TOYOTA CAMRY 1999 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 2271 of 4592

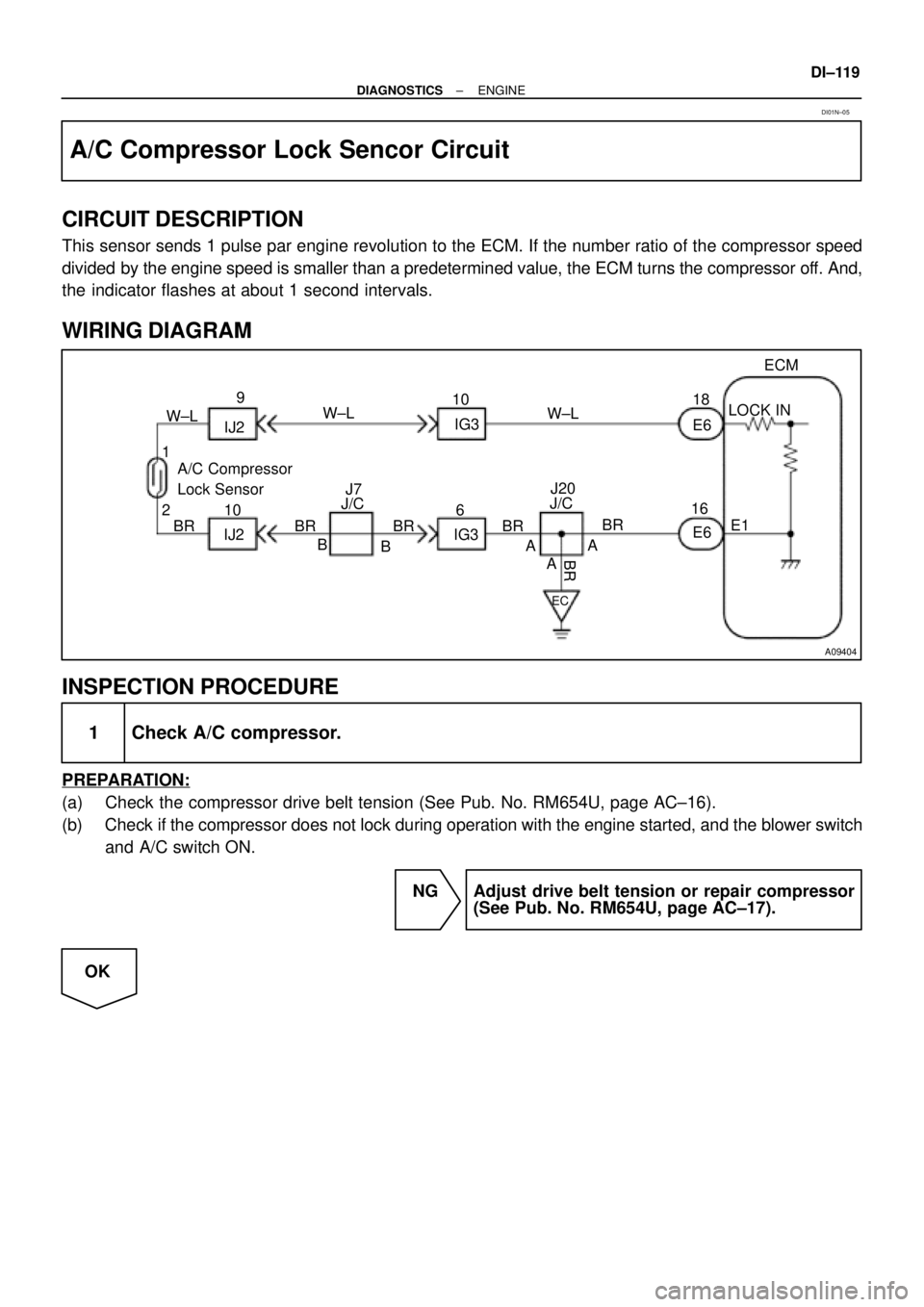

A09404

9

W±L

IJ2

E6 10

IG3

E6 18

LOCK IN

E1 16

EC

BRJ20

IJ210

BR 1

2A/C Compressor

Lock SensorECM

BR W±L

W±L

B

B BRJ/C

AA

A

BR

IG3 J7

6J/C

BR

± DIAGNOSTICSENGINE

DI±119

A/C Compressor Lock Sencor Circuit

CIRCUIT DESCRIPTION

This sensor sends 1 pulse par engine revolution to the ECM. If the number ratio of the compressor speed

divided by the engine speed is smaller than a predetermined value, the ECM turns the compressor off. And,

the indicator flashes at about 1 second intervals.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 Check A/C compressor.

PREPARATION:

(a) Check the compressor drive belt tension (See Pub. No. RM654U, page AC±16).

(b) Check if the compressor does not lock during operation with the engine started, and the blower switch

and A/C switch ON.

NG Adjust drive belt tension or repair compressor

(See Pub. No. RM654U, page AC±17).

