OBD port TOYOTA CAMRY 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: TOYOTA, Model Year: 1999, Model line: CAMRY, Model: TOYOTA CAMRY 1999Pages: 4592, PDF Size: 55.16 MB

Page 3912 of 4592

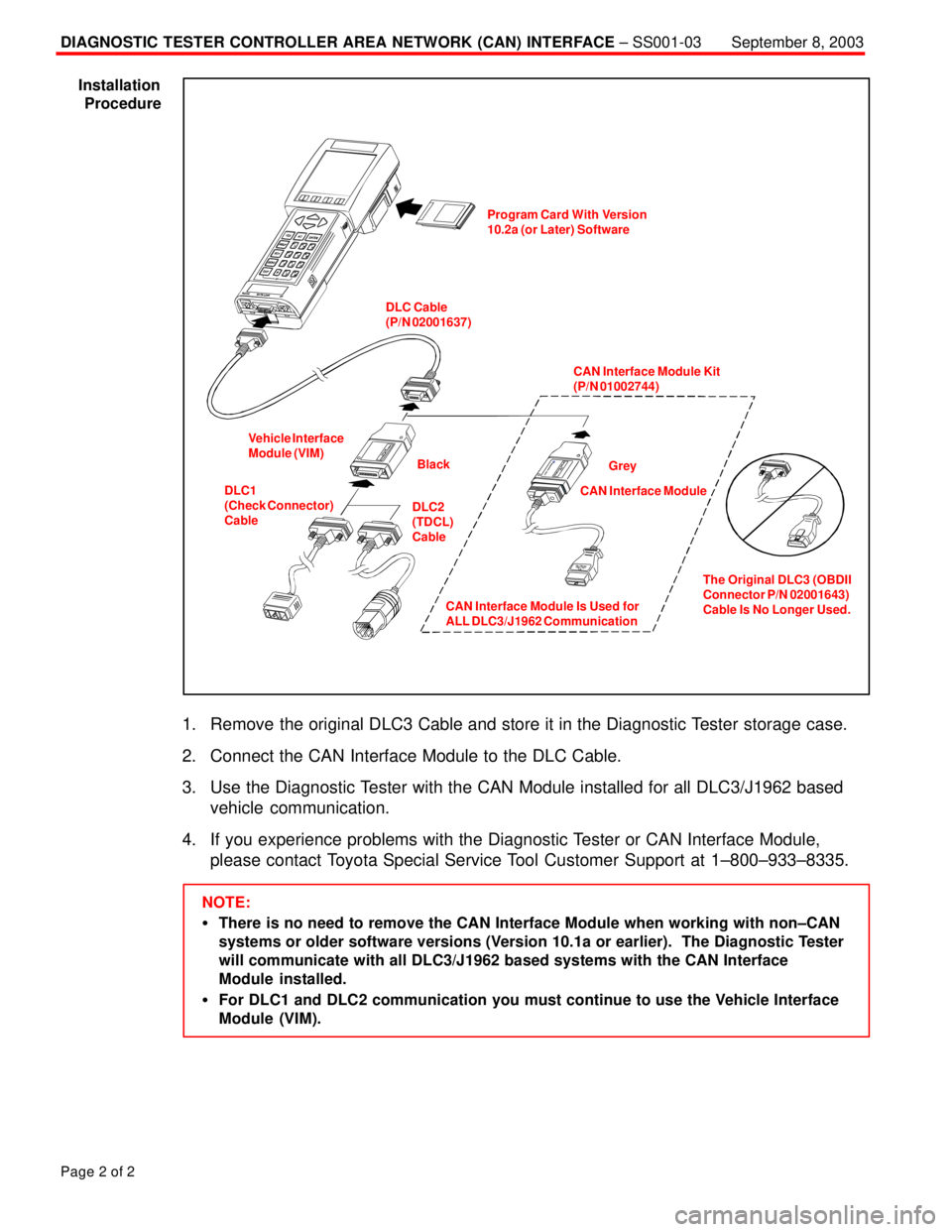

DIAGNOSTIC TESTER CONTROLLER AREA NETWORK (CAN) INTERFACE ± SS001-03September 8, 2003

Page 2 of 2

Program Card With Version

10.2a (or Later) Software

CAN Interface Module Kit

(P/N 01002744)

