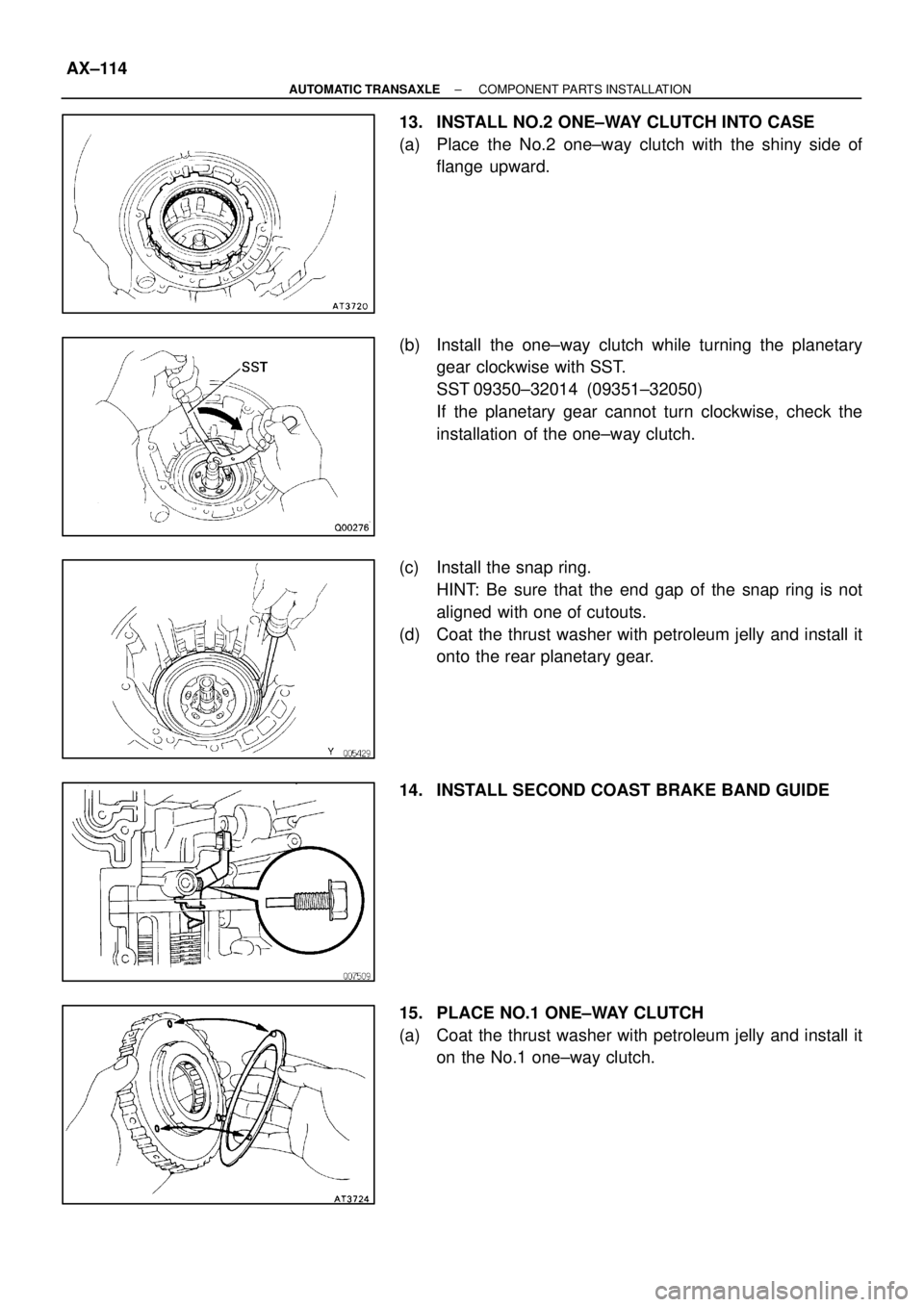

13. INSTALL NO.2 ONE±WAY CLUTCH INTO CASE

(a) Place the No.2 one±way clutch with the shiny side of

flange upward.

(b) Install the one±way clutch while turning the planetary

gear clockwise with SST.

SST 09350±32014 (09351±32050)

If the planetary gear cannot turn clockwise, check the

installation of the one±way clutch.

(c) Install the snap ring.

HINT: Be sure that the end gap of the snap ring is not

aligned with one of cutouts.

(d) Coat the thrust washer with petroleum jelly and install it

onto the rear planetary gear.

14. INSTALL SECOND COAST BRAKE BAND GUIDE

15. PLACE NO.1 ONE±WAY CLUTCH

(a) Coat the thrust washer with petroleum jelly and install it

on the No.1 one±way clutch.