OK

DI01N±05

Page 2272 of 4592

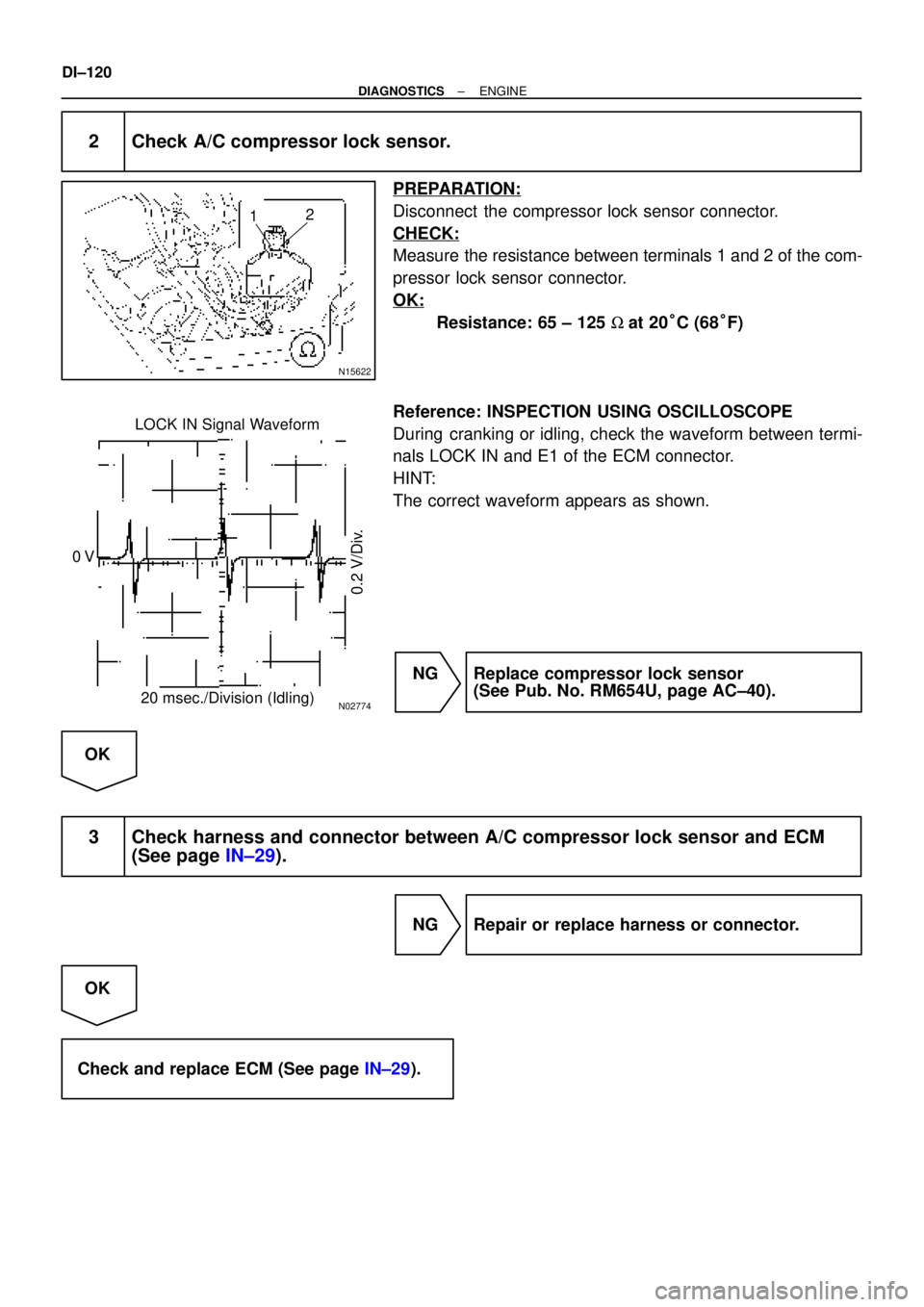

N15622

12

N02774

LOCK IN Signal Waveform

20 msec./Division (Idling) 0 V

0.2 V/Div.

DI±120

± DIAGNOSTICSENGINE

2 Check A/C compressor lock sensor.

PREPARATION:

Disconnect the compressor lock sensor connector.

CHECK:

Measure the resistance between terminals 1 and 2 of the com-

pressor lock sensor connector.

OK:

Resistance: 65 ± 125 W at 20°C (68°F)

Reference: INSPECTION USING OSCILLOSCOPE

During cranking or idling, check the waveform between termi-

nals LOCK IN and E1 of the ECM connector.

HINT:

The correct waveform appears as shown.

NG Replace compressor lock sensor

(See Pub. No. RM654U, page AC±40).

OK

3 Check harness and connector between A/C compressor lock sensor and ECM

(See page IN±29).

NG Repair or replace harness or connector.

OK

Check and replace ECM (See page IN±29).