Grey

CAN Interface Module

CAN Interface Module Is Used for

ALL DLC3/J1962 CommunicationThe Original DLC3 (OBDII

Connector P/N 02001643)

Cable Is No Longer Used. Black DLC Cable

(P/N 02001637)

Vehicle Interface

Module (VIM)

DLC1

(Check Connector)

CableDLC2

(TDCL)

Cable

1. Remove the original DLC3 Cable and store it in the Diagnostic Tester storage case.

2. Connect the CAN Interface Module to the DLC Cable.

3. Use the Diagnostic Tester with the CAN Module installed for all DLC3/J1962 based

vehicle communication.

4. If you experience problems with the Diagnostic Tester or CAN Interface Module,

please contact Toyota Special Service Tool Customer Support at 1±800±933±8335.

NOTE:

�There is no need to remove the CAN Interface Module when working with non±CAN

systems or older software versions (Version 10.1a or earlier). The Diagnostic Tester

will communicate with all DLC3/J1962 based systems with the CAN Interface

Module installed.

�For DLC1 and DLC2 communication you must continue to use the Vehicle Interface

Module (VIM). Installation

Procedure

Page 3957 of 4592

Toyota Supports ASE CertificationPage 1 of 43

SS002-03Title:

O2S TEST RESULTS (MODE 05)

Models:

All '96 ± '03, '04 Corolla, ECHO, Matrix, Sienna

& Scion xA & xBTechnical Service

BULLETIN

December 17, 2003

This Service Bulletin contains Oxygen Sensor (O2S) Monitor threshold values for all

models from 1996 to 2003 and some 2004 models. Starting in 2004, the O2S Monitor

threshold values can be found in the repair manual. These values are used when

analyzing the O2S test results to determine the O2S condition.

�All 1996 ± 2003 model year Toyota vehicles.

�2004 model year Corolla, ECHO, Matrix and Sienna vehicles.

�2004 model year Scion xA and xB vehicles.

Checking O2S Test Results

To view O2S test results, the O2S Monitor must be completed and the test results must

be checked within the same key cycle. If the ignition key is cycled OFF, the O2S test

results will be set to the minimum or maximum limits, and all test results will be erased.

The O2S test results are stored in the ECU (SAE term: Powertrain Control Module/PCM)

when the monitor is completed. The test results are static and will not change once the

monitor is complete.

The process for checking O2S test results is described in the following three basic steps:

1. Completing the O2S Readiness Monitor (page 2).

2. Accessing O2S Test Results (page 3).

3. Comparing O2S Test Results to Failure Thresholds (page 4).

SPECIAL SERVICE TOOLS (SSTs)PART NUMBERQUANTITY

Toyota Diagnostic Tester Kit*

(or any OBDII Scantool)

010012711

12 Megabyte Diagnostic Tester Program Card

with version 10.1a Software (or later)*01002593-0051

* Essential SSTs.

NOTE:

Additional Diagnostic Tester Kits, Program Cards or other SSTs may be ordered by

calling SPX/OTC at 1-800-933-8335.