Page 2273 of 4592

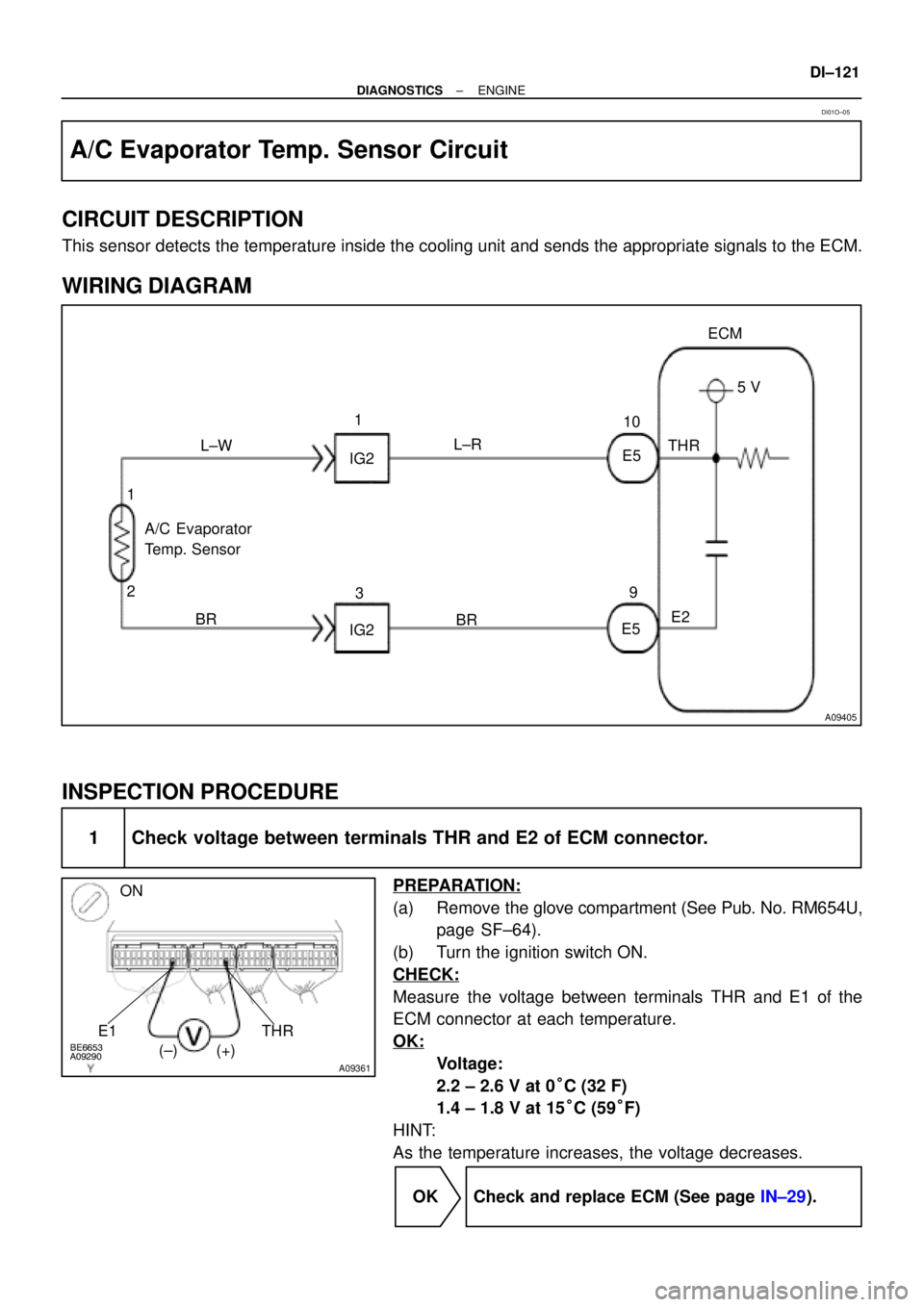

A09405

E5

IG2 L±W1

L±R

THR5 V ECM

E2

E59

BR

IG23

BR A/C Evaporator

Temp. Sensor

2 110

A09290BE6653

A09361

ON

E1 THR

(±) (+)

± DIAGNOSTICSENGINE

DI±121

A/C Evaporator Temp. Sensor Circuit

CIRCUIT DESCRIPTION

This sensor detects the temperature inside the cooling unit and sends the appropriate signals to the ECM.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 Check voltage between terminals THR and E2 of ECM connector.

PREPARATION:

(a) Remove the glove compartment (See Pub. No. RM654U,

page SF±64).

(b) Turn the ignition switch ON.

CHECK:

Measure the voltage between terminals THR and E1 of the

ECM connector at each temperature.

OK:

Voltage:

2.2 ± 2.6 V at 0°C (32 F)

1.4 ± 1.8 V at 15°C (59°F)

HINT:

As the temperature increases, the voltage decreases.

OK Check and replace ECM (See page IN±29).

DI01O±05

Page 2274 of 4592

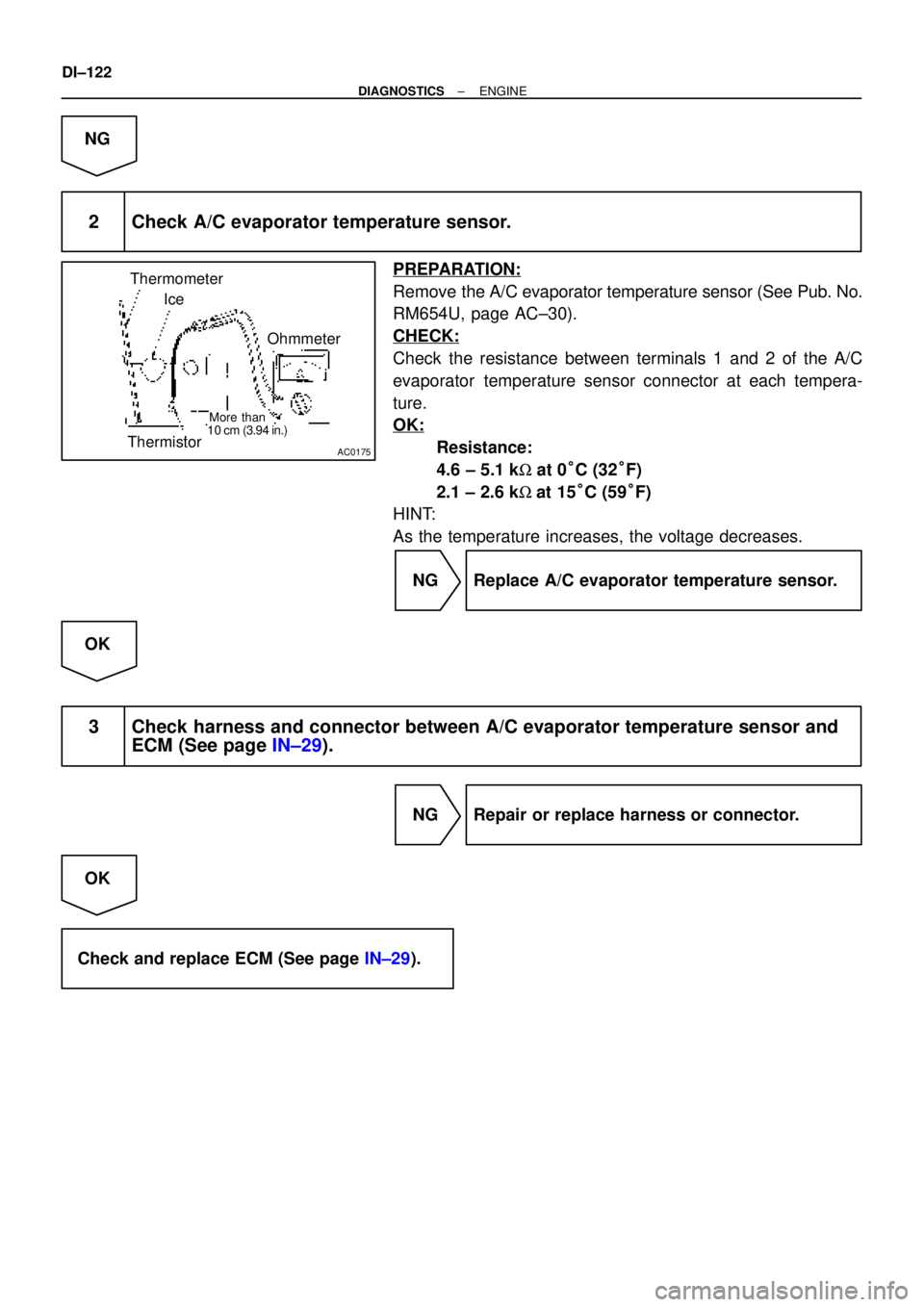

AC0175

Thermometer

Ice

Ohmmeter

Thermistor

More than

10 cm (3.94 in.)

DI±122

± DIAGNOSTICSENGINE

NG

2 Check A/C evaporator temperature sensor.

PREPARATION:

Remove the A/C evaporator temperature sensor (See Pub. No.

RM654U, page AC±30).

CHECK:

Check the resistance between terminals 1 and 2 of the A/C

evaporator temperature sensor connector at each tempera-

ture.

OK:

Resistance:

4.6 ± 5.1 kW at 0°C (32°F)

2.1 ± 2.6 kW at 15°C (59°F)

HINT:

As the temperature increases, the voltage decreases.

NG Replace A/C evaporator temperature sensor.

OK

3 Check harness and connector between A/C evaporator temperature sensor and

ECM (See page IN±29).

NG Repair or replace harness or connector.

OK

Check and replace ECM (See page IN±29).