OP CODEDESCRIPTIONTIMEOFPT1T2

N/ANot Applicable to Warranty±±±±

SPECIAL SERVICE TOOLS

Introduction

Applicable

Vehicles

Function

Description

Required

SSTs

Warranty

Information

Page 4190 of 4592

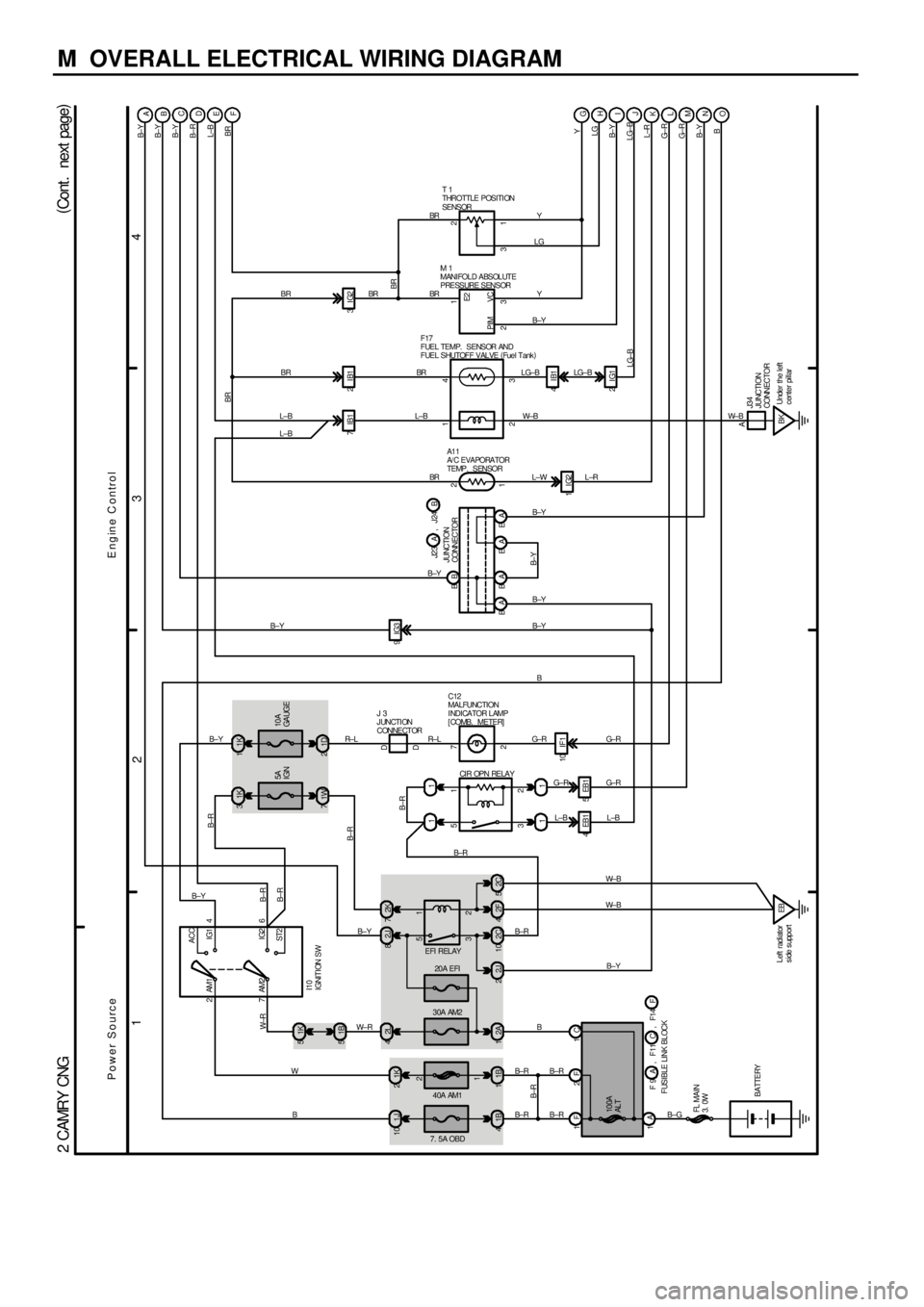

M OVERALL ELECTRICAL WIRING DIAGRAM

1

234

(

Cont . next page)

2 CAMRY CNG

EFI RELAYCIR OPN RELAY

20A EFI

40A AM1 30A AM2

7. 5A OBD

2 1

3 5

2 1

3 5 1J 10 1K22L 41K 5

82J 2K7

11

1B 41B12A12C10 2J 22F4

11 1B 5

L±B

AM2 6

I10

IGNITION SW4 AM1

ST2IG2

2 IG1 ACC

7 2

11K 31K

5A

IGN

4EB1 5EB1

EB Left radiator

s ide s upport 1F 2F 1C

1A

B±G

BATTERY10A

GA UGE

71WB± Y B± Y

1D 2B± Y

FUSIBLE LINK BLOCK10 IF1

FL MAIN

3. 0WBA

100A

AL T

B±Y

1B±R

BB W±R

2

B±R

BR

IG3 9

BR

A

B±R

B±RB

Y

C

LG

Y

B±Y

LG±B

L±W

B±Y

B±Y B±Y

R± L G± R G± R

2

G± R

3

BB±Y W± B M 1

MANIFOLD ABSOLUTE

PRESSURE SENSORT 1

THROTTLE POSITI ON

SENSOR

B±RL±B L±B

L±B G±R

W± R

W

B

IG2 1

B± R F17

FUEL TEMP. SENSOR AND

FUEL SHUTOFF VALVE (

Fuel Tank)