Page 2275 of 4592

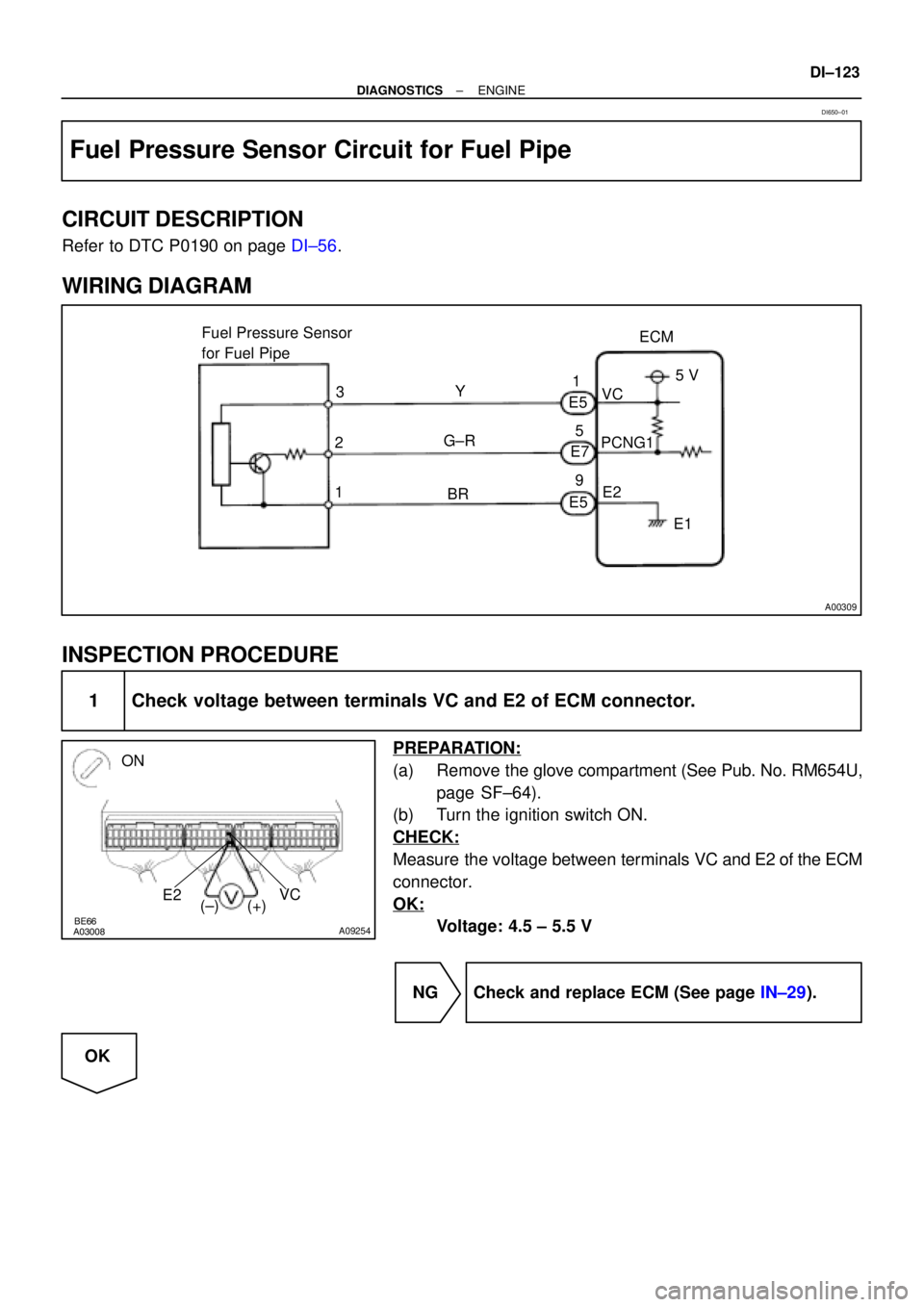

A00309

ECM Fuel Pressure Sensor

for Fuel Pipe

1PCNG1VC

E2 Y

G±RE5

E7

E5 3

25 V

E1 1

5

9

BR

BE6653A03008A09254

ON

E2VC

(±) (+)

± DIAGNOSTICSENGINE

DI±123

Fuel Pressure Sensor Circuit for Fuel Pipe

CIRCUIT DESCRIPTION

Refer to DTC P0190 on page DI±56.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 Check voltage between terminals VC and E2 of ECM connector.

PREPARATION:

(a) Remove the glove compartment (See Pub. No. RM654U,

page SF±64).

(b) Turn the ignition switch ON.

CHECK:

Measure the voltage between terminals VC and E2 of the ECM

connector.

OK:

Voltage: 4.5 ± 5.5 V

NG Check and replace ECM (See page IN±29).

OK

DI650±01

Page 2276 of 4592

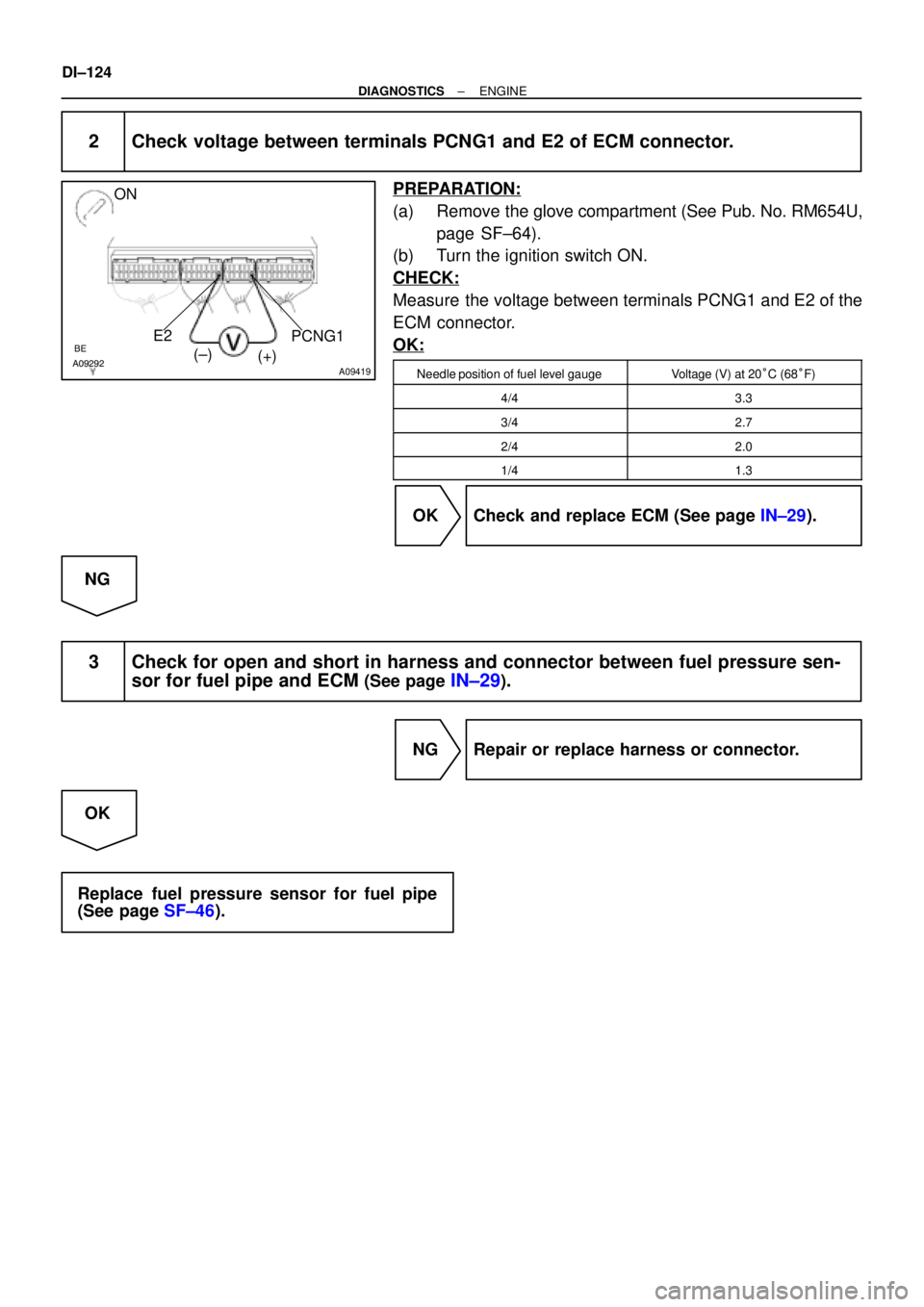

BE6653A09292A09419

E2 ONPCNG1

(±)

(+)

DI±124

± DIAGNOSTICSENGINE

2 Check voltage between terminals PCNG1 and E2 of ECM connector.

PREPARATION:

(a) Remove the glove compartment (See Pub. No. RM654U,

page SF±64).

(b) Turn the ignition switch ON.

CHECK:

Measure the voltage between terminals PCNG1 and E2 of the

ECM connector.

OK:

Needle position of fuel level gaugeVoltage (V) at 20°C (68°F)

4/43.3

3/42.7

2/42.0

1/41.3

OK Check and replace ECM (See page IN±29).

NG

3 Check for open and short in harness and connector between fuel pressure sen-

sor for fuel pipe and ECM

(See page IN±29).

NG Repair or replace harness or connector.

OK

Replace fuel pressure sensor for fuel pipe

(See page SF±46).

Page 2277 of 4592

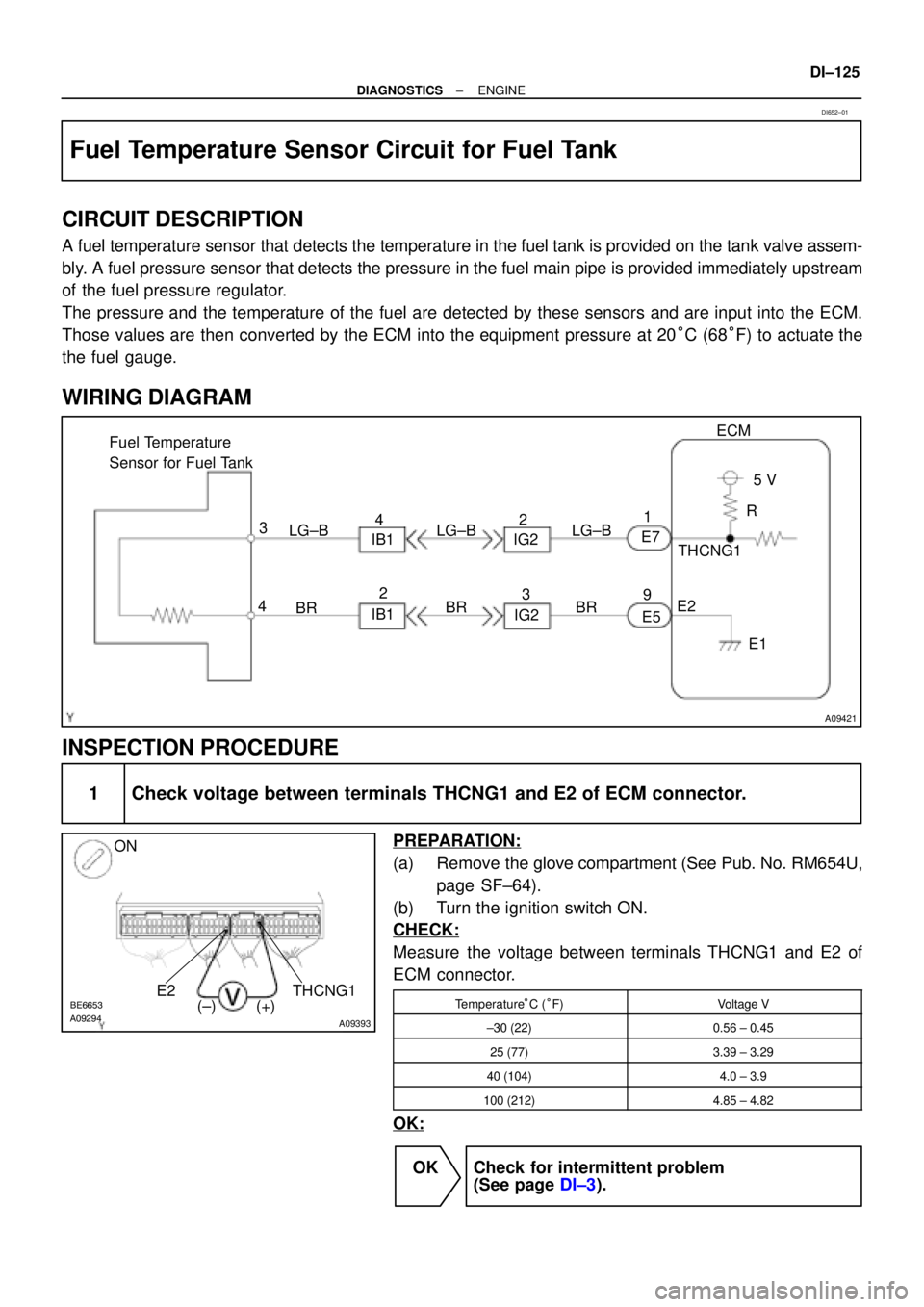

A09421

E7

E51

9ECM

5 V

THCNG1

E2

E1 R

BR 3

4

BR Fuel Temperature

Sensor for Fuel Tank

BR IB1

IG2 LG±B

IB1IG2 LG±B LG±B 42

3 2

A09294BE6653

A09393

ON

THCNG1 E2

(±) (+)

± DIAGNOSTICSENGINE

DI±125

Fuel Temperature Sensor Circuit for Fuel Tank

CIRCUIT DESCRIPTION

A fuel temperature sensor that detects the temperature in the fuel tank is provided on the tank valve assem-

bly. A fuel pressure sensor that detects the pressure in the fuel main pipe is provided immediately upstream

of the fuel pressure regulator.

The pressure and the temperature of the fuel are detected by these sensors and are input into the ECM.