B± R

1

A1 1

A/ C EVAPORATOR

TEMP. SENSOR

ON ML KJI H G

B±R

Y

LG

B± Y

LG±B

L±R

G±R

G±R

B± Y

B

C12

MALFUNCTION

I NDI CA TOR L AMP

[COMB. METER]

7

2 D D

J 3

JUNCTION

CONNECTOR

JUNCTION

CONNECTOR

B±Y

23 31 1

12

R± LB

PIM VCE2

B± R

Power SourceEngine Control

D

E

F

BR

4IB1 BR

3IG2

BR BR

7IB1

LG±B

EA

W±B

L±R

EA BAL±B

B±YB± Y

, F11 F 9 A C , F14 FB J23 J24A,

2C 5

W± B

B±Y L±B

2IG1

BKUnder the left

center pillar B±RB±R

B±Y

B±R

A

J34

JUNCTION

CONNECTOR

W± B

LG±BBR

B± R BR

2IB1

BR4BR

Page 4547 of 4592

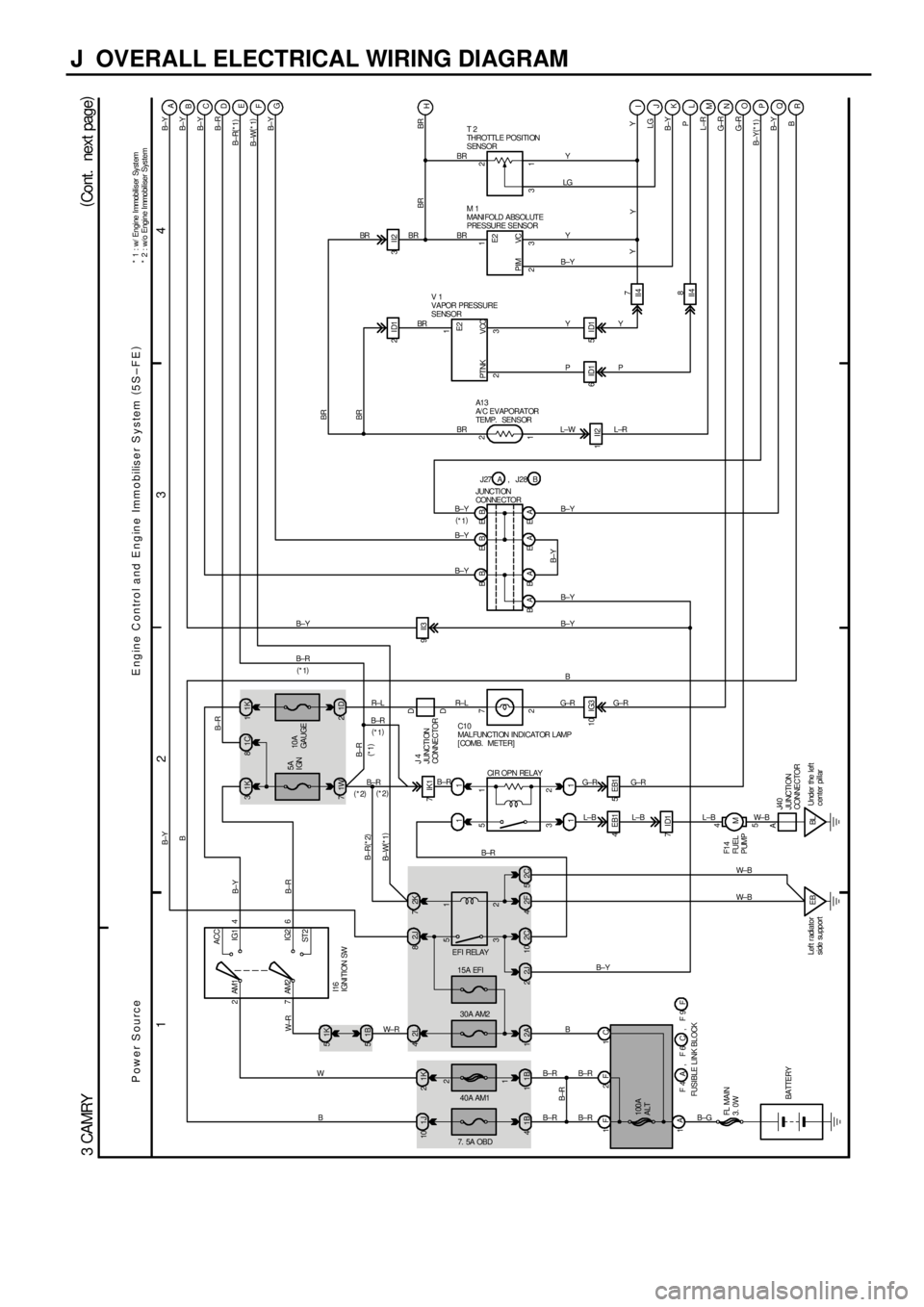

J OVERALL ELECTRICAL WIRING DIAGRAM

1

234

3 CAMRY(

Cont. next page)

2 1

3 5

2 1

3 5 1J 10 1K22L 41K 5

2J 82K7

11

1B 41B12A12C10 2J 22F4

11 1B 52

7ACC

IG1

IG2

ST 2 AM1 4

6 AM2

4 EB1

7ID15EB1

5 4

M

BLUnder the left

center pillar EB Lef t r adiator

side support 1F 2F 1C

1A

B±G

7. 5A OBD40A AM1 30A AM2 15A EFI EFI RELAYCI R OP N RE L AY

5A

IGN 1K 31C81K1

10A

GA U GE

1W 71D2

BABB 9 II3A

B

C

T 2

THROTTL E POSITI ON