Those values are then converted by the ECM into the equipment pressure at 20°C (68°F) to actuate the

the fuel gauge.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 Check voltage between terminals THCNG1 and E2 of ECM connector.

PREPARATION:

(a) Remove the glove compartment (See Pub. No. RM654U,

page SF±64).

(b) Turn the ignition switch ON.

CHECK:

Measure the voltage between terminals THCNG1 and E2 of

ECM connector.

Temperature°C (°F)Voltage V

±30 (22)0.56 ± 0.45

25 (77)3.39 ± 3.29

40 (104)4.0 ± 3.9

100 (212)4.85 ± 4.82

OK:

OK Check for intermittent problem

(See page DI±3).

DI652±01

Page 2278 of 4592

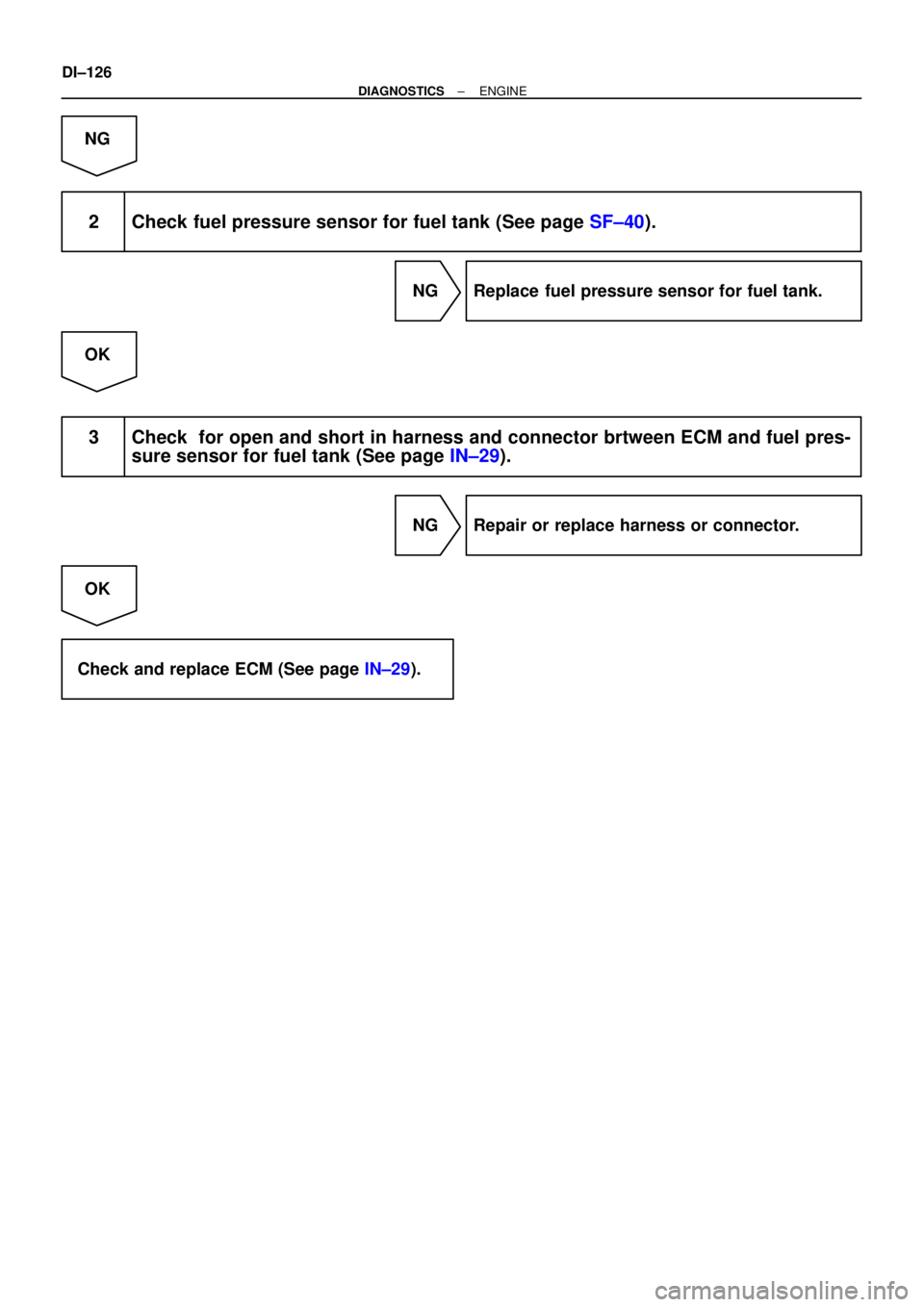

DI±126

± DIAGNOSTICSENGINE

NG

2 Check fuel pressure sensor for fuel tank (See page SF±40).

NG Replace fuel pressure sensor for fuel tank.

OK

3 Check for open and short in harness and connector brtween ECM and fuel pres-

sure sensor for fuel tank (See page IN±29).

NG Repair or replace harness or connector.

OK

Check and replace ECM (See page IN±29).

Page 2279 of 4592

A09422

#10

#20

#30

#40

E01

E05 E6

E6

E6

E6

E6

E6 12

11

25

24

13

26#10+

#20+

#30+

#40+ E6

E6

E6

E62

1

15

14

BR

BR

J19

J/CA

A Injector

1 2

Injector

1 2

Injector

1 2

Injector

1 2L

B±W

BR

B±R No. 1

No. 2

No. 3

No. 4G

R

L

B±W

BR

ECEC

Voltage

Booster

Circuit

Voltage

Booster

Circuit

Voltage

Booster

Circuit

Voltage

Booster

Circuit

ECM

+B

± DIAGNOSTICSENGINE

DI±127

Injector Circuit

CIRCUIT DESCRIPTION

For the injection of fuel in the gaseous state, injectiors that allow the flow of a large volume of fuel and provide

improved sealing performance have been adopted.

These injectors are actuated by the voltage (150 V) that has been increased by the voltage booster circuit

provided in the ECM.

WIRING DIAGRAM

INSPECTION PROCEDURE

1 Check wire harness, connector and vacuum hose in engine room.

CHECK:

(a) Check the connection conditions of the wire harness and connector.

(b) Check the disconnection, piping and break of the vacuum hose.

NG Repair or replace, then confirm that there is no

misfire (See the confirmation driving pattern).

OK

DI651±01

Page 2280 of 4592

A09304BE6653

A09431

#10#20 ON

#30#40

(±) (+)

FI6588

FI6538

A00064

Injector Signal Waveform

10 V/

Division

GND

100 msec./Division (Idling)GND

Injection duration1 msec./Division (Idling) 10 V/

Division(Magnification)

DI±128

± DIAGNOSTICSENGINE

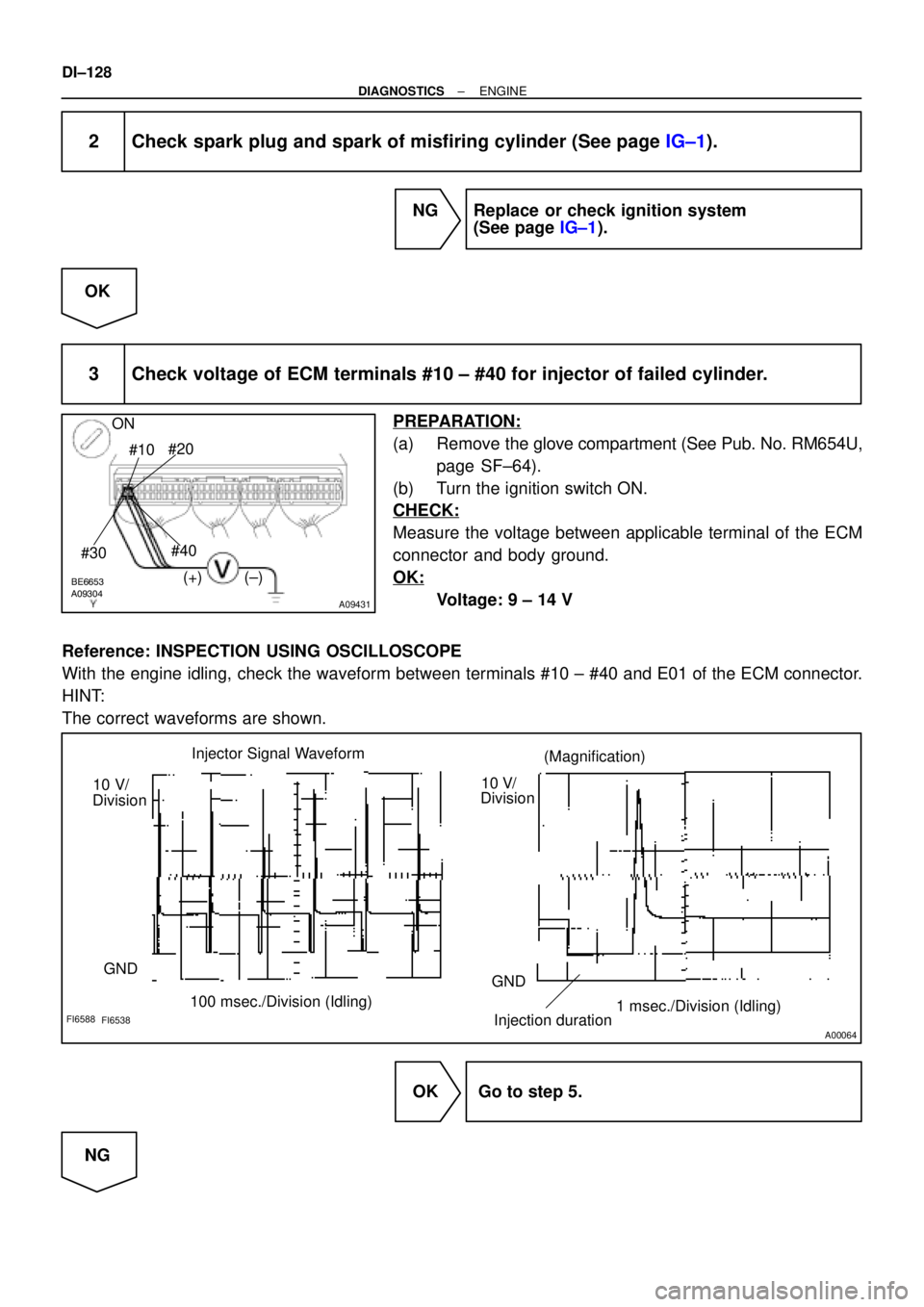

2 Check spark plug and spark of misfiring cylinder (See page IG±1).

NG Replace or check ignition system

(See page IG±1).

OK

3 Check voltage of ECM terminals #10 ± #40 for injector of failed cylinder.

PREPARATION:

(a) Remove the glove compartment (See Pub. No. RM654U,

page SF±64).

(b) Turn the ignition switch ON.

CHECK:

Measure the voltage between applicable terminal of the ECM

connector and body ground.

OK:

Voltage: 9 ± 14 V

Reference: INSPECTION USING OSCILLOSCOPE

With the engine idling, check the waveform between terminals #10 ± #40 and E01 of the ECM connector.

HINT:

The correct waveforms are shown.

OK Go to step 5.

NG