SENSOR

M 1

MANI FOLD ABSOLUTE

PRESSURE SENSOR

V 1

VAPOR PRESSURE

SENSOR

1

A1 3

A/ C EVAPORATOR

TEMP. SENSOR

R Q O N ML KJI 1II2 10 IG3

Y

LG

B±Y

P

L±R

G±R

G±R

B±Y

B

B±R B±R

B±R B±R

B WW± R BB±YW± BW± B L±B L±B L±B G±R G±RG±R G±R R± L B±YB±Y B±Y L±WP Y B±YY LGY

B±RW±R B±RB±YB±Y

B

B±RB±R B±Y

B±Y

B±Y

BATTERYFUSIBLE LINK BLOCK

FL MAIN

3. 0W 100A

ALT1 2I16

IGNITION SW

B±R(

*2)

B±R

A

C10

MALFUNCTI ON INDICATOR LAMP

[COMB. METER]

7

2 D D

F1 4

FUEL

PUMP

J40

JUNCTI ON

CONNE CTORJ 4

JUNCTI ON

CONNE CTOR

JUNCTI ON

CONNE CTOR

B±Y

BR BR

BR BR

23

23 31 1

12

R± LB

PT NK VCC

PIM VC E2

E2

Y

B±R

2

BR

Power Source Engine Control and Engine Immobiliser System (

5S±FE)

D

E

F

B±W(

*1)B±R

5ID1 6ID13II2 2ID1

II47

II48 EA EB EB

EA BAG

P * 2 : w/o Engine Immobiliser System * 1 : w/ Engine Immobilis er Sy st em

(

*2)

(

*1)B±R(

*1)

B±W(

*1)

B±Y

B±Y(

*1)

B±Y B±Y B±YB±YH

L±R P Y BR BR

BRBR BR

Y

(

*1)

, F 6 F 4 A C , F 9 F

B J27 J28A,

2C 5W± B

7IK1

B±RB±R

(

*2)(

*1) B± R

(

*